Analysis of Heat Transfer Characteristics of a Heat Exchanger Based on a Lattice Filling

Abstract

:1. Introduction

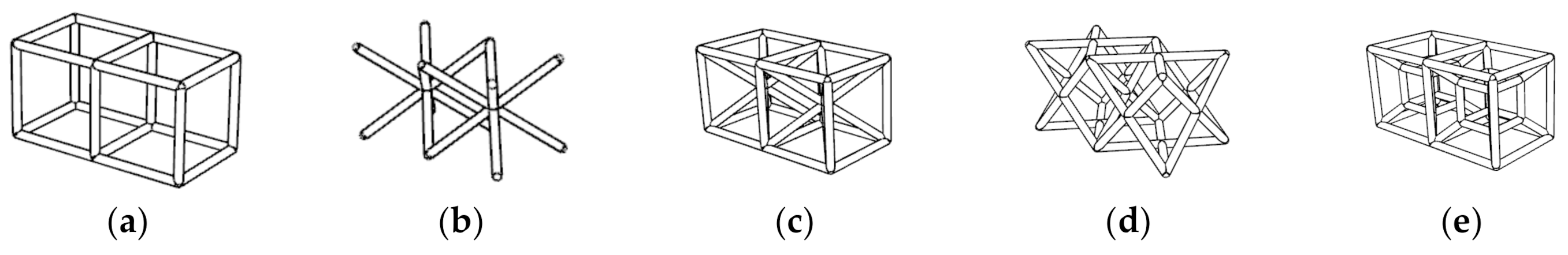

2. Establishment of a Parametric Model of the Unit Cell Lattice Structure

- According to the structural characteristics of the hexahedron, the key parameters such as the side length, diagonal length, body center coordinates and face center coordinates of each cell are calculated and stored in the array.

- The cell structure is initialized according to the characteristics of the wireframe structure in Figure 2, and the truss length data are retrieved from the database.

- The length, width and height of the bounding box are changed to obtain the distribution of trusses in different spatial orientations.

- The radius of the dot matrix truss is changed to achieve continuous adjustment of relative density.

- Combined with the numerical results of different structures, the characteristic parameters and mechanical properties of lattice structure are stored in the database for comparison and selection with the subsequent structural data.

3. Analysis of Fluid–Solid Coupling Heat Transfer

3.1. Calculation Model and Boundary Conditions

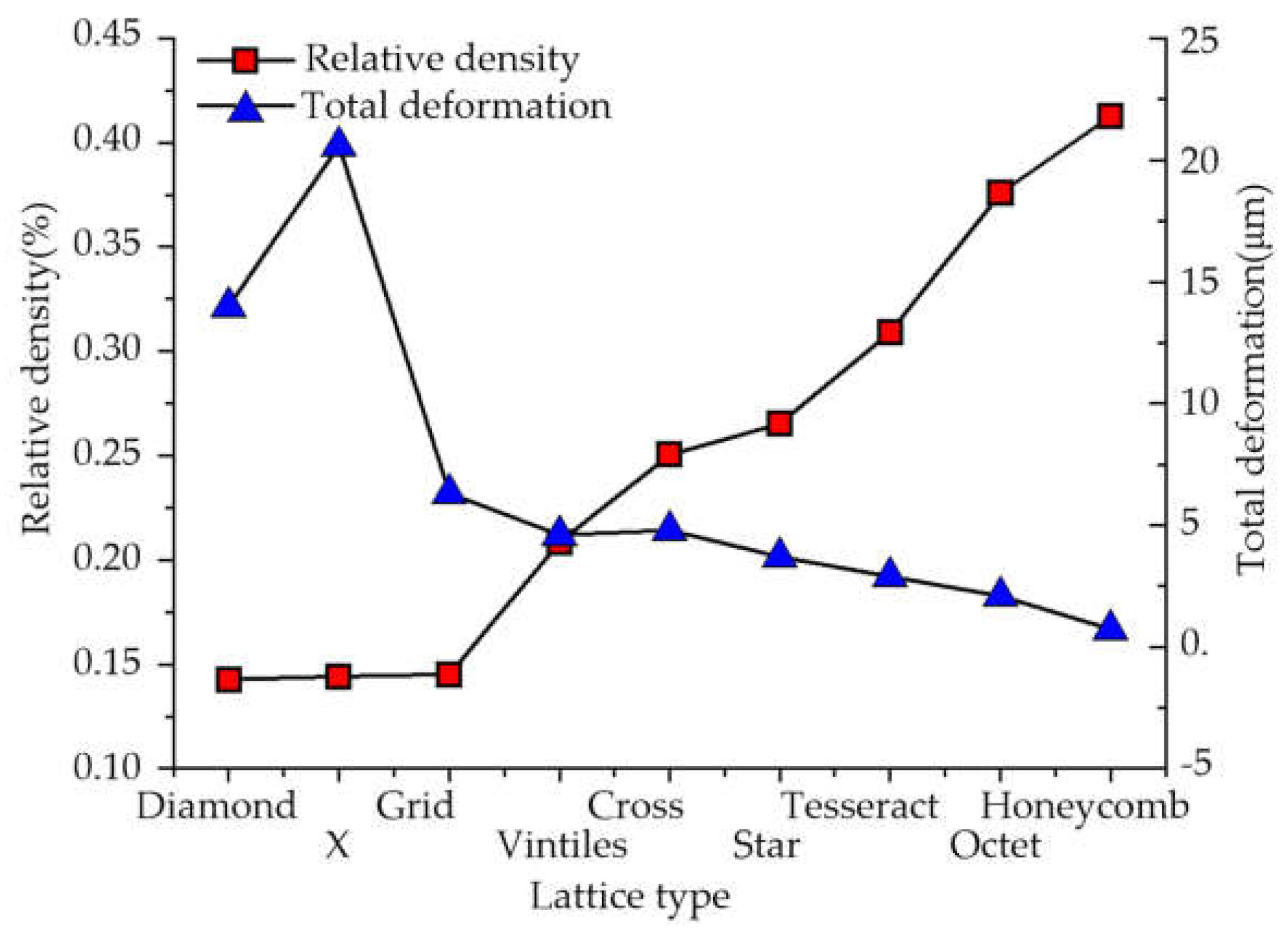

3.2. Discussion

3.3. Analysis of Thermal Structure Response of Star Type Lattice Cell

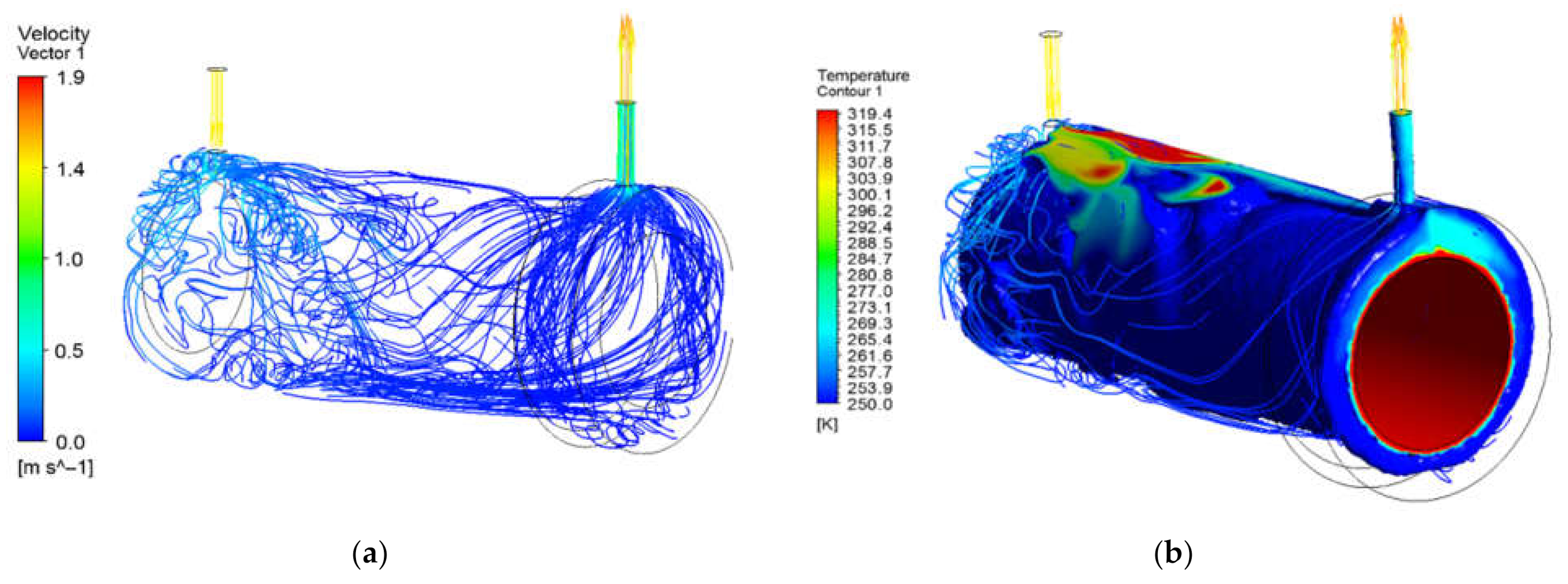

4. Model Design and Flow Heat Transfer Analysis of Heat Exchanger

4.1. Model Design

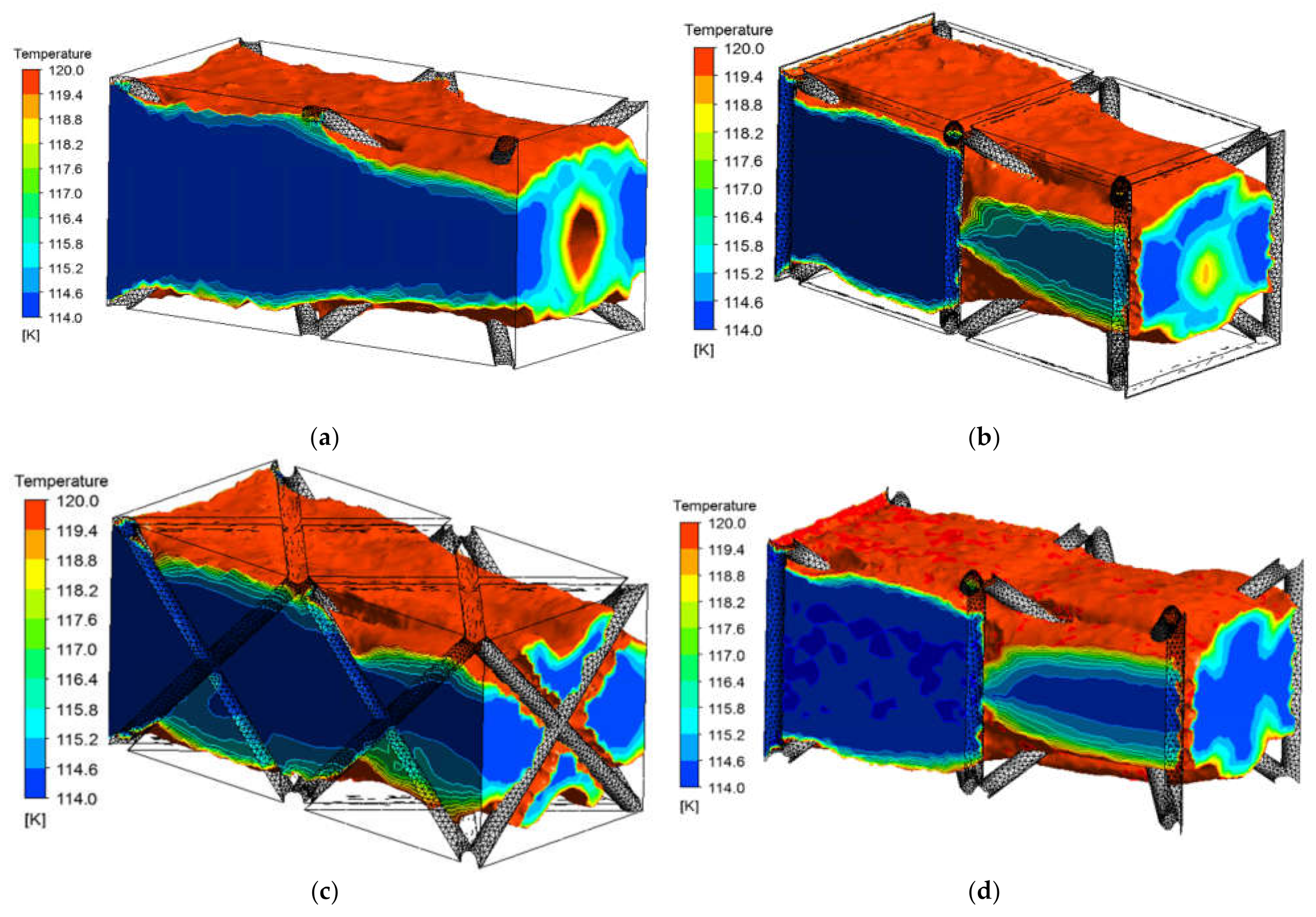

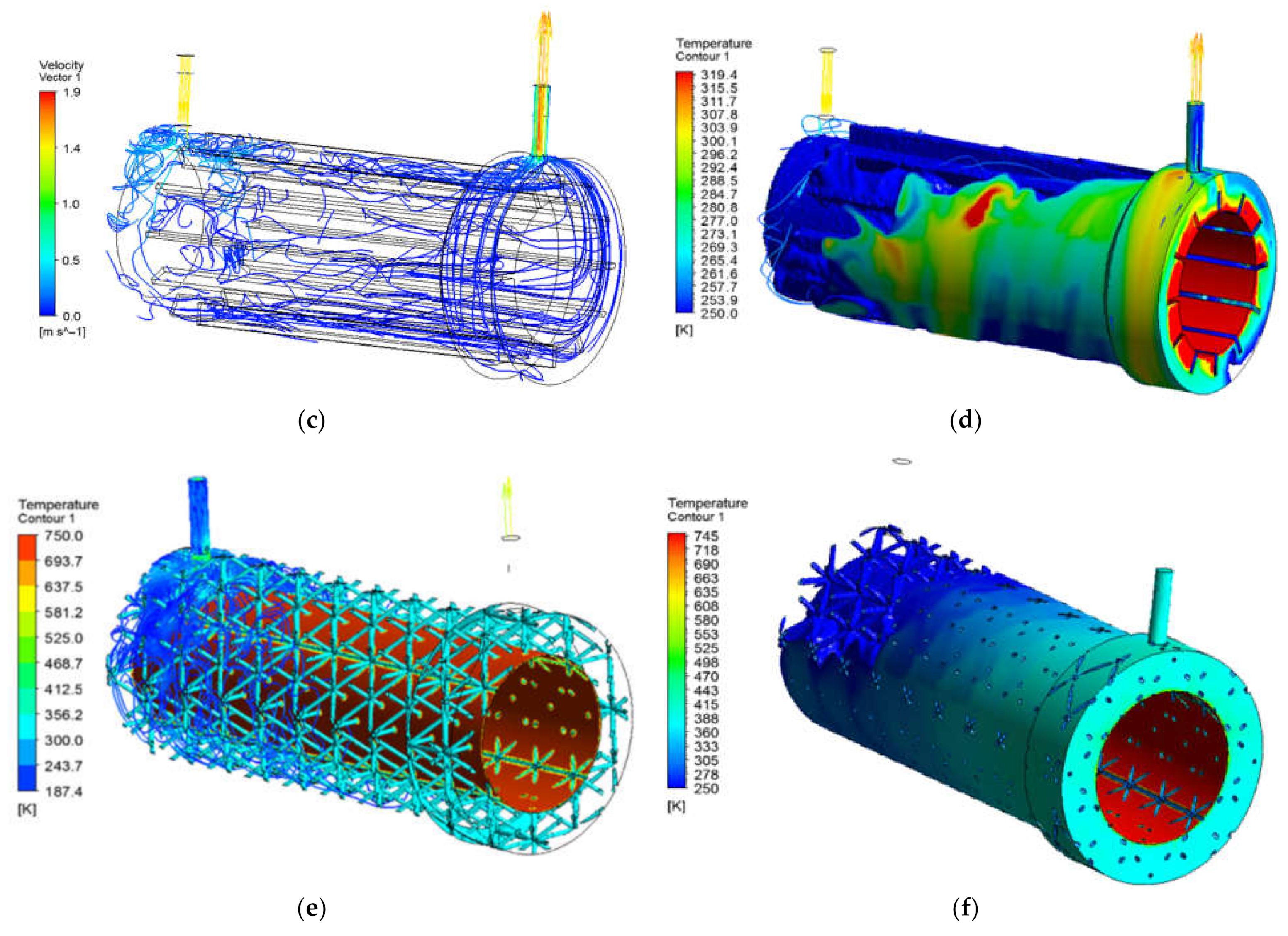

4.2. Numerical Calculation and Discussion

5. Conclusions

- The support rod of the lattice structure can be used as a fluid disturbance feature, which is beneficial for driving the heated fluid near the wall to the center of the fluid, thereby improving heat transfer efficiency.

- The maximum temperature gradient appears at the junction of the support trusses and the heating surface. Considering the strength of the lattice structure and the temperature conductivity, the star type lattice cell is selected as the basic filling structure of the heat exchanger.

- After the flow is fully developed, the volume of the heated fluid in the star lattice structure accounts for 85.60%, and the heat exchange efficiency is increased by 1.4 times compared with the light pipe structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, H.; Liu, H.; Zou, Z. Experimental study and performance analysis of high-performance micro- channel heat exchanger for hypersonic precooled aero-engine. Appl. Therm. Eng. 2020, 182, 116108. [Google Scholar] [CrossRef]

- Xia, G.; Zhuang, D.; Ding, G.; Lu, J.; Han, W.; Qi, H. A distributed parameter model for multi-row separated heat pipe with micro-channel heat exchangers. Appl. Therm. Eng. 2020, 182, 116113. [Google Scholar] [CrossRef]

- She, H.; Cui, X.; Weng, J.; Geng, H.; Chang, Z. A combined experimental and numerical approach for printed circuit rectangular microchannel J-T cooler using argon. Appl. Therm. Eng. 2021, 182, 116107. [Google Scholar] [CrossRef]

- Ravi, R.; Pachamuthu, S.; Kasinathan, P. Computational and experimental investigation on effective utilization of waste heat from diesel engine exhaust using a fin protracted heat exchanger. Energy 2020, 200, 117489. [Google Scholar] [CrossRef]

- Knoke, T.; Kronberg, A.; Glushenkov, M.; Kenig, E.Y. On the design of heat exchanger equipment for novel-type isobaric expansion engines. Appl. Therm. Eng. 2020, 167, 114382. [Google Scholar] [CrossRef]

- Kiatpachai, P.; Pikulkajorn, S.; Wongwises, S. Air-side performance of serrated welded spiral fin-and-tube heat exchangers. Int. J. Heat Mass Transf. 2015, 29, 724–732. [Google Scholar] [CrossRef]

- Zhicheng, Y.; Lijun, W.; Zhaokuo, Y.; Haowen, L. Shape optimization of welded plate heat exchangers based on grey correlation theory. Appl. Therm. Eng. 2017, 123, 763–769. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology: Bending versus stretching dominated architectures. Acta Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Ali, D.; Ozalp, M.; Blanquer, S.B.; Onel, S. Permeability and fluid flow-induced wall shear stress in bone scaffolds with TPMS and lattice architectures: A CFD analysis. Eur. J. Mech. B Fluid 2020, 79, 376–385. [Google Scholar] [CrossRef]

- Bayomy, A.M.; Saghir, M.Z.; Yousefi, T. Electronic cooling using water flow in aluminum metal foam heat sink: Experimental and numerical approach. Int. J. Therm. Sci. 2016, 109, 182–200. [Google Scholar] [CrossRef]

- Hossain, S.Z.; Irfan, M.F.; Elkanzi, E.M.; Saif, K.M. Fabrication of a hybrid shell and double pipe heat exchanger by means of design and performance assessment. Chem. Eng. Process. Process Intensif. 2021, 165, 108430. [Google Scholar] [CrossRef]

- Abraham, P.; Sharqawy, M.H.; Shawkat, M.E. Thermal and hydraulic characteristics of multiple row spiral finned tube heat exchangers. Int. J. Refrig. 2021, 130, 56–66. [Google Scholar] [CrossRef]

- Li, K.; Wen, J.; Yang, H.; Wang, S.; Li, Y. Sensitivity and stress analysis of serrated fin structure in plate-fin heat exchanger on cryogenic condition. Int. J. Therm. Sci. 2019, 145, 106013. [Google Scholar] [CrossRef]

- Liu, L.; Ning, D.; Shi, J.; Xu, N.; Guo, W.; Wu, C.L. Failure analysis of tube-to-tubesheet welded joints in a shell-tube heat exchanger. Case Stud. Eng. Fail. Analysis 2016, 7, 32–40. [Google Scholar] [CrossRef] [Green Version]

- Kou, H.S.; Lee, J.J.; Chen, C.W. Optimum thermal performance of microchannel heat sink by adjusting channel width and height. Int. Commun. Heat Mass Transf. 2008, 35, 577–582. [Google Scholar] [CrossRef]

- Zargoushi, A.; Talebi, F.; Hosseini, S.H. CFD modeling of industrial cold box with plate-fin heat exchanger: Focusing on phase change phenomenon. Int. Commun. Heat Mass Transf. 2019, 147, 118936. [Google Scholar] [CrossRef]

- Promvonge, P.; Sripattanapipat, S.; Kwankaomeng, S. Laminar periodic flow and heat transfer in square channel with 45° inline baffles on two opposite walls. Int. J. Therm. Sci. 2010, 49, 963–975. [Google Scholar] [CrossRef]

- Goldstein, L.; Sparrow, E.M. Experiments on the transfer characteristics of a corrugated fin and tube heat exchanger configuration. J. Heat Transf. 1976, 98, 26. [Google Scholar] [CrossRef]

- Billerot, P.L.; Dufresne, L.; Lemaire, R.; Seers, P. 3D CFD analysis of a diamond lattice-based porous burner. Energy 2020, 207, 118160. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Ztop, H.F. Optimization of convective heat transfer performance for fluid flow over a facing step by using an elliptic porous object. Case Stud. Therm. Eng. 2021, 27, 101233. [Google Scholar] [CrossRef]

- Jin, N.; Yan, Z.; Wang, Y.; Zhang, H. Effects of heat treatment on microstructure and mechanical properties of selective laser melted Ti-6Al-4V lattice materials. Int. J. Mech. Sci. 2020, 190, 106042. [Google Scholar] [CrossRef]

- Kaur, I.; Singh, P. Critical evaluation of additively manufactured metal lattices for viability in advanced heat exchangers. Int. J. Heat Mass Transf. 2021, 168, 120858. [Google Scholar] [CrossRef]

- Kaur, I.; Singh, P. Endwall heat transfer characteristics of octahedron family lattice-frame materials. Int. Commun. Heat Mass Transf. 2021, 127, 105522. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef] [Green Version]

- Yu, Z.Q.; Feng, Y.L.; Zhou, W.J.; Jin, Y.; Li, M.J.; Li, Z.Y.; Tao, W.Q. Study on flow and heat transfer characteristics of composite porous material and its performance analysis by FSP and EDEP. Appl. Energy 2013, 112, 1367–1375. [Google Scholar] [CrossRef]

- Liang, D.; Bai, W.; Chen, W.; Chyu, M.K. Investigating the effect of element shape of the face-centered cubic lattice structure on the flow and endwall heat transfer characteristics in a rectangular channel. Int. J. Heat Mass Transf. 2020, 153, 119579. [Google Scholar] [CrossRef]

- Ekade, P.; Krishnan, S. Fluid flow and heat transfer characteristics of octet truss lattice geometry. Int. J. Therm. Sci. 2019, 137, 253–261. [Google Scholar] [CrossRef]

- Yan, H.; Yang, X.; Lu, T.; Xie, G. Convective heat transfer in a lightweight multifunctional sandwich panel with X-type metallic lattice core. Appl. Therm. Eng. 2017, 127, 1293–1304. [Google Scholar] [CrossRef]

| Type of Heat Exchanger | Outlet Temperature/K | High-Temperature Fluid Volume/m³ | Total Volume/m³ | Percentage of High-Temperature Fluid Volume | Heat Exchange Efficiency |

|---|---|---|---|---|---|

| Without baffle | 322 | 4.66 × 10−5 | 9.37 × 10−5 | 49.73% | 29.84% |

| With baffle | 282 | 6.21 × 10−5 | 8.61 × 10−5 | 72.13% | 23.28% |

| With Star type lattice structure | 394 | 7.67 × 10−5 | 8.96 × 10−5 | 85.60% | 41.64% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, X.; Wang, C.; Peng, D.; Yang, H.; Wei, Z. Analysis of Heat Transfer Characteristics of a Heat Exchanger Based on a Lattice Filling. Coatings 2021, 11, 1089. https://doi.org/10.3390/coatings11091089

Lai X, Wang C, Peng D, Yang H, Wei Z. Analysis of Heat Transfer Characteristics of a Heat Exchanger Based on a Lattice Filling. Coatings. 2021; 11(9):1089. https://doi.org/10.3390/coatings11091089

Chicago/Turabian StyleLai, Xuhui, Caihua Wang, Dongjian Peng, Huanqing Yang, and Zhengying Wei. 2021. "Analysis of Heat Transfer Characteristics of a Heat Exchanger Based on a Lattice Filling" Coatings 11, no. 9: 1089. https://doi.org/10.3390/coatings11091089

APA StyleLai, X., Wang, C., Peng, D., Yang, H., & Wei, Z. (2021). Analysis of Heat Transfer Characteristics of a Heat Exchanger Based on a Lattice Filling. Coatings, 11(9), 1089. https://doi.org/10.3390/coatings11091089