Epitaxial Growth of Single Crystal YAG for Optical Devices

Abstract

1. Introduction

2. Experimental

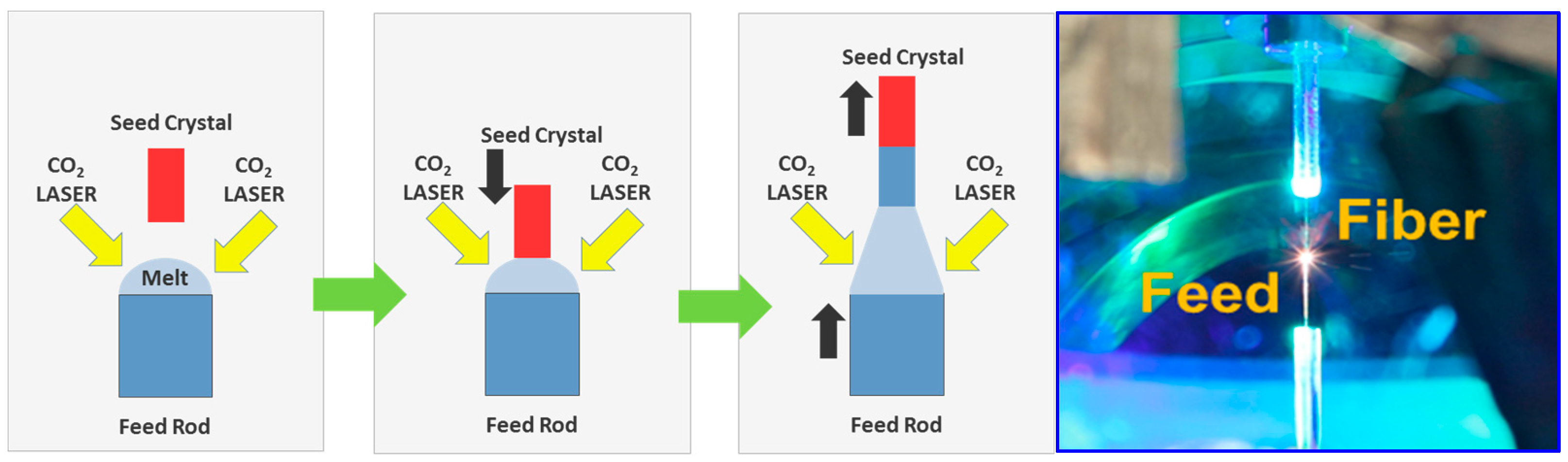

2.1. Fabrication of Doped Yttrium Aluminum Garnet (YAG) Core Fibers

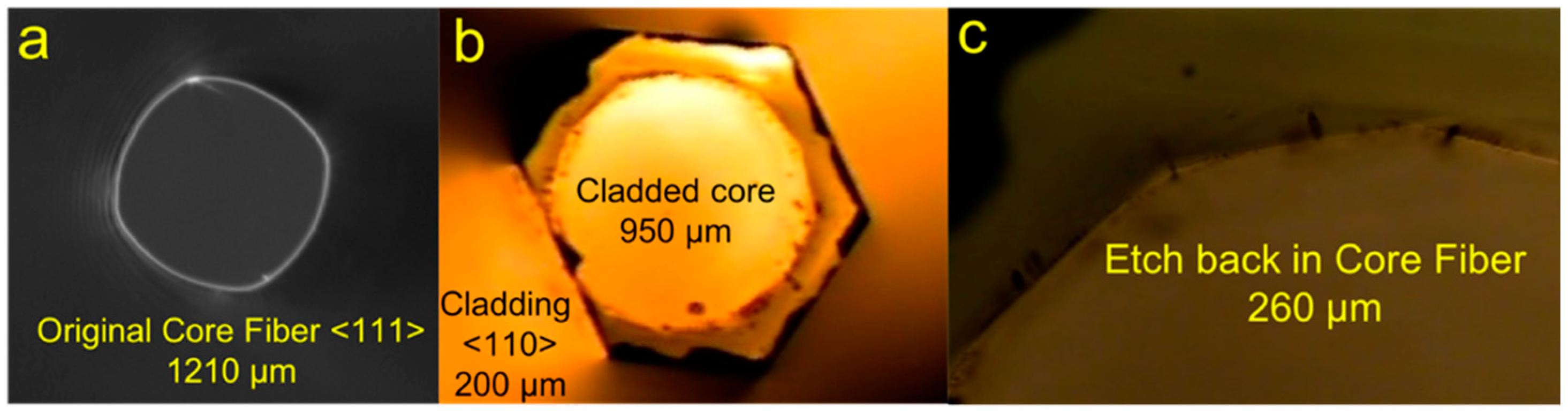

2.2. Undoped YAG Cladding Processes on Fibers

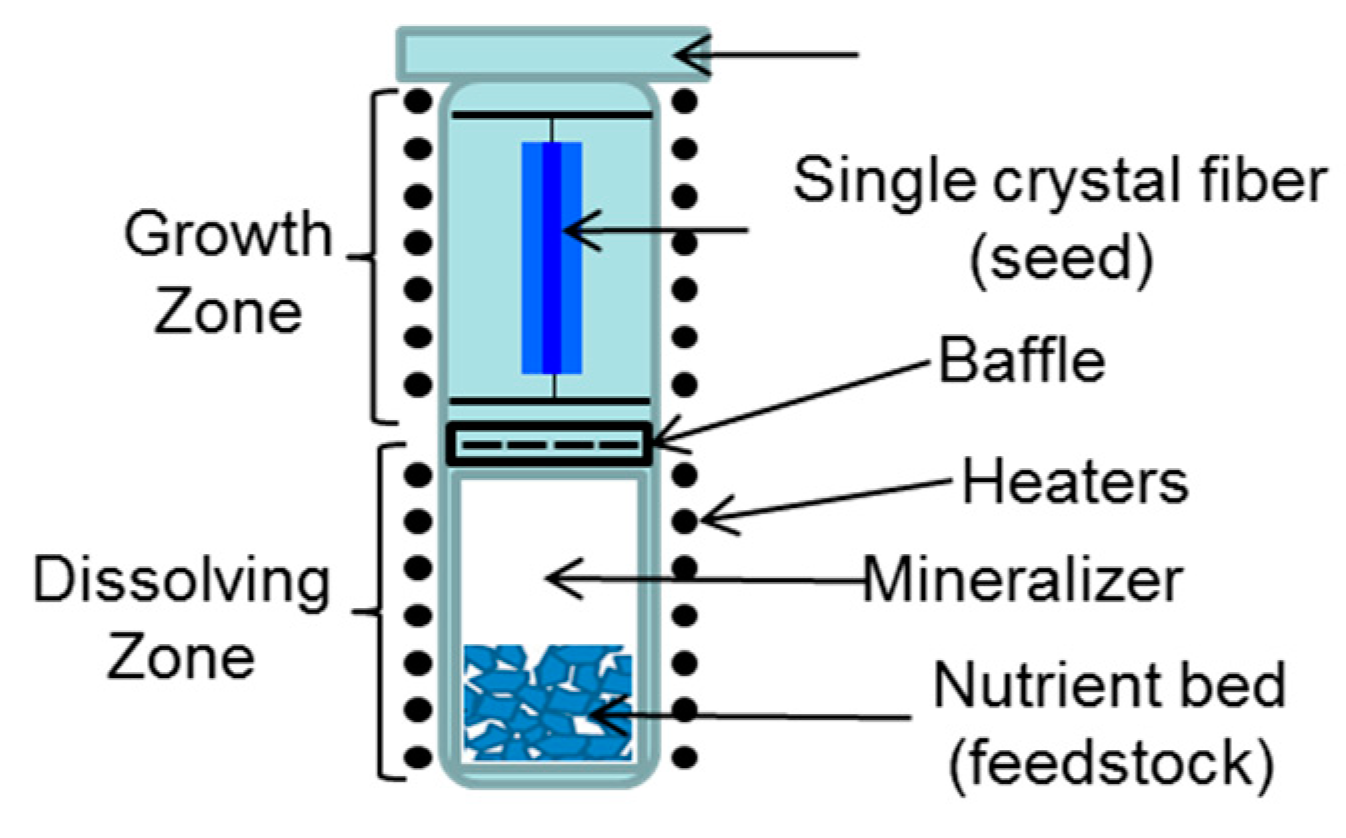

2.2.1. Hydrothermal Growth

2.2.2. Liquid Phase Epitaxial Growth

3. Results

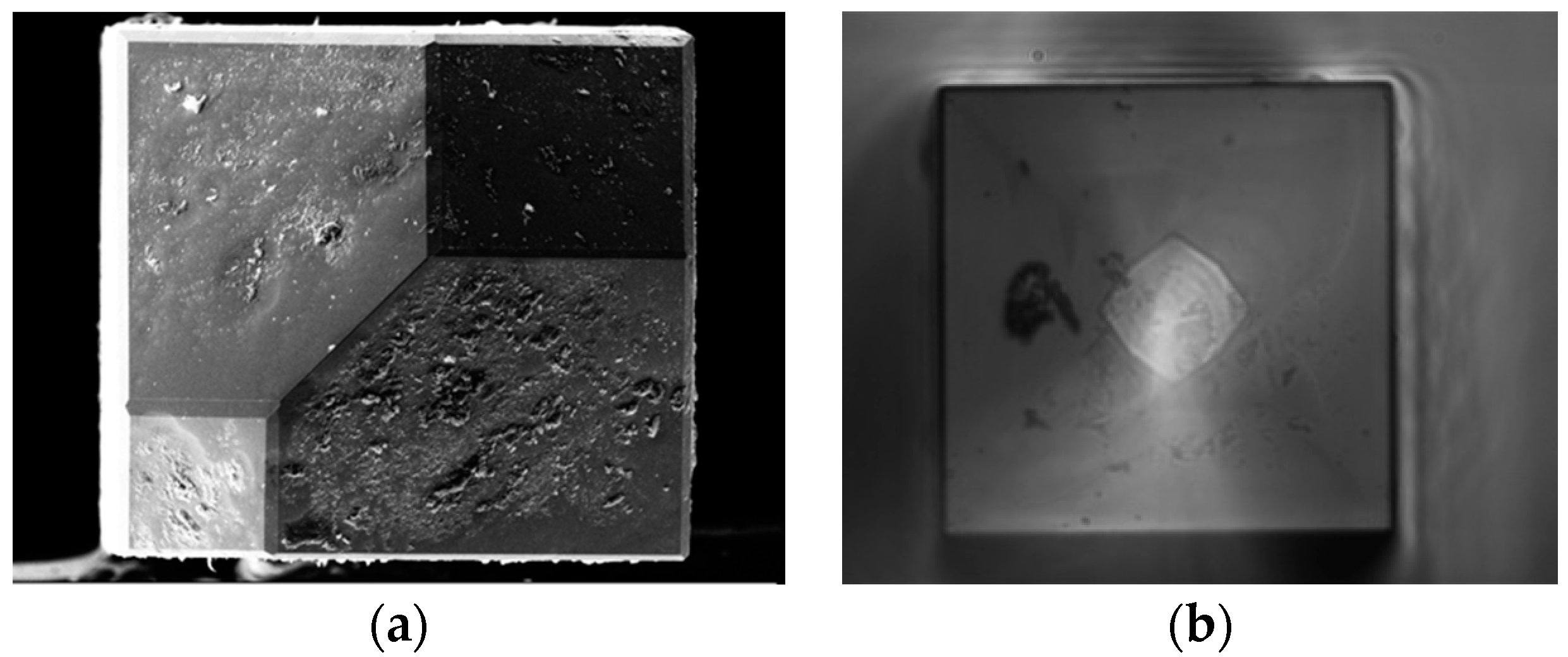

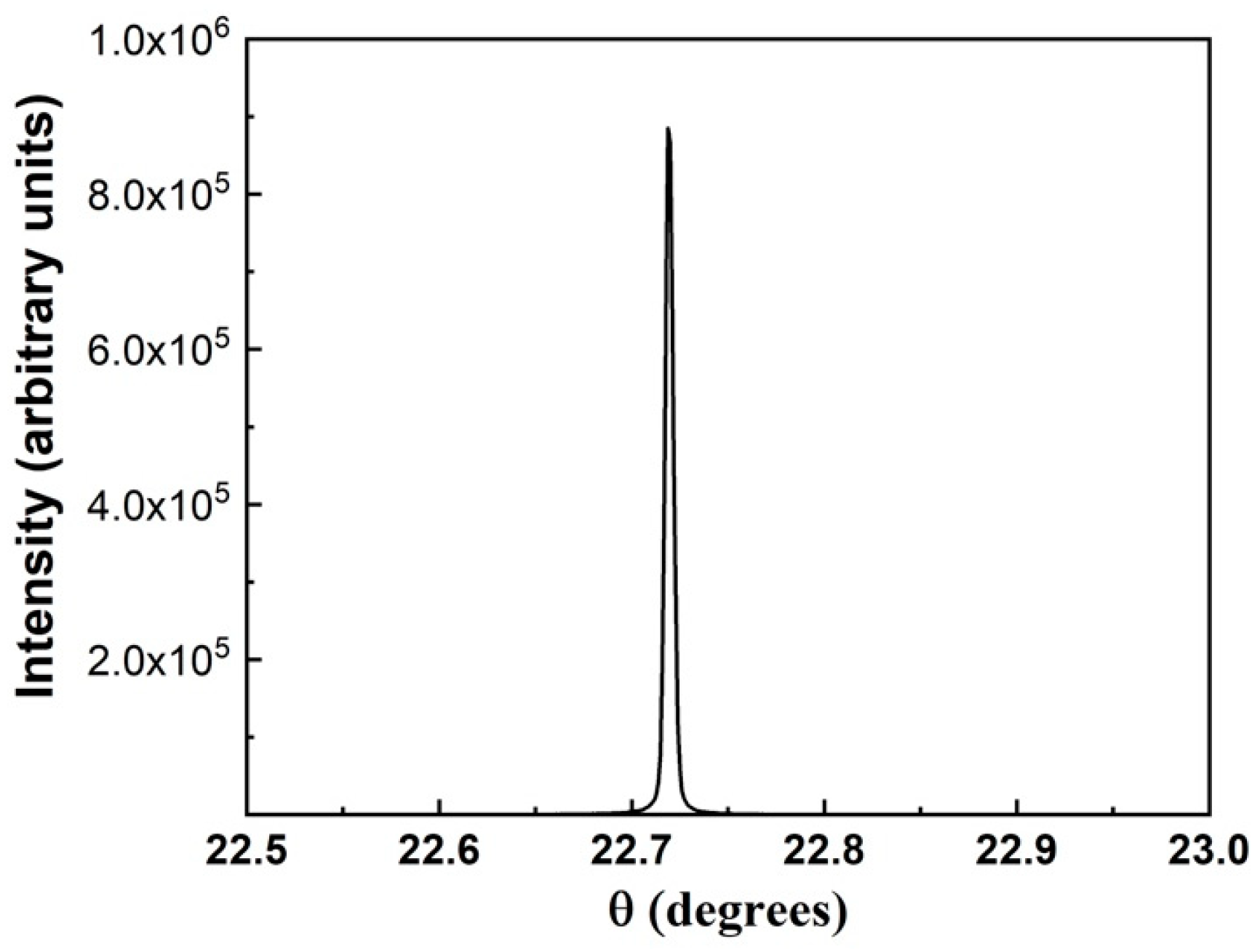

3.1. Characterization

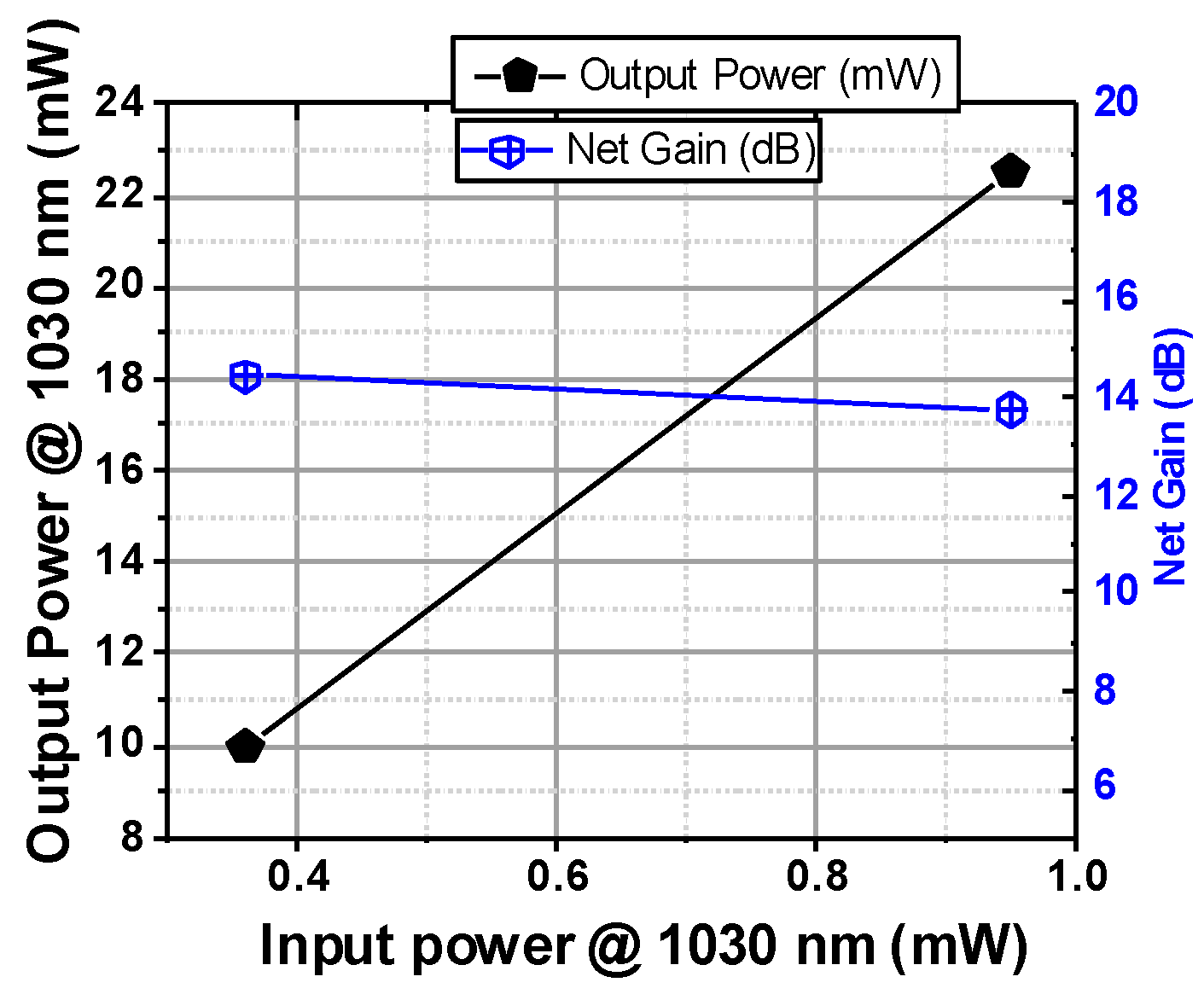

3.2. Demonstrated Power Gain in Hydrothermal Cladded Fiber

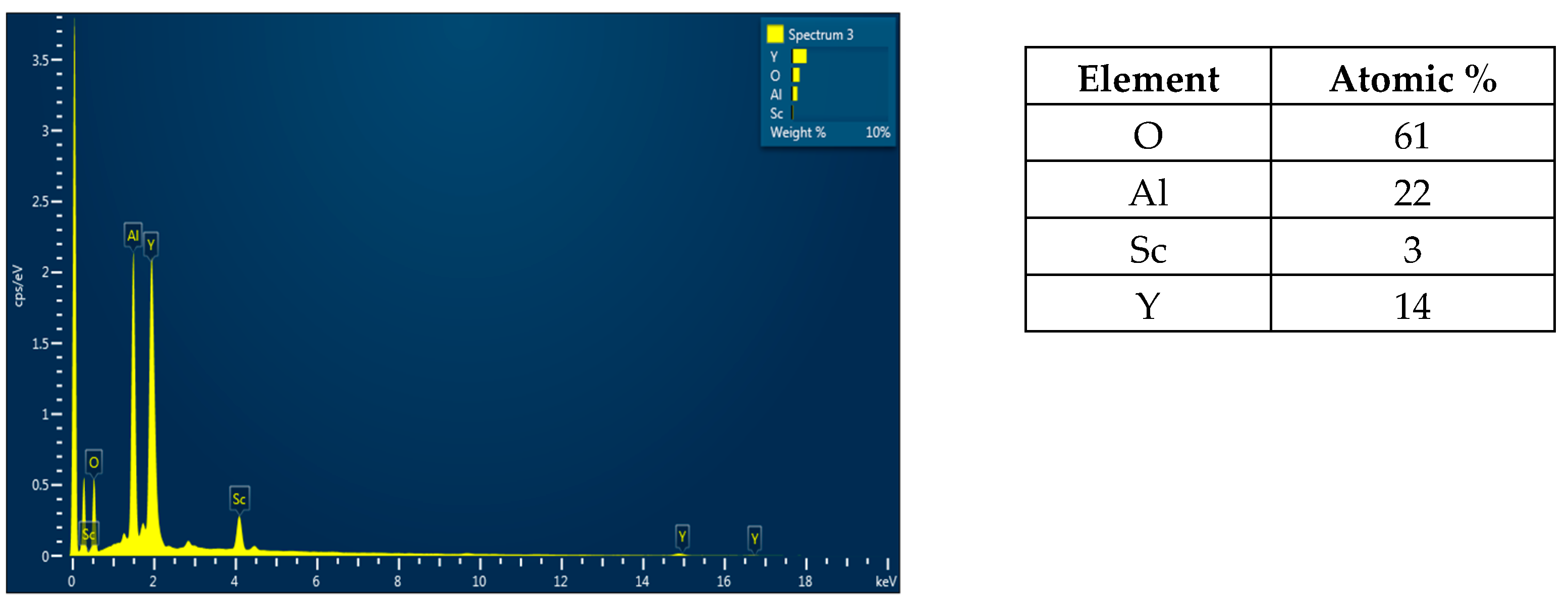

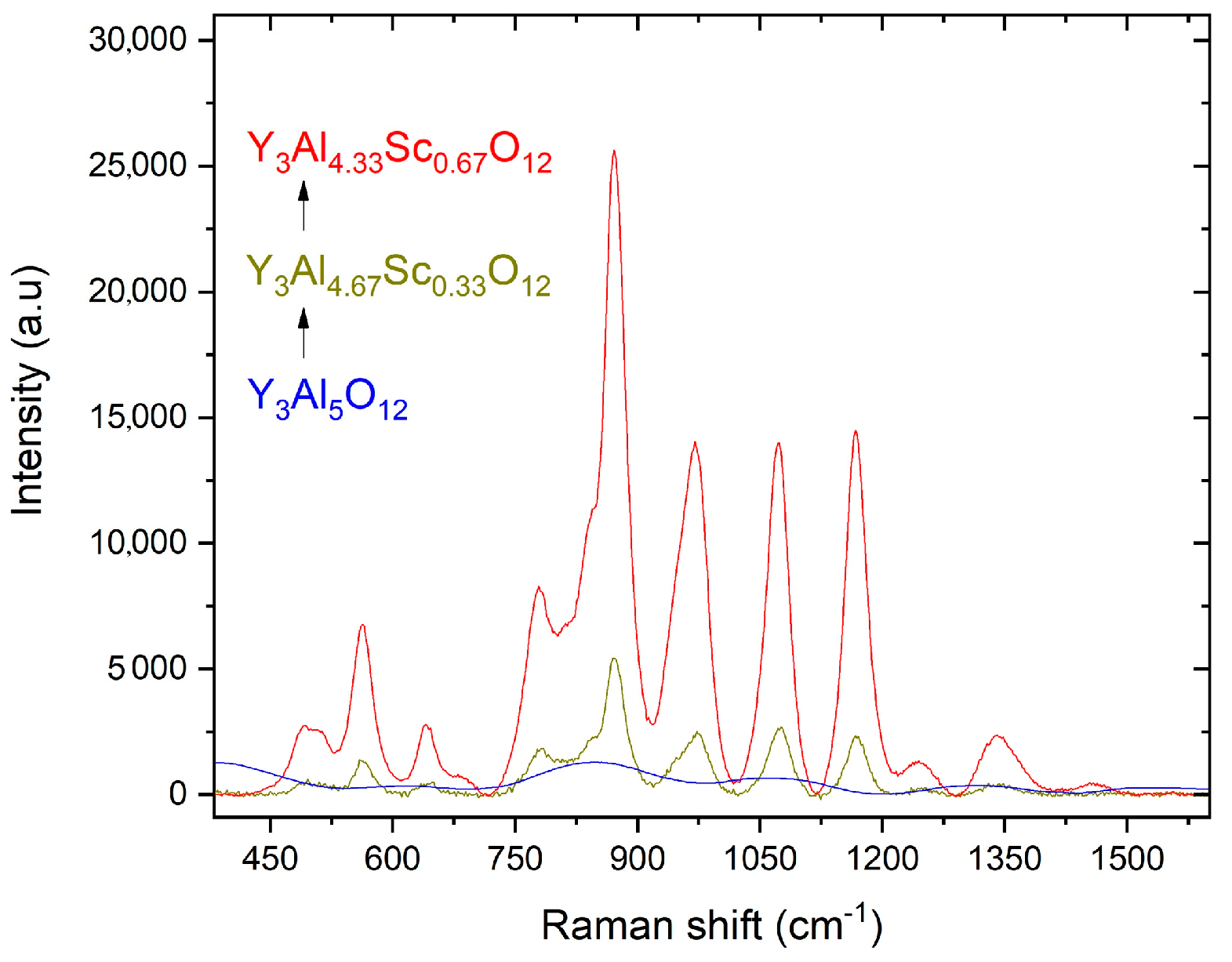

3.3. Liquid Phase Epitaxial Growth of Scandium (Sc):YAG

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nilsson, J.; Payne, D.N. High-power fiber lasers. Science 2011, 332, 921–922. [Google Scholar] [CrossRef] [PubMed]

- Fomin, V.; Abramov, M.; Ferin, A.; Abramov, A.; Mochalov, D.; Platonov, N.; Gapontsev, V. 10 kW single-mode fiber laser. In Proceedings of the Symposium on High-Power Fiber Lasers, 14th International Conference on Laser Optics SyTu-1.3, St. Petersburg, Russia, 28 June–1 July 2010. [Google Scholar]

- Dawson, J.W.; Messerly, M.J.; Beach, R.J.; Shverdin, M.Y.; Stappaerts, E.A.; Sridharan, A.K.; Pax, P.H.; Heebner, J.E.; Siders, C.W.; Barty, C.P.J. Analysis of the scalability of diffraction-limited fiber lasers and amplifiers to high average power. Opt. Express 2008, 16, 13240–13266. [Google Scholar] [CrossRef] [PubMed]

- Jauregui, C.; Eidam, T.; Otto, H.J.; Stutzki, F.; Jansen, F.; Limpert, J.; Tünnermann, A. Physical origin of mode instabilities in high-power fiber laser systems. Opt. Express 2012, 20, 12912–12925. [Google Scholar] [CrossRef] [PubMed]

- Sincore, A.; Bradford, J.D.; Cook, J.; Shah, L.; Richardson, M.C. High average power thulium-doped silica fiber lasers: Review of systems and concepts. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 1–8. [Google Scholar] [CrossRef]

- Zheng, J.; Zhao, W.; Zhao, B.; Hou, C.; Li, Z.; Li, G.; Gao, Q.; Ju, P.; Gao, W.; She, S.; et al. 4.62 kW excellent beam quality laser output with a low-loss Yb/Ce co-doped fiber fabricated by chelate gas phase deposition technique. Opt. Mater. Express 2017, 7, 1259–1266. [Google Scholar] [CrossRef]

- Beier, F.; Hupel, C.; Kuhn, S.; Hein, S.; Nold, J.; Proske, F.; Sattler, B.; Liem, A.; Jauregui, C.; Limpert, J.; et al. Single mode 4.3 kW output power from a diode-pumped Yb-doped fiber amplifier. Opt. Express 2017, 25, 14892–14899. [Google Scholar] [CrossRef] [PubMed]

- Parthasarathy, T.; Hay, R.S.; Fair, G.; Hopkins, F.K. Predicted performance limits of yttrium aluminum garnet fiber lasers. Opt. Eng. 2010, 49, 094302. [Google Scholar] [CrossRef]

- Dawson, J.W.; Messerly, M.J.; Heebner, J.E.; Pax, P.H.; Sridharan, A.K.; Bullington, A.L.; Beach, R.J.; Siders, C.W.; Barty, C.P.J.; Dubinskii, M. Power scaling analysis of fiber lasers and amplifiers based on non-silica materials. In Proceedings of the Laser Technology for Defense and Security VI, Orlando, FL, USA, 5–9 April 2010; Volume 7686, p. 768611. [Google Scholar]

- Brown, D.C.; Hoffman, H.J. Thermal, stress, and thermo-optic effects in high average power double-clad silica fiber lasers. IEEE J. Quantum Electron. 2001, 37, 207–217. [Google Scholar] [CrossRef]

- Smith, R.G. Optical power handling capacity of low loss optical fibers as determined by stimulated Raman and Brillouin scattering. Appl. Opt. 1972, 11, 2489–2494. [Google Scholar] [CrossRef]

- Mezeix, L.; Green, D.J. Comparison of the mechanical properties of single crystal and polycrystalline yttrium aluminum garnet. Int. J. Appl. Ceram. Technol. 2006, 3, 166–176. [Google Scholar] [CrossRef]

- Kim, W.; Shaw, B.; Bayya, S.; Askins, C.; Peele, J.; Rhonehouse, D.; Myers, J.; Thapa, R.; Bowman, S.; Gibson, D.; et al. Cladded single crystal fibers. MS&T 2016, 2016, 4–8. [Google Scholar]

- Bera, S.; Nie, C.D.; Harrington, J.A.; Chick, T.; Chakrabarty, A.; Trembath-Reichert, S.; Chapman, J.; Rand, S.C. Cladding single crystal YAG fibers grown by laser heated pedestal growth. In Proceedings of the Solid State Lasers XXV: Technology and Devices, San Francisco, CA, USA, 13–18 February 2016; p. 97260C. [Google Scholar] [CrossRef]

- Kim, W.; Shaw, B.; Bayya, S.; Askins, C.; Peele, J.; Rhonehouse, D.; Meyers, J.; Thapa, R.; Gibson, D.; Sanghera, J. Cladded single crystal fibers for high power fiber lasers. In Proceedings of the Photonic Fiber and Crystal Devices: Advances in Materials and Innovations in Device Applications X, San Diego, CA, USA, 28 August–1 September 2016; Volume 9958, p. 99580O. [Google Scholar]

- Kim, W.; Bayya, S.; Shaw, L.B.; Myers, J.; Qadri, S.N.; Thapa, R.; Askins, C.; Peele, J.; Rhonehouse, D.; Bowman, S.; et al. Crystal fiber lasers. In Proceedings of the Photonic Fiber and Crystal Devices: Advances in Materials and Innovations in Device Applications XI, San Diego, CA, USA, 6–10 August 2017. [Google Scholar] [CrossRef]

- Shaw, L.B.; Bayya, S.; Kim, W.; Myers, J.; Rhonehouse, D.; Qadri, S.N.; Askins, C.; Peele, J.; Thapa, R.; Gibson, D.; et al. Fabrication of cladded single crystal fibers for all—crystalline fiber lasers. In Proceedings of the Advanced Photonics 2018 (BGPP, IPR, NP, NOMA, Sensors, Networks, SPPCom, SOF), Zurich, Switzerland, 2–5 July 2018. [Google Scholar]

- Shaw, L.B.; Askins, C.; Kim, W.; Bayya, S.; Peele, J.; Rhonehouse, D.; Thapa, R.; Gibson, D.; Myers, J.; Gattass, R.R.; et al. Development of Clad Single Crystal Fiber. In Proceedings of the Photonics and Fiber Technology 2016 (ACOFT, BGPP, NP), Sydney, Australia, 5–8 September 2016. [Google Scholar] [CrossRef]

- Dubinskii, M.; Zhang, J.; Fromzel, V.; Chen, Y.; Yin, S.; Luo, C. Low-loss ‘crystalline-core/crystalline-clad’ (C4) fibers for highly power scalable high efficiency fiber lasers. Opt. Express 2018, 26, 5092–5101. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Baker, C.; Villalobos, G.; Frantz, J.; Shaw, B.; Lutz, A.; Bryan, S.; Frederic, K.; Machael, H.; Jasbinder, S.; et al. Synthesis of high purity Yb3+-Doped Lu2O3 powder for high power solid-state lasers. J. Am. Ceram. Soc. 2011, 94, 3001–3005. [Google Scholar] [CrossRef]

- Kim, W.; Baker, C.; Villalobos, G.; Frantz, J.; Shaw, B.; Sadowski, B.; Hunt, M.; Aggarwal, I.; Sanghera, J. Highly transparent ceramics obtained from jet milled sesquioxide powders synthesized by co-precipitation method. Opt. Mater. Express 2014, 4, 2497. [Google Scholar] [CrossRef]

- Laudise, R.A.; Crocket, J.H.; Ballman, A.A. The hydrothermal crystallization of yttrium iron garnet and yttrium gallium garnet and a part of the crystallization diagram Y2O3-Fe2O3-H2O-Na2CO3. J. Phys. Chem. 1961, 65, 359–361. [Google Scholar] [CrossRef]

- Mcmillen, C.D.; Mann, M.; Fan, J.; Zhu, L.; Kolis, J.W. Revisiting the Hydrothermal growth of YAG. J. Cryst. Growth 2012, 356, 58–64. [Google Scholar] [CrossRef]

- Thapa, R.; Gibson, D.; Gattass, R.R.; Askins, C.; Kim, W.; Bayya, S.; Shaw, L.B.; Sanghera, J.S. Fusion splicing of highly dissimilar YAG crystal fiber and silica fiber with reaction bonding. Opt. Mater. Express 2016, 6, 2560. [Google Scholar] [CrossRef]

- Ferrand, B.; Pelenc, D.; Chartier, I.; Wyon, C. Growth by LPE of Nd: YAG single crystal layers for waveguide laser applications. J. Cryst. Growth 1993, 128, 966–969. [Google Scholar] [CrossRef]

- Ferrand, B.; Chambaz, B.; Couchaud, M. Liquid phase epitaxy: A versatile technique for the development of miniature optical components in single crystal dielectric media. Opt. Mater. 1999, 11, 101–114. [Google Scholar] [CrossRef]

- Lacmann, R.; Franke, W.; Heimann, R. The dissolution forms of single crystal spheres: I. Theory for the molecular-kinetics interpretation. J. Cryst. Growth 1974, 26, 107–116. [Google Scholar] [CrossRef]

- Hartmann, E.; Beregi, E. Face statistics on the dissolution forms of garnet crystals. J. Cryst. Growth 1993, 128, 74–81. [Google Scholar] [CrossRef]

- Sun, C.; Xue, D. Chemical bonding theory of single crystal growth and its application to ϕ 3′′ YAG bulk crystal. CrystEngComm 2014, 16, 2129–2135. [Google Scholar] [CrossRef]

- Kim, W.; Bayya, S.; Shaw, B.; Myers, J.; Qadri, S.N.; Thapa, R.; Gibson, D.; Mcclain, C.; Kung, F.; Kolis, J.; et al. Hydrothermally cladded crystalline fibers for laser applications [Invited]. Opt. Mater. Express 2019, 9, 2716. [Google Scholar] [CrossRef]

- NIST Inorganic Crystal Structure Database; NIST Standard Reference Database Number 3; National Institute of Standards and Technology; Gaithersburg, M.D. 20899; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018. [CrossRef]

- Qadri, S.B.; Horwitz, J.S.; Chrisey, D.B.; Auyeung, R.C.Y.; Grabowski, K.S. X-ray characterization of extremely high quality (Sr,Ba)TiO3 films grown by pulsed laser deposition. Appl. Phys. Lett. 1995, 66, 1605. [Google Scholar] [CrossRef]

- Qadri, S.B.; Dinan, J.H. X-ray determination of dislocation density in epitaxial ZnCdTe. Appl. Phys. Lett. 1985, 47, 1066–1068. [Google Scholar] [CrossRef]

- Chani, V.I.; Yoshikawa, A.; Kuwano, Y.; Hasegawa, K. Growth of Y3Al5O12: Nd fiber crystals by micro-pulling-down technique. J. Cryst. Growth 1999, 204, 155–162. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, H.; Han, J.; Zhang, H.; Xu, C. Distribution of Neodymium and properties of Nd:YAG crystal by horizontal directional solidification. J. Cryst. Growth 2012, 340, 130–134. [Google Scholar] [CrossRef]

- Upasani, M. Synthesis of Y3Al5O12: Eu and Y3Al5O12: Eu, Si phosphors by combustion method: Comparative investigations on the structural and spectral properties. J. Adv. Ceram. 2016, 5, 344–355. [Google Scholar] [CrossRef]

- Ferrier, A.; Ilas, S.; Goldner, P.; Louchet-Chauvet, A. Scandium doped Tm:YAG ceramics and single crystals: Coherent and high resolution spectroscopy. J. Lumin. 2018, 194, 116–122. [Google Scholar] [CrossRef]

- Kokta, M.; Laboratories, B.; Hill, M. Solubility enhancement of Nd7+ in scandium-substituted rare earth- aluminum garnets. J. Solid State Chem. 1973, 8, 39–42. [Google Scholar] [CrossRef]

- Kostić, S.; Lazarević, Z.Ž.; Radojević, V.; Milutinović, A.; Romčević, M.; Romčević, N.Ž.; Valčić, A. Study of structural and optical properties of YAG and Nd:YAG single crystals. Mater. Res. Bull. 2015, 63, 80–87. [Google Scholar] [CrossRef]

- Ding, S.; Ren, H.; Li, H.; He, A. Hardness, Raman spectrum, thermal properties, and laser damage threshold of Y3Sc2Ga3O12 single crystal. J. Mater. Sci. Mater. Electron. 2021, 32, 1616–1622. [Google Scholar] [CrossRef]

- Lupei, A.; Lupei, V.; Hau, S.; Gheorghe, C.; Voicu, F. Structure and temperature effects on Nd3+ spectra in polycrystalline mixed scandium aluminum garnets Y3ScxAl5-xO12. Opt. Mater. 2015, 47, 465–472. [Google Scholar] [CrossRef]

| Composition | O | Al | Y | Yb |

|---|---|---|---|---|

| Core (10% Yb:YAG) | 65 | 21 | 12 | 2 |

| Cladding (YAG) | 67 | 19 | 14 | 0 |

| Composition | Phase ID | Space Group | Cell Parameters (Å) | Volume (Å3) |

|---|---|---|---|---|

| 10.0% Yb:YAG core before Hydrothermal growth | YAG | F-43m (216) | a = b = c = 11.9787 | 1718.796 |

| Undoped YAG cladding after Hydrothermal Growth | YAG | F-43m (216) | a = b = c = 12.0113 | 1732.871 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qadri, S.N.; Kim, W.; Bayya, S.; Shaw, L.B.; Qadri, S.B.; Kolis, J.; Stadelman, B.; Sanghera, J. Epitaxial Growth of Single Crystal YAG for Optical Devices. Coatings 2021, 11, 644. https://doi.org/10.3390/coatings11060644

Qadri SN, Kim W, Bayya S, Shaw LB, Qadri SB, Kolis J, Stadelman B, Sanghera J. Epitaxial Growth of Single Crystal YAG for Optical Devices. Coatings. 2021; 11(6):644. https://doi.org/10.3390/coatings11060644

Chicago/Turabian StyleQadri, Syed N., Woohong Kim, Shyam Bayya, L. Brandon Shaw, Syed B. Qadri, Joseph Kolis, Bradley Stadelman, and Jasbinder Sanghera. 2021. "Epitaxial Growth of Single Crystal YAG for Optical Devices" Coatings 11, no. 6: 644. https://doi.org/10.3390/coatings11060644

APA StyleQadri, S. N., Kim, W., Bayya, S., Shaw, L. B., Qadri, S. B., Kolis, J., Stadelman, B., & Sanghera, J. (2021). Epitaxial Growth of Single Crystal YAG for Optical Devices. Coatings, 11(6), 644. https://doi.org/10.3390/coatings11060644