Microstructure, Mechanical Properties and Tribological Behavior of Magnetron-Sputtered MoS2 Solid Lubricant Coatings Deposited under Industrial Conditions

Abstract

1. Introduction

2. Materials and Methods

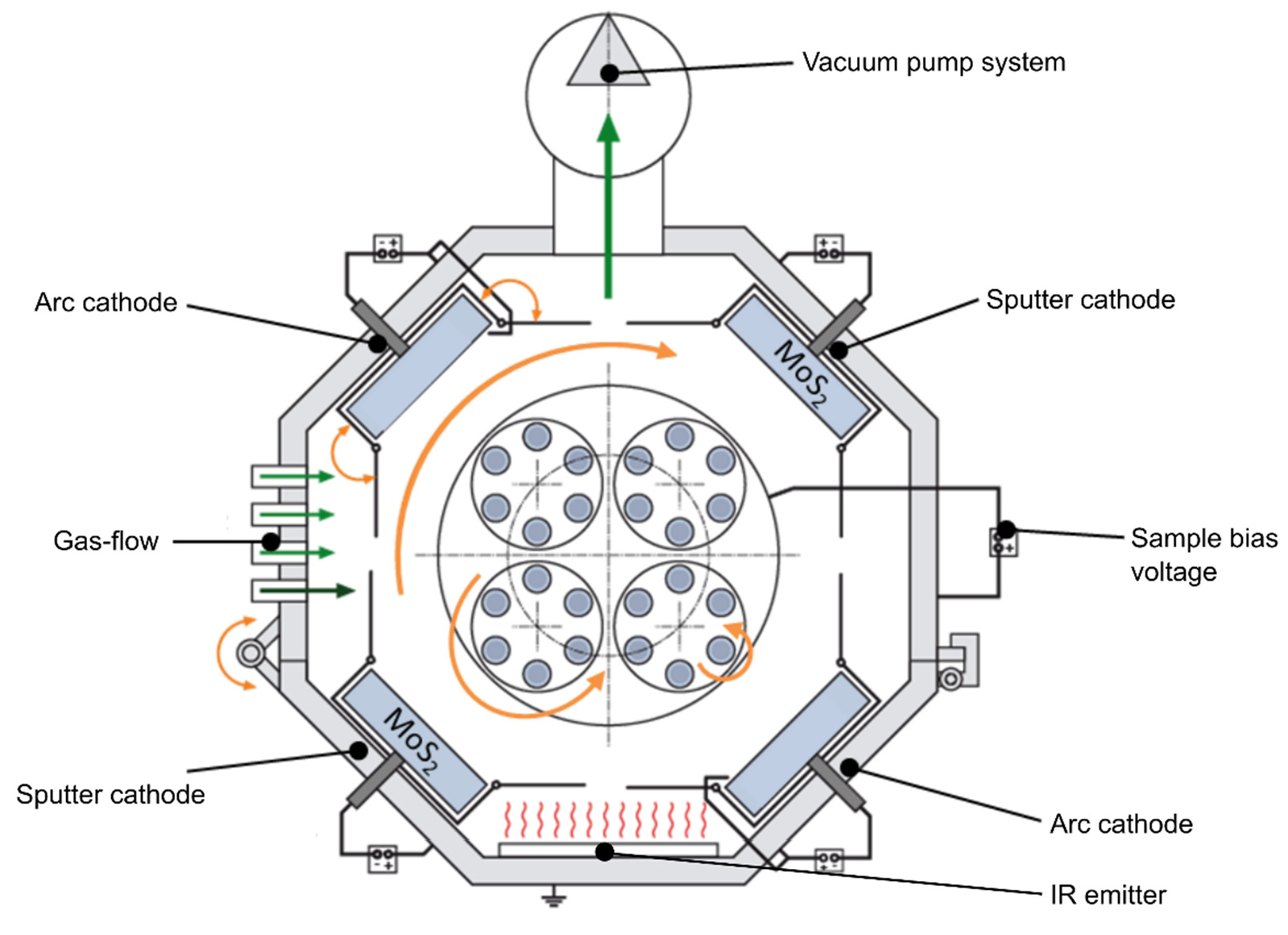

2.1. Deposition Process and Specimens

2.2. Microscopical Analysis

2.3. Mechanical Properties by Indentation Testing

2.4. Tribological Tests

2.4.1. Macroscale Tests

2.4.2. Microscale Tests

3. Results

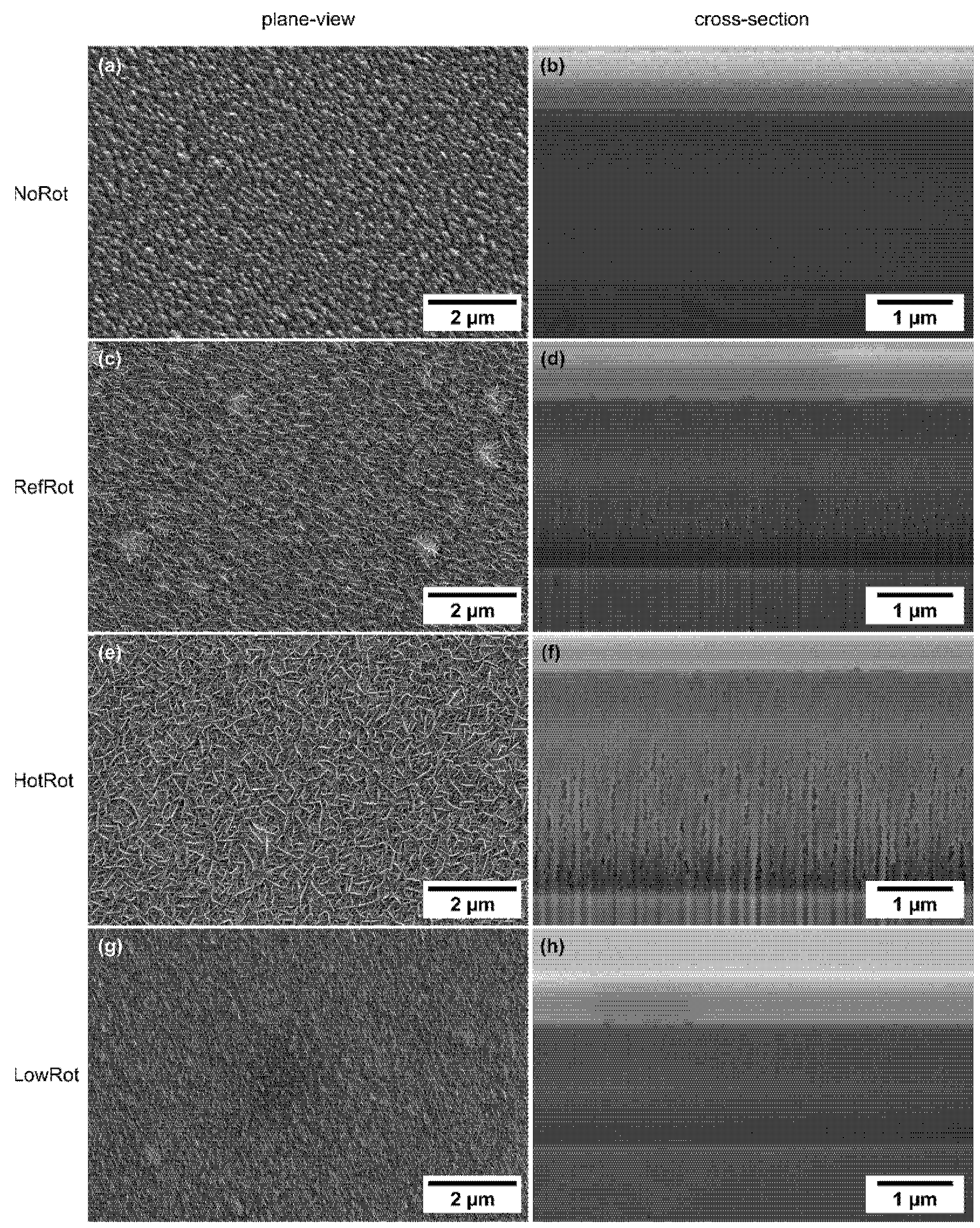

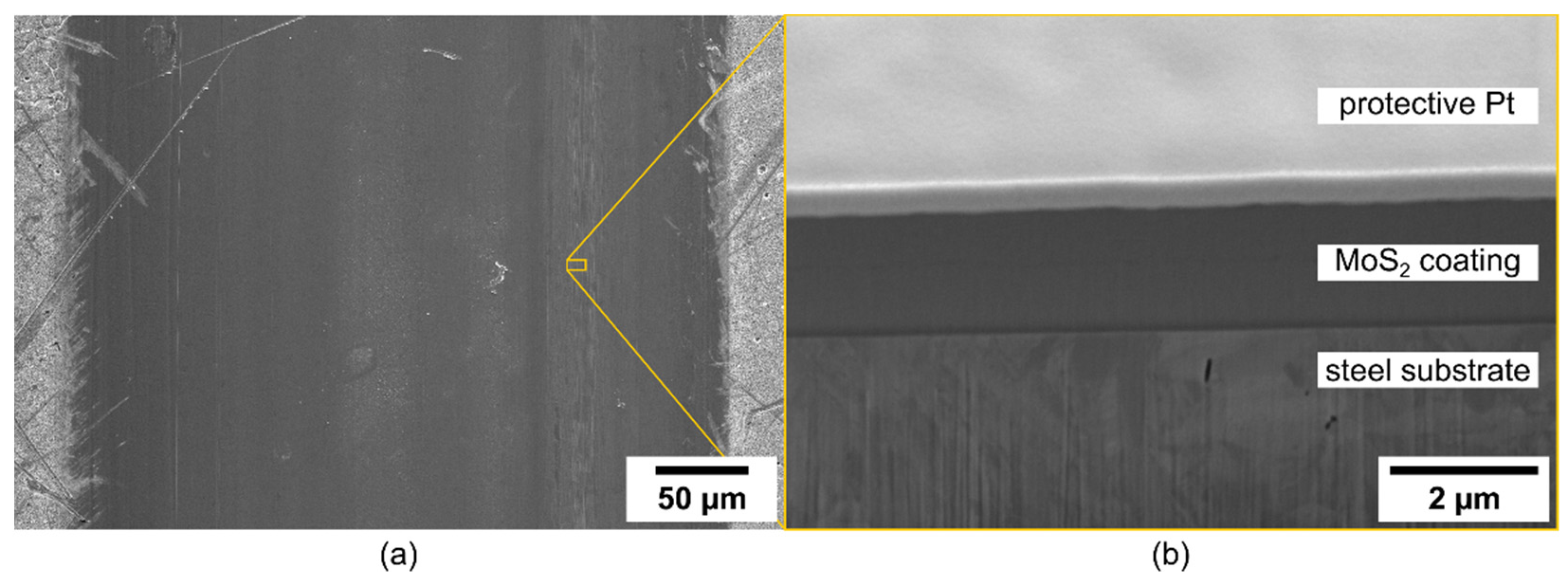

3.1. Structure of MoS2 Coatings

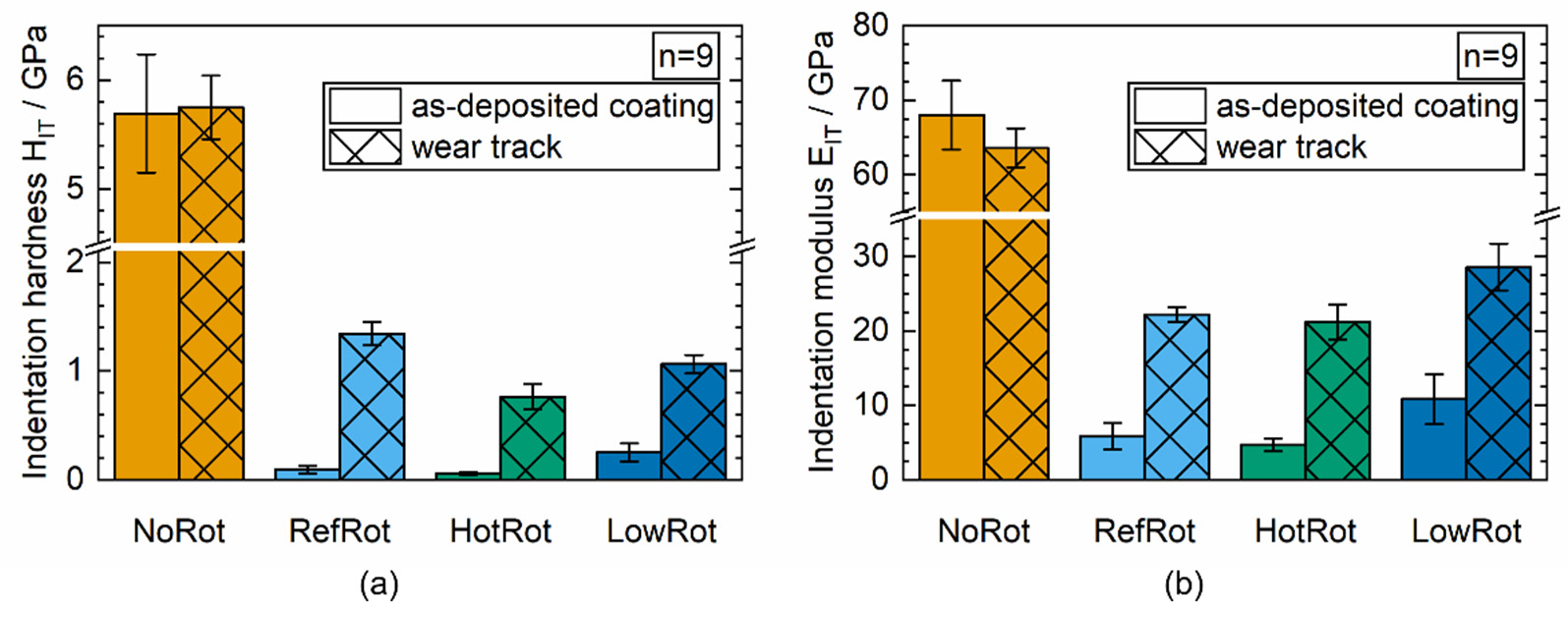

3.2. Mechanical Properties

3.3. Tribological Behavior

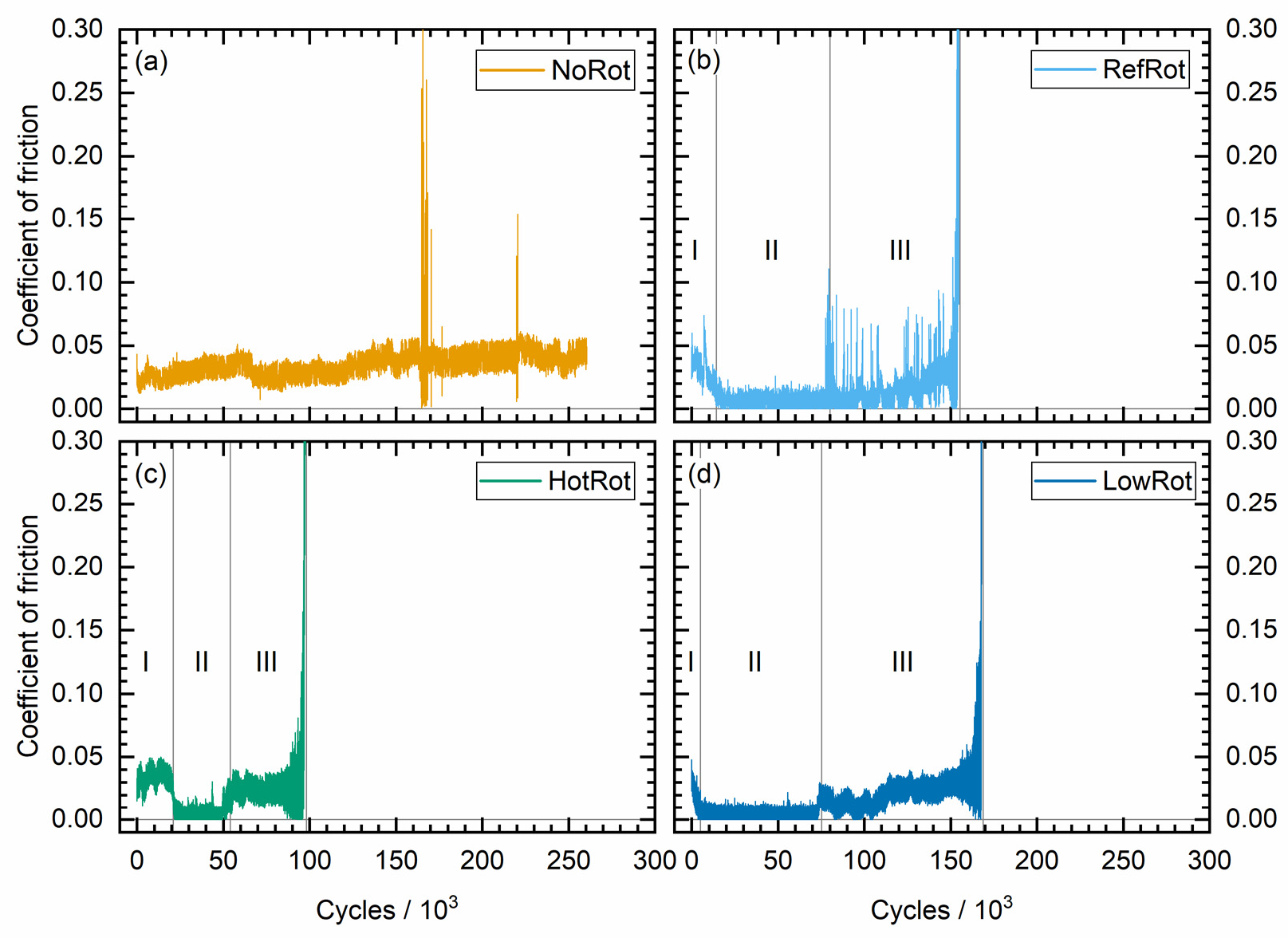

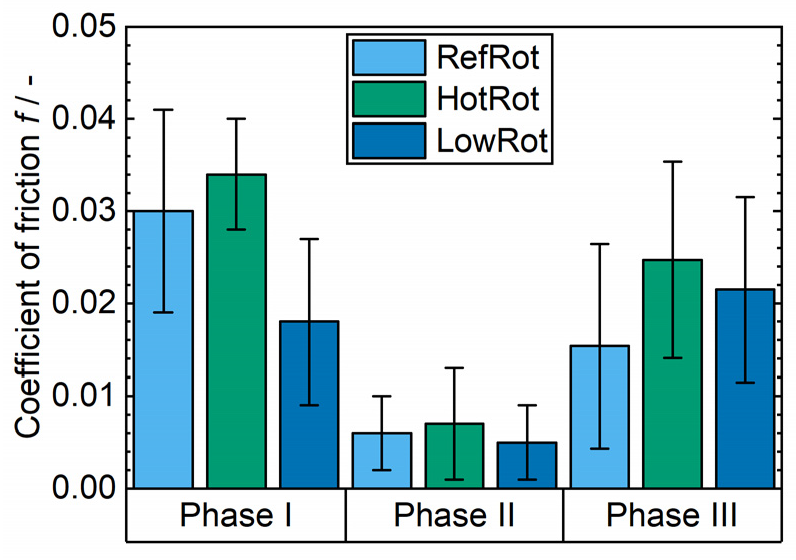

3.3.1. Frictional Behavior and Endurance Performance

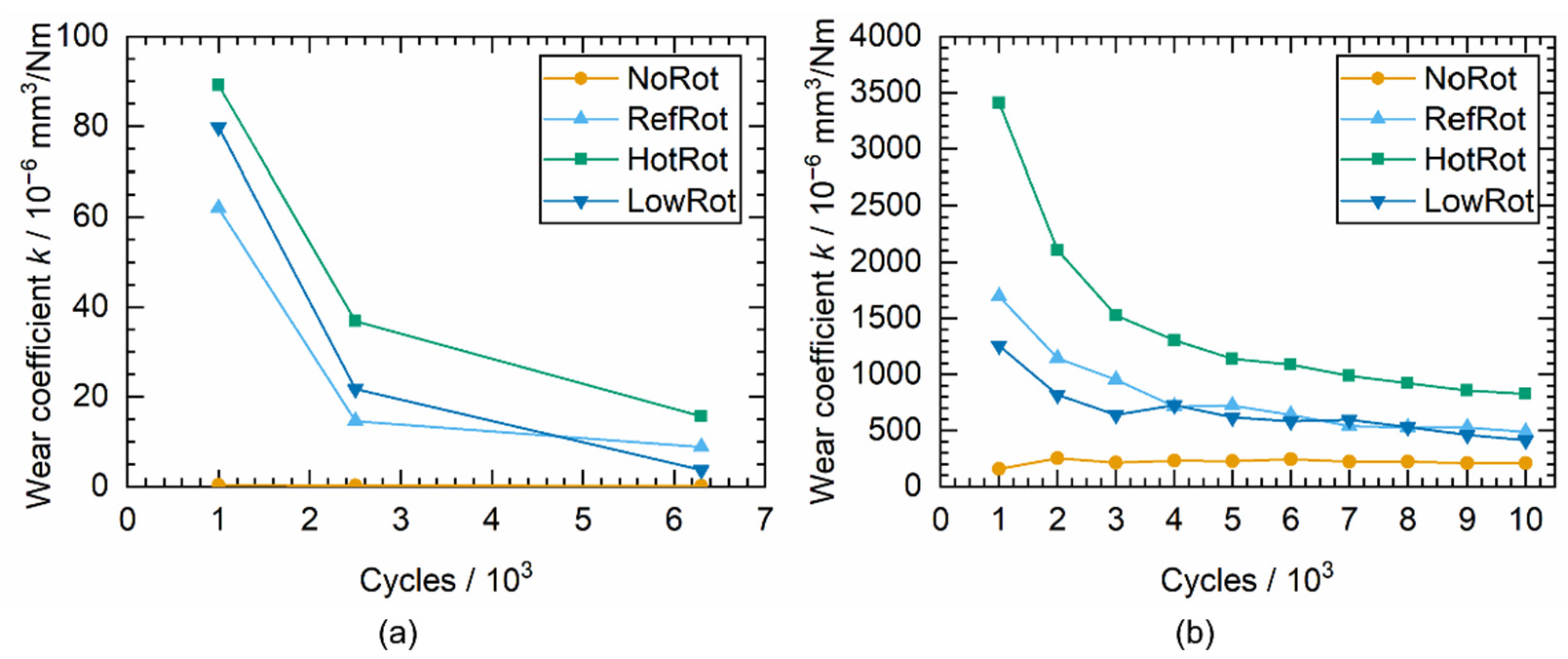

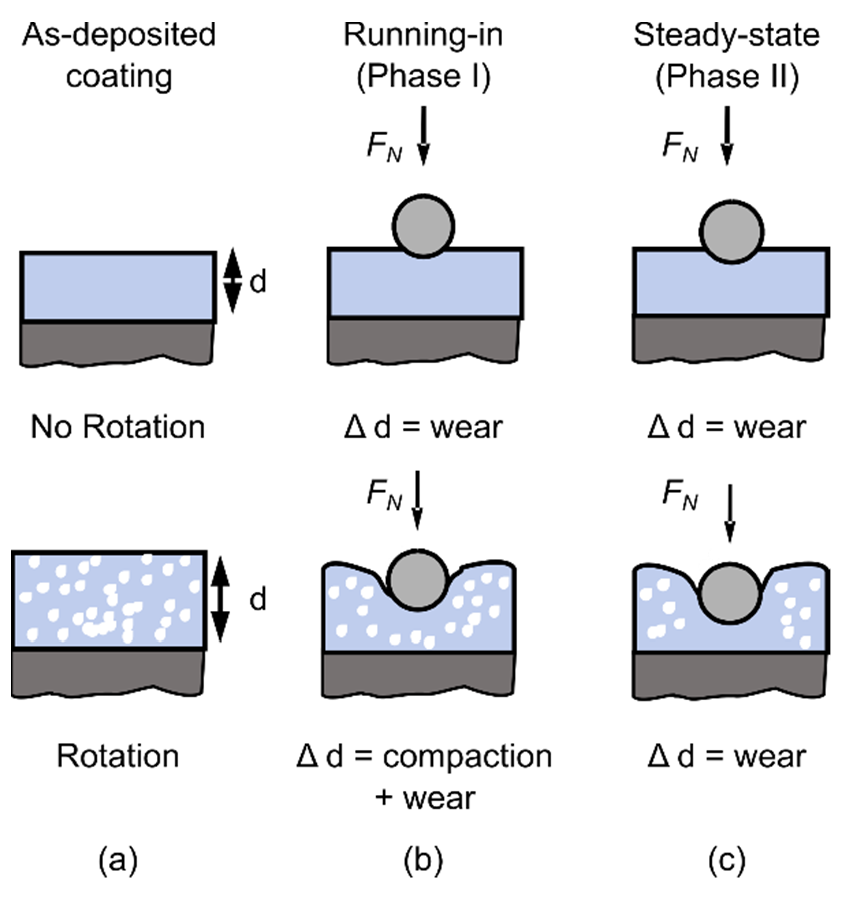

3.3.2. Wear Behavior

4. Discussion

4.1. Structure of MoS2 Coatings

4.2. Mechanical Properties

4.3. Tribological Behavior

4.3.1. Frictional Behavior and Endurance Performance

4.3.2. Wear Behavior

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, X. Solid Lubricants for Space Mechanisms. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.-W., Eds.; Springer: Boston, MA, USA, 2013; pp. 3165–3172. ISBN 978-0-387-92896-8. [Google Scholar]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid Lubrication with MoS2: A Review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S.V. Solid Lubricants: A Review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Chen, Z.; He, X.; Xiao, C.; Kim, S. Effect of Humidity on Friction and Wear—A Critical Review. Lubricants 2018, 6, 74. [Google Scholar] [CrossRef]

- Martin, J.M.; Donnet, C.; Le Mogne, T.; Epicier, T. Superlubricity of Molybdenum Disulphide. Phys. Rev. B 1993, 48, 10583–10586. [Google Scholar] [CrossRef] [PubMed]

- Martin, J.M.; Pascal, H.; Donnet, C.; Le Mogne, T.; Loubet, J.L.; Epicier, T. Superlubricity of MoS2: Crystal Orientation Mechanisms. Surf. Coat. Technol. 1994, 68–69, 427–432. [Google Scholar] [CrossRef]

- Donnet, C.; Martin, J.M.; Le Mogne, T.; Belin, M. Super-Low Friction of MoS2 Coatings in Various Environments. Tribol. Int. 1996, 29, 123–128. [Google Scholar] [CrossRef]

- Hilton, M.R.; Fleischauer, P.D. TEM Lattice Imaging of the Nanostructure of Early-Growth Sputter-Deposited MoS2 Solid Lubricant Films. J. Mater. Res. 1990, 5, 406–421. [Google Scholar] [CrossRef]

- Fleischauer, P.D. Effects of Crystallite Orientation on Environmental Stability and Lubrication Properties of Sputtered MoS2 Thin Films. A S L E Trans. 1984, 27, 82–88. [Google Scholar] [CrossRef]

- Spalvins, T. Lubrication with Sputtered MoS2 Films: Principles, operation, and Limitations. J. Mater. Eng. Perform. 1992, 1, 347–351. [Google Scholar] [CrossRef]

- Kokalj, D.; Debus, J.; Stangier, D.; Moldenhauer, H.; Nikolov, A.; Wittig, A.; Brümmer, A.; Tillmann, W. Controlling the Structural, Mechanical and Frictional Properties of MoSx Coatings by High-Power Impulse Magnetron Sputtering. Coatings 2020, 10, 755. [Google Scholar] [CrossRef]

- Dimigen, H.; Hübsch, H.; Willich, P.; Reichelt, K. Stoichiometry and Friction Properties of Sputtered MoSx Layers. Thin Solid Films 1985, 129, 79–91. [Google Scholar] [CrossRef]

- Zhang, X.; Vitchev, R.; Lauwerens, W.; Stals, L.; He, J.; Celis, J.-P. Effect of Crystallographic Orientation on Fretting Wear Behaviour of MoSx Coatings in Dry and Humid Air. Thin Solid Films 2001, 396, 69–77. [Google Scholar] [CrossRef]

- Thornton, J.A. Influence of Apparatus Geometry and Deposition Conditions on the Structure and Topography of Thick Sputtered Coatings. J. Vac. Sci. Technol. 1974, 11, 666–670. [Google Scholar] [CrossRef]

- Messier, R.; Giri, A.P.; Roy, R.A. Revised Structure Zone Model for Thin Film Physical Structure. J. Vac. Sci. Technol. Vac. Surf. Films 1984, 2, 500–503. [Google Scholar] [CrossRef]

- Weise, G.; Teresiak, A.; Bächer, I.; Markschläger, P.; Kampschulte, G. Influence of Magnetron Sputtering Process Parameters on Wear Properties of Steel/Cr3Si or Cr/MoSx. Surf. Coat. Technol. 1995, 76–77, 382–392. [Google Scholar] [CrossRef]

- Weise, G.; Mattern, N.; Hermann, H.; Teresiak, A.; Bächer, I.; Brückner, W.; Bauer, H.-D.; Vinzelberg, H.; Reiss, G.; Kreissig, U.; et al. Preparation, Structure and Properties of MoSx Films. Thin Solid Films 1997, 298, 98–106. [Google Scholar] [CrossRef]

- Vierneusel, B.; Tremmel, S.; Wartzack, S. Effects of Deposition Parameters on Hardness and Lubrication Properties of Thin MoS2 Films. Mater. Werkst. 2012, 43, 1029–1035. [Google Scholar] [CrossRef]

- Vierneusel, B.; Tremmel, S.; Wartzack, S. Monte Carlo Simulation of the MoS2 Sputtering Process and the Influence of the Normalized Momentum on Residual Stresses. J. Vac. Sci. Technol. Vac. Surf. Films 2015, 33, 061501. [Google Scholar] [CrossRef]

- Vierneusel, B.; Schneider, T.; Tremmel, S.; Wartzack, S.; Gradt, T. Humidity Resistant MoS2 Coatings Deposited by Unbalanced Magnetron Sputtering. Surf. Coat. Technol. 2013, 235, 97–107. [Google Scholar] [CrossRef]

- Vierneusel, B.; Benker, L.; Tremmel, S.; Göken, M.; Merle, B. Isolating the Effect of Residual Stresses on Coating Wear by a Mechanical Stress Relaxation Technique. Thin Solid Films 2017, 638, 159–166. [Google Scholar] [CrossRef]

- Fleischauer, P.D. Fundamental Aspects of the Electronic Structure, Materials Properties and Lubrication Performance of Sputtered MoS2 Films. Thin Solid Films 1987, 154, 309–322. [Google Scholar] [CrossRef]

- Holmberg, K.; Ronkainen, H.; Laukkanen, A.; Wallin, K.; Hogmark, S.; Jacobson, S.; Wiklund, U.; Souza, R.M.; Ståhle, P. Residual Stresses in TiN, DLC and MoS2 Coated Surfaces with Regard to Their Tribological Fracture Behaviour. Wear 2009, 267, 2142–2156. [Google Scholar] [CrossRef]

- Bückle, H. Mikrohärteprüfung und ihre Anwendung; Berliner Union: Stuttgart, Germany, 1965. [Google Scholar]

- Merle, B.; Higgins, W.H.; Pharr, G.M. Critical Issues in Conducting Constant Strain Rate Nanoindentation Tests at Higher Strain Rates. J. Mater. Res. 2019, 34, 3495–3503. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Buck, V. Lattice Parameters of Sputtered MoS2 Films. Thin Solid Films 1991, 198, 157–167. [Google Scholar] [CrossRef]

- Moser, J.; Liao, H.; Levy, F. Texture Characterisation of Sputtered MoS2 Thin Films by Cross-Sectional TEM Analysis. J. Phys. Appl. Phys. 1990, 23, 624–626. [Google Scholar] [CrossRef]

- Bertrand, P.A. Orientation of Rf-Sputter-Deposited MoS2 Films. J. Mater. Res. 1989, 4, 180–184. [Google Scholar] [CrossRef]

- Müller, K. Dependence of Thin-film Microstructure on Deposition Rate by Means of a Computer Simulation. J. Appl. Phys. 1985, 58, 2573–2576. [Google Scholar] [CrossRef]

- Adamik, M.; Tomov, I.; Kaiser, U.; Laux, S.; Schmidt, C.; Richter, W.; Safran, G.; Barna, P.B. Structure Evolution of Stratified NdF3 Optical Thin Films; Hall, R.L., Ed.; SPIE: San Diego, CA, USA, 1997; p. 123. [Google Scholar]

- Renevier, N.; Fox, V.; Teer, D.; Hampshire, J. Coating Characteristics and Tribological Properties of Sputter-Deposited MoS2/Metal Composite Coatings Deposited by Closed Field Unbalanced Magnetron Sputter Ion Plating. Surf. Coat. Technol. 2000, 127, 24–37. [Google Scholar] [CrossRef]

- Colas, G.; Serles, P.; Saulot, A.; Filleter, T. Strength Measurement and Rupture Mechanisms of a Micron Thick Nanocrystalline MoS2 Coating Using AFM Based Micro-Bending Tests. J. Mech. Phys. Solids 2019, 128, 151–161. [Google Scholar] [CrossRef]

- Kao, W.H. Tribological Properties and High Speed Drilling Application of MoS2–Cr Coatings. Wear 2005, 258, 812–825. [Google Scholar] [CrossRef]

- Moser, J.; Lévy, F. Crystal Reorientation and Wear Mechanisms in MoS2 Lubricating Thin Films Investigated by TEM. J. Mater. Res. 1993, 8, 206–213. [Google Scholar] [CrossRef]

- Roberts, E. Ultralow Friction Films of MoS2 for Space Applications. Thin Solid Films 1989, 181, 461–473. [Google Scholar] [CrossRef]

- Theiler, G.; Gradt, T.; Österle, W.; Brückner, A.; Weihnacht, V. Friction and Endurance of MoS2/Ta-C Coatings Produced by Laser Arc Deposition. Wear 2013, 297, 791–801. [Google Scholar] [CrossRef]

- Roberts, E.W.; Williams, B.J.; Ogilvy, J.A. The Effect of Substrate Surface Roughness on the Friction and Wear of Sputtered MoS2 Films. J. Phys. Appl. Phys. 1992, 25, A65–A70. [Google Scholar] [CrossRef]

- Fleischauer, P.D.; Hilton, M.R.; Bauer, R. Paper V (i) Effects of microstructure and adhesion on performance of sputter-deposited MoS2 solid lubricant coatings. In Tribology Series; Elsevier: Amsterdam, The Netherlands, 1990; Volume 17, pp. 121–128. ISBN 978-0-444-88676-7. [Google Scholar]

- Wang, J.; Lauwerens, W.; Wieers, E.; Stals, L.M.; He, J.; Celis, J.P. Structure and Tribological Properties of MoSx Coatings Prepared by Bipolar DC Magnetron Sputtering. Surf. Coat. Technol. 2001, 139, 143–152. [Google Scholar] [CrossRef]

- Finkin, E.F. Examination of Abrasion Resistance Criteria for Some Ductile Metals. J. Lubr. Technol. 1974, 96, 210–214. [Google Scholar] [CrossRef]

| Deposition Parameters | Coating Designation | |||

|---|---|---|---|---|

| NoRot | RefRot | HotRot | LowRot | |

| Rotation strategy | - | 3-fold | 3-fold | 3-fold |

| Target–substrate distance in mm | 65 | 250 | 250 | 250 |

| Duration in s | 300 | 4200 | 4200 | 4200 |

| Sputtering power in kW | 1.3 | 2.0 | 2.1 | 2.1 |

| Bias voltage in V | 0 | 0 | 0 | 0 |

| Argon gas flow in sccm | 115 | 120 | 120 | 120 |

| Argon pressure in Pa | 0.70 | 0.71 | 0.76 | 0.70 |

| Chamber temperature in °C | 50 | 50 | 150 | 50 |

| Rotational speed in rpm | - | 6 | 6 | 1 |

| Parameter | NoRot | RefRot | HotRot | LowRot |

|---|---|---|---|---|

| Mo/S-ratio | 1.14 | 1.67 | 1.65 | 1.61 |

| Coating thickness in µm | 2.3 | 2.3 | 3.0 | 1.6 |

| Parameter | NoRot | RefRot | HotRot | LowRot |

|---|---|---|---|---|

| As-Deposited Coating | ||||

| HIT in GPa | 5.69 ± 0.54 | 0.09 ± 0.03 | 0.06 ± 0.01 | 0.25 ± 0.09 |

| EIT in GPa | 68.0 ± 4.7 | 5.86 ± 1.7 | 4.7 ± 0.9 | 10.8 ± 3.3 |

| HIT/EIT ratio | 0.084 ± 0.010 | 0.016 ± 0.007 | 0.012 ± 0.004 | 0.023 ± 0.011 |

| Wear Track | ||||

| HIT in GPa | 5.75 ± 0.29 | 1.34 ± 0.11 | 0.76 ± 0.12 | 1.06 ± 0.08 |

| EIT in GPa | 63.6 ± 2.6 | 22.2 ± 1.0 | 21.2 ± 2.4 | 28.6 ± 3.1 |

| Coating Designation | Cycles in 103 | ||

|---|---|---|---|

| Phase I | Phase II | Phase III | |

| RefRot | 14.3 | 65.7 | 74.0 |

| HotRot | 21.0 | 33.0 | 42.5 |

| LowRot | 5.0 | 70.3 | 92.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seynstahl, A.; Krauß, S.; Bitzek, E.; Meyer, B.; Merle, B.; Tremmel, S. Microstructure, Mechanical Properties and Tribological Behavior of Magnetron-Sputtered MoS2 Solid Lubricant Coatings Deposited under Industrial Conditions. Coatings 2021, 11, 455. https://doi.org/10.3390/coatings11040455

Seynstahl A, Krauß S, Bitzek E, Meyer B, Merle B, Tremmel S. Microstructure, Mechanical Properties and Tribological Behavior of Magnetron-Sputtered MoS2 Solid Lubricant Coatings Deposited under Industrial Conditions. Coatings. 2021; 11(4):455. https://doi.org/10.3390/coatings11040455

Chicago/Turabian StyleSeynstahl, Armin, Sebastian Krauß, Erik Bitzek, Bernd Meyer, Benoit Merle, and Stephan Tremmel. 2021. "Microstructure, Mechanical Properties and Tribological Behavior of Magnetron-Sputtered MoS2 Solid Lubricant Coatings Deposited under Industrial Conditions" Coatings 11, no. 4: 455. https://doi.org/10.3390/coatings11040455

APA StyleSeynstahl, A., Krauß, S., Bitzek, E., Meyer, B., Merle, B., & Tremmel, S. (2021). Microstructure, Mechanical Properties and Tribological Behavior of Magnetron-Sputtered MoS2 Solid Lubricant Coatings Deposited under Industrial Conditions. Coatings, 11(4), 455. https://doi.org/10.3390/coatings11040455