Fabrication and Characterization of Fiber-Reinforced Composite Sandwich Structures Obtained by Fused Filament Fabrication Process

Abstract

1. Introduction

2. Materials and Methods

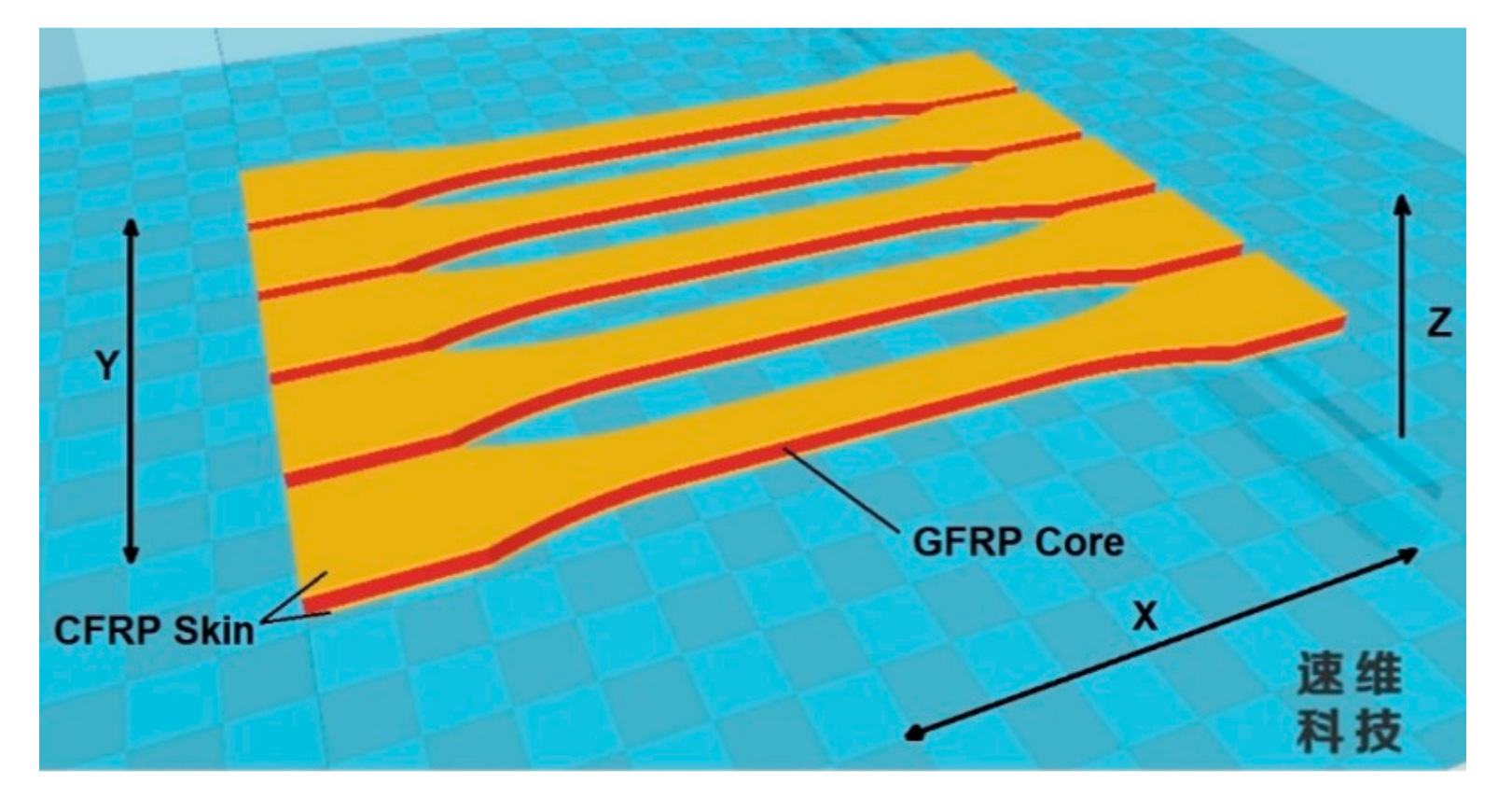

2.1. Materials Properties and Manufacturing Conditions of the Sandwich Specimens

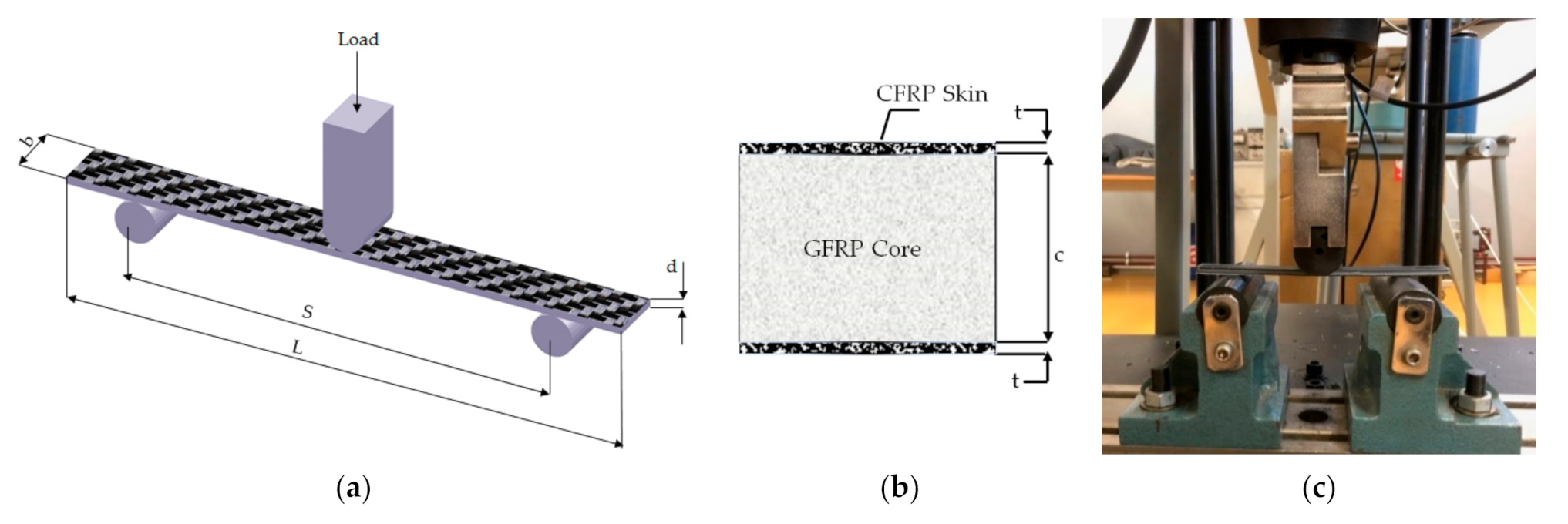

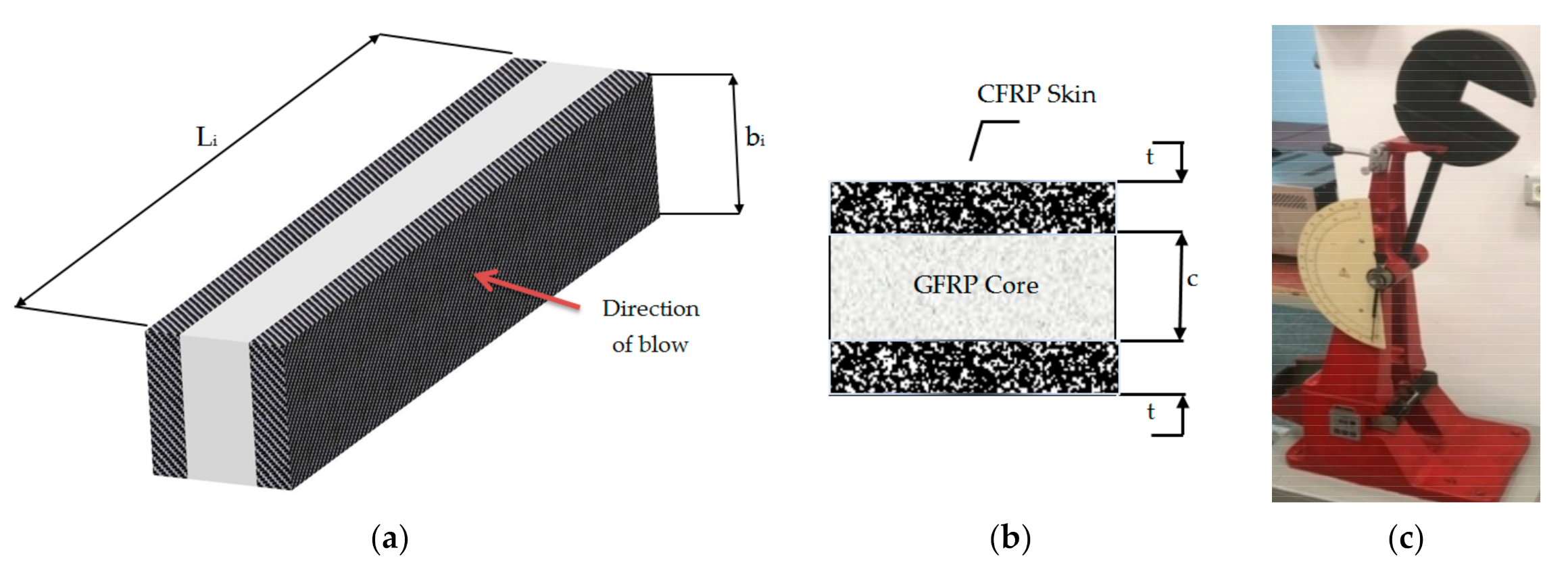

2.2. Mechanical Testing

2.3. Statistical Analysis

3. Results and Discussion

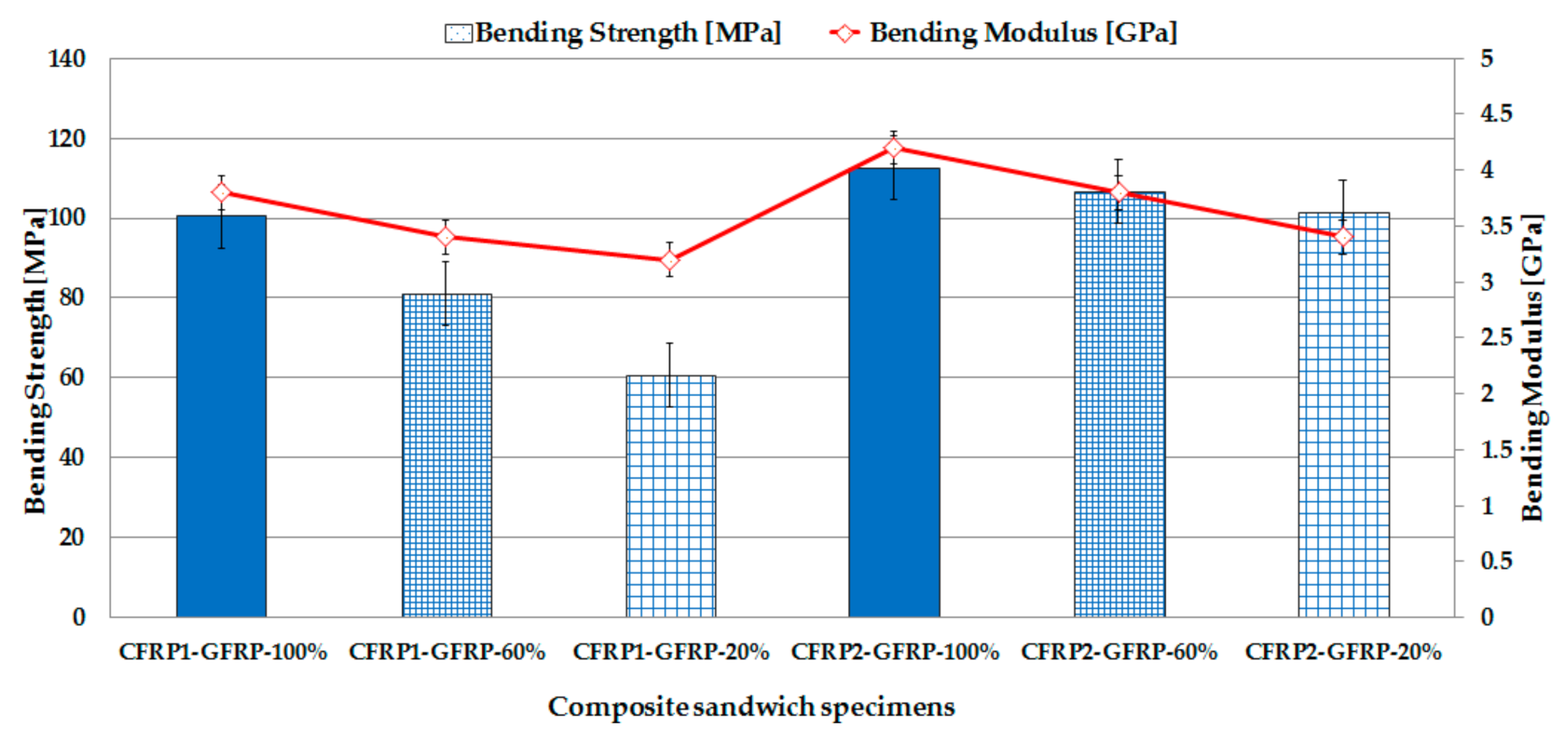

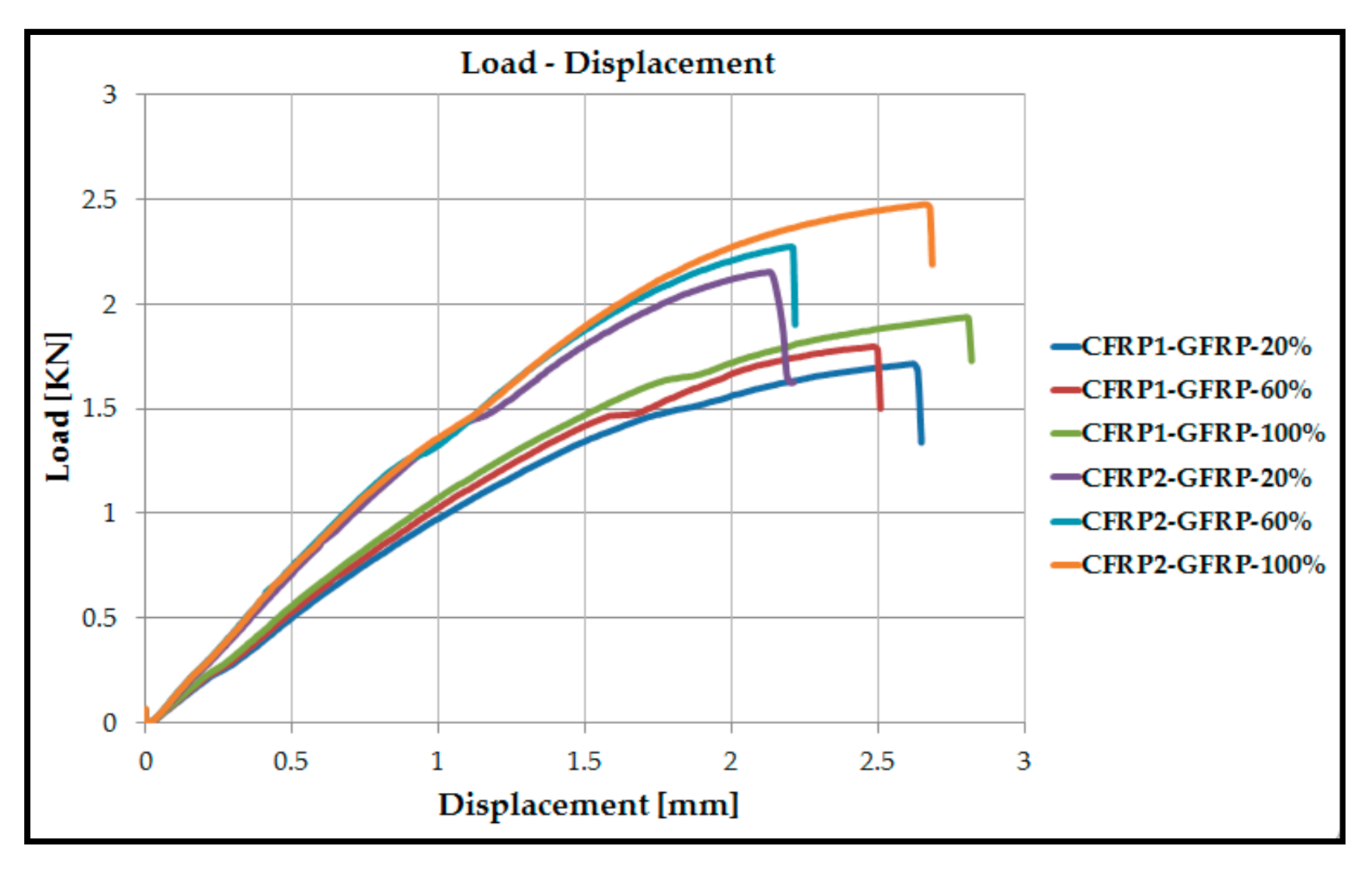

3.1. Three-Point Bending Behavior of the Fiber-Reinforced Composite Sandwich Structures

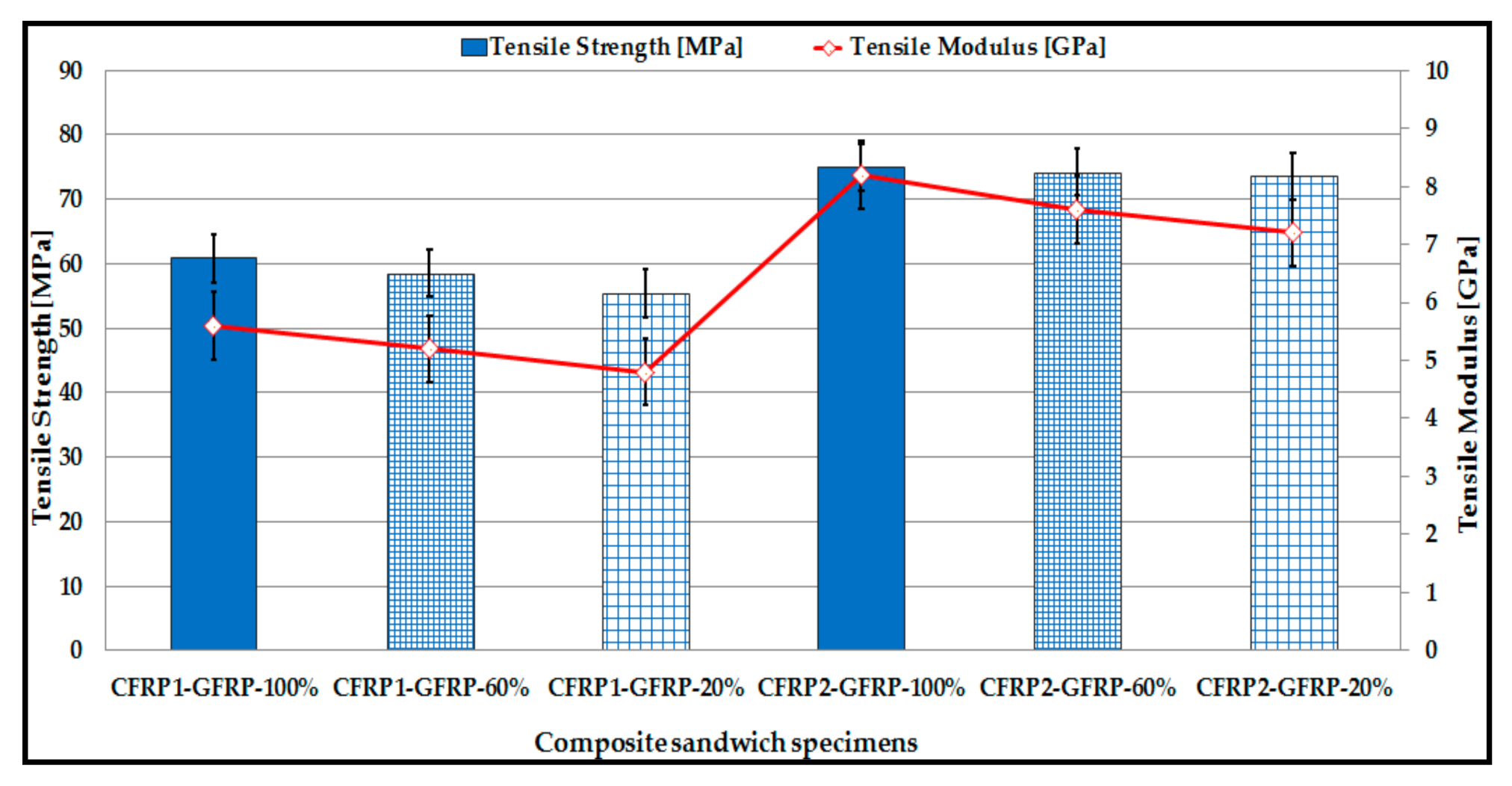

3.2. Tensile Performances of the Fiber-Reinforced Composite Sandwich Structures

3.3. Mechanical Shock Properties of the Fiber-Reinforced Composite Sandwich Structures

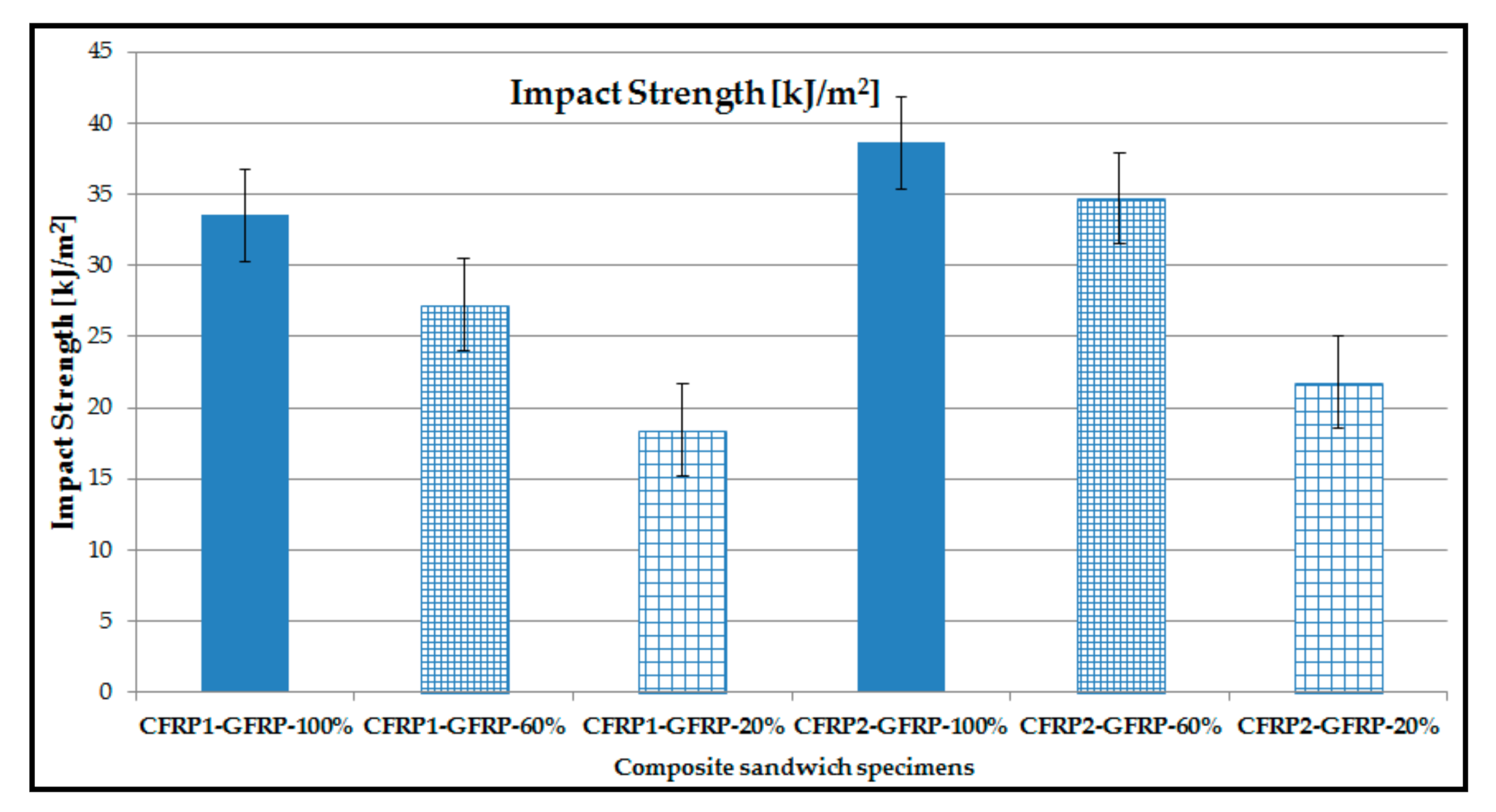

3.4. Impact Properties of the Fiber-Reinforced Composite Sandwich Structures

3.5. Strength-to-Mass Ratio of the 3D Printed Sandwich Structures

- In the case of three-point bending tests, for CFRP1-GFRP sandwich structures, the strength-to-mass ratio is directly proportional to the infill density. In contrast, for the second structure CFRP2-GFRP, the ratio values are very close, a fact which indicates that a lower infill density can be used, maintaining approximately the same value of the strength-to-mass ratio. For this structure, using a lower infill density reduces the time and costs of 3D printing.

- In the case of tensile strength tests, both sandwich structures have very close strength-to-mass ratio values. Thus, it can be highlighted that the infill density does not significantly change the values of the strength-to-mass ratio.

- In the case of impact tests, the results have shown that the higher the infill density, the higher the strength-to-mass ratio. Therefore, it can be stated that the value of the strength-to-mass ratio is directly proportional to the value of impact strength.

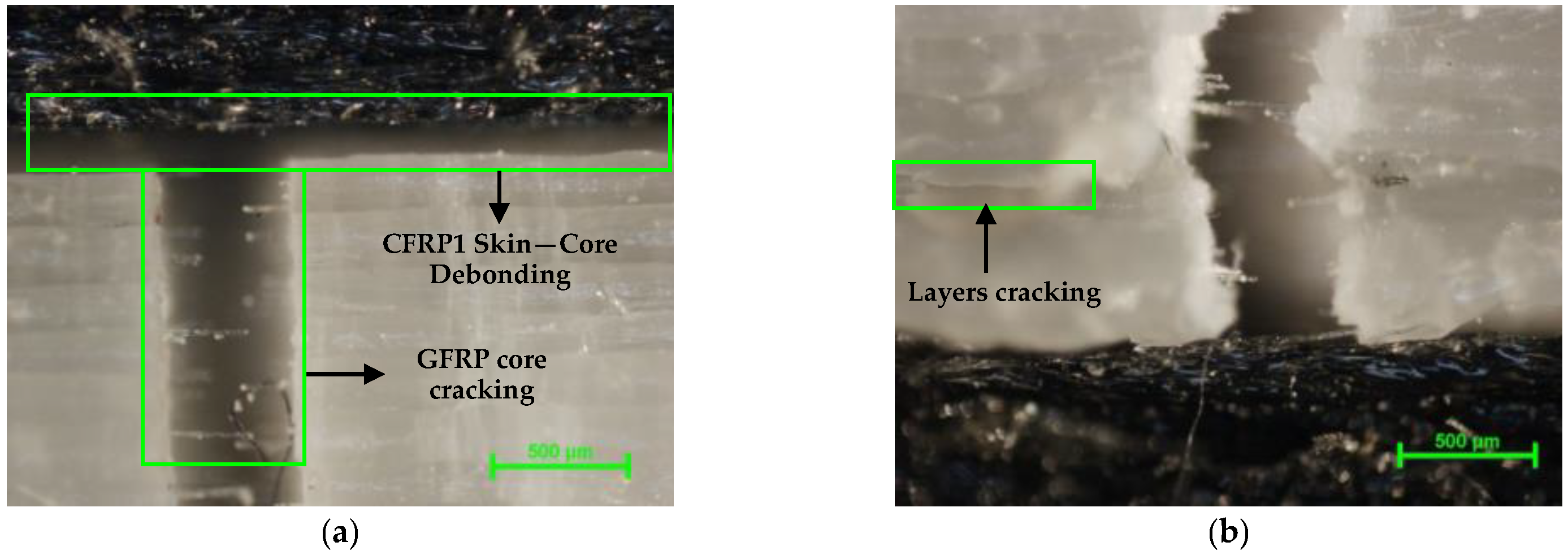

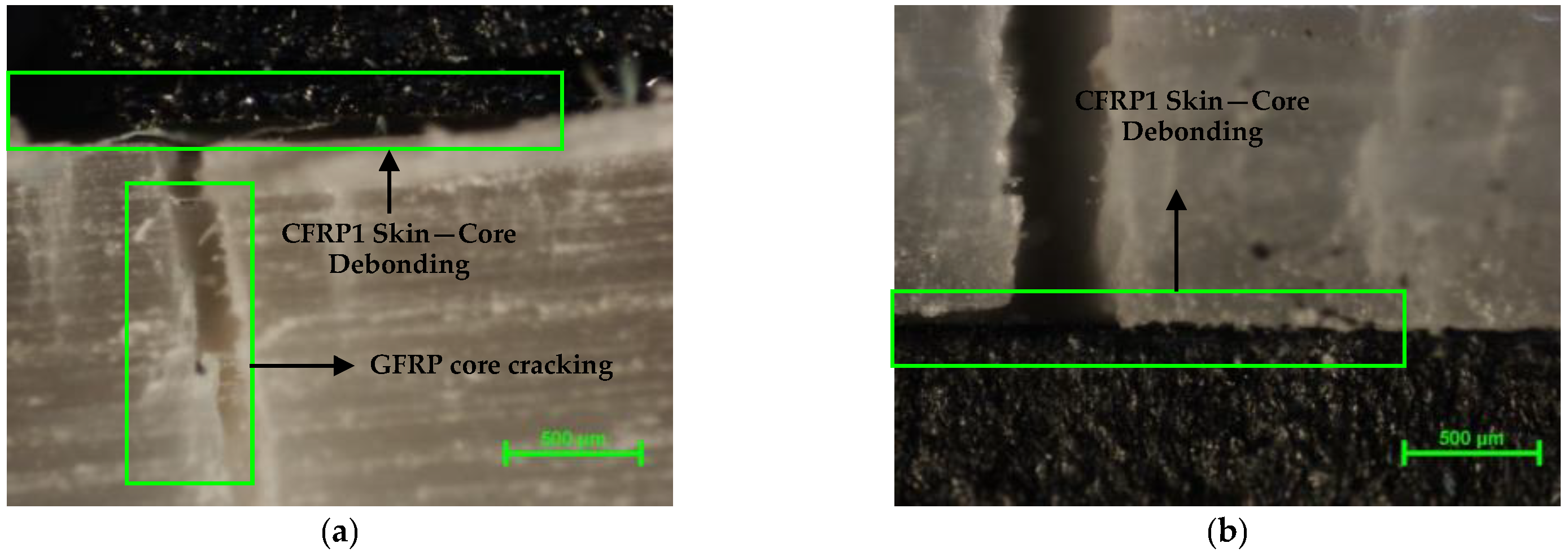

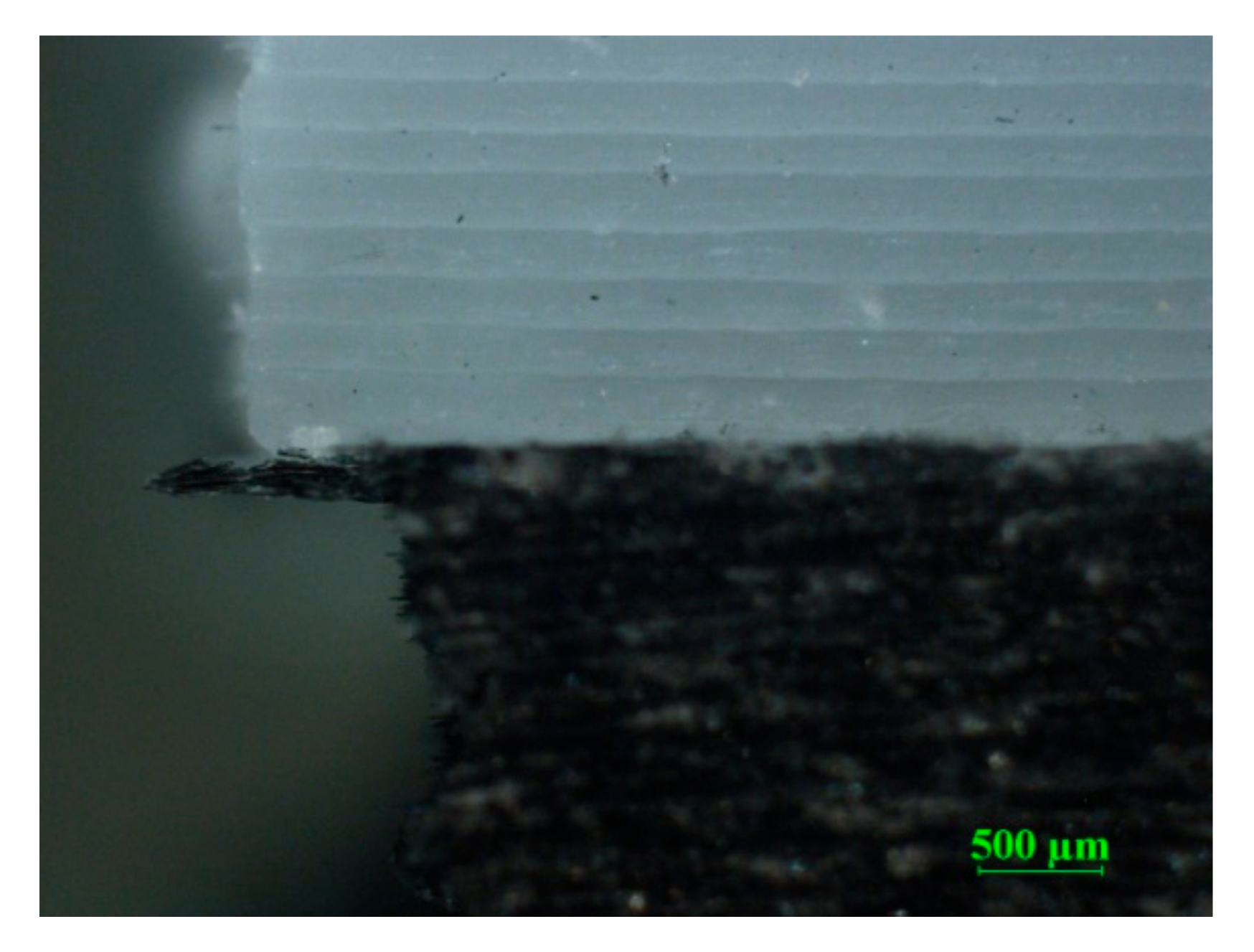

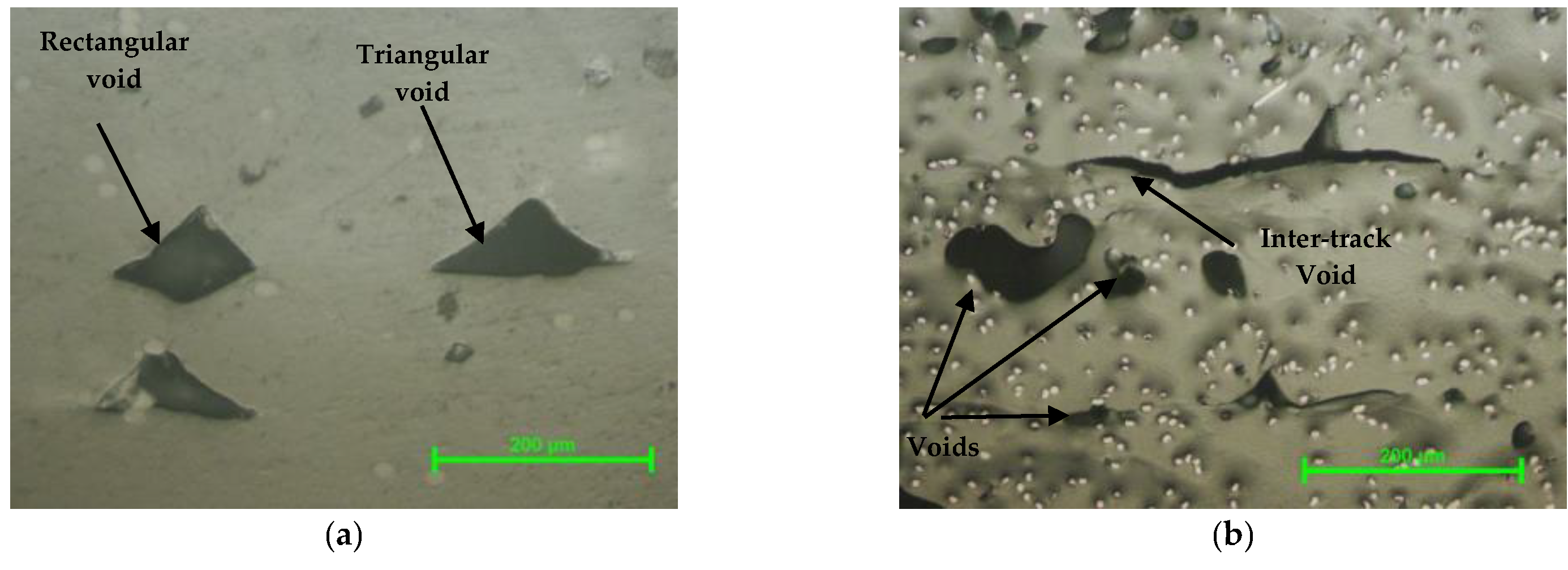

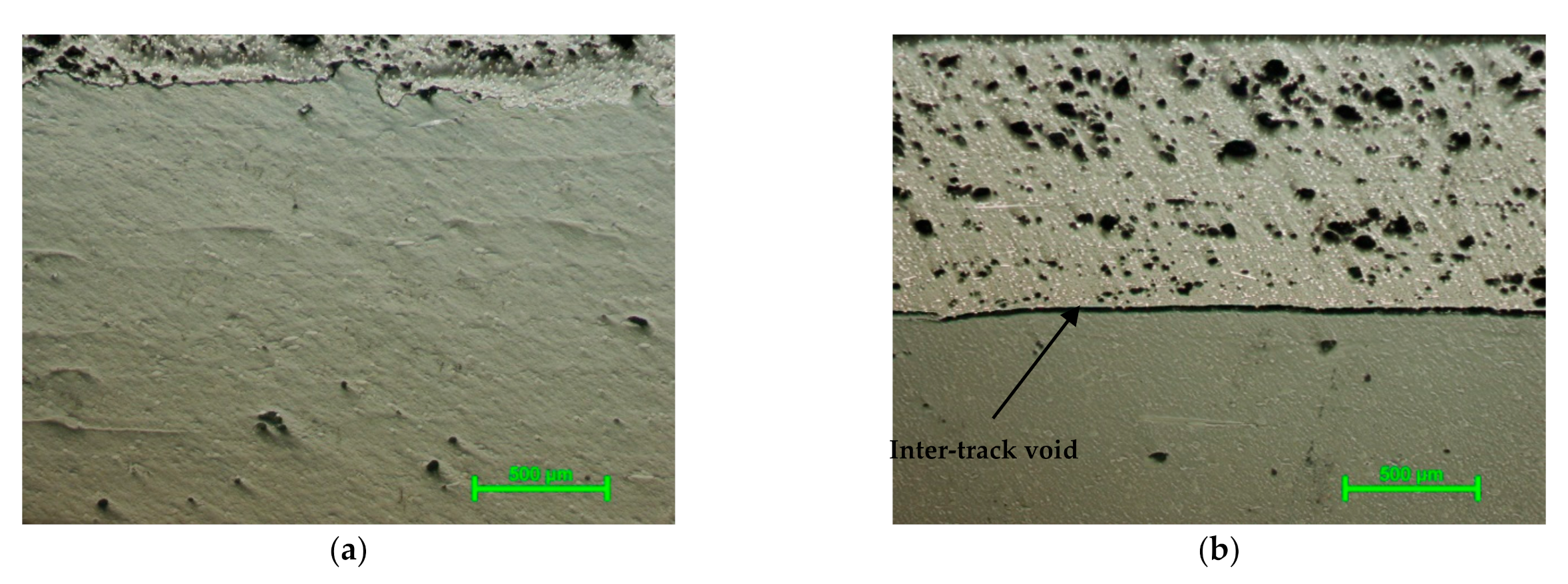

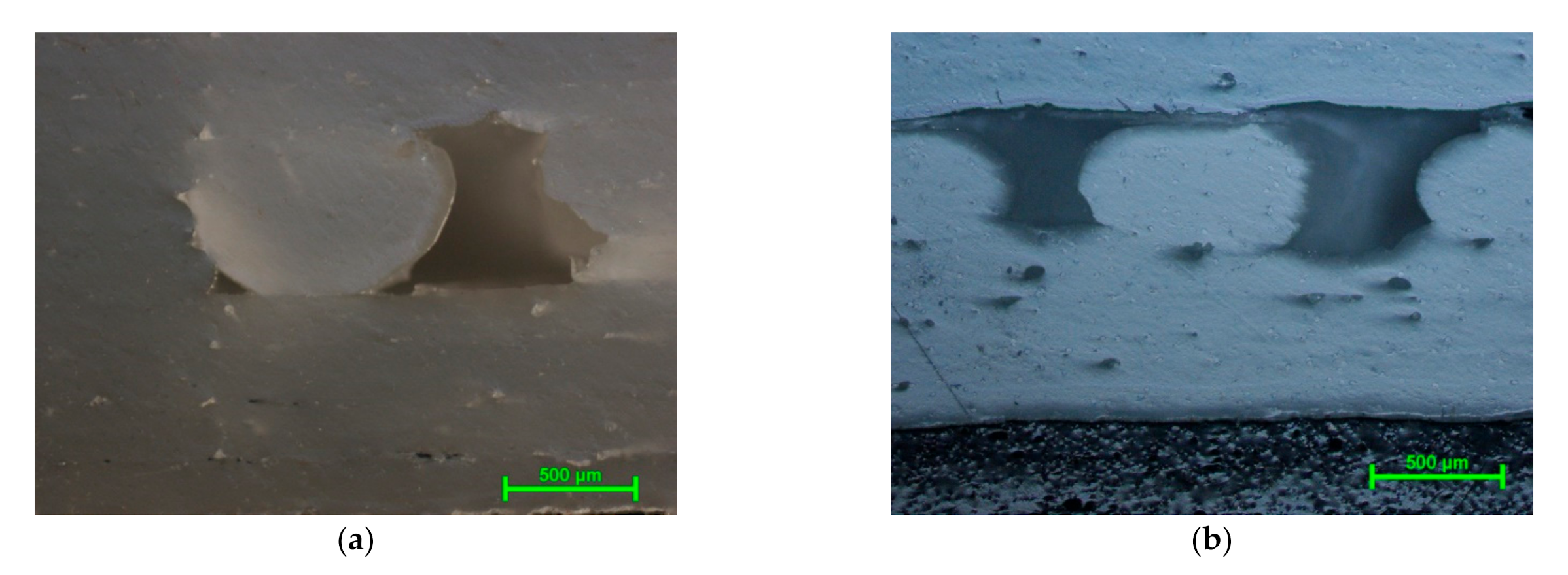

3.6. Microscopic Analysis of Breaking Mode and Manufacturing Defects of the Fiber-Reinforced Composite Sandwich Structures

3.7. Finite Element Analysis of the Fiber-Reinforced Composite Sandwich Structures

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kalender, M.; Bozkurt, Y.; Ersoy, S.; Salman, S. Product development by additive manufacturing and 3D printer technology in aerospace industry. J. Aeronaut. Space Technol. 2020, 13, 129–138. [Google Scholar]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Pascariu, I.S.; Zaharia, S.M. Design and testing of an unmanned aerial vehicle manufactured by fused deposition modeling. J. Aerosp. Eng. 2020, 33, 06020002. [Google Scholar] [CrossRef]

- Heras, E.S.; Haro, F.B.; de Agustín del Burgo, J.M.; Marcos, M.E.I. Plate auto-level system for fused deposition modelling (FDM) 3D printers. Rapid Prototyp. J. 2017, 23, 401–413. [Google Scholar] [CrossRef]

- Sharma, N.; Aghlmandi, S.; Cao, S.; Kunz, C.; Honigmann, P.; Thieringer, F.M. Quality characteristics and clinical relevance of in-house 3D-printed customized polyetheretherketone (PEEK) implants for craniofacial reconstruction. J. Clin. Med. 2020, 9, 2818. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Li, D.; Jin, Z. Preliminary investigation of poly-ether-ether-ketone based on fused deposition modeling for medical applications. Materials 2018, 11, 288. [Google Scholar] [CrossRef] [PubMed]

- Vaezi, M.; Yang, S. Extrusion-based additive manufacturing of PEEK for biomedical applications. Virtual Phys. Prototyp. 2015, 10, 123–135. [Google Scholar] [CrossRef]

- Noort, M.; van Bommel, K.; Renzetti, S. 3D-printed cereal foods. Cereal Foods World 2017, 62, 222–227. [Google Scholar] [CrossRef]

- Zhang, L.; Lou, Y.; Schutyser, M.A.I. 3D printing of cereal-based food structures containing probiotics. Food Struct. 2018, 18, 14–22. [Google Scholar] [CrossRef]

- Varghese, C.; Wolodko, J.; Chen, L.; Doschak, M.; Srivastav, P.P.; Roopesh, M.S. Influence of selected product and process parameters on microstructure, rheological, and textural properties of 3D printed cookies. Foods 2020, 9, 907. [Google Scholar] [CrossRef]

- Blanco, I. The use of composite materials in 3D printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K.S. An investigation into 3D printing of fiber reinforced thermoplastic composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar]

- Nakagawa, Y.; Mori, K.; Maeno, T. 3D printing of carbon fiber-reinforced plastic parts. Int. J. Adv. Manuf. Technol. 2017, 91, 2811–2817. [Google Scholar] [CrossRef]

- Shulga, E.; Karamov, R.; Sergeichev, I.S.; Konev, S.D.; Shurygina, L.I.; Akhatov, I.S.; Shandakov, S.D.; Nasibulin, A.G. Fused filament fabricated polypropylene composite reinforced by aligned glass fibers. Materials 2020, 13, 3442. [Google Scholar] [CrossRef]

- Sodeifian, G.; Ghaseminejad, S.; Yousefid, A.A. Physics Preparation of polypropylene/short glass fiber composite as Fused Deposition Modeling (FDM) filament. Results Phys. 2019, 12, 205–222. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Henri, R.; Fayazbakhsh, K.; Lessard, L. Recycled glass fiber composites from wind turbine waste for 3D printing feedstock: Effects of fiber content and interface on mechanical performance. Materials 2019, 12, 3929. [Google Scholar] [CrossRef]

- Mei, H.; Ali, Z.; Ali, I.; Cheng, L. Tailoring strength and modulus by 3D printing different continuous fibers and filled structures into composites. Adv. Compos. Hybrid. Mater. 2019, 2, 312–319. [Google Scholar] [CrossRef]

- Dickson, A.N.; Barry, J.N.; McDonnell, K.A.; Dowling, D.P. Fabrication of continuous carbon, glass and kevlar fiber reinforced polymer composites using additive manufacturing. Addit. Manuf. 2017, 16, 146–152. [Google Scholar]

- Dong, G.; Tang, Y.; Li, D.; Zhao, Y.F. Mechanical properties of continuous kevlar fiber reinforced composites fabricated by fused deposition modeling process. Procedia Manuf. 2018, 26, 774–781. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. Part B 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.-K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [PubMed]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Efects of process parameters on tensile properties. J. Compos. Mater. 2017, 51, 451–462. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Z.; Huang, K. Additive manufacturing of thermoplastic matrix composites using fused deposition modeling: A comparison of two reinforcements. J. Compos. Mater. 2017, 51, 3733–3742. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S.; Hunag, C.; Shi, Z.; Ma, Y.; Yao, P. Preparation of short CF/GF reinforced PEEK composite filaments and their comprehensive properties evaluation for FDM-3D printing. Compos. Part B 2020, 198, 108175. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-based 3D printing of polymer and associated composite: A review on mechanical properties, defects and treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Sanei, S.H.R.; Popescu, D. 3D-printed carbon fiber reinforced polymer composites: A systematic review. J. Compos. Sci. 2020, 4, 98. [Google Scholar] [CrossRef]

- Naranjo-Lozada, J.; Ahuett-Garza, H.; Orta-Castañón, P.; Verbeeten, W.M.H.; Sáiz-González, D. Tensile properties and failure behavior of chopped and continuous carbon fiber composites produced by additive manufacturing. Addit. Manuf. 2019, 26, 227–241. [Google Scholar] [CrossRef]

- Abdullah, A.M.; Mohamad, D.; Rahim, T.N.A.T.; Akil, H.M.; Rajion, Z.A. Effect of narrow infill density gap on the compressive properties of 3D printed carbon fibre reinforced acrylonitrile butadiene styrene. J. Mech. Sci. Technol. 2019, 33, 2339–2343. [Google Scholar] [CrossRef]

- Yazdani Sarvestani, H.; Akbarzadeh, A.H.; Niknam, H.; Hermenean, K. 3D printed architected polymeric sandwich panels: Energy absorption and structural performance. Compos. Struct. 2018, 200, 886–909. [Google Scholar] [CrossRef]

- Sarvestani, H.Y.; Akbarzadeh, A.; Mirbolghasemi, A.; Hermenean, K. 3D printed meta-sandwich structures: Failure mechanism, energy absorption and multi-hit capability. Mater. Des. 2018, 160, 179–193. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Nagarajan, R.; Kuzman, M.K. Effects of the face/core layer ratio on the mechanical properties of 3D printed wood/polylactic acid (PLA) green biocomposite panels with a gyroid core. Polymers 2020, 12, 2929. [Google Scholar] [CrossRef]

- Zaharia, S.M.; Enescu, L.A.; Pop, M.A. Mechanical performances of lightweight sandwich structures produced by material extrusion-based additive manufacturing. Polymers 2020, 12, 1740. [Google Scholar] [CrossRef]

- Antony, S.; Cherouat, A.; Montay, G. Fabrication and characterization of hemp fibre based 3D printed honeycomb sandwich structure by FDM process. Appl. Compos. Mater. 2020, 27, 935–953. [Google Scholar] [CrossRef]

- Sugiyama, K.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of composite sandwich structures using continuous carbon fiber and fiber tension. Compos. Part A Appl. Sci. Manuf. 2018, 113, 114–121. [Google Scholar] [CrossRef]

- Wang, Z.; Luan, C.; Liao, G.; Yao, X.; Fu, J. Mechanical and self-monitoring behaviors of 3D printing smart continuous carbon fiber-thermoplastic lattice truss sandwich structure. Compos. Part B Eng. 2019, 176, 107215. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber—Polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Papon, E.A.; Haque, A. Fracture toughness of additively manufactured carbon fiber reinforced composites. Addit. Manuf. 2019, 26, 41–52. [Google Scholar] [CrossRef]

- Oztan, C.; Karkkainen, R.; Fittipaldi, M.; Nygren, G.; Roberson, L.; Lane, M.; Celik, E. Microstructure and mechanical properties of three dimensional-printed continuous fiber composites. J. Compos. Mater. 2019, 53, 271–280. [Google Scholar] [CrossRef]

- Galatas, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Additive manufactured sandwich composite/ABS parts for unmanned aerial vehicle applications. Polymers 2018, 10, 1262. [Google Scholar] [CrossRef]

- Bodaghi, M.; Serjouei, A.; Zolfagharian, A.; Fotouhi, M.; Hafizur, R.; Durand, D. Reversible energy absorbing meta-sandwiches by FDM 4D printing. Int. J. Mech. Sci. 2020, 173, 105451. [Google Scholar] [CrossRef]

- ISO 527-2:2012. Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- ISO 1183-1:2019. Plastics—Methods for Determining the Density of Non Cellular Plastics—Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method; ISO: Geneva, Switzerland, 2019. [Google Scholar]

- ASTM D638-10. Standard Test Method for Tensile Properties of Plastics; American Society for Testing and Materials: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM C393/C393M-2011. Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure; American Society for Testing and Materials: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Pop, M.A.; Geamăn, V.; Radomir, I.; Bedo, T. Capacity of energy absorption by flick through shock in cooper foams. J. Porous Media 2017, 20, 405–415. [Google Scholar] [CrossRef]

- German Institute for Standardization. Plastics-Determination of Charpy Impact Properties-Part 1: Non-Instrumented Impact Test (German Version ISO 179-1:2010); DIN EN ISO 179-1; DIN: Dublin, Germany, 2010. [Google Scholar]

- De Toro, E.V.; Sobrino, J.C.; Martínez, A.M.; Eguía, V.M.; Pérez, J.A. Investigation of a short carbon fibre-reinforced polyamide and comparison of two manufacturing processes: Fused deposition modelling (FDM) and polymer injection moulding (PIM). Materials 2020, 13, 672. [Google Scholar] [CrossRef]

- Yasa, E.; Ersoy, K. Dimensional accuracy and mechanical properties of chopped carbon reinforced polymers produced by material extrusion additive manufacturing. Materials 2019, 12, 3885. [Google Scholar] [CrossRef]

- Yasa, E. Anisotropic impact toughnness of chopped carbon fiber reinforced nylon fabricated by material-extrusion-based additive manufacturing. Anadolu Univ. Sci. Technol. A Appl. Sci. Eng. 2019, 20, 195–203. [Google Scholar] [CrossRef][Green Version]

- Krajangsawasdi, N.; Blok, L.G.; Hamerton, I.; Longana, M.L.; Woods, B.K.S.; Ivanov, D.S. Fused deposition modelling of fibre reinforced polymer composites: A parametric review. J. Compos. Sci. 2021, 5, 29. [Google Scholar] [CrossRef]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Wei, J.; Yeong, W.Y. Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Zhuo, P.; Li, S.; Ashcroft, I.; Jones, A.; Pu, J. 3D printing of continuous fibre-reinforced thermoplastic composites. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017; pp. 20–25. [Google Scholar]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Hou, Z.; Fan, L.; Zhang, X.; Zhai, S.; Zhang, C.; Li, C.; Du, Y.; Zhao, H. Failure mechanism of brass with three V-notches characterized by acoustic emission in in situ three-point bending tests. Adv. Eng. Mater. 2016, 18, 2047–2056. [Google Scholar] [CrossRef]

- Ghebretinsae, F.; Mikkelsen, O.; Akessa, A.D. Strength analysis of 3D printed carbon fibre reinforced thermoplastic using experimental and numerical methods. IOP Conf. Ser. Mater. Sci. Eng. 2019, 700. [Google Scholar] [CrossRef]

- Sauer, M.J. Evaluation of the Mechanical Properties of 3D Printed Carbon Fiber Composites. Ph.D. Thesis, South Dakota State University, Brookings, SD, USA, 2018. [Google Scholar]

- Vemuganti, S.; Soliman, E.; Taha, M.R. 3D-printed pseudo ductile fiber-reinforced polymer (FRP) composite using discrete fiber orientations. Fibers 2020, 8, 53. [Google Scholar] [CrossRef]

| Mechanical Properties | NOVAMID ID 1030 CF10 | Standard |

|---|---|---|

| Tensile Strength [MPa] | 110 | ISO 527 [41] |

| Tensile modulus [MPa] | 7630 | ISO 527 |

| Strain at yield [%] | 2.5 | ISO 527 |

| Density [g/cm3] | 1.17 | ISO 1183 [42] |

| Mechanical Properties | ColorFabb PA-CF | Standard |

|---|---|---|

| Tensile Strength [MPa] | 107 | ISO 527 |

| Tensile modulus [MPa] | 8110 | ISO 527 |

| Strain at yield [%] | 2 | ISO 527 |

| Density [g/cm3] | 1.4 | ISO 1183 |

| Mechanical Properties | PLA Glass-Reinforced | Standard |

|---|---|---|

| Tensile strength [MPa] | 57 | ASTM D638 [43] |

| Tensile modulus [MPa] | 4000 | ASTM D638 |

| Strain at yield [%] [%] | 3.4 | ASTM D638 |

| Parameter | CFRP1 | CFRP2 | GFRP |

|---|---|---|---|

| Layer height [mm] | 0.2 | 0.2 | 0.2 |

| Print speed [mm/s] | 40 | 40 | 40 |

| Extrusion Temperature [°C] | 250 | 260 | 230 |

| Building plate temperature [°C] | 75 | 75 | 75 |

| Filament diameter [mm] | 2.85 | 2.85 | 2.85 |

| Material | Length L (mm) | Thickness d (mm) | Width b (mm) | Span Length S (mm) | Core Thickness c (mm) | Skin Thickness t (mm) |

| CFRP1-GFRP | 160 | 4 | 16 | 110 | 2 | 1 |

| CFRP2-GFRP | 160 | 4 | 16 | 110 | 2 | 1 |

| Material | Length Overall L0 (mm) | Distance between Grips D (mm) | Length of Narrow Section Ln (mm) | Radius of Fillet R (mm) | Width W0 (mm) | Core Thickness c (mm) | Skin Thickness t (mm) |

| CFRP1-GFRP | 165 | 115 | 57 | 76 | 19 | 2 | 1 |

| CFRP2-GFRP | 165 | 115 | 57 | 76 | 19 | 2 | 1 |

| Material | Length Li (mm) | Width bi (mm) | Core Thickness c (mm) | Skin Thickness t (mm) |

|---|---|---|---|---|

| CFRP1-GFRP | 55 | 10 | 5 | 2.5 |

| CFRP2-GFRP | 55 | 10 | 5 | 2.5 |

| Sandwich Specimen | Standard Deviation (s) | Coefficient of Variation (δ)% |

|---|---|---|

| CFRP1-GFRP—100% Bending Strength [MPa]/Bending Modulus [GPa] | 6.107/0.447 | 6.082/11.763 |

| CFRP1-GFRP—60% Bending Strength [MPa]/Bending Modulus [GPa] | 3.701/0.548 | 4.557/16.117 |

| CFRP1-GFRP—20% Bending Strength [MPa]/Bending Modulus [GPa] | 5.119/0.447 | 8.419/13.968 |

| CFRP2-GFRP—100% [MPa] Bending Strength [MPa]/Bending Modulus [GPa] | 8.019/0.447 | 7.121/10.642 |

| CFRP2-GFRP—60% [MPa] Bending Strength [MPa]/Bending Modulus [GPa] | 3.130/0.447 | 2.936/11.763 |

| CFRP2-GFRP—20% [MPa] Bending Strength [MPa]/Bending Modulus [GPa] | 8.792/0.548 | 8.653/16.117 |

| Sandwich Specimen | Standard Deviation (s) | Coefficient of Variation (δ)% |

|---|---|---|

| CFRP1-GFRP—100% Tensile Strength [MPa]/Tensile Modulus [GPa] | 2.168/0.548 | 3.565/9.785 |

| CFRP1-GFRP—60% Tensile Strength [MPa]/Tensile Modulus [GPa] | 1.817/0.447 | 3.100/8.596 |

| CFRP1-GFRP—20% Tensile Strength [MPa]/Tensile Modulus [GPa] | 1.140/0.447 | 2.057/9.312 |

| CFRP2-GFRP—100% [MPa] Tensile Strength [MPa]/Tensile Modulus [GPa] | 2.915/0.447 | 3.886/5.451 |

| CFRP2-GFRP—60% [MPa] Tensile Strength [MPa]/Tensile Modulus [GPa] | 2.775/0.548 | 3.739/7.210 |

| CFRP2-GFRP—20% [MPa] Tensile Strength [MPa]/Tensile Modulus [GPa] | 4.278/0.447 | 5.812/6.208 |

| Sandwich Specimen | Standard Deviation (s) | Coefficient of Variation (δ)% |

|---|---|---|

| CFRP1-GFRP—100% Impact Strength [kJ/m2] | 5.254 | 15.665 |

| CFRP1-GFRP—60% Impact Strength [kJ/m2] | 4.353 | 15.967 |

| CFRP1-GFRP—20% Impact Strength [kJ/m2] | 3.823 | 20.735 |

| CFRP2-GFRP—100% Impact Strength [kJ/m2] | 3.643 | 9.428 |

| CFRP2-GFRP—60% Impact Strength [kJ/m2] | 3.959 | 11.403 |

| CFRP2-GFRP—20% Impact Strength [kJ/m2] | 2.442 | 11.216 |

| Test Type | Reaction Forces- Experimental [kN] | Reaction Forces- FEA [kN] | Relative Error (%) |

|---|---|---|---|

| Three-point bending | 0.19 | 0.20 | 5.20 |

| Tensile | 2.50 | 2.62 | 4.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buican, G.R.; Zaharia, S.-M.; Pop, M.A.; Chicos, L.-A.; Lancea, C.; Stamate, V.-M.; Pascariu, I.S. Fabrication and Characterization of Fiber-Reinforced Composite Sandwich Structures Obtained by Fused Filament Fabrication Process. Coatings 2021, 11, 601. https://doi.org/10.3390/coatings11050601

Buican GR, Zaharia S-M, Pop MA, Chicos L-A, Lancea C, Stamate V-M, Pascariu IS. Fabrication and Characterization of Fiber-Reinforced Composite Sandwich Structures Obtained by Fused Filament Fabrication Process. Coatings. 2021; 11(5):601. https://doi.org/10.3390/coatings11050601

Chicago/Turabian StyleBuican, George Razvan, Sebastian-Marian Zaharia, Mihai Alin Pop, Lucia-Antoneta Chicos, Camil Lancea, Valentin-Marian Stamate, and Ionut Stelian Pascariu. 2021. "Fabrication and Characterization of Fiber-Reinforced Composite Sandwich Structures Obtained by Fused Filament Fabrication Process" Coatings 11, no. 5: 601. https://doi.org/10.3390/coatings11050601

APA StyleBuican, G. R., Zaharia, S.-M., Pop, M. A., Chicos, L.-A., Lancea, C., Stamate, V.-M., & Pascariu, I. S. (2021). Fabrication and Characterization of Fiber-Reinforced Composite Sandwich Structures Obtained by Fused Filament Fabrication Process. Coatings, 11(5), 601. https://doi.org/10.3390/coatings11050601