1. Introduction

Amaranthus cruentus is an annual herb native to temperate and tropical regions. It is cultivated for the nutritional properties of its seeds [

1,

2,

3]. It is a promising raw material as all parts are potentially usable for both food and non-food applications.

The amaranth seed contains a lipid fraction (7–8%), rich in squalene of vegetal origin (5–6%) [

4]. Acting as an essential intermediate in the biosynthesis of cholesterol, steroid hormones, and vitamin D for humans, squalene is a triterpene largely used as food supplement or for cosmetics [

5]. In particular, squalene is used in pharmaceutical and especially in cosmetic formulations for the treatment of skin disorders because of its moisturizing and protective activity against external agents, e.g., air, light, UV rays, environmental pollution, etc. [

6]. It is a good emollient, and the cosmetic industry uses it especially for the manufacture of moisturizers, make-up, lipstick, and hair care products. Besides squalene, its hydrogenated product, squalane, is even often preferred to squalene as it has a greater oxidation stability, due to the absence of double bonds [

7].

The amaranth seed also contains a substantial amount of proteins (15%). The latter could be used for bread flours as a protein reinforcement [

8], and for their biocidal and antioxidant activities [

9]. In addition, they would be potentially usable for their emulsifying capacity (surfactants for food or in cosmetic creams) [

10] or for their adhesive properties in the panel industry [

11,

12,

13].

Lastly, the amaranth seed is particularly rich in starch (up to 55%). After its plasticization/gelatinization (plus the denaturation of proteins) through a thermo-mechano-chemical pre-treatment using the twin-screw extrusion technology, amaranth seed (or cake) could thus be possibly transformed into thermoplastic granules for injection-molding applications [

14,

15].

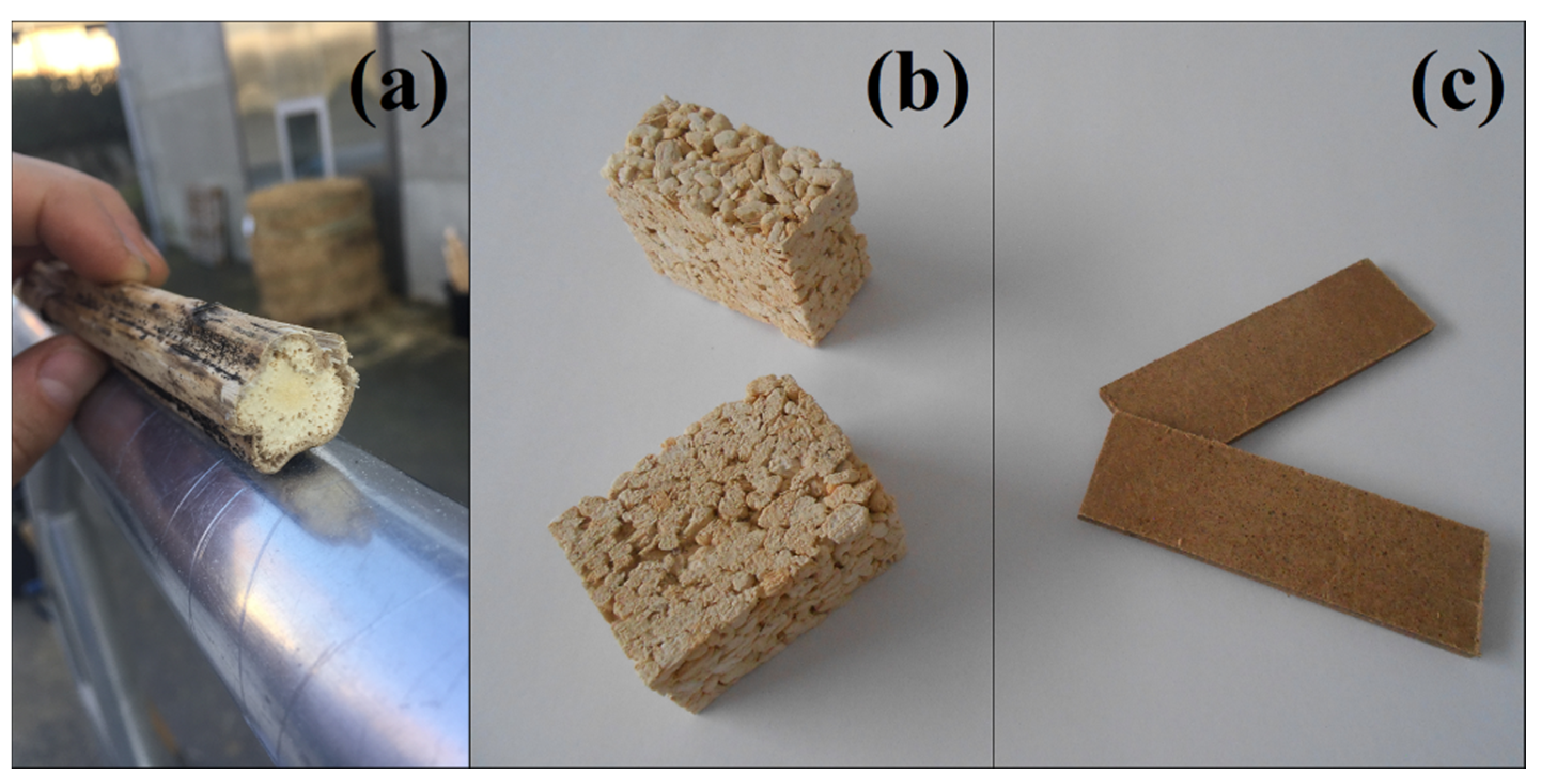

During amaranth cultivation, a stem is also produced. Representing up to 80% (

w/

w) of the plant aerial part, it is composed of a pith fraction in its middle, and a bark (i.e., a woody part, or ligneous fraction) on its periphery. To our knowledge, the scientific literature does not refer to works that have already used the amaranth stem in the manufacture of bio-based materials, particularly for construction applications. Nevertheless, the use of natural fibers (or aggregates) in composites as a replacement for mineral fillers or glass or carbon fibers has many advantages. Especially, composites made from natural by-products are highly recyclable, environmentally friendly, cost-effective, and also safe for society. By way of an example, flax and jute fibers have already shown their full potential for the reinforcement of an acrylic resin, the obtained composites being usable in the automotive sector [

16]. In addition, with a pith in its middle and a bark on its periphery, the structure of the amaranth stem is close to that of sunflower, which is already used in the building sector. For these different reasons, it is reasonable to assume that the pith and bark particles from the amaranth stem could also be used for the manufacture of bio-based building composite materials, thus providing real benefits for the near future.

Firstly, pith particles reveal an alveolar structure close to that of expanded polystyrene. The same was true for the pith fraction coming from sunflower stem [

17], and this has recently allowed the development of sunflower-based low-density insulation materials for buildings [

18,

19,

20]. The construction sector generates major environmental impacts, e.g., consumption of non-renewable raw materials, greenhouse gas (GHG) emissions, waste production, etc. [

21]. Numerous research projects are therefore currently aimed at developing alternative materials with low environmental costs. In particular, the use of plant co-products in building materials is particularly interesting. Indeed, vegetable aggregates are renewable. They are mainly produced locally, and they also constitute a carbon sink.

In this topic, a low-density insulation block consisting solely of sunflower pith particles and a starch-based glue was recently developed [

20]. Its good mechanical resistance allowed machining. In addition, its thermal insulating ability in dry state (32 mW/(m.K) at 25 °C) was equivalent to those of stone wool and expanded polystyrene, therefore corresponding to current standards for heat transfer. However, while the thermal conductivity of expanded polystyrene was not affected by ambient humidity, that of the sunflower-based samples increased by about 15% (i.e., reduced insulating properties), which was explained by the highly hygroscopic nature of these bio-based materials. Conversely, the latter revealed a high water vapor permeability (i.e., five to ten times higher than expanded polystyrene). Their power as water regulators could be useful in houses to regulate indoor humidity variation. For example, the risk of condensation at the interface between different layers of materials could be limited, and this could be useful in the case of the renovation of old buildings [

20].

A more recent improvement has been the application of a surface treatment made of glycerol esters to make these sunflower-based insulation blocks more resistant to microbial growth [

22]. Even in the presence of the glycerol esters, the potential of the light insulation made of sunflower pith was highlighted, with a 50 kg/m

3 density and a 35 mW/(m.K) thermal conductivity at 25 °C. Its high water vapor permeability was also preserved. The antimicrobial efficiency of glycerol esters was evidenced, contributing to better protection of these bio-based materials from microbial proliferation. At the same time, a non-flammability classification has been surprisingly assigned to the untreated insulation materials.

On its side, the amaranth bark reveals a high amount of lignocellulosic fibers. Such a characteristic could allow its use as a mechanical reinforcement inside biocomposites, in particular injection-moldable materials [

23,

24] or fiberboards (e.g., hardboards). For this second purpose, the bark pre-treatment through twin-screw extrusion-refining could make this reinforcement capability even more important, thanks to an improvement in the morphological characteristics of the fibers (i.e., increase in their mean aspect ratio, defined as the ratio of the length to the diameter, after refining).

The twin-screw extrusion technology has already proven itself in the processing of biomass, including mechanical pressing of vegetable oil from various oilseeds, continuous liquid/solid extraction of active biomolecules, starch plasticization, protein destructurization and denaturation, compounding of matrix/fiber type thermoplastic granules, production of second-generation bioethanol, etc. [

25,

26]. Especially, it has also recently been used as an alternative tool for the thermo-mechanical defibration of various agricultural by-products or those resulting from a first agro-industrial transformation such as rice straw [

27,

28], coriander straw [

13,

29], oleaginous flax shives [

30,

31], and sunflower bark [

22], prior to hot pressing.

The function of defibration is to break down the lignins that protect cellulose and hemicelluloses. This pre-treatment contributes to increase the fiber-specific surface and to promote their self-adhesion [

30]. The applied pre-treatments are most often mechanical, thermal, and/or chemical ones [

32]. As a first non-expensive solution, a simple grinding enables the improvement of the particle size profile of micrometric fibers [

30,

33,

34]. Defibration is however much more efficient when thermo-mechanical pulps are produced. Widely used in the paper industry, the thermo-mechanical defibration can be carried out from different pulping processes [

35], including digestion plus defibration [

36] and steam explosion [

37,

38,

39,

40,

41]. More original pre-treatment methods involving enzymes have also been considered [

42,

43,

44]. However, they have the disadvantage of being rather difficult to implement on a large scale.

Twin-screw extrusion, on the other hand, can be more easily deployed in the industry. Above all, it has recently shown its full potential for an efficient thermo-mechanical defibration of lignocellulosic by-products at a moderate cost. It was compared with a digestion plus defibration process from the paper industry for the pre-treatment of rice straw [

27]. A significantly reduced cost (i.e., nine times less) was observed for the extrusion-refining process. In parallel, this technology was much more efficient, even with reduced amount of water added (i.e., 0.4–1.0 instead of at least 4.0 in the case of the pulping method), as the length of the refined fibers was better preserved using the extrusion-refining process: 21.2–22.6 for their average aspect ratio instead of 16.3–17.9 in the case of the digestion plus defibration process. With such significantly improved mechanical reinforcement capability, the extrusion-refined rice straw thus enabled the manufacture of fiberboards with particularly promising usage properties [

28]. The optimal one was molded after the addition of 8.9% (

w/

w) commercial Biolignin™ (i.e., a pure and non-deteriorated

Organosolv lignin extracted from wheat straw using a mixture of acetic acid and formic acid) as a binder. With a density of 1414 kg/m

3, the latter revealed very high bending properties (i.e., strength at break and elastic modulus of 50 MPa and 8.6 GPa, respectively), simultaneously with good water resistance (i.e., thickness swelling and water absorption of 24% and 18%, respectively, after 24 h soaking in water). Such a rice straw-based material could be used as a load-bearing board under high stress.

Another recent study focused on the extrusion-refining of coriander straw [

13]. The results obtained during this study confirmed the interest of the twin-screw extrusion pre-treatment with regard to the average aspect ratio of the obtained fibres, which was evaluated at values of between 22.9 and 26.5 depending on the amount of water added during extrusion, as opposed to only 4.5 in the case of a straw that was simply crushed using a hammer mill. During this study, fiberboards combining the straw as a reinforcement and the cake resulting from the extraction of vegetable oil from the coriander seeds as a protein binder were manufactured through hot pressing. All biocomposites made of the extrusion-refined coriander fibers have shown better usage properties, and the optimal 100% coriander-based board was the one containing 40% (

w/

w) cake. The latter had the next characteristics: 1195 kg/m

3 density, 29.1 MPa flexural strength at break, 3.9 GPa elastic modulus, 24% thickness swelling, and 24% water absorption. Less dense and with lower bending properties than the optimal hardboard developed by Theng et al. from rice straw [

28], it still had a water resistance after 24 h immersion of the same order of magnitude, thanks to a heat post-treatment applied after hot pressing. Its bending properties were nonetheless sufficient to use it in dry conditions, for general purposes (e.g., carcasses, domestic flooring, etc.) as well as furniture grade and load-bearing board (e.g., shelving). Additionally, the VOC and carbonyl compound emissions from this hardboard were studied, and no formaldehyde emission was detected [

29]. In comparison with most of the wood-based materials available on the market (e.g., medium-density fiberboard (MDF) or chipboard, which have also been tested in that study), it was thus more environmentally and human-health friendly.

A single twin-screw extruder can even be used both as a continuous fiber-refining tool and as a tool for adding continuously an exogenous binder to the previously refined fibers, resulting at the extruder outlet in an homogeneous premix made of reinforcing fibers and a binder, ready to be transformed into cohesive fiberboards through hot pressing [

13,

31].

In respect with the biorefinery concept of whole plants, this study aimed to develop a continuous mechanical process allowing the fractionation of the amaranth stem into bark and pith, and to investigate the use of those two fractions for building material applications. Two families of innovative bio-based materials were investigated, i.e., bulk (loose fill) insulation and low-density blocks from the pith fraction on the one hand, and hardboards from the bark fraction on the other hand. The use as a natural binder of the solid residue (i.e., the cake) obtained after extraction of vegetable oil from the amaranth seeds using an apolar solvent was also investigated in this study, due to its natural richness in proteins and especially starch.

2. Materials and Methods

2.1. Raw Materials and Natural Binders

The amaranth (Amaranthus cruentus) stems and seeds used in this study were from the South-West part of France. They were cultivated near the city of Auch during the summer of 2018. They were supplied by Ovalie Innovation (Auch, France).

The starch-based binder used for producing the low-density insulation blocks had an 85% (w/w) starch content. Supplied by Bostik (Colombes, France) with reference number 28474, it is usually used as a glue for wallpapers.

The amaranth-based binder (AB) used for obtaining the hardboards was prepared from the seeds supplied by Ovalie Innovation. Firstly, the latter were grinded using a Foss (Hilleroed, Denmark) Cyclotec 1093 sample mill fitted with a 1 mm screen. Deoiling was then conducted using a Soxhlet extraction apparatus (Lenz Laborglas, Wertheim, Germany), and cyclohexane as extracting solvent.

2.2. Analytical Methods

Mineral content inside amaranth pith and bark were determined according to the ISO 749:1977 standard [

45]. An estimation of the three parietal constituents, i.e., cellulose, hemicelluloses, and lignins, was made from the ADF-NDF (ADF, Acid Detergent Fiber; NDF, Neutral Detergent Fiber) method of Van Soest and Wine [

46,

47]. The water-soluble components were determined by measuring the mass loss of the test sample after 1 h in boiling water. All determinations were made in triplicate.

2.3. Grinding of Amaranth Stems and Separation between Bark and Pith Particles

The grinding of amaranth stems was done using an Electra (Poudenas, France) Goulu N hammer mill with no grid. The separation between bark and pith particles was then conducted using a vacuum cleaner. The suction step was repeated three times, first on a Ritec 600 (Signes, France) vibrating sieve shaker and then twice on a rough and inclined conveyor belt.

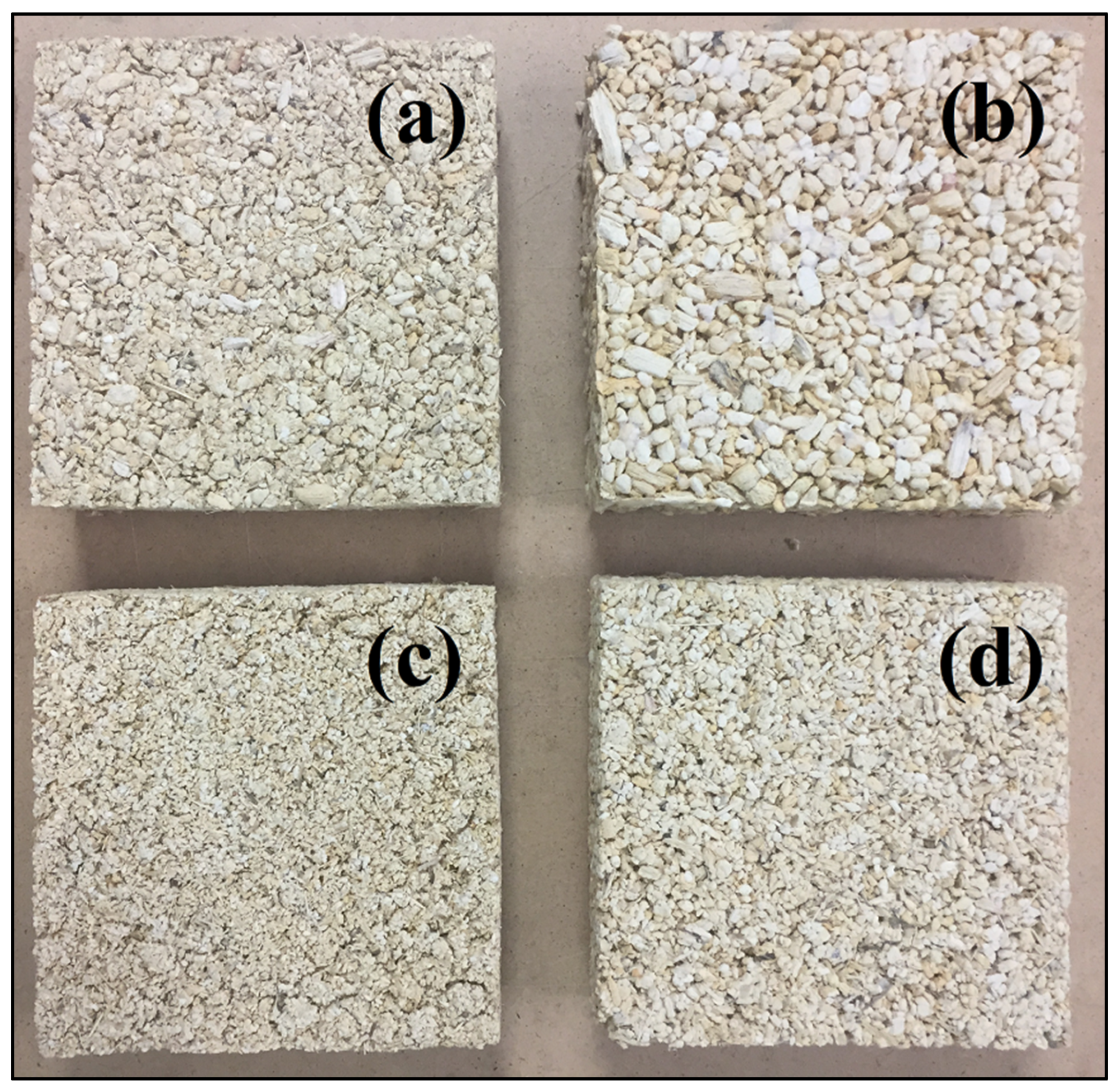

During the initial sieving stage, the sieve shaker was fitted with two sieves with a mesh of 2 mm and 1 mm, respectively, from top to bottom. Three different fractions made of dense bark particles were thus generated, i.e., fines (<1 mm), and medium (from 1 to 2 mm) and large particles (>2 mm). Additionally, thanks to the vacuum cleaner positioned above the upper sieve, the light pith particles were sucked continuously.

The three bark fractions collected at the level of the sieve shaker were almost pure. On the opposite, the pith one still contained some bark impurities, which were sucked simultaneously with the pith particles. Two additional purification extra-steps were thus required. The latter were conducted using an inclined conveyor belt made of a rough rubber band. A ventilator with an air speed from 1.0 to 2.5 m/s was positioned at 1.3 m from the bottom of the conveyor belt, and the vacuum cleaner at its bottom. The movement of the conveyor belt was at constant speed, from bottom to top.

The pith fraction to be purified was fed at a constant mass flow rate onto the conveyor belt just in front of the ventilator. In doing so, the ventilation opposed the movement of the conveyor belt, and this allowed the pith particles, which were light and rather cylindrical in shape, to roll down to the bottom of the device where they were sucked. The bark particles to be removed, on the other hand, were much denser and had an elongated shape, so that they remained attached to the rough surface of the rubber band. They could then be picked up from the top of the device. In order to obtain a pith fraction with a purity of more than 90% (w/w), two successive passes of the pith on the conveyor belt were necessary, using an angle of inclination equal to 32° and 23°, respectively.

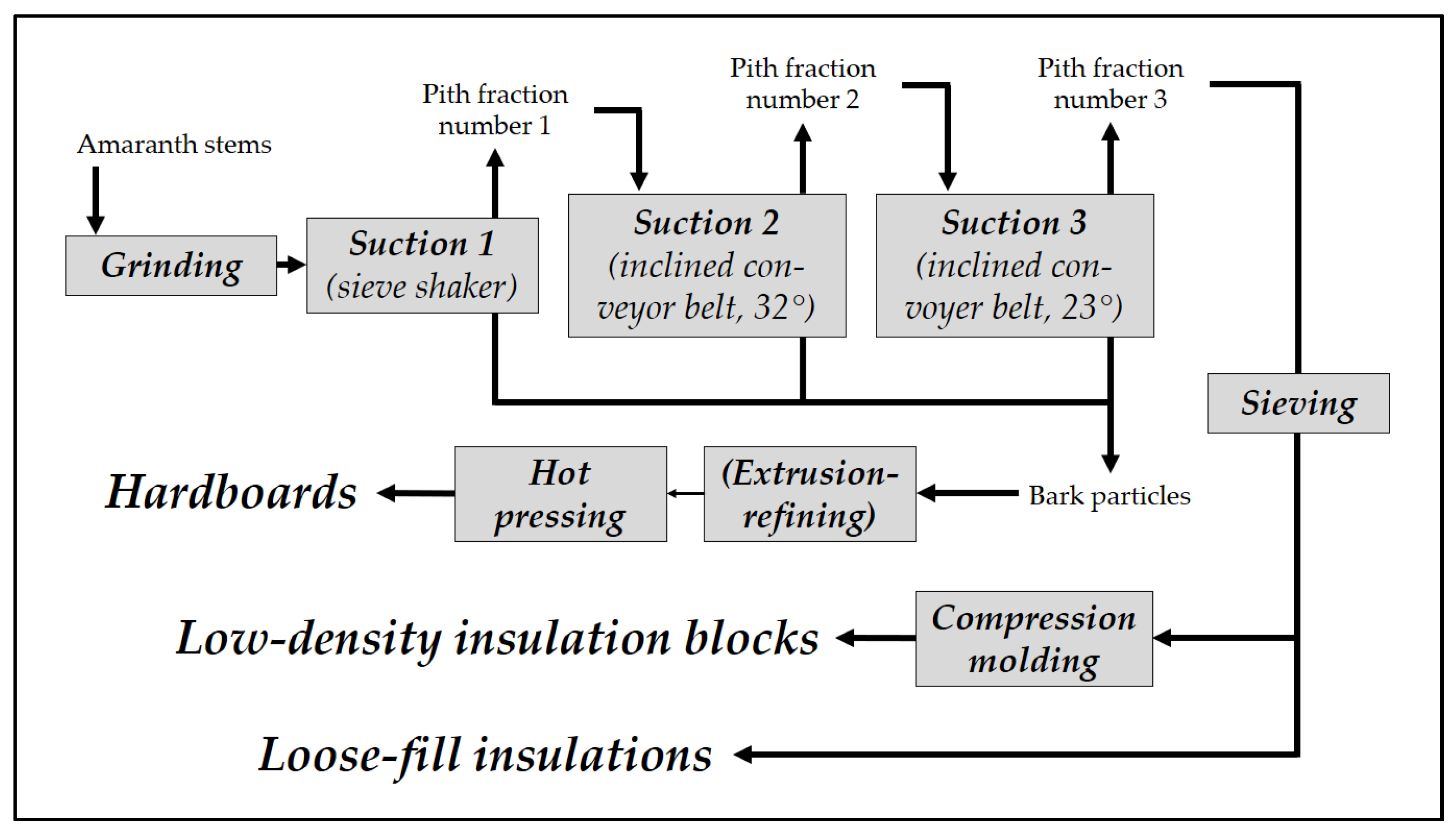

In

Figure 1, a schematic diagram of the fractionation process of the amaranth stems, including their grinding and then their separation between bark and pith particles through three successive suction stages, is presented. This diagram also includes the building materials obtained from each of these two fractions and the equipment used to obtain them.

2.4. Sieving of Pith Particles

To determine the particle size distribution of the pith particles, a Retsch AS 300 (Haan, Germany) vibratory sieve shaker was used. The three implemented sieves had a mesh of 4 mm, 2 mm and 1 mm, respectively, from top to bottom. A sieve acceleration of 1.5× g and a sieving time of 10 min were chosen for sieving.

2.5. Twin-Screw Extrusion-Refining of Fibers from Amaranth Bark

Amaranth bark particles with a diameter of more than 2 mm and a moisture content of 6.0 ± 0.0% were extrusion-refined in the presence of water using a Clextral (Firminy, France) Evolum HT 53 co-rotating and co-penetrating twin-screw extruder. The screws were 53 mm in diameter (D), and the barrel was 36 D in length with nine successive modules, each 4 D in length.

The thermo-mechanical fiber pre-treatment was inspired by a previous work developed from the coriander straw [

13]. Amaranth bark was fed using a weight dosing device in module 1, and water was injected using a piston pump at the end of module 2. In particular, to prevent water from clogging the twin-screw extruder, a filtration module equipped with two filter grids made of 1 mm diameter holes was positioned at the end of the barrel, i.e., in penultimate position. The excess of water was thus removed (in the form of an aqueous filtrate).

The screw profile used was that of Uitterhaegen et al. [

13]. In particular, two successive pairs (i.e., 2 D in length) of BB bilobe paddles mounted in a staggered pattern (i.e., with a 90° angle) were positioned in module 5 to ensure intimate mixing and homogenization of solid and liquid phases. In addition, four successive pairs (i.e., 1.5 D in length) of CF1C screws (i.e., conjugated cut-flight, single-flight screws with left-handed pitch) were positioned at the beginning of module 9. Thanks to the intense mechanical shear applied to the raw material in this location, this enabled an efficient extrusion-refining of fibers in amaranth bark.

The temperature profile used was as follows: 25 °C for module 1 (feeding module), 50 °C for module 2, 80 °C for module 3, 100 °C for modules 4 to 7, and 110 °C for module 9 (thermo-mechanical refining module).

The screw rotation speed was 250 rpm. The inlet flow rate of amaranth bark particles was 10 kg/h. Three different inlet flow rates of water were tested (i.e., 10 kg/h, 20 kg/h and 40 kg/h, respectively), corresponding to liquid/solid ratios of 1, 2, and 4, respectively.

2.6. Molding of Insulation Blocks and Hardboards

The compression molding of the insulation blocks was conducted at room temperature inside an aluminium mold with 15 cm sides using a conventional hydraulic press. A pressure of 9 kPa was applied at room temperature for 5 min to the mixture composed of pith particles (bulk test sample volume equal to 2700 cm3), starch-based binder (10% (w/w) in proportion to the sum of the pith and binder masses), and water (3.7% (w/w) for the binder to water ratio). For the medium size (2–4 mm) of pith particles only, starch-based binder contents of 15%, 20% and 25% (w/w) were also tested.

Once molded, the insulation blocks were dried at 60 °C in a France Etuves (Chelles, France) XL2520 ventilated oven until constant weight (i.e., mass variation less than 0.1% after 24 h). The drying step was conducted with the objective to eliminate the water added to dissolve the binder. As the external starchy binder used was with physical curing, the adhesion was achieved as water evaporated.

The hot pressing of hardboards was conducted using 400 tons capacity Pinette Emidecau Industrie (Chalon-sur-Saône, France) heated hydraulic press. The conditions were standard ones [

13,

30], i.e., 200 °C for the mold temperature, 20 MPa for the applied pressure, and 5 min for the molding time.

A 150 mm × 150 mm aluminium mold was used to perform both compression molding and hot pressing. The material thickness was 4 cm and around 4.5 mm, respectively, for the insulation blocks and hardboards. All materials were then equilibrated in a climatic chamber at 60% relative humidity (RH) and 25 °C until constant weight (i.e., mass variation less than 0.1% after 24 h). The equilibration lasted around three weeks, after which the materials were analyzed.

2.7. Density Measurements

The bulk density of the pith and bark particles was measured using a 2 L test tube. Once filled with the particles, the latter were weighed in order to determine the bulk density. The tapped density of bark particles, before and after the extrusion-refining step, was determined using a Granuloshop (Chatou, France) Densitap ETD-20 volumenometer. All determinations were carried out in triplicate.

The density of the insulation blocks and hardboards was conducted from the bending test specimens. An electronic digital sliding caliper having a resolution of 0.01 mm was used to measure their thickness, width, and length, allowing the specimen volume to be calculated. In parallel, all the test specimens were also weighed, enabling their density to be determined. All determinations were carried out four times.

2.8. Physical Characterization of the Building Materials

The flexural properties of the insulation blocks and hardboards were measured using the three points bending technique according to the ISO 16978:2003 standard [

48]. The universal testing machine used for those tests was an Instron (Norwood, MA, USA) 5500R machine fitted with a 500 N load cell. All test specimens were 3 cm wide, and 12 cm long. The grip separation was 8 cm, and the test speed was 2 mm/min. All determinations were conducted four times.

The thermal conductivity of loose pith particles and insulation blocks was measured at 25 °C using a Neotim (Albi, France) FP2C thermal conductivimeter with a hot wire. A 5% accuracy was obtained for these measurements. During the hot wire test, an electric current through the linear wire generated heat, which resulted in the increase of the temperature of the material tested. The wire length was considered as infinite, and its diameter as negligible. The wire and thermocouple were included in a Kapton probe. During the test, the probe was placed in the middle of the pith particles arranged in bulk, or between two samples of the insulation block. As the material tested was considered as semi-infinite, the heat conduction equation was solved in cylindrical coordinates. This allowed the determination of the thermal conductivity. Then, the thermal resistance was deduced from the thermal conductivity value by considering a 4 cm thickness for the loose pith particles as for the insulation blocks. Before the test, the pith particles were equilibrated in a climatic chamber under the same conditions as those used for the insulation blocks, i.e., 60% RH and 25 °C for three weeks. All determinations were conducted in triplicate.

The thickness swelling of hardboards was measured after 24 h immersion in water according to the ISO 16983:2003 standard [

49]. Expressed in mass percentage, their water absorption level was determined at the same time. All determinations were conducted four times.

2.9. Statistical Analyses

Results are expressed as mean value ± standard deviation. One-way analysis of variance (ANOVA) was used in order to examine the significance of the effect of factors on studied traits. Duncan’s multiple range test was used to compare individual means at a 5% probability level.