Frequency Effect on the Structure and Properties of Mo-Zr-Si-B Coatings Deposited by HIPIMS Using a Composite SHS Target

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Deposition Parameters

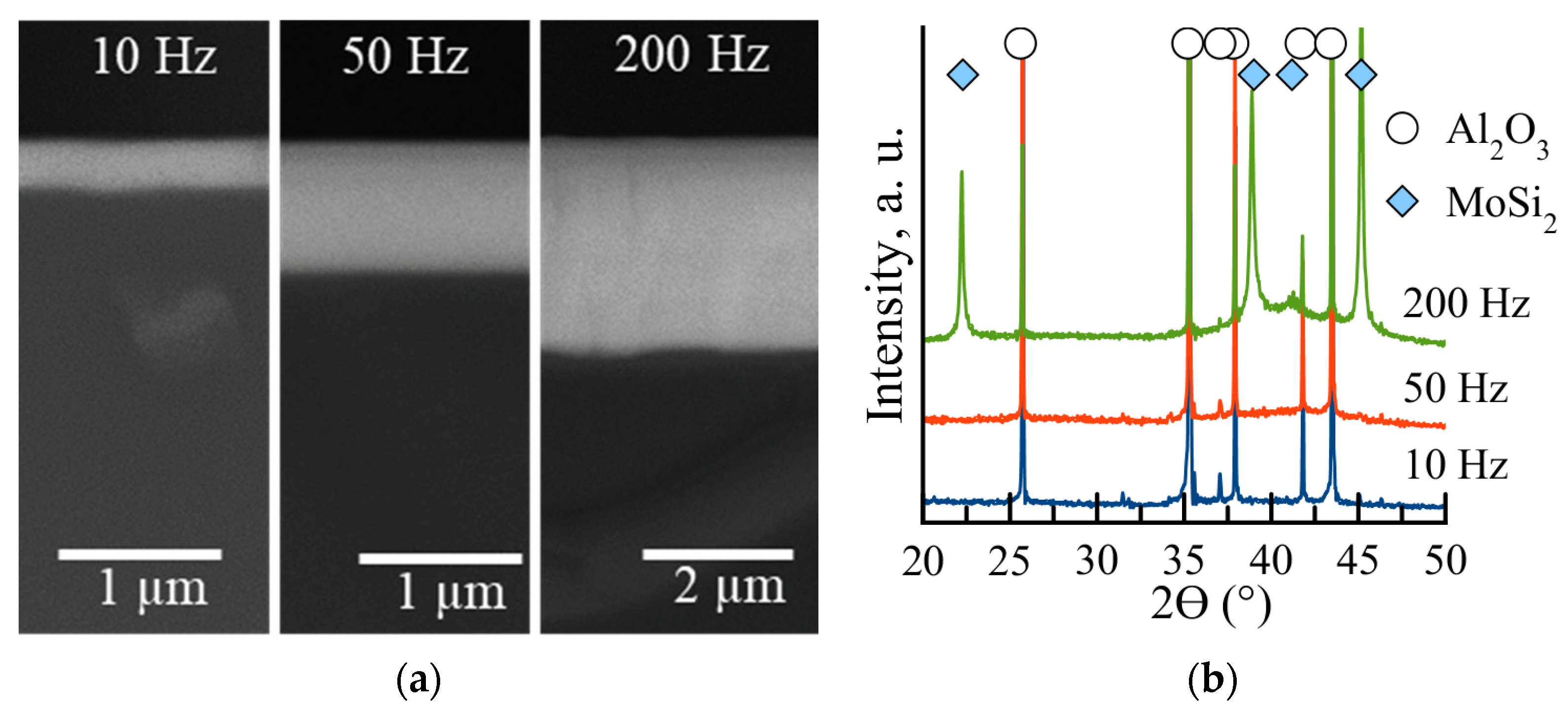

3.2. Composition and Structure

3.3. Mechanical Properties

3.4. Adhesion Strength

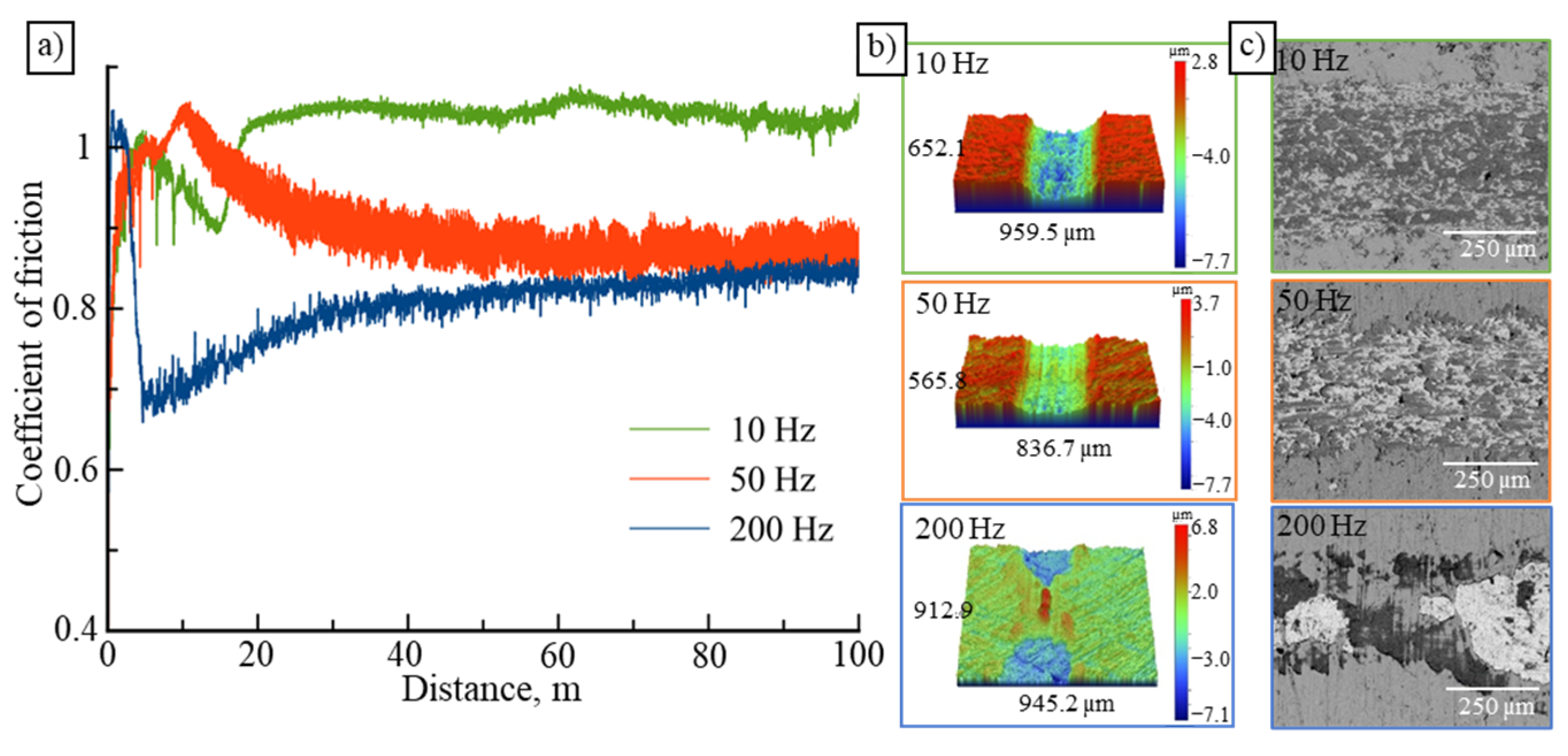

3.5. Tribological Characteristics

3.6. Resistance to Dynamic Impact Loading

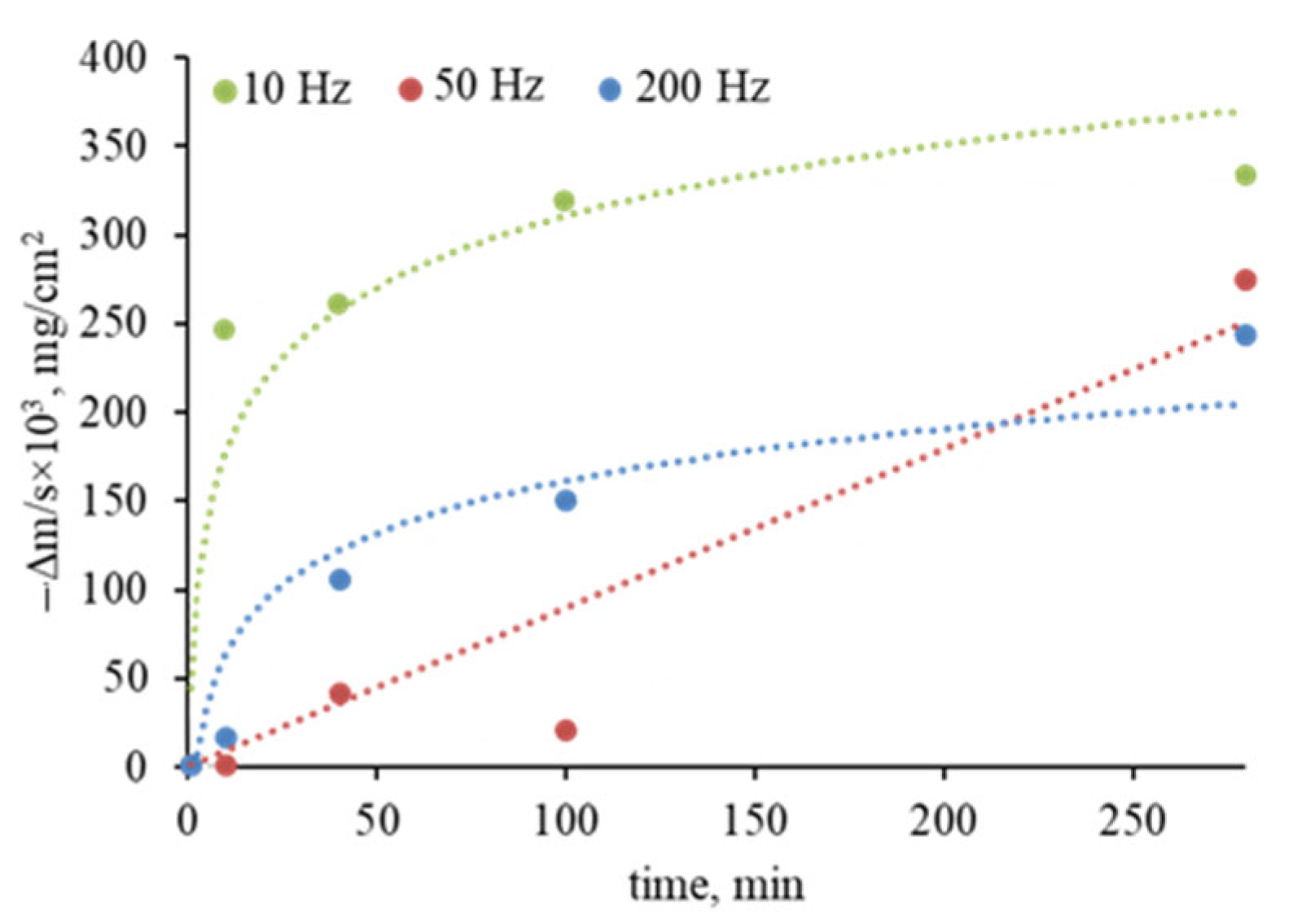

3.7. High-Temperature Oxidation Resistance

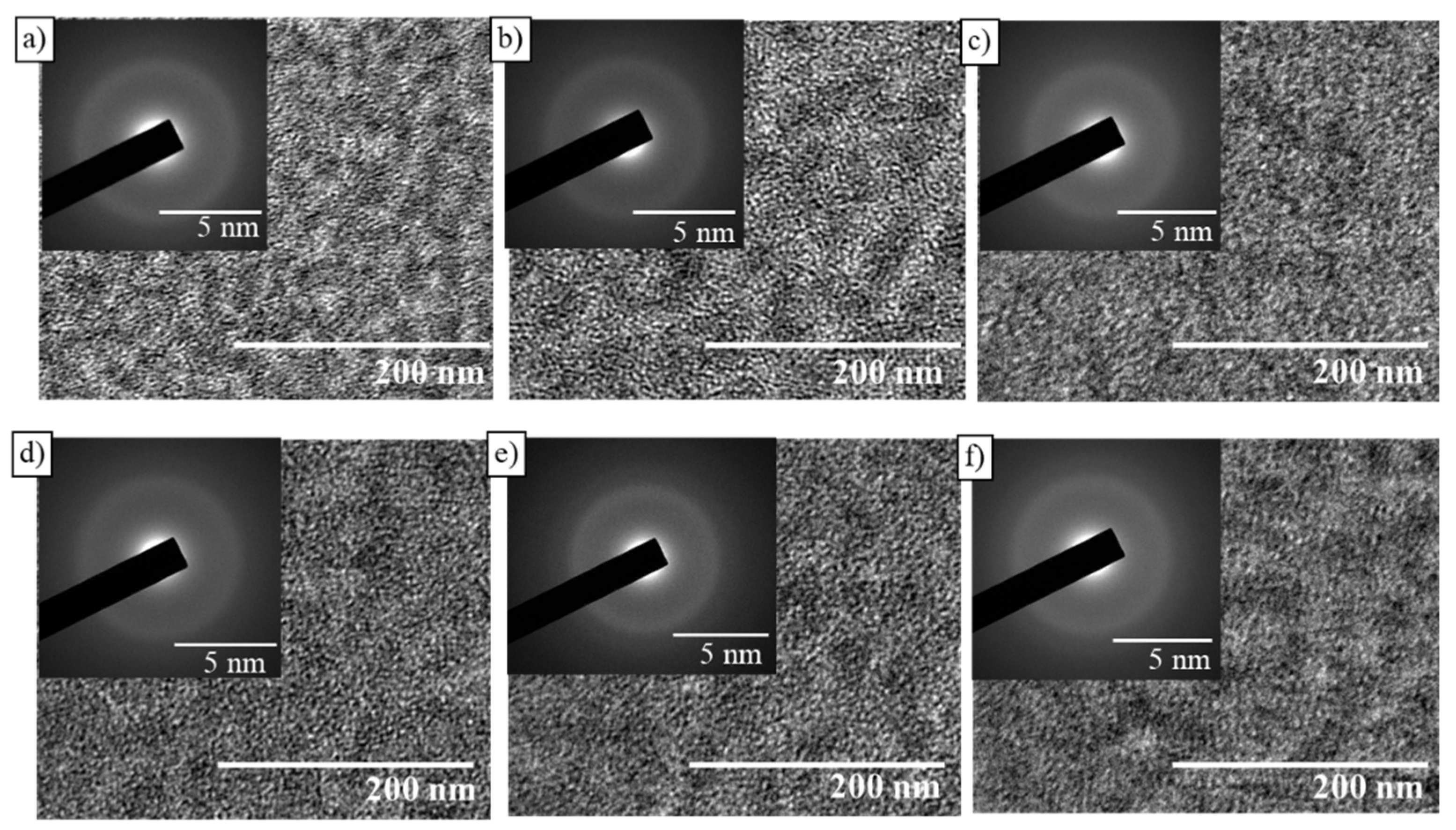

3.8. Thermal Stability

4. Conclusions

- The Mo-Zr-Si-B coatings deposited by HIPIMS at frequencies of 10, 50, and 200 Hz had a dense and homogeneous structure. The minimal growth rate (7.5 nm/min) was observed at 10 Hz for the highest maximum peak current. As frequency was increased to 50 and 200 Hz, the growth rate rose to 17.5 and 67.5 nm/min, respectively.

- The hardness of the Mo-Zr-Si-B coatings deposited at 10, 50, and 200 Hz was 8, 15, and 23 GPa, respectively. The coating deposited at 50 Hz was characterized by a higher resistance to wear and cyclic-dynamic-impact loading, as well as high-temperature oxidation resistance at 1300 and 1500 °C.

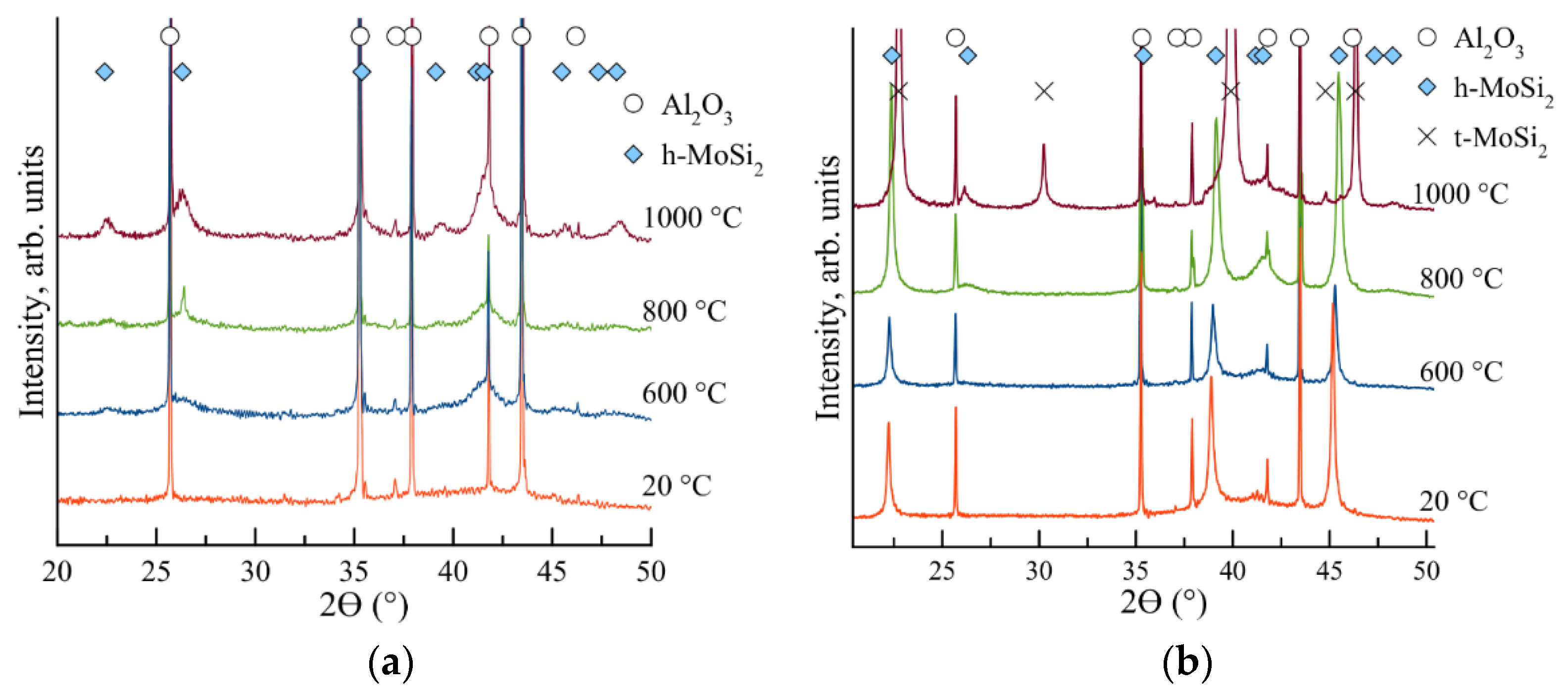

- Heating in the transmission electron microscope column at temperatures of 20–1000 °C did not result in structural changes, and the coating deposited at 50 Hz remained amorphous. The segregation and growth of MoSi2 phase grains were observed in the temperature range of 600–1000 °C during vacuum annealing because of the longer exposure time and low heating/cooling rates. The hardness and Young’s modulus of the coatings deposited at frequencies of 10 and 200 Hz decreased after vacuum annealing. The self-hardening effect was detected for the coating deposited at 50 Hz. As the temperature rose from 20 to 1000 °C, the hardness and Young’s modulus increased from 15 and 250 GPa to 37 and 380 GPa, respectively, due to the crystallization process and the transformation of the amorphous structure into a nanocomposite one.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, H.; Yao, D.; Fu, Q.; Liu, L.; Zhang, Y.; Yao, X.; Wang, Y.; Li, H. Anti-Oxidation and Ablation Properties of Carbon/Carbon Composites Infiltrated by Hafnium Boride. Carbon 2013, 52, 418–426. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Vereschaka, A.A.; Volosova, M.A.; Sitnikov, N.N.; Sotova, E.S.; Seleznev, A.E.; Bublikov, J.I.; Batako, A.D. Improved Efficiency of Ceramic Cutting Tools in Machining Hardened Steel—An Application with Nanostructured Multilayered Coatings. Handb. Mod. Coat. Technol. 2021, 381–433. [Google Scholar] [CrossRef]

- Kim, Y.H.; Shin, T.H.; Myung, J. ha MoSi2-Based Cylindrical Susceptor for Rapid High-Temperature Induction Heating in Air. Ceram. Int. 2020, 46, 23636–23642. [Google Scholar] [CrossRef]

- Feng, P.; Wu, J.; Islam, S.H.; Liu, W.; Niu, J.; Wang, X.; Qiang, Y. Effects of Boron Addition on the Formation of MoSi2 by Combustion Synthesis Mode. J. Alloys Compd. 2010, 494, 161–165. [Google Scholar] [CrossRef]

- Zhang, L.; Tong, Z.; He, R.; Xie, C.; Bai, X.; Yang, Y.; Fang, D. Key Issues of MoSi2-UHTC Ceramics for Ultra High Temperature Heating Element Applications: Mechanical, Electrical, Oxidation and Thermal Shock Behaviors. J. Alloys Compd. 2019, 780, 156–163. [Google Scholar] [CrossRef]

- Xin, L.; Chen, Q.; Teng, Y.; Wang, W.; Sun, A.; Zhu, S.; Wang, F. Effects of Silicon and Multilayer Structure of TiAl(Si)N Coatings on the Oxidation Resistance of Ti6Al4V. Surf. Coat. Technol. 2013, 228, 48–58. [Google Scholar] [CrossRef]

- Bae, K.E.; Chae, K.W.; Park, J.K.; Lee, W.S.; Baik, Y.J. Oxidation Behavior of Amorphous Boron Carbide–Silicon Carbide Nano-Multilayer Thin Films. Surf. Coat. Technol. 2015, 276, 55–58. [Google Scholar] [CrossRef]

- Niu, Y.; Wang, H.; Li, H.; Zheng, X.; Ding, C. Dense ZrB2-MoSi2 Composite Coating Fabricated by Low Pressure Plasma Spray (LPPS). Ceram. Int. 2013, 39, 9773–9777. [Google Scholar] [CrossRef]

- Ren, X.; Li, H.; Chu, Y.; Li, K.; Fu, Q. ZrB2–SiC Gradient Oxidation Protective Coating for Carbon/Carbon Composites. Ceram. Int. 2014, 40, 7171–7176. [Google Scholar] [CrossRef]

- Zhestkov, B.E.; Terent’eva, V.S. Multifunctional Coating MAI D5 Intended for the Protection of Refractory Materials. Russ. Metall. 2010, 2010, 33–40. [Google Scholar] [CrossRef]

- Yang, J.; Liu, H.; Gao, W.; Su, L.; Jiang, K. Effect of Different Fillers on the Microstructural Evolution and High Temperature Oxidation Resistance of Mo-Si-B Coatings Prepared by Pack Cementation. Int. J. Refract. Met. Hard Mater. 2021, 100, 105625. [Google Scholar] [CrossRef]

- Shrestha, S.; Hodgkiess, T.; Neville, A. Erosion–Corrosion Behaviour of High-Velocity Oxy-Fuel Ni–Cr–Mo–Si–B Coatings under High-Velocity Seawater Jet Impingement. Wear 2005, 259, 208–218. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Iatsyuk, I.V.; Shvindina, N.V.; Levashov, E.A.; Shtansky, D.V. Comparative Investigation of Structure, Mechanical Properties, and Oxidation Resistance of Mo-Si-B and Mo-Al-Si-B Coatings. Corros. Sci. 2017, 123, 319–327. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sytchenko, A.D.; Sviridova, T.A.; Sidorenko, D.A.; Andreev, N.V.; Klechkovskaya, V.V.; Polčak, J.; Levashov, E.A. Effects of Doping with Zr and Hf on the Structure and Properties of Mo-Si-B Coatings Obtained by Magnetron Sputtering of Composite Targets. Surf. Coat. Technol. 2022, 442, 128141. [Google Scholar] [CrossRef]

- Veprek, S.; Jilek, M. Super- and Ultrahard Nanacomposite Coatings: Generic Concept for Their Preparation, Properties and Industrial Applications. Vacuum 2002, 67, 443–449. [Google Scholar] [CrossRef]

- Kelly, P.J.; Beevers, C.F.; Henderson, P.S.; Arnell, R.D.; Bradley, J.W.; Bäcker, H. A Comparison of the Properties of Titanium-Based Films Produced by Pulsed and Continuous DC Magnetron Sputtering. Surf. Coat. Technol. 2003, 174–175, 795–800. [Google Scholar] [CrossRef]

- Elmkhah, H.; Attarzadeh, F.; Fattah-alhosseini, A.; Kim, K.H. Microstructural and Electrochemical Comparison between TiN Coatings Deposited through HIPIMS and DCMS Techniques. J. Alloys Compd. 2018, 735, 422–429. [Google Scholar] [CrossRef]

- Helmersson, U.; Lattemann, M.; Bohlmark, J.; Ehiasarian, A.P.; Gudmundsson, J.T. Ionized Physical Vapor Deposition (IPVD): A Review of Technology and Applications. Thin Solid Films 2006, 513, 1–24. [Google Scholar] [CrossRef]

- Lattemann, M.; Ehiasarian, A.P.; Bohlmark, J.; Persson, P.Å.O.; Helmersson, U. Investigation of High Power Impulse Magnetron Sputtering Pretreated Interfaces for Adhesion Enhancement of Hard Coatings on Steel. Surf. Coat. Technol. 2006, 200, 6495–6499. [Google Scholar] [CrossRef]

- Lu, C.Y.; Diyatmika, W.; Lou, B.S.; Lu, Y.C.; Duh, J.G.; Lee, J.W. Influences of Target Poisoning on the Mechanical Properties of TiCrBN Thin Films Grown by a Superimposed High Power Impulse and Medium-Frequency Magnetron Sputtering. Surf. Coat. Technol. 2017, 332, 86–95. [Google Scholar] [CrossRef]

- Mei, H.; Ding, J.C.; Xiao, X.; Luo, Q.; Wang, R.; Zhang, Q.; Gong, W.; Wang, Q. Influence of Pulse Frequency on Microstructure and Mechanical Properties of Al-Ti-V-Cu-N Coatings Deposited by HIPIMS. Surf. Coat. Technol. 2021, 405, 126514. [Google Scholar] [CrossRef]

- Nedfors, N.; Mockute, A.; Palisaitis, J.; Persson, P.O.Å.; Näslund, L.Å.; Rosen, J. Influence of Pulse Frequency and Bias on Microstructure and Mechanical Properties of TiB2 Coatings Deposited by High Power Impulse Magnetron Sputtering. Surf. Coat. Technol. 2016, 304, 203–210. [Google Scholar] [CrossRef]

- Dai, W.; Kwon, S.H.; Wang, Q.; Liu, J. Influence of Frequency and C2H2 Flow on Growth Properties of Diamond-like Carbon Coatings with AlCrSi Co-Doping Deposited Using a Reactive High Power Impulse Magnetron Sputtering. Thin Solid Films 2018, 647, 26–32. [Google Scholar] [CrossRef]

- Samuelsson, M.; Sarakinos, K.; Högberg, H.; Lewin, E.; Jansson, U.; Wälivaara, B.; Ljungcrantz, H.; Helmersson, U. Growth of Ti-C Nanocomposite Films by Reactive High Power Impulse Magnetron Sputtering under Industrial Conditions. Surf. Coat. Technol. 2012, 206, 2396–2402. [Google Scholar] [CrossRef]

- Polaček, M.; Souček, P.; Alishahi, M.; Koutná, N.; Klein, P.; Zábranský, L.; Czigány, Z.; Balázsi, K.; Vašina, P. Synthesis and Characterization of Ta–B–C Coatings Prepared by DCMS and HiPIMS Co-Sputtering. Vacuum 2022, 199, 110937. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, F.V. Possibilities of Glow Discharge Optical Emission Spectroscopy in the Investigation of Coatings. Russ. J. Non-Ferrous Met. 2014, 55, 494–504. [Google Scholar] [CrossRef]

- Daghbouj, N.; Sen, H.S.; Čížek, J.; Lorinčík, J.; Karlík, M.; Callisti, M.; Čech, J.; Havránek, V.; Li, B.; Krsjak, V.; et al. Characterizing Heavy Ions-Irradiated Zr/Nb: Structure and Mechanical Properties. Mater. Des. 2022, 219, 110732. [Google Scholar] [CrossRef]

- Shimizu, T.; Teranishi, Y.; Morikawa, K.; Komiya, H.; Watanabe, T.; Nagasaka, H.; Yang, M. Impact of Pulse Duration in High Power Impulse Magnetron Sputtering on the Low-Temperature Growth of Wurtzite Phase (Ti,Al)N Films with High Hardness. Thin Solid Films 2015, 581, 39–47. [Google Scholar] [CrossRef]

- Papa, F.; Gerdes, H.; Bandorf, R.; Ehiasarian, A.P.; Kolev, I.; Braeuer, G.; Tietema, R.; Krug, T. Deposition Rate Characteristics for Steady State High Power Impulse Magnetron Sputtering (HIPIMS) Discharges Generated with a Modulated Pulsed Power (MPP) Generator. Thin Solid Films 2011, 520, 1559–1563. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High Power Pulsed Magnetron Sputtering: A Review on Scientific and Engineering State of the Art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Brugnara, R.H. Aluminum-Rich HPPMS (Cr1−xAlx)N Coatings Deposited with Different Target Compositions and at Various Pulse Lengths. Vacuum 2015, 122, 201–207. [Google Scholar] [CrossRef]

- Musil, J.; Novák, P.; Čerstvý, R.; Soukup, Z. Tribological and Mechanical Properties of Nanocrystalline-TiC/a-C Nanocomposite Thin Films. J. Vac. Sci. Technol. Vacuum Surfaces Film. 2010, 28, 244. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. Optimization of Nanostructured Tribological Coatings. In Nanostructured Coatings. Nanostructure Science and Technology; Cavaleiro, A., de Hosson, J.T.M., Eds.; Springer: New York, NY, USA, 2006; pp. 511–538. [Google Scholar]

- Ge, F.F.; Sen, H.S.; Daghbouj, N.; Callisti, M.; Feng, Y.J.; Li, B.S.; Zhu, P.; Li, P.; Meng, F.P.; Polcar, T.; et al. Toughening Mechanisms in V-Si-N Coatings. Mater. Des. 2021, 209, 109961. [Google Scholar] [CrossRef]

- Berg, G.; Friedrich, C.; Broszeit, E.; Berger, C. Data Collection of Properties of Hard Material. Handb. Ceram. Hard Mater. 2008, 965–995. [Google Scholar] [CrossRef]

- Gutman, M.B. Materials for Electrothermal Plants: Handbook; Energoatomizdat: Moscow, Russia, 1987. (in Russian) [Google Scholar]

- Veprek, S.; Mukherjee, S.; Karvankova, P.; Männling, H.D.; He, J.L.; Moto, K.; Prochazka, J.; Argon, A.S. Hertzian Analysis of the Self-Consistency and Reliability of the Indentation Hardness Measurements on Superhard Nanocomposite Coatings. Thin Solid Films 2003, 436, 220–231. [Google Scholar] [CrossRef]

- Rezakhanlou, R.; von Stebut, J. Paper VII (Iii) Damage Mechanisms of Hard Coatings on Hard Substrates: A Critical Analysis of Failure in Scratch and Wear Testing. Tribol. Ser. 1990, 17, 183–192. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sheveyko, A.N.; Vorotilo, S.A.; Levashov, E.A. Wear-Resistant Ti–Al–Ni–C–N Coatings Produced by Magnetron Sputtering of SHS-Targets in the DC and HIPIMS Modes. Ceram. Int. 2020, 46, 1775–1783. [Google Scholar] [CrossRef]

- Kudryashov, A.E.; Lebedev, D.N.; Potanin, A.Y.; Levashov, E.A. Structure and Properties of Coatings Produced by Pulsed Electrospark Deposition on Nickel Alloy Using Mo-Si-B Electrodes. Surf. Coat. Technol. 2018, 335, 104–117. [Google Scholar] [CrossRef]

- Xi, H.H.; He, P.F.; Wang, H.D.; Liu, M.; Chen, S.Y.; Xing, Z.G.; Ma, G.Z.; Lv, Z.L. Microstructure and Mechanical Properties of Mo Coating Deposited by Supersonic Plasma Spraying. Int. J. Refract. Met. Hard Mater. 2020, 86, 105095. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sytchenko, A.D. Influence of Physical and Mechanical Properties of the Substrate on the Behavior of Zr–Si–B Coatings under Sliding Friction and Cyclic Impact-Dynamic Loading. Prot. Met. Phys. Chem. Surfaces 2020, 56, 981–989. [Google Scholar] [CrossRef]

- Perepezko, J.H. High Temperature Environmental Resistant Mo-Si-B Based Coatings. Int. J. Refract. Met. Hard Mater. 2018, 71, 246–254. [Google Scholar] [CrossRef]

- Deng, X.; Zhang, G.; Wang, T.; Ren, S.; Shi, Y.; Bai, Z.; Cao, Q. Microstructure and Oxidation Resistance of a Multiphase Mo-Si-B Ceramic Coating on Mo Substrates Deposited by a Plasma Transferred Arc Process. Ceram. Int. 2019, 45, 415–423. [Google Scholar] [CrossRef]

- Wang, F.; Shan, A.; Dong, X.; Wu, J. Oxidation Behavior of Mo–12.5Si–25B Alloy at High Temperature. J. Alloys Compd. 2008, 459, 362–368. [Google Scholar] [CrossRef]

- Yang, Y.; Bei, H.; Chen, S.; George, E.P.; Tiley, J.; Chang, Y.A. Effects of Ti, Zr, and Hf on the Phase Stability of Mo_ss + Mo3Si + Mo5SiB2 Alloys at 1600 °C. Acta Mater. 2010, 58, 541–548. [Google Scholar] [CrossRef]

- Ha, Y.; Kim, T.C.; Baeg, J.H.; Kim, J.S.; Shon, M.; Cho, Y.R. Effect of Cooling Rate on Surface Properties of ZnMgAl Coating and Adhesion to Epoxy Adhesive. Int. J. Adhes. Adhes. 2022, 117, 103182. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, L.; Qiao, Y.; Gao, Q.; Xiao, Z. A New C11b-Type High Entropy Refractory Metal Silicide to Improve MoSi2 Mechanical Properties More Easily. Scr. Mater. 2022, 218, 114798. [Google Scholar] [CrossRef]

| Deposition Parameters | Coating 1 | Coating 2 | Coating 3 |

|---|---|---|---|

| Frequency, Hz | 10 | 50 | 200 |

| Pulse duration, µs | 200 | 200 | 200 |

| Pulse voltage, V | 940 | 950 | 963 |

| Pulse current, A | 42 | 22 | 27 |

| Average power, kW | 0.1 | 0.2 | 1 |

| Maximum peak power, kW | 35 | 30 | 30 |

| Maximum peak current, A | 33 | 25–30 | 30 |

| Frequency, Hz | Elemental Composition, at.% | Thickness, µm | Growth Rate, nm/min | ||||

|---|---|---|---|---|---|---|---|

| Mo | Si | B | Zr | C + O | |||

| 10 | 30.1 ± 1.3 | 63.2 ± 1.2 | 5.3 ± 0.2 | 1.2 ± 0.1 | 0.2 ± 0.1 | 0.3 | 7.5 |

| 50 | 25.8 ± 1.3 | 60.2 ± 1.4 | 9.1 ± 0.4 | 3.8 ± 0.2 | 1.1 ± 0.4 | 0.7 | 17.5 |

| 200 | 28.0 ± 2.0 | 56.8 ± 1.5 | 9.6 ± 0.4 | 4.5 ± 0.4 | 1.1 ± 0.4 | 2.7 | 67.5 |

| Frequency, Hz | H, GPa | E, GPa | W, % | H/E | H3/E2, GPa | f | Vw, ×10−4 mm3·N−1·m−1 | V, ×103 µm3 |

|---|---|---|---|---|---|---|---|---|

| 10 | 8 ± 1 | 196 ± 29 | 35 ± 4 | 0.041 | 0.013 | 1.01 | 3.0 | 309 |

| 50 | 15 ± 3 | 251 ± 30 | 44 ± 6 | 0.060 | 0.054 | 0.90 | 1.9 | 281 |

| 200 | 23 ± 3 | 299 ± 18 | 65 ± 4 | 0.077 | 0.136 | 0.81 | 2.3 | 561 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiryukhantsev-Korneev, P.V.; Sytchenko, A.D.; Loginov, P.A.; Orekhov, A.S.; Levashov, E.A. Frequency Effect on the Structure and Properties of Mo-Zr-Si-B Coatings Deposited by HIPIMS Using a Composite SHS Target. Coatings 2022, 12, 1570. https://doi.org/10.3390/coatings12101570

Kiryukhantsev-Korneev PV, Sytchenko AD, Loginov PA, Orekhov AS, Levashov EA. Frequency Effect on the Structure and Properties of Mo-Zr-Si-B Coatings Deposited by HIPIMS Using a Composite SHS Target. Coatings. 2022; 12(10):1570. https://doi.org/10.3390/coatings12101570

Chicago/Turabian StyleKiryukhantsev-Korneev, Philipp V., Alina D. Sytchenko, Pavel A. Loginov, Anton S. Orekhov, and Evgeny A. Levashov. 2022. "Frequency Effect on the Structure and Properties of Mo-Zr-Si-B Coatings Deposited by HIPIMS Using a Composite SHS Target" Coatings 12, no. 10: 1570. https://doi.org/10.3390/coatings12101570

APA StyleKiryukhantsev-Korneev, P. V., Sytchenko, A. D., Loginov, P. A., Orekhov, A. S., & Levashov, E. A. (2022). Frequency Effect on the Structure and Properties of Mo-Zr-Si-B Coatings Deposited by HIPIMS Using a Composite SHS Target. Coatings, 12(10), 1570. https://doi.org/10.3390/coatings12101570