Review of Functional Treatments for Modified Wood

Abstract

1. Introduction

2. The Main Modification Systems

- Thermal modification—the process of altering hygroscopicity through use of elevated temperatures (160 °C to approx. 230 °C) in an inert atmosphere, steam or vacuum, including Thermowood®, VacWood®, LunaWood®, VAP Holzsystemr® [11]

- Resin or polymer modification—the process of impregnating wood with thermosetting resins, monomers or oligomers capable of cross-linking in situ in the wood cell wall and/or cell lumena to form a non-leachable polymeric system, including furfurylation (Kebony®, NobelWood® [10]), resin modification (ImpregTM, InduriteTM, Lignia® [12]) and polymer impregnations (Permagrain, Permali®, Jabroc®).

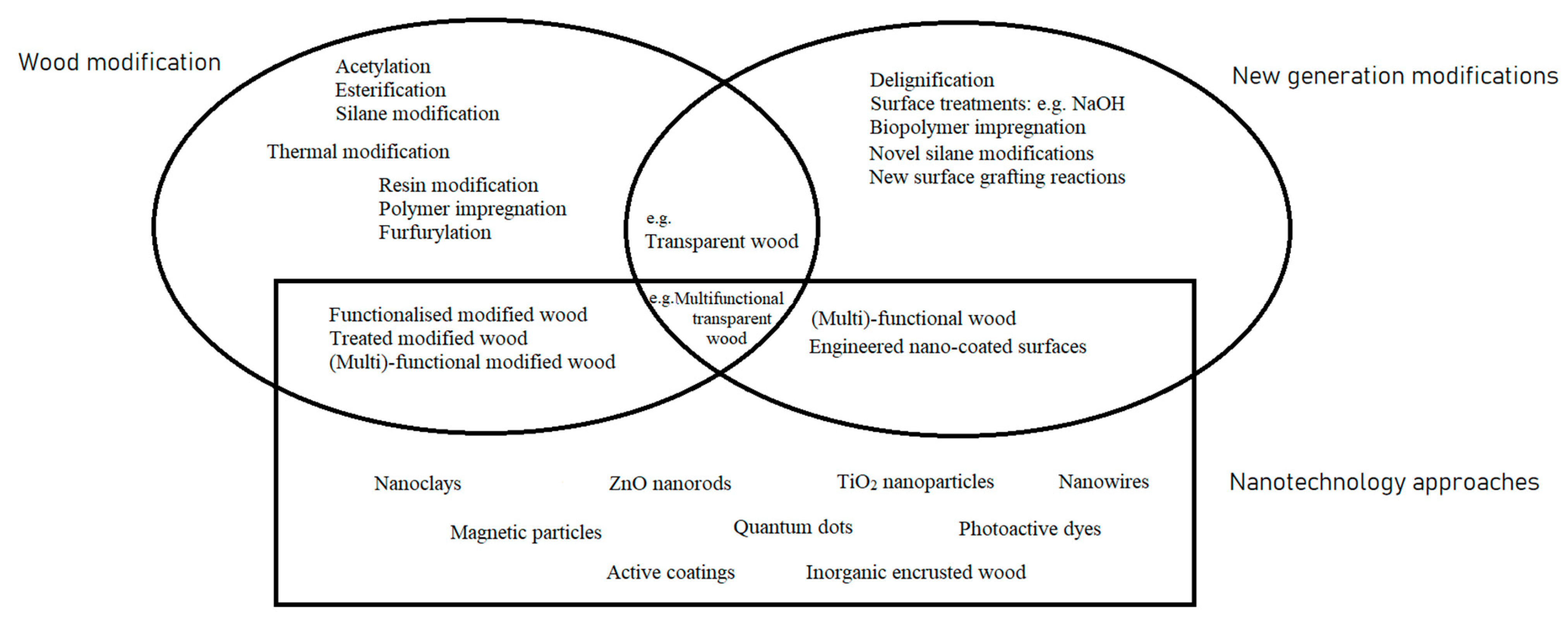

3. Adding Functionality to Modified Wood

3.1. Thermally Modified Wood with Functionality

3.1.1. TiO2 for Weathering Resistance

3.1.2. Silica Nanosols

3.1.3. Suppressing Mould Growth

3.1.4. Other Improvements through Concurrent Treatments

3.2. Resin Modified Wood with Functionality

UV Resistance Promotion for Resin Modified Timber

3.3. Acetylation and Esterification of Wood with Added Functionality

3.3.1. Chemical Modification with UV Stability

3.3.2. Esterification as a Pre-Treatment for Other Purposes

3.4. Polymer Impregnation with Functionality

3.4.1. Biodegradability in Impregnated Wood

3.4.2. Pretreatments and Grafting for Polymer Impregnation Modifications

3.4.3. Delignification Combined with Polymer Impregnation—Transparent Wood

4. Functionality and Multi-Functionality through Other Wood Modifications

4.1. New Approaches for Functionality

4.2. Delignified Wood with Functionality

4.3. Sodium Hydroxide Treatment

4.4. Other Modifications with Functionality

| Additive | Used during Modification | Used after Modification | Properties Given or Enhanced | Refs. |

|---|---|---|---|---|

| Metal oxides nanoparticles: TiO2, ZnO, CeO2 | - | Unmodified wood | Photocatalytic properties; UV-protection; Self-cleaning | [19] |

| Silicon nanoparticles; TiO2 nanoparticles; ZnO nanorods | - | Unmodified wood | Superhydrophobic properties; Fire retardancy | [97,98] |

| TiO2 (anatase form) | Polymer impregnated wood | Unmodified wood [99] Thermal mod. [17,21] | Hydrophobic surface treatment | [17,21,99,100] |

| TiO2 (rutile form) | - | Unmodified wood [101]; Thermal mod. [16] | UV resistance | [16,101] |

| Nanoclay (layered aluminosilicates) | PF Resin modification, Polymer impregnation | - | Quicker reaction, Improved dimensional stability | [100,102] |

| Halloysite, Montmorillonite, Calcium carbonate, TiO2, silica nanoparticles | - | - | As a carrier for biocides | [103] |

| Montmorillonite clay | - | Delignified wood | Fire retardancy; Readily splits into multiple platelets | [84,98] |

| Fe3O4 particles; MnFe2O4 particles; CoFe2O4 particles | - | - | Magnetic properties | [83] |

| Fe3O4 nanoparticles | Before PMMA impregnation | - | Magnetic properties | [78] |

| CoFe2O4 nanoparticles | Before silane treatment | - | Magnetic properties; hydrophobicity when combined with OTS | [77] |

| Metal organic frameworks (MOFs) ZIF-8 & MOF199 | - | NaOH pretreated scaffold | Adsorption of gases | [89] |

| Metal oxides (atomic layer deposition) | - | Unmodified wood | Hygroscopicity and resistance to mould growth | [104] |

| MXene (transition metal carbides, carbonitrides and nitrides) | - | Unmodified wood | Elecrtomagnetic shielding | [105] |

| Silver nanoparticles | Before thermal modification | Unmodified wood | Decay resistance; electrical conduction | [106,107,108] |

| Quantum dots (Si and CdSe) (CdSe and ZnS) | PMMA impregnation (transparent) | Delignified scaffold | Luminescence—red & green excitation caused by blue or UV light | [68,109] |

| Electrochromic polymers (ECPs) | PMMA impregnation (transparent) | - | Colour change on electrical current | [74] |

| Rh6G dye (Rhodamine 6G) | PMMA impregnation (transparent) | - | Red colour of transparent wood; laser output (565 to 570 nm) from the wood perpendicular to input laser (532 nm) | [70,71] |

| Carnauba wax and organoclay | - | Thermal modification | Reduction in water uptake; increase in strength properties; improved photostability | [110] |

5. Targeted Properties

5.1. Hydrophobicity

5.2. Self-Healing

5.3. Indoor Environment Improvement

5.4. UV Resistance

5.5. Photochromic Behaviour

5.6. Acoustic Properties

5.7. Electrical Conductivity

5.8. Fire-Retardant Properties

6. Discussion

- The action of chemical, physical or biological agents on the cell wall—in the case of this review, primarily chemical processes have been described, but also compression which is a physical process.

- Achievement of property enhancement has been achieved, in a very diverse set of properties.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ross, P.; Downes, G.; Lawrence, A. Timber in Contemporary Architecture; TRADA Technology Ltd.: London, UK, 2009. [Google Scholar]

- Ansell, M.P. Hybrid wood composites–integration of wood with other engineering materials. In Wood Composites; Ansell, M.P., Ed.; Chapman & Hall: London, UK, 2015; pp. 411–426. [Google Scholar]

- Hill, C.A.S. Wood Modification—Chemical, Thermal and Other Processes; Wiley Series in Renewable Resources; John Wiley & Sons: Chichester, UK, 2006; p. 260. [Google Scholar]

- Ormondroyd, G.A.; Spear, M.J.; Curling, S.C. Modified wood: Review of efficacy and service life testing. Constr. Mater. 2015, 168, 187–203. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. iForest 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Jones, D.; Sandberg, D. A review of wood modification globally–updated findings from COST FP1407. Interdiscip. Perspect. Built Environ. 2020, 1, 1. [Google Scholar] [CrossRef]

- Spear, M.J. Preservation, protection and modification of wood composites. In Wood Composites; Ansell, M.P., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 253–310. [Google Scholar]

- Eaton, R.A.; Hale, M.D.C. Wood: Decay Pests and Protection; Chapman and Hall: London, UK, 1993. [Google Scholar]

- Rowell, R.M. Acetylation of wood—A Review. Int. J. Lignocellul. Prod. 2014, 1, 1–27. [Google Scholar]

- Mantanis, G.I. Chemical reaction of wood by acetylation and furfurylation: A review of the present scaled up technologies. BioResources 2017, 12, 4478–4489. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. BioResources 2009, 3, 142–154. [Google Scholar] [CrossRef]

- Stefanowski, B.; Spear, M.; Pitman, A. Review of the use of PF and related resins for modification of solid wood. In Timber 2018; Spear, M.J., Ed.; IOM3: London, UK, 2018; pp. 165–179. [Google Scholar]

- Srinivas, K.; Pandey, K. Photodegradation of thermally modified wood. J. Photochem. Photobiol. 2012, 117, 140–145. [Google Scholar] [CrossRef]

- Huang, X.; Kocaefe, D.; Kocaefe, Y.; Boluk, Y.; Krause, C. Structural analysis of heat-treated birch (Betula papyrifera) surface during artificial weathering. Appl. Surf. Sci. 2013, 264, 117–127. [Google Scholar] [CrossRef]

- Ayadi, N.; Lejeune, F.; Charrier, F.; Charrier, B.; Merlin, A. Color stability of heat-treated wood during artificial weathering. Holz Als Roh-Und Werkst. 2003, 61, 221–226. [Google Scholar] [CrossRef]

- Miklecic, J.; Turkulin, H.; Jirous-Rajkovic, V. Weathering performance of surface of thermally modified wood finished with nanoparticles-modified waterborne polyacrylate coatings. Appl. Surf. Sci. 2017, 408, 103–109. [Google Scholar] [CrossRef]

- Shen, H.; Zhang, S.; Cao, J.; Jiang, J.; Wang, W. Improving anti-weathering performance of thermally modified wood by TiO2 or/and paraffin emulsion. Constr. Build. Mater. 2018, 169, 372–378. [Google Scholar] [CrossRef]

- Veronovski, N.; Verhofsek, D.; Godmjavec, J. The influence of surface treated nano-TiO2 (rutile) incorporation in water-based acrylic coatings on wood protection. Wood Sci. Technol. 2013, 47, 317–328. [Google Scholar] [CrossRef]

- Faure, B.; Salazar-Alvarez, G.; Ahniyaz, A.; Villaluenga, L.; Berriozabal, G.; De Miguel, R.D.M.; Bergstrom, L. Dispersion and surface functionalisation of oxide nanoparticles for transparent photocatalytic and sunscreens. Sci. Technol. Adv. Mater. 2013, 14, 023001. [Google Scholar] [CrossRef]

- Guo, H.; Klose, D.; Hou, Y.; Jesche, G.; Burgert, I. Highly efficient UV protection of the biomaterial wood by a transparent TiO2/Ce xerogel. ACS Appl. Mater. Interfaces 2017, 9, 39040–39047. [Google Scholar] [CrossRef]

- Shen, H.; Cao, J.; Jiang, J.; Xu, J. Antiweathering properties of a thermally treated wood surface by two-step treatment with titanium dioxide nanoparticle growth and polydimethylsiloxane. Prog. Org. Coat. 2018, 125, 1–7. [Google Scholar] [CrossRef]

- Papadopoulos, A.; Taghiyari, H.R. Innovative wood surface treatments based on nanotechnology. Coatings 2019, 9, 866. [Google Scholar] [CrossRef]

- Mahltig, B.; Swaboda, C.; Roessler, A.; Böttcher, H. Functionalising wood by nanosol application. J. Mater. Chem. 2008, 18, 3180. [Google Scholar] [CrossRef]

- Wang, X.; Chai, Y.; Liu, J. Formation of highly hydrophobic wood surfaces using silica nanoparticles modified with long-chain alkylsilane. Holzforschung 2013, 67, 667–672. [Google Scholar] [CrossRef]

- Mahltig, B.; Arnold, M.; Löthman, P. Surface properties of sol–gel treated thermally modified wood. J. Sol-Gel Sci. Technol. 2010, 55, 221–227. [Google Scholar] [CrossRef]

- Kwaśniewska-Sip, P.; Bartkowiak, M.; Cofta, G.; Bolesław Nowak, P. Resistance of Scots Pine (Pinus sylvestris L.) after Treatment with Caffeine and Thermal Modification against Aspergillus niger. BioResources 2019, 14, 1890–1898. [Google Scholar]

- Karlsson, O.; Myronycheva, O.; Jones, D.; Sandberg, D. Thermally modified wood treated with methacrylate. In Proceedings of the IRG Annual Meeting IRG49 Scientific Conference on Wood Protection, Sandton, Johannesburg, South Africa, 29 April–3 May 2018. [Google Scholar]

- Kim, I.; Karlsson, O.; Myronycheva, O.; Jones, D.; Sandberg, D. Methacrylic Resin for Protection of Wood from Discoloration by Mould Growth and Weathering. BioResources 2020, 15, 7018–7033. [Google Scholar]

- Duarte, S.; Nunes, L.; Kržišnik, D.; Humar, M.; Jones, D. Influence of zwitterionic buffer effects with thermal modification treatments of wood on symbiotic protists in Reticulotermes grassei Clement. Insects 2021, 12, 139. [Google Scholar] [CrossRef]

- Popescu, C.-M.; Jones, D.; Kržišnik, D.; Humar, M. Determination of the effectiveness of a combined thermal/chemical wood modification by the use of FT–IR spectroscopy and chemometric methods. J. Mol. Struct. 2020, 1200, 12713. [Google Scholar] [CrossRef]

- Salman, S.; Thevenon, M.-F.; Petrissans, A.; Dumarcay, S.; Candelier, K.; Gerardin, P. Improvement of the durability of heat-treated wood against termites. Maderas Cienc. Y Tecnol. 2017, 19, 317–328. [Google Scholar] [CrossRef]

- Kielmann, B.C.; Mai, C. Application and artificial weathering performance of translucent coatings on resin-treated and dye-stained beech-wood. Prog. Org. Coat. 2016, 95, 54–63. [Google Scholar] [CrossRef]

- Evans, P.D.; Gibson, S.K.; Cullis, I.; Liu, C.; Sebe, G. Photostabilisation of wood using low molecular weight phenol formaldehyde resin and hindered amine light stabilisers. Polym. Degrad. Stab. 2013, 98, 158–168. [Google Scholar] [CrossRef]

- Stefanowski, B.K.; Spear, M.J.; Curling, S.F.; Pitman, A.J.; Bailey, R.J.D.; Mathias, J.; Evans, N.; Ayala, L.; Theobald, T.; Ormondroyd, G.A. Properties of LIGNIA modified wood. In Timber 2020; Spear, M., Ed.; IOM3: London, UK, 2020; pp. 177–188. [Google Scholar]

- Wang, Z.; Han, X.; Wang, S.; Lv, Y.; Pu, J. Enhancing the thermal stability, water repellency, and flame retardancy of wood treated with succinic anhydride and melamine-urea formaldehyde resins. Holzforschung 2020, 74, 957–965. [Google Scholar] [CrossRef]

- Evans, P.D.; Wallis, A.F.A.; Owen, N.L. Weathering of chemically modified wood surfaces: Natural weathering of Scots pine acetylated to different weight gains. Wood. Sci. Technol. 2000, 32, 151–165. [Google Scholar] [CrossRef]

- Chang, S.-T.; Chang, H.-T. Comparisons of the photostability of esterified wood. Polym. Degrad. Stab. 2001, 71, 261–266. [Google Scholar] [CrossRef]

- Pandey, K.K.; Chandrashekar, N. Photostability of wood surfaces esterified by benzoyl chloride. J. Appl. Polym. Sci. 2005, 99, 2367–2374. [Google Scholar] [CrossRef]

- Feist, W.C.; Hon, D.N.S. Chemistry of weathering and protection. In The Chemistry of Solid Wood; Rowell, R.M., Ed.; Advances in Chemistry Series; American Chemistry Society: Washington, DC, USA, 1984; Volume 207. [Google Scholar]

- Rosu, D.; Bodirlau, R.; Teaca, C.-A.; Rosu, L.; Varganici, C.D. Epoxy and succinic anhydride functionalized soybean oil for wood protection against UV light action. J. Clean. Prod. 2016, 112, 1175–1183. [Google Scholar] [CrossRef]

- Olsson, S.K.; Johansson, M.; Westin, M.; Östmark, E. Reactive UV-absorber and epoxy functionalized soybean oil for enhanced UV-protection of clear coated wood. Polym. Degrad. Stab. 2014, 110, 405–414. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Q.; Li, J.; Liu, Y.; Wang, X.-M.; Liu, Z. Improvement of dimensional stability of wood via combination treatment: Swelling with maleic anhydride and grafting with glycidyl methacrylate and methyl methacrylate. Holzforschung 2012, 66, 59–66. [Google Scholar] [CrossRef]

- Schneider, M.H.; Phillips, J.G. Elasticity of wood and wood polymer composites in tension and compression loading. Wood Sci. Technol. 1991, 25, 361–364. [Google Scholar] [CrossRef]

- Ermeyden, M.A.; Babacan, M.; Tomak, E.D. Evaluation of dimensional stability, weathering and decay resistance of modified pine wood by in-situ polymerisation of styrene. J. Wood Chem. Technol. 2020, 40, 294–305. [Google Scholar] [CrossRef]

- Devi, R.R.; Maji, T.K. Effect of glycidyl methacrylate on the physical properties of wood-polymer composites. Polym. Compos. 2007, 28, 1–5. [Google Scholar] [CrossRef]

- Curling, S.F.; Spear, M.J.; Ormondroyd, G. A Gibson R Physical properties and durability of methacrylate impregnated timber. In Proceedings of the 13th Annual Meeting of the Northern European Network for Wood Science and Engineering, Copenhagen, Denmark, 28–29 September 2017; pp. 32–37. [Google Scholar]

- Ermeyden, M.A.; Cabane, E.; Hass, P.; Koetz, J.; Burgert, I. Fully biodegradable modification of wood for improvement of dimensional stability and water absorption properties by poly(ε-caprolactone) grafting into the cell walls. Green Chem. 2014, 16, 3313–3321. [Google Scholar] [CrossRef]

- Noel, M.; Grigsby, W.J.; Vitkeviciute, I.; Volkmer, T. Modifying wood with biopolyesters: Analysis and performance. Int. Wood Prod. J. 2014, 6, 14–20. [Google Scholar] [CrossRef]

- Noel, M.; Grigsby, W.J.; Volkmer, T. Evaluating the extent of bio-polyester polymerization in solid wood by thermogravimetric analysis. J. Wood Chem. Technol. 2015, 35, 325–336. [Google Scholar] [CrossRef]

- Noel, M.; Grigsby, W.J.; Ormondroyd, G.A.; Spear, M.J. Influence of water and humidity on chemically modifying wood with polybutylene succinate bio-polyester. Int. Wood Prod. J. 2016, 7, 80–88. [Google Scholar] [CrossRef]

- Grosse, C.; Noel, M.; Thevenon, M.-F.; Rautkari, L.; Gerardin, P. Influence of water and humidity on wood modification with lactic acid. J. Renew. Mater. 2017, 6, 259–269. [Google Scholar] [CrossRef]

- Berglund, L.; Burgert, I. Bioinspired wood nanotechnology for functional materials. Adv. Mater. 2018, 30, 1704285. [Google Scholar] [CrossRef] [PubMed]

- Cabane, E.; Keplinger, T.; Merk, V.; Hass, P.; Burgert, I. Renewable and functional wood materials by grafting polymerization within cell walls. ChemSusChem 2014, 7, 1020–1025. [Google Scholar] [CrossRef]

- Cabane, E.; Keplinger, T.; Künniger, T.; Merk, V.; Burgert, I. Functional lignocellulosics prepared by ATRP from a wood scaffold. Sci. Rep. 2016, 6, 31287. [Google Scholar] [CrossRef] [PubMed]

- Trey, S.; Jafarzadeh, S.; Johansson, M. In-situ polymerization of polyaniline in wood veneers. ACS Appl. Mater. Interfaces 2012, 4, 1760–1769. [Google Scholar] [CrossRef] [PubMed]

- Hassel, B.I.; Trey, S.; Leijonmarck, S.; Johansson, M. A study on the morphology mechanical and electrical performance of polyaniline-modified wood—A semiconducting material. BioResources 2014, 9, 5007–5023. [Google Scholar] [CrossRef][Green Version]

- Li, Y.; Fu, Q.; Yu, S.; Yan, M.; Berglund, L. Optically transparent wood from nanoporous cellulosic template combining functional and structural performance. Biomacromolecules 2016, 17, 1358–1364. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Song, J.; Li, T.; Gong, A.; Wang, Y.; Dai, J.; Yao, Y.; Luo, W.; Henderson, D.; Hu, L. Highly anisotropic, highly transparent wood composites. Adv. Mater. 2016, 28, 5181–5187. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Fu, Q.; Yang, X.; Berglund, L. Transparent wood for functional and structural applications. Phil. Trans. R. Soc. A 2017, 376, 20170182. [Google Scholar] [CrossRef]

- Wu, J.M.; Wu, Y.; Yang, F.; Tang, C.Y.; Huang, Q.T.; Zhang, J.L. Impact of delignification on morphological, optical and mechanical properties of transparent wood. Compos. Part A 2019, 117, 324–331. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Rojas, R.; Yan, M.; Lawoko, M.; Berglund, L. Lignin-retaining transparent wood. ChemSusChem 2017, 10, 3445–3451. [Google Scholar] [CrossRef]

- Mi, R.; Li, T.; Dalgo, D.; Chen, C.; Kuang, Y.; He, S.; Zhao, X.; Xie, W.; Gan, W.; Zhu, J.; et al. A clear strong and thermally insulated transparent wood for energy efficient windows. Adv. Funct. Mater. 2020, 30, 1907511. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Y.; Yang, F.; Wang, J.; Wang, X. Study on the properties of transparent bamboo prepared by epoxy resin impregnation. Polymers 2020, 12, 863. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Montanari, C.; Yan, M.; Popov, S.; Li, Y.; Sychugov, I.; Berglund, L.A. Refractive index of delignified wood for transparent biocomposites. RSC Adv. 2020, 67, 40719. [Google Scholar] [CrossRef]

- Wang, X.; Zhan, T.; Liu, Y.; Shi, J.; Pan, B.; Zhang, Y.; Cai, L.; Shi, S.Q. Large-size transparent wood for energy-saving building applications. ChemSusChem 2018, 11, 4086–4093. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Zhu, M.; Yang, Z.; Song, J.; Dai, J.; Yao, Y.; Luo, W.; Pastel, G.; Hu, L. Wood composite as an energy efficient building material: Guided sunlight transmittance and effective thermal insulation. Adv. Energy Mater. 2016, 6, 1601122. [Google Scholar] [CrossRef]

- Zhu, M.; Li, T.; Davis, C.S.; Yao, Y.; Dai, J.; Wang, Y.; AlQatari, F.; Gilman, J.F.; Hu, L. Transparent and haze wood composites for highly efficient broadband light management in solar cells. Nano Energy 2016, 26, 332–339. [Google Scholar] [CrossRef]

- Chen, L.; Xu, Z.; Wand, F.; Duan, G.; Xu, W.; Zhang, G.; Yang, H.; Liu j Jiang, S. A flame-retardant and Transparent wood/polyamide composite with excellent mechanical strength. Compos. Commun. 2020, 20, 100355. [Google Scholar] [CrossRef]

- Li, Y.; Yu, S.; Veinot, J.G.C.; Linnros, J.; Berglund, L.; Sychugov, I. Luminescent transparent wood. Adv. Opt. Mater. 2017, 5, 1600834. [Google Scholar] [CrossRef]

- Vasileva, E.; Li, Y.; Sychugov, I.; Mensi, M.; Berglund, L.; Popov, S. Lasing from organic dye molecules embedded in transparent wood. Adv. Opt. Mater. 2017, 5, 1700057. [Google Scholar] [CrossRef]

- Koivurova, M.; Vasileva, E.; Li, Y.; Berglund, L.; Popov, S. Complete spatial coherence characterization of quasi-random laser emission from dye doped transparent wood. Opt. Express 2018, 26, 13474. [Google Scholar] [CrossRef]

- Yu, Z.; Yao, Y.; Yao, J.; Zhang, L.; Chen, Z.; Gao, Y.; Luo, H. Transparent wood containing CsxWO3 nanoparticles for heat-shielding windows. J. Mater. Chem. Part A 2017, 5, 6019–6024. [Google Scholar] [CrossRef]

- Qiu, Z.; Wang, S.; Wang, Y.; Li, J.; Xiao, Z.; Wang, H.; Lian, D. Transparent wood with thermo-reversible optical properties based on phase-change material. Compos. Sci. Technol. 2020, 200, 108407. [Google Scholar] [CrossRef]

- Lang, A.W.; Li, Y.; De Keersmaecker, M.; Shen, D.E.; Österholm, A.M.; Berglund, L.; Reynolds, J. Transparent wood smart windows: Polymer electrochromic devices based on poly(3,4-ethylenedioxythiophene):poly(styrene sulphonate) electrodes. ChemSusChem 2018, 11, 854–863. [Google Scholar] [CrossRef]

- Montanari, C.; Li, Y.; Chen, H.; Yan, M.; Berglund, L.A. Transparent wood for thermal energy storage and reversible optical transmittance. Appl. Mater. Interfaces 2019, 11, 20465–20472. [Google Scholar] [CrossRef] [PubMed]

- Gan, W.; Xiao, S.; Gao, L.; Gao, R.; Li, J.; Zhan, X. Luminescent and Transparent Wood Composites Fabricated by Poly(methyl methacrylate) and γ-Fe2O3@YVO4,Eu3+ Nanoparticle Impregnation. ACS Sustain. Chem. Eng. 2017, 5, 3855–3862. [Google Scholar] [CrossRef]

- Gan, W.; Gao, L.; Xiao, S.; Zhang, W.; Zhan, X.; Li, J. Transparent magnetic wood composites based on immobilising Fe3O4 nanoparticles into a delignified wood template. J. Mater. Sci. 2017, 52, 3321–3329. [Google Scholar] [CrossRef]

- Wang, X.; Shan, S.; Shi, S.Q.; Zhang, Y.; Cai, L.; Smith, L.M. Optically transparent bamboo with high strength and low thermal conductivity. ACS Appl. Mater. Interfaces 2021, 13, 1662–1669. [Google Scholar] [CrossRef] [PubMed]

- Montanari, C.; Olsen, P.; Berglund, L.A. Interface tailoring by a versatile functionalisation platform for nanostructured wood biocomposites. Green Chem. 2020, 22, 8012. [Google Scholar] [CrossRef]

- Burgert, I.; Cabane, E.; Zollfrank, C.; Berglund, L. Bio-inspired functional wood-based materials–hybrids and replicates. Int. Mater. Rev. 2015, 60, 431–450. [Google Scholar] [CrossRef]

- Merk, V.; Chanana, M.; Keplinger, T.; Gaand, S.; Burgert, I. Hybrid wood materials with improved fire retardance by bio-inspired mineralisation on the nano- and submicron level. Green Chem. 2015, 17, 1423–1428. [Google Scholar] [CrossRef]

- Gan, W.; Gao, L.; Sun, Q.; Jin, C.; Lu, Y.; Li, J. Multifunctional wood with magnetic, superhydrophobic and anti-ultraviolet properties. Appl. Surf. Sci. 2015, 332, 565–572. [Google Scholar] [CrossRef]

- Trey, S.; Olsson, R.T.; Ström, V.; Berglund, L.; Johnasson, M. Controlled deposition of magnetic particles within the 3D template of wood: Making use of the natural hierarchical structure of wood. RSC Adv. 2014, 4, 35678. [Google Scholar] [CrossRef]

- Guo, H.; Fuchs, P.; Cabane, E.; Michen, B.; Hagendorfer, H.; Romanyuk, Y.E.; Burgert, I. UV-protection of wood surfaces by controlled morphology fine-tuning of ZnO nanostructures. Holzforschung 2016, 70, 699–708. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, W.; Wang, C.; Li, Y.; Chen, C.; Song, J.; Dai, J.; Hitz, E.M.; Xu, S.; Yang, C.; et al. High capacity, low-tortuosity and channel-guided lithium metal anode. Proc. Natl. Acad. Sci. USA 2017, 114, 3584–3589. [Google Scholar] [CrossRef]

- Fu, Q.L.; Medina, L.L.; Li, Y.Y.; Carosio, F.; Alireza, H.J.; Berglund, L.A. Nanostructured wood hybrids for fire-retardancy prepared by clay impregnation into the cell wall. ACS Appl. Mater. Interfaces 2017, 9, 36154–36163. [Google Scholar] [CrossRef] [PubMed]

- Frey, M.; Widner, D.; Segmehl, J.S.; Casdorff, K.; Keplinger, T.; IBurgert, I. Delignified and Densified Cellulose Bulk Materials with Excellent Tensile Properties for Sustainable Engineering. ACS Appl. Mater. Interfaces 2018, 10, 5030–5037. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Chen, C.; Yang, Z.; Kuang, Y.; Li, T.; Li, Y.; Huang, H.; Kierzewski, I.; Liu, B.; He, S.; et al. Highly Compressible, Anisotropic Aerogel with Aligned Cellulose Nanofibers. ACS Nano 2018, 12, 140–147. [Google Scholar] [CrossRef]

- Deshpande, A.; Burgert, I.; Paris, O. Hierarchically Structured Ceramics by High-Precision Nanoparticle Casting of Wood. Small 2006, 2, 994–998. [Google Scholar] [CrossRef]

- Tu, K.; Puertolas, B.; Adobes-Vidal, M.; Wang, Y.; Sun, J.; Traber, J.; Burgert, I.; Perez-Ramirez, J.; Keplinger, T. Green synthesis of hierarchical metal-organic framework/wood functional composites with superior mechanical properties. Adv. Sci. 2020, 7, 1902897. [Google Scholar] [CrossRef]

- Blanchet, P.; Landry, V. Nanocomposite coatings and plasma-treatments for wood-based products. In Wood Composites; Ansell, M.P., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 335–355. [Google Scholar]

- Petric, M. Surface modification of wood: A critical review. Rev. Adhes. Adhes. 2013, 1, 216–247. [Google Scholar] [CrossRef]

- Nikolic, M.; Lawther, J.M.; Sanadi, A.R. Use of nanofillers in wood coatings: A scientific review. J. Coat. Technol. Res. 2015, 12, 445–461. [Google Scholar] [CrossRef]

- Mishra, P.K.; Giagli, K.; Tsalagas, D.; Mishra, H.; Talegaonkar, S.; Gyrc, V.; Wimmer, R. Changing face of wood science in modern era: Contribution of nanotechnology. Recent Pat. Nanotechnol. 2018, 12, 13–21. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Insights in the application of stoichiometric and non-stoichiometric titanium oxides for the design of sensors for the determination of gases and VOCs (TiO2-x and TinO2n-1 vs. TiO2). Sensors 2020, 20, 6833. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Progress and insights in the application of MXenes as new 2D nano-materials suitable for biosensors and biofuel cell design. Int. J. Mol. Sci. 2020, 21, 9224. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Fuchs, P.; Casdorff, K.; Michen, B.; Chanana, M.; Hagendorfer, H.; Romanyuk, Y.E.; Burgert, I. Bio-inspired superhydrophobic and omniphobic wood surfaces. Adv. Mater. Interfaces 2017, 4, 1600289. [Google Scholar] [CrossRef]

- Vakhitova, L.N. Fire retardant nanocoating for wood protection. In Nanotechnology in Eco-Efficient Construction; Pacheco-Torgal, F., Diamanti, M.V., Nazari, A., Goran-Granqvist, C., Pruna, A., Amirkhanian, S., Eds.; Woodhead: Cambridge, UK, 2019; pp. 361–383. [Google Scholar]

- Sun, Q.; Lu, Y.; Liu, Y. Growth of hydrophobic TiO2 on wood surface using a hydrothermal method. J. Mater. Sci 2011, 46, 7706–7712. [Google Scholar] [CrossRef]

- Devi, R.R.; Maji, T.K. Study on properties of simul wood (Bombax ceiba L.) impregnated with styrene acrylonitrile polymer, TiO2 and nanoclay. Polym. Bull. 2012, 69, 105–123. [Google Scholar] [CrossRef]

- Sun, Q.; Lu, Y.; Zhang, H.; Zhao, H.; Yu, H.; Xu, J.; Fu, U.; Yang, D.; Liu, Y. Hydrothermal fabrication of rutile TiO2 submicrospheres on wood surface: An efficient method to prepare UV-protective wood. Mater. Chem. Phys. 2012, 133, 253–258. [Google Scholar] [CrossRef]

- Leemon, N.F.; Ashaari, Z.; Uyup, M.K.A.; Bakar, E.S.; Tahir, P.M.; Saliman, M.A.R.; Ghani, M.A.; Lee, S.H. Characterisation of phenolic resin and nanoclay admixture and its effect on impreg wood. Wood Sci. Technol. 2015, 49, 1209–1224. [Google Scholar] [CrossRef]

- Teng, T.-J.; Arip, M.N.M.; Sudesh, K.; Nemoikina, A.; Jalaludin, Z.; Ng, E.-P.; Lee, N.-L. Conventional technology and nanotechnology in wood preservation: A review. BioResources 2018, 13, 9220–9252. [Google Scholar] [CrossRef]

- Gregory, S.A.; McGettigan, C.P.; McGuinness, E.K.; Rodin, D.M.; Yee, S.K.; Losego, M.D. Single-cycle atomic layer deposition on bulk wood lumber for managing moisture content, mold growth and thermal conductivity. Langmuir 2020, 36, 1633–1641. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Han, X.; Wang, S.; Han, X.; Pu, J. MXene/wood-based composite materials with electromagnetic shielding properties. Holzforschung 2020. [Google Scholar] [CrossRef]

- Bayani, S.; Taghiyari, H.R.; Papodopoulos, A.N. Physical and mechanical properties of thermally modified beech wood impregnated with silver nano-suspension and their relationship with the crystallinity of cellulose. Polymers 2019, 11, 1538. [Google Scholar] [CrossRef]

- Akhtari, M.; Ganjipour, M. Effect of nano-silver and nano-copper and nano zinc oxide on Paulownia wood exposed to white rot fungus. Agric. Sci. Dev. 2013, 2, 116–119. [Google Scholar]

- Gao, L.; Lu, Y.; Li, J.; Sun, S. Superhydrophobic conductive wood with oil repellency obtained by coating with silver nanoparticles modified with fluoroalkyl silane. Holzforschung 2016, 70, 63–68. [Google Scholar] [CrossRef]

- Fu, Q.; Tu, K.; Goldhahn, C.; Keplinger, T.; Adobes-Vidal, M.; Sorieul, M.; Burgert, I. Luminescent and hydrophobic wood films as optical lighting materials. ACS Nano 2020, 14, 13775–13783. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Ran, Y.; Wang, J. Improved performance of thermally modified wood via impregnation with carnauba wax/organoclay emulsion. Constr. Build. Mater. 2020, 247, 118586. [Google Scholar] [CrossRef]

- Tshabalala, M.A.; Libert, R.; Schaller, C.M. Photostability and moisture uptake properties of wood veneers coated with a combination of thin sol-gel films and light stabilizers. Holzforschung 2011, 65, 215–220. [Google Scholar] [CrossRef]

- Gholamlyan, H.; Tarmiam, A.; Ranjbar, Z.; Abdulkhani, A.; Asadfallah, M.; Mai, C. Silane nanofilm formation by sol-gel processes for promoting adhesion of waterborne and solventborne coatings to wood surface. Holzforschung 2016, 70, 429–437. [Google Scholar] [CrossRef]

- Mahr, M.S.; Hubert, T.; Stephan, I.; Bucker, M.; Militz, H. Reducing copper leaching from treated wood by sol-gel derived TiO2 and SiO2 depositions. Holzforschung 2016, 67, 429–435. [Google Scholar] [CrossRef]

- Donath, S.; Militz, H.; Mai, C. Creating Water-Repellent Effects on Wood by Treatment with Silanes. Holzforschung 2006, 60, 40–46. [Google Scholar] [CrossRef]

- Mai, C.; Militz, H. Modification of wood with silicon compounds. Treatment systems based on organic silicon compounds—A review. Wood Sci. Technol. 2004, 37, 453–461. [Google Scholar] [CrossRef]

- Bhusan, B.; Nosonovski, M. The rose petal effect and the modes of superhydrophobicity. Philos. Trans. R. Soc. A 2010, 368, 4713–4728. [Google Scholar] [CrossRef]

- Spear, M. Emerging nature-based materials and their use in new products. In Designing with Natural Materials; Ormondroyd, G.A., Morris, A.F., Eds.; Taylor Francis: Boca Raton, FL, USA, 2019; pp. 217–320. [Google Scholar]

- Yang, D.; Liu, H.; Zheng, Z.; Yuan, Y.; Zhao, J.-C.; Waclawik, E.R.; Ke, X.; Zhu, H. An efficient photocatalyst structure: TiO2(B) nanofibers with a shell of anatase nanocrystals. J. Am. Chem. Soc. 2009, 131, 17885–17893. [Google Scholar] [CrossRef]

- Kong, L.; Tu, K.; Guan, H.; Wang, X. Growth of high-density ZnO nanorods on wood with enhanced photostability, flame retardancy and water repellency. Appl. Surf. Sci. 2017, 407, 479–484. [Google Scholar] [CrossRef]

- Jia, S.; Liu, M.; Wu, Y.; Luo, S.; Qing, Y.; Chen, H. Facile and scalable preparation of highly wear-resistance superhydrophobic surface on wood substrates using silica nanoparticles modified by VTES. Appl. Surf. Sci. 2016, 386, 115–124. [Google Scholar] [CrossRef]

- Filgueira, D.; Moldes, D.; Fuentealba, C.; García, D.E. Condensed tannins from pine bark: A novel wood surface modifier assisted by laccase. Ind. Crops Prod. 2017, 103, 185–194. [Google Scholar] [CrossRef]

- Tu, K.; Wang, X.; Kong, L.; Guan, H. Facile preparation of mechanically durable, self-healing and multifunctional hydrophobic surfaces on solid wood. Mater. Des. 2018, 140, 30–36. [Google Scholar] [CrossRef]

- Nyrud, A.Q.; Bringslimark, T. Is interior wood use psychologically beneficial? A Review of psychological responses toward wood. Wood Fiber Sci. 2010, 42, 202–218. [Google Scholar]

- Simonson, C.; Salonvaara, M.; Ojanen, T. Humidity, comfort and air quality in a bedroom with hygroscopic wooden structures. In Proceedings of the 6th Symposium on Building Physics in the Nordic Countries; SINTEF: Oslo, Norway, 2002; Volume 2, pp. 743–750. [Google Scholar]

- Rode, C.; Peuhkuri, R.; Lone, H.; Time, B.; Gustavsen, A.; Ojanen, T.; Ahonen, J.; Svennberg, K.; Harderup, L.-E.; Arfvidsson, J. (Eds.) Moisture Buffering of Building Materials; DTU BYG-Rapporter No. R-126; Technical University of Denmark DTU: Kongens Lyngby, Denmark, 2006. [Google Scholar]

- Bhatta, S.R.; Tiippana, K.; Vahtikari, K.; Kiviluoma, P.; Hughes, M.; Kyttä, M. Quantifying the sensation of temperature: A new method for evaluating the thermal behaviour of building materials. Energy Build. 2019, 195, 26–32. [Google Scholar] [CrossRef]

- Salonvaara, M.; Ojanen, T.; Holm, A.; Kunzel, H.; Kuragiozis, A. Moisture buffering effects on indoor air quality-Experimental and simulation results. In Performance of Exterior Envelopes of Whole Buildings: Proceedings of the IX International Conference ASHRAE; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2004. [Google Scholar]

- Legros, C.; Piot, A.; Woloszyn, M.; Pailha, M. Effect of moisture buffering on surface temperature variation: Study of different indoor cladding materials. In 12th Nordic Symposium on Building Physics, E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2020; p. 06002. [Google Scholar]

- Lozhechnikova, A.; Vahtikari, K.; Hughes, M.; Österberg, M. Toward energy efficiency through an optimized use of wood: The development of natural hydrophobic coatings that retain moisture-buffering ability. Energy Build. 2015, 105, 37–42. [Google Scholar] [CrossRef][Green Version]

- Lozhechnikova, A.; Bellanger, H.; Michen, B.; Burgert, I.; Österberg, M. Surfactant-free carnauba wax dispersion and its use for layer-by-layer assembled protective surface coatings on wood. Appl. Surf. Sci. 2017, 396, 1273–1281. [Google Scholar] [CrossRef]

- Yang, H.; Zhu, S.; Pan, N. Studying the mechanisms of titanium dioxide as ultraviolet-blocking additive for films and fabrics by an improved scheme. J. Appl. Polym. Sci. 2004, 92, 3201–3210. [Google Scholar] [CrossRef]

- Gascon-Garrido, P.; Mainusch, N.; Militz, H.; Viol Mai, C. Effects of copper-plasma deposition on weathering properties of wood surfaces. Appl. Surf. Sci. 2016, 366, 112–119. [Google Scholar] [CrossRef]

- Hui, B.; Li, Y.; Huang, Q.; Li, G.; Li, J.; Cai, L.; Yu, H. Fabrication of smart coatings based on wood substrates with photoresponsive behaviour and hydrophobic performance. Mater. Des. 2015, 84, 277–284. [Google Scholar] [CrossRef]

- Kang, C.-W.; Kim, G.-C.; Park, H.-J.; Lee, N.-H.; Kang, W.; Matsumura, J. Changes in Permeability and Sound Absorption Capability of Yellow Poplar Wood by Steam Explosion Treatment. J. Fac. Agric. 2010, 55, 327–332. [Google Scholar]

- Wang, D.; Peng, L.; Zhu, G.; Fu, F.; Zhou, Y.; Song, B. Improving the Sound Absorption Capacity of Wood by Microwave Treatment. BioResources 2014, 9, 7504–7518. [Google Scholar] [CrossRef]

- Kang, C.-W.; Jang, E.-S.; Jang, S.S.; Cho, J.-I.; Kim, N.-H. Effect of Heat Treatment on the Gas Permeability, Sound Absorption Coefficient, and Sound Transmission Loss of Paulownia tomentosa Wood. J. Korean Wood Sci. Technol. 2019, 47, 644–654. [Google Scholar]

- Esmailpour, A.; Norton, J.; Taghiyari, H.; Zolfaghari, H.; Asadi, S. Effects of heat treatment on sound absorption coefficients in nanosilver-impregnated and normal solid woods. IET Nanobiotechnology 2017, 11, 365–369. [Google Scholar] [CrossRef]

- Kang, C.-W.; Li, C.; Jang, E.-S.; Jang, S.-S.; Kang, H.-Y. Changes in Sound Absorption Capability and Air Permeability of Malas (Homalium foetidum) Specimens after High Temperature Heat Treatment. J. Korean Wood Sci. Technol. 2018, 46, 149–154. [Google Scholar]

- Chung, H.; Park, Y.; Yang, S.Y.; Kim, H.; Han, Y.; Chang, Y.-S.; Yeo, H. Effect of heat treatment temperature and time on sound absorption coefficient of Larix kaempferi wood. J. Wood Sci. 2017, 63, 575–579. [Google Scholar] [CrossRef]

- Kolya, H.; Kang, C.-W. Hygrothermal treated paulownia hardwood reveals enhanced sound absorption coefficient: An effective and facile approach. Appl. Acoust. 2021, 174, 107758. [Google Scholar] [CrossRef]

- Yano, H.; Minato, K. Improvement of the acoustic and hygroscopic properties of wood by a chemical treatment and application to the violin parts. J. Acoust. Soc. Am. 1992, 92, 1222–1227. [Google Scholar] [CrossRef]

- Chang, S.-T.; Chang, H.-T.; Huang, Y.-S.; Hsu, F.-L. Effects of Chemical Modification Reagents on Acoustic Properties of Wood. Holzforschung 2000, 54, 669–675. [Google Scholar] [CrossRef]

- Yano, H.; Minato, K. Controlling the timbre of wooden musical instruments by chemical modification. Wood Sci. Technol. 1993, 27, 287–293. [Google Scholar] [CrossRef]

- Yano, H.; Kajita, H.; Minato, K. Chemical treatment of wood for musical instruments. J. Acoust. Soc. Am. 1994, 96, 3380–3391. [Google Scholar] [CrossRef]

- Ahmed, S.A.; Adamopoulos, S. Acoustic properties of modified wood under different humid conditions and their relevance for musical instruments. Appl. Acoust. 2018, 140, 92–99. [Google Scholar] [CrossRef]

- Mania, P.; Moliński, W.; Roszyk, E.; Górska, M. Optimization of Spruce (Picea abies L.) Wood Thermal Treatment Temperature to Improve Its Acoustic Properties. BioResources 2020, 15, 505–516. [Google Scholar]

- Pfriem, A. Thermally Modified Wood for Use in Musical Instruments. Drvna Ind. 2015, 66, 251–253. [Google Scholar] [CrossRef]

- Mohebby, B.; Yaghoubi, K.; Roohnia, M. Acoustical properties of hydrothermally modified mulberry (Morus alba L.) wood. In Proceedings of the Third European Conference on Wood Modification, Cardiff, UK, 15–16 October 2007; pp. 283–286. [Google Scholar]

- Obataya, E. Effects of natural and artificial ageing on the physical and acoustic properties of wood in musical instruments. J. Cult. Herit. 2017, 27, S63–S69. [Google Scholar] [CrossRef]

- Mania, P.; Gasiorek, M. Acoustic Properties of Resonant Spruce Wood Modified Using Oil-Heat Treatment (OHT). Materials 2020, 13, 1962. [Google Scholar] [CrossRef]

- Lv, S.; Fu, F.; Wang, S.; Huang, J.; Hu, L. Novel wood-based all-solid-state flexible supercapacitors fabricated with a natural porous wood slice and polypyrrole. RSC Adv. 2015, 5, 2813–2818. [Google Scholar] [CrossRef]

- Guo, H.; Büchel, M.; Li, X.; Wäckerlin, A.; Chen, Q.; Burgert, I. Dictating anisotropic electric conductivity of a transparent copper nanowire coating by the surface structure of wood. J. R. Soc. Interface 2018, 15, 20170864. [Google Scholar] [CrossRef] [PubMed]

- Ansell, M.P. Carbonised and mineralised wood composites. In Wood Composites; Ansell, M.P., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 395–409. [Google Scholar]

- Sun, J.; Guo, H.; Ribera, J.; Wu, C.; Tu, K.; Binelli, M.; Panzarasa, G.; Schwarze, F.W.M.R.; Wang, Z.L.; Burgert, I. Sustainable and biodegradable wood sponge nanogenerator for sensing and energy harvesting applications. ACS Nano 2020, 14, 14665–14674. [Google Scholar] [CrossRef]

- Lowden, L.A.; Hull, T.R. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci. Rev. 2013, 2, 4. [Google Scholar] [CrossRef]

- Martinka, J.; Chrebet, T.; Kral, J.; Balog, K. An examination of the behavior of thermally treated spruce wood under fire conditions. Wood Res. 2013, 58, 599–606. [Google Scholar]

- Čekovská, H.; Gaff, M.; Osvald, A.; Kačik, F.; Kubš, J.; Kaplan, L. Fire resistance of thermally modified spruce wood. BioResources 2017, 12, 947–959. [Google Scholar] [CrossRef]

- Luptakova, J.; Kacik, F.; Mitterova, I.; Zachar, M. Influence of temperature of thermal modification on the fire-technical characteristics of spruce wood. BioResources 2019, 14, 3795–3807. [Google Scholar]

- Xing, D.; Li, J. Effect of heat treatment on thermal decomposition and combustion performance of Larix spp. Wood. BioResources 2014, 9, 4274–4287. [Google Scholar] [CrossRef]

- Gasparik, M.; Osvaldova, M.L.; Cekovska, H.; Potucek, D. Flammability characteristics of thermally modified oak wood treated with fire retardant. BioResources 2017, 12, 8451–8467. [Google Scholar]

- Mohebby, B.; Talaii, A.; Najafi, S.K. Influence of acetylation on fire resistance of beech plywood. Mater. Lett. 2007, 61, 359–362. [Google Scholar] [CrossRef]

- Marney, D.C.O.; Russell, L.J. Combined fire retardant and wood preservative treatments for outdoor wood applications- A review of the literature. Fire Technol. 2008, 44, 1–14. [Google Scholar] [CrossRef]

- Sweet, M.S.; LeVan, S.L.; Tran, H.C.; DeGroot, R. Fire Performance of Wood Treated with Combined Fire-Retardant and Preservative Systems; FPL-RP-545; USDA Forest Products Laboratory: Madison, WI, USA, 1996; 12p. [Google Scholar]

- Baysal, E. Determination of oxygen index levels and thermal analysis of Scots Pine (Pinus sylvestris L.) impregnated with melamine formaldehyde–Boron combinations. J. Fire Sci. 2002, 20, 373–389. [Google Scholar] [CrossRef]

- Lewin, M. Flame retarding of wood by chemical modification with bromate-bromide solutions. J. Fire Sci. 1997, 15, 29–51. [Google Scholar] [CrossRef]

- Lee, H.L.; Chen, G.C.; Rowell, R.M. Chemical modification of wood to improve decay and thermal resistance. In Proceedings of the 5th Pacific Rim Biobased Composites Symposium, Canberra, Australia, 10–13 December 2000. [Google Scholar]

- Tsunoda, K. Preservative properties of vapor-boron-treated wood and wood-based composites. J. Wood Sci. 2001, 47, 149–153. [Google Scholar] [CrossRef]

- Kartal, S.N.; Yoshimura, T.; Imamura, Y. Decay and termite resistance of boron-treated and chemically modified wood by in situ co-polymerization of allyl glycidyl ether (AGE) with methyl methacrylate (MMA). Int. Biodeterior. Biodegrad. 2004, 53, 111–117. [Google Scholar] [CrossRef]

- Baysal, E.; Sonmez, A.; Colak, M.; Toker, H. Amount of leachant and water absorption levels of wood treated with borates and water repellents. Bioresour. Technol. 2006, 97, 2271–2279. [Google Scholar] [CrossRef]

- Jiang, T.; Feng, X.; Wang, Q.; Xiao, Z.; Wang, F.; Xie, Y. Fire performance of oak wood modified with N-methylol resin and methylolated guanyl urea phosphate/boric acid-based fire retardant. Constr. Build. Mater. 2014, 72, 1–6. [Google Scholar] [CrossRef]

- Yue, K.; Chen, Z.; Lu, W.; Liu, W.; Li, M.; Shao, Y.; Tang, L.; Wan, L. Evaluating the Mechanical and fire-resistance properties of modified fast-growing Chinese fir timber with boric-phenol-formaldehyde resin. Constr. Build. Mater. 2017, 154, 956–962. [Google Scholar] [CrossRef]

- Yue, K.; Wu, J.; Xu, L.; Tang, Z.; Chen, Z.; Liu, W.; Wang, L. Use impregnation and densification to improve mechanical properties and combustion performance of Chinese fir. Constr. Build. Mater. 2020, 241, 118101. [Google Scholar] [CrossRef]

- Rabe, S.; Klack, P.; Bahr, H.; Schartel, B. Assessing the fire behavior of woods modified by N-methylol crosslinking, thermal treatment, and acetylation. Fire Mater. 2020, 44, 530–539. [Google Scholar] [CrossRef]

- Morozovs, A.; Buksans, E. Fire performance characteristics of acetylated ash (Fraxinus excelsior L.) wood. Wood Mater. Sci. Eng. 2009, 4, 76–79. [Google Scholar] [CrossRef]

- Accsys. Accoya Wood Information Guide, v3.9. 2020. Available online: https://www.accoya.com/app/uploads/2020/04/Accoya_WoodInfoGuide-1.pdf (accessed on 13 February 2021).

| Modification | Estimated Volumes (m3) | ||||

|---|---|---|---|---|---|

| Europe | China | N America | Oceania/Japan | Other | |

| Thermally modified timber | 695,000 | 250,000 | 140,000 | 15,000 | 10,000 |

| Densified wood | 2000 | <1000 | - | <1000 | - |

| Acetylation | 120,000 | - | - | - | - |

| Furfurylation | 45,000 | - | - | - | - |

| Other methods | 35,000 | 290,000 * | - | 5000 | TBD |

| Process | Typical Species Used Commercially | Dimensional stability | Durability | Hardness | Electrical Resistance | High Density | Low Mould Resistance | Corrosive to Fasteners | Reduced Mechanical Properties | Oil Exudation | Notes |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Accoya® | Radiata pine | yes | yes | - | - | - | yes | yes | - | - | - |

| Thermal modification | Norway spruce, Scots pine, various hardwoods | yes | mod. | - | - | - | - | - | yes | - | mod. = moderate |

| Kebony® NobelWood® | Radiata pine, Scots pine | yes | yes | yes | - | - | - | yes | yes | - | - |

| CompregTM | European beech veneer | - | yes | yes | yes | yes | - | - | - | - | - |

| ImpregTM | European beech, Scots pine | yes | yes | - | - | - | - | - | yes | - | - |

| Lignia® | Radiata pine | yes | yes | - | - | - | - | - | - | - | - |

| HartHolz® (DMDHEU) | European beech, Scots pine | - | yes | - | - | - | - | - | - | - | - |

| Organowood® (Silicate modification) | Norway spruce, Scots pine | - | yes | - | - | - | - | - | - | - | Stable silver grey surface |

| Linotech (Linseed oil derrivatives) | Scots pine, (Norway spruce) | - | yes | - | - | - | - | - | - | yes | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spear, M.J.; Curling, S.F.; Dimitriou, A.; Ormondroyd, G.A. Review of Functional Treatments for Modified Wood. Coatings 2021, 11, 327. https://doi.org/10.3390/coatings11030327

Spear MJ, Curling SF, Dimitriou A, Ormondroyd GA. Review of Functional Treatments for Modified Wood. Coatings. 2021; 11(3):327. https://doi.org/10.3390/coatings11030327

Chicago/Turabian StyleSpear, Morwenna J., Simon F. Curling, Athanasios Dimitriou, and Graham A. Ormondroyd. 2021. "Review of Functional Treatments for Modified Wood" Coatings 11, no. 3: 327. https://doi.org/10.3390/coatings11030327

APA StyleSpear, M. J., Curling, S. F., Dimitriou, A., & Ormondroyd, G. A. (2021). Review of Functional Treatments for Modified Wood. Coatings, 11(3), 327. https://doi.org/10.3390/coatings11030327