Effect of Low-Energy Nitrogen Ion Implantation on Friction and Wear Properties of Ion-Plated TiC Coating

Abstract

1. Introduction

2. Materials and Methods

3. Results

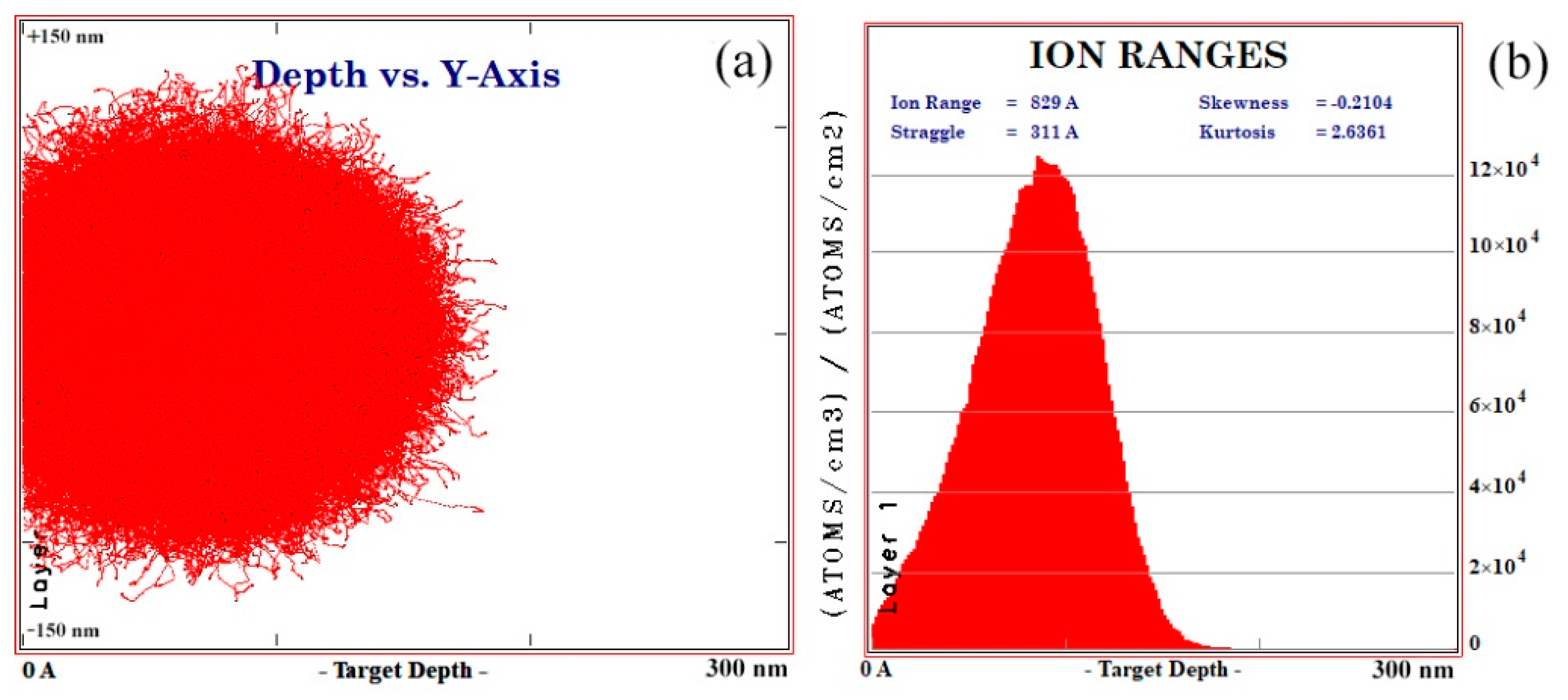

3.1. Ions Penetration Data

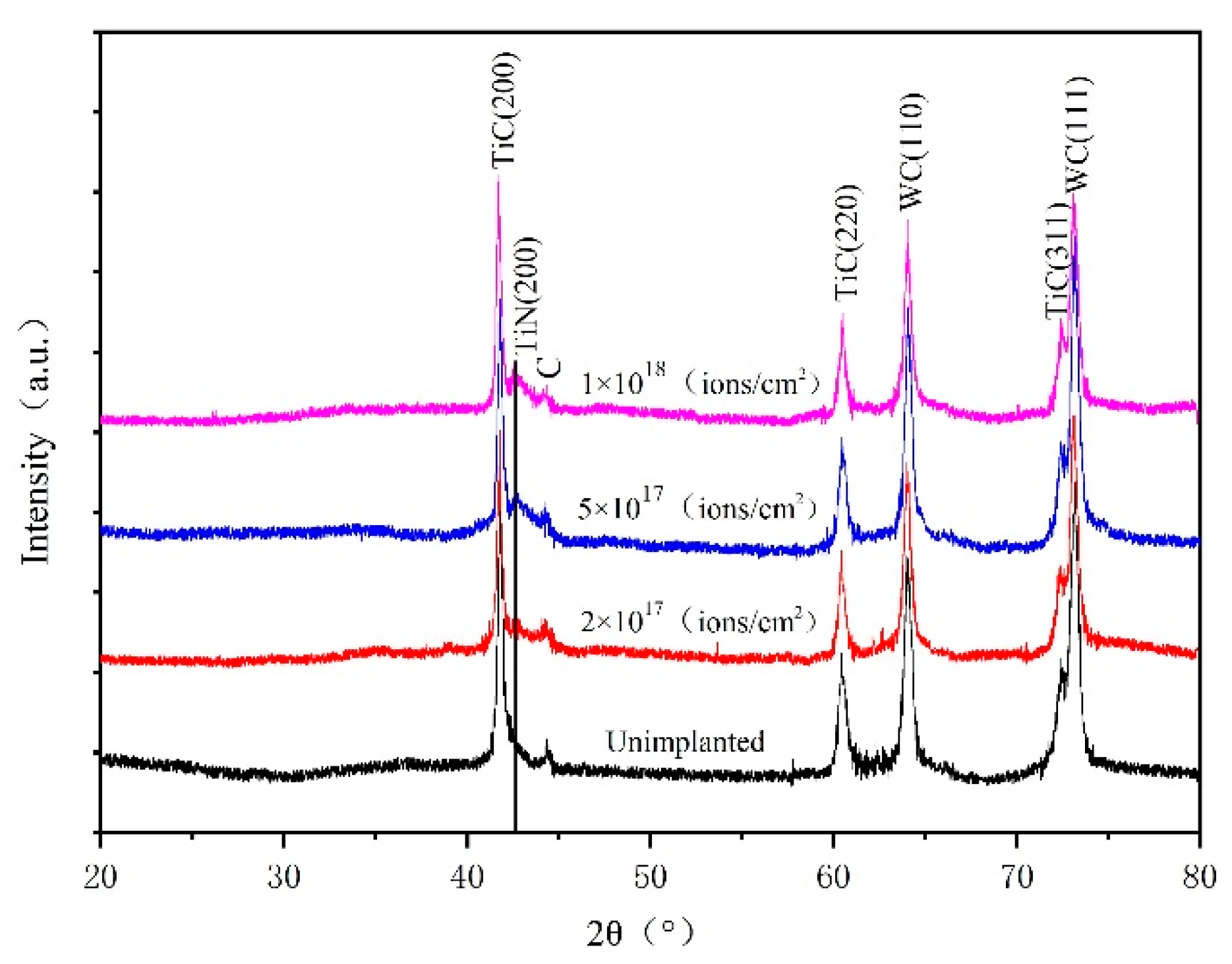

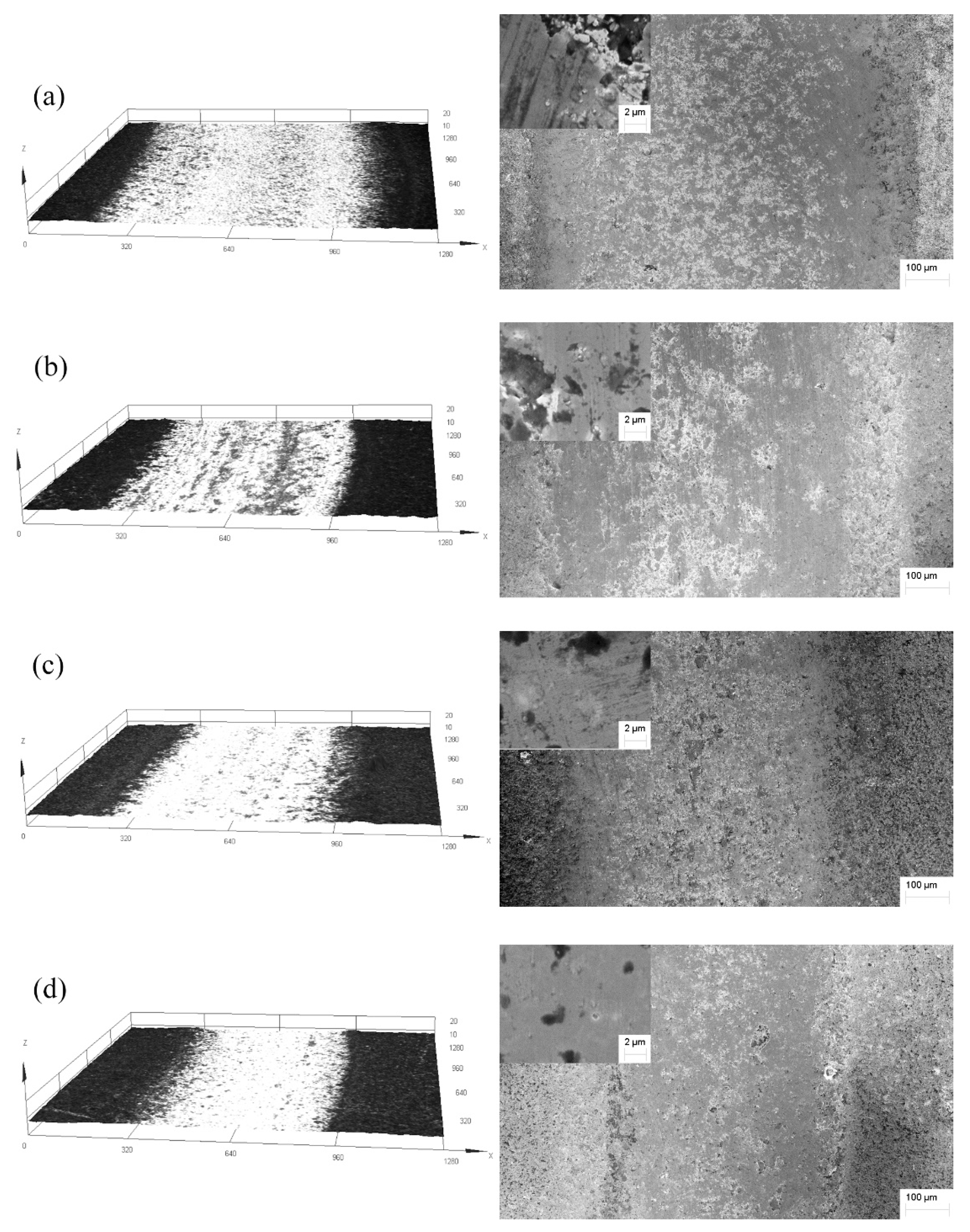

3.2. The Structure and Surface Morphology of the Coatings

3.3. Hardness Measurement

3.4. Friction and Wear Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, S.; Hu, Y.; Zhang, X.; Zou, Y.; Ahmad, T.; Zhang, W.; Tang, F.; Liang, T. Experimental investigation on ultrasonic shot peening of WC-Co alloy. Mater. Manuf. Process. 2020, 35, 1576–1583. [Google Scholar] [CrossRef]

- Tang, Y.; Li, Y.S.; Yang, Q.; Hirose, A. Deposition and characterization of diamond coatings on WC-Co cutting tools with W/Al interlayer. Diam. Relat. Mater. 2009, 19, 496–499. [Google Scholar] [CrossRef]

- Malarvannan, R.R.R.; Moorthy, T.V.; Ravi, S. Improvement of wear performance of high speed steel tool using physical vapour deposition coating process. Appl. Mech. Mater. 2015, 4123, 391–395. [Google Scholar] [CrossRef]

- Adaskin, A.M.; Butrim, V.N.; Vereshchaka, A.S. Wear resistance of a coated hard-alloy tool in the machining of high-temperature chromium alloys. Russ. Eng. Res. 2016, 36, 867–871. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chang, H.; Jhao, L.-J.; Chuang, C.-C. Tribological and mechanical properties of multilayered TiVN/TiSiN coatings synthesized by cathodic arc evaporation. Surf. Coat. Technol. 2018, 350, 1071–1079. [Google Scholar] [CrossRef]

- Yasuoka, M.; Wang, P.; Murakami, R. Comparison of the mechanical performance of cutting tools coated by either a TiCxN1−x single-layer or a TiC/TiC0.5N0.5/TiN multilayer using the hollow cathode discharge ion plating method. Surf. Coat. Technol. 2011, 206, 2168–2172. [Google Scholar] [CrossRef]

- Iram, S.; Cai, F.; Wang, J.; Zhang, J.; Liang, J.; Ahmad, F.; Zhang, S. Effect of Addition of Mo or V on the structure and cutting performance of AlCrN-based coatings. Coatings 2020, 10, 298. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Meng, R.; Lei, S.; Yu, X. Influence of laser substrate pretreatment on anti-adhesive wear properties of WC/Co-based TiAlN coatings against AISI 316 stainless steel. Int. J. Refract. Met. Hard Mater. 2016, 57, 101–114. [Google Scholar] [CrossRef]

- Li, G.; Li, L.; Han, M.; Luo, S.; Jin, J.; Wang, L.; Gu, J.; Miao, H. The performance of TiAlSiN coated cemented carbide tools enhanced by inserting Ti interlayers. Metals 2019, 9, 918. [Google Scholar] [CrossRef]

- Krzysztof, S.; Jerzy, M.; Łukasz, M.; Małgorzata, P.; Michał, T.; Oleh, T.; Iryna, P.; Tadeusz, W. Effect of nitriding conditions of Ti6Al7Nb on microstructure of TiN surface layer. J. Alloy. Compd. 2020, 845, 156320. [Google Scholar]

- Yanfeng, W.; Zhengxian, L.; Wei, L.; Jihong, D.; Shouchang, J.; Changwei, Z. Effect of substrate pre-carburizing on properties of TiN (Ti) hard coatings deposited on Ti-6Al-4V alloy. Rare Met. Mater. Eng. 2018, 47, 3295–3300. [Google Scholar] [CrossRef]

- Song, Y.; Fu, B.; Dong, T.; Li, G.; Wang, F.; Zhao, X.; Liu, J. Effect of vacuum annealing treatment on dry sliding wear behavior of TiC/Ti-1100-0.5Nb composite under different operating temperatures. Mater. Today Commun. 2020, 23, 101136. [Google Scholar] [CrossRef]

- Ward, L.P.; Purushotham, K.P.; Manory, R.R. MEVVA ion implantation of TiCN coatings; structural and tribological properties. Nuclear Inst. Methods Phys. Res. B 2019, 449, 40–48. [Google Scholar] [CrossRef]

- Vlcak, P.; Cerny, F.; Drahokoupil, J.; Sepitka, J.; Tolde, Z. The microstructure and surface hardness of Ti6Al4V alloy implanted with nitrogen ions at an elevated temperature. J. Alloy. Compd. 2015, 620, 48–54. [Google Scholar] [CrossRef]

- Ying, Z.; Man, W.S.; Man, W.H.; Shuilin, W.; Tao, H.; Kelvin, Y.W.K.; Chu, P.K. Effects of carbon and nitrogen plasma immersion ion implantation on in vitro and in vivo biocompatibility of titanium alloy. ACS Appl. Mater. Interfaces 2013, 5, 1510–1516. [Google Scholar]

- Dai, J.; Liu, Z.; Yu, B.; Ruan, Q.; Chu, P.K. Effects of Ti, Ni, and dual Ti/Ni plasma immersion ion implantation on the corrosion and wear properties of magnesium alloy. Coatings 2020, 10, 313. [Google Scholar] [CrossRef]

- Sharma, P.; Dhawan, A.; Sharma, S.K. Influence of nitrogen ion implantation on corrosion behavior of Zr55Cu30Ni5Al10 amorphous alloy. J. Non-Cryst. Solids 2019, 511, 186–193. [Google Scholar] [CrossRef]

- Sharkeev, Y.P.; Bull, S.J.; Perry, A.J.; Klingenberg, M.L.; Fortuna, S.; Michler, M.; Manory, R.R.; Shulepov, I.A. On high dose nitrogen implantation of PVD titanium nitride. Surf. Coat. Technol. 2005, 2000, 5915–5920. [Google Scholar] [CrossRef]

- Yang, J.H.; Cheng, M.F.; Luo, X.D.; Zhang, T.H. Surface properties and microstructure of implanted TiN films using MEVVA ion source. Mater. Sci. Eng. A 2006, 445, 558–562. [Google Scholar] [CrossRef]

- PShum, W.; Zhou, Z.F.; Li, K.Y. A Study of the structural, mechanical and tribological properties of Ti-Al-N coatings post-treated by carbon implantation. Adv. Mater. Res. 2009, 844, 7–12. [Google Scholar]

- Cheng, Y.; Zheng, Y.F. Characterization of TiN, TiC and TiCN coatings on Ti–50.6 at.% Ni alloy deposited by PIII and deposition technique. Surf. Coat. Technol. 2006, 201, 4909–4912. [Google Scholar] [CrossRef]

- Fang, T.-H.; Jian, S.-R.; Chuu, D.-S. Nanomechanical properties of TiC, TiN and TiCN thin films using scanning probe microscopy and nanoindentation. Appl. Surf. Sci. 2004, 228, 365–372. [Google Scholar] [CrossRef]

- Rani, R.; Kumar, N.; Kumar, D.D.; Panda, K.; Srivastava, S.K.; Dash, S.; Tyagi, A.K. Improvement in wear resistance of C + ion implanted DC magnetron sputtered TiC film. Tribol. Int. 2016, 104, 121–130. [Google Scholar] [CrossRef]

- Shum, P.W.; Xu, Y.F.; Zhou, Z.F.; Cheng, W.L.; Li, K.Y. Study of TiAlSiN coatings post-treated with N and C + N ion implantations. Part 2: The tribological analysis. Wear 2012, 274, 274–280. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM–The stopping and range of ions in matter (2010). Nucl. Inst. Methods Phys. Res. B 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Singh, O.; Malik, H.K.; Dahiya, R.P.; Kulriya, P.K. Tuning of mechanical and structural properties of 20 MC 5 steel using N ion implantation and subsequent annealing. J. Alloy. Compd. 2017, 710, 253–259. [Google Scholar] [CrossRef]

- Solati, E.; Dorranian, D. Investigation of the structure and properties of nanoscale grain-size β-tantalum thin films. Mol. Cryst. Liq. Cryst. 2013, 571, 67–76. [Google Scholar] [CrossRef]

- Alipour, R.; Khani, A.A.; Mohammadi, R.; Rostami, S. The effect of formation of titanium nitride thin film on surface characteristics of titanium by nitrogen ion implantation. J. Chem. Res. 2016, 40, 12–15. [Google Scholar] [CrossRef]

- Yu, X.; Shanhua, C.; Zhaoyuan, N.; Mingrong, S.; Qian, X. The influence of different deposition gases on the preparation of TiC films by multi-arc method. Funct. Mater. 2000, 31, 16–18. [Google Scholar]

- Ye, Y.; Wang, Y.; Chen, H.; Li, J.; Yao, Y.; Wang, C. Doping carbon to improve the tribological performance of CrN coatings in seawater. Tribol. Int. 2015, 90, 362–371. [Google Scholar] [CrossRef]

- Chao, Y.; Qunfeng, Z.; Wanjun, H.; Jianing, Z. Enhanced surface hardness and tribocorrosion performance of 60NiTi by boron ion implantation and post-annealing. Tribol. Int. 2021, 155, 106816. [Google Scholar]

- Narojczyk, J.; Morozow, D. Modification of TiN coatings by ion implantation. Acta Mech. Et Autom. 2017, 11, 190–193. [Google Scholar] [CrossRef][Green Version]

- Purushotham, K.P.; Ward, L.P.; Brack, N.; Pigram, P.J.; Evans, P.; Noorman, H.; Manory, R.R. Tribological studies of Zr-implanted PVD TiN coatings deposited on stainless steel substrates. Wear 2003, 254, 589–596. [Google Scholar] [CrossRef]

- Martínez-Martínez, D.; López-Cartes, C.; Fernández, A.; Sánchez-López, J.C. Influence of the microstructure on the mechanical and tribological behavior of TiC/a-C nanocomposite coatings. Thin Solid Film. 2008, 517, 1662–1671. [Google Scholar] [CrossRef]

- Fasce, L.; Cura, J.; del Grosso, M.; Bermúdez, G.G.; Frontini, P. Effect of nitrogen ion irradiation on the nano-tribological and surface mechanical properties of ultra-high molecular weight polyethylene. Surf. Coat. Technol. 2010, 204, 3887–3894. [Google Scholar] [CrossRef]

- Mahmood, K.; Bashir, S.; Akram, M.; Hayat, A.; Rafique, M.S.; Mahmood, A. Surface, structural, electrical and mechanical modifications of pulsed laser deposited ZrN thin films by implantation of MeV carbon ions. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2019, 448, 61–69. [Google Scholar] [CrossRef]

- Ahmad, S.; Bashir, S.; Ali, N.; Yousaf, D.; Naeem, A.; Ahmad, R.; Khlaeeq-ur-Rahman, M. Effect of ion irradiation on the surface, structural and mechanical properties of brass. Nucl. Inst. Methods Phys. Res. B 2014, 325, 5–10. [Google Scholar] [CrossRef]

- Kenneth, H. A concept for friction mechanisms of coated surfaces. Elsevier 1992, 56, 1–10. [Google Scholar]

- Ludema, K. Mechanical wear prediction and prevention. Wear 1995, 184, 215–216. [Google Scholar] [CrossRef]

- Zhang, H.S.; Endrino, J.L.; Anders, A. Comparative surface and nano—Tribological characteristics of nanocomposite diamond—Like carbon thin films doped by silver. Appl. Surf. Sci. 2008, 255, 2551–2556. [Google Scholar] [CrossRef]

| Sample | Dose (ions/cm2) | Implant Energy (keV) | Implanted Ion |

|---|---|---|---|

| S1 | 0 | 40 | Nitrogen |

| S2 | 2 × 1017 | 40 | Nitrogen |

| S3 | 5 × 1017 | 40 | Nitrogen |

| S4 | 1 × 1018 | 40 | Nitrogen |

| Sample (#) | Pristine | 2 × 1017 (ion/cm2) | 5 × 1017 (ion/cm2) | 1 × 1018 (ion/cm2) |

|---|---|---|---|---|

| RMS roughness (nm) | 12.8 | 27.6 | 38.4 | 12.3 |

| Average roughness (nm) | 9.59 | 21.6 | 26.9 | 9.96 |

| Sample (#) | Pristine | 2 × 1017 (ion/cm2) | 5 × 1017 (ion/cm2) | 1 × 1018 (ion/cm2) |

|---|---|---|---|---|

| Average hardness (GPa) | 20.586 | 4.332 | 6.758 | 7.265 |

| Young’s modulus (GPa) | 231.9 | 130.8 | 163.3 | 280.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dou, Z.; Guo, Y.; Zhang, F.; Zhang, D. Effect of Low-Energy Nitrogen Ion Implantation on Friction and Wear Properties of Ion-Plated TiC Coating. Coatings 2021, 11, 775. https://doi.org/10.3390/coatings11070775

Dou Z, Guo Y, Zhang F, Zhang D. Effect of Low-Energy Nitrogen Ion Implantation on Friction and Wear Properties of Ion-Plated TiC Coating. Coatings. 2021; 11(7):775. https://doi.org/10.3390/coatings11070775

Chicago/Turabian StyleDou, Zhongyu, Yinglu Guo, Faguang Zhang, and Dianxi Zhang. 2021. "Effect of Low-Energy Nitrogen Ion Implantation on Friction and Wear Properties of Ion-Plated TiC Coating" Coatings 11, no. 7: 775. https://doi.org/10.3390/coatings11070775

APA StyleDou, Z., Guo, Y., Zhang, F., & Zhang, D. (2021). Effect of Low-Energy Nitrogen Ion Implantation on Friction and Wear Properties of Ion-Plated TiC Coating. Coatings, 11(7), 775. https://doi.org/10.3390/coatings11070775