Effects of Different Post-Treatments on Arc Erosion Resistance of Cold-Sprayed AgC Composite Electric Contact

Abstract

1. Introduction

2. Experimental Details

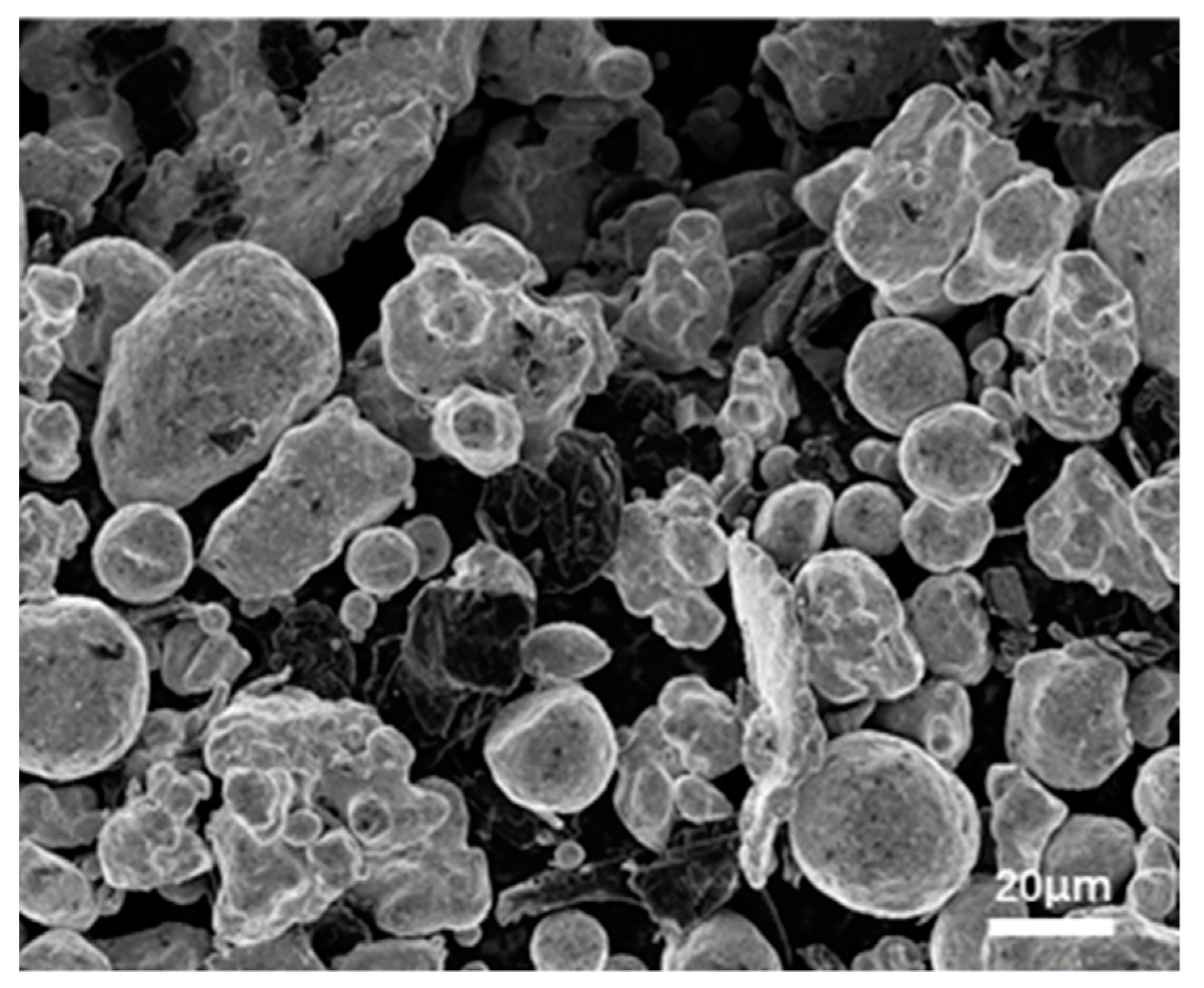

2.1. Materials

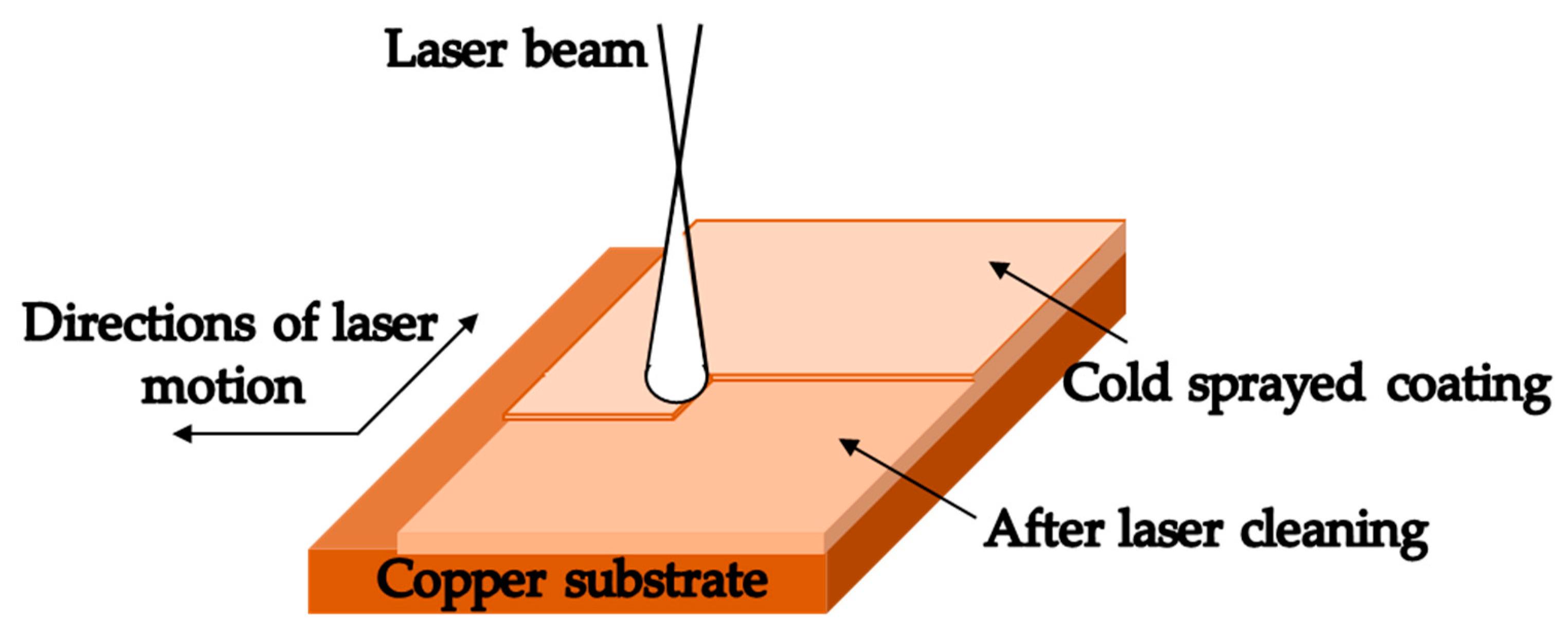

2.2. Coating Preparation

2.3. Material Characterizations

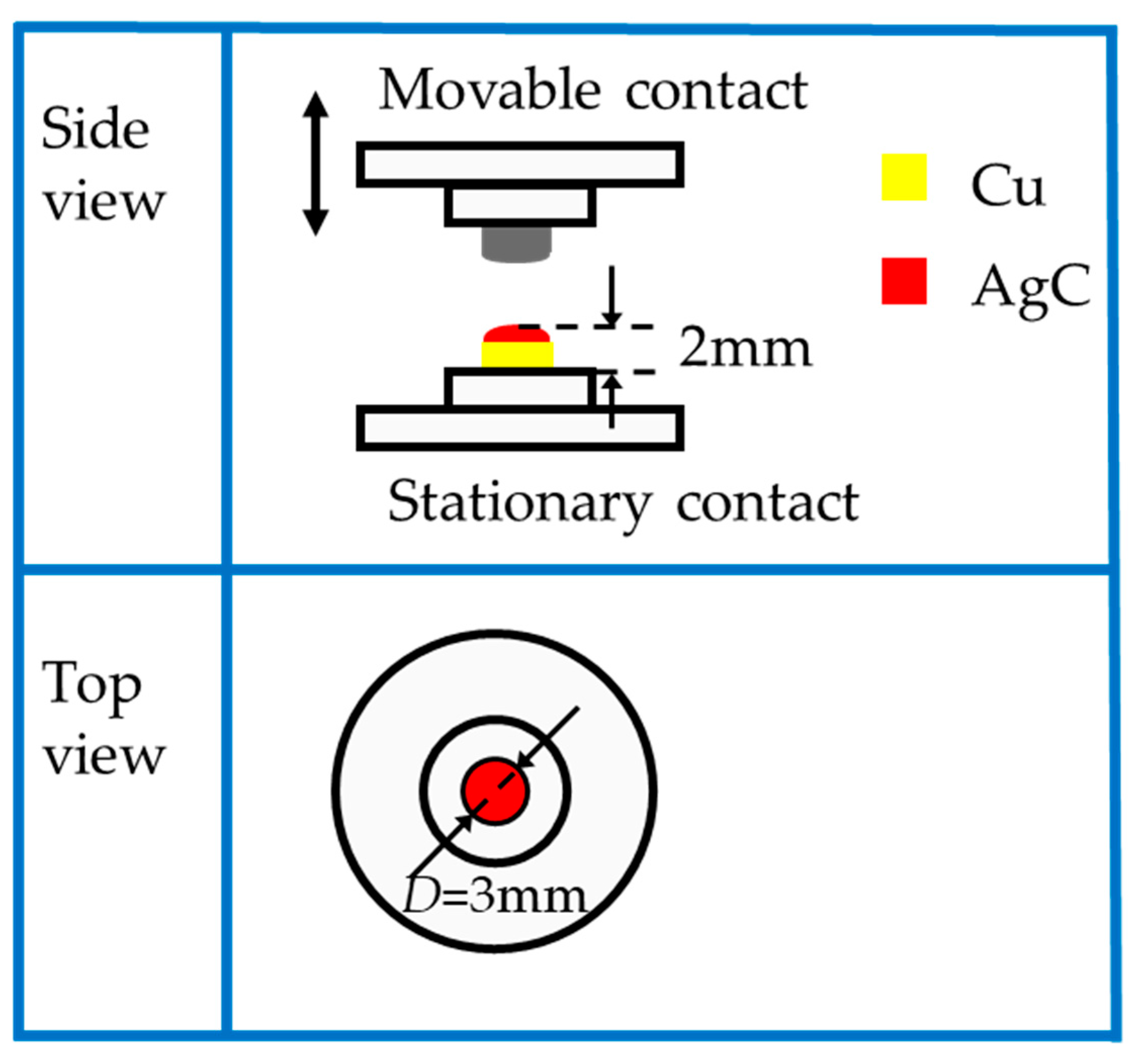

2.4. Arc Erosion Rate Test

3. Results and Discussion

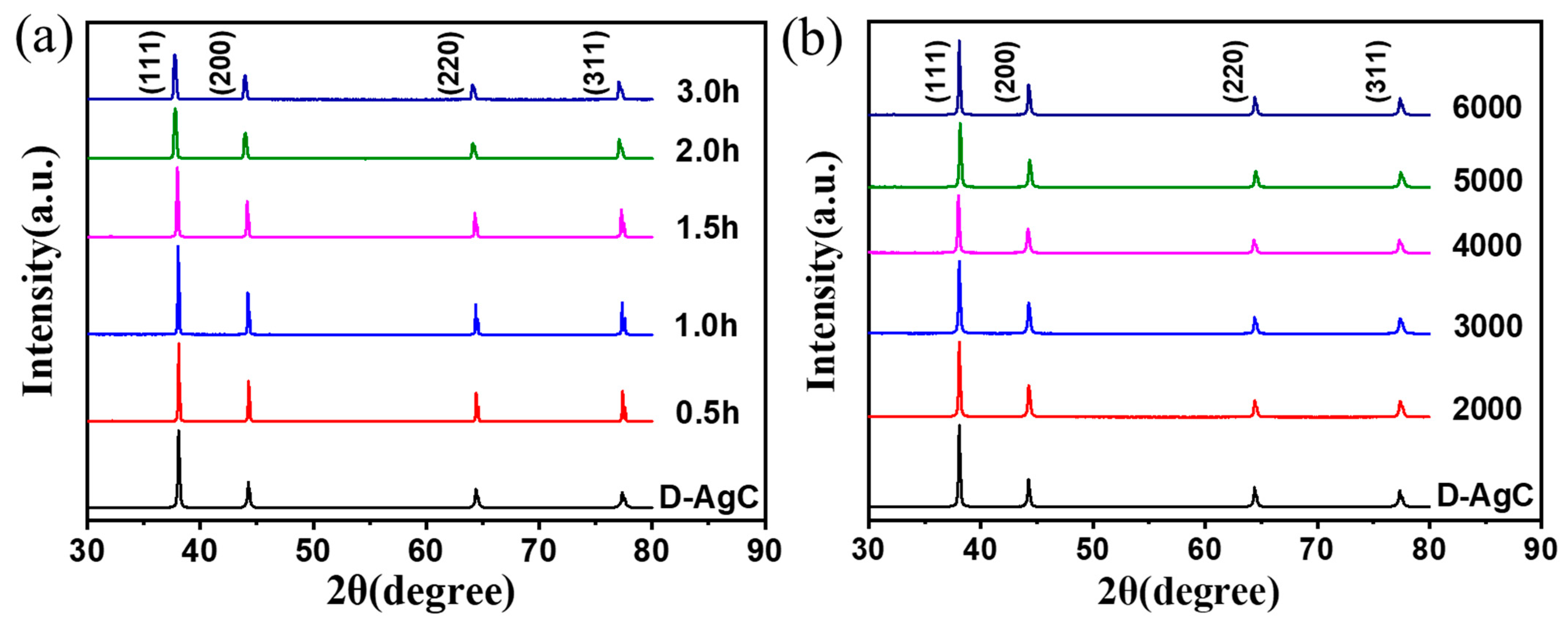

3.1. Effects of Post-Treatments on Phase Structure

3.2. Effects of Post-Treatments on Morphologies and Wettability

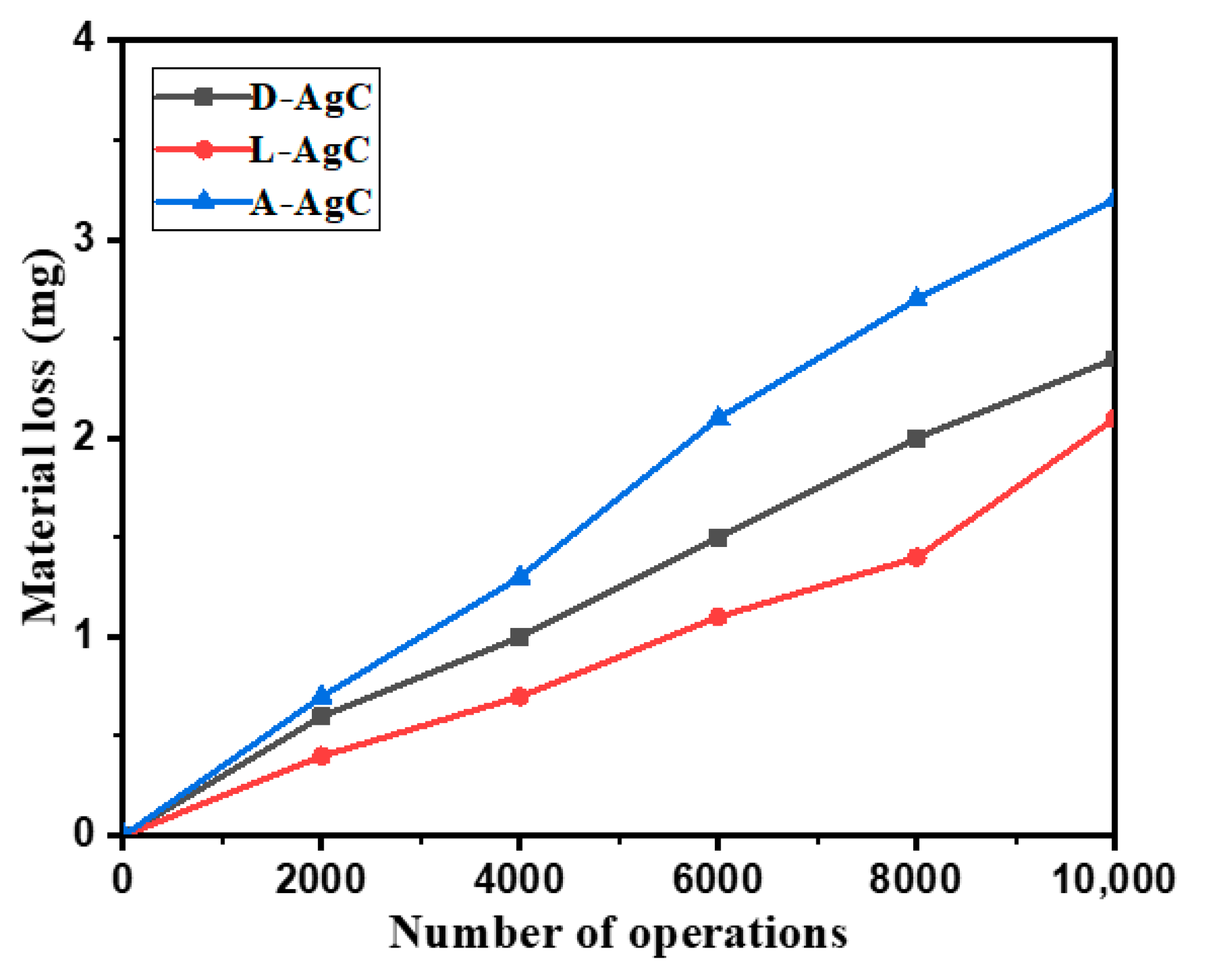

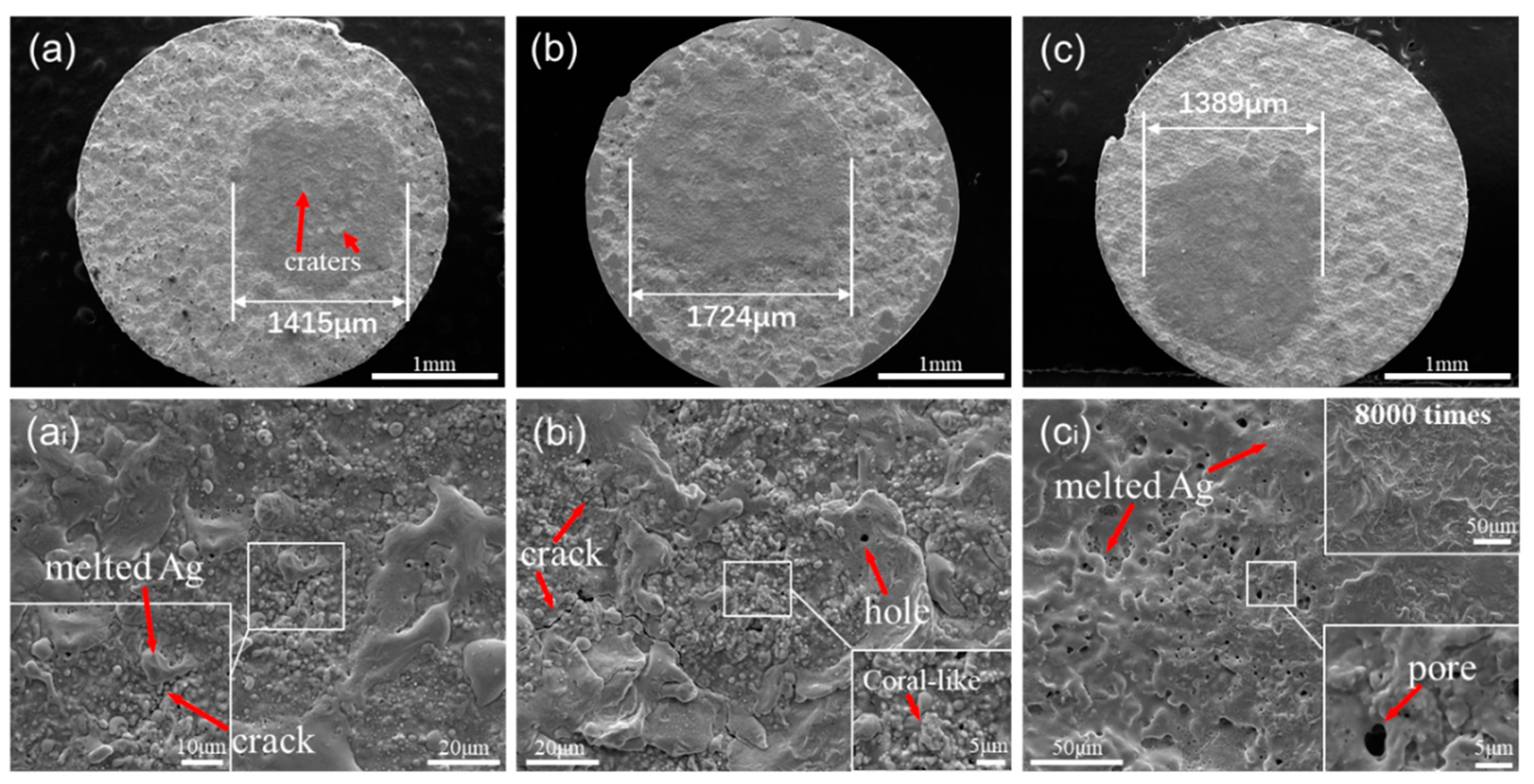

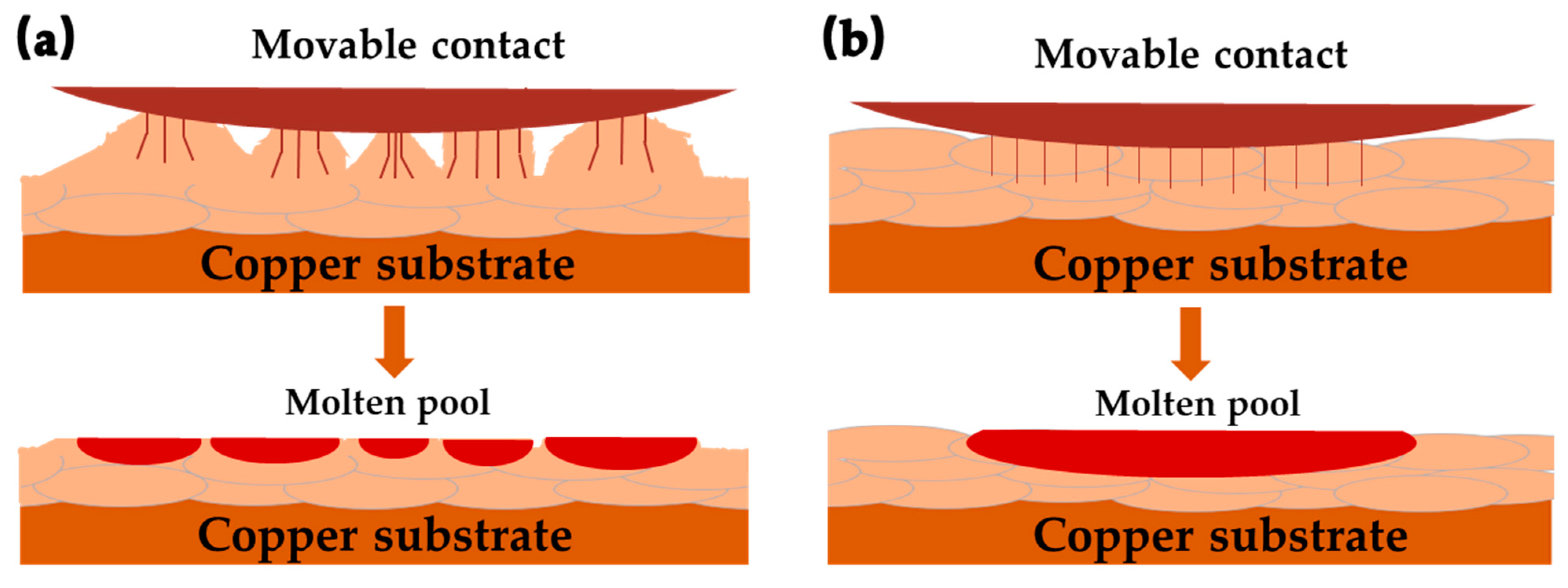

3.3. Effects of Post-Treatments on Arc Erosion Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jaćimović, J.; Felberbaum, L.; Giannini, E.; Teyssier, J. Electro-mechanical properties of composite materials for high-current contact applications. J. Phys. D Appl. Phys. 2014, 47. [Google Scholar] [CrossRef]

- Ding, J.; Sun, Z.; Zhang, P.; Tian, W.; Zhang, Y. Current Research Status and Outlook of Ag-based Contact Materials. Mater. Rev. 2018, 32, 58–66. [Google Scholar] [CrossRef]

- Mutzel, T.; Kempf, B. Silver tungsten carbide contacts fork circuit breaker applications. Electr. Contacts Proc. Annu. Holm Conf. Electr. Contacts 2015. [Google Scholar] [CrossRef]

- Borkowski, P.; Walczuk, E.; Wojcik-Grzybek, D.; Frydman, K.; Zasada, D. Electrical properties of Ag-C contact materials containing different allotropes of carbon. Electr. Contacts Proc. Annu. Holm Conf. Electr. Contacts 2010, 167–175. [Google Scholar] [CrossRef]

- Rehani, B.R.; Joshi, P.B.; Kaushik, V.K. Nanostructured silver-graphite electrical contact materials processed by mechanical milling. Indian J. Eng. Mater. Sci. 2009, 16, 281–287. [Google Scholar]

- Rehani, B.; Joshi, P.B.; Khanna, P.K. Fabrication of silver-graphite contact materials using silver nanopowders. J. Mater. Eng. Perform. 2010, 19, 64–69. [Google Scholar] [CrossRef]

- Liu, A.; Ren, X.; Zhang, J.; Li, D.; An, M. Complexing agent study for environmentally friendly silver electrodeposition (II): Electrochemical behavior of silver complex. RSC Adv. 2016, 6, 7348–7355. [Google Scholar] [CrossRef]

- Bomparola, R.; Caporali, S.; Lavacchi, A.; Bardi, U. Silver electrodeposition from air and water-stable ionic liquid: An environmentally friendly alternative to cyanide baths. Surf. Coat. Technol. 2007, 201, 9485–9490. [Google Scholar] [CrossRef]

- Srikanth, A.; Bolleddu, V. A review on characteristics of cold sprayed coatings. Aust. J. Mech. Eng. 2020, 1–17. [Google Scholar] [CrossRef]

- Singh, S.; Singh, H.; Buddu, R.K. Microstructural investigations on bonding mechanisms of cold-sprayed copper with SS316L steel. Surf. Eng. 2020, 36, 1067–1080. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Ma, K.; Pan, X.-D.; Li, C.-X.; Yang, G.-J.; Li, C.-J. Microstructure and Transparent Super-Hydrophobic Performance of Vacuum Cold-Sprayed Al2O3 and SiO2 Aerogel Composite Coating. J. Therm. Spray Technol. 2018, 27, 471–482. [Google Scholar] [CrossRef]

- Huang, C.; Li, W.; Xie, Y.; Planche, M.P.; Liao, H.; Montavon, G. Effect of Substrate Type on Deposition Behavior and Wear Performance of Ni-Coated Graphite/Al Composite Coatings Deposited by Cold Spraying. J. Mater. Sci. Technol. 2017, 33, 338–346. [Google Scholar] [CrossRef]

- Li, W.; Assadi, H.; Gaertner, F.; Yin, S. A Review of Advanced Composite and Nanostructured Coatings by Solid-State Cold Spraying Process. Crit. Rev. Solid State Mater. Sci. 2019, 44, 109–156. [Google Scholar] [CrossRef]

- Chavan, N.M.; Ramakrishna, M.; Phani, P.S.; Rao, D.S.; Sundararajan, G. The influence of process parameters and heat treatment on the properties of cold sprayed silver coatings. Surf. Coat. Technol. 2011, 205, 4798–4807. [Google Scholar] [CrossRef]

- Wang, J.; Wang, C.; Kang, Y. The effects of annealing treatment on microstructure and contact resistance properties of cold sprayed Ag-SnO2 coating. J. Alloy. Compd. 2017, 714, 698–703. [Google Scholar] [CrossRef]

- Xiong, W.; Hao, L.; Li, Y.; Tang, D.; Cui, Q.; Feng, Z.; Yan, C. Effect of selective laser melting parameters on morphology, microstructure, densification and mechanical properties of supersaturated silver alloy. Mater. Des. 2019, 170, 107697. [Google Scholar] [CrossRef]

- Major, B.; Ciach, R.; Ebner, R.; Jeglitsch, F.; Kriszt, B.; Rabitsch, K. Laser microstructure modification of aluminium alloys and steels. Phys. Status Solidi 1994, 141, 15–30. [Google Scholar] [CrossRef]

- Won, S.J.; Kim, H.S. Effects of laser parameters on morphological change and surface properties of aluminum alloy in masked laser surface texturing. J. Manuf. Process. 2019, 48, 260–269. [Google Scholar] [CrossRef]

- Xie, J.; Cao, S.; Bai, X.; Li, G.; Yan, X.; Zheng, L. Preparation of electrical contact materials by cold gas-spray. Rare Met. Mater. Eng. 2014, 43, 2989–2992. [Google Scholar] [CrossRef]

- Ghelichi, R.; Guagliano, M. Coating by the Cold Spray Process: A state of the art. Frat. Integrità Strutt. 2009, 3, 30–44. [Google Scholar] [CrossRef]

- Raza, M.S.; Das, S.S.; Tudu, P.; Saha, P. Excimer laser cleaning of black sulphur encrustation from silver surface. Opt. Laser Technol. 2019, 113, 95–103. [Google Scholar] [CrossRef]

- Wu, Q.; Xu, G.; Yuan, M.; Wu, C. Influence of operation numbers on arc erosion of Ag/CuO electrical contact material. J. Mater. Sci. Mater. Electron. 2020, 31, 2497–2513. [Google Scholar] [CrossRef]

- Niu, L.; Liu, M. Studty of the Arc Erosion in Electromobile Contactor Electrode Consisting of Ag and C Composites. In Proceedings of the 2020 5th Asia Conference on Power and Electrical Engineering, ACPEE 2020, Chengdu, China, 4–7 June 2020; pp. 1923–1927. [Google Scholar]

- Wójcik-Grzybek, D.; Frydman, K.; Borkowski, P. The influence of the microstructure on the switching properties of Ag-C, Ag-WC-CAND Ag-W-C contact materials. Arch. Metall. Mater. 2013, 58, 1059–1065. [Google Scholar] [CrossRef]

- Peat, T.; Galloway, A.; Toumpis, A.; McNutt, P.; Iqbal, N. The erosion performance of cold spray deposited metal matrix composite coatings with subsequent friction stir processing. Appl. Surf. Sci. 2017, 396, 1635–1648. [Google Scholar] [CrossRef]

- Li, S.; Guo, X.; Zhang, S.; Feng, J.; Song, K.; Liang, S. Arc erosion behavior of TiB2/Cu composites with single-scale and dual-scale TiB2 particles. Nanotechnol. Rev. 2019, 8, 619–627. [Google Scholar] [CrossRef]

- Li, L.T.; Liang, X.M.; Xing, Y.Z.; Yan, D.; Wang, G.F. Measurement of real contact area for rough metal surfaces and the distinction of contribution from elasticity and plasticity. J. Tribol. 2021, 143, 071501. [Google Scholar] [CrossRef]

- Saputra, E.; Ismail, R.; Jamari, J.; Bayuseno, A.P. Analysis of the contact area of smooth and rough surfaces in contact with sphere indenter using finite element method. MATEC Web Conf. 2016, 58, 04007. [Google Scholar] [CrossRef]

- Wang, D.D.; Tian, W.B.; Ding, J.X.; Zhu, Y.F.; Zhang, P.G.; Zhang, Y.; He, W.; Sun, Z.M. The beauty and the deed of silver during arc erosion of Ag/Ti3AlC2 contacts. J. Alloy. Compd. 2020, 820. [Google Scholar] [CrossRef]

- Shea, J.J. High Current AC break Arc Contact Erosion. In Proceedings of the 54th IEEE Holm Conference on Electrical Contacts, Orlando, FL, USA, 27–29 October 2008. [Google Scholar] [CrossRef]

| Contact Material | AgC with Different Treatments |

|---|---|

| Circuit condition | DC18V, 10A, resistive load |

| Frequency | 1 Hz |

| Number of operations | 2000, 4000, 6000, 8000, 10,000 |

| Switching mode | DC (direct current) mode |

| Contact force | 0.8 N |

| Surrounding gas | Air |

| Electrode spacing | 1.3 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhou, X.; Liu, Y.; Chen, Y.; Zhang, J.; Huang, R.; Tan, J.; Li, Z.; Yang, B. Effects of Different Post-Treatments on Arc Erosion Resistance of Cold-Sprayed AgC Composite Electric Contact. Coatings 2021, 11, 363. https://doi.org/10.3390/coatings11030363

Li J, Zhou X, Liu Y, Chen Y, Zhang J, Huang R, Tan J, Li Z, Yang B. Effects of Different Post-Treatments on Arc Erosion Resistance of Cold-Sprayed AgC Composite Electric Contact. Coatings. 2021; 11(3):363. https://doi.org/10.3390/coatings11030363

Chicago/Turabian StyleLi, Jingyu, Xin Zhou, Yan Liu, Yanming Chen, Jun Zhang, Renzhong Huang, Jun Tan, Zhenggang Li, and Bing Yang. 2021. "Effects of Different Post-Treatments on Arc Erosion Resistance of Cold-Sprayed AgC Composite Electric Contact" Coatings 11, no. 3: 363. https://doi.org/10.3390/coatings11030363

APA StyleLi, J., Zhou, X., Liu, Y., Chen, Y., Zhang, J., Huang, R., Tan, J., Li, Z., & Yang, B. (2021). Effects of Different Post-Treatments on Arc Erosion Resistance of Cold-Sprayed AgC Composite Electric Contact. Coatings, 11(3), 363. https://doi.org/10.3390/coatings11030363