1. Introduction

Today, concentrating solar power (CSP) is became the major source of renewable electricity generation in Morocco. The country has implemented the world’s largest concentrated solar farm in Ouarzazate city that will provide 580 megawatts and save the planet from over 760,000 tons of carbon emissions [

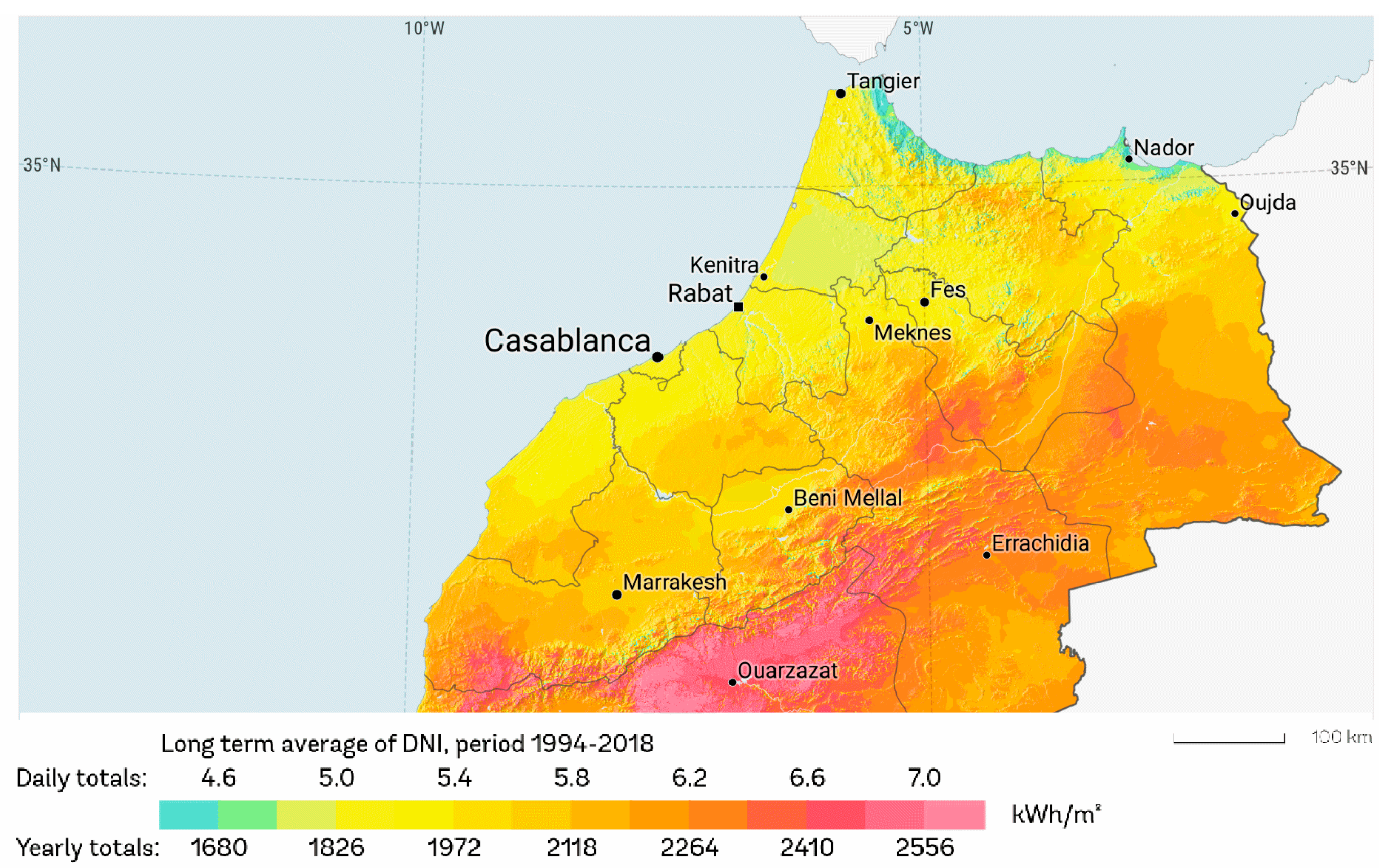

1]. Morocco has one of the best solar regimes in the world with an average direct insulation of 2200 kWh·m

−2·year

−1 and a wide range of climates (desert and arid areas). It has one of most ambitious energy targets in the world. The goal is for 52% of its power to come from renewable sources (20% solar, 20% wind, 12% hydro) by 2030 [

1,

2,

3]. The country is well on track to hit its target, too, with 35% of its energy being already renewable thanks to sites such as Noor Ouarzazate, Noor Midelt and Noor Boujdour.

Moroccan research institutions must support these industrial challenges through the launch of several research programs in order to contribute to CSP technology development, market deployment, and energy partnerships for sustainable, reliable, efficient, and cost-competitive concentrating solar technologies. Moreover, those research programs should provide information and recommendations to policy-makers. Within this context, MAScIR (Moroccan Foundation for Advanced Science, Innovation and Research) has launched in collaboration with CEA (Commissariat à l’Energie Atomique et aux Énergies Alternatives, France) a study that has as main objective testing the durability of solar mirrors used for CSP plants under different Moroccan weather conditions [

4,

5,

6,

7,

8,

9,

10].

In the last decade, scientists have been endeavoring to develop new materials for solar technologies with ideal performances for CSP plants [

11,

12,

13,

14,

15,

16,

17]. The conducted studies have yielded important technical improvements which help to increase the overall efficiency of CSP technologies. However, more improvements are needed in order to achieve a large portion of the world’s demand for electricity. Reflectors (mirrors) are the major components of the solar field in all CSP technologies (parabolic trough, solar power tower, linear Fresnel, and dish Stirling). Since the solar field accounts for nearly half the total plant construction cost, optical performances and durability of reflectors are paramount. The reflector cost for all CSP technologies represents about 30% of the collector cost. Mirrors reflect and focus the sunlight onto a receiver to create high-temperature steam to drive conventional steam turbines. Thus, optical performance of mirrors used should ensure high efficiency and stability over the lifetime of the CSP plant, which is required to be at least 25 years [

11].

Monolithic glass mirrors are the main technology used as solar reflectors in CSP power plants. This technology consists of a 1–4 mm low iron glass layer coated with a reflective silver layer which is protected with a layer of copper and a protective paint system composed by several coatings on the mirrors back. The role of these coatings is to protect the metallic layers against corrosion by creating a barrier to the diffusion of contaminants present in the atmosphere to the metallic layers [

18]. The paint material used in monolithic mirrors consists of two (thin mirrors) or three (thick mirrors) protective coatings. The primer and intermediate layers contain zinc, magnesium, calcium, barium, sulfur, iron, silicon, and lead in oxide, sulphate, or borate states. The prime layer acts as a corrosion preventer and the intermediate layer as a diffusion barrier. The top coat contains a polymeric binder and stabilizers, such as TiO

2 (rutile) and ZnO, which prevent UV radiation from reaching the intermediate paint layer [

15]. Paint coatings for exterior applications are made up of four compound types: Binder, fillers, solvents, and additives [

19,

20,

21]. The binder is the main part of paint coatings. The binder is mainly responsible for adhesion with the substrate. In most cases, it is a macromolecular organic compound [

20,

21]. Binders for mirrored paint coatings are commonly based on poly acrylates, melamine, urethane, and epoxy bases. Fillers influence the physical properties of the coating, its appearance and its resistance to corrosion. The main used pigments are titanium dioxide (TiO

2) and iron oxides (FeO or Fe

2O

3). The first is a white pigment used in exterior coatings and provides good UV protection thanks to its high refractive index. The second is found in a wide variety of forms, has a red color, and can be contained in both primer and top layers. Other inorganic pigments are used to modify paint density, permeability, flow, and hardness. The three most common are calcium carbonates (CaCO

3), silicates like talc (Mg

3Si

4O

10(OH)

2), and barium sulfate (BaSO

4). Solvents, usually organic, are used to modulate the viscosity of the binder in order to apply more easily the coating to the substrate with conventional methods. Solvents evaporate when the coating crosslinks [

19]. Additives are chemical compounds that are added in small amounts to modify the properties of the paint systems.

Many coating systems were developed and tested by solar mirror manufacturers in order to provide new solar reflectors with less paint layer thickness and enhanced lifetime [

22].

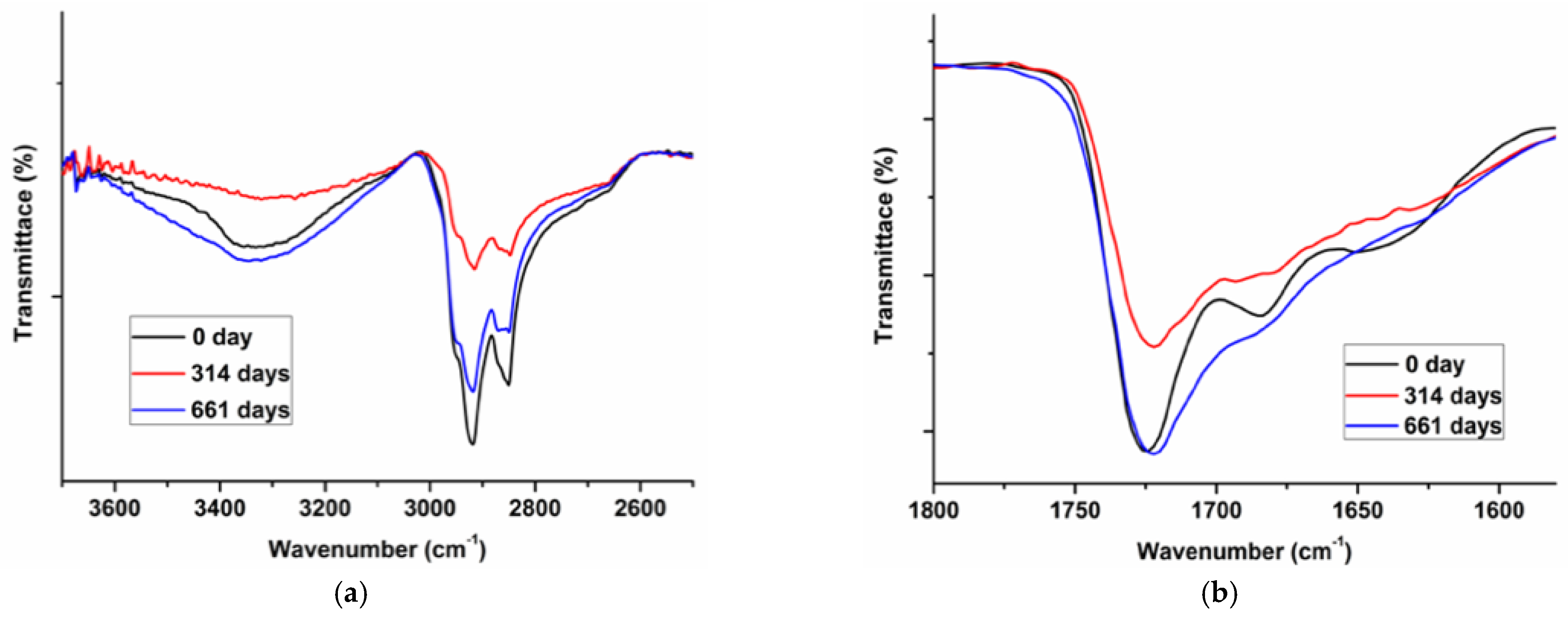

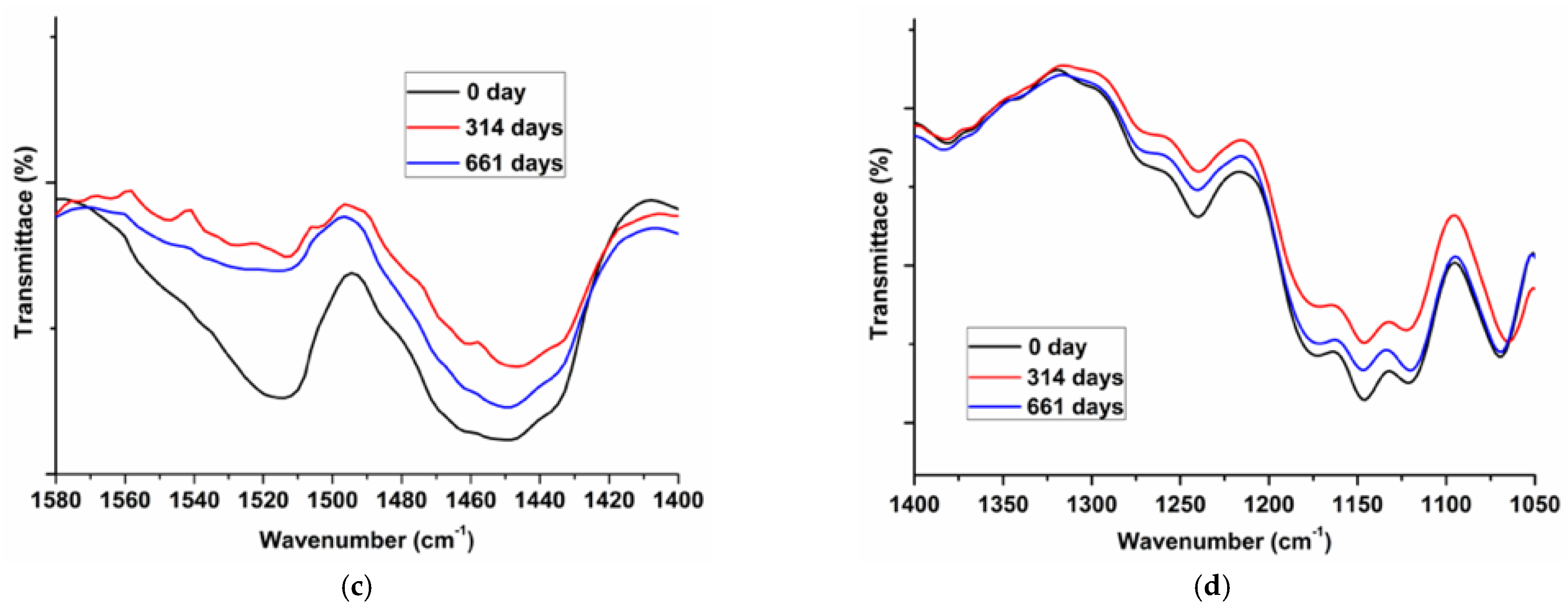

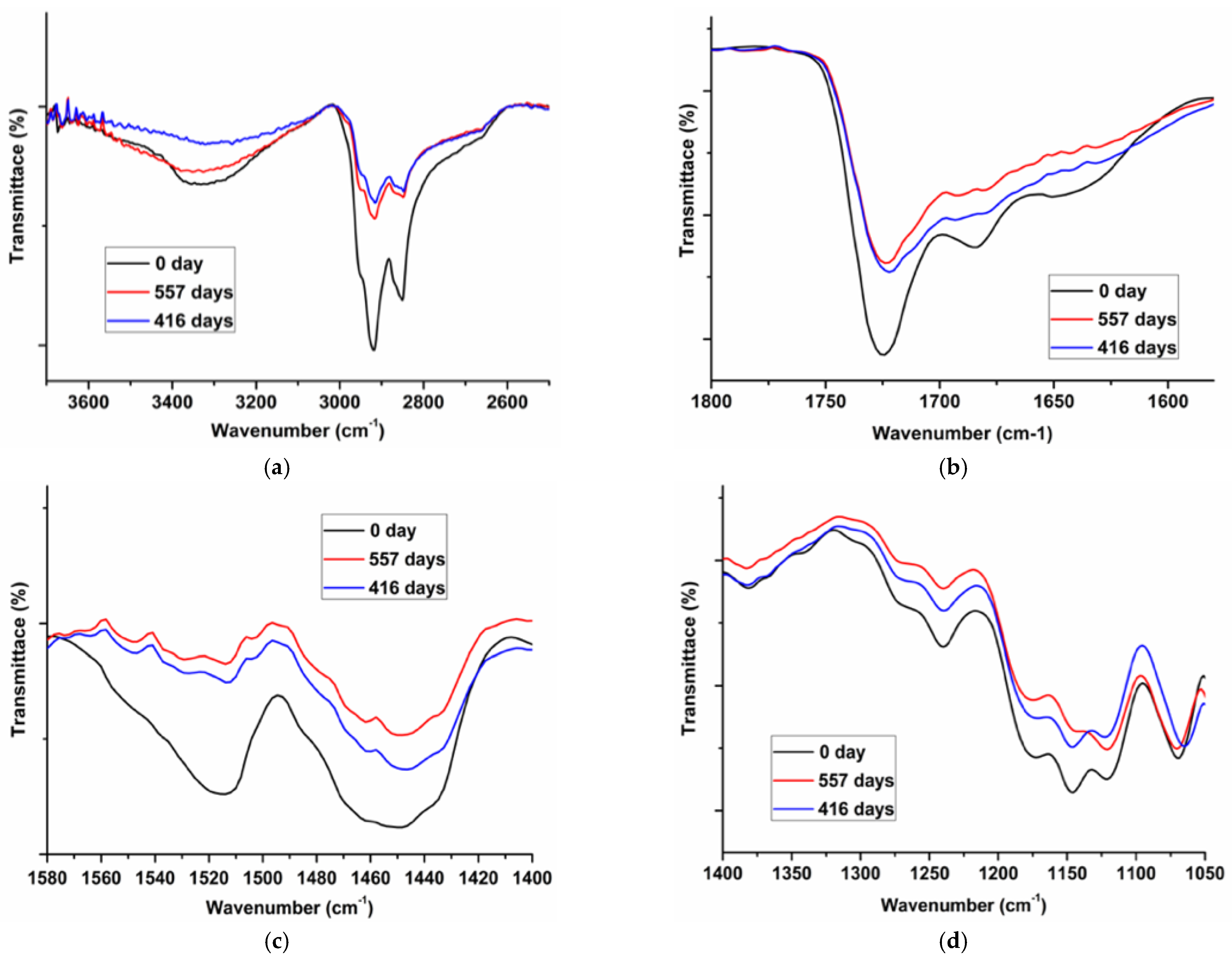

Paint coatings, as well as other layers composed monolithic glass mirrors, are subject to physico-chemical degradation when exposed to natural environments. The most common chemical mechanisms leading to degradation of coatings are photochemical degradation and hydrolysis resulting from UV radiation, air, and water [

20,

21]. These processes can sometimes work together, such that the overall rate of degradation is greater than the sum of the individual components. Those degradation mechanisms are thermally-activated processes, whose rate increases with exposure temperature. Hydrolytic degradation maybe enhanced by exposure to acid, from acid rain or from acids that reside in the coating, for example, acid catalysts used to enhance the rate of cross-linking. Other atmospheric degrading factors, such as ozone and oxides of nitrogen and sulfur, play a minor role compared to photo-oxidation and hydrolysis [

20,

21].

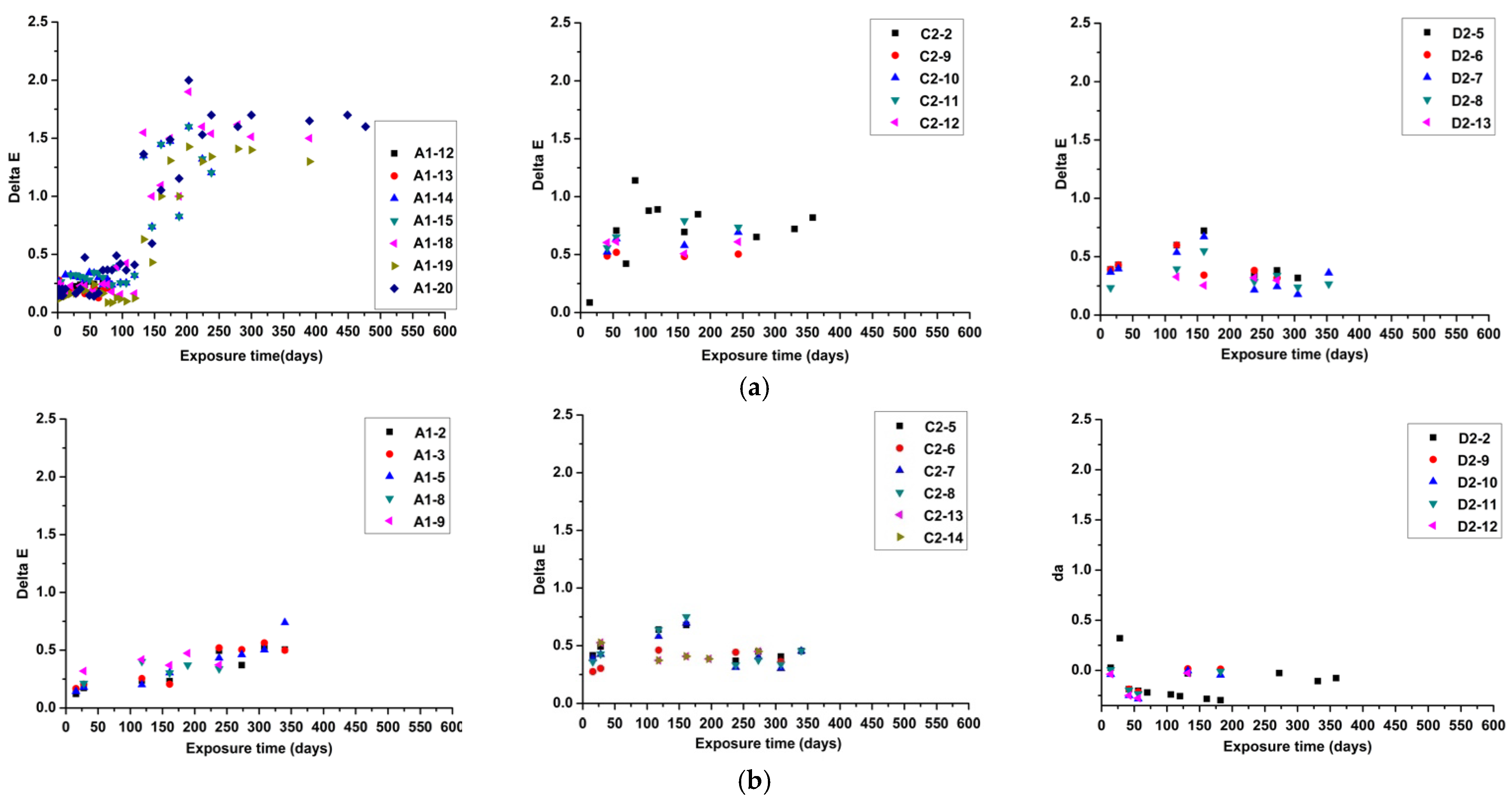

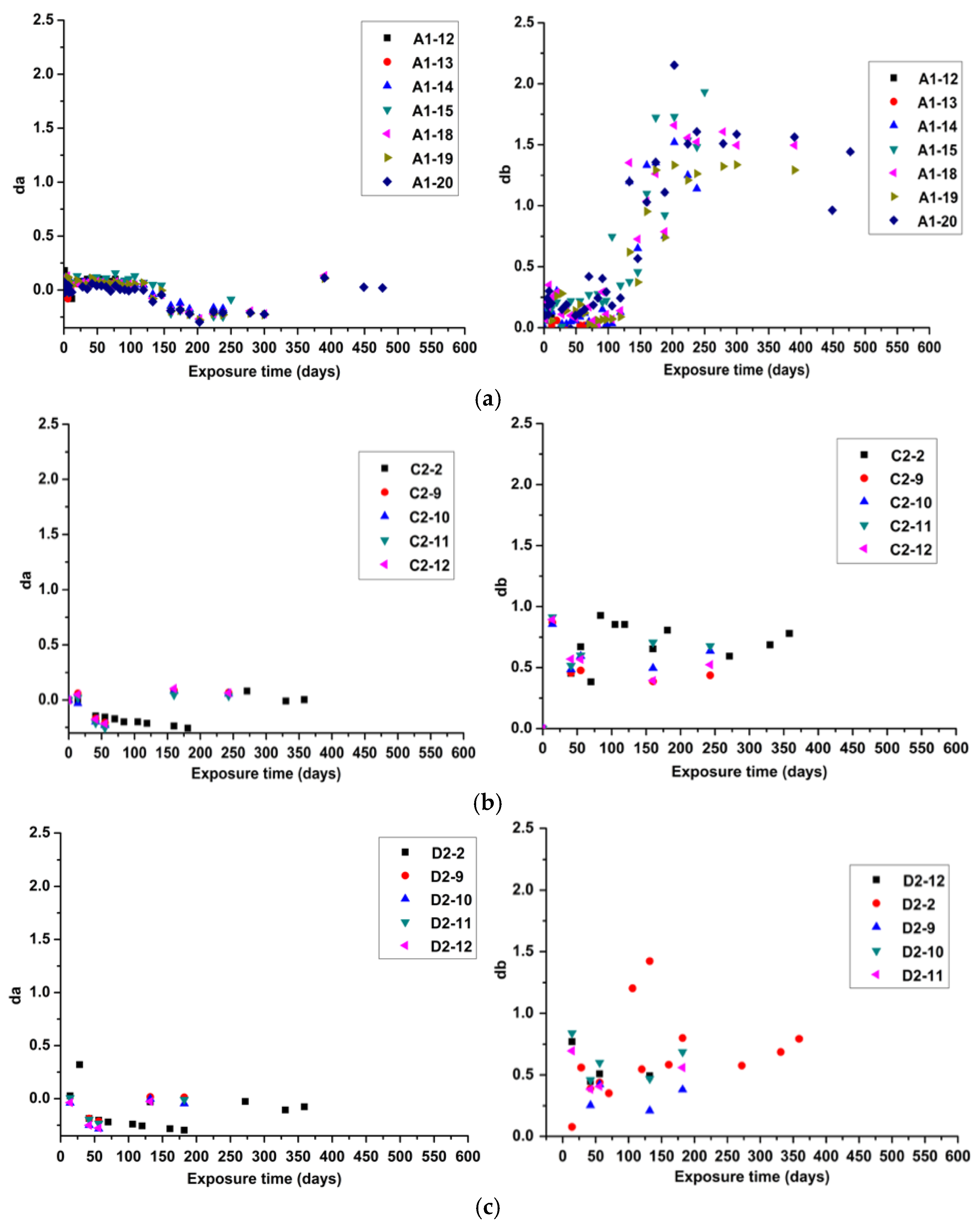

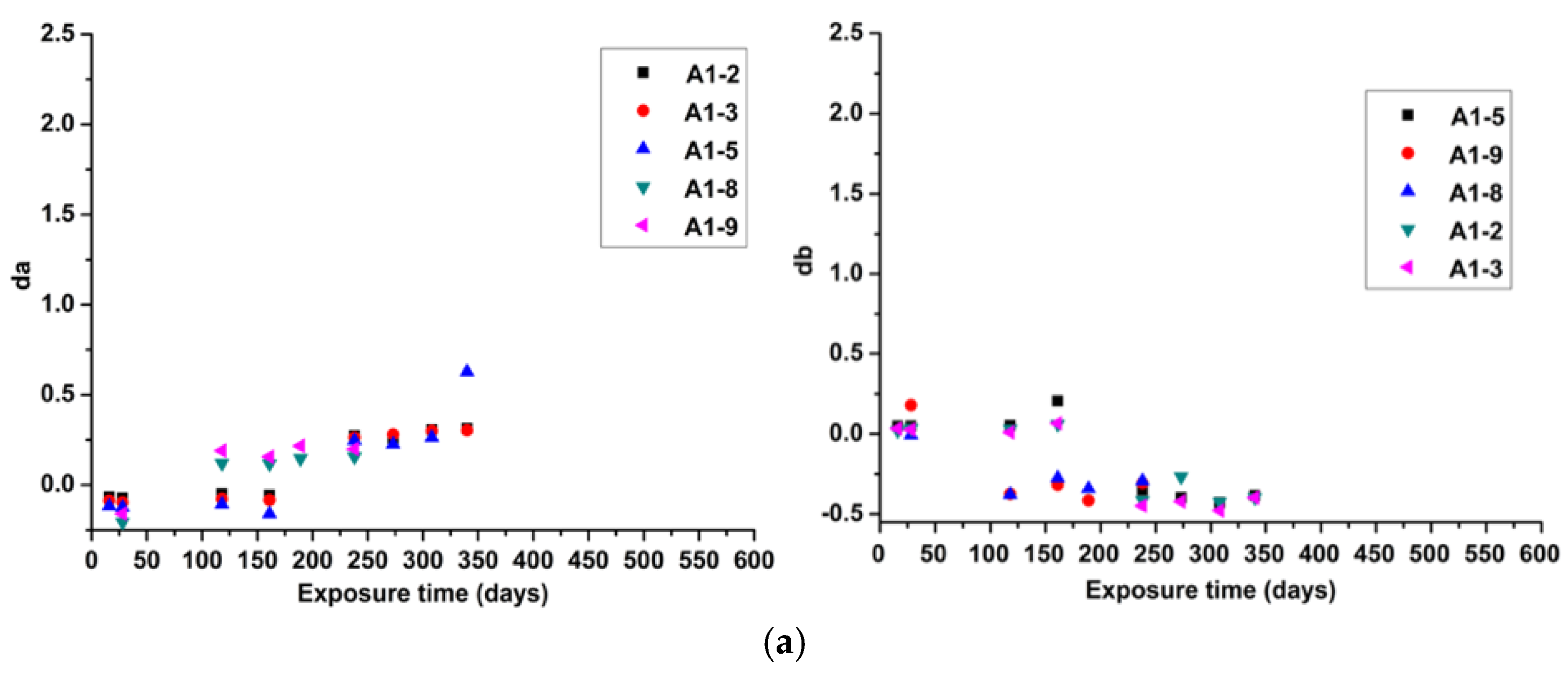

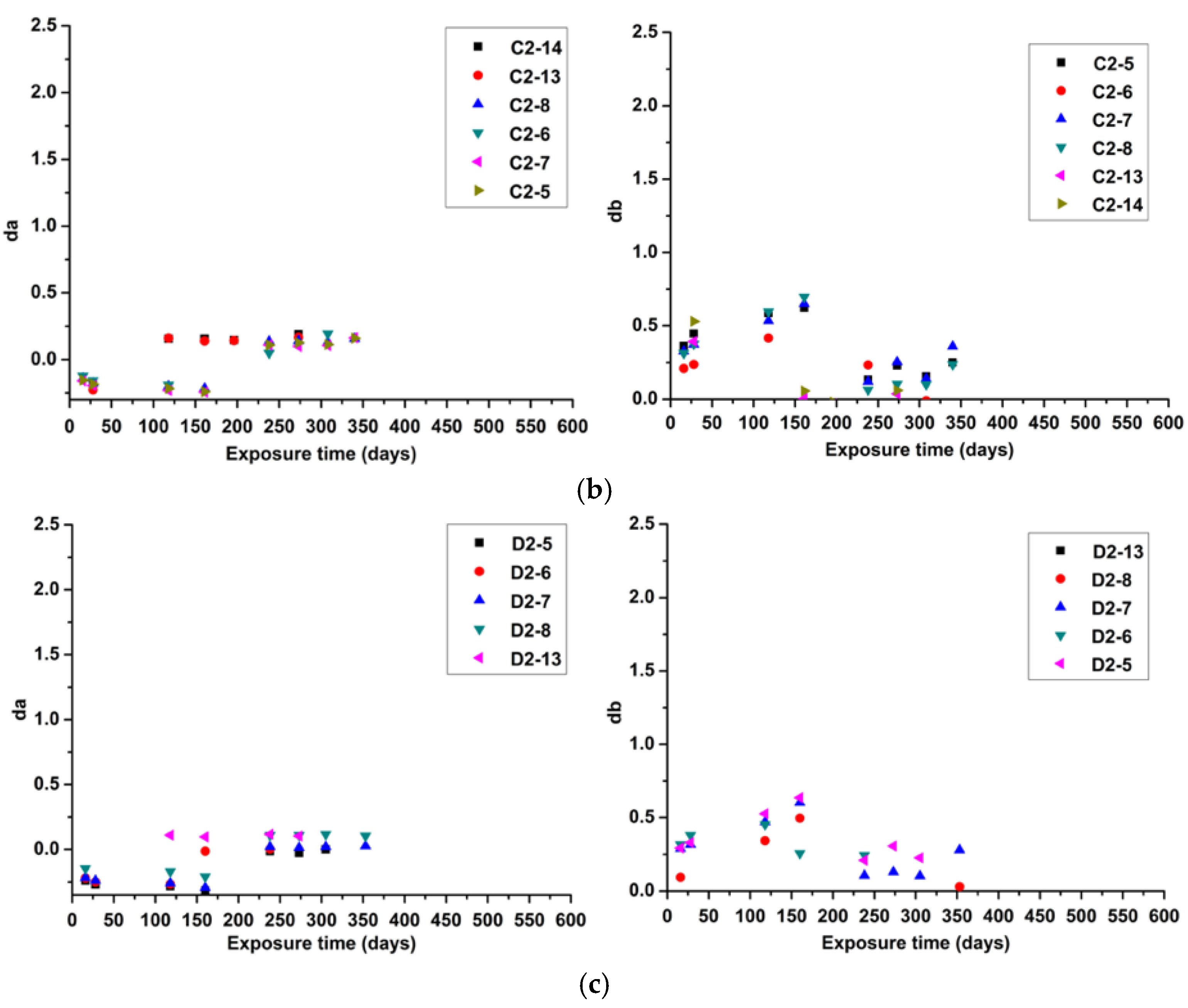

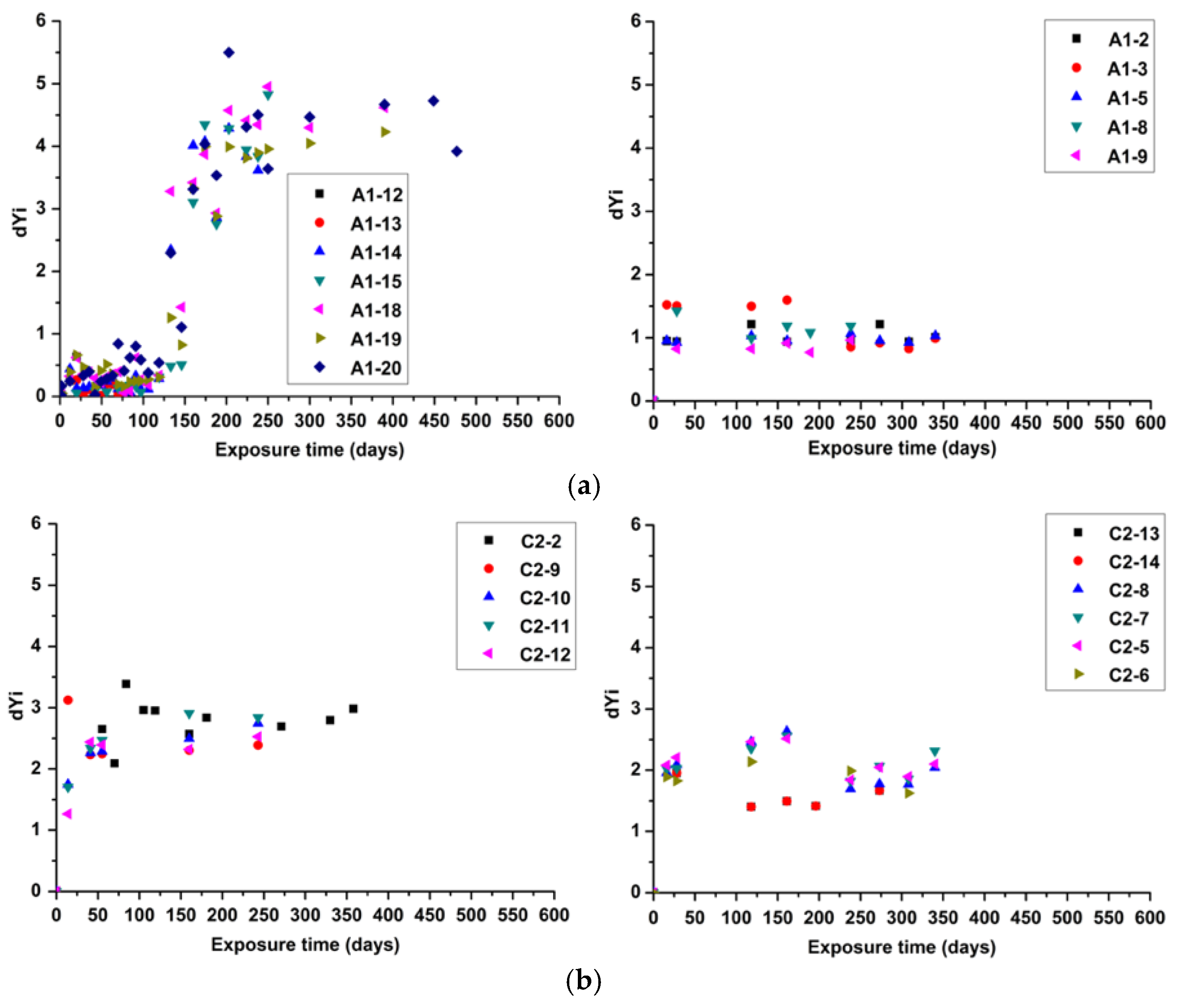

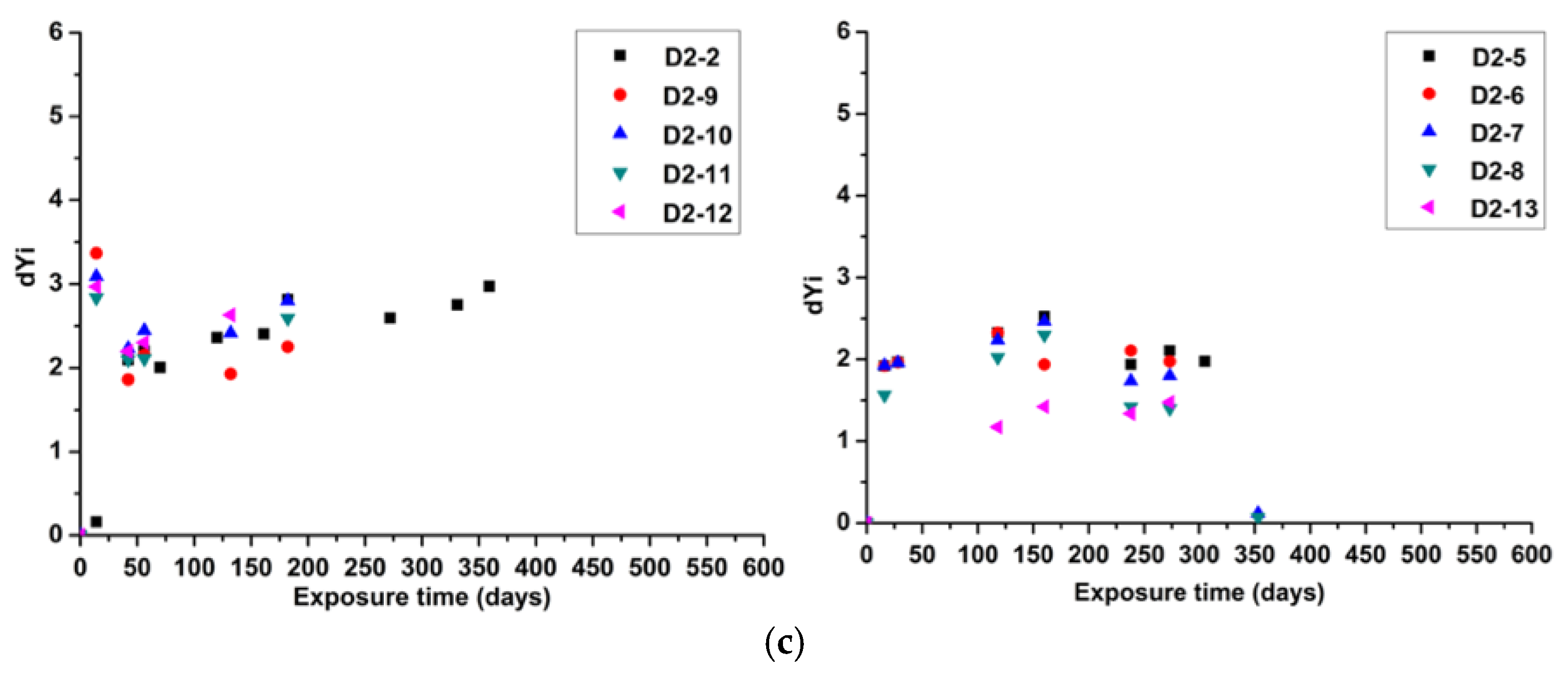

The severity of degradation is related to the aggressivity of exposure environments. The degradation of paint films alters their protective role and causes corrosion of reflective layer and, therefore, decreases the lifetime of solar mirrors. Depending to their application, several factors could influence the durability of paints, such as temperature, solar irradiation, humidity, pollution, and moisture [

23,

24]. The resistance of paint coatings to environmental stress is usually evaluated in term of changes in physical properties or appearance. Thus, paint system weatherability is assessed in terms of embrittlement and cracking, loss of adhesion, loss of gloss, and color change, while corrosion protection is assessed in terms of paint blistering, loss of paint adhesion, and pitting or perforation of the substrate.

Accelerated tests, such as salt-spray test, wet/dry cycle corrosion tests, and a combination of corrosion/weathering tests, and wet/dry corrosion cycles with ultraviolet (UV) condensation cycles, allow evaluating paint resistance under extreme conditions and permit understanding of the effect of each degrading parameter on paint behavior [

20,

25]. These tests are based on correlation of the physical changes induced by the selected test exposure conditions with those observed under some standard conditions (e.g., a defined course of natural exposure). However, analyzing the synergic effect of degradations resulting from all/or some combinations of the degrading factors (temperature, UV irradiation, humidity, salinity, pollution, and moisture) is only possible by using outdoor exposure tests. To achieve a better understanding of the real behavior of paint coatings, indoor tests results should be compared and validated by outdoor testing data.

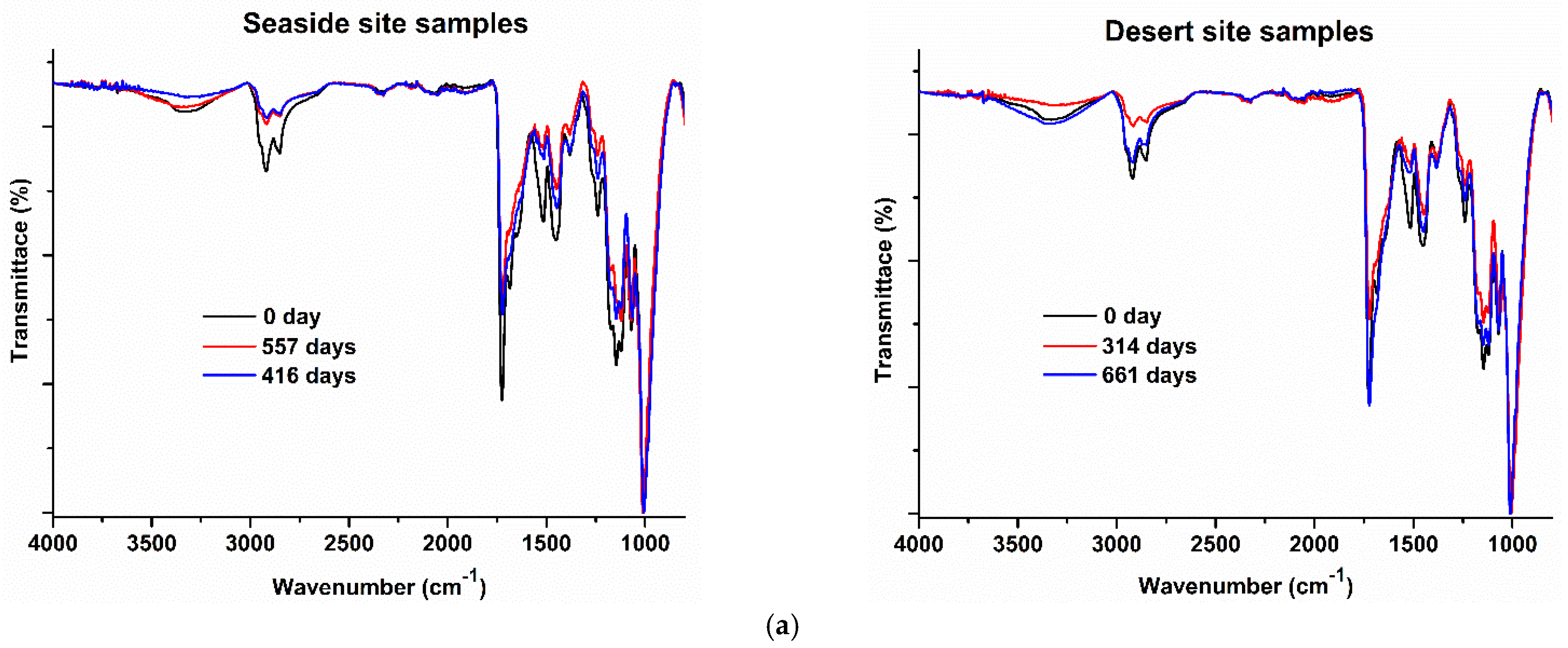

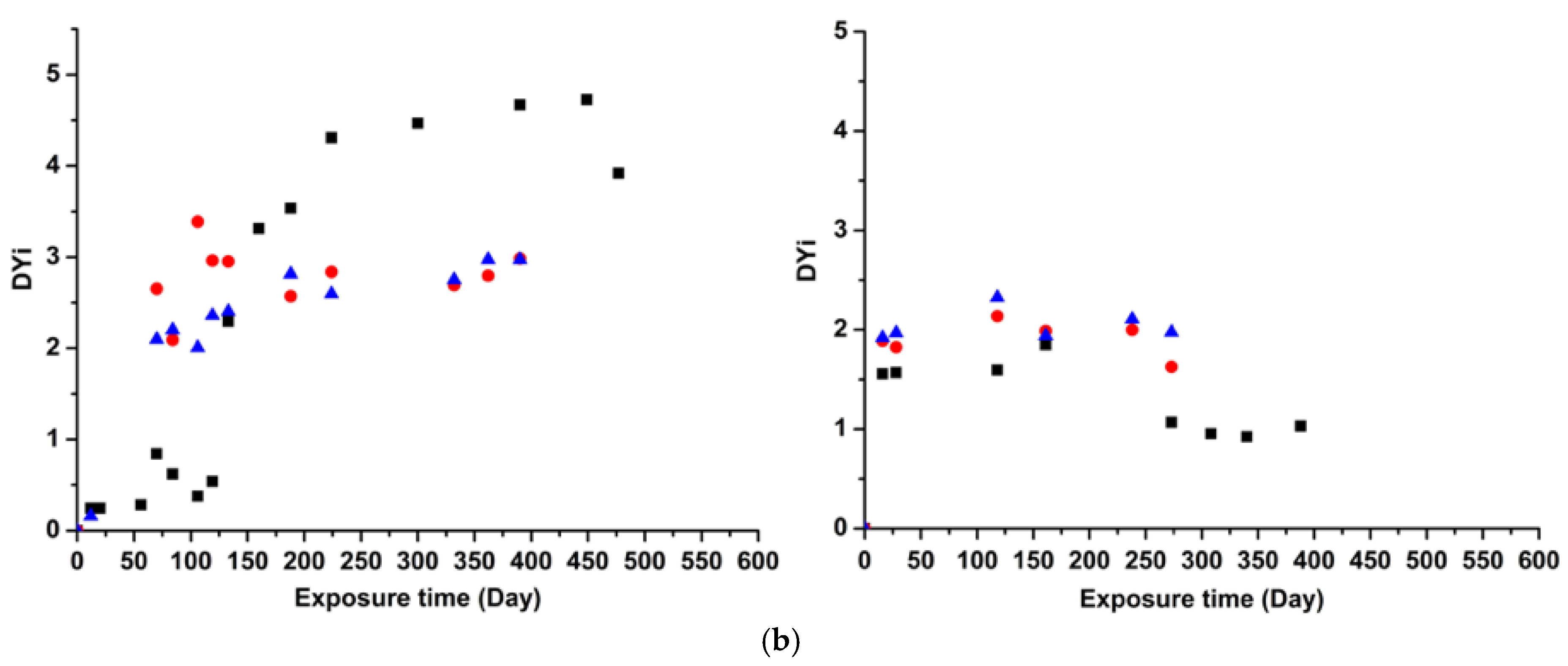

This paper presents the results of outdoor exposure tests of paint coating applied to the backs of three commercial solar glass mirrors exposed under two different climates (marine and desert) in Morocco.

4. Overview and Recommendations

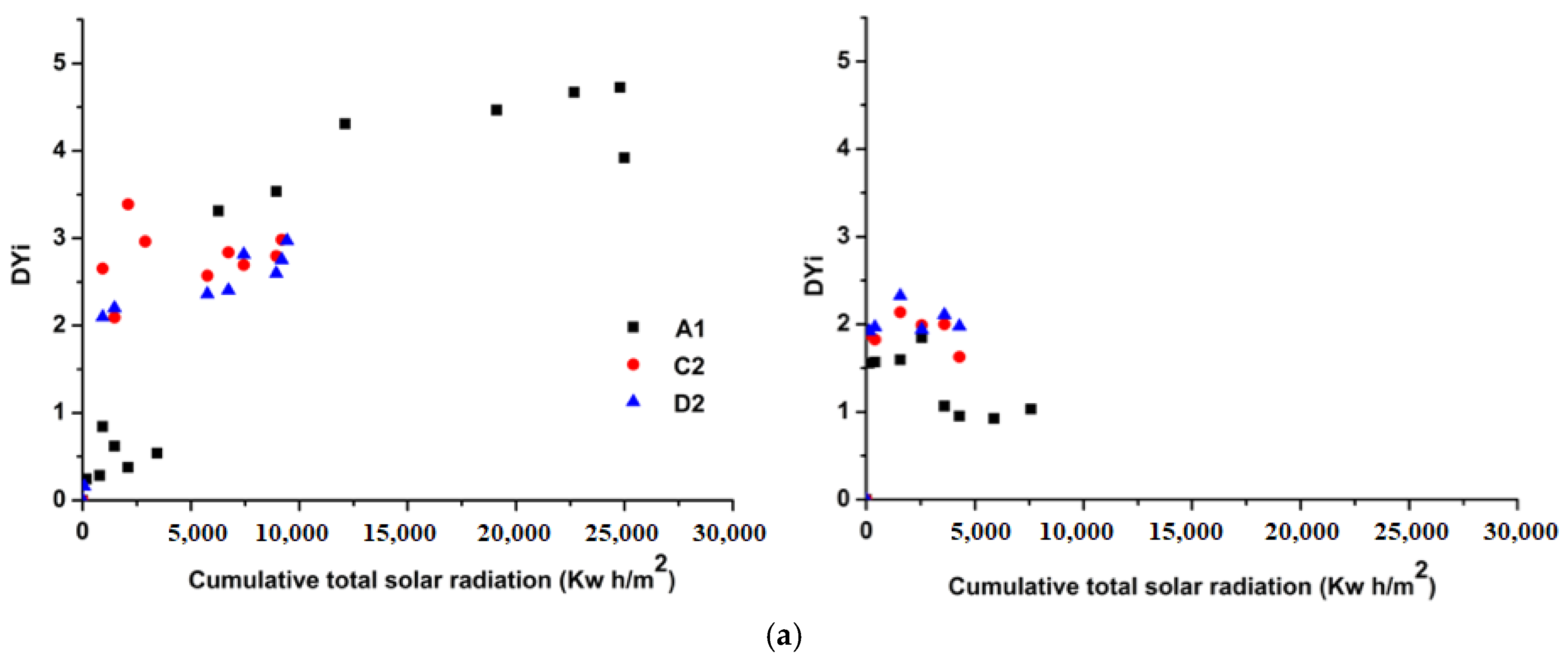

The outdoor tests parameters and the main results obtained from characterizing the aged paints in both exposure sites are summarized in

Table 8. The use of these data will give solar mirrors manufacturers relevant information about the real behavior of paint in desert and marine environmental climates. This will help them to develop best practices for durability testing of solar components and also to choose the most reliable technology of protective paint coatings depending to service conditions of glass mirrors. According to the experimental results of this study, the successful performance of all paints at the desert site, which is characterized by higher irradiation and temperature, indicates that tested paints have high resistance to photo degradation.

For this reason, desert and dry environments could be used to test the resistance of paint against UV radiation. In other hand, the higher rate of degradation in the marine site, characterized by high humidity and salinity, suggests that such extreme environments should be used in order to accelerate the degradation of new developed paints during natural exposure. This will help manufactures to have faster results about paint behavior under natural exposure. As consequence, they will have the possibility to make necessary modifications to their new products after shorter testing time than when using real service conditions or other exposure environments. Additionally, such environments will allow testing the synergic effect of photo degradation and degradation resulting from humidity, salinity, moisture, and rain on paint durability.

Finally, the effect of each climatic and environmental parameter on paint degradation cannot be sufficient analyzed under outdoor exposure. Accelerated exposure tests are important to provide complementary results and also to have an indication of the long-term durability of paints in their end use environment.