Experimental Research on Dynamic Response of Layered Medium under Impact Load

Abstract

1. Introduction

2. Model Test Design

2.1. Specimen Dimension Determination

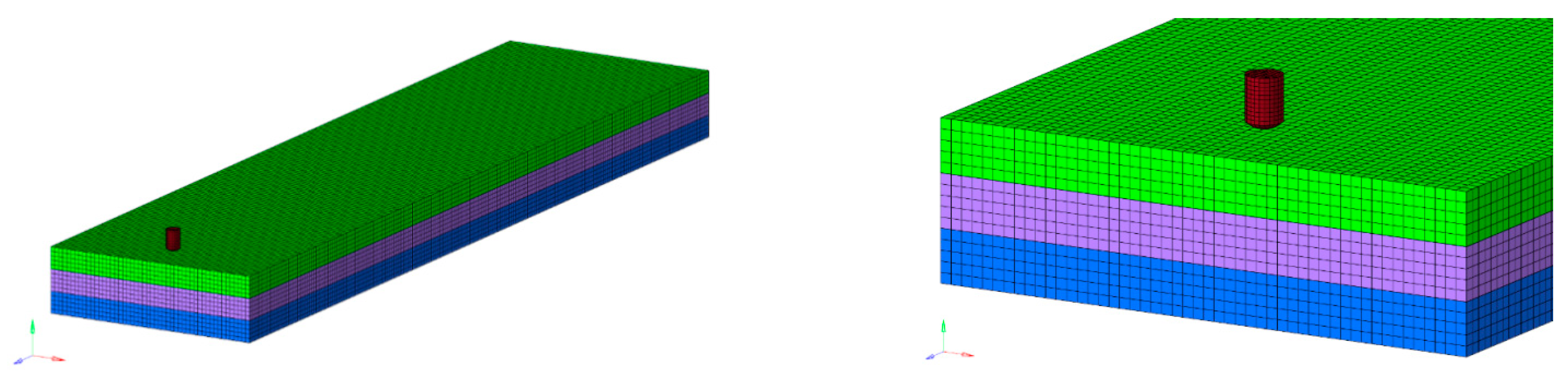

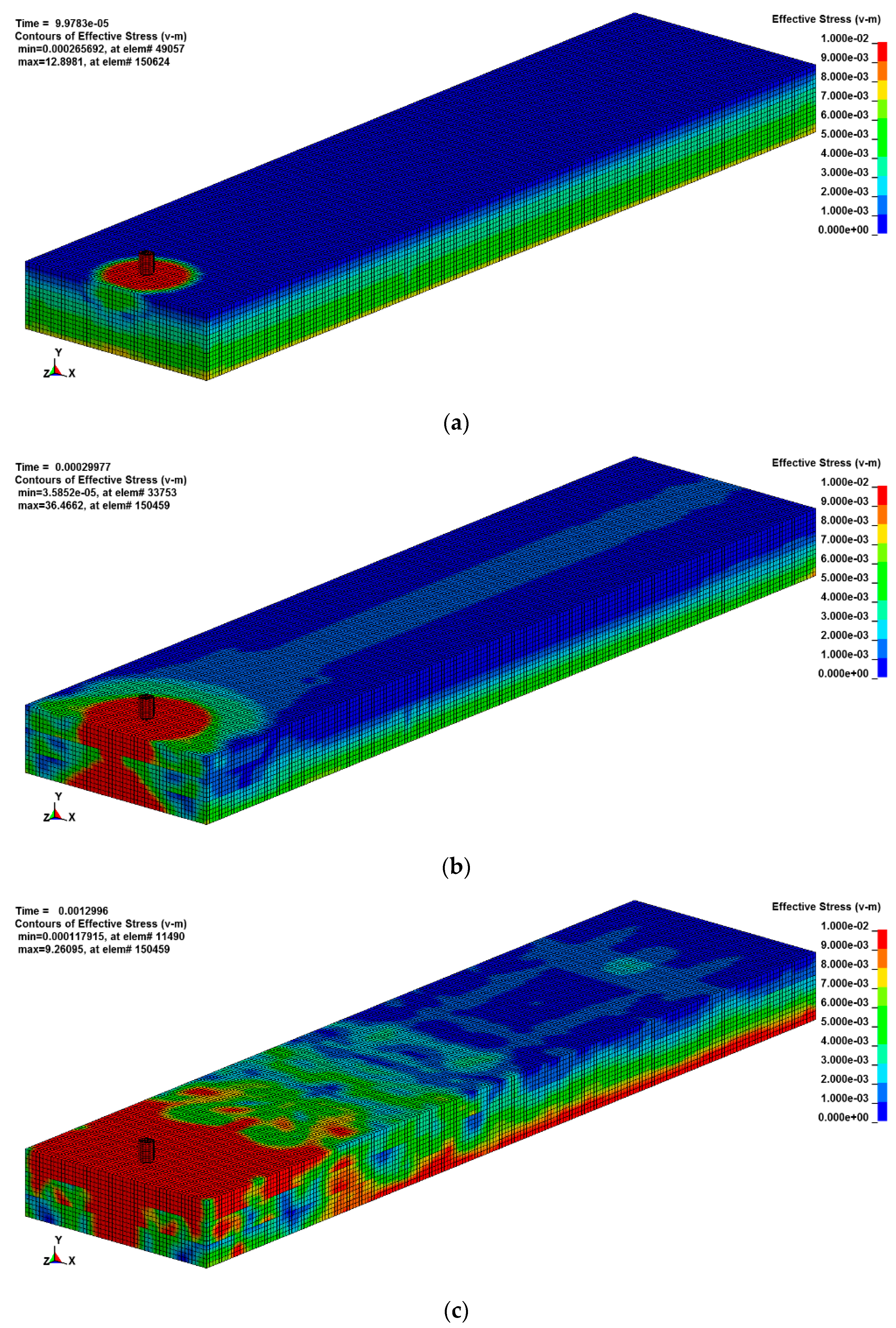

2.1.1. Calculation Model Establishment

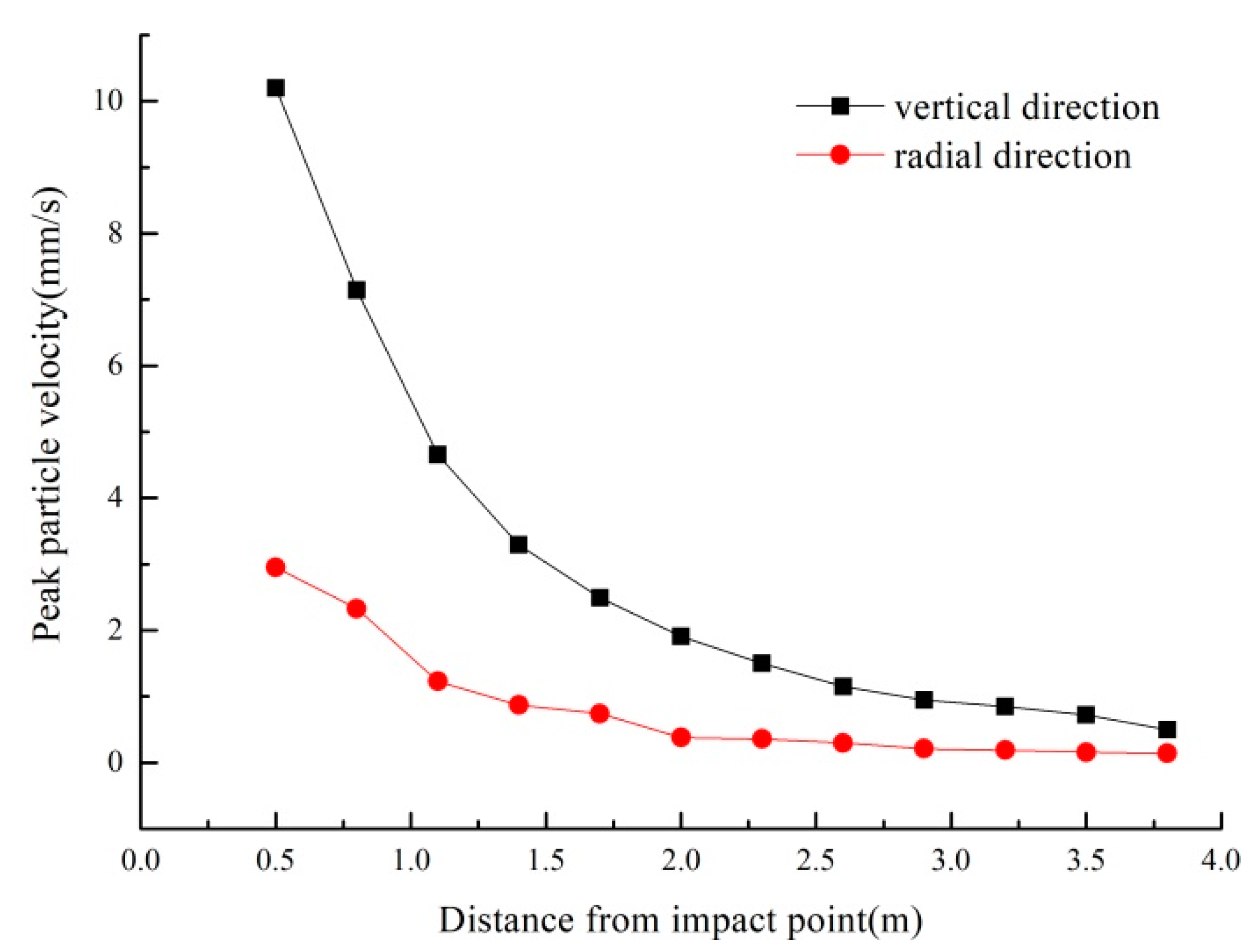

2.1.2. Numerical Results Analysis

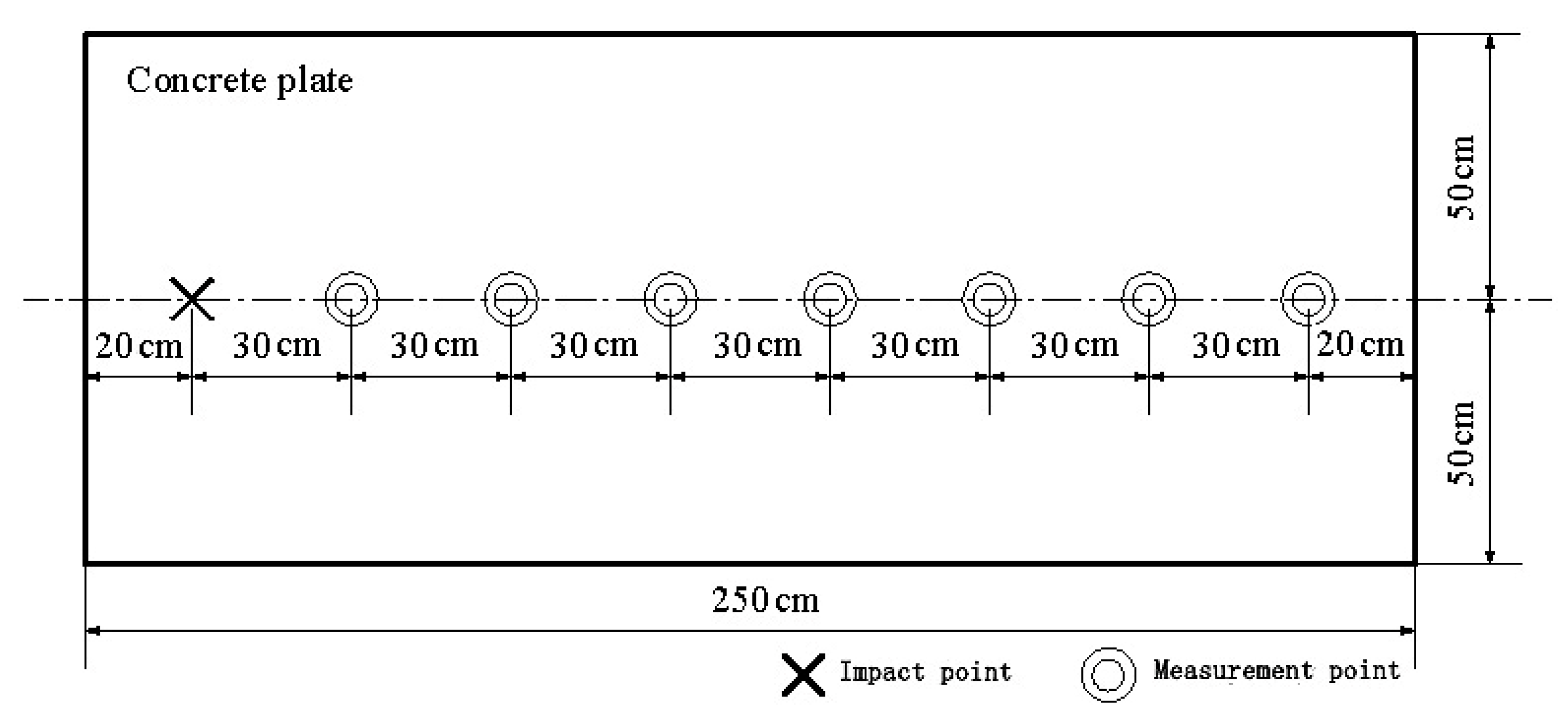

2.2. Model Making

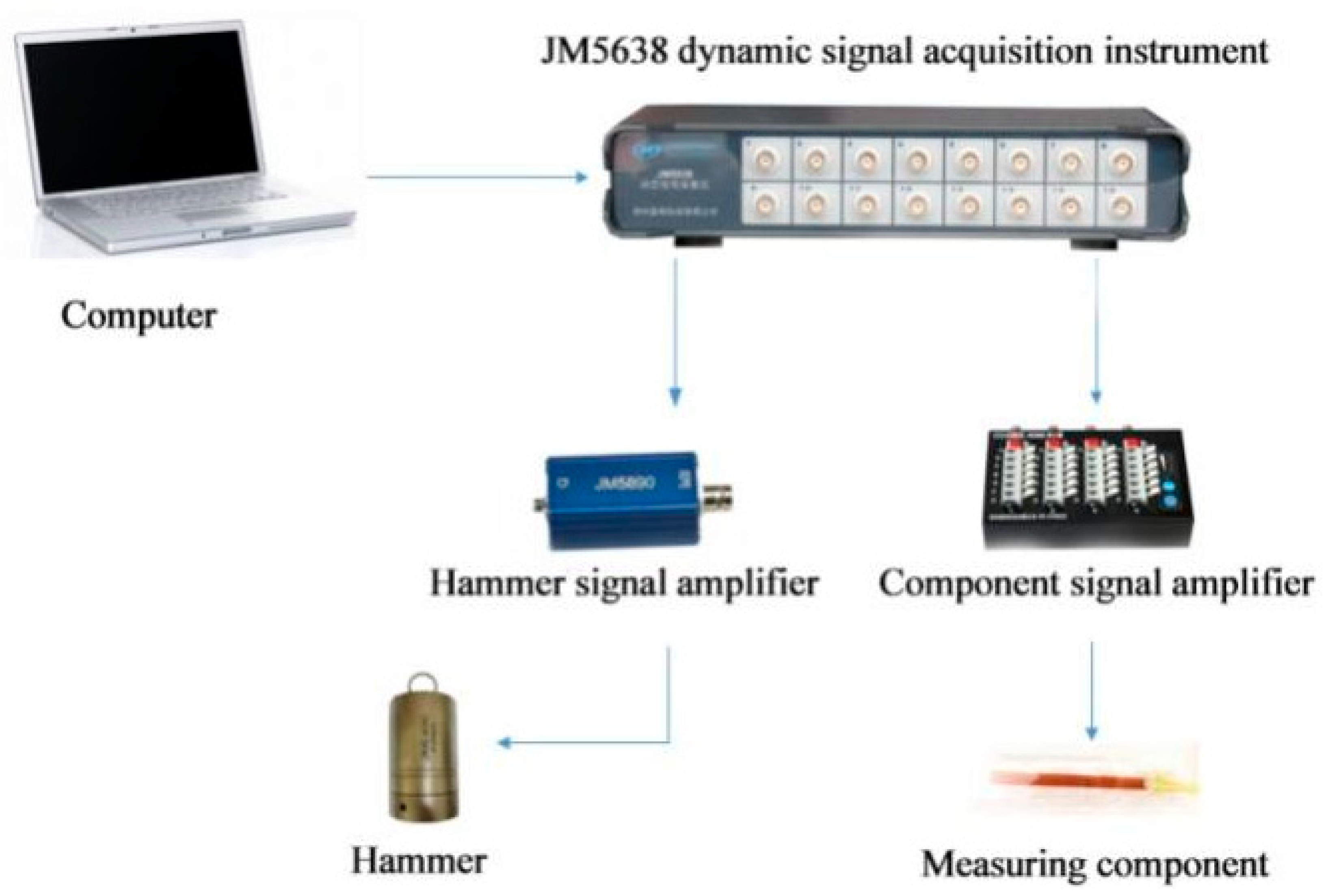

2.3. Testing Process

3. Experimental Results Analysis

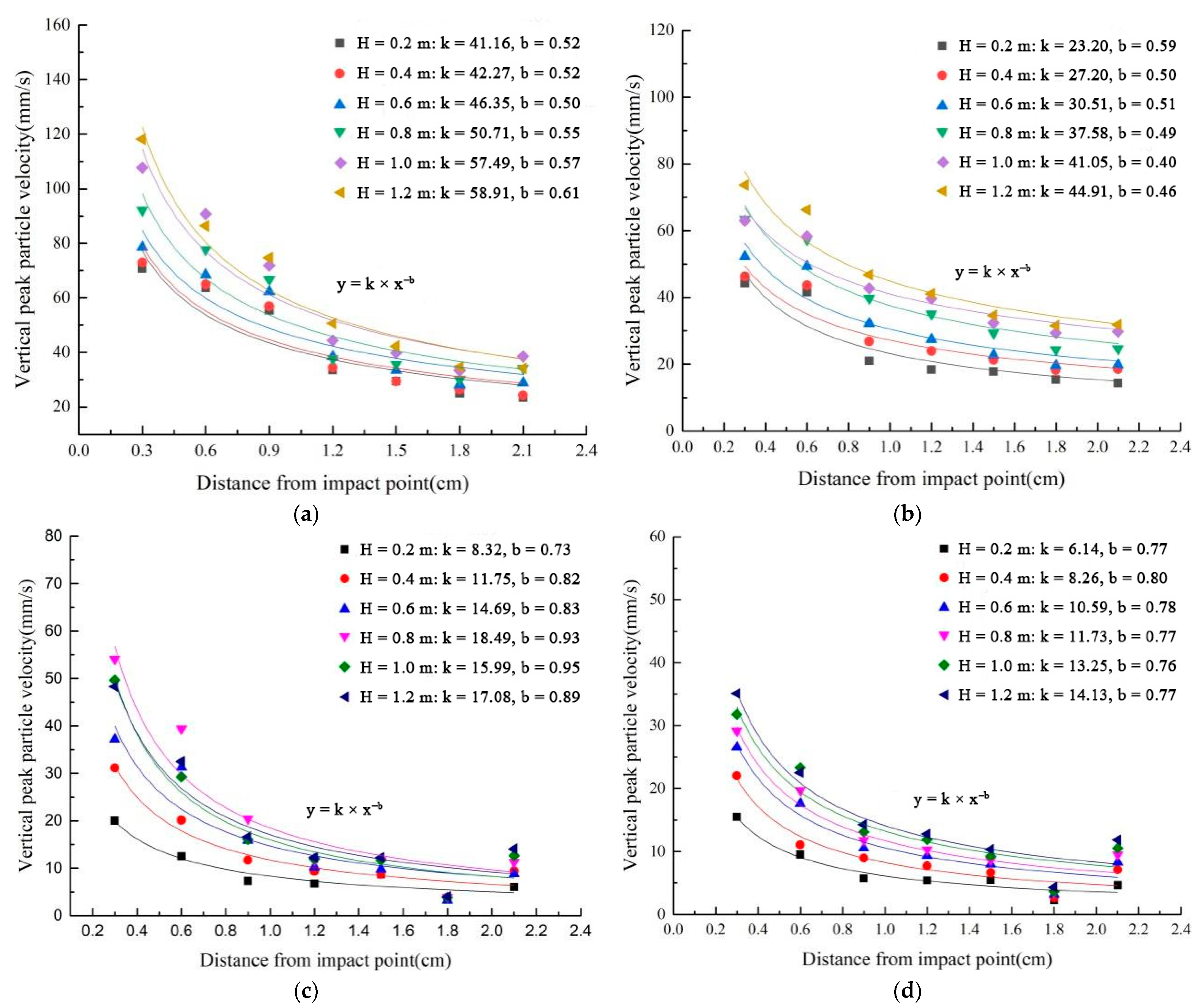

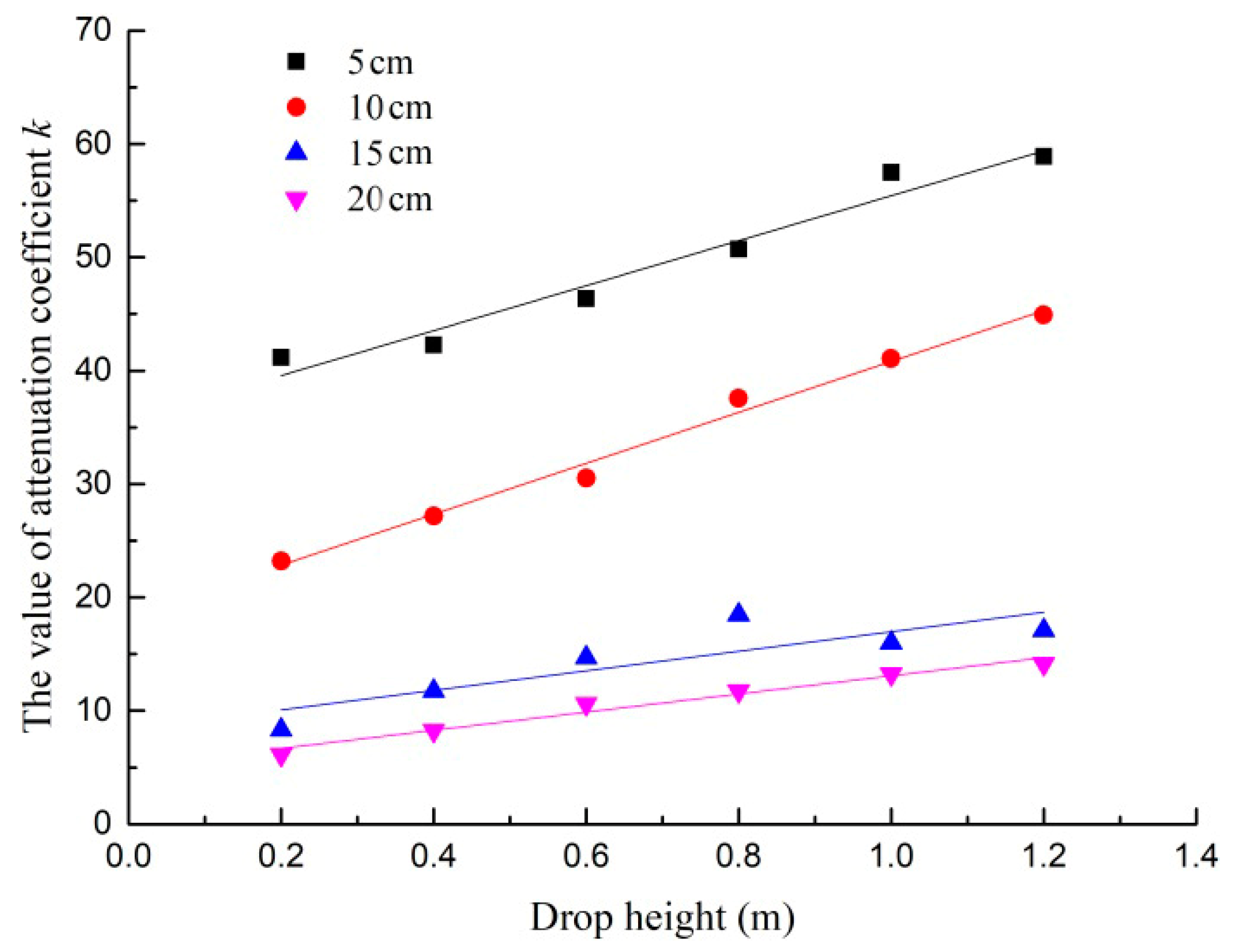

3.1. Dynamic Response Analysis of Single-Layer Plate

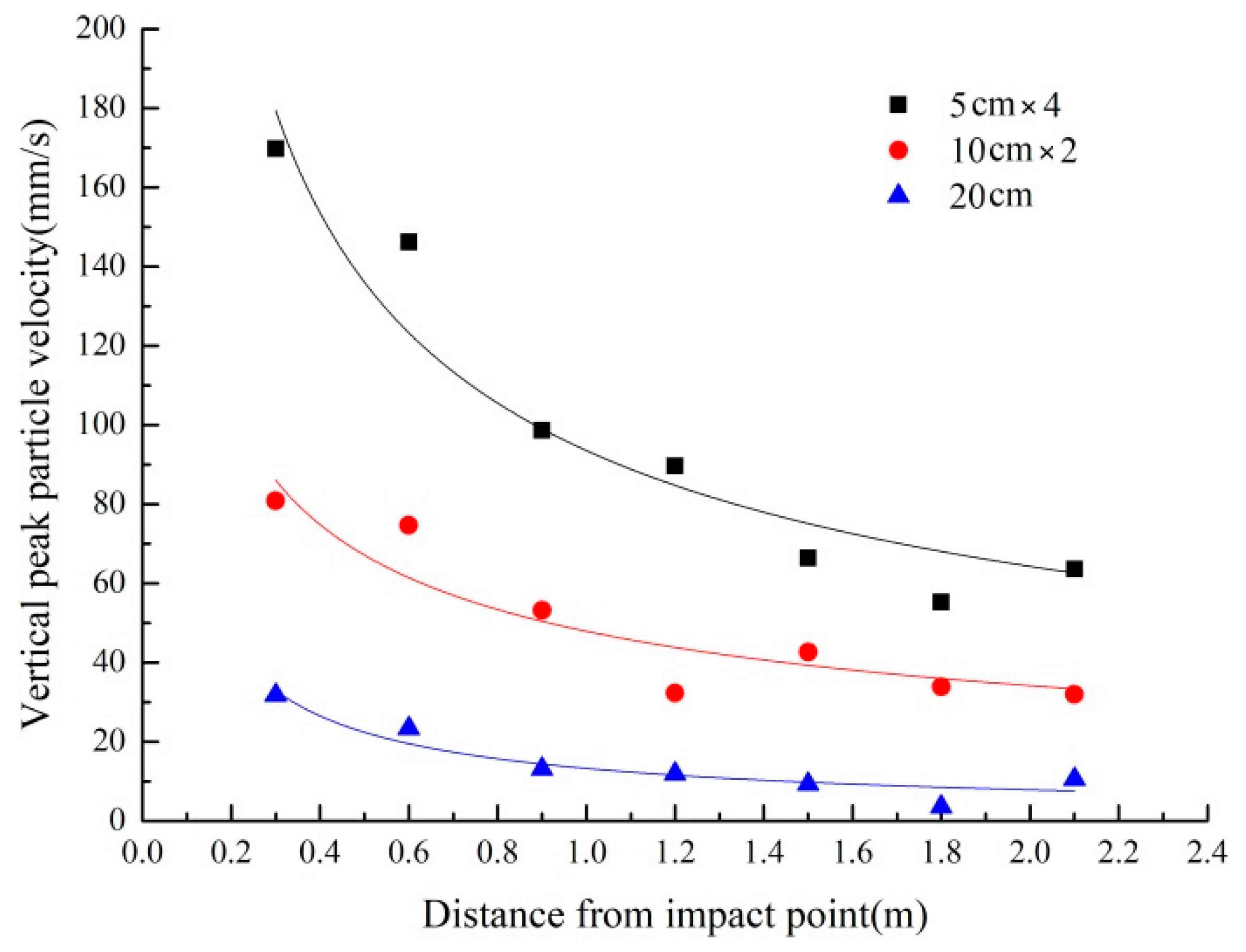

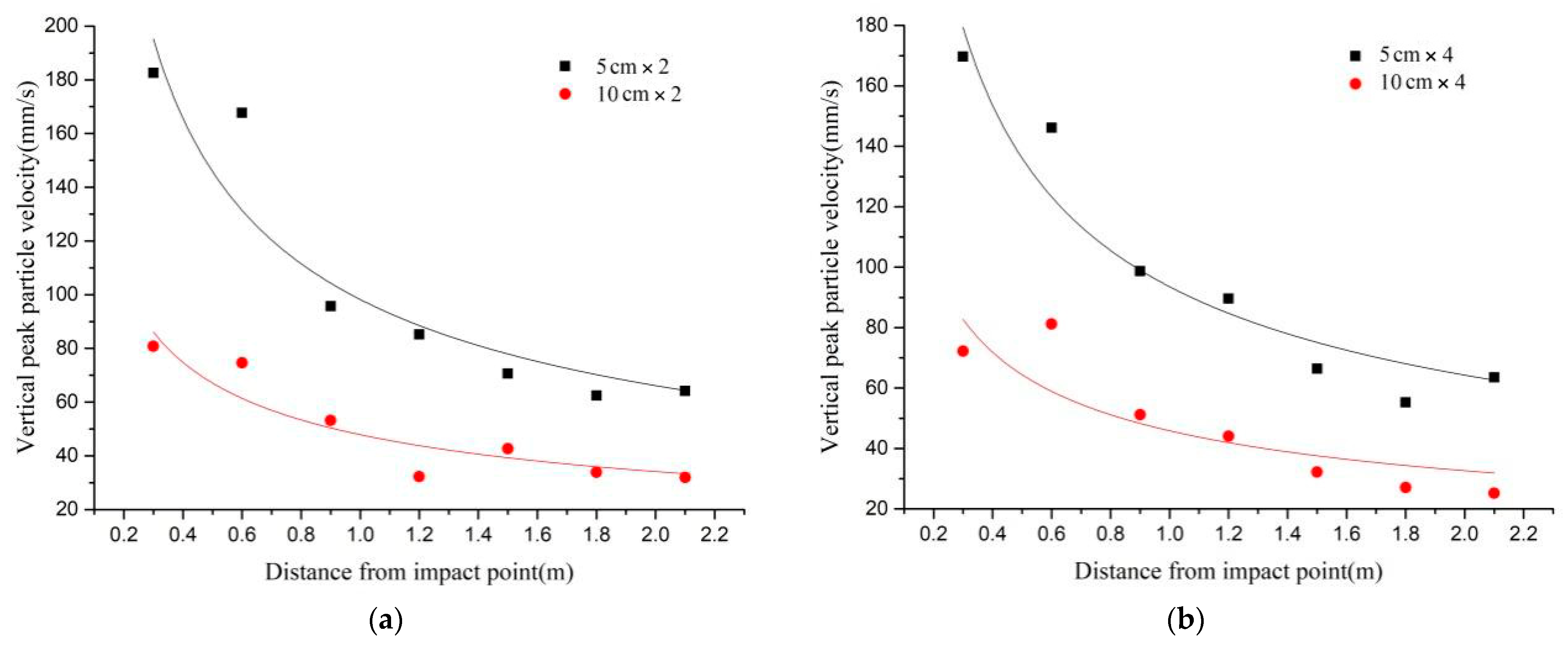

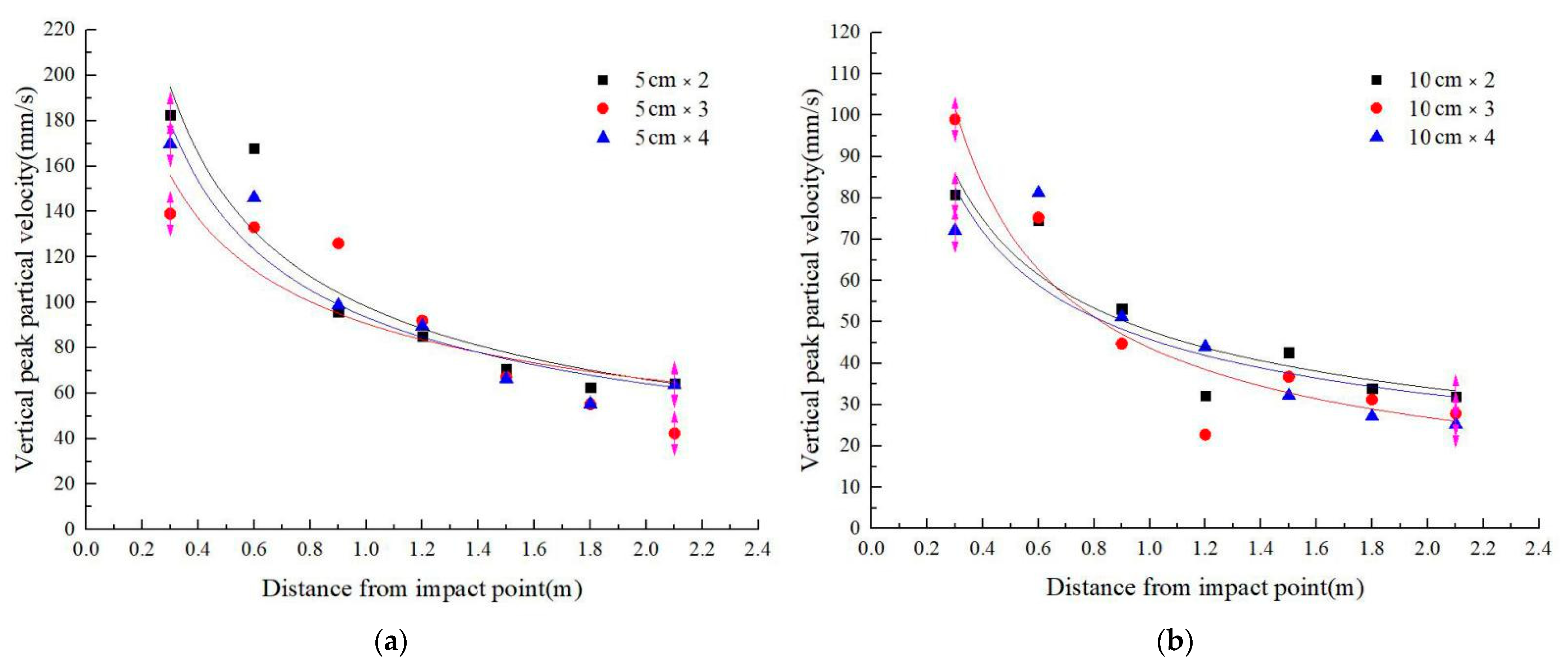

3.2. Dynamic Response Analysis of Multi-Layer Plate

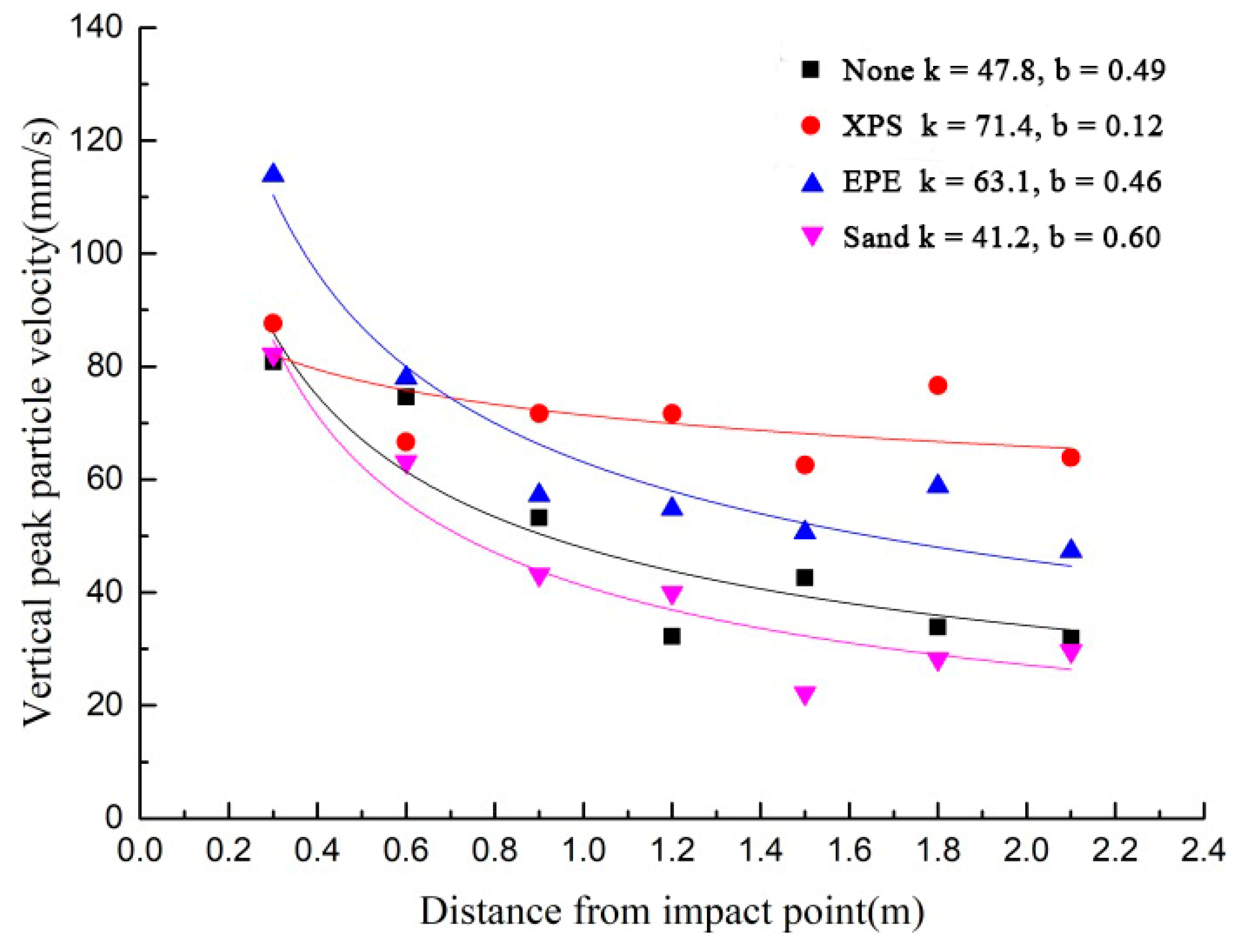

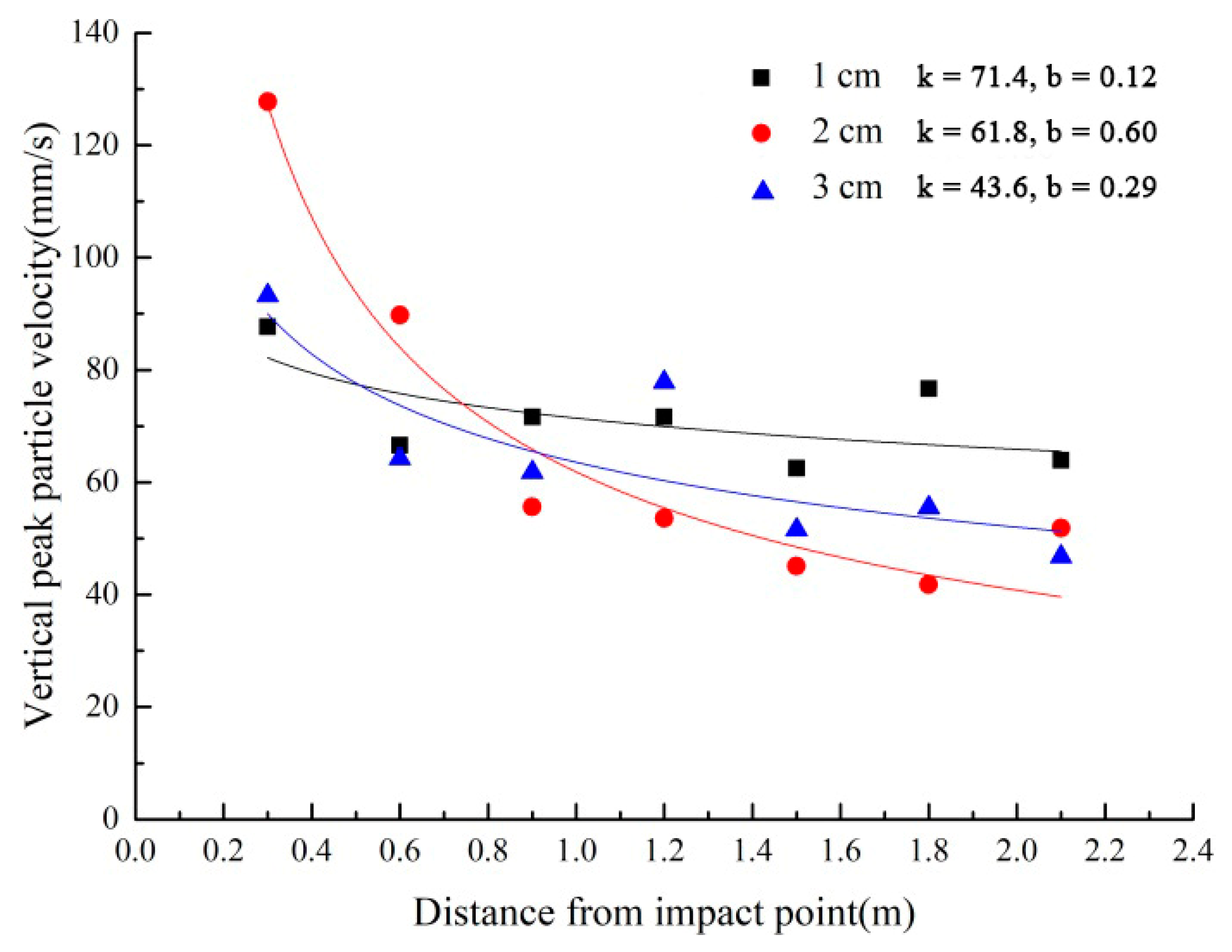

3.3. Dynamic Response Analysis of Multi-Layer Plate Considering Cementing Joints

4. Discussion and Conclusions

- (1)

- Sadovsky’s empirical formula can fit the attenuation law of the vertical peak particle velocity well, with the ranging in the horizontal direction, and the fitting attenuation’s coefficient k and index b can directly reflect the characteristics of the wave attenuation. The attenuation coefficient k has a linear positive correlation with the impact height under the same plate thickness, while it is negatively correlated with the thickness of the concrete plate under the same impact height.

- (2)

- The thickness of the layer is the main factor affecting the dynamic response of the layered medium, so the number of plates and joints and the total thickness of the medium have little influence. The value of the vertical peak particle velocity is larger, and the attenuation law is more obvious, with an increase in the number of layers and a decrease in the thickness of layers under the same total thickness of the layered medium.

- (3)

- The dynamic response of the multi-layer plate, when considering the cementing joints filled with different materials, varies significantly, and the thickness of the cementing joint has a great influence on the wave propagation of the layered medium. However, the effects of the material and thickness are only presented apparently, so the internal connection and the mechanism between the media and the joint need to be discussed deeply. The properties of the cementing joints and their effects need to be conducted systematically in subsequent studies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, R.K. An Approximate Method of Analysis of the Transmission of Elastic Waves Through a Frictional Boundary. J. Appl. Mech. 1977, 44, 652. [Google Scholar] [CrossRef]

- Miller, R.K. The effects of boundary friction on the propagation of elastic waves. Bull. Seismol. Soc. Am. 1978, 68, 987–998. [Google Scholar] [CrossRef]

- Schoenberg, M.; Sayers, C.M. Seismic anisotropy of fractured rock. Geophysics 1995, 60, 204–211. [Google Scholar] [CrossRef]

- Schoenberg, M. Elastic wave behavior across linear slip interfaces. J. Acoust. Soc. Am. 1980, 68, 1516–1521. [Google Scholar] [CrossRef]

- Pyrak-Nolte, L.J.; Myer, L.R.; Cook NG, W. Transmission of seismic waves across single natural fractures. J. Geophys. Res. Solid Earth 1990, 95, 8617–8638. [Google Scholar] [CrossRef]

- Pyrak-Nolte, L.J. The seismic response of fractures and the interrelations among fracture properties. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1996, 33, 787–802. [Google Scholar] [CrossRef]

- Hopkins, D.L.; Myer, L.R.; Cook NG, W. Seismic wave attenuation across parallel fractures as a function of fracture stiffness and spacing. Eos Trans. AGU 1988, 69, 1427–1436. [Google Scholar]

- Pyrak-Nolte, L.J.; Myer, L.R.; Cook NG, W. Anisotropy in seismic velocities and amplitudes from multiple parallel fractures. J. Geophys. Res. Solid Earth 1990, 95, 11345–11358. [Google Scholar] [CrossRef]

- Chai, S.B.; Li, J.C.; Zhang, Q.B.; Li, H.B.; Li, N.N. Stress wave propagation across a rock mass with two non-parallel joints. Rock Mech. Rock Eng. 2016, 49, 4023–4032. [Google Scholar] [CrossRef]

- Zhu, J.B.; Deng, X.F.; Zhao, X.; Zhao, J. A numerical study on wave transmission across multiple intersecting joint sets in rock masses with UDEC. Rock Mech. Rock Eng. 2013, 46, 1429–1442. [Google Scholar] [CrossRef]

- Goodman, R.E.; Taylor, R.L.; Brekke, T.L. A model for the mechanics of jointed rock. J. Soil Mech. Found. Div. 1968, 94, 637–659. [Google Scholar] [CrossRef]

- Lu, W. A Study on Interaction Between Stress Wave and Slipping Rock Interface. Rock Soil Mech. 1996, 17, 70–75. [Google Scholar]

- Li, N.N.; Li, J.C.; Li, H.B.; Liu, T.T.; Chai, S.B. SHPB Experiment on Influence of Contact Area of Joints on Propagation of Stress Wave. Chin. J. Rock Mech. Eng. 2015, 34, 1994–2000. [Google Scholar]

- Ju, Y.; Li, Y.; Xie, H.; Song, Z.; Tian, L. Stress Wave Propagation and Energy Dissipation in Jointed Rocks. Chin. J. Rock Mech. Eng. 2006, 25, 2426–2434. [Google Scholar]

- Gu, B.; Suárez-Rivera, R.; Nihei, K.T.; Myer, L.R. Incidence of plane waves upon a fracture. J. Geophys. Res. Solid Earth 1996, 101, 25337–25346. [Google Scholar] [CrossRef]

- Gu, B.; Nihei, K.T.; Myer, L.R.; Pyrak-Nolte, L.J. Fracture interface waves. J. Geophys. Res. Solid Earth 1996, 101, 827–835. [Google Scholar]

- Cai, J.G.; Zhao, J. Effects of multiple parallel fractures on apparent attenuation of stress waves in rock masses. Int. J. Rock Mech. Min. Sci. 2000, 37, 661–682. [Google Scholar]

- Zhao, J.; Zhao, X.B.; Cai, J.G. A further study of P-wave attenuation across parallel fractures with linear deformational behaviour. Int. J. Rock Mech. Min. Sci. 2006, 43, 776–788. [Google Scholar]

- Zhao, J.; Cai, J.G.; Zhao, X.B.; Li, H.B. Experimental study of ultrasonic wave attenuation across parallel fractures. Geomech. Geoengin. Int. J. 2006, 1, 87–103. [Google Scholar] [CrossRef]

- Zhao, J.; Cai, J.G. Transmission of elastic P-waves across single fractures with a nonlinear normal deformational behavior. Rock Mech. Rock Eng. 2001, 34, 3–22. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Zhang, S.; Xie, H.P. Rock dynamic fracture toughness tested with holed-cracked flattened Brazilian discs diametrically impacted by SHPB and its size effect. Exp. Mech. 2010, 50, 877–885. [Google Scholar] [CrossRef]

- Lu, F.; Lin, Y.; Wang, X.; Lu, L.; Chen, R. A theoretical analysis about the influence of interfacial friction in SHPB tests. Int. J. Impact Eng. 2015, 79, 95–101. [Google Scholar] [CrossRef]

- Li, J.C.; Li, N.N.; Li, H.B.; Zhao, J. An SHPB test study on wave propagation across rock masses with different contact area ratios of joint. Int. J. Impact Eng. 2017, 105, 109–116. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, R.S.; Wang, J.G. Simulation Material Experiment on Dynamic Mechanical Properties of Jointed Rock Affected by Joint Thickness. J. China Univ. Min. Technol. 2016, 45, 21–26. [Google Scholar]

- Wang, W.; Li, K.; Yan, Z.; Tang, X. Study on the Closure Deformation Properties of Joint Fractal under SHPB Load. Gold Sci. Technol. 2017, 25, 75–83. [Google Scholar]

- Challita, G.; Othman, R. Finite-element analysis of SHPB tests on double-lap adhesive joints. Int. J. Adhes. Adhes. 2010, 30, 236–244. [Google Scholar] [CrossRef]

- Tian, Z.N.; Li, S.H.; Xiao, N. Experimental Studies and Numerical Simulation of Stress Wave Propagation in One-dimensional Rock Mass. Chin. J. Rock Mech. Eng. 2008, 27, 2687–2693. [Google Scholar]

- Sun, B.; Guo, S.S.; Zeng, S.; Ma, A.Y.; Deng, X.S. Transmission and Reflection and the Attenuation Law of Stress Wave in Layered Joint Rock Mass. J. Disaster Prev. Mitig. Eng. 2015, 35, 828–832. [Google Scholar]

- Peng, F.H.; Li, S.L.; Cheng, J.Y. Experimental study on characteristics of stress wave propagation in mesoscale and complex rock mass by microseismic monitoring. Chin. J. Geotech. Eng. 2014, 36, 312–319. [Google Scholar]

- Wang, Z.J.; Li, X.L.; Ge, L.; Wang, P.Y. Free-field stress wave propagation induced by underground chemical explosion in granite. Chin. J. Rock Mech. Eng. 2003, 22, 1827–1831. [Google Scholar]

- Ghaboussi, J.; Wilson, E.L.; Isenberg, J. Finite element for rock joints and interfaces: 11F, 8R. J. SOIL MECH. FOUND. DIV. V99, SM10, 1973, P833–848. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1974, 11, 66. [Google Scholar]

- Schwer, L.E.; Lindberg, H.E. A finite element slideline approach for calculating tunnel response in jointed rock. Int. J. Numer. Anal. Methods Geomech. 1992, 16, 529–540. [Google Scholar] [CrossRef]

- Coates, R.T.; Schoenberg, M. Finite difference modelling of faults and fractures. Geophysics 1994, 60, 1514–1526. [Google Scholar] [CrossRef]

- Fan, S.C.; Jiao, Y.Y.; Zhao, J. On modelling of incident boundary for wave propagation in jointed rock masses using discrete element method. Comput. Geotech. 2004, 31, 57–66. [Google Scholar] [CrossRef]

- Cundall, P.A. A computer model for simulating progressive, large-scale movements in blocky rock systems. In Proceedings of the International Symposium on Rock Mechanics, Nancy, France, 4–6 October 1971; Volume 1, pp. 11–18. [Google Scholar]

- Brady, B.H.; Hsiung, S.H.; Chowdhury, A.H.; Philip, J. Verification studies on the UDEC computational model of jointed rock. In Proceedings of the International Conference on Mechanics of Jointed and Faulted Rock, Vienna, Austria, 18–20 April 1990; pp. 551–558. [Google Scholar]

- Zhao, X.; Zhao, J.; Cai, J.; Hefny, A.M. UDEC modelling on wave propagation across fractured rock masses. Comput. Geotech. 2008, 35, 97–104. [Google Scholar] [CrossRef]

- Zhao, G.F.; Zhao, J. Microscopic Numerical Modelling of the Dynamic Strength of Brittle Rock. In Proceedings of the International Conference on Analysis of Discontinues Deformation: New Developments & Applications, Singapore, 25–27 November 2010. [Google Scholar]

- Deng, X.F.; Zhu, J.B.; Chen, S.G.; Zhao, J. Some Fundamental Issues and Verification of 3DEC in Modeling Wave Propagation in Jointed Rock Masses. Rock Mech. Rock Eng. 2012, 45, 943–951. [Google Scholar] [CrossRef]

- Zhu, J.B.; Zhao, G.; Zhao, X.; Zhao, J. Validation study of the distinct lattice spring model (DLSM) on P-wave propagation across multiple parallel joints. Comput. Geotech. 2011, 38, 298–304. [Google Scholar] [CrossRef]

| Concrete Slab | Drop Hammer | ||||

|---|---|---|---|---|---|

| Density (kg/m3) | Compressive Strength (MPa) | Aggregate Size (m) | Density (kg/m3) | Elasticity Modulus (GPa) | Yield Strength (MPa) |

| 2.35 × 103 | 23.5 | 0.01 | 8.32 × 103 | 200 | 400 |

| Type | Size (cm × cm × cm) | Number |

|---|---|---|

| B1 | 250 × 100 × 5 | 4 |

| B2 | 250 × 100 × 10 | 4 |

| B3 | 250 × 100 × 15 | 1 |

| B4 | 250 × 100 × 20 | 1 |

| Parameters | Single-Layer Plate | Double-Layer Plate | Triple-Layer Plate | Four-Layer Plate | |||||

|---|---|---|---|---|---|---|---|---|---|

| 10 cm | 15 cm | 20 cm | 5 cm × 2 | 10 cm × 2 | 5 cm × 3 | 10 cm × 3 | 5 cm × 4 | 10 cm × 4 | |

| k | 41.1 | 16.0 | 13.2 | 98.2 | 47.9 | 90.7 | 43.7 | 93.5 | 45.8 |

| b | 0.40 | 0.95 | 0.76 | 0.57 | 0.49 | 0.45 | 0.70 | 0.54 | 0.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Gan, Q. Experimental Research on Dynamic Response of Layered Medium under Impact Load. Coatings 2022, 12, 1474. https://doi.org/10.3390/coatings12101474

Liu M, Gan Q. Experimental Research on Dynamic Response of Layered Medium under Impact Load. Coatings. 2022; 12(10):1474. https://doi.org/10.3390/coatings12101474

Chicago/Turabian StyleLiu, Mingqing, and Qinyu Gan. 2022. "Experimental Research on Dynamic Response of Layered Medium under Impact Load" Coatings 12, no. 10: 1474. https://doi.org/10.3390/coatings12101474

APA StyleLiu, M., & Gan, Q. (2022). Experimental Research on Dynamic Response of Layered Medium under Impact Load. Coatings, 12(10), 1474. https://doi.org/10.3390/coatings12101474