Effects of Surface Pretreatment of Titanium Substrates on Properties of Electrophoretically Deposited Biopolymer Chitosan/Eudragit E 100 Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrate Pretreatment

2.2. Deposition of Chitosan/Eudragit E 100 Coatings

2.3. Structure and Morphology Studies

2.4. Wettability Study

2.5. Adhesion Study

2.6. Corrosion Study

3. Results and Discussion

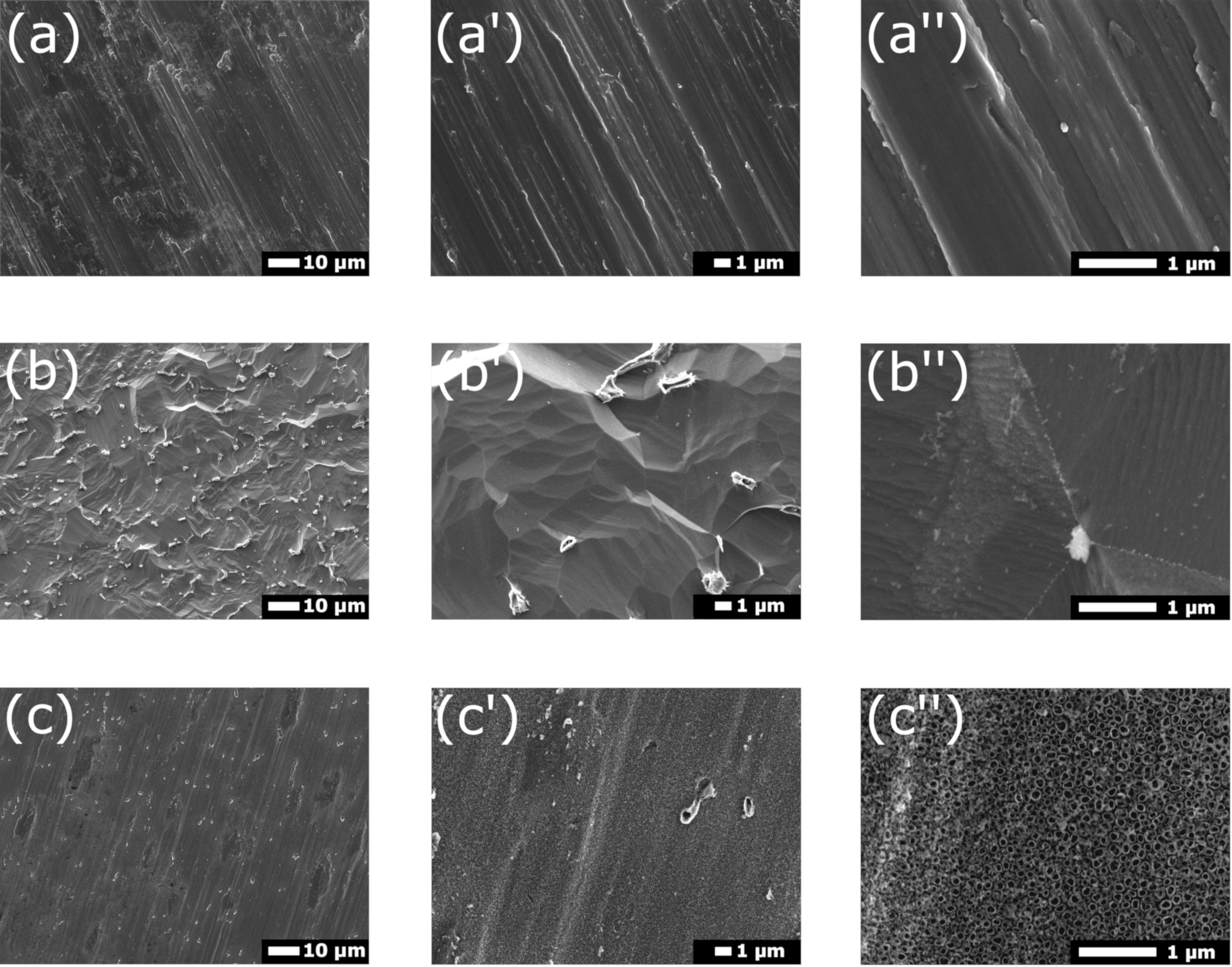

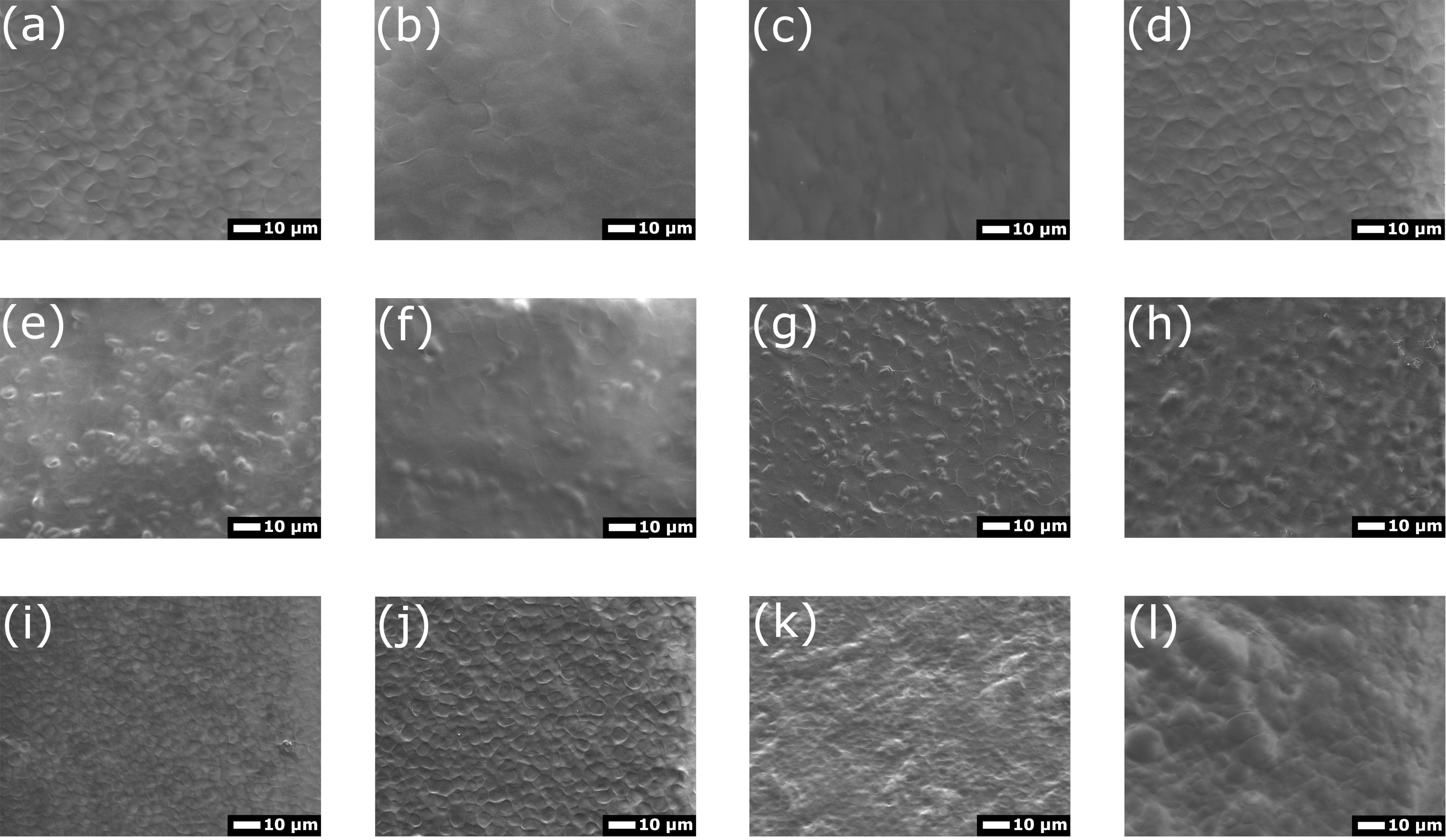

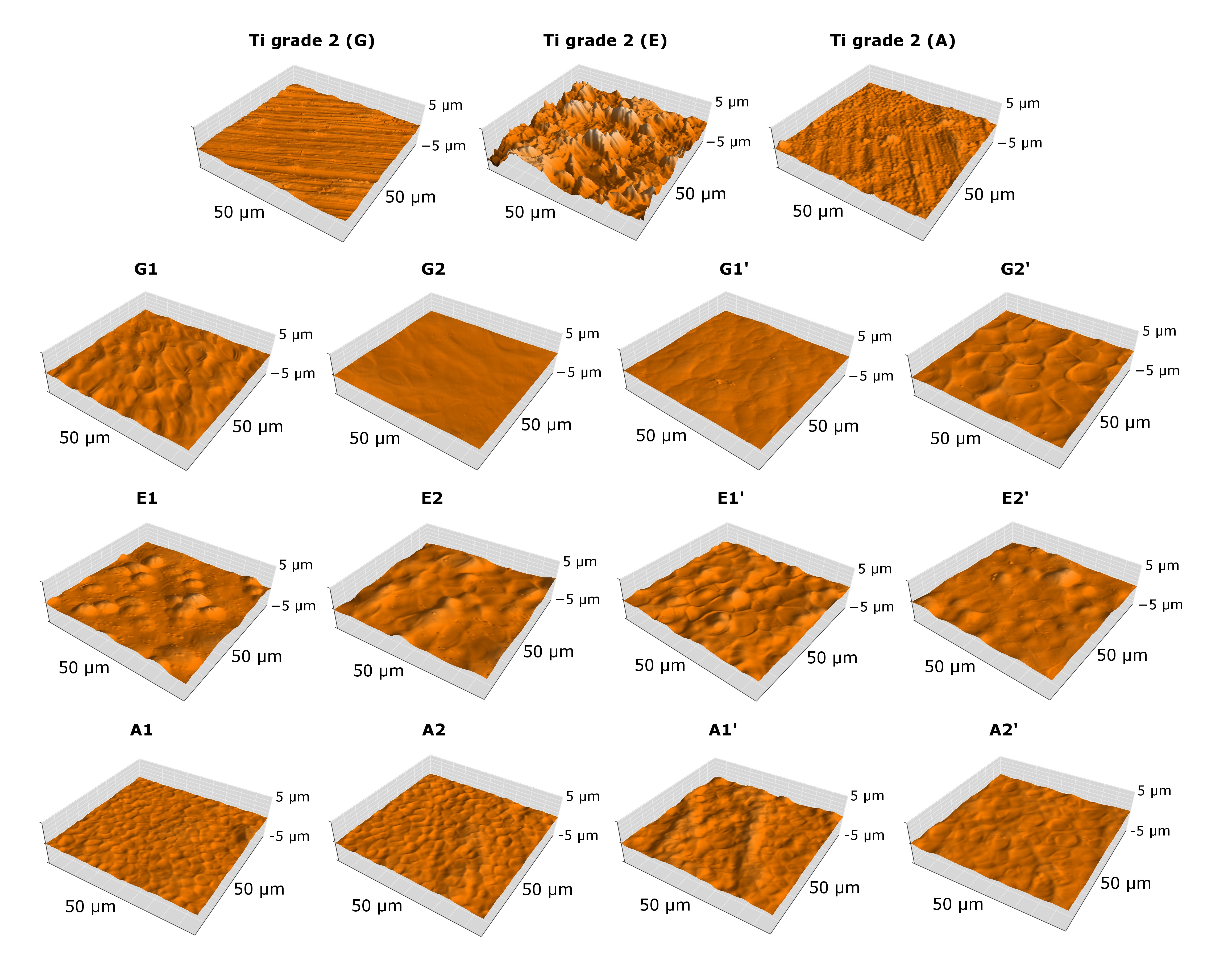

3.1. Structure and Morphology Studies

3.2. Wettability Study

3.3. Adhesion Study

3.4. Corrosion Studies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Casagrande, R.B.; Kunst, S.R.; Beltrami, L.V.R.; Aguzzoli, C.; Brandalise, R.N.; de Fraga Malfatti, C. Pretreatment effect of the pure titanium surface on hybrid coating adhesion based on tetraethoxysilane and methyltriethoxysilane. J. Coat. Technol. Res. 2018, 15, 1089–1106. [Google Scholar] [CrossRef]

- Chouirfa, H.; Bouloussa, H.; Migonney, V.; Falentin-Daudré, C. Review of titanium surface modification techniques and coatings for antibacterial applications. Acta Biomater. 2019, 83, 37–54. [Google Scholar] [CrossRef] [PubMed]

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef]

- Spriano, S.; Yamaguchi, S.; Baino, F.; Ferraris, S. A critical review of multifunctional titanium surfaces: New frontiers for improving osseointegration and host response, avoiding bacteria contamination. Acta Biomater. 2018, 79, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Bartmański, M.; Pawłowski, Ł.; Zieliński, A.; Mielewczyk-Gryń, A.; Strugała, G.; Cieslik, B. Electrophoretic deposition and characteristics of chitosan / nanosilver composite coatings on the nanotubular TiO2 layer. Coatings 2020, 10, 245. [Google Scholar] [CrossRef] [Green Version]

- Doe, Y.; Ida, H.; Seiryu, M.; Deguchi, T.; Takeshita, N.; Sasaki, S.; Sasaki, S.; Irie, D.; Tsuru, K.; Ishikawa, K.; et al. Titanium surface treatment by calcium modification with acid-etching promotes osteogenic activity and stability of dental implants. Materialia 2020, 12, 100801. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, Y.; Wang, D.-n.; Zhao, B.-h.; Li, J. chang Porous structure preparation and wettability control on titanium implant. Surf. Coat. Technol. 2013, 228, S131–S136. [Google Scholar] [CrossRef]

- Manivasagam, G.; Dhinasekaran, D.; Rajamanickam, A. Biomedical Implants: Corrosion and its Prevention-A Review Surface modification of Ti alloys by plasma cleaning to enhance antibacterial activity-BRNS View project Biomedical Implants: Corrosion and its Prevention-A Review. Recent Pat. Corros. Sci. 2010, 2, 40–54. [Google Scholar] [CrossRef] [Green Version]

- Tolde, Z.; Starý, V.; Cvrček, L.; Vandrovcová, M.; Remsa, J.; Daniš, S.; Krčil, J.; Bačáková, L.; Špatenka, P. Growth of a TiNb adhesion interlayer for bioactive coatings. Mater. Sci. Eng. C 2017, 80, 652–658. [Google Scholar] [CrossRef]

- Lackner, J.M.; Waldhauser, W.; Schwarz, M.; Mahoney, L.; Major, L.; Major, B. Polymer pre-treatment by linear anode layer source plasma for adhesion improvement of sputtered TiN coatings. Vacuum 2008, 83, 302–307. [Google Scholar] [CrossRef]

- Ergün, Y.; Başpınar, M.S. Effect of acid passivation and H2 sputtering pretreatments on the adhesive strength of sol–gel derived Hydroxyapatite coating on titanium surface. Int. J. Hydrog. Energy 2017, 42, 20420–20429. [Google Scholar] [CrossRef]

- Sasikumar, Y.; Indira, K.; Rajendran, N. Surface Modification Methods for Titanium and Its Alloys and Their Corrosion Behavior in Biological Environment: A Review. J. Bio-Tribo-Corros. 2019, 5, 1–25. [Google Scholar] [CrossRef]

- Man, H.C.; Chiu, K.Y.; Cheng, F.T.; Wong, K.H. Adhesion study of pulsed laser deposited hydroxyapatite coating on laser surface nitrided titanium. Thin Solid Film. 2009, 517, 5496–5501. [Google Scholar] [CrossRef]

- Soro, N.; Saintier, N.; Attar, H.; Dargusch, M.S. Surface and morphological modification of selectively laser melted titanium lattices using a chemical post treatment. Surf. Coat. Technol. 2020, 393, 125794. [Google Scholar] [CrossRef]

- Basiaga, M.; Walke, W.; Antonowicz, M.; Kajzer, W.; Szewczenko, J.; Domanowska, A.; Michalewicz, A.; Szindler, M.; Staszuk, M.; Czajkowski, M. Impact of surface treatment on the functional properties stainless steel for biomedical applications. Materials 2020, 13, 4767. [Google Scholar] [CrossRef] [PubMed]

- Iwaya, Y.; Machigashira, M.; Kanbara, K.; Miyamoto, M.; Noguchi, K.; Izumi, Y.; Ban, S. Surface Properties and Biocompatibility of Acid-etched Titanium. Dent. Mater. J. 2008, 27, 415–421. [Google Scholar] [CrossRef] [Green Version]

- Ren, B.; Wan, Y.; Wang, G.; Liu, Z.; Huang, Y.; Wang, H. Morphologically modified surface with hierarchical micro-/nano-structures for enhanced bioactivity of titanium implants. J. Mater. Sci. 2018, 53, 12679–12691. [Google Scholar] [CrossRef]

- Yang, G.L.; He, F.M.; Yang, X.F.; Wang, X.X.; Zhao, S.F. Bone responses to titanium implants surface-roughened by sandblasted and double etched treatments in a rabbit model. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endodontology 2008, 106, 516–524. [Google Scholar] [CrossRef]

- De Lima, G.G.; da Luz, A.R.; Pereira, B.L.; Szesz, E.M.; de Souza, G.B.; Lepienski, C.M.; Kuromoto, N.K.; Nugent, M.J.D. Tailoring surface properties from nanotubes and anodic layers of titanium for biomedical applications. In Applications of Nanocomposite Materials in Orthopedics; Elsevier: Amsterdam, The Netherlands, 2018; pp. 179–199. ISBN 9780128137574. [Google Scholar]

- Jiang, T.; Zhang, Z.; Zhou, Y.; Liu, Y.; Wang, Z.; Tong, H.; Shen, X.; Wang, Y. Surface functionalization of titanium with chitosan/gelatin via electrophoretic deposition: Characterization and cell behavior. Biomacromolecules 2010, 11, 1254–1260. [Google Scholar] [CrossRef]

- Bartmanski, M.; Cieslik, B.; Glodowska, J.; Kalka, P.; Pawlowski, L.; Pieper, M.; Zielinski, A. Electrophoretic deposition (EPD) of nanohydroxyapatite—Nanosilver coatings on Ti13Zr13Nb alloy. Ceram. Int. 2017, 43, 11820–11829. [Google Scholar] [CrossRef]

- Cheung, K.H.; Pabbruwe, M.B.; Chen, W.F.; Koshy, P.; Sorrell, C.C. Effects of substrate preparation on TiO2 morphology and topography during anodization of biomedical Ti6Al4V. Mater. Chem. Phys. 2020, 252, 123224. [Google Scholar] [CrossRef]

- Nicoli, L.G.; de Oliveira, G.J.P.L.; Lopes, B.M.V.; Marcantonio, C.; Zandim-Barcelos, D.L.; Marcantonio, E. Survival/success of dental implants with acid—Etched surfaces: A retrospective evaluation after 8 to 10 years. Braz. Dent. J. 2017, 28, 330–336. [Google Scholar] [CrossRef] [Green Version]

- Szmukler-Moncler, S.; Bischof, M.; Nedir, R.; Ermrich, M. Titanium hydride and hydrogen concentration in acid-etched commercially pure titanium and titanium alloy implants: A comparative analysis of five implant systems. Clin. Oral Implant. Res. 2010, 21, 944–950. [Google Scholar] [CrossRef]

- Zhao, G.; Schwartz, Z.; Wieland, M.; Rupp, F.; Geis-Gerstorfer, J.; Cochran, D.L.; Boyan, B.D. High surface energy enhances cell response to titanium substrate microstructure. J. Biomed. Mater. Res. Part A 2005, 74, 49–58. [Google Scholar] [CrossRef] [PubMed]

- Matos, G.R.M. Surface Roughness of Dental Implant and Osseointegration. J. Maxillofac. Oral Surg. 2021, 20, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Lim, Y.C.; Zainal, Z.; Tan, W.T.; Hussein, M.Z. Anodization parameters influencing the growth of titania nanotubes and their photoelectrochemical response. Int. J. Photoenergy 2012, 2012. [Google Scholar] [CrossRef]

- Lü, W.L.; Wang, N.; Gao, P.; Li, C.Y.; Zhao, H.S.; Zhang, Z.T. Effects of anodic titanium dioxide nanotubes of different diameters on macrophage secretion and expression of cytokines and chemokines. Cell Prolif. 2015, 48, 95–104. [Google Scholar] [CrossRef]

- Oh, S.; Jin, S. Titanium oxide nanotubes with controlled morphology for enhanced bone growth. Mater. Sci. Eng. C 2006, 26, 1301–1306. [Google Scholar] [CrossRef]

- Coelho, L.C.B.B.; Correia, M.T.S.; Silva, G.M.M.; Arruda, I.R.S.; Oliveira, W.F.; Machado, G. Functionalization of titanium dioxide nanotubes with biomolecules for biomedical applications. Mater. Sci. Eng. C 2017, 81, 597–606. [Google Scholar]

- Çelik, I.; Alsaran, A.; Purcek, G. Effect of different surface oxidation treatments on structural, mechanical and tribological properties of ultrafine-grained titanium. Surf. Coat. Technol. 2014, 258, 842–848. [Google Scholar] [CrossRef]

- Lin, Z.; Li, S.J.; Sun, F.; Ba, D.C.; Li, X.C. Surface characteristics of a dental implant modified by low energy oxygen ion implantation. Surf. Coat. Technol. 2019, 365, 208–213. [Google Scholar] [CrossRef]

- Du Plooy, R.; Akinlabi, E.T. Analysis of laser cladding of Titanium alloy. In Materials Today: Proceedings; Elsevier: Amsterdam, The Netherlands, 2018; Volume 5, pp. 19594–19603. [Google Scholar]

- Sharma, V.; Prakash, U.; Kumar, B.V.M. Surface composites by friction stir processing: A review. J. Mater. Process. Technol. 2015, 224, 117–134. [Google Scholar] [CrossRef]

- Liu, W.; Liu, S.; Wang, L. Surface Modification of Biomedical Titanium Alloy: Micromorphology, Microstructure Evolution and Biomedical Applications. Coatings 2019, 9, 249. [Google Scholar] [CrossRef] [Green Version]

- Morshed, M.M.; Cameron, D.C.; McNamara, B.P.; Hashmi, M.S.J. Pre-treatment of substrates for improved adhesion of diamond-like carbon films on surgically implantable metals deposited by saddle field neutral beam source. Surf. Coat. Technol. 2003, 174–175, 579–583. [Google Scholar] [CrossRef]

- Shum, P.W.; Zhou, Z.F.; Li, K.Y. Enhancement of adhesion strength and tribological performance of pure carbon coatings on Ti-6Al-4V biomaterials with ion implantation pre-treatments. Tribol. Int. 2007, 40, 313–318. [Google Scholar] [CrossRef]

- Eliaz, N.; Ritman-Hertz, O.; Aronov, D.; Weinberg, E.; Shenhar, Y.; Rosenman, G.; Weinreb, M.; Ron, E. The effect of surface treatments on the adhesion of electrochemically deposited hydroxyapatite coating to titanium and on its interaction with cells and bacteria. J. Mater. Sci. Mater. Med. 2011, 22, 1741–1752. [Google Scholar] [CrossRef]

- Ágata de Sena, L.; Calixto de Andrade, M.; Malta Rossi, A.; de Almeida Soares, G. Hydroxyapatite deposition by electrophoresis on titanium sheets with different surface finishing. J. Biomed. Mater. Res. 2002, 60, 1–7. [Google Scholar] [CrossRef]

- Kar, A.; Raja, K.S.; Misra, M. Electrodeposition of hydroxyapatite onto nanotubular TiO2 for implant applications. Surf. Coat. Technol. 2006, 201, 3723–3731. [Google Scholar] [CrossRef]

- Hallmann, L.; Mehl, A.; Sereno, N.; Hämmerle, C.H.F. The improvement of adhesive properties of PEEK through different pre-treatments. Appl. Surf. Sci. 2012, 258, 7213–7218. [Google Scholar] [CrossRef]

- Kumaravel, V.; Nair, K.M.; Mathew, S.; Bartlett, J.; Kennedy, J.E.; Manning, H.G.; Whelan, B.J.; Leyland, N.S.; Pillai, S.C. Antimicrobial TiO2 nanocomposite coatings for surfaces, dental and orthopaedic implants. Chem. Eng. J. 2021, 416, 129071. [Google Scholar] [CrossRef] [PubMed]

- Wieszczycka, K.; Staszak, K.; Woźniak-Budych, M.J.; Litowczenko, J.; Maciejewska, B.M.; Jurga, S. Surface functionalization—The way for advanced applications of smart materials. Coord. Chem. Rev. 2021, 436, 213846. [Google Scholar] [CrossRef]

- Yuan, Z.; He, Y.; Lin, C.; Liu, P.; Cai, K. Antibacterial surface design of biomedical titanium materials for orthopedic applications. J. Mater. Sci. Technol. 2021, 78, 51–67. [Google Scholar] [CrossRef]

- Schmaljohann, D. Thermo- and pH-responsive polymers in drug delivery. Adv. Drug Deliv. Rev. 2006, 58, 1655–1670. [Google Scholar] [CrossRef] [PubMed]

- Pawłowski, Ł. pH-dependent composite coatings for controlled drug delivery system—Review. Inżynieria Mater. 2019, 1, 4–9. [Google Scholar] [CrossRef]

- Pawłowski, Ł.; Bartmański, M.; Strugała, G.; Mielewczyk-Gryń, A.; Jażdżewska, M.; Zieliński, A. Electrophoretic Deposition and Characterization of Chitosan/Eudragit E 100 Coatings on Titanium Substrate. Coatings 2020, 10, 607. [Google Scholar] [CrossRef]

- Loch, J.; Krawiec, H. Corrosion behaviour of cobalt alloys in artifical salvia solution. Arch. Foundry Eng. 2013, 13, 101–106. [Google Scholar]

- Lim, H.S.; Hwang, M.J.; Jeong, H.N.; Lee, W.Y.; Song, H.J.; Park, Y.J. Evaluation of surface mechanical properties and grindability of binary Ti alloys containing 5 wt % Al, Cr, Sn, and V. Metals 2017, 7, 487. [Google Scholar] [CrossRef] [Green Version]

- Hung, K.Y.; Lin, Y.C.; Feng, H.P. The effects of acid etching on the nanomorphological surface characteristics and activation energy of titanium medical materials. Materials 2017, 10, 1164. [Google Scholar] [CrossRef]

- Wang, Q.; Huang, J.Y.; Li, H.Q.; Chen, Z.; Zhao, A.Z.; Wang, Y.; Zhang, K.Q.; Sun, H.T.; Al-Deyab, S.S.; Lai, Y.K. TiO2 nanotube platforms for smart drug delivery: A review. Int. J. Nanomed. 2016, 11, 4819–4834. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cipriano, A.F.; Miller, C.; Liu, H. Anodic growth and biomedical applications of TiO2 nanotubes. J. Biomed. Nanotechnol. 2014, 10, 2977–3003. [Google Scholar] [CrossRef]

- Tsuchiya, H.; Macak, J.M.; Taveira, L.; Balaur, E.; Ghicov, A.; Sirotna, K.; Schmuki, P. Self-organized TiO2 nanotubes prepared in ammonium fluoride containing acetic acid electrolytes. Electrochem. Commun. 2005, 7, 576–580. [Google Scholar] [CrossRef]

- Kodama, A.; Bauer, S.; Komatsu, A.; Asoh, H.; Ono, S.; Schmuki, P. Bioactivation of titanium surfaces using coatings of TiO2 nanotubes rapidly pre-loaded with synthetic hydroxyapatite. Acta Biomater. 2009, 5, 2322–2330. [Google Scholar] [CrossRef]

- Poddar, S.; Bit, A.; Sinha, S.K. A study on influence of anodization on the morphology of titania nanotubes over Ti6Al4V alloy in correlation to hard tissue engineering application. Mater. Chem. Phys. 2020, 254, 123457. [Google Scholar] [CrossRef]

- Varghese, O.K.; Gong, D.; Paulose, M.; Grimes, C.A.; Dickey, E.C. Crystallization and high-temperature structural stability of titanium oxide nanotube arrays. J. Mater. Res. 2003, 18, 156–165. [Google Scholar] [CrossRef]

- Prakasam, H.E.; Shankar, K.; Paulose, M.; Varghese, O.K.; Grimes, C.A. A new benchmark for TiO2 nanotube array growth by anodization. J. Phys. Chem. C 2007, 111, 7235–7241. [Google Scholar] [CrossRef]

- Sorkhi, L.; Farrokhi-Rad, M.; Shahrabi, T. Electrophoretic deposition of chitosan in different alcohols. J. Coat. Technol. Res. 2014, 11, 739–746. [Google Scholar] [CrossRef]

- Jugowiec, D.; Kot, M.; Moskalewicz, T. Electrophoretic deposition and characterisation of chitosan coatings on near-β titanium alloy. Arch. Metall. Mater. 2016, 61, 657–664. [Google Scholar] [CrossRef]

- Rautray, T.R.; Narayanan, R.; Kim, K.H. Ion implantation of titanium based biomaterials. Prog. Mater. Sci. 2011, 56, 1137–1177. [Google Scholar] [CrossRef] [Green Version]

- Gross, K.A.; Babovic, M. Influence of abrasion on the surface characteristics of thermally sprayed hydroxyapatitae coatings. Biomaterials 2002, 23, 4731–4737. [Google Scholar] [CrossRef]

- Ehlert, M.; Radtke, A.; Jędrzejewski, T.; Roszek, K.; Bartmański, M.; Piszczek, P. In Vitro Studies on Nanoporous, Nanotubular and Nanosponge-Like Titania Coatings, with the Use of Adipose-Derived Stem Cells. Materials 2020, 13, 1574. [Google Scholar] [CrossRef] [Green Version]

- Alam, F.; Balani, K. Adhesion force of staphylococcus aureus on various biomaterial surfaces. J. Mech. Behav. Biomed. Mater. 2017, 65, 872–880. [Google Scholar] [CrossRef]

- Besra, L.; Liu, M. A review on fundamentals and applications of electrophoretic deposition (EPD). Prog. Mater. Sci. 2007, 52, 1–61. [Google Scholar] [CrossRef]

- Balagani, P.G.A. Formulation and evaluation of nizatidine solid dispersions. World J. Pharm. Pharm. Sci. 2015, 4, 810–817. [Google Scholar]

- Dimzon, I.K.D.; Knepper, T.P. Degree of deacetylation of chitosan by infrared spectroscopy and partial least squares. Int. J. Biol. Macromol. 2015, 72, 939–945. [Google Scholar] [CrossRef] [PubMed]

- Menzies, K.L.; Jones, L. The impact of contact angle on the biocompatibility of biomaterials. Optom. Vis. Sci. 2010, 87, 387–399. [Google Scholar] [CrossRef]

- Tang, H.; Cao, T.; Liang, X.; Wang, A.; Salley, S.O.; McAllister, J.; Ng, K.Y.S. Influence of silicone surface roughness and hydrophobicity on adhesion and colonization of Staphylococcus epidermidis. J. Biomed. Mater. Res. Part A 2009, 88, 454–463. [Google Scholar] [CrossRef]

- Roosjen, A.; Norde, W.; Van Der Mei, H.C.; Busscher, H.J. The use of positively charged or low surface free energy coatings versus polymer brushes in controlling biofilm formation. Prog. Colloid Polym. Sci. 2006, 132, 138–144. [Google Scholar]

- Cordero-Arias, L.; Cabanas-Polo, S.; Gao, H.; Gilabert, J.; Sanchez, E.; Roether, J.A.; Schubert, D.W.; Virtanen, S.; Boccaccini, A.R. Electrophoretic deposition of nanostructured-TiO2/chitosan composite coatings on stainless steel. RSC Adv. 2013, 3, 11247–11254. [Google Scholar] [CrossRef] [Green Version]

- Pawłowski, Ł.; Bartmański, M.; Mielewczyk-Gryń, A.; Cieślik, B.M.; Gajowiec, G.; Zieliński, A. Electrophoretically Deposited Chitosan/Eudragit E 100/AgNPs Composite Coatings on Titanium Substrate as a Silver Release System. Materials 2021, 14, 4533. [Google Scholar] [CrossRef]

- Bartmanski, M.; Zielinski, A.; Jazdzewska, M.; Głodowska, J.; Kalka, P. Effects of electrophoretic deposition times and nanotubular oxide surfaces on properties of the nanohydroxyapatite/nanocopper coating on the Ti13Zr13Nb alloy. Ceram. Int. 2019, 45, 20002–20010. [Google Scholar] [CrossRef]

- Im, K.H.; Lee, S.B.; Kim, K.M.; Lee, Y.K. Improvement of bonding strength to titanium surface by sol-gel derived hybrid coating of hydroxyapatite and titania by sol-gel process. Surf. Coat. Technol. 2007, 202, 1135–1138. [Google Scholar] [CrossRef]

- Aydemir, T.; Pastore, J.I.; Jimenez-Pique, E.; Roa, J.J.; Boccaccini, A.R.; Ballarre, J. Morphological and mechanical characterization of chitosan/gelatin/silica-gentamicin/bioactive glass coatings on orthopaedic metallic implant materials. Thin Solid Film. 2021, 732, 138780. [Google Scholar] [CrossRef]

- Łosiewicz, B.; Maszybrocka, J.; Kubisztal, J.; Skrabalak, G.; Stwora, A. Corrosion resistance of the cpti g2 cellular lattice with tpms architecture for gas diffusion electrodes. Materials 2021, 14, 1–18. [Google Scholar]

- Wu, S.; Wang, S.; Liu, W.; Yu, X.; Wang, G.; Chang, Z.; Wen, D. Microstructure and properties of TiO2 nanotube coatings on bone plate surface fabrication by anodic oxidation. Surf. Coat. Technol. 2019, 374, 362–373. [Google Scholar] [CrossRef]

- Bartmanski, M.; Zielinski, A.; Majkowska-Marzec, B.; Strugala, G. Effects of solution composition and electrophoretic deposition voltage on various properties of nanohydroxyapatite coatings on the Ti13Zr13Nb alloy. Ceram. Int. 2018, 44, 19236–19246. [Google Scholar] [CrossRef]

- Meng, F.; Liu, L. Electrochemical Evaluation Technologies of Organic Coatings. In Coatings and Thin-Film Technologies; IntechOpen: London, UK, 2019; Volume 32, pp. 137–144. [Google Scholar]

- Tabesh, E.; Salimijazi, H.R.; Kharaziha, M.; Mahmoudi, M.; Hejazi, M. Development of an in-situ chitosan—Copper nanoparticle coating by electrophoretic deposition. Surf. Coat. Technol. 2019, 364, 239–247. [Google Scholar] [CrossRef]

- Karimi, A.R.; Rostaminejad, B.; Rahimi, L.; Khodadadi, A.; Khanmohammadi, H.; Shahriari, A. Chitosan hydrogels cross-linked with tris(2-(2-formylphenoxy)ethyl)amine: Swelling and drug delivery. Int. J. Biol. Macromol. 2018, 118, 1863–1870. [Google Scholar] [CrossRef] [PubMed]

| Element | N | C | H | Fe | O | Ti |

|---|---|---|---|---|---|---|

| wt.% | 0.009 | 0.013 | 0.001 | 0.168–0.179 | 0.170–0.190 | rest |

| Sample | Substrate Pretreatment | Suspension | Voltage (V) | Time (min) |

|---|---|---|---|---|

| G1 | Grinding | 100 mL of 1% (v/v) acetic acid with 0.1 g of chitosan and 0.25 g of Eudragit E 100 | 10 | 1 |

| G2 | 2 | |||

| G1′ | 20 | 1 | ||

| G2′ | 2 | |||

| E1 | Etching | 10 | 1 | |

| E2 | 2 | |||

| E1′ | 20 | 1 | ||

| E2′ | 2 | |||

| A1 | Anodization | 10 | 1 | |

| A2 | 2 | |||

| A1′ | 20 | 1 | ||

| A2′ | 2 |

| Sample | Surface Topography Parameters | Coating Thickness (µm) | ||

|---|---|---|---|---|

| Sa (nm) | Sp (nm) | Sv (nm) | ||

| Ti grade 2 (G) | 128 ± 8 | 943 ± 291 | −672 ± 195 | – |

| Ti grade 2 (E) | 582 ± 47 | 4458 ± 213 | −2684 ± 178 | – |

| Ti grade 2 (A) | 157 ± 18 | 1232 ± 479 | −591 ± 79 | – |

| G1 | 111 ± 1 | 578 ± 25 | −470 ± 55 | 2.86 ± 0.51 |

| G2 | 75 ± 11 | 698 ± 202 | −263 ± 59 | 6.24 ± 0.69 |

| G1′ | 75 ± 1 | 464 ± 32 | −299 ± 33 | 3.54 ± 0.97 |

| G2′ | 106 ± 13 | 596 ± 178 | −397 ± 17 | 6.45 ± 1.57 |

| E1 | 272 ± 41 | 1765 ± 331 | −1252 ± 226 | 2.19 ± 0.15 |

| E2 | 251 ± 16 | 1364 ± 356 | −1009 ± 120 | 2.29 ± 0.24 |

| E1′ | 219 ± 12 | 1059 ± 95 | −732 ± 56 | 1.66 ± 0.23 |

| E2′ | 156 ± 25 | 1001 ± 254 | −673 ± 156 | 2.60 ± 0.91 |

| A1 | 96 ± 12 | 536 ± 114 | −445 ± 133 | 1.46 ± 0.71 |

| A2 | 103 ± 11 | 454 ± 47 | −436 ± 53 | 2.14 ± 0.44 |

| A1′ | 214 ± 6 | 770 ± 9 | −679 ± 37 | 1.74 ± 0.39 |

| A2′ | 145 ± 12 | 452 ± 41 | −491 ± 81 | 1.84 ± 0.49 |

| Sample | Critical Load (mN) | Critical Friction (mN) |

|---|---|---|

| G1 | 37.63 ± 4.63 | 55.56 ± 8.28 |

| G2 | 57.18 ± 4.22 | 97.77 ± 9.94 |

| G1′ | 55.84 ± 2.12 | 97.91 ± 5.96 |

| G2′ | 43.54 ± 6.48 | 90.46 ± 17.18 |

| E1 | 23.29 ± 4.67 | 44.85 ± 12.06 |

| E2 | 31.91 ± 4.42 | 59.40 ± 10.55 |

| E1′ | 19.53 ± 5.17 | 35.98 ± 11.60 |

| E2′ | 34.11 ± 7.24 | 59.32 ± 13.16 |

| A1 | 53.31 ± 4.41 | 100.19 ± 10.65 |

| A2 | 54.15 ± 8.31 | 123.11 ± 22.05 |

| A1′ | 52.07 ± 5.89 | 117.52 ± 14.69 |

| A2′ | 44.82 ± 4.54 | 104.10 ± 14.00 |

| Sample | OCP (V) | Ecorr (V) | icorr (nA/cm2) | βa (mV) | βc (mV) | Rpol (kΩ·cm2) |

|---|---|---|---|---|---|---|

| Ti grade 2 (G) | −0.307 | −0.234 | 84.905 | 314.318 | 219.406 | 660.804 |

| Ti grade 2 (E) | −0.282 | −0.257 | 101.973 | 423.702 | 159.648 | 493.759 |

| Ti grade 2 (A) | −0.376 | −0.340 | 64.237 | 513.015 | 113.258 | 627.128 |

| G1 | 0.115 | −0.041 | 654.635 | 175.330 | 370.191 | 78.918 |

| E1 | 0.097 | −0.065 | 393.674 | 446.942 | 379.676 | 226.428 |

| A1 | −0.049 | −0.062 | 190.636 | 327.120 | 568.025 | 472.877 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pawłowski, Ł.; Bartmański, M.; Mielewczyk-Gryń, A.; Zieliński, A. Effects of Surface Pretreatment of Titanium Substrates on Properties of Electrophoretically Deposited Biopolymer Chitosan/Eudragit E 100 Coatings. Coatings 2021, 11, 1120. https://doi.org/10.3390/coatings11091120

Pawłowski Ł, Bartmański M, Mielewczyk-Gryń A, Zieliński A. Effects of Surface Pretreatment of Titanium Substrates on Properties of Electrophoretically Deposited Biopolymer Chitosan/Eudragit E 100 Coatings. Coatings. 2021; 11(9):1120. https://doi.org/10.3390/coatings11091120

Chicago/Turabian StylePawłowski, Łukasz, Michał Bartmański, Aleksandra Mielewczyk-Gryń, and Andrzej Zieliński. 2021. "Effects of Surface Pretreatment of Titanium Substrates on Properties of Electrophoretically Deposited Biopolymer Chitosan/Eudragit E 100 Coatings" Coatings 11, no. 9: 1120. https://doi.org/10.3390/coatings11091120

APA StylePawłowski, Ł., Bartmański, M., Mielewczyk-Gryń, A., & Zieliński, A. (2021). Effects of Surface Pretreatment of Titanium Substrates on Properties of Electrophoretically Deposited Biopolymer Chitosan/Eudragit E 100 Coatings. Coatings, 11(9), 1120. https://doi.org/10.3390/coatings11091120