Water Repellency/Proof/Vapor Permeability Characteristics of Coated and Laminated Breathable Fabrics for Outdoor Clothing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabric Specimens

2.2. Measurement of the Physical Properties of the Fabric Specimens

2.2.1. Water Repellency

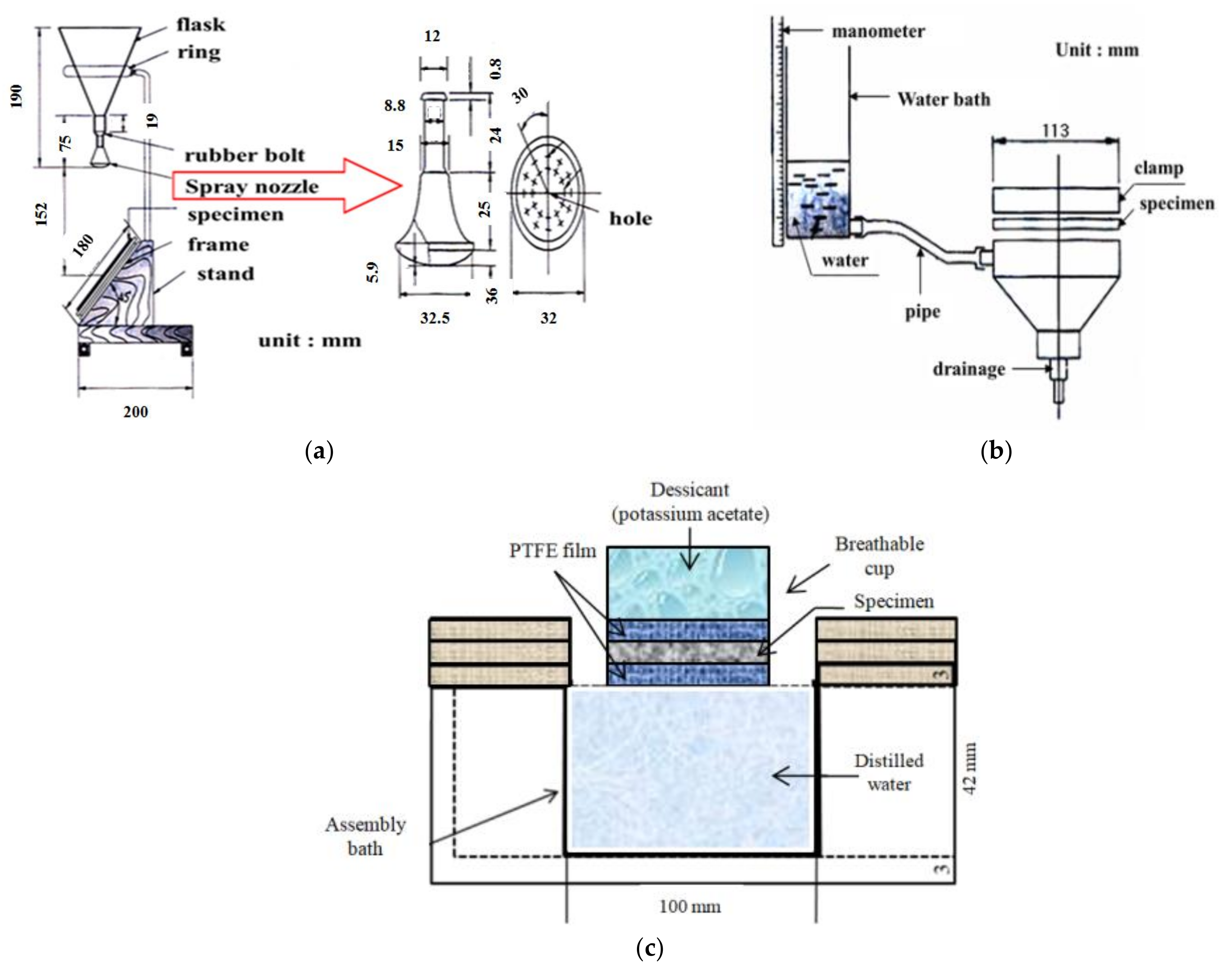

2.2.2. Waterproof by Hydrostatic Pressure Test

2.2.3. Water Vapor Permeability

2.3. Fabric Structural Parameter

3. Results and Discussion

3.1. Water Repellency of Breathable Fabric Specimens

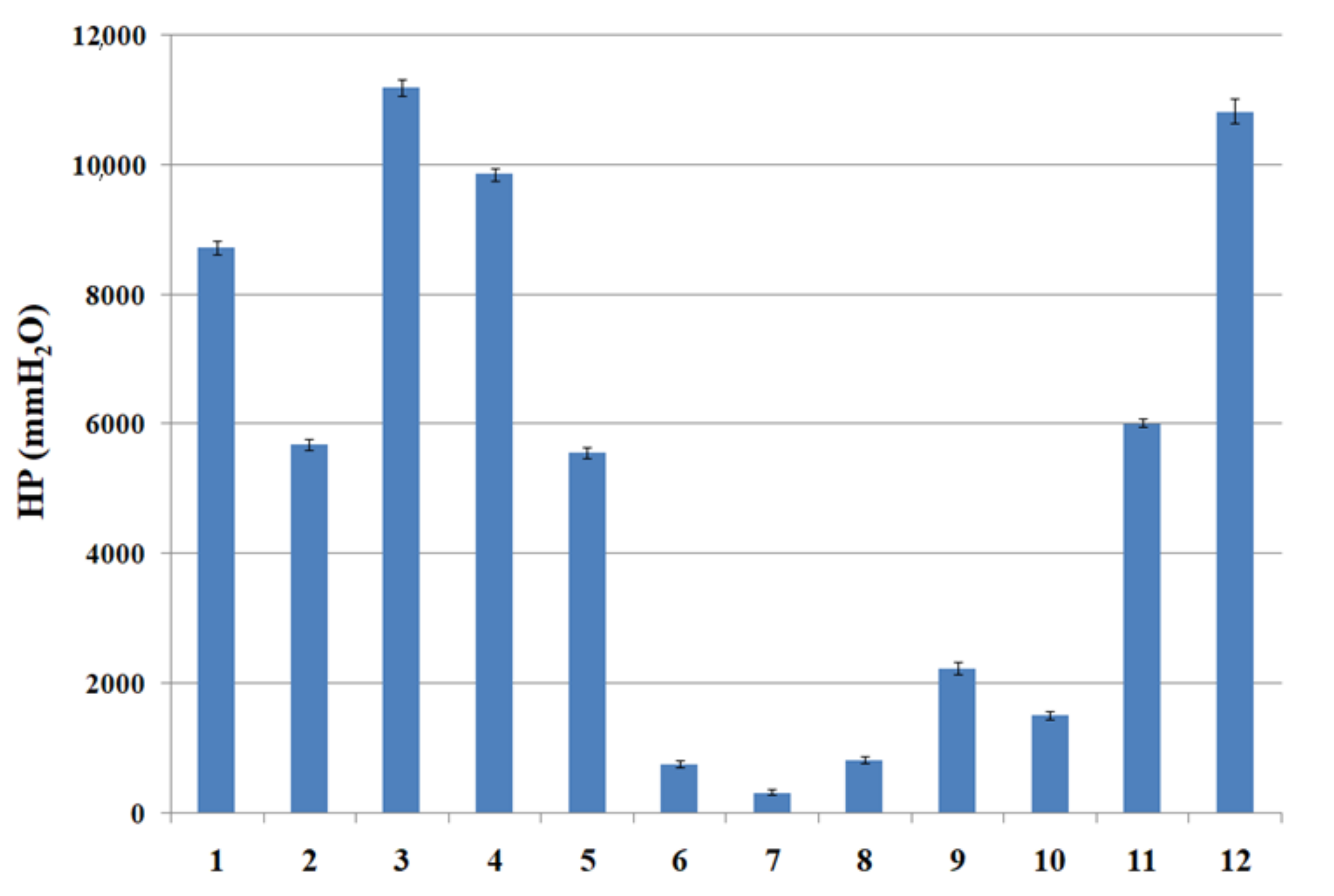

3.2. Waterproof Characteristics of Breathable Fabric Specimens

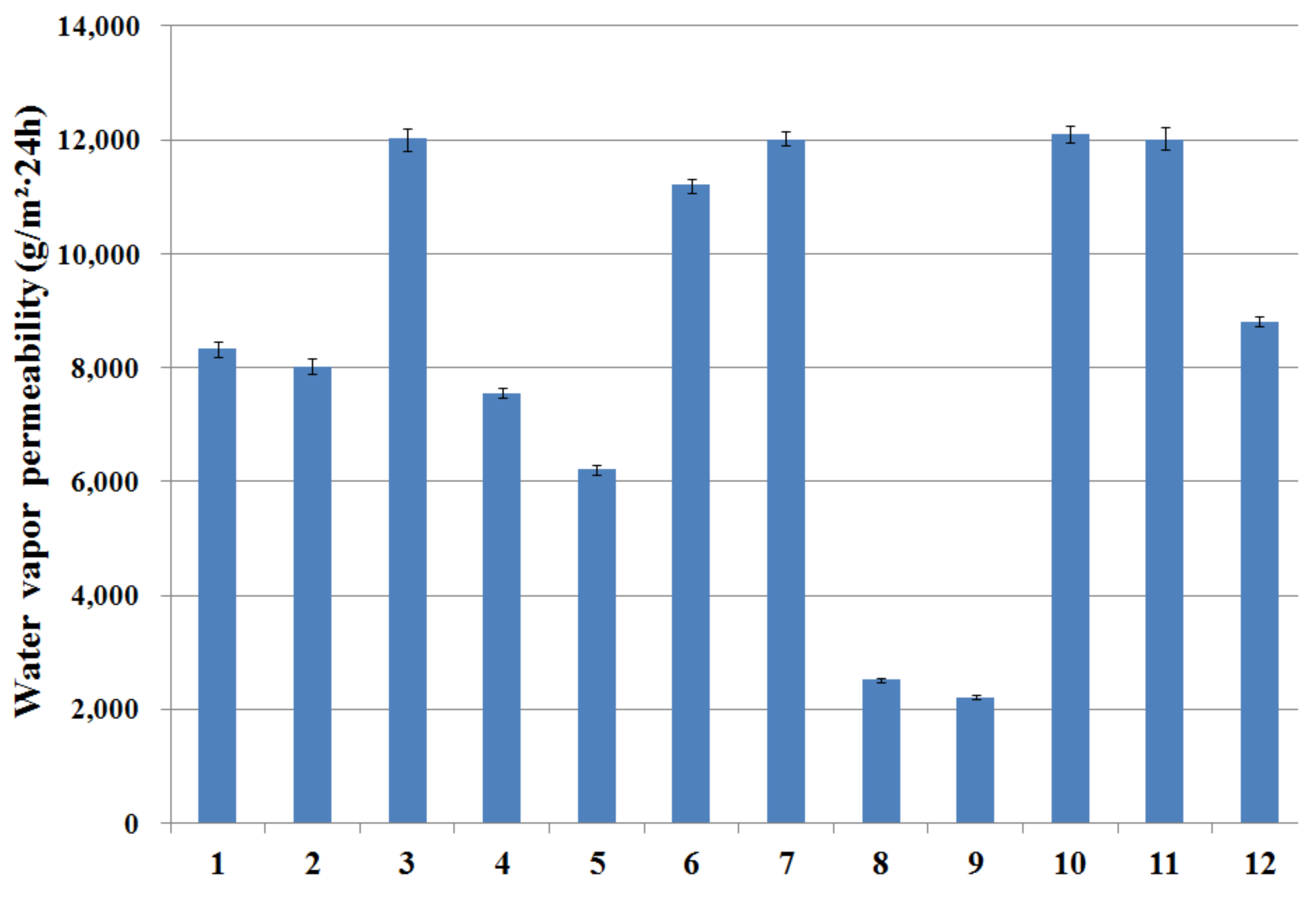

3.3. Water-Vapor-Permeable Characteristics of Breathable Fabric Specimens

3.4. Effect of Fabric Structural Parameters and Surface Modification to WVP

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, J.; Hunter, L. Engineering Apparel Fabrics and Garments; The Textile Institute: Manchester, UK; Woodhead Publishing Ltd.: Cambridge, UK, 2009; pp. 283–308. [Google Scholar]

- Jassal, M.; Khunger, A.; Bajaj, P.; Shnha, T.J.M. Waterproof breathable polymeric coatings based on polyurethane. J. Ind. Text. 2004, 33, 269–280. [Google Scholar] [CrossRef]

- Tanner, J.C. Breathability, comfort and Gore-Tex Laminated. J. Coat. Fabr. 1979, 8, 312–322. [Google Scholar] [CrossRef]

- Coffin, D.P. Stalking the perfect raincoat. Thread Mag. 1988, 19, 26. [Google Scholar]

- Sellers, G. Breathable waterproofs under the microscope. Climb. Rambl. 1985, 24, 49. [Google Scholar]

- Ozcan, G. Performance evaluation of water repellent finishes on woven fabric properties. Text. Res. J. 2007, 77, 265–270. [Google Scholar] [CrossRef]

- Scott, R.A. Textiles for Protection; The Textile Institute: Manchester, UK; Woodhead Publishing Ltd.: Cambridge, UK, 2005; p. 601. [Google Scholar]

- Scott, R.A. Coated and Laminated Fabrics. In Chemistry of the Textile Industry; Carr, C.M., Ed.; Blackie Academic & Professional: London, UK, 1995; pp. 234–243. [Google Scholar]

- Drinkmann, M. Structure & processing of Sympatex laminates. J. Coat. Fabr. 1992, 21, 199–211. [Google Scholar] [CrossRef]

- Huang, J.; Qian, X. Comparison of test methods for measuring water vapor permeability of fabrics. Text. Res. J. 2008, 78, 342–352. [Google Scholar] [CrossRef]

- Gibson, P.W. Factors influencing steady-state heat and water vapor transfer measurement for clothing materials. Text. Res. J. 1993, 63, 749–764. [Google Scholar] [CrossRef]

- McCullough, E.A.; Kwon, M.S.; Shim, H.S. A comparison of standard methods for measuring water vapour permeability of fabrics. Meas. Sci. Technol. 2003, 14, 1402–1408. [Google Scholar] [CrossRef]

- Cubric, I.S.; Skenderi, Z.; Havenith, G. Impact of raw material, yarn and fabric parameters and finishing on water vapor resistance. Text. Res. J. 2013, 83, 1215–1228. [Google Scholar] [CrossRef] [Green Version]

- Yoo, S.J.; Kim, E.A. Effects of multilayer clothing system array on water vapor transfer and condensation in cold weather clothing ensemble. Text. Res. J. 2008, 78, 189–197. [Google Scholar] [CrossRef]

- Yoo, S.J.; Kim, E.A. Wear trial assessment of layer structure effects on vapor permeability and condensation in a cold weather clothing ensemble. Text. Res. J. 2012, 82, 1079–1091. [Google Scholar] [CrossRef]

- Gorjanc, D.Š.; Dimitrovski, K.; Bizjak, M. Thermal and water vapor resistance of the elastic and conventional cotton fabrics. Text. Res. J. 2012, 82, 1498–1506. [Google Scholar] [CrossRef]

- Lee, S.S.; Obendorf, S.K. Statistical modeling of water vapor transport through woven fabrics. Text. Res. J. 2012, 82, 211–219. [Google Scholar] [CrossRef]

- Rego, J.M.; Verdu, P.; Nieto, J.; Blanes, M. Comfort analysis of woven cotton/polyester fabrics modified with a new elastic fiber, part 2: Detailed study of mechanical, thermo-physiological and skin sensorial properties. Text. Res. J. 2010, 80, 206–215. [Google Scholar] [CrossRef]

- Ruckmann, J.E. Water vapour transfer in waterproof breathable fabrics : I. Under steady state conditions. Int. J. Cloth. Sci. Technol. 1997, 9, 10–22. [Google Scholar] [CrossRef]

- Ruckmann, J.E. Water vapour transfer in waterproof breathable fabrics : II. Under windy conditions. Int. J. Cloth. Sci. Technol. 1997, 9, 23–33. [Google Scholar] [CrossRef]

- Ruckmann, J.E. Water vapour transfer in waterproof breathable fabrics : III. Under rainy and windy conditions. Int. J. Cloth. Sci. Technol. 1997, 9, 141–153. [Google Scholar] [CrossRef]

- Ruckmann, J.E.; Murray, R. Engineering of clothing systems for improved thermophsiological comfort. Int. J. Cloth. Sci. Technol. 1999, 11, 37–52. [Google Scholar] [CrossRef]

- Ren, Y.J.; Ruckman, J.E. Effect of condensation on water vapour transfer through waterproof breathable fabrics. J. Coat. Fabr. 1999, 29, 20–36. [Google Scholar]

- Ren, Y.J.; Ruckman, J.E. Water vapour transfer in wet waterproof breathable fabrics. J. Coat. Fabr. 2003, 32, 165–175. [Google Scholar] [CrossRef]

- Kim, H.A. Moisture vapor resistance of coated and laminated breathable fabrics using evaporative wet heat transfer method. Coatings 2021, 11, 1157. [Google Scholar] [CrossRef]

- Scott, R.A. Cold weather clothing for military applications Chapter 14. In Textiles for Cold Weather Apparel; The Textile Institute: Manchester, UK; Woodhead Publishing Ltd.: Cambridge, UK, 2009; pp. 305–328. [Google Scholar]

- Saltz, P. Testing the quality of breathable textiles. In Performance of Protective Clothing: Second Symposium; ASTM Special Technical Publication 989; American Society for Textile and Materials: Philadelphia, PA, USA, 1988; p. 295. [Google Scholar]

- Holmes, D.A. Waterproof breathable fabrics Chapter 12. In Handbook of Technical Textiles; The Textile Institute: Manchester, UK; Woodhead Publishing Ltd.: Cambridge, UK, 2000; p. 282. [Google Scholar]

- Holmes, D.A.; Grundy, C.; Rowe, H.D. The characteristics of waterproof breathable fabric. J. Cloth. Technol. Manag. 1995, 12, 142. [Google Scholar]

- Kim, S.J. Moisture vapor permeability and thermal wear comfort of ecofriendly fiber-embedded woven fabrics for high-performance clothing. Materials 2021, 14, 6205. [Google Scholar] [CrossRef] [PubMed]

- JIS L 1096; Testing Methods for Woven and Knitted Fabrics. Japanese Standards Association: Tokyo, Japan, 2015.

- JIS L 1092; Testing Methods for Water Resistance of Textiles. Japanese Standards Association: Tokyo, Japan, 2009.

- JIS L 1099; Test Methods for Water Vapour Permeability of Textiles. Japanese Standards Association: Tokyo, Japan, 2021.

- Kim, S.J.; Kim, H.A. Effect of fabric structural parameters and weaving conditions to warp tension of aramid fabrics for protective garments. Text. Res. J. 2018, 88, 987–1001. [Google Scholar] [CrossRef]

| Specimen No. | Yarn Number (d) | Fabric Density | Material Characteristics | Remark | |||

|---|---|---|---|---|---|---|---|

| Wp | Wf | Wp (ends/in) | Wf (picks/in) | ||||

| Group A | 1 | 80 | 83 | 232 | 120 | Nylon hydrophilic PU-laminated fabric | 2 layer |

| 2 | 56 | 71 | 170 | 93 | Nylon hydrophilic PU-coated fabric | 2 layer | |

| 3 | 84 | 108 | 85 | 85 | Nylon hydrophilic PU-laminated and tricot-layered fabric | 2.5 layer | |

| Group B | 4 | 131 | 121 | 95 | 140 | Polyester hydrophilic-laminated fabric | 2 layer |

| 5 | 68 | 164 | 233 | 100 | Polyester-coated fabric | 2 layer | |

| 6 | 56 | 65 | 212 | 130 | Polyester microfiber high-density fabric | 1 layer | |

| 7 | 53 | 54 | 158 | 72 | Polyester microfiber high-density fabric | 1 layer | |

| Group C | 8 | 92 | 183 | 160 | 68 | Nylon-66 Teflon finished and microfiber high-density fabric | 1 layer |

| 9 | 177 | 80 | 165 | 124 | Nylon-66 hydrophilic PU-coated fabric | 2 layer | |

| 10 | 89 | 178 | 152 | 70 | Nylon-66 microporous PU-coated fabric | 2 layer | |

| Group D | 11 | 41 | 272 | 118 | 83 | Nylon/cotton-laminated fabric | 2 layer |

| 12 | 64 | 67 | 120 | 108 | Nylon/cotton-laminated fabric | 2 layer | |

| Sample No. | Materials | Surface Modification Method | WR (%) | HP (mmH2O) | WVP (g/(m²·24h)) | Structure (Layers) | Cover Factor (WDC) | Thickness (mm) | Weight (g/cm²) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Dev. | Mean | Dev. | |||||||||

| Group A | 1 | Nylon | Laminated | 100 | 8720.8 | 206.1 | 8336.8 | 260.1 | 2 | 1.23 | 0.189 | 0.0110 |

| 2 | Nylon | Coating | 100 | 5689.4 | 165.3 | 8024.2 | 276.3 | 2 | 0.96 | 0.112 | 0.0096 | |

| 3 | Nylon | Laminated with tricot | 100 | 11,200.5 | 267.2 | 12,017.2 | 393.4 | 2.5 | 0.66 | 0.321 | 0.0137 | |

| Group B | 4 | PET | Laminated | 100 | 9870.6 | 190.3 | 7542.5 | 178.1 | 2 | 1.60 | 0.256 | 0.0143 |

| 5 | PET | Coating | 100 | 5562.5 | 168.1 | 6217.8 | 179.3 | 2 | 1.09 | 0.291 | 0.0163 | |

| 6 | PET | HD fabric | 90 | 762.8 | 100.3 | 11,214.2 | 249.5 | 1 | 1.60 | 0.154 | 0.0091 | |

| 7 | PET | HD fabric | 90 | 325.5 | 84.1 | 12,013.2 | 232.4 | 1 | 1.58 | 0.117 | 0.0070 | |

| Group C | 8 | Nylon | HD and Teflon-finished | 100 | 821.6 | 105.3 | 2513.6 | 89.3 | 1 | 2.44 | 0.315 | 0.0110 |

| 9 | Nylon | H-PU Coating | 100 | 2236.2 | 174.1 | 2212.5 | 80.1 | 2 | 1.33 | 0.346 | 0.0150 | |

| 10 | Nylon | M-PU Coating | 100 | 1518.8 | 126.3 | 12,112.4 | 285.2 | 2 | 0.73 | 0.370 | 0.0150 | |

| Group D | 11 | Nylon/ Cotton | Laminated | 100 | 6011.5 | 131.2 | 12,012.1 | 378.1 | 2 | 0.81 | 0.109 | 0.0081 |

| 12 | Nylon/ Cotton | Laminated | 100 | 10,820.5 | 379.1 | 8812.4 | 176.2 | 2 | 0.95 | 0.382 | 0.0225 | |

| Physical Properties | F-Value (F0) | F (11, 48, 0.95) | p-Value |

|---|---|---|---|

| HP | 15617.86 | 1.99 | 2.56 × 10−81(p < 0.05) |

| WVP | 6410.45 | 1.99 | 4.84 × 10−72(p < 0.05) |

| Water Vapor Permeability (WVP) | Fabric Stuructural Parameter (xi) | Regression Equation | Reg. Coeff. | R2 | p-Value (α = 0.05) |

|---|---|---|---|---|---|

| WVP by 4 vaiables | x1 = thickness x2 = weight x3 = thickness/weight x4 = cover factor | y = −312.5 − 81276.2 x1 + 1127124.5 x2 + 12016.2 x3 − 5412.72 x4 | 0.801 | 0.642 | 0.095 |

| WVP by 5 variables | x1 = thickness x2 = weight x3 = thickness/weight x4 = cover factor x5 = layer | y = 1124.2 − 84612.5 x1 + 1141213.4 x2 + 9376.5 x3 − 5542.2 x4 − 248.4 x5 | 0.805 | 0.648 | 0.020 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-A. Water Repellency/Proof/Vapor Permeability Characteristics of Coated and Laminated Breathable Fabrics for Outdoor Clothing. Coatings 2022, 12, 12. https://doi.org/10.3390/coatings12010012

Kim H-A. Water Repellency/Proof/Vapor Permeability Characteristics of Coated and Laminated Breathable Fabrics for Outdoor Clothing. Coatings. 2022; 12(1):12. https://doi.org/10.3390/coatings12010012

Chicago/Turabian StyleKim, Hyun-Ah. 2022. "Water Repellency/Proof/Vapor Permeability Characteristics of Coated and Laminated Breathable Fabrics for Outdoor Clothing" Coatings 12, no. 1: 12. https://doi.org/10.3390/coatings12010012

APA StyleKim, H.-A. (2022). Water Repellency/Proof/Vapor Permeability Characteristics of Coated and Laminated Breathable Fabrics for Outdoor Clothing. Coatings, 12(1), 12. https://doi.org/10.3390/coatings12010012