Manipulation of Magnetization Reversal by Electric Field in a FePt/(011)PMN-PT/Au

Abstract

1. Introduction

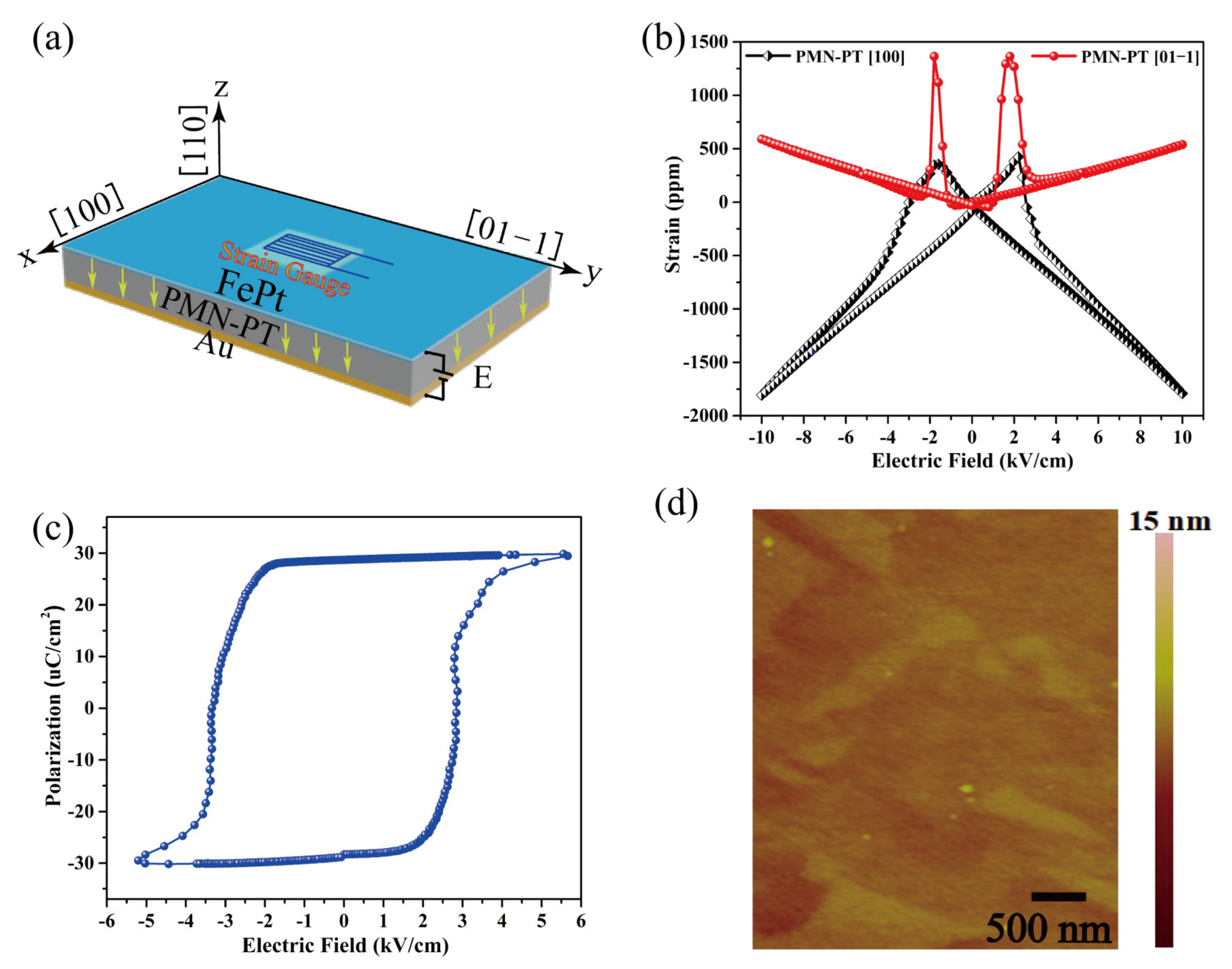

2. Experimental Section

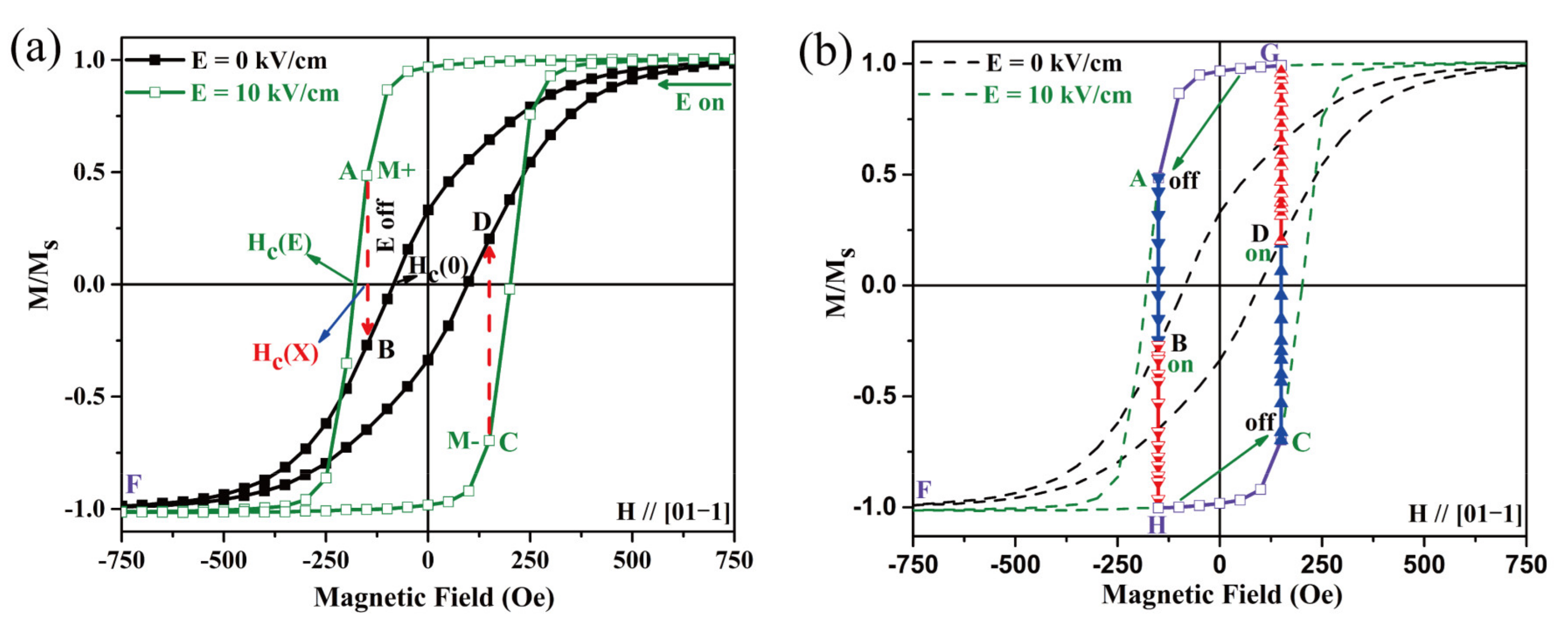

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ikegawa, S.; Mancoff, F.B.; Janesky, J.; Aggarwal, S. Magnetoresistive Random Access Memory: Present and Future. IEEE Trans. Electron Devices 2020, 67, 1407–1419. [Google Scholar] [CrossRef]

- Wong, H.S.P.; Lee, H.Y.; Yu, S.M.; Chen, Y.S.; Wu, Y.; Chen, P.S.; Lee, B.; Chen, F.T.; Tsai, M.J. Metal-Oxide RRAM. Proc. IEEE 2012, 100, 1951–1970. [Google Scholar] [CrossRef]

- Gao, Z.M.; Huang, X.S.; Li, P.; Wang, L.F.; Wei, L.; Zhang, W.F.; Guo, H.Z. Reversible Resistance Switching of 2D Electron Gas at LaAlO3/SrTiO3 Heterointerface. Adv. Mater. Interfaces 2018, 5, 1701565. [Google Scholar] [CrossRef]

- Tian, J.J.; Wu, H.J.; Fan, Z.; Zhang, Y.; Pennycook, S.J.; Zheng, D.F.; Tan, Z.W.; Guo, H.Z.; Yu, P.; Lu, X.B.; et al. Nanoscale Topotactic Phase Transformation in SrFeOx Epitaxial Thin Films for High-Density Resistive Switching Memory. Adv. Mater. 2019, 31, 1903679. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.Y. ReRAM: History, Status, and Future. IEEE Trans. Electron Devices 2020, 67, 1420–1433. [Google Scholar] [CrossRef]

- Scott, J.F.; Paz de Araujo, C.A. Ferroelectric Memories. Science 1989, 246, 1400–1405. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.L.; Kwon, S.; Stamenova, M.; Sanvito, S.; Kioussis, N. Electric Field Modulation of Magnetism in Ferrimagnetic Heusler Heterostructures. Phys. Rev. B 2020, 101, 134419. [Google Scholar] [CrossRef]

- Liu, L.; Qin, Q.; Lin, W.N.; Li, C.J.; Xie, Q.D.; He, S.K.; Shu, X.Y.; Zhou, C.H.; Lim, Z.S.; Yu, J.H.; et al. Current-induced Magnetization Switching in All-oxide Heterostructures. Nat. Nanotechnol. 2019, 14, 939–944. [Google Scholar] [CrossRef] [PubMed]

- Tang, M.; Shen, K.; Xu, S.J.; Yang, H.L.; Hu, S.; Lü, W.M.; Li, C.J.; Li, M.S.; Yuan, Z.; Pennycook, S.J.; et al. Bulk Spin Torque-Driven Perpendicular Magnetization Switching in L10 FePt Single Layer. Adv. Mater. 2020, 32, 2002607. [Google Scholar] [CrossRef]

- Chappert, C.; Fert, A.; Van, D.F. The Emergence of Spin Electronics in Data Storage. Nat. Mater. 2007, 6, 813–823. [Google Scholar] [CrossRef] [PubMed]

- Prinz, G.A. Magnetoelectronics. Science 1998, 282, 1660–1663. [Google Scholar] [CrossRef]

- Lin, H.; Gao, Y.; Wang, X.J.; Nan, T.X.; Liu, M.; Lou, J.; Yang, G.M.; Zhou, Z.Y.; Yang, X.; Wu, J.; et al. Integrated Magnetics and Multiferroics for Compact and Power-Efficient Sensing, Memory, Power, RF, and Microwave Electronics. IEEE Trans. Magn. 2016, 52, 4002208–4002215. [Google Scholar] [CrossRef]

- Lou, J.; Liu, M.; Reed, D.; Ren, Y.H.; Sun, N.X. Giant Electric Field Tuning of Magnetism in Novel Multiferroic FeGaB/Lead Zinc Niobate–Lead Titanate (PZN-PT) Heterostructures. Adv. Mater. 2009, 21, 4711–4715. [Google Scholar] [CrossRef]

- Hu, J.M.; Chen, L.Q.; Nan, C.W. Multiferroic Heterostructures Integrating Ferroelectric and Magnetic Materials. Adv. Mater. 2016, 28, 15–39. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Hu, J.M.; Li, Z.; Nan, C.W. Recent Progress in Multiferroic Magnetoelectric Composites: From Bulk to Thin Films. Adv. Mater. 2011, 23, 1062–1087. [Google Scholar] [CrossRef]

- Yan, H.; Feng, Z.X.; Shang, S.L.; Wang, X.N.; Hu, Z.X.; Wang, J.H.; Zhu, Z.W.; Wang, H.; Chen, Z.H.; Hua, H.; et al. A Piezoelectric, Strain-controlled Antiferromagnetic Memory Insensitive to Magnetic Fields. Nat. Nanotechnol. 2019, 14, 131–136. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.Q.; Feng, Z.X.; Yan, H.; Wang, X.N.; Zhou, X.R.; Qin, P.X.; Guo, H.X.; Yu, R.H.; Jiang, C.B. Antiferromagnetic Piezospintronics. Adv. Electron. Mater. 2019, 5, 1900176. [Google Scholar] [CrossRef]

- Ma, C.; Luo, Z.; Huang, W.C.; Zhao, L.T.; Chen, Q.L.; Lin, Y.; Liu, X.; Chen, Z.W.; Liu, C.C.; Sun, H.Y.; et al. Sub-nanosecond Memristor Based on Ferroelectric Tunnel Junction. Nat. Commun. 2020, 11, 1439. [Google Scholar] [CrossRef]

- Qiao, K.M.; Hu, F.X.; Liu, Y.; Li, J.; Kuang, H.; Zhang, H.R.; Liang, W.H.; Wang, J.; Sun, J.R.; Shen, B.G. Novel Reduction of Hysteresis Loss Controlled by Strain Memory Effect in FeRh/PMN-PT heterostructures. Nano Energy 2019, 59, 285–294. [Google Scholar] [CrossRef]

- Qiao, K.M.; Wang, J.L.; Hu, F.X.; Li, J.; Zhang, C.; Liu, Y.; Yu, Z.B.; Gao, Y.H.; Su, J.; Shen, F.R.; et al. Regulation of phase transition and magnetocaloric effect by ferroelectric domains in FeRh/PMN-PT heterojunctions. Acta Mater. 2020, 191, 51–59. [Google Scholar] [CrossRef]

- Liu, M.; Obi, O.; Lou, J.; Chen, Y.J.; Cai, Z.H.; Stoute, S.; Espanol, M.; Lew, M.; Situ, X.D.; Ziemer, K.S.; et al. Giant Electric Field Tuning of Magnetic Properties in Multiferroic Ferrite/Ferroelectric Heterostructures. Adv. Funct. Mater. 2009, 19, 1826–1831. [Google Scholar] [CrossRef]

- Li, Q.; Tan, A.; Scholl, A.; Young, A.T.; Yang, M.; Hwang, C.; N’Diaye, A.T.; Arenholz, E.; Li, J.; Qiu, Z.Q. Electrical Switching of the Magnetic Vortex Circulation in Artificial Multiferroic Structure of Co/Cu/PMN-PT(011). Appl. Phys. Lett. 2017, 110, 262405. [Google Scholar] [CrossRef]

- Stöhr, J.; Siegmann, H.C.; Kashuba, A.; Gamble, S.J. Magnetization Switching Without Charge or Spin Currents. Appl. Phys. Lett. 2009, 94, 072504. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, Y.G.; Xiao, X.; Wu, Y.Z.; Rizwan, S.; Yang, L.F.; Li, P.S.; Wang, J.W.; Zhu, M.H.; Zhang, H.Y.; et al. Giant Electrical Modulation of Magnetization in Co40Fe40B20/Pb(Mg1/3Nb2/3)0.7Ti0.3O3(011) Heterostructure. Sci. Rep. 2014, 4, 3727. [Google Scholar] [CrossRef]

- Wu, T.; Bur, A.; Wong, K.; Hockel, J.L.; Hsu, C.J.; Kim, H.K.D.; Wang, K.L.; Carman, G.P. Electric-poling-induced Magnetic Anisotropy and Electric-field-induced Magnetization Reorientation in Magnetoelectric Ni/(011) [Pb(Mg1/3Nb2/3)O3](1-x)-[PbTiO3]x heterostructure. J. Appl. Phys. 2011, 109, 07D732. [Google Scholar] [CrossRef]

- Yang, S.W.; Peng, R.C.; Jiang, T.; Liu, Y.K.; Feng, L.; Wang, J.J.; Chen, L.Q.; Li, X.G.; Nan, C.W. Non-Volatile 180° Magnetization Reversal by an Electric Field in Multiferroic Heterostructures. Adv. Mater. 2014, 26, 7091–7095. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.J.; Yang, M.M.; Luo, Z.L.; Huang, H.L.; Wang, H.B.; Bao, J.; Hu, C.S.; Pan, G.Q.; Yao, Y.P.; Liu, Y.K.; et al. Large Anisotropic Remnant Magnetization Tunability in (011)-La2/3Sr1/3MnO3/0.7Pb(Mg2/3Nb1/3)O3-0.3PbTiO3 Multiferroic Epitaxial Heterostructures. Appl. Phys. Lett. 2012, 100, 043506. [Google Scholar] [CrossRef]

- BinekA, C.; Chen, H.X.; Borisov, P.; Doudin, W.K. Electrically Controlled Exchange Bias for Spintronic Applications. J. Appl. Phys. 2005, 97, 10C514. [Google Scholar] [CrossRef]

- Chen, A.T.; Zhao, Y.G.; Li, P.S.; Zhang, X.; Peng, R.C.; Huang, H.L.; Zou, L.K.; Zheng, X.L.; Zhang, S.; Miao, P.X.; et al. Angular Dependence of Exchange Bias and Magnetization Reversal Controlled by Electric-Field-Induced Competing Anisotropies. Adv. Mater. 2016, 28, 363–369. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Lou, J.; Li, S.D.; Sun, N.X. E-Field Control of Exchange Bias and Deterministic Magnetization Switching in AFM/FM/FE Multiferroic Heterostructures. Adv. Funct. Mater. 2011, 21, 2593–2598. [Google Scholar] [CrossRef]

- Gong, Y.Y.; Wang, D.H.; Cao, Q.Q.; Liu, E.K.; Liu, J.; Du, Y.W. Electric Field Control of the Magnetocaloric Effect. Adv. Mater. 2015, 27, 801–805. [Google Scholar] [CrossRef]

- Hu, Q.B.; Li, J.; Wang, C.C.; Zhou, Z.J.; Cao, Q.Q.; Zhou, T.J.; Wang, D.H.; Du, Y.W. Electric Field Tuning of Magnetocaloric Effect in FeRh0.96Pd0.04/PMN-PT Composite Near Room Temperature. Appl. Phys. Lett. 2017, 110, 222408. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Wen, J.H.; Gong, Y.Y.; Ma, S.C.; Hu, Q.B.; Wang, D.H. Nonvolatile manipulation of the magnetocaloric effect in Ni43Co7Mn39Sn11/(011)PMN-PT composite by electric fields. Scr. Mater. 2019, 167, 41–45. [Google Scholar] [CrossRef]

- Song, C.; Cui, B.; Li, F.; Zhou, X.J.; Pan, F. Recent Progress in Voltage Control of Magnetism: Materials, Mechanisms, and Performance. Prog. Mater. Sci. 2017, 87, 33–82. [Google Scholar] [CrossRef]

- Zhou, W.P.; Ma, C.L.; Gan, Z.X.; Zhang, Z.M.; Wang, X.X.; Tan, W.S.; Wang, D.H. Manipulation of Anisotropic Magnetoresistance and Domain Configurationin Co/PMN-PT (011) Multiferroic Heterostructures by Electric Field. Appl. Phys. Lett. 2017, 111, 052401. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Wen, J.H.; Yang, B.; Zhu, H.C.; Cao, Q.Q.; Wang, D.H.; Qian, Z.H.; Du, Y.W. Electric Field Manipulated Multilevel Magnetic States Storage in FePt/(011) PMN-PT Heterostructure. ACS Appl. Mater. Interfaces 2017, 9, 36038–36044. [Google Scholar] [CrossRef]

- Tiercelin, N.; Dusch, Y.; Klimov, A.; Giordano, S.; Preobrazhensky, V.; Pernod, P. Room Temperature Magnetoelectric Memory Cell using Stress-mediated Magnetoelastic Switching in Nanostructured Multilayers. Appl. Phys. Lett. 2011, 99, 192507. [Google Scholar] [CrossRef]

- Chen, Y.J.; Fitchorov, T.; Vittoria, C.; Harris, V.G. Electrically Controlled Magnetization Switching in a Multiferroic Heterostructure. Appl. Phys. Lett. 2010, 97, 052502. [Google Scholar] [CrossRef]

- Yang, Y.T.; Wang, D.H.; Song, Y.Q.; Gao, J.L.; Lv, L.Y.; Cao, Q.Q.; Du, Y.W. Electric-field-assisted Magnetization Switching in FePd/Pb(Mg1/3Nb2/3)O3-PbTiO3 Heterostructure at Room Temperature. J. Appl. Phys. 2013, 114, 144902. [Google Scholar] [CrossRef]

- Yang, Y.T.; Zhang, Q.M.; Wang, D.H.; Song, Y.Q.; Wang, L.Y.; Lv, L.Y.; Cao, Q.Q.; Du, Y.W. Electric Field Control of Magnetic Properties in CoPt/Pb(Mg1/3Nb2/3)O3-PbTiO3 Heterostructure at Room Temperature. Appl. Phys. Lett. 2013, 103, 082404. [Google Scholar] [CrossRef]

- Peng, R.C.; Wang, J.J.; Hu, J.M.; Chen, L.Q.; Nan, C.W. Electric-field-driven Magnetization Reversal in Square-shaped Nanomagnet-based Multiferroic Heterostructure. Appl. Phys. Lett. 2015, 106, 142901. [Google Scholar] [CrossRef]

- Peng, R.C.; Hu, J.M.; Momeni, K.; Wang, J.J.; Chen, L.Q.; Nan, C.W. Fast 180 °C Magnetization Switching in a Strain-mediated Multiferroic Heterostructure Driven by a Voltage. Sci. Rep. 2016, 6, 27561. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.J.; Hu, J.M.; Ma, J.; Zhang, J.X.; Chen, L.Q.; Nan, C.W. Full 180 °C Magnetization Reversal with Electric Fields. Sci. Rep. 2014, 4, 7507. [Google Scholar] [CrossRef]

- Liu, M.F.; Hao, L.; Jin, T.L.; Cao, J.W.; Bai, J.M.; Wu, D.P.; Wang, Y.; Wei, F.L. Electric-field Manipulation of Coercivity in FePt/Pb(Mg1/3Nb2/3)O3–PbTiO3 Heterostructures Investigated by Anomalous Hall Effect Measurement. Appl. Phys. Express 2015, 8, 063006. [Google Scholar] [CrossRef]

- Li, P.S.; Chen, A.T.; Li, D.L.; Zhao, Y.G.; Zhang, S.; Yang, L.F.; Liu, Y.; Zhu, M.H.; Zhang, H.Y.; Han, X.F. Electric Field Manipulation of Magnetization Rotation and Tunneling Magnetoresistance of Magnetic Tunnel Junctions at Room Temperature. Adv. Mater. 2014, 26, 4320–4325. [Google Scholar] [CrossRef]

- Wu, T.; Zhao, P.; Bao, M.Q.; Bur, A.; Hockel, L.J.; Wong, K.; Mohanchandra, K.P.; Lynch, C.S.; Carman, G.P. Domain Engineered Switchable Strain States in Ferroelectric (011)[Pb(Mg1/3Nb2/3)O3](1-x)-[PbTiO3]x (PMN-PT, x = 0.32) Single Crystals. J. Appl. Phys. 2011, 109, 124101. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Yan, Y.; Wen, J.; Zhang, X.; Wang, D. Manipulation of Magnetization Reversal by Electric Field in a FePt/(011)PMN-PT/Au. Coatings 2021, 11, 730. https://doi.org/10.3390/coatings11060730

Zhao X, Yan Y, Wen J, Zhang X, Wang D. Manipulation of Magnetization Reversal by Electric Field in a FePt/(011)PMN-PT/Au. Coatings. 2021; 11(6):730. https://doi.org/10.3390/coatings11060730

Chicago/Turabian StyleZhao, Xiaoyu, Yaxin Yan, Jiahong Wen, Xiaolong Zhang, and Dunhui Wang. 2021. "Manipulation of Magnetization Reversal by Electric Field in a FePt/(011)PMN-PT/Au" Coatings 11, no. 6: 730. https://doi.org/10.3390/coatings11060730

APA StyleZhao, X., Yan, Y., Wen, J., Zhang, X., & Wang, D. (2021). Manipulation of Magnetization Reversal by Electric Field in a FePt/(011)PMN-PT/Au. Coatings, 11(6), 730. https://doi.org/10.3390/coatings11060730