Abstract

In this paper, AA5250 aluminum sheets are reinforced with boron nitride (BN), silicon carbide (SiC), aluminum oxide (Al2O3), and vanadium carbide (VC). The nanocomposites metal matrix are manufactured using friction stir processing (FSP). A novel analytical comparison based on an assessment of mechanical, physical properties and the cost of manufactured materials was conducted to help the engineers and designers choose the most economically feasible nanocomposite. The results revealed extra grain refining for all composites in the stirred zone (SZ) due to the Zener-pinning mechanism. The smallest grain size was obtained in AA5250/BN, and it decreased 20 times that of the base metal (BM). The highest wear resistance was achieved in AA5250/SiC, followed by AA5250/VC and AA5250/BN. The lowest coefficient of friction was obtained for AA5250/BN due to the self-lubrication property of BN; which was μ = 0.28. SiC AA5250 had the highest hardness, increasing three times more than the base metal in terms of its hardness. There was a detailed discussion of the probable explanations for the improvements. However, the outstanding characteristics of the BN nanoparticles, the AA5250/BN was reported to be lower than the AA5250/SiC. In comparison, the AA5250/SiC nanocomposite exhibits the optimum value due to its fitting for different properties relative to the cost.

1. Introduction

The AA5250 alloy is considered one of the primary aluminum alloys used in aircraft, general sheet metal work, and heat exchangers. In addition, many advanced applications need strong and light alloy. However, it has some good properties to meet with various applications. On the other hand, it is not enough for some applications that require more advanced properties, such as high hardness and wear resistance. Fabrication of the metal matrix composite has been investigated using different techniques [1,2,3,4]. However, friction stir processing (FSP) is the most advanced method used to fabricate surface and metal matrix composites in a solid-state [5,6,7,8,9,10]. The improvement is due to the stirring action of FSP reflected on the microstructure refinement of the processed material. Furthermore, the ductility and deformability of the processed alloy FSP were enhanced [11,12]. Reinforcement of the aluminum base alloy such as AA5251, AA6061, AA2024, etc., was developed using many investigators, in which they impeded the ceramics and hard particles to enhance their mechanical properties, wear-resistance, and hardness behavior of such an alloy [8,13,14,15,16].

The base aluminum alloy’s wear rate is greater than the composite matrix of the same alloy reinforced with ceramic particles, which is attributed to the superior hardness and wear resistance properties of such particles [17,18,19,20,21]. The incorporation of SiC particles in the aluminum sheets and age hardening of the FSP sample has been developed to improve the fabricated composite wear resistance using FSP [22]. Graphitized-TiC particles reinforced the AA7075 alloy to enhance the wear resistance of the fabricated composite. The investigators reveal that the percentage of graphite contents inside the aluminum metal matrix composite AMMC was considered a function of the wear rate behavior. Hence, the higher graphite contents reduce the abrasion wear mechanism during the dry sliding action. Moreover, TiC and graphite were observed to have a suitable interfacial bond. Therefore, TiC particles play an essential role in the wear rate enhancement [23]. Graphene is one of the most common reinforcing nanoparticles used to fabricate the metal matrix nanocomposite for wear resistance applications. To increase the tensile strength and refine grain microstructure, graphene nanoplates GNPs are added to an Al-Mg alloy. Due to the generation of lubricant layer during the sliding surfaces’ friction process, the GNPs addition reduces the friction coefficient up to 60% compared to the base alloy [24,25].

Alumina nanoparticles were one of the most used particles in the AMMCs for their availability and properties. The wear resistance of the aluminum nanocomposite matrix was increased by adding 5% alumina particles into the matrix. Moreover, the hardness behavior was increased by 26% compared to the base metal [26]. Hexagonal boron nitride (HBN) particles were recently used to reinforce aluminum alloys using FSP. The mechanical properties and wear resistance were observed to improve significantly due to their solid lubrication nature. However, these particles’ have low electrical and thermal conductivity [27,28,29]. The vanadium carbide VC and aluminum particle decomposition reaction occur at 900 °C, forming Al3V as reported by [30]. However, the intermetallic and compounds such as Al4C3 and AlV2C were observed at low temperatures in addition to Al3V. Vanadium carbide VC particles reinforced the 1056 aluminum powder using mechanical alloy, the optimum mechanical properties were achieved using spark plasma sintering [31]. The competition towards manufacturing lightweight, high strength, high wear resistance, and low-cost composite materials has become the main challenge in designing such materials. FSP was utilized to fabricate different metal composite matrices using four different ceramic particles. Hence, BN, SiC, Al2O3, and VC nanoparticles were used to reinforce the base alloy. An advanced and unique AA5250/VC composite matrix was fabricated. Hence, previous studies do not mention this composite before using the current method.

Furthermore, a lack of literature has taken up the comparison set of various reinforcement ceramic particles on the same base alloy (AA5250). Therefore, the current investigation aims to obtain the most influential particles on the wear and hardness behavior through a comparative study. Moreover, in this paper, we construct a novel assessment tool based on the cost analysis and different physical and mechanical properties to facilitate the decision-makers mission.

2. Materials and Methods

2.1. Materials

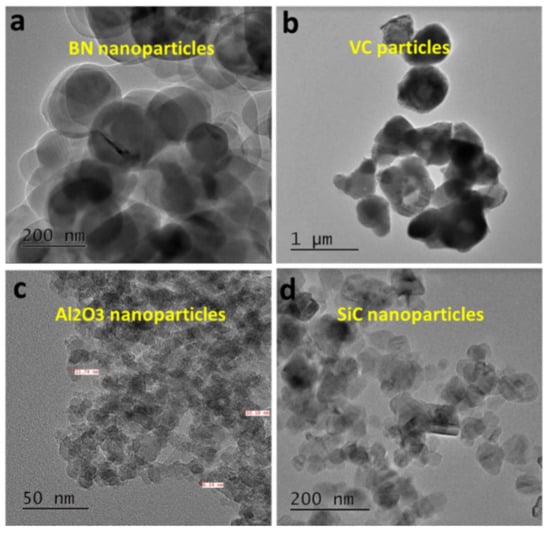

The AA5250 wrought aluminum sheets were used as the base matrix of the fabricated surface nanocomposites, the chemical composition of the base AA5250 is shown in Table 1. BN, SiC, Al2O3, and VC nanoparticles were employed as reinforcement elements on the base alloy’s surface. The Nanoshel-UK-Ltd company (Congleton, UK) supplied the reinforcements. The characteristics of nanoparticles were as follows: SiC-beta phase, 99.9% purity, 45–65 nm average size, hBN, purity: 99%, average size: 100 nm, and VC, purity: >99%, typical size: 300–550 nm. Figure 1 shows the transmission electron microscope (TEM, JEOL, Tokyo, Japan) images of the various particles used in the current study. The TEM analysis confirms the measurements of the average particles size of as-received reinforcements.

Table 1.

Chemical composition of AA5250 aluminum alloy, wt.%.

Figure 1.

TEM image of the reinforcement particles. (a) Hexagonal boron nitride BN nanoparticles, (b) vanadium carbide VC particles, (c) alumina Al2O3 nanoparticles, and (d) silicon carbide SiC nanoparticles.

2.2. Surface Composite Fabrication Process

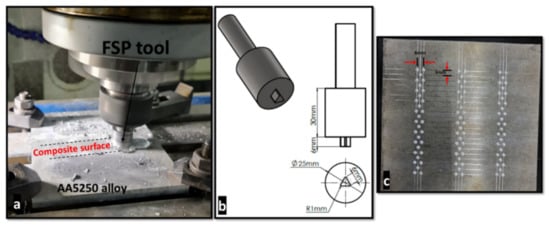

Using an automated milling machine (Bridgeport, Elmira, NY, USA), FSP is used to create aluminum metal matrix nanocomposites AMMNCs. Figure 2 depicts a typical FSP fabrication process, complete with tool design and specifications. The reinforcement nanoparticles were introduced into the chamber of the hole at the base matrix surface, which had been pre-holed in a linear pattern using a standard milling machine with a 2 mm diameter for each hole (Figure 2c). All the FSP experiments were performed with a constant tilting angle of 1° along the rolling direction of the AA5250 base alloy. The processing parameters were selected in accordance with [29,32]. In this study, the tool rotation speed was set at 1120 rpm, and the travel speed was set at 40 mm/min for the fabrication of MMNCs. The FSP tool was made of hot work tool steel W302, Table 2 shows the FSP tool’s chemical makeup.

Figure 2.

(a) Typical fabrication process of the nanocomposite surface using the friction stir process (FSP), (b) design of the FSP tool, (c) base matrix holes pattern.

Table 2.

Chemical composition of W 302 tool steel, wt.%.

2.3. Characterization and Tests

2.3.1. Microstructure Analysis

The microstructure examination of the processed composites samples’ was selected to be cut from the cross-section of the stirred zone. The metallographic process began with grinding the samples using a set of silicon carbide papers with a grit size of 320, 800, 1200, 2400, and 4000, respectively. After polishing, all the samples were etched with Keller’s etchant, which consisted of 2.5 mL HNO3, 1.5 mL HCl, 1 mL HF, and 95 mL H2O. For the microstructure analysis of the processed samples, an optical microscope was utilized. Tuscan-VEGA3 (Tescan Brno s.r.o., Kohoutovice, Czech Republic) was connected to an X-MAX80 (Oxford Instruments plc, Abingdon, UK) EDS system through a SEM. A mapping study known as EDS was utilized to see if the reinforcements were agglomerating and clustering. The standard linear intercept technique was used to determine the grain size using an AxioVision 4.5 software attached to the microscope (Olympus BX51, Miami, FL, USA). During the FSP, the temperature distribution in the processed plats and the tool was measured and recorded using an infra-red thermal image camera (Fluke Ti32).

2.3.2. Wear and Friction Tests

Both wear tests, the volume loss technique, and the weight-loss method were accomplished with the pin-on-disk and pin-on-ring aid, respectively. All the samples for wear tests were polished well using a set of grinding papers with different grades from 600 to 4000 to ensure high surface finish quality and unify the surface roughness’s initial condition for all the samples. The volume loss and friction coefficient are carried out using tribometers (CSM Instruments SA Rue de la Gare 42,034 Peseux, Switzerland), and the weight loss wear was performed using TNO (Delft, The Netherlands). The specimens were prepared, and the weight loss was measured and recorded via a digital balance with a precision of 10−4 g. The test conditions were 0.3 bar and 265 rpm speed for 10 min. The test on tribometers was performed at a constant normal load of 10 N. The radius of the traveling pin was 2 mm and the linear speed was 0.1 cm/s. The friction coefficient was estimated from the normal load and friction force ratio between the steel pin and the sample, while the wear volume loss rate was calculated using the penetration distance (Dektak XTL Stylus Profiler System, Bruker, Bremen, Germany).

2.3.3. Micro-Hardness Test

The Vickers micro-hardness test was carried out using ZwickRoell (Zwick/Roell, Kennesaw, GA, USA) under the ASTM E-384-17 standard using a shutter speed of 10 s and a load of 100 g. For all the samples, the Vickers micro-hardness profile was taken at the center of the SZ (the cross-section perpendicular to the process direction), starting from the base metal on the right side and ending in the base metal on the left side with an equal distance step ≈ 1 mm.

3. Results and Discussion

3.1. Microstructure Analysis

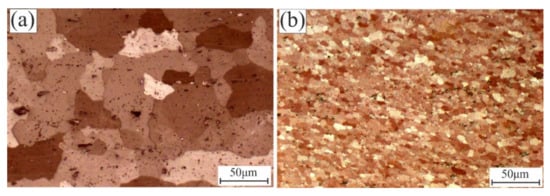

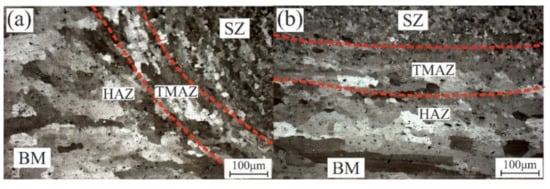

Figure 3 shows the micrographs of the base alloy AA5250 sheets and the stirred zone after FSP at 1120 rpm and 40 mm/min. The as-received sheet was rolled resulting in an elongated, non-recrystallized grains structure in the direction of rolling (Figure 3a). After friction stir processing, refined equiaxed grains were observed (Figure 3b). A severe plastic deformation during FSP generates additional heat in the SZ, leading to a dynamically recrystallized (DRX) microstructure. Therefore, this assumption interpreted why the SZ consists of more uniform equiaxed refined grains than those in the base metal (BM). The as-processed BM exhibited an average grain size of 70 ± 10 μm (Table 3) with an aspect ratio close to 4:1. After FSP, the SZ exhibited an average grain size of 8 ± 1.1 μm and aspect ratio close to 1.05 ± 0.02 (Table 3). Figure 4 shows the retreating side (Figure 4a) and the bottom part (Figure 4b) obtained after FSP. The three distinct microstructure zones: The nugget or stirred zone (SZ), thermomechanical affected zone (TMAZ), and heat-affected zone (HAZ), were observed. The SZ exhibits dynamically recrystallized (DRX) refined equiaxed grains as a result of intensive plastic deformation. The TMAZ exhibits partially recrystallized grains as a result of the plastic deformation and the generated heat flux. The material has undergone a thermal cycle in the HAZ area without any plastic deformation resulting in a modified microstructure [33,34].

Figure 3.

The microstructure of (a) as-processed AA5250 alloy plates and (b) stirred zone after FSP of the investigated alloy.

Table 3.

The average grain size of the as-processed AA5250 sheets and the stirred zone on FSP and the composites.

Figure 4.

The microstructure of (a) the retreating side and (b) bottom area after FSP.

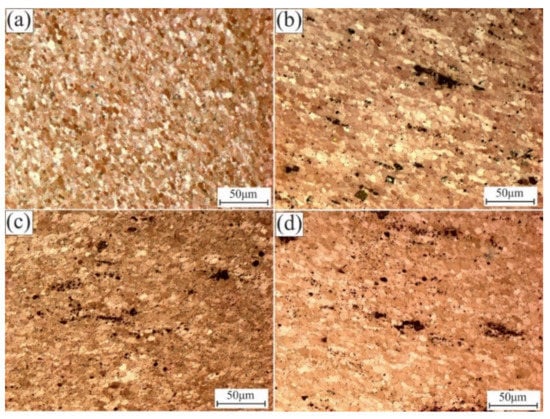

Figure 5 shows micrographs of AA5250 sheets reinforced with various nanoparticles using FSP at 1120 rpm and 40 mm/min. In general, nano-reinforcing particles have a substantial impact on dynamic restorative processes during FSP. According to particle stimulated nucleation (PSN) and Zener-pinning methods verified by Humphreys et al. [30], the nano reinforcement particles improve the refining activity of the grains in the SZ by increasing the number of nucleation sites for new grains. Furthermore, nonreinforcement particles in the SZ limit grain development following DRX. There is no substantial variation in grain size structure when different types of nanoparticles are used. The nanoparticles are clearly dispersed evenly in the base metal matrix. Table 3 shows the average grain size of the stirred zone following FSP and reinforcement with various nanoparticles. Without any reinforcing particles, the average grain size of the FSPed zone is 81.1 m. The typical grain size ranges from 3.5 to 5 m with reinforcing BN, SiC, Al2O3, and VC. All fabricated composites have an aspect ratio approximately close to 1.05, verifying the equiaxed homogenous grains.

Figure 5.

The microstructure of the stirred zone reinforced with different mono-nanoparticles (a) BN, (b) SiC, (c) Al2O3, and (d) VC processed at 1120 rpm and 40 mm/min.

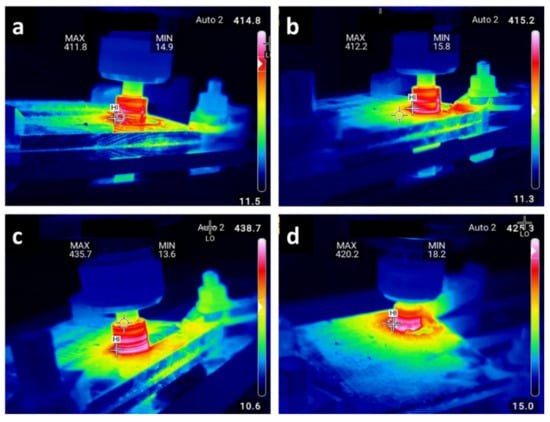

Figure 6 shows the thermal images that map the temperature distribution on the processed nano-surface composites and stir the tool via a high-resolution infra-red thermal image camera (Fluke Ti32). The maximum temperature was observed in the contact area between the tool and the surface of the sheets. The temperature between the shoulder and the workpiece was 415–425 °C for all the composites. The heat generated was sufficient to allow the DRX process to be fully executed in the SZ. It was around 415 °C in the case of reinforcing the base metal matrix with BN and SiC (Figure 6a,b), resulting in more refined grains due to the DRX in the SZ (Figure 5a,b and Table 3).

Figure 6.

Thermal images of the processed surface using the high-resolution thermal camera of the manufactured composites reinforced with (a) BN, (b) SiC, (c) Al2O3, and (d) VC.

In comparison, it was 438 °C in the case of Al2O3 (Figure 6c). In that case, the increase in the temperature led to insignificant grains growth after the DRX (Figure 5c). Therefore, the manufactured composite reinforced with Al2O3 that exhibited the largest grain size was 5 ± 1.3 μm (Table 3). The maximum generated temperature for the AA5250/VC composite was 425 °C resulting in 4.5 ± 1 μm. The resulting microstructure, grain size, and texture would affect the whole properties of the manufactured composite. According to the Hall-Petch equation, smaller grain size, higher strength, and ductility [35], the reduction in grain size and grain boundaries act as obstacles to the dislocation motion besides nanoceramics, resulting in high composite strength. Therefore, controlling the microstructure and grain size is essential to obtain the desired properties.

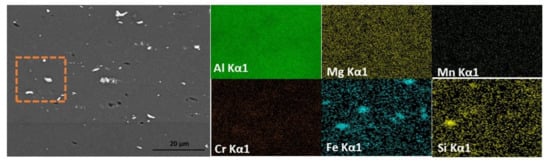

Figure 7 shows the SEM micrographs and EDS maps of the alloying elements of the AA5250 alloy in SZ after FSP without reinforcement nanoceramics particles. The SEM micrographs and EDS maps of the SZ after FSP show the uniform distribution of the formed phases in the investigated alloy. Moreover, the FSP achieves excellent refinement of the intermetallic alloy in the SZ (Figure 7).

Figure 7.

SEM micrograph and EDS mapping analysis in SZ of the investigated alloy after FSP without reinforcements.

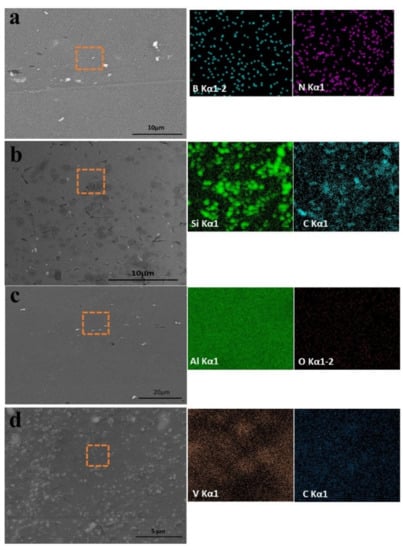

The ultimate goal of FSP is to create homogeneous dispersion of nanoparticles. However, the degree of heterogeneity and severity of agglomeration relies on the nanoparticle type, matrix chemistry, and processing parameters. EDS maps revealed the existence of reinforced particles in the SZ following FSP in this investigation. In general, it is seen that the reinforcing nanoparticles were almost uniformly distributed throughout the SZ in all the samples (Figure 8a–d).

Figure 8.

SEM micrographs and EDS mapping analysis in SZ of the manufactured composites reinforced with (a) BN, (b) SiC, (c) Al2O3, and (d) VC.

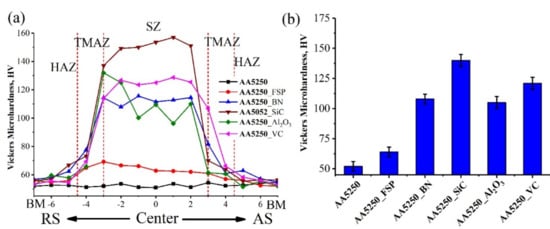

3.2. Micro-Hardness

The Vickers micro-hardness profile is shown in Figure 9a for the AA5250 base alloy and the fabricated nanocomposites. The average Vickers micro-hardness of the BM and SZ is depicted in Figure 9b. The AA5250 sheets have an average hardness value of 52 ± 3 HV. According to Figure 9, after FSP, the average measured hardness in the SZ is significantly enhanced due to the structural refinement and is reinforced by SiC, hence, it reached 63 ± 4 HV.

Figure 9.

(a) Vickers micro-hardness profile across all the samples and (b) the average Vickers micro-hardness in the BM and the SZ of all the samples.

The hardness is considerably improved in the SZ of the surface composite layer after FSP by reinforcing various nanoceramics. The enhancement in hardness is attributed to the matrix’s refinement action and uniform dispersion of hard nanoceramics into the matrix. The hardness is dramatically increased by reinforcing SiC nanoparticles into the matrix, reaching 160 HV, these results were consistent with [36]. The highest value of the hardness is obtained via SiC, followed by VC and then BN and Al2O3. The hardness value is affected by the morphology of grain structure (fine grains), the type of the reinforced nanoparticles (SiC has the most considerable hardness value than other particles), and the nanoparticles’ distribution in the matrix.

3.3. Tribological (Wear and Coefficient of Friction) Behavior

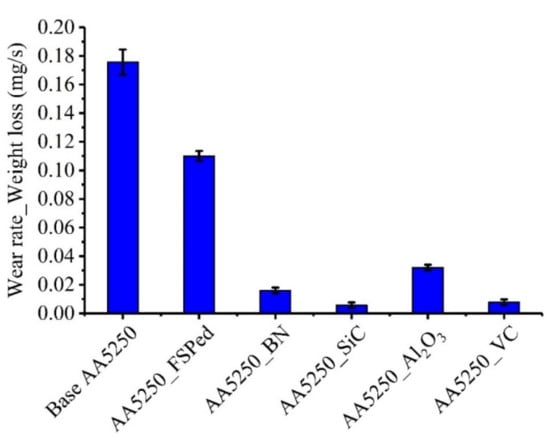

3.3.1. Wear Characterization by Weight Loss

In addition to improving the dispersion and homogeneity of the reinforcement nanoparticles in the composite matrix by reducing defects and voids created during the manufacturing process, the inclusion of reinforcement nanoparticles in the MMNCs has had a significant impact on the wear resistance of the composite matrix. Figure 10 shows the wear rate measured in milligrams per second (mg/s) of the as-processed AA5250 BM and across the SZ after FSP and reinforced with different nanoparticles, which is BN, SiC, Al2O3, and VC. In addition, the wear rate measured in milligrams per second of the as-processed AA5250 BM and across the SZ after FSP and reinforced with different nanoparticles, which is BN and SiC. The AA5250 BM displays the greatest weight loss rate, with a rate of 0.176 0.009 mg/s in its as-received state. After FSP, the SZ loses weight at a rate of 0.11 0.0035 mg/s, which is a prolonged rate. AbuShanab, W.S. and E.B. Moustafa [15] found that the refining process in the SZ was responsible for the increased wear rate seen after FSP. This finding is similar to previous findings. The use of various nanoparticles to reinforce one another resulted in a considerable improvement in the wear behavior. When BN, SiC, VC, and Al2O3 were used to reinforce the structure, the weight loss rate reduced to 0.0161 0.002, 0.0157 0.002, 0.0178 0.002, and 0.0332 0.002 mg/s (0.016 0.002 mg/s for Al2O3). Adding nanoparticles to the base matrix and improving the wear behavior further might be attributed to the homogeneity and excellent dispersion of the nanoparticles in the base matrix’s reinforcement nanoparticles.

Figure 10.

Wear rate by weight loss in mg/s of the as-processed AA5250 base alloy and friction stirred zone without and with different reinforcements nanoparticles processed at 1120 rpm and 40 mm/min.

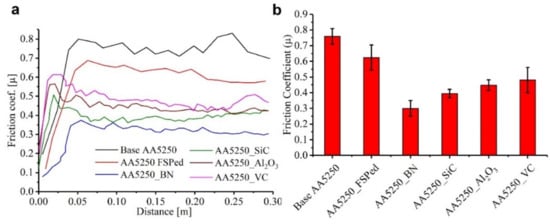

3.3.2. Wear Characterization by Volume Loss

A tribometer instrument was used to calculate the friction coefficient and the wear volume loss according to Equation (1). The coefficient of friction is assessed versus time and the sliding distance for a running period of 820 s and a normal load of 10 N. According to Figure 11a, the friction coefficient has a slightly increasing tendency. After the transition period, the curve’s gross trend becomes stable, indicating that the wear rate has transitioned from the initial wear in the transition state to the steady-state wear rate. Furthermore, the surface roughness parameters play a vital role in evaluating the friction coefficient. Hence, the initial transition wear rate takes longer than the composites with lower roughness. The reinforcement nanoparticles provide advanced and refined microstructure grains to the produced surface composite, lowering the friction coefficient value. Figure 11b shows the mean value of the friction coefficient. Based on the worn track section data, the basic AA5250 and AA5250 FSP had the highest COF values of 0.76 and 0.62, respectively, while the mono composite of AA5250 BN had the lowest COF value of 0.29. This result is due to the boron nitride particles’ ability to serve as a self-lubricant during the sliding wear action. As a result of the BN lubricating effect, the adhesion between the mono BN/AA5251 composite surface and the sliding wear tool decreases. This abrasive wear type description consists of [37,38]:

Figure 11.

(a) Friction coefficient behavior vs. distance on the surface of the fabricated nanocomposites, (b) mean value of the friction coefficient.

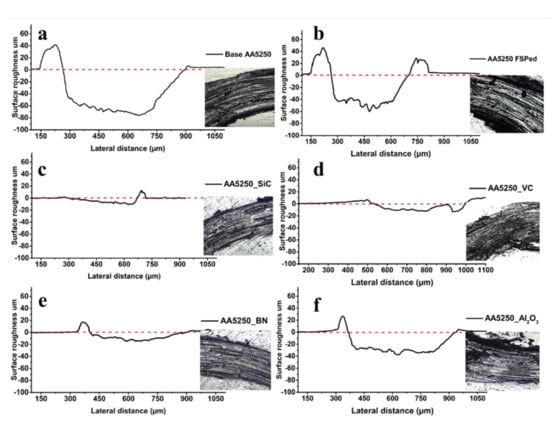

The BN, SiC, Al2O3, and VC particles reduced the COF values of their composites, resulting in COF values of 0.39, 0.44, and 0.48 for the AA5250 BN, AA5250 SiC, and AA5250 VC composites, respectively. Therefore, the dispersion and distribution of reinforcements following FSP significantly impact the microstructure, mechanical, wear, and hardness characteristics of the produced composites. With the addition of reinforcement particles, the wear rates of the examined samples were reduced in general. The wear rate and hardness behavior of composite materials are directly related, hard reinforcing particles are absorbed into the nanocomposite matrix and improve wear resistance. Figure 12 shows the plowing track surfaces formed during the dry wear sliding route. Despite the basic AA5250 and FSP alloys, the wear mechanism in all manufactured composites was abrasive. The adhesive wear was noted due to the lack of ceramic particles and plastic deformation of the base alloy AA5250 during the wear test. The worn surface of the AA5250 alloy showed delamination and extensive exfoliation, resulting in severe wear. The mono AA5250 BN, AA5250 SiC, and AA5250 VC have cleaner worn surfaces than the mono AA5250 Al2O3, FSP, and base alloy AA5250. The hard VC, SiC, and BN particles prevent the worn tool pin from penetrating wide regions, as illustrated in Figure 12c–e.

Figure 12.

Surface roughness profile of the fabricated nanocomposites measured using the stylus contact-surface profiler. (a) base AA5250, (b) AA5250_FSPed, (c) AA5250_SiC, (d) AA5250_VC, (e) AA5250_BN, (f) AA5250_Al2O3.

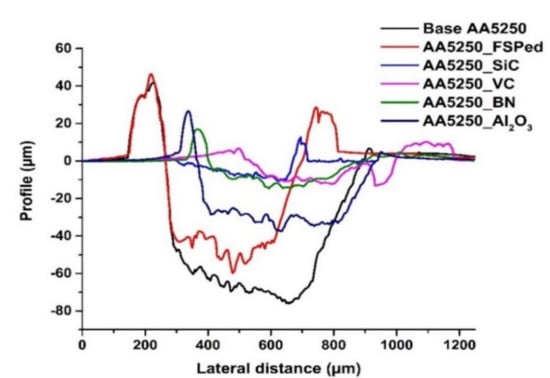

In Figure 12a,b, the base and FSP AA5250 revealed a significant amount of wear. Furthermore, the lateral distance in the composites AA5250 SiC, AA5250 BN, and AA5250 VC was less than that in the composites AA5250 Al2O3, FSPed, and AA5250 base alloy. The inclusion of hard ceramics particles of VC, SiC, and BN particles in the manufactured composite can explain the observation.

Figure 13 compares the wear profiles between the base AA5250 and the fabricated nanocomposites. The AA5250 alloy and FSP exhibited a more extensive volume loss than all the composites. The wear penetration depth was decreased by approximately 10, 15, and 18 μm at a 10 N load by adding SiC, VC, and BN, respectively. There is material uplift on the inside and outside circumference of the wear track profiles due to the steel pin penetrating the material, causing plastic deformation.

Figure 13.

Comparison of the wear surfaces profile of the investigated nanocomposites under a constant load of 10 N.

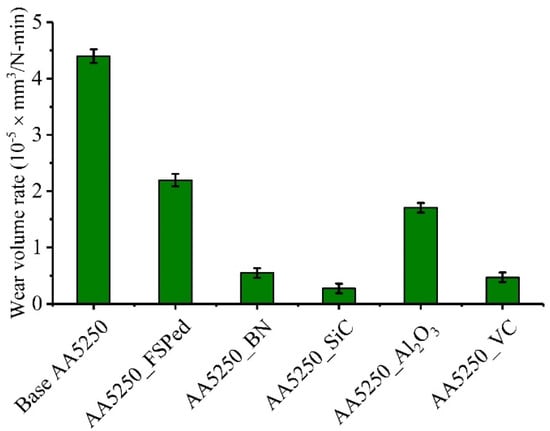

The experimental wear rate by volume loss of the base AA5250 alloy and the fabricated composites is presented in Figure 14. The total volume loss was calculated by integrating the area of the measured average depth during each scratch. It is possible to calculate a sample’s volume based on how wide the scratched or worn region is. The wear rate using the volume loss can be formulated by Equation (2) [39]:

Figure 14.

Effect of ceramics nanoparticles on the wear rate using the volume loss.

Table 4 shows the experimental wear volume loss, the AA5250 alloy exhibits a significant wear volume loss of 3.41 × 10−3 mm3 at 10 N load. The SiC nanoparticles play a substantial role in enhancing the wear performance of the nanocomposite matrix. Hence, the minimum wear rate was achieved using the AA5250_SiC, AA5250_VC, and AA5250_BN nanocomposites. Furthermore, the SiC, VC, and BN nanoparticles significantly improved the tribological behavior of AA5250 based MMC. In contrast, reinforcing the matrix with Al2O3 shows a slight increase in the wear resistance than the other ceramics particles, these results are consistent with [26,40,41,42].

Table 4.

Volume loss (mm3) of the worn samples’ values.

3.4. Weight and Cost Analysis of the Manufactured Composites

It is helpful to identify the manufactured composite economically. In particular, these composites are used in various industries, such as aerospace and marine. The materials utilized should have a low density (weight), while also enhancing wear resistance. As a result, the density and cost of composites reinforced with various nanoceramics were assessed. The cost of the fabrication process in the workshop was omitted from the calculations.

The total volume of the produced composite can be computed by Equations (3) and (4):

The volume of the used nanoceramics and the matrix can be calculated by Equations (5) and (6):

The volume fraction of the used nanoceramics and the matrix can be calculated by Equations (7) and (8):

The overall theoretical density of the composite can be computed as follows (Equations (9) and (10)):

Table 5 and Table 6 summarize the theoretical densities and the costs of the manufactured composites reinforced with different nanoceramics. The volume fraction of the reinforced nanoceramics within the matrix was 11.6%. The overall densities of the fabricated nanocomposites were tabulated in Table 5, the last column. The results show that adding BN nanoparticles decreased the composite density by 2.7%. On the contrary, in the other nanoceramics, the densities of the manufactured composites were increased. They increased by 2.2, 5, and 11.6% using SiC, Al2O3, and VC, respectively.

Table 5.

The theoretical density of the fabricated composites.

Table 6.

The cost of the fabricated composites.

The mass of the used nanoceramics and the matrix are calculated and listed in Table 6. The Nanoshel company offered the cost of ceramics nanoparticles. The total cost of the manufactured composites was calculated by summating the cost of the base matrix and the cost of the reinforcement nanoceramics particles per gram. It is noted that the total cost of the manufactured composite with reinforcing BN was the maximum, USD 4.5/g, while the minimum cost USD 1.045/g, was obtained when reinforcing Al2O3 nanoparticles.

3.5. Overall Assessment of Fabricated Nanocomposites

Table 7 illustrates the proportionate increase in hardness, wear resistance, friction coefficient, density, and cost relative to the base metal. It should be highlighted that employing SiC as a reinforcement resulted in the greatest improvement in hardness and wear resistance. When the BN was used, the coefficient of friction and density was the lowest. Furthermore, compared to the BM and other composites, the AA5250/BN had the highest cost. The increase in hardness, wear resistance, and decrease in COF are considered strengths. The increase in density and cost are considered weaknesses for using BN, SiC, Al2O3, and VC nanoceramics as reinforcements, these strengths and weaknesses are illustrated in the percentage relative to the BM.

Table 7.

The increase in hardness, wear resistance, decrease in COF, increase in density, and cost relative to the BM for the manufactured composites.

The cost of the manufactured composites increased dramatically in comparison to the basic matrix due to the high cost of raw nanoceramics components. As a result, the composites should be made using a very precise method, resulting in good dispersion of the nanoparticles in the matrix, allowing the nanoparticles to be saved rather than wasted. Furthermore, Table 7 can assist us in determining which nanoceramic is most suited to our requirements. For example, if wear resistance is a top requirement, SiC reinforcement particles should be used. If COF and density are priorities, the BN nanoparticles will be the top choice. On the other hand, if all hardness, wear resistance, COF, density, and cost have the same weight, and the increase in density and cost are considered weak points (negative effect), the overall assessment can be computed as in Equation (11). For a particular application, the weight of density can be larger than the other parameters, so the overall assessment should be changed accordingly. Since the weight is considered to be equal for all points, the overall assessment equals the total of the strengths and weaknesses (Wh = Ww = Wf = Wd = Wc).

All five characteristics, hardness, wear resistance, COF, density, and cost, were standardized within the range of 0 to 20 prior to algebraic summing by Equation (10) to determine the total evaluation. (Equations (12) and (13)) to achieve equality between all parameters.

- X is the unified value corresponding to Y;

- Y is the relative strength and weakness points values;

- Ymax is the maximum value in strength points, in hardness, wear resistance, and COF;

- Ymin is the minimum value in weakness points, in density, and cost.For example, normalizing strength points, in the case of hardness, the Ymax = 169.2, so we take it = 20. For the AA5250/BN composite, the Y= 107.7, then the . In the same way, all the values for hardness, wear, and COF can be calculated.

- For example, in the case of cost, normalizing weakness points, Ymin = 2222.2, so we take it = 20. For the AA5250/BN composite, the Y= 10,000, then the . In the same way, all the values for cost and densities can be calculated.

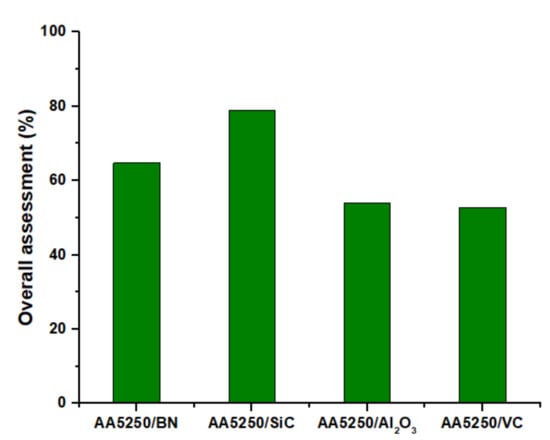

The highest value of the comprehensive evaluation is achieved using SiC, followed by BN, then Al2O3, and finally the VC. Therefore, from our perspective, the rank for choosing the nanoceramics is in the last column in Table 8. However, many studies recommended using the BN as reinforcement in manufacturing composites [40,41,43], where it was the second choice. This is due to the fact that the previous research overlooked the impact of cost and density on the produced composites.

Table 8.

The overall assessment and the rank of the nanoceramics choice.

Figure 15 shows the overall assessment as a percentage for each fabricated nanocomposite. The AA5250/SiC nanocomposite exhibits the optimal value, which was the first option due to its fitting for various properties cost. Despite the high price of the BN nanoparticles, the improvement in wear, hardness, density, and COF characteristics was significant. As a result, the AA5250/BN noticed the second choice among the investigated nanocomposite matrices.

Figure 15.

Overall assessment of the manufactured nanocomposites.

4. Conclusions

The current research investigates the physical, microstructure, and tribological properties of the AA5250 matrix nanocomposite reinforced with different nanoparticles. The comparative study was carried out among various ceramics nanoparticles, SiC, VC, BN, and Al2O3, to investigate which composite achieves the highest balance between different properties and the materials cost. After FSP, the grains were refined and became equiaxed. They decreased 10 times than those in the as-processed BM. Reinforcing different nanoceramics particles increased the refining action in the SZ due to PSN and Zener-pinning mechanisms. The maximum refining was recorded in the AA5250/BN composite, and the grains decreased 20 times than the BM. Therefore, it is observed that the FSP successfully manufactured surface nanocomposites with nearly uniformly distributed reinforcements in the AA5250 matrix.

- The manufactured composites reinforced with SiC and VC nanoparticles have the maximum wear resistance and hardness behavior than the other investigated composites.

- The BN nanoparticles significantly affected the dry friction behavior when impeded into the AA5250 metal matrix. Hence, the lower friction coefficient value was achieved in the AA5250/BN nanocomposite, which was μ = 0.28.

- BN nanoparticles reduced the composite density by 2.7%. While, SiC, Al2O3, and VC increased the nanocomposite density.

There is a lack of evaluation for nanocomposite materials based on mechanical and physical properties without considering the cost of these materials. Therefore, the overall assessment based on the testing properties besides the cost of these materials helps decision-makers choose the most appropriate nanocomposites.

Author Contributions

Conceptualization, E.B.M. and A.O.M.; methodology, E.B.M. and A.O.M.; validation, A.A.M.; formal analysis, A.D.K.; investigation, E.B.M., A.D.K. and A.O.M.; resources, W.S.A.; data curation, A.D.K.; writing—original draft preparation, E.B.M. and A.O.M.; writing—review and editing, W.S.A. and A.A.M.; supervision, E.B.M. and A.O.M.; project administration, W.S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Deanship of Scientific Research (DSR), King Abdulaziz University, under grant No. RG-3-150-38.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Acknowledgments

This research was funded by the Deanship of Scientific Research (DSR), King Abdulaziz University, Jeddah, under grant No. RG-3-150-38. Therefore, the authors gratefully acknowledge technical and financial support from the ministry of education and King Abdulaziz University, DSR, Jeddah, Saudi Arabia.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Al2O3 | Aluminum oxide |

| AMM | Aluminum metal matrix |

| AMMCs | Aluminum metal matrix composites |

| BM | Base metal |

| BN | Boron nitride |

| EDS | Energy-dispersive spectroscopy |

| FSP | Friction stir processing |

| HAZ | Heat-affected zone |

| HBN | Hexagonal boron nitride |

| MMC | Metal matrix composite |

| OM | Optical microscopy |

| SD | Standard deviation |

| SEM | Scanning electron microscopy |

| SiC | Silicon carbide |

| SZ | Nugget or stirred zone |

| TEM | Transmission electron microscopy |

| TMAZ | Thermomechanical affected zone |

| VC | Vanadium carbide |

| Vc, p,m | Volume of composite, nanoparticles, and matrix |

| L | Length of the composite |

| VFP,m | Volume fraction of the nanoparticles and matrix |

| ρc, p,m | Density composite, nanoparticles, and matrix |

| Mc, p, m | Mass of the composite, nanoparticles, and matrix |

| Wh,w,f,d,c | Weight fraction of hardness, wear resistance, COF, density, and cost |

| Y | The relative strength and weakness points values |

| X | The unified value corresponding to Y |

| Ymax | The maximum value in strength points, hardness, wear resistance, and COF |

| Ymin | The minimum value in weakness points, density, and cost |

References

- Ervina Efzan, M.N.; Siti Syazwani, N.; Al Bakri Abdullah, M.M. Fabrication method of aluminum matrix composite (AMCs): A review. Key Eng. Mater. 2016, 700, 102–110. [Google Scholar] [CrossRef]

- Chao, W.; Xue, X.; Cao, X.; He, Y.; Gongjin, C. The effect of Ti addition on the microstructure and fracture toughness of Bn-Al composite materials synthesized by vacuum infiltration. Arch. Metall. Mater. 2013, 58, 509–512. [Google Scholar] [CrossRef] [Green Version]

- Xiaozhou, C.; Chao, W.; Xiangxin, X.; Cheng, G. Effect of Ti addition on the residual aluminium content and mechanical properties of the B4C-Al composites produced by vacuum infiltration/wpływ dodatku tytanu na resztkową zawartość aluminium i właściwości mechaniczne kompozytów B4C-Al wytworzonych przez infiltrację próżniową. Arch. Metall. Mater. 2015, 60, 2493–2498. [Google Scholar]

- Essam Moustafa, S.A.-W.; Tamer Mahmoud, E.-S.E.-K. Review multi pass friction stir processing. Am. Sci. Res. J. Eng. Technol. Sci. 2006, 22, 98–108. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y.; Charit, I. Friction stir processing: A novel technique for fabrication of surface composite. Mater. Sci. Eng. A 2003, 341, 307–310. [Google Scholar] [CrossRef]

- AbuShanab, W.S.; Moustafa, E.B. Detection of friction stir welding defects of AA1060 aluminum alloy using specific damping capacity. Materials 2018, 11, 2437. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nirmal Kumar, K.; Aravindkumar, N.; Eswaramoorthi, K. Fabrication of AA6016/(Al2O3 + AlN) hybrid surface composite using friction stir processing. Mater. Today Proc. 2020, 33, 315–319. [Google Scholar] [CrossRef]

- Moustafa, E. Effect of multi-pass friction stir processing on mechanical properties for AA2024/Al2O3 nanocomposites. Materials 2017, 10, 1053. [Google Scholar] [CrossRef] [Green Version]

- El-Danaf, E.A.; El-Rayes, M.M.; Soliman, M.S. Friction stir processing: An effective technique to refine grain structure and enhance ductility. Mater. Des. 2010, 31, 1231–1236. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Taha, M.A. Preparation of high strength graphene reinforced Cu-based nanocomposites via mechanical alloying method: Microstructural, mechanical and electrical properties. Appl. Phys. A 2020, 126, 220. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Mosleh, A.O. Effect of (Ti–B) modifier elements and FSP on 5052 aluminum alloy. J. Alloys Compd. 2020, 823, 153745. [Google Scholar] [CrossRef]

- Moustafa, E.B. Dynamic characteristics study for surface composite of AMMNCs matrix fabricated by friction stir process. Materials 2018, 11, 1240. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- AbuShanab, W.S.; Moustafa, E.B. Effects of friction stir processing parameters on the wear resistance and mechanical properties of fabricated metal matrix nanocomposites (MMNCs) surface. J. Mater. Res. Technol. 2020, 9, 7460–7471. [Google Scholar] [CrossRef]

- Otitoju, T.A.; Okoye, P.U.; Chen, G.; Li, Y.; Okoye, M.O.; Li, S. Advanced ceramic components: Materials, fabrication, and applications. J. Ind. Eng. Chem. 2020, 85, 34–65. [Google Scholar] [CrossRef]

- Pol, N.; Verma, G.; Pandey, R.P.; Shanmugasundaram, T. Fabrication of AA7005/TiB2-B4C surface composite by friction stir processing: Evaluation of ballistic behaviour. Def. Technol. 2019, 15, 363–368. [Google Scholar] [CrossRef]

- Zayed, A.S.; Kamel, B.M.; Abdelsadek Osman, T.; Elkady, O.A.; Ali, S. Experimental study of tribological and mechanical properties of aluminum matrix reinforced by Al2O3/CNTs. Fuller. Nanotub. Carbon Nanostruct. 2019, 27, 538–544. [Google Scholar] [CrossRef]

- Heidarpour, A.; Mazaheri, Y.; Roknian, M.; Ghasemi, S. Development of Cu-TiO2 surface nanocomposite by friction stir processing: Effect of pass number on microstructure, mechanical properties, tribological and corrosion behavior. J. Alloys Compd. 2019, 783, 886–897. [Google Scholar] [CrossRef]

- Kumar, P.A.; Madhu, H.C.; Pariyar, A.; Perugu, C.S.; Kailas, S.V.; Garg, U.; Rohatgi, P. Friction stir processing of squeeze cast A356 with surface compacted graphene nanoplatelets (GNPs) for the synthesis of metal matrix composites. Mater. Sci. Eng. A 2020, 769, 138517. [Google Scholar] [CrossRef]

- Deore, H.A.; Bhardwaj, A.; Rao, A.G.; Mishra, J.; Hiwarkar, V.D. Consequence of reinforced SiC particles and post process artificial ageing on microstructure and mechanical properties of friction stir processed AA7075. Def. Technol. 2020, 16, 1039–1050. [Google Scholar] [CrossRef]

- Patil, N.A.; Pedapati, S.R.; Mamat, O.; Lubis, A.M.H.S. Morphological characterization, statistical modeling and wear behavior of AA7075-titanium carbide-graphite surface composites via friction stir processing. J. Mater. Res. Technol. 2021, 11, 2160–2180. [Google Scholar] [CrossRef]

- Mondal, S. Aluminum or its alloy matrix hybrid nanocomposites. Met. Mater. Int. 2020, 27, 1–17. [Google Scholar] [CrossRef]

- Arab, M.; Marashi, S.P.H. Graphene nanoplatelet (GNP)-incorporated AZ31 magnesium nanocomposite: Microstructural, mechanical and tribological properties. Tribol. Lett. 2018, 66, 1–11. [Google Scholar] [CrossRef]

- Al-Salihi, H.A.; Mahmood, A.A.; Alalkawi, H.J. Mechanical and wear behavior of AA7075 aluminum matrix composites reinforced by Al2O3nanoparticles. Nanocomposites 2019, 5, 67–73. [Google Scholar] [CrossRef] [Green Version]

- Moustafa, E.B.; Melaibari, A.; Basha, M. Wear and microhardness behaviors of AA7075/SiC-BN hybrid nanocomposite surfaces fabricated by friction stir processing. Ceram. Int. 2020, 46, 16938–16943. [Google Scholar] [CrossRef]

- Kheirkhah, S.; Imani, M.; Aliramezani, R.; Zamani, M.H.; Kheilnejad, A. Microstructure, mechanical properties and corrosion resistance of Al6061/BN surface composite prepared by friction stir processing. Surf. Topogr. Metrol. Prop. 2019, 7, 035002. [Google Scholar] [CrossRef]

- Moustafa, E.B.; AbuShanab, W.S.; Ghandourah, E.; Taha, M.A. Microstructural, mechanical and thermal properties evaluation of AA6061/Al2O3-BN hybrid and mono nanocomposite surface. J. Mater. Res. Technol. 2020, 9, 15486–15495. [Google Scholar] [CrossRef]

- Bodrova, L.E.; Pastukhov, E.A. Interaction between vanadium carbide and aluminum and copper melts. Russ. Metall. 2013, 2013, 112–114. [Google Scholar] [CrossRef]

- Ghasali, E.; Pakseresht, A.H.; Alizadeh, M.; Shirvanimoghaddam, K.; Ebadzadeh, T. Vanadium carbide reinforced aluminum matrix composite prepared by conventional, microwave and spark plasma sintering. J. Alloys Compd. 2016, 688, 527–533. [Google Scholar] [CrossRef]

- Babu, N.A.; Ravi, B.; Rajkumar, G. Process Parameter optimization for Producing AA7075/WC composites by Friction stir welding. Mater. Today Proc. 2018, 5, 18992–18999. [Google Scholar] [CrossRef]

- Humphreys, J.; Rohrer, G.S.; Rollett, A. Hot Deformation and Dynamic Restoration. In Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2017; pp. 469–508. [Google Scholar]

- Valiev, R.Z. 1—Producing bulk nanostructured metals and alloys by severe plastic deformation (SPD). In Nanostructured Metals and Alloys; Whang, S.H., Ed.; Woodhead Publishing: Cambridge, UK, 2011; pp. 3–39. [Google Scholar]

- Whang, S.H. (Ed.) Nanostructured Metals and Alloys: Processing, Microstructure, Mechanical Properties and Applications; Woodhead Publishing: Cambridge, UK, 2011; pp. 178–208. [Google Scholar]

- Thorsen, P.A.; Bilde-Sørensen, J.B. The Influence of Grain Boundary Structure on Diffusional Creep. Mater. Sci. Forum 1998, 131–134. [Google Scholar] [CrossRef]

- Abdel Aziz, S.S.; Abulkhair, H.; Moustafa, E.B. Role of hybrid nanoparticles on thermal, electrical conductivity, microstructure, and hardness behavior of nanocomposite matrix. J. Mater. Res. Technol. 2021, 13, 1275–1284. [Google Scholar] [CrossRef]

- Mucelin, K.J.; da Costa Gonçalves, P.; Hammes, G.; Binder, R.; Janssen, R.; Klein, A.N.; de Mello, J.D.B. Tribological Study of Self-Lubricating Composites with Hexagonal Boron Nitride and Graphite as Solid Lubricants. In Proceedings of the 2nd International Brazilian Conference on Tribology, Foz do Iguaçu, Brazil, 3–5 November 2014; pp. 3772–3781. [Google Scholar]

- Menezes, P.L.; Kailas, S.V. Studies on friction and transfer layer using inclined scratch. Scratch. Mater. Appl. 2006, 29, 262–279. [Google Scholar]

- Cowap, M.J.; Moghaddam, S.R.; Menezes, P.L.; Beschorner, K.E. Contributions of adhesion and hysteresis to coefficient of friction between shoe and floor surfaces: Effects of floor roughness and sliding speed. Tribol. Mater. Surf. Interfaces 2015, 9, 77–84. [Google Scholar] [CrossRef]

- Totten, G.E. (Ed.) Handbook, ASM in Friction, Lubrication, and Wear Technology; ASM International: Novelty, OH, USA, 2017. [Google Scholar]

- Manivannan, I.; Ranganathan, S.; Gopalakannan, S.; Suresh, S.; Nagakarthigan, K.; Jubendradass, R. Tribological and surface behavior of silicon carbide reinforced aluminum matrix nanocomposite. Surf. Interfaces 2017, 8, 127–136. [Google Scholar] [CrossRef]

- Gostariani, R.; Ebrahimi, R.; Asadabad, M.A.; Paydar, M.H. Mechanical properties of Al/BN nanocomposites fabricated by planetary ball milling and conventional hot extrusion. Acta Metall. Sin. Engl. Lett. 2017, 31, 245–253. [Google Scholar] [CrossRef]

- Öner, M.; Kızıl, G.; Keskin, G.; Pochat-Bohatier, C.; Bechelany, M. The Effect of boron nitride on the thermal and mechanical properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Nanomaterials 2018, 8, 940. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Tantawy, A.; Daoush, W.M.; El-Nikhaily, A.E. Microstructure and properties of BN/Ni-Cu composites fabricated by powder technology. J. Exp. Nanosci. 2018, 13, 174–187. [Google Scholar] [CrossRef] [Green Version]

- Paulraj, P.; Harichandran, R. The tribological behavior of hybrid aluminum alloy nanocomposites at high temperature: Role of nanoparticles. J. Mater. Res. Technol. 2020, 9, 11517–11530. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).