Influence of Lightly Burned MgO on the Mechanical Properties and Anticarbonization of Cement-Based Materials

Abstract

1. Introduction

2. Experimental Section

2.1. Raw Materials

2.2. Samples Preparation

2.3. Measurement

3. Results and Discussion

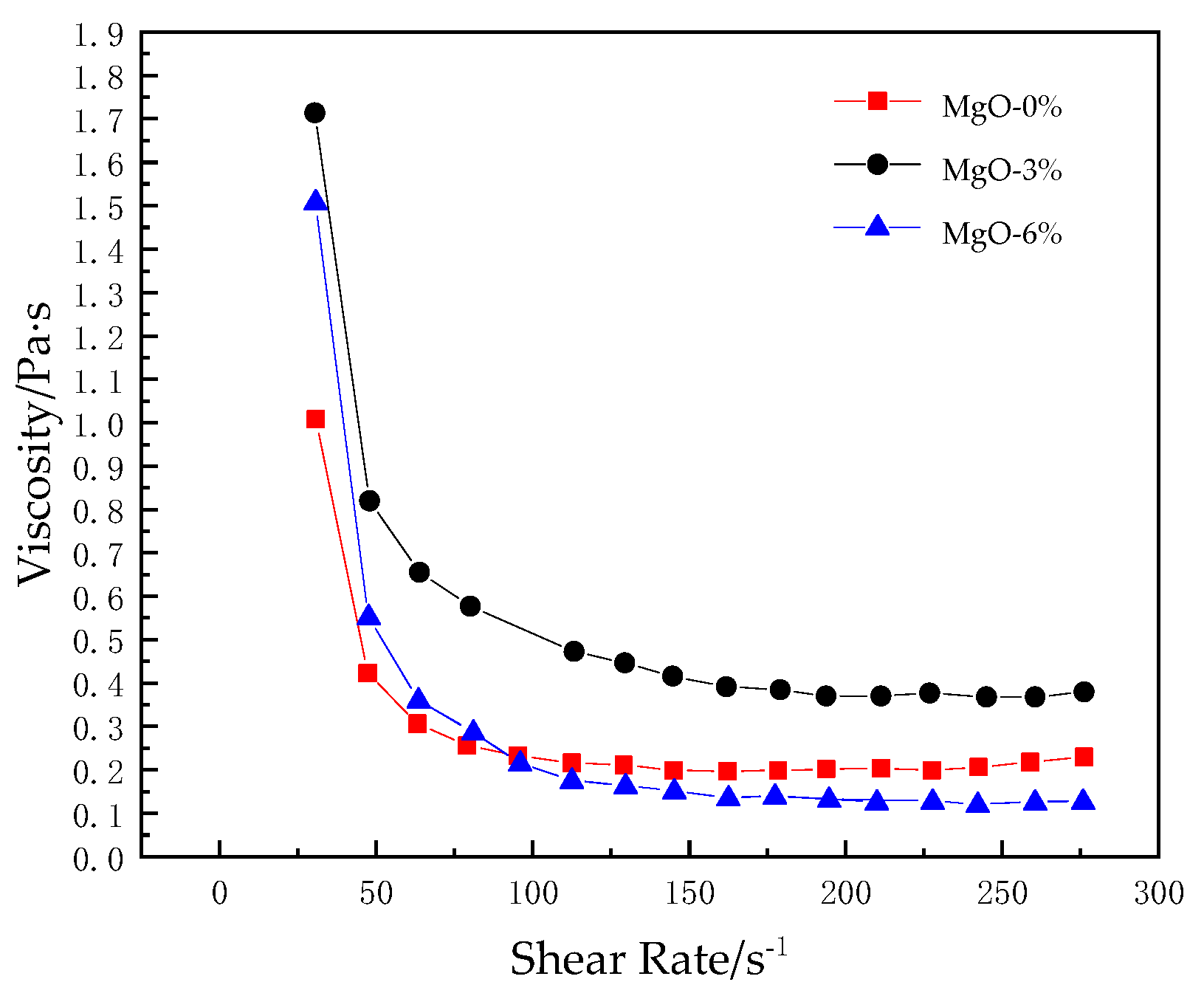

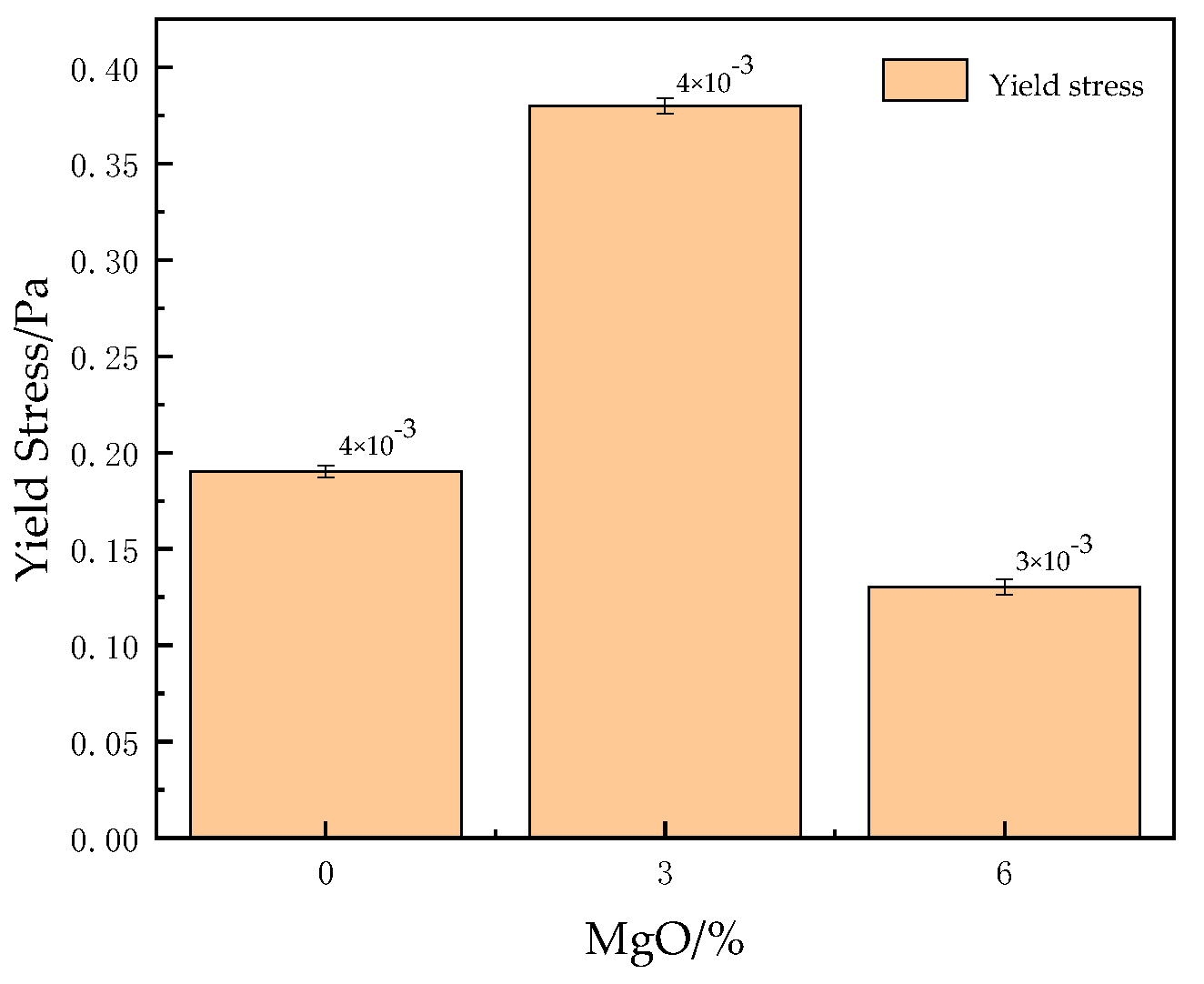

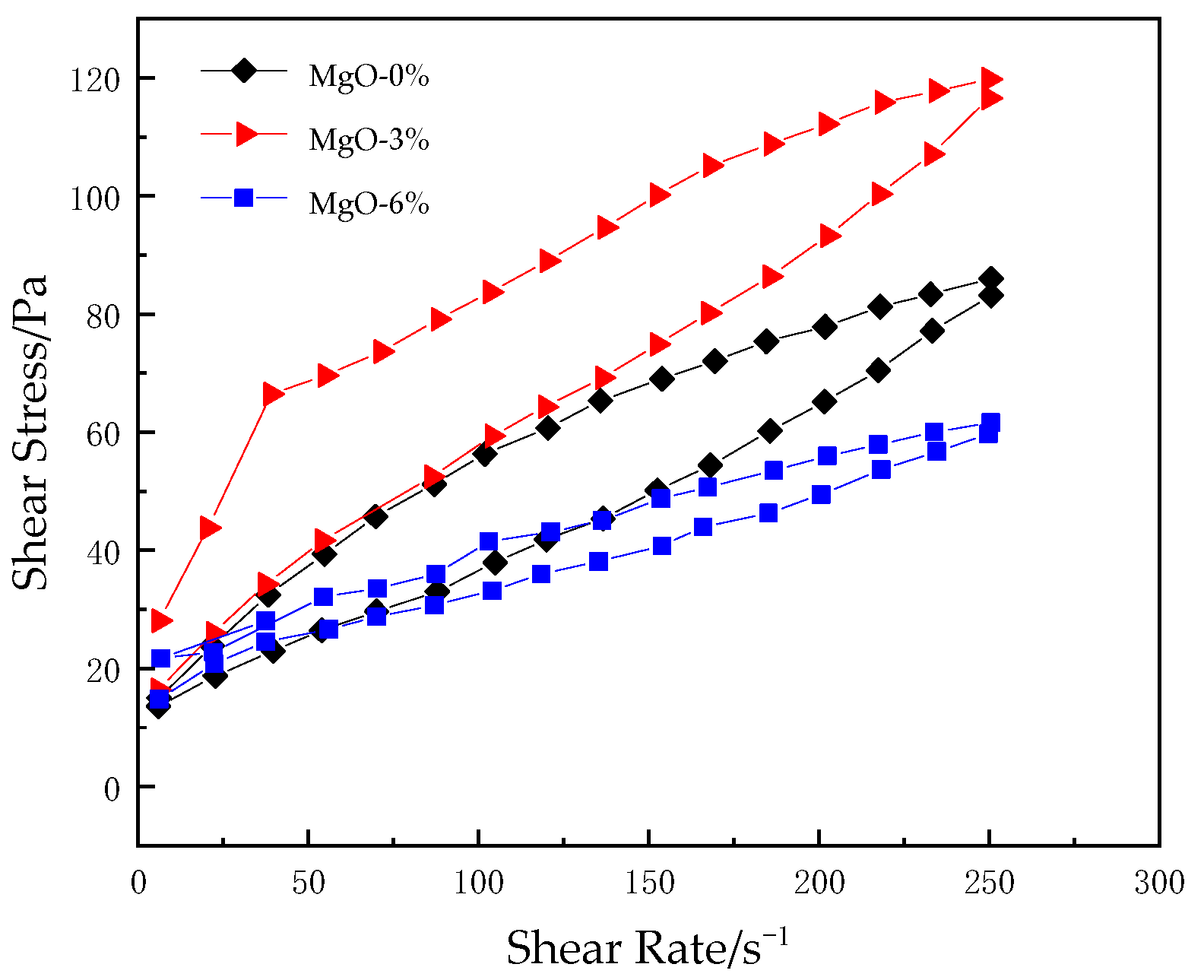

3.1. The Rheological Properties of Fresh Cement Paste

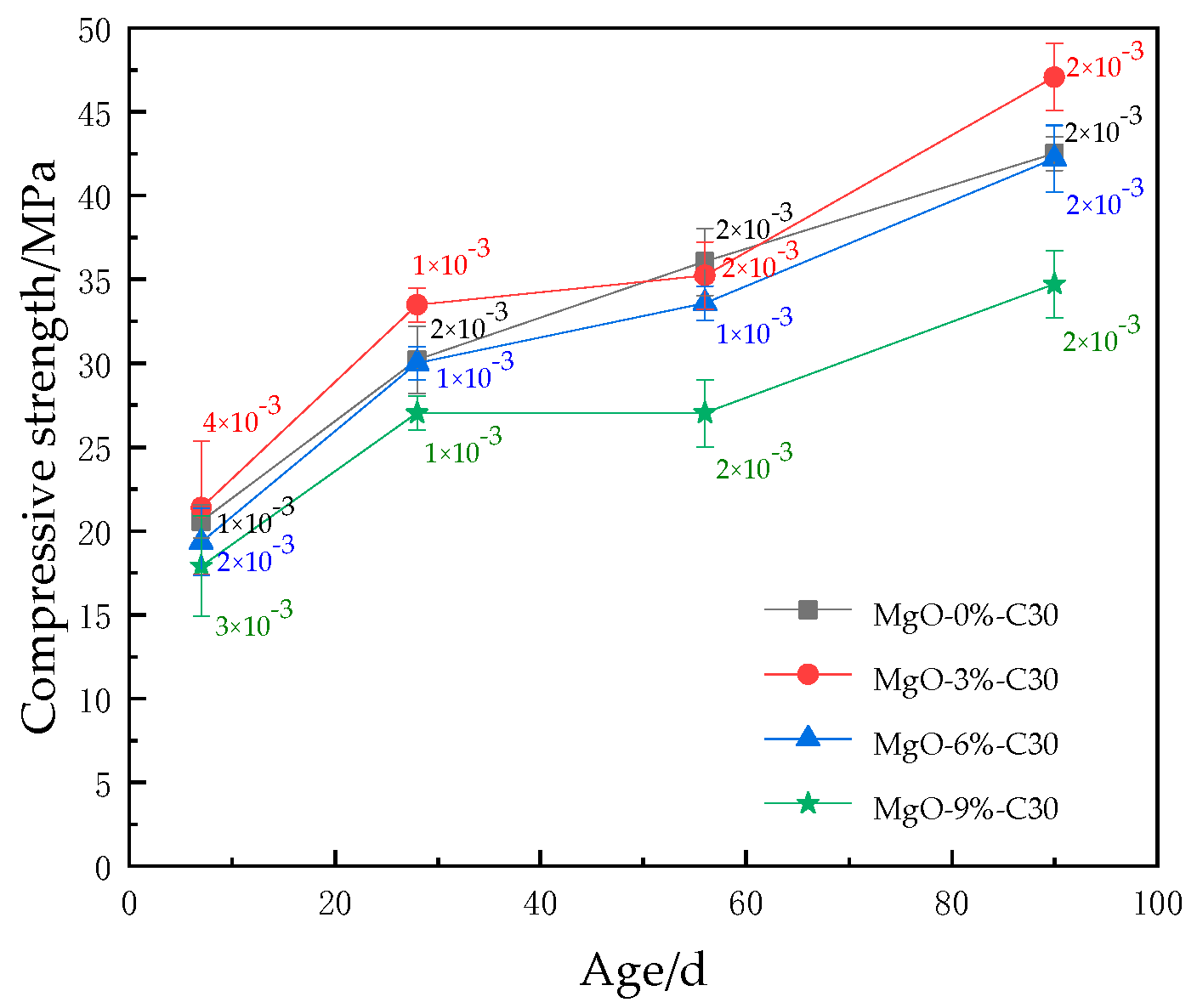

3.2. The Compressive Strength and Expansion Value Rate of Concrete

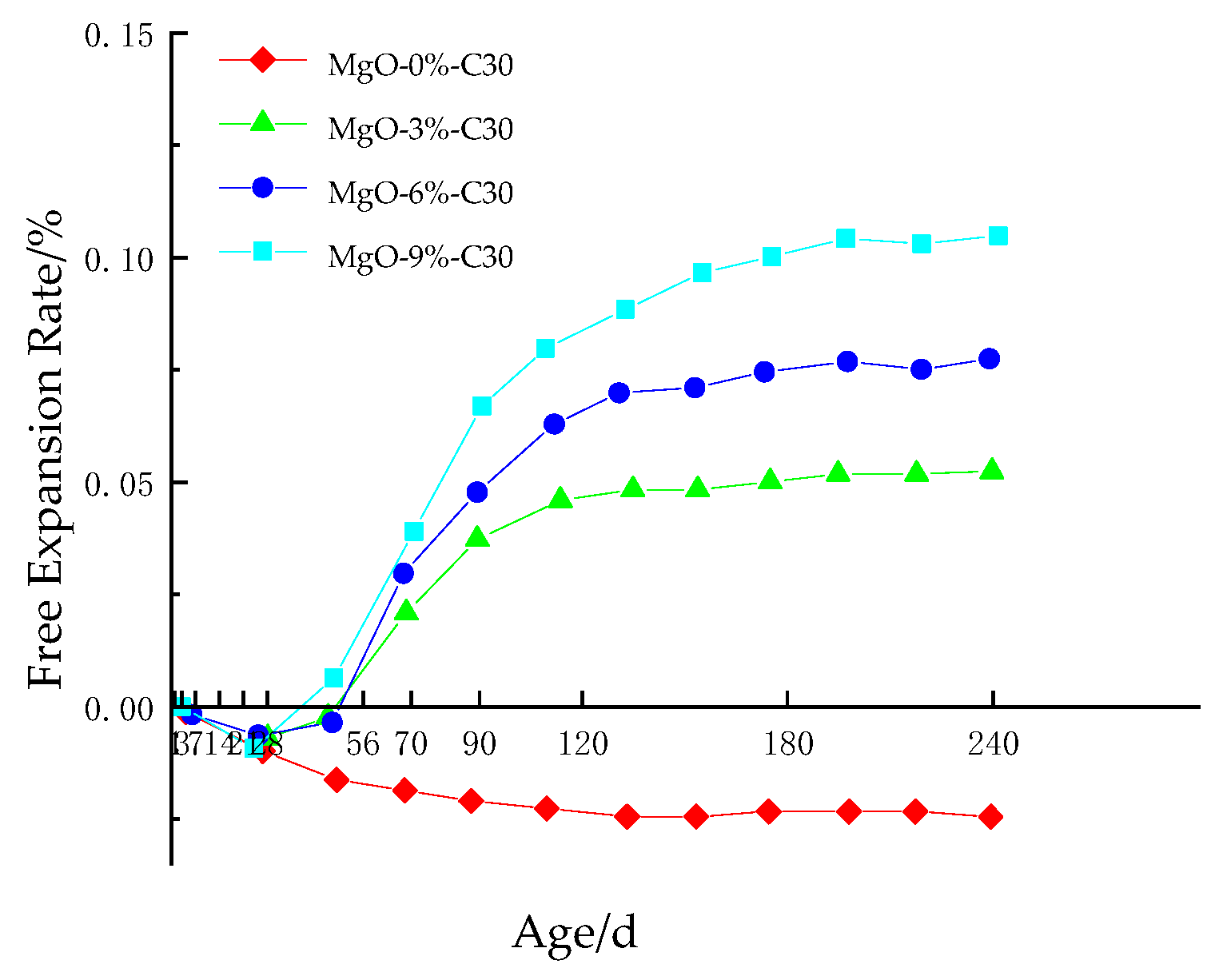

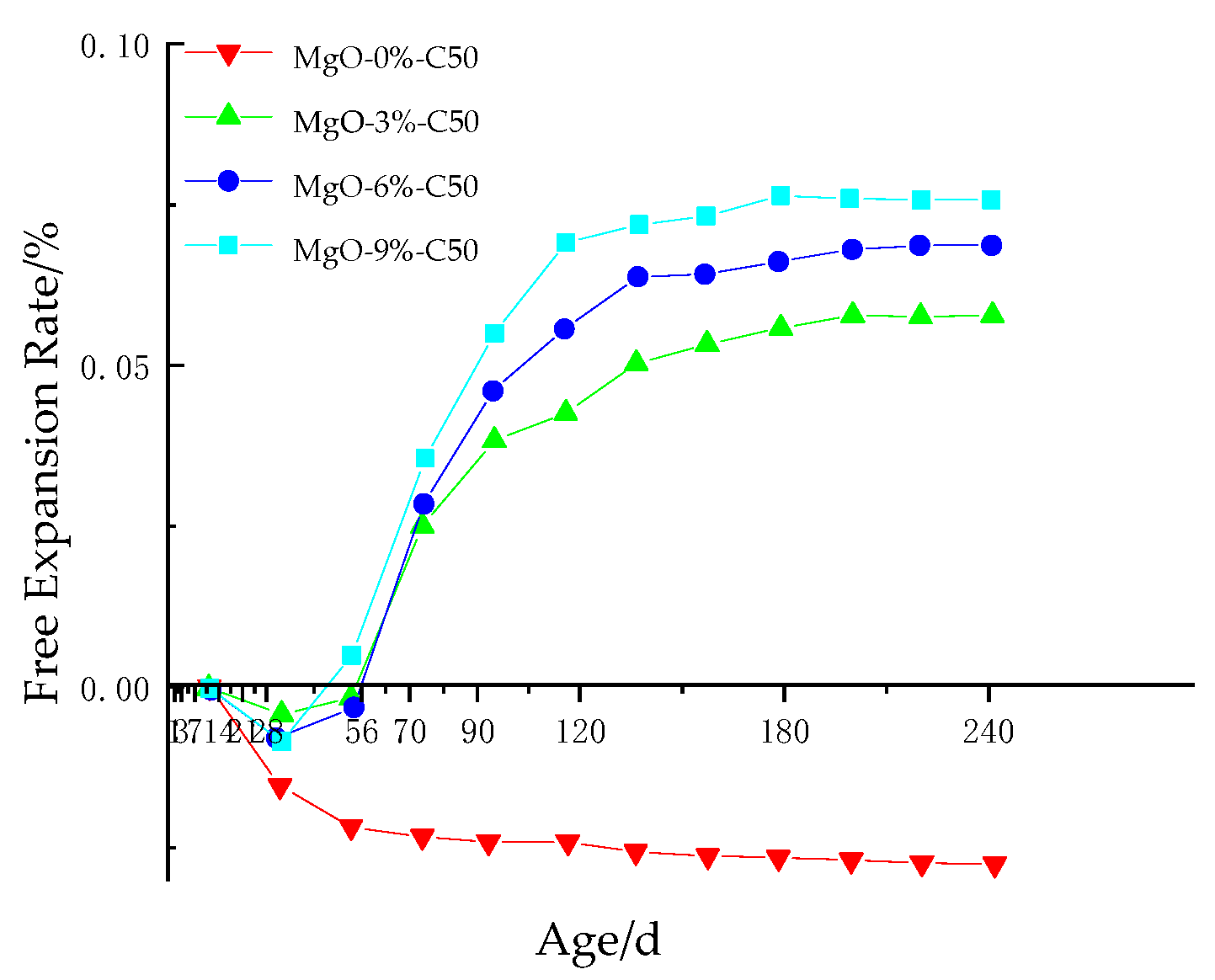

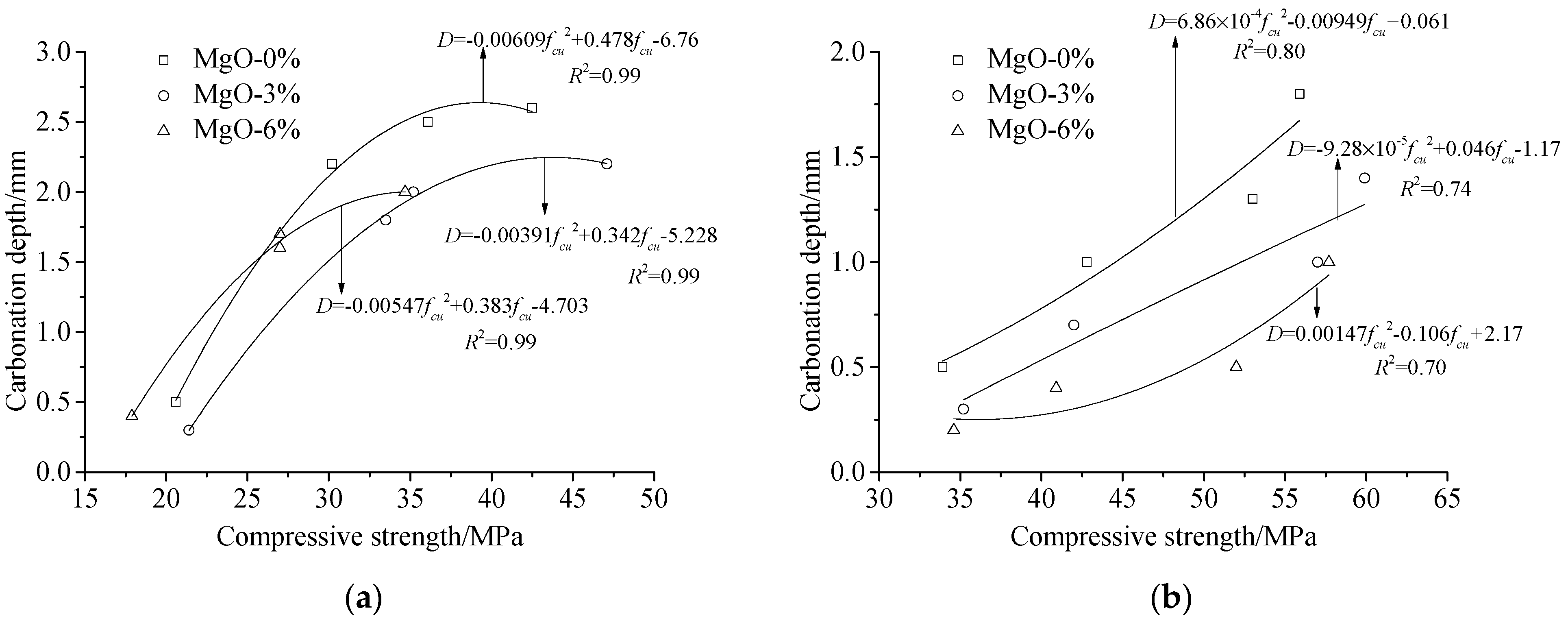

3.3. Carbonation Depth of Concrete

4. Conclusions

- The lightly burned magnesium oxide expansion agent demonstrates a decreased effect on the fluidity and an improved effect on the plastic viscosity of fresh cement paste.

- When the dosage of the lightly burned magnesium oxide expansion agent is higher than 3%, the compressive strength of concrete is decreased due to the induced deformation of lightly burned magnesium oxide. When the content of the lightly burned magnesium oxide expansion agent is 6%, cracks occur in concrete.

- The expansion of concrete is increased effectively by lightly burned magnesium oxide. The influence of lightly burned magnesium oxide on the compressive strength and expansion is similar when the strength grades of concrete are C30 and C50.

- The increased dosage of LBMO, curing age and strength grade lead to improving the carbonization resistance of concrete. As obtained from this study, the relationship between carbonization depth and compressive strength correlates well with the quadratic function.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Chen, T.; Gao, X. Incorporation of self-ignited coal gangue in steam cured precast concrete. J. Clean. Prod. 2021, 292, 126004. [Google Scholar] [CrossRef]

- Mo, Z.; Gao, X.; Su, A. Mechanical performances and microstructures of metakaolin contained UHPC matrix under steam curing conditions. Constr. Build. Mater. 2021, 268, 121112. [Google Scholar] [CrossRef]

- Ren, G.; Yao, B.; Huang, H.; Gao, X. Influence of sisal fibers on the mechanical performance of ultra-high performance concretes. Constr. Build. Mater. 2021, 286, 122958. [Google Scholar] [CrossRef]

- Yang, J.; Huang, J.; Su, Y.; He, X.; Tan, H.; Yang, W.; Strnadel, B. Eco-friendly treatment of ow-calcium coal fly ash for high pozzolanic reactivity: A step towards waste utilization in sustainable building material. J. Clean. Prod. 2019, 238, 117962. [Google Scholar] [CrossRef]

- He, X.; Zheng, Z.; Ma, M.; Su, Y.; Yang, J.; Tan, H.; Wang, Y.; Strnadel, B. New treatment technology: The use of wet-milling concrete slurry waste to substitute cement. J. Clean. Prod. 2020, 242, 118347. [Google Scholar] [CrossRef]

- Yuan, X.; Chen, W. Shrinkage compensation of alkali-activated slag concrete and microstructural analysis. Constr. Build. Mater. 2014, 66, 422–428. [Google Scholar] [CrossRef]

- Choi, H.; Tsujino, M.; Noguchi, T.; Kitagaki, R. Expansion/contraction behavior and cracking control effect of expansive concrete in building structure. Proc. Jpn. Concr. Inst. 2012, 34, 424–429. [Google Scholar]

- Meddah, M.; Suzuki, M.; Sato, R. Influence of a combination of expansive and shrinkage-reducing admixture on autogenous deformation and self-stress of silicafumehigh-performance concrete. Constr. Build. Mater. 2011, 25, 239–250. [Google Scholar] [CrossRef]

- Abdel-Gawwad, H.; Heikal, M.; Mohammed, M.; Abd El-Aleem, S.; Hassan, S.; Vasquez-Garcia, S.R.; Alomayri, T. Sustainable disposal of cement kiln dust in the production of cementitious materials. J. Clean. Prod. 2019, 232, 1218–1229. [Google Scholar] [CrossRef]

- Cao, F.; Yan, P. The influence of the hydration procedure of MgO expansive agent on the expansive behavior of shrinkage-compensating mortar. Constr. Build. Mater. 2019, 202, 162–168. [Google Scholar] [CrossRef]

- Juenger, M.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Ruan, S.; Cise, U. Comparative life cycle assessment of reactive MgO and Portland cement production. J. Clean. Prod. 2016, 137, 258–273. [Google Scholar] [CrossRef]

- Su, A.; Qin, L.; Zhang, S.; Zhang, J. Effects of shrinkage-reducing agent and expansive admixture on the volume deformation of ultrahigh performance concrete. Adv. Mater. Sci. Eng. 2017, 2017, 6384859. [Google Scholar]

- Li, H.; Wang, Y.; Wang, Y.; Liu, J.; Tian, Q. Effect of CaO and MgO based expansive agent on deformation and mechanical properties of concrete-filled steel tubes. Constr. Build. Mater. 2020, 250, 118723. [Google Scholar] [CrossRef]

- Ruan, S.; Cise, U. Influence of supplementary cementitious materials on the performance and environmental impacts of reactive magnesia cement concrete. J. Clean. Prod. 2017, 159, 62–73. [Google Scholar] [CrossRef]

- Guo, S.; Bu, Y.; Lu, Y. Addition of tartaric acid to prevent delayed setting of oilwell cement containing retarder at high temperatures. J. Petrol. Sci. Eng. 2019, 172, 269–279. [Google Scholar] [CrossRef]

- Ma, S.; Li, W.; Zhang, S.; Ge, D.; Yu, J.; Shen, X. Influence of sodium gluconate on the performance and hydration of Portland cement. Constr. Build. Mater. 2015, 91, 138–144. [Google Scholar] [CrossRef]

- Choi, S.; Jang, B.; Kim, J.; Lee, K. Durability characteristics of fly ash concrete containing lightly-burnt MgO. Constr. Build. Mater. 2014, 58, 77–84. [Google Scholar] [CrossRef]

- Choi, S.; Jang, B.; Lee, K. Fundamental properties of fly ash concrete containing lightly burnt MgO Powder. J. Korean Soc. Civ. Eng. 2013, 33, 475–481. [Google Scholar] [CrossRef]

- Mo, L.; Panesar, D. Effects of accelerated carbonation on the microstructure of Portland cement pastes containing reactive MgO. Cem. Concr. Res. 2012, 42, 769–777. [Google Scholar] [CrossRef]

- Qian, S.; Zhou, J.; Schlangen, E. Influence of curing condition and precracking time on the self-healing behavior of engineered cementitious composites. Cem. Concr. Compos. 2010, 32, 686–693. [Google Scholar] [CrossRef]

- Chen, L.; Jiang, L.; Chu, H.; Xu, P.; Jin, W.; Chen, C.; Zhi, F.; Ben, X. Effect of retarder on hydration properties of lightly burned magnesia. Constr. Build. Mater. 2020, 263, 119762. [Google Scholar] [CrossRef]

- Gao, S.; Wang, Z.; Wang, W.; Qiu, H. Effect of shrinkage-reducing admixture and expansive agent on mechanical properties and drying shrinkage of engineered cementitious composite (ECC). Constr. Build. Mater. 2018, 179, 172–185. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Tang, M. MgO expansive cement and concrete in china: Past, present and future. Cem. Concr. Res. 2014, 57, 1–12. [Google Scholar] [CrossRef]

- Yahia, A.; Tanimura, M. Rheology of belite-cement–effect of w/c and high-range water-reducer type. Constr. Build. Mater. 2015, 88, 169–174. [Google Scholar] [CrossRef]

- Khayat, K. Viscosity-enhancing admixtures for cement-based materials–an overview. Cement Concr. Compos. 1998, 20, 171–188. [Google Scholar] [CrossRef]

- Cao, F.; Liu, Y.; Yan, P. Properties and mechanism of the compound MgO expansive agent (CMEA) produced by calcining the mixture of dolomite and serpentine tailings. Constr. Build. Mater. 2021, 277, 122331. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H.; Li, W. Factors analysis on autogenous volume deformation of MgO concrete and early thermal cracking evaluation. Constr. Build. Mater. 2016, 118, 276–285. [Google Scholar] [CrossRef]

- Gao, P.; Xu, S.; Chen, X.; Li, J.; Lu, X. Research on autogenous volume deformation of concrete with MgO. Constr. Build. Mater. 2013, 40, 998–1001. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Tang, M. Effects of calcination condition on expansion property of MgO-type expansive agent used in cement-based materials. Cem. Concr. Res. 2010, 40, 437–446. [Google Scholar] [CrossRef]

- Cao, F.; Miao, M.; Yan, P. Effects of reactivity of MgO expansive agent on its performance in cement-based materials and an improvement of the evaluating method of MEA reactivity. Constr. Build. Mater. 2018, 187, 257–266. [Google Scholar] [CrossRef]

- Temiz, H.; Kantarci, F.; Inceer, M. Influence of blast-furnace slag on behaviour of dolomite used as a raw material of MgO-type expansive agent. Constr. Build. Mater. 2015, 94, 528–535. [Google Scholar] [CrossRef]

- Xu, L.; Deng, M. Dolomite used as raw material to produce MgO-based expansive agent. Cem. Concr. Res. 2005, 35, 1480–1485. [Google Scholar]

- Jung, I.; Decterov, S.; Pelton, A. Critical thermodynamic evaluation and optimization of the CaO–MgO–SiO2 system. J. Euro. Ceram. Soc. 2005, 25, 313–333. [Google Scholar] [CrossRef]

- Mo, L.; Liu, M.; Al-Tabbaa, A. Deformation and mechanical properties of quaternary blended cements containing ground granulated blast furnace slag, fly ash and magnesia. Cem. Concr. Res. 2015, 71, 7–13. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, S.; Yang, B. Experimental study on the stability of RCC mixed with MgO. IOP Natl. Conf. Concr. Expans. Agents 2010, 39, 56–58. [Google Scholar]

- Sherir, M.; Hossain, K.; Lachemi, M. Self-healing and expansion characteristics of cementitious composites with high volume fly ash and MgO-type expansive agent. Constr. Build. Mater. 2016, 127, 80–92. [Google Scholar] [CrossRef]

- Ruan, S.; Cise, U. Effect of air entrainment on the performance of reactive MgO and PC mixes. Constr. Build. Mater. 2017, 142, 221–232. [Google Scholar] [CrossRef]

| Types | MgO | Al2O3 | SiO2 | P2O5 | SO3 | Cl | K2O | CaO | MnO | Fe2O3 |

|---|---|---|---|---|---|---|---|---|---|---|

| LBMO | 79.12 | 0.44 | 4.36 | 0.13 | 0.11 | 0.07 | 0.27 | 10.80 | 0.49 | 4.26 |

| Cement | 0 | 5.47 | 20.86 | 0 | 2.66 | 0 | 0.48 | 62.23 | 0 | 3.94 |

| BFS | 0 | 14.74 | 34.06 | 0 | 0.23 | 0 | 3.51 | 35.93 | 0.74 | 0.83 |

| FA | 0 | 13.99 | 32.95 | 0 | 0 | 0 | 0 | 7.66 | 0 | 2.91 |

| Group | Cement | Fly Ash | BFS | Magnesia Expansion Agent | Water |

|---|---|---|---|---|---|

| MgO-0% | 80 | 60 | 60 | 0 | 76 |

| MgO-3% | 78 | 58 | 58 | 6 | 76 |

| MgO-6% | 75 | 56 | 56 | 12 | 76 |

| MgO-9% | 73 | 55 | 55 | 18 | 76 |

| Group | Cement | Fly Ash | BFS | MgO | Total Binder Material | Water | Sand | Coarse Aggregate |

|---|---|---|---|---|---|---|---|---|

| MgO-C30-0 | 148 | 111 | 111 | 0 | 370 | 163 | 833 | 1017 |

| MgO-C30-3 | 143.56 | 107.67 | 107.67 | 11.1 | 370 | 163 | 833 | 1017 |

| MgO-C30-6 | 139.12 | 104.34 | 104.34 | 22.2 | 370 | 163 | 833 | 1017 |

| MgO-C30-9 | 134.68 | 101.01 | 101.01 | 33.3 | 370 | 163 | 833 | 1017 |

| MgO-C50-0 | 194 | 145.5 | 145.5 | 0 | 485 | 155 | 673 | 1098 |

| MgO-C50-3 | 188.18 | 141.14 | 141.14 | 14.55 | 485 | 155 | 673 | 1098 |

| MgO-C50-6 | 182.36 | 136.77 | 136.77 | 29.10 | 485 | 155 | 673 | 1098 |

| MgO-C50-9 | 176.54 | 132.41 | 132.41 | 43.65 | 485 | 155 | 673 | 1098 |

| Group | Slump Slow (mm) | Expansion Value (mm) | Water-Reducing Agent (%) |

|---|---|---|---|

| MgO-C30-0 | 245 | −10 | 0 |

| MgO-C30-3 | 240 | 0 | 0.5% |

| MgO-C30-6 30-6 | 240 | 0 | 1.2% |

| MgO-C30-9 | 220 | 10 | 2.5% |

| MgO-C50-0 | 240 | −50 | 0% |

| MgO-C50-3 | 240 | −30 | 0.7% |

| MgO-C50-6 30-6 | 235 | −40 | 1.5% |

| MgO-C50-9 | 230 | 20 | 3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Li, C.; Shu, C.; Yong, H.; Wang, J.; Wang, H. Influence of Lightly Burned MgO on the Mechanical Properties and Anticarbonization of Cement-Based Materials. Coatings 2021, 11, 714. https://doi.org/10.3390/coatings11060714

Wang L, Li C, Shu C, Yong H, Wang J, Wang H. Influence of Lightly Burned MgO on the Mechanical Properties and Anticarbonization of Cement-Based Materials. Coatings. 2021; 11(6):714. https://doi.org/10.3390/coatings11060714

Chicago/Turabian StyleWang, Lin, Chao Li, Chunxue Shu, Han Yong, Jianmin Wang, and Hui Wang. 2021. "Influence of Lightly Burned MgO on the Mechanical Properties and Anticarbonization of Cement-Based Materials" Coatings 11, no. 6: 714. https://doi.org/10.3390/coatings11060714

APA StyleWang, L., Li, C., Shu, C., Yong, H., Wang, J., & Wang, H. (2021). Influence of Lightly Burned MgO on the Mechanical Properties and Anticarbonization of Cement-Based Materials. Coatings, 11(6), 714. https://doi.org/10.3390/coatings11060714