Microstructure and Wear Behaviors of Plasma-Sprayed MoAlB Ceramic Coating

Abstract

1. Introduction

2. Materials and Methods

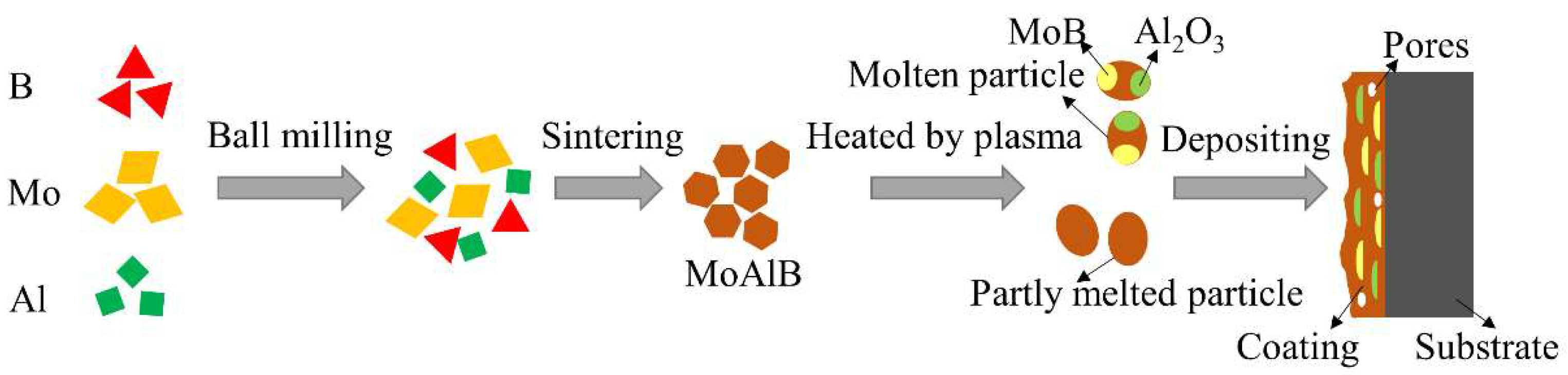

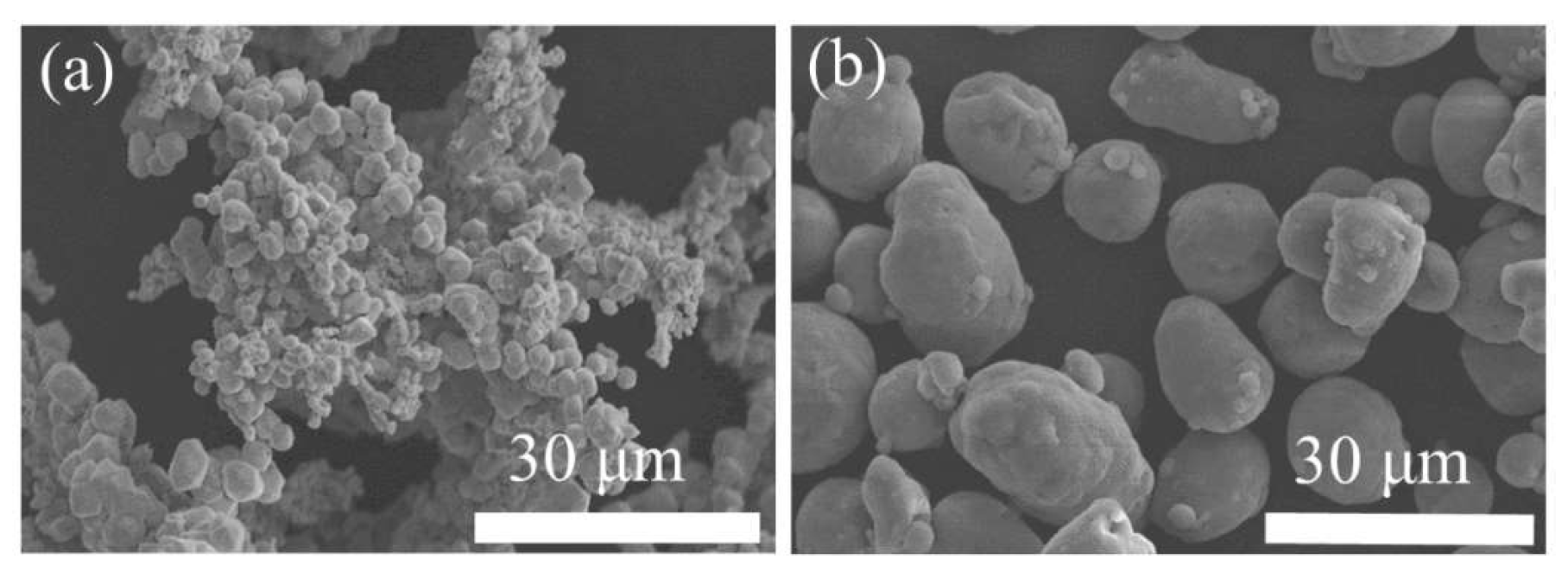

2.1. Fabrication of Feedstock Powder and Coatings

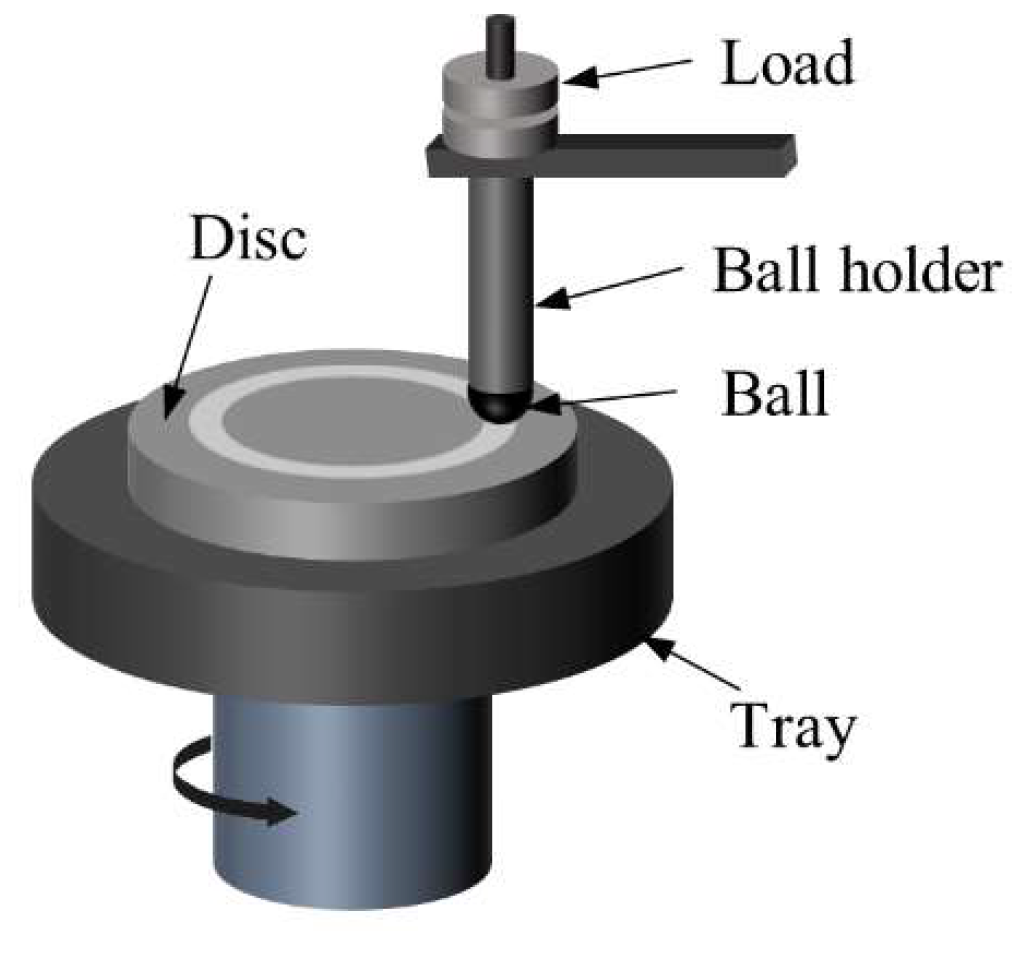

2.2. Tribological Testing

2.3. Characterizations

3. Results

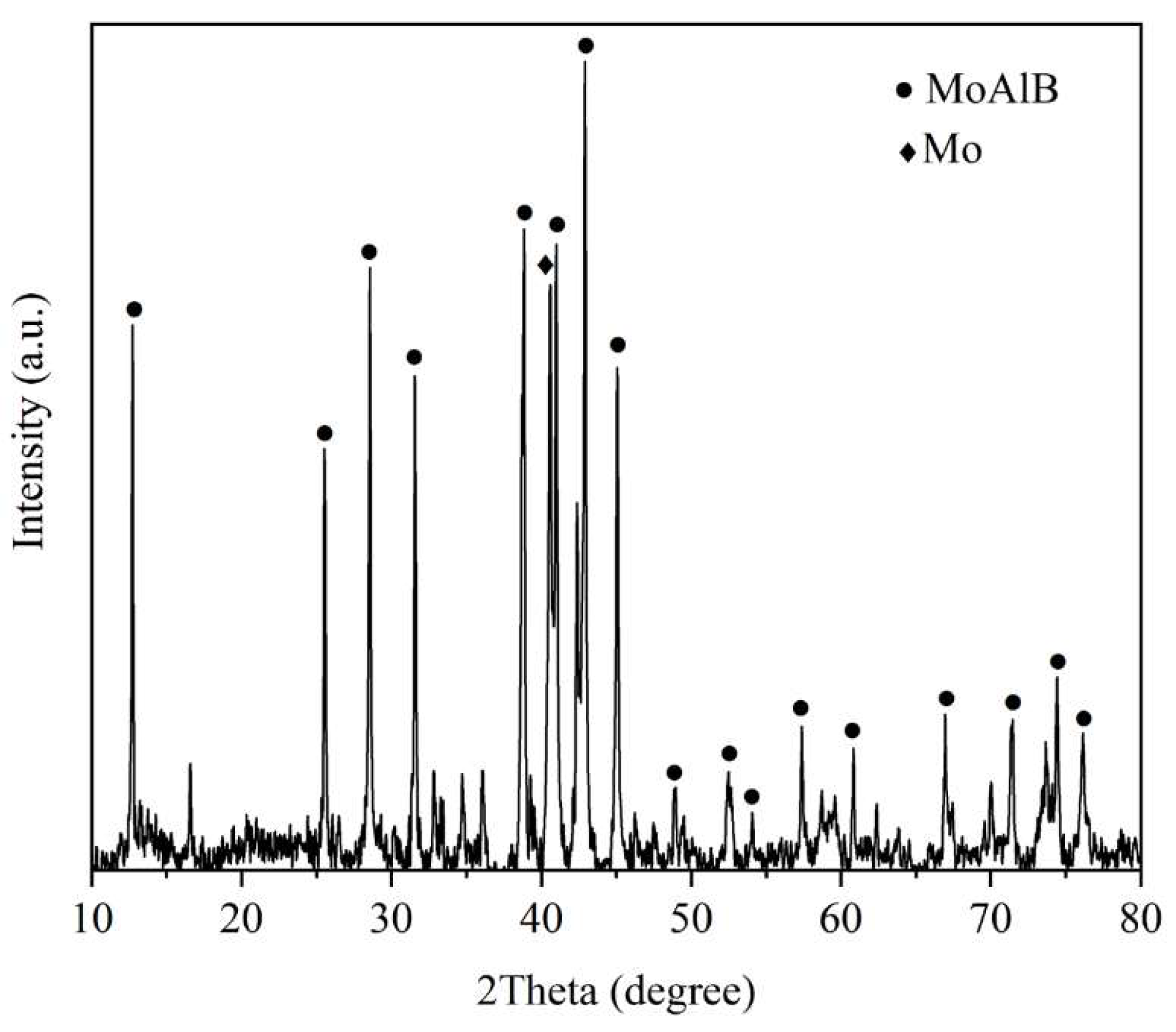

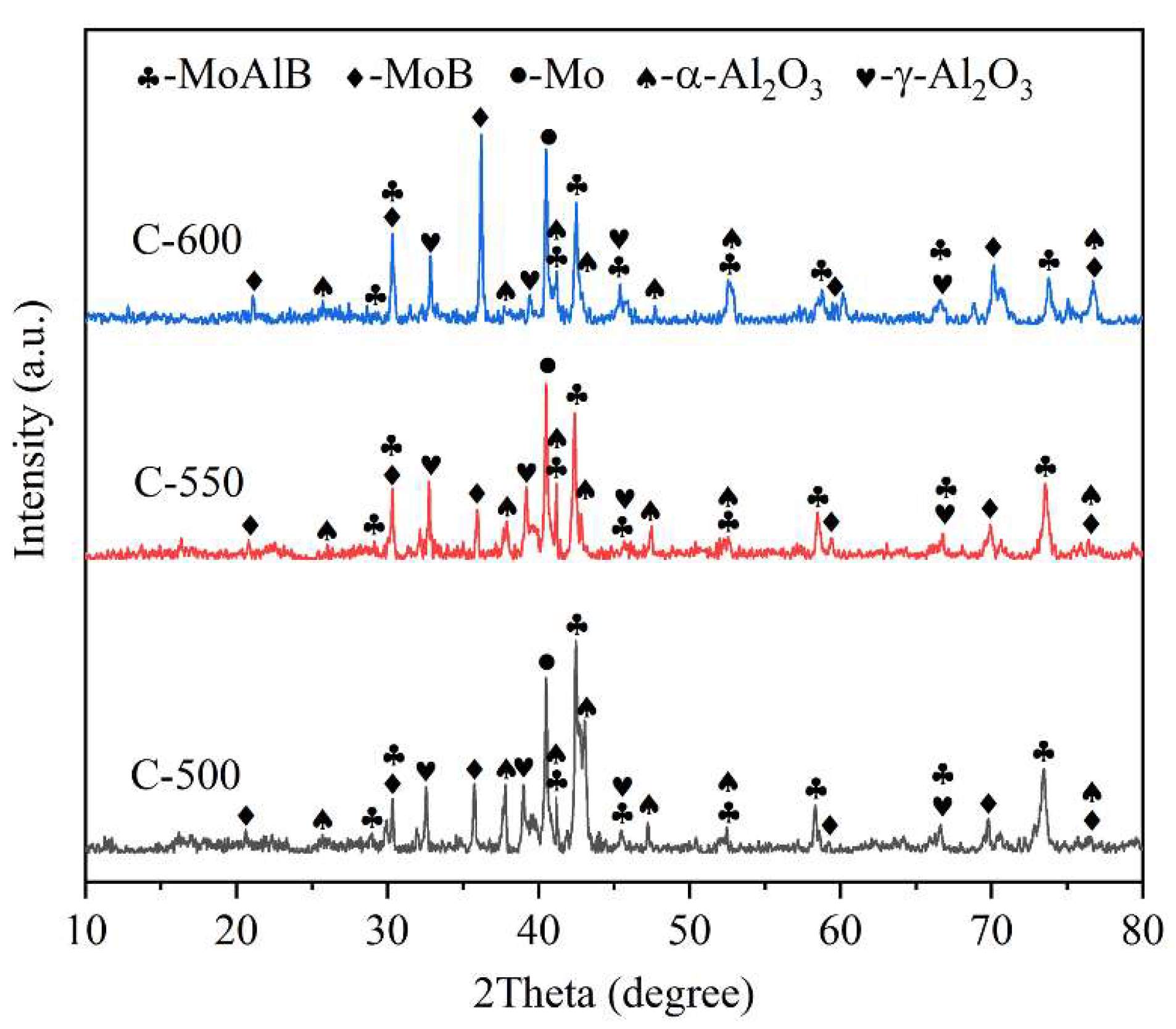

3.1. Characterization of Powders

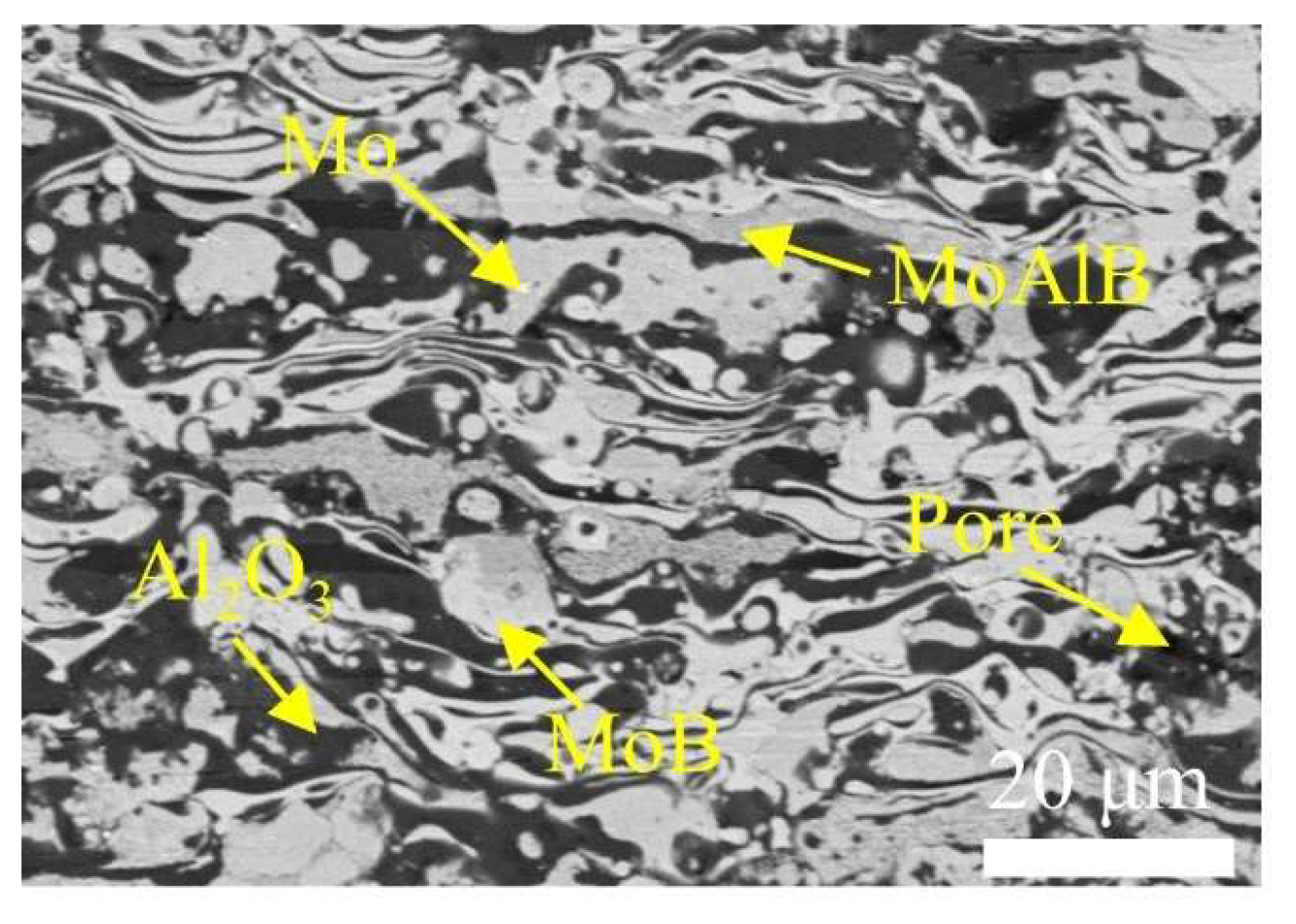

3.2. Microstructure of the Plasma-Sprayed MoAlB Coatings

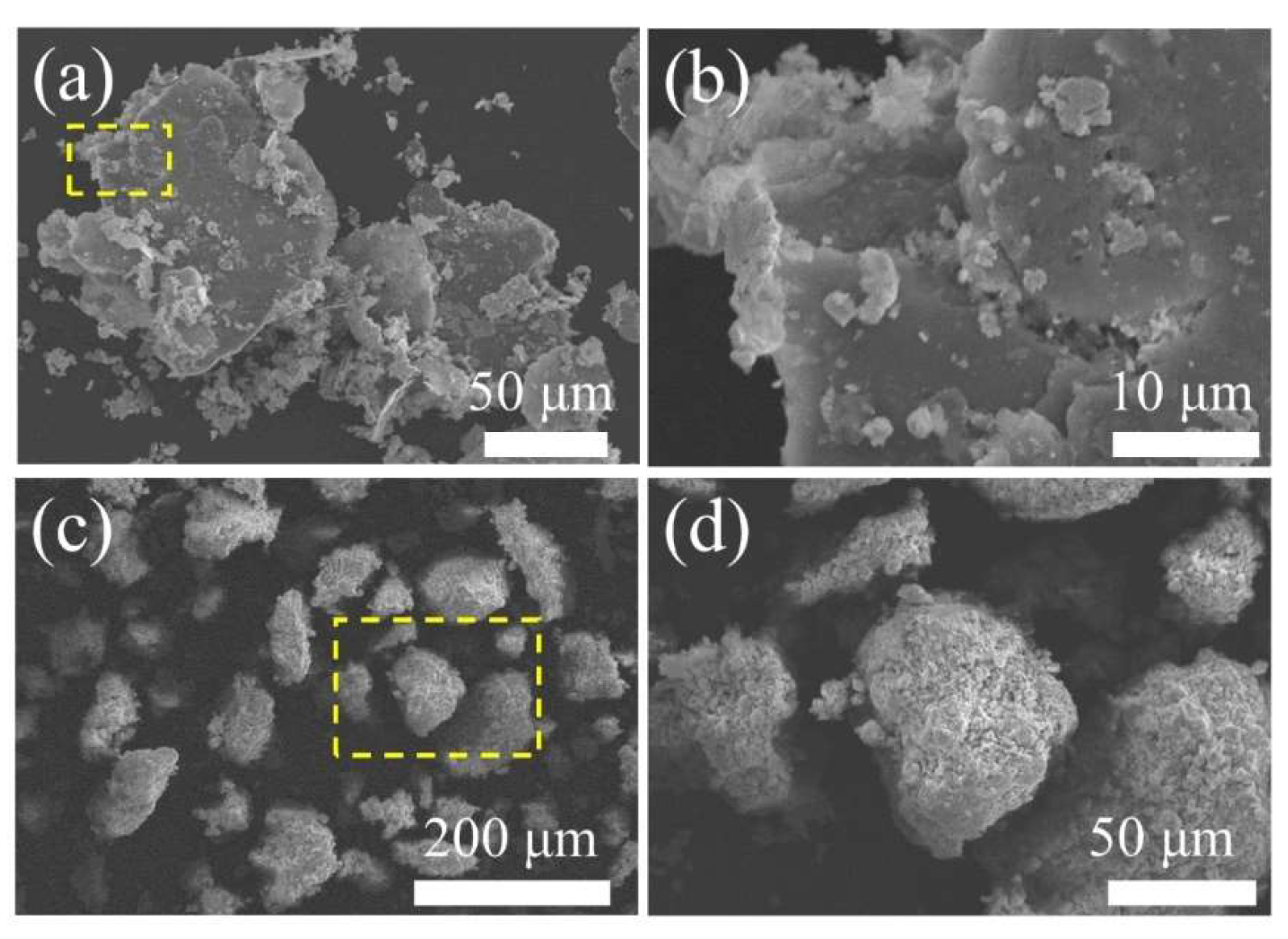

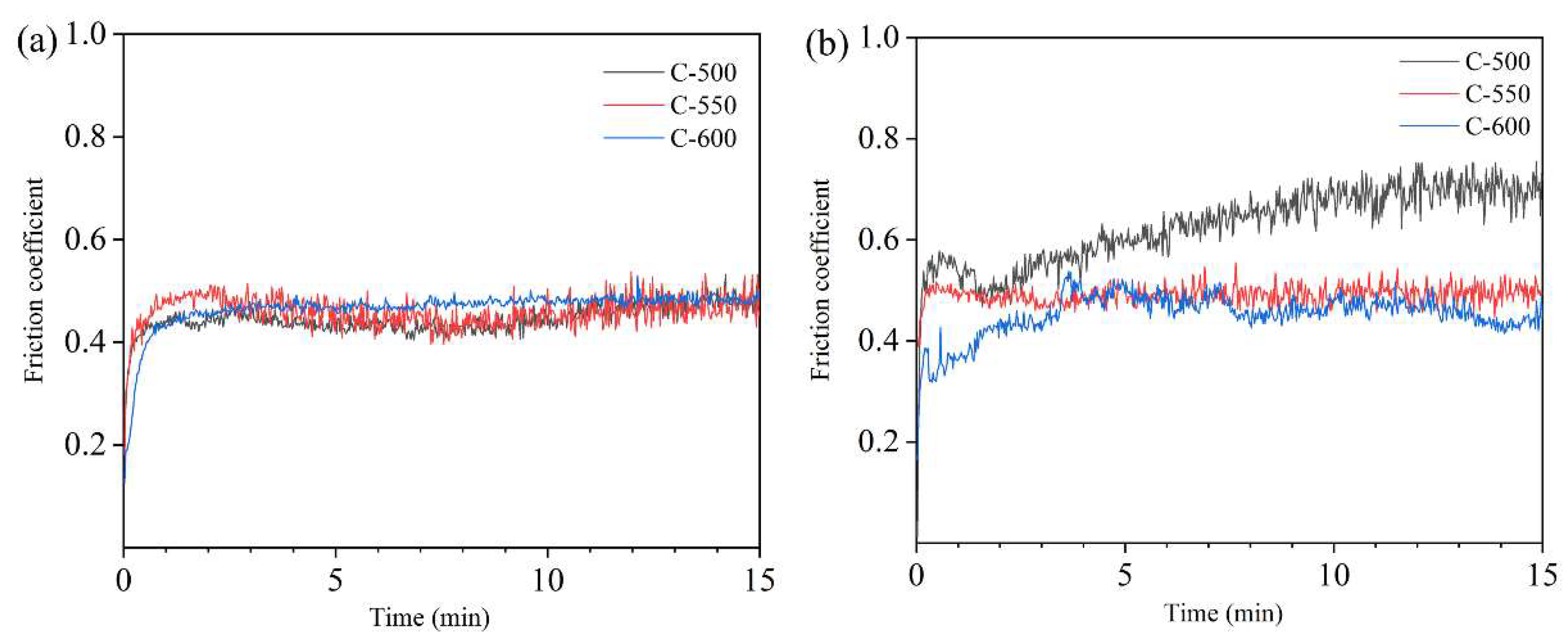

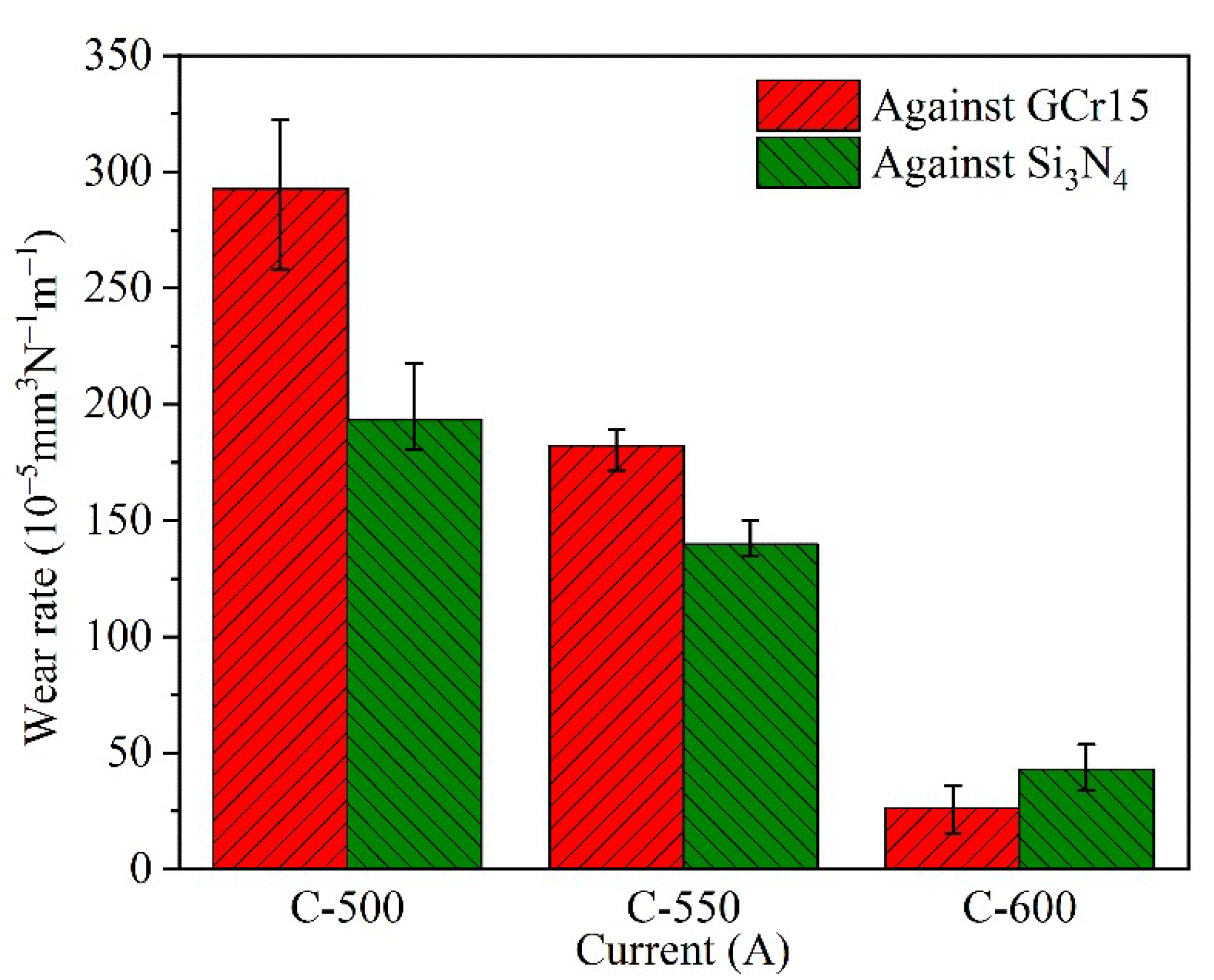

3.3. Tribological Properties

4. Conclusions

- The sprayed MoAlB coatings with different arc power levels consisted of MoAlB, MoB and Al2O3 phases. The MoAlB powder partly decomposed and was oxidized to form MoB and Al2O3. With the increase of power, the decomposition of MoAlB increased, and the compactness of the coatings and the bonding strength of splats increased greatly.

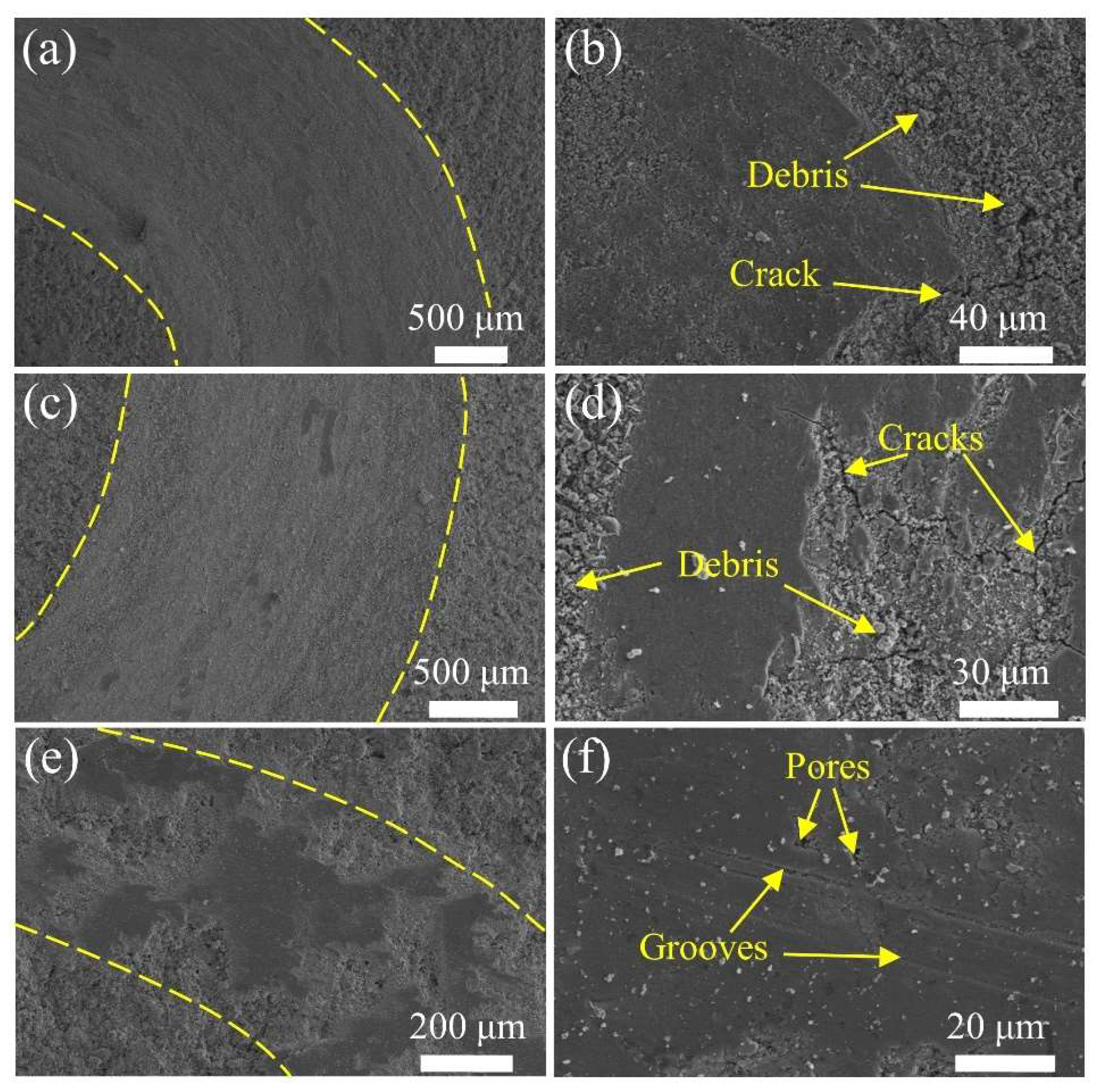

- When MoAlB coatings slid against GCr15, the main wear mechanisms were changed from severe abrasive and adhesive wear to slight abrasive and adhesive wear as the arc power increased from 30 and 33 kW to 36 kW. When the arc power increased to 36 kW, the wear rate was the lowest (26.30 × 10−5 mm3∙N−1m−1).

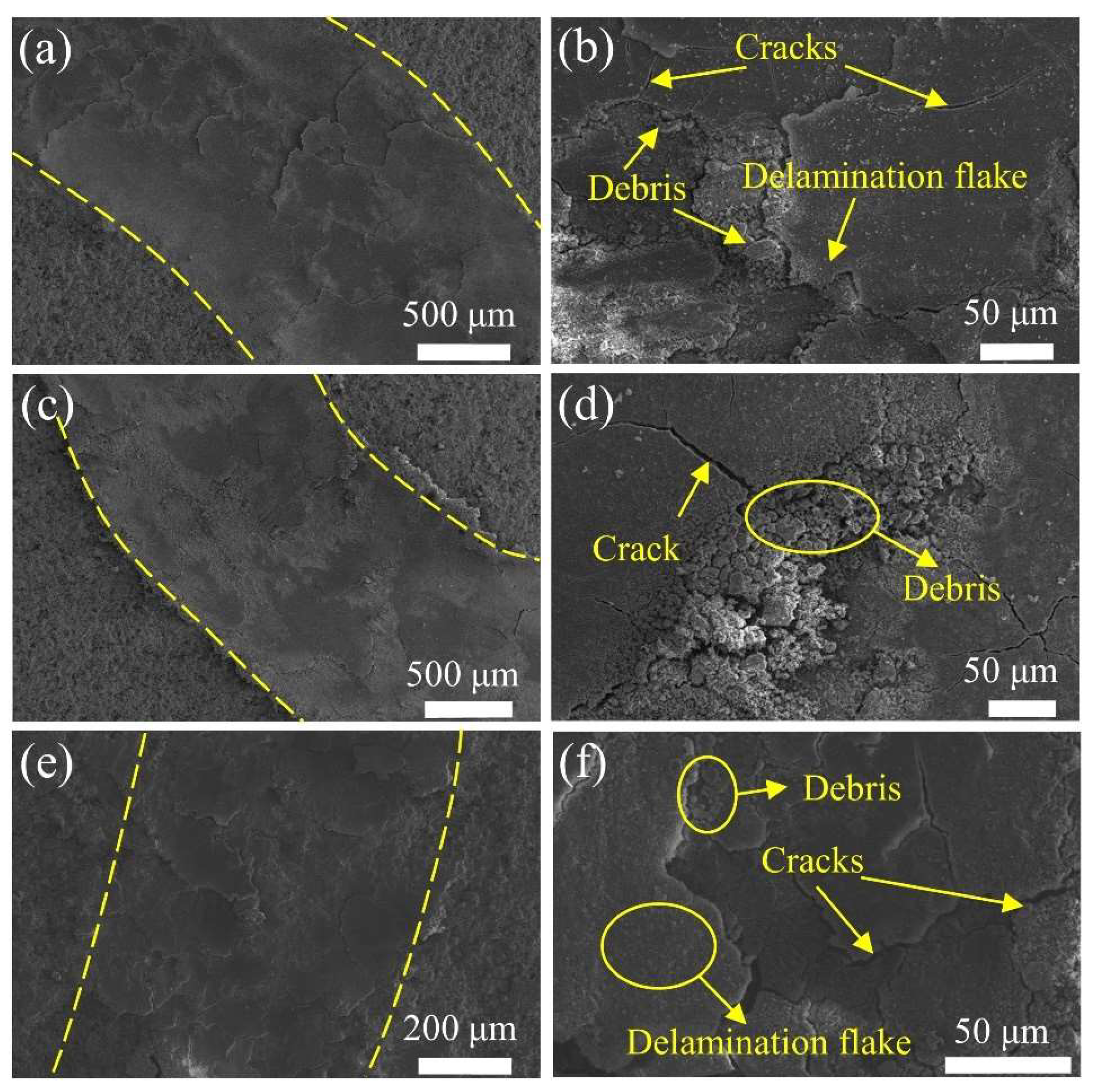

- The main wear mechanism of MoAlB coatings against Si3N4 was abrasive and fatigue wear. The friction coefficient decreased with the arc power, and C-600 showed the lowest wear rate and presented excellent wear resistance. Moreover, MoB and Al2O3 with high hardness greatly improved the wear resistance of the MoAlB coatings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abbas, A.T.; Abubakr, M.; Hassan, M.A.; Luqman, M.; Soliman, M.S.; Hegab, H. An adaptive design for cost, quality and productivity-oriented sustainable machining of stainless steel 316. J. Mater. Res. Technol. 2020, 9, 14568–14581. [Google Scholar] [CrossRef]

- Baltatu, M.S.; Vizureanu, P.; Sandu, A.V.; Munteanu, C.; Istrate, B. Microstructural analysis and tribological behavior of Ti-based alloys with a ceramic layer using the thermal spray method. Coatings 2020, 10, 1216. [Google Scholar] [CrossRef]

- Lamuta, C.; Di Girolamo, G.; Pagnotta, L. Microstructural, mechanical and tribological properties of nanostructured YSZ coatings produced with different APS process parameters. Ceram. Int. 2015, 41, 8904–8914. [Google Scholar] [CrossRef]

- Wang, H.; Yan, X.; Liu, X.; Lu, H.; Hou, C.; Song, X.; Nie, Z. Microstructure, mechanical and tribological properties of WC-WCoB coating. J. Eur. Ceram. Soc. 2018, 38, 4874–4881. [Google Scholar] [CrossRef]

- Bhosale, D.G.; Rathod, W.S. Tribo-behaviour of APS and HVOF sprayed WC–Cr3C2–Ni coatings for gears. Surf. Eng. 2020, 37, 80–90. [Google Scholar] [CrossRef]

- Xiao, J.; Wu, Y.; Zhang, W.; Chen, J.; Wei, X.; Zhang, C. Microstructure, wear and corrosion behaviors of plasma sprayed NiCrBSi-Zr coating. Surf. Coat. Technol. 2019, 360, 172–180. [Google Scholar] [CrossRef]

- Su, X.; Dong, J.; Chu, L.; Sun, H.; Grasso, S.; Hu, C. Synthesis, microstructure and properties of MoAlB ceramics prepared by in situ reactive spark plasma sintering. Ceram. Int. 2020, 46, 15214–15221. [Google Scholar] [CrossRef]

- Wang, S.; Xu, Y.; Yu, Z.; Tan, H.; Du, S.; Zhang, Y.; Yang, J.; Liu, W. Synthesis, microstructure and mechanical properties of a MoAlB ceramic prepared by spark plasma sintering from elemental powders. Ceram. Int. 2019, 45, 23515–23521. [Google Scholar] [CrossRef]

- Xu, L.; Shi, O.; Liu, C.; Zhu, D.; Grasso, S.; Hu, C. Synthesis, microstructure and properties of MoAlB ceramics. Ceram. Int. 2018, 44, 13396–13401. [Google Scholar] [CrossRef]

- Benamor, A.; Kota, S.; Chiker, N.; Haddad, A.; Hadji, Y.; Natu, V.; Abdi, S.; Yahi, M.; Benamar, M.E.; Sahraoui, T.; et al. Friction and wear properties of MoAlB against Al2O3 and 100Cr6 steel counterparts. J. Eur. Ceram. Soc. 2019, 39, 868–877. [Google Scholar] [CrossRef]

- Yu, Z.; Tan, H.; Wang, S.; Cheng, J.; Sun, Q.; Yang, J.; Liu, W. High-temperature tribological behaviors of MoAlB ceramics sliding against Al2O3 and Inconel 718 alloy. Ceram. Int. 2020, 46, 14713–14720. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, D.; Li, M.; Ren, F.; Duan, C.; Zhao, Z.; Chen, Y.; Wang, Y. Preparation and anisotropic tribological properties of MoAlB/Al laminated composites. Ceram. Int. 2021, 47, 5028–5037. [Google Scholar] [CrossRef]

- Tan, H.; Sun, Q.; Zhu, S.; Cheng, J.; Wang, S.; Yang, J. High temperature tribological behavior of Mo–12Si–8.5B alloy reinforced with MoAlB ceramic. Tribol. Int. 2020, 150, 106344. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Y.; Yu, Z.; Planche, M.-P.; Peyraut, F.; Liao, H.; LaSalle, A.; Allimant, A.; Montavon, G. Microstructural, mechanical and tribological properties of suspension plasma sprayed YSZ/h-BN composite coating. J. Eur. Ceram. Soc. 2018, 38, 4512–4522. [Google Scholar] [CrossRef]

- Babu, P.S.; Sen, D.; Jyothirmayi, A.; Krishna, L.R.; Rao, D.S. Influence of microstructure on the wear and corrosion behavior of detonation sprayed Cr2O3-Al2O3 and plasma sprayed Cr2O3 coatings. Ceram. Int. 2018, 44, 2351–2357. [Google Scholar] [CrossRef]

- Wang, C.; Gao, P.; Liu, T.; Li, L.; Wang, E.; Wang, Q. Microstructure and wear performance of Ni-10 wt.%Al coatings plasma sprayed on Ni-based superalloys with a sound field. Surf. Coat. Technol. 2019, 370, 157–162. [Google Scholar] [CrossRef]

- Zhang, Z.; Lim, S.H.; Chai, J.; Lai, D.M.Y.; Cheong, A.K.H.; Cheong, K.L.; Wang, S.J.; Jin, H.; Pan, J.S. Plasma spray of Ti2AlC MAX phase powders: Effects of process parameters on coatings’ properties. Surf. Coat. Technol. 2017, 325, 429–436. [Google Scholar] [CrossRef]

- Zhang, L.; Liao, X.-J.; Zhang, S.-L.; Luo, X.-T.; Li, C.-J. Effect of powder particle size and spray parameters on the Ni/Al reaction during plasma spraying of Ni–Al composite powders. J. Therm. Spray Technol. 2021, 30, 181–195. [Google Scholar] [CrossRef]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; De Lacalle, L.N.L.; Polvorosa, R. Enhanced performance of nanostructured coatings for drilling by droplet elimination. Mater. Manuf. Process. 2016, 31, 593–602. [Google Scholar] [CrossRef]

- Kota, S.; Agne, M.; Zapata-Solvas, E.; Dezellus, O.; Lopez, D.; Gardiola, B.; Radovic, M.; Barsoum, M.W. Elastic properties, thermal stability, and thermodynamic parameters of MoAlB. Phys. Rev. B 2017, 95, 144108. [Google Scholar] [CrossRef]

- Bei, G.; Van Der Zwaag, S.; Kota, S.; Barsoum, M.W.; Sloof, W.G. Ultra-high temperature ablation behavior of MoAlB ceramics under an oxyacetylene flame. J. Eur. Ceram. Soc. 2019, 39, 2010–2017. [Google Scholar] [CrossRef]

- Kota, S.; Zapata-Solvas, E.; Chen, Y.; Radovic, M.; Lee, W.E.; Barsoum, M.W. Isothermal and cyclic oxidation of MoAlB in air from 1100 °C to 1400 °C. J. Electrochem. Soc. 2017, 164, C930–C938. [Google Scholar] [CrossRef]

- Basha, G.M.T.; Srikanth, A.; Venkateshwarlu, B. Effect of reinforcement of carbon nanotubes on air plasma sprayed conventional Al2O3-3%TiO2 ceramic coatings. Mater. Today Proc. 2019, 20, 191–194. [Google Scholar] [CrossRef]

- Yang, K.; Li, J.; Wang, Q.; Li, Z.; Jiang, Y.; Bao, Y. Effect of laser remelting on microstructure and wear resistance of plasma sprayed Al2O3-40%TiO2 coating. Wear 2019, 426–427, 314–318. [Google Scholar] [CrossRef]

- Zhu, L.; Zhu, Y.; Ren, X.; Zhang, P.; Qiao, J.; Feng, P. Microstructure, properties and oxidation behavior of MoSi2-MoB-ZrO2 coating for Mo substrate using spark plasma sintering. Surf. Coat. Technol. 2019, 375, 773–781. [Google Scholar] [CrossRef]

- Zhang, P.; Guo, X.; Ren, X.; Chen, Z.; Shen, C. Development of Mo(Si,Al)2-MoB composite coatings to protect TZM alloy against oxidation at 1400 °C. Intermetallics 2018, 93, 134–140. [Google Scholar] [CrossRef]

- Kowalski, S. Failure analysis of the elements of a forced-in joint operating in rotational bending conditions. Eng. Fail. Anal. 2020, 118, 104864. [Google Scholar] [CrossRef]

- Polvorosa, R.; Suárez, A.; de Lacalle, L.L.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Lu, X.; Li, S.; Zhang, W.; Yu, W.; Zhou, Y. Thermal shock behavior of a nanolaminated ternary boride: MoAlB. Ceram. Int. 2019, 45, 9386–9389. [Google Scholar] [CrossRef]

- Chen, Y.; Kota, S.; Barsoum, M.W.; Radovic, M. Compressive deformation of MoAlB up to 1100 °C. J. Alloys Compd. 2019, 774, 1216–1222. [Google Scholar] [CrossRef]

- Rajpoot, P.; Rastogi, A.; Verma, U.P. Systematic investigation of structural, electronic, optical and thermal properties of ternary MoAlB; an ab initio approach. Mater. Res. Express 2018, 5, 025701. [Google Scholar] [CrossRef]

- Shi, O.; Xu, L.; Jiang, A.; Xu, Q.; Xiao, Y.; Zhu, D.; Grasso, S.; Hu, C. Synthesis and oxidation resistance of MoAlB single crystals. Ceram. Int. 2019, 45, 2446–2450. [Google Scholar] [CrossRef]

- Hashemi, S.M.; Parvin, N.; Valefi, Z. Effect of microstructure and mechanical properties on wear behavior of plasma-sprayed Cr2O3-YSZ-SiC coatings. Ceram. Int. 2019, 45, 5284–5296. [Google Scholar] [CrossRef]

- Fernández-Abia, A.I.; Barreiro, J.; De Lacalle, L.N.L.; González-Madruga, D. Effect of mechanical pre-treatments in the behaviour of nanostructured PVD-coated tools in turning. Int. J. Adv. Manuf. Technol. 2014, 73, 1119–1132. [Google Scholar] [CrossRef]

- Huang, C.; Yang, K.; Li, N.; Li, W.; Planche, M.; Verdy, C.; Liao, H.; Montavon, G. Microstructures and wear-corrosion performance of vacuum plasma sprayed and cold gas dynamic sprayed Muntz alloy coatings. Surf. Coat. Technol. 2019, 371, 172–184. [Google Scholar] [CrossRef]

- Huang, T.; Deng, C.; Song, P.; Lü, J.; Li, C.; Shu, Y.; Sun, B.; Ahmad, S.A.; Ji, Q.; Yi, J. Effect of the interface morphology and initial nanocrack on the fracture property of a ceramic reinforced plasma-sprayed coating. Ceram. Int. 2020, 46, 24930–24939. [Google Scholar] [CrossRef]

- Venkateshwarlu, B.; Basha G, M.T.; Srikanth, A. Influence of critical plasma spray parameter on microstructural and tribo-logical characteristics of nanostructured tungsten carbide-cobalt coatings. Proced. Manuf. 2019, 30, 339–346. [Google Scholar] [CrossRef]

- Xu, X.; Su, F.; Li, Z. Microstructure and tribological behaviors of MoN-Cu nanocomposite coatings sliding against Si3N4 ball under dry and oil-lubricated conditions. Wear 2019, 434–435, 202994. [Google Scholar] [CrossRef]

- Kota, S.; Zapata-Solvas, E.; Ly, A.; Lu, J.; Elkassabany, O.; Huon, A.; Lee, W.E.; Hultman, L.; May, S.J.; Barsoum, M.W. Synthesis and characterization of an alumina forming nanolaminated boride: MoAlB. Sci. Rep. 2016, 6, 26475. [Google Scholar] [CrossRef]

- Misra, V.C.; Chakravarthy, Y.; Khare, N.; Singh, K.; Ghorui, S. Strongly adherent Al2O3 coating on SS 316L: Optimization of plasma spray parameters and investigation of unique wear resistance behaviour under air and nitrogen environment. Ceram. Int. 2020, 46, 8658–8668. [Google Scholar] [CrossRef]

- Li, M.; Wei, K.X.; Wei, W.; Du, Q.B.; Zhao, X.B.; Hu, J. Thermal shock behaviours of atmospheric plasma sprayed NiCrAlY/Al2O3–20%TiO2 gradient coating on Cu–Be alloy. Surf. Eng. 2020, 36, 1113–1120. [Google Scholar] [CrossRef]

- Deng, W.; Li, S.; Hou, G.; Liu, X.; Zhao, X.; An, Y.; Zhou, H.; Chen, J. Comparative study on wear behavior of plasma sprayed Al2O3 coatings sliding against different counterparts. Ceram. Int. 2017, 43, 6976–6986. [Google Scholar] [CrossRef]

- Gou, J.; Zhang, J.; Zhang, Q.; Wang, Y.; Wang, C. Effect of Nano-Si3N4 Additives and plasma treatment on the dry sliding wear behavior of plasma sprayed Al2O3-8YSZ ceramic coatings. J. Therm. Spray Technol. 2017, 26, 764–777. [Google Scholar] [CrossRef]

- Tillmann, W.; Khalil, O.; Baumann, I. Influence of direct splat-affecting parameters on the splat-type distribution, porosity, and density of segmentation cracks in plasma-sprayed YSZ coatings. J. Therm. Spray Technol. 2021, 1–13. [Google Scholar] [CrossRef]

- Liu, C.; Sun, J.; Venturi, F.; Romero, A.R.; Hussain, T. Microstructure and wear performance of alumina/graphene coating on textured Al2O3/TiC substrate composites. J. Eur. Ceram. Soc. 2021, 41, 1438–1451. [Google Scholar] [CrossRef]

- Xiao, J.; Li, T.; Wu, Y.; Chen, J.; Zhang, C. Microstructure and tribological properties of plasma-sprayed CoCrFeNi-based high-entropy alloy coatings under dry and oil-lubricated sliding conditions. J. Therm. Spray Technol. 2021, 1–11. [Google Scholar] [CrossRef]

- Xi, H.-H.; He, P.-F.; Wang, H.-D.; Liu, M.; Chen, S.-Y.; Xing, Z.-G.; Ma, G.-Z.; Lv, Z.-L. Microstructure and mechanical properties of Mo coating deposited by supersonic plasma spraying. Int. J. Refract. Met. Hard Mater. 2020, 86, 105095. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Arc power, kW | 30, 33, 36 |

| Arc current, A | 500, 550, 600 |

| Arc voltage, V | 60 |

| Primary gas (Ar), L/min | 45 |

| Secondary gas (H2), L/min | 6 |

| Powder feed rate, L/min | 5 |

| Powder feed speed, r/min | 2 |

| Spraying distance, mm | 70 |

| Element | C-500 | C-550 | C-600 | |||

|---|---|---|---|---|---|---|

| wt.% | at.% | wt.% | at.% | wt.% | at.% | |

| Mo | 30.25 | 13.17 | 20.1 | 7.01 | 7.47 | 2.56 |

| Al | 10.32 | 14.40 | 9.3 | 11.53 | 3.83 | 4.41 |

| O | 16.67 | 40.39 | 26.25 | 54.85 | 24.08 | 50.78 |

| Fe | 40.83 | 30.63 | 43.06 | 25.78 | 63.21 | 41.30 |

| Cr | 1.92 | 1.42 | 1.29 | 0.83 | 1.41 | 0.95 |

| Element | C-500 | C-550 | C-600 | |||

|---|---|---|---|---|---|---|

| wt.% | at.% | wt.% | at.% | wt.% | at.% | |

| Mo | 43.74 | 14.16 | 59.65 | 30.34 | 59.42 | 23.93 |

| Al | 14.79 | 15.04 | 17.36 | 19.03 | 9.41 | 12.66 |

| O | 36.30 | 65.63 | 20.97 | 48.06 | 22.27 | 51.99 |

| Si | 5.18 | 5.17 | 2.02 | 2.57 | 8.91 | 11.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Sun, S.; Xu, Y.; Tian, L.; Wang, Y.; Xu, Z.; Li, R. Microstructure and Wear Behaviors of Plasma-Sprayed MoAlB Ceramic Coating. Coatings 2021, 11, 474. https://doi.org/10.3390/coatings11040474

Li F, Sun S, Xu Y, Tian L, Wang Y, Xu Z, Li R. Microstructure and Wear Behaviors of Plasma-Sprayed MoAlB Ceramic Coating. Coatings. 2021; 11(4):474. https://doi.org/10.3390/coatings11040474

Chicago/Turabian StyleLi, Fuzhu, Shengnan Sun, Yong Xu, Lihui Tian, Yun Wang, Zhenying Xu, and Ruitao Li. 2021. "Microstructure and Wear Behaviors of Plasma-Sprayed MoAlB Ceramic Coating" Coatings 11, no. 4: 474. https://doi.org/10.3390/coatings11040474

APA StyleLi, F., Sun, S., Xu, Y., Tian, L., Wang, Y., Xu, Z., & Li, R. (2021). Microstructure and Wear Behaviors of Plasma-Sprayed MoAlB Ceramic Coating. Coatings, 11(4), 474. https://doi.org/10.3390/coatings11040474