1. Introduction

A circular economy aims at reusing consumed materials and ideally, product cycles become closed according to the cradle-to-cradle principle [

1,

2]. “Bio-based” means the use of biogenic raw materials to manufacture a variety of products instead of fossil gas, coal, or petroleum as part of the bioeconomy. Lastly, “biodegradable” means that a material can be degraded in the environment by microorganisms and physicochemical impact. Recently, the societies of the countries of the Global North have experienced a strong change in their mindset due to the discussion about climate change, finiteness of resources, the overutilization of ecosystems, and the pollution of the environment by non-degradable or harmful substances. This affects especially the consumer goods industry and the designers of new materials aim to replace fossil-based polymers with biogenic and fully biodegradable materials while being animal-free and without the use of any harmful substances. Ideally, the new materials are made from domestic waste, sawdust, or organic garbage [

3,

4,

5].

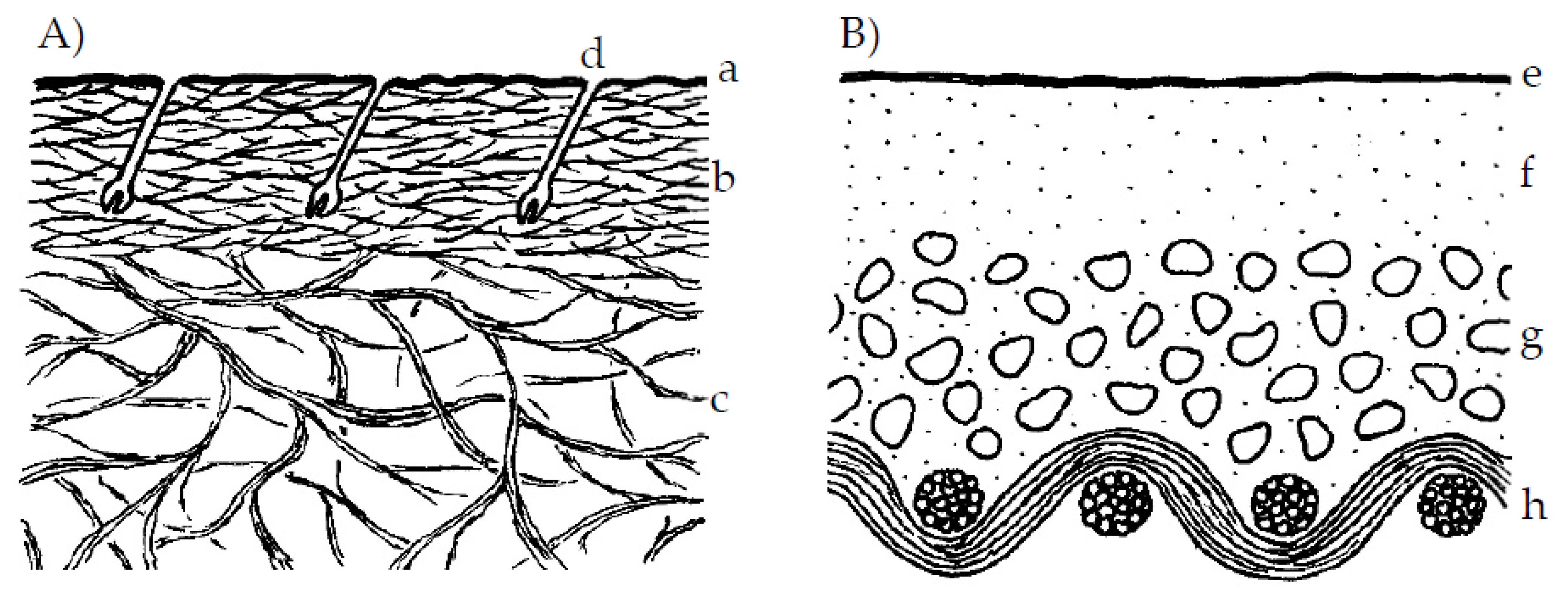

Leather is a bio-based and biodegradable material with a tradition nearly as long as mankind. For centuries, it was used as a strong and long-lasting material with a broad spectrum of materials properties. Leather was used as protective and decorative clothing for sports goods and as technical material, e.g., for transmission belts, buckets, or as wineskin. Until the middle of the 19th century, leather occupied the materials property gap of a flexible material besides stone, metal, and wood as hard materials and various textiles, which were not waterproof. Processing allowed adjusting the leather properties from a hard board-like appearance, e.g., as sole leather to very soft touch textile-like glove leathers. To manufacture shoes, leather is made hydrophobic, and as wash leather, it absorbs much liquid. The basic structure is an animal skin, which can be described as a non-woven with different density gradients in grain, papillary and reticular layer (

Figure 1A).

During industrialization, alternative materials were invented, first and foremost the oil clothes made from textiles (linen, cotton), which were soaked or coated with boiled linseed oil and added with fillers, siccatives, and pigments [

6]. The next level of coating textiles was achieved by the use of natural rubber but only the discovery of vulcanization led to non-sticky films [

7]. More and more new materials emerged with the invention of additional synthetic polymers, which allowed the replacement of leather in many applications. Synthetic polymers enabled customized and high-performance solutions that outperformed leather by far for technical applications in gears, conveyor belts, or vessels. Alternatives were developed as well in design-driven applications such as upholstery, shoes, and clothing. Often, it is aimed to imitate leather by these materials.

Leather shows a number of unique properties, which are highly valued for purposes such as strength and elasticity, water vapor permeability, abrasion resistance, durability, and longevity. In the past, synthetic materials competing with leather triumphed due to lower prices, they are often easier to be processed and can be manufactured as a continuous material according to industrial needs in roll-to-roll production lines. However, leather is still popular due to its beneficial properties, natural appearance, and a touch of noble material.

Synthetic alternatives usually consist of textile support covered by two or more synthetic polymer layers (

Figure 1B). Nowadays, often polyester textiles coated by PVC or polyurethane films are used, making them a completely fossil-based material. The surface optic can be designed leather-like by embossing a grain structure. Many different terms are used to describe these materials in the market, e.g., artificial leather, synthetic leather, leatherette, imitation leather, faux leather, man-made leather, bonded leather, pleather, textile leather, or polyurethane (PU)-leather. Meanwhile, the usage of these terms is restricted in the European standard EN 15987. Here, we will use the term “artificial leather” to describe synthetic materials imitating the optical appearance of leather.

In recent years, concerns over sustainability in any field of industrial production have led to a pressing rationale to enhance the use of natural materials and replace non-renewable fossil-based raw materials. Although leather is bio-based and renewable, these considerations did not lead to a renaissance of leather. Instead, leather got even more under pressure due to ongoing discussions over the greenhouse gas emission of cattle breeding, the sustainability of leather production, and animal welfare. At the same time, an increasing number of people want to eat consciously meat-free or to do without any products of animal origin entirely. All these needs pose new challenges in culture and material development [

3].

One strategy pursues the development of alternative nature-based, animal-free fibrous materials. This material is trama, the bulk material of some mushroom fruitbodies (e.g.,

Fomes fomentarius,

Phellinus ellipsoideus). The extraordinary soft feel of the dry mycelium makes it a precious material for cups and handcraft accessories and already the Ice-man used it as a material in combination with leather [

8,

9]. Muskin

® is an example of this material. Due to the complicated harvest, the restricted availability of the mentioned fungi, and the limited areas that can be obtained it seems to be far from being able to replace leather.

Further new ways are paved by using biotechnological processes to produce fiber-based materials. Namely, fungi and symbiosis of bacteria and yeast are used to produce fibrous networks aiming to imitate the fibrous structure similar to an animal skin as single materials or as support for a coating layer. Micro-cellulosic fiber networks are produced by bacteria (e.g.,

Acetobacter xylinum), the mycelium fiber networks of fungi hyphae consist of chitin, cellulose, and proteoglycans [

5,

10,

11]. These mycelia grow on organic waste [

11,

12].

In a second strategy, it is tried to reduce the non-renewable content of artificial leather by replacing parts of the synthetic component polyvinylchloride (PVC) or polyurethane (PUR) of synthetic coatings with agricultural waste-derived products as filling material, such as grain, apple pomace (Vegea®, Appleskin®), or milled cactus leaves (Desserto®).

A third way to replace all fossil-based raw materials in a coated textile has been explored in Pinatex

®. Renewable fibers of pineapple leaves are processed into non-woven support coated with polylactic acid (PLA) produced from corn starch [

13].

Regardless of the type of material, it can be leather, artificial leather, or a trendy alternative a couple of physical and mechanical limits are usually defined and have to be achieved. These limits must be evaluated in regard to the stresses associated with the production, processing, and use of the materials. In general, examinations to qualify materials and to quantify their properties need to be performed according to standardized testing procedures.

Here, we present a comparative study of leather and alternative materials, which are used for similar final applications, focused on material structures, physical, and mechanical performance. Additionally, the materials were screened for hazardous substances by established standardized test methods with respect to shoe, glove, and apparel goods applications. Materials intended for automotive and upholstery applications are explicitly not included in this study, because they have to meet many superior specifications.

We focused on material performance. Other important aspects such as the origin of the raw material (renewable or oil-based), the carbon footprint, the environmental footprint, traceability, and biodegradability are not dealt with in this study. Alternative materials of different sources were tested in comparison to a common shoe-upper leather as a reference and a conventional PUR-coated textile (artificial leather) as used for footwear as a second reference. All materials are commercially available and have already been applied in various types of final products. The materials were tested according to the appropriate internationally harmonized and accepted specifications for shoe, glove, and apparel goods [

14,

15,

16].

2. Materials and Methods

Nine materials, which are offered as an alternative for leather and represent different principal structures, have been investigated by light microscopy; their physical properties were measured and their chemical compositions were analyzed (

Table 1). The registered trademarks are specified in the table. Additionally, a shoe upper leather and a polyurethane-coated textile as artificial leather were tested as a reference. The Noani

® sample was obtained as a belt consisting of several materials, which had been combined by sewing.

The physical characterization comprised standardized measurements of thickness, tensile strength, tear strength, flex resistance, water vapor absorption, and water vapor permeability [

17,

18,

19,

20,

21,

22]. The cross sections, surfaces, and the reverse side of the materials were portrayed by light microscopy at different magnifications. Chemical constitution and additives were investigated by FTIR (fourier transform infrared spectroscopy) and thermal desorption GC/MS (gas chromatography/mass spectroscopy). FTIR spectra were measured using a diamond ATR (attenuated total reflection) technique with 16 scans in a range of 4000–650 cm

−1. Evaluation of the spectra was based on own and various commercial databases. Volatile and harmful substances were measured according to VDA 278 [

23] (VDA—Verband der Automobilindustrie, Germany). A total of 5 mg to 10 mg of material were heated to 120 °C for 60 min, and all volatile compounds were collected from the evaporate by cooling with liquid nitrogen to minus 100 °C. The substances were vaporized from the trap for 5 min at 280 °C, separated and characterized by GC/MS (GC: 50 °C for 2 min, 25 K/min to 160 °C, 10 K/min to 280, 10 min at 280 °C, column Ultra 2 (5% phenyl-methylsiloxane), 50 m × 320 µm × 0.52 µm, flow 1.3 mL/min constant pressure, MS: 29–450 m/z).

For evaluation, 10 well-trained panelists assessed the materials to evaluate touch and feel. No material related information was provided to them in advance of the evaluation. The materials were presented to the panelists always in the same order either by laying it directly on a table board or placing it on a soft PUR foam of 4 mm thickness. The surfaces of the materials were blindly touched without any stretching or folding. The touch and feel properties of all materials were referenced to leather—temperature sensation (warmer or colder), deformation in z-direction (softer or harder), roughness, slipperiness/blocking behavior, pleasant or unpleasant, natural or artificial touch, high- or low-quality feeling.

3. Research Results

3.1. Material Composition and Structure

All materials are composed of fibers. However, chemical constitution, arrangement, fiber size, and coating follow different principal concepts. The results of the light microscopic investigations, thermal desorption analysis, and FTIR spectra allow us to identify the compositions of the materials (

Table 1).

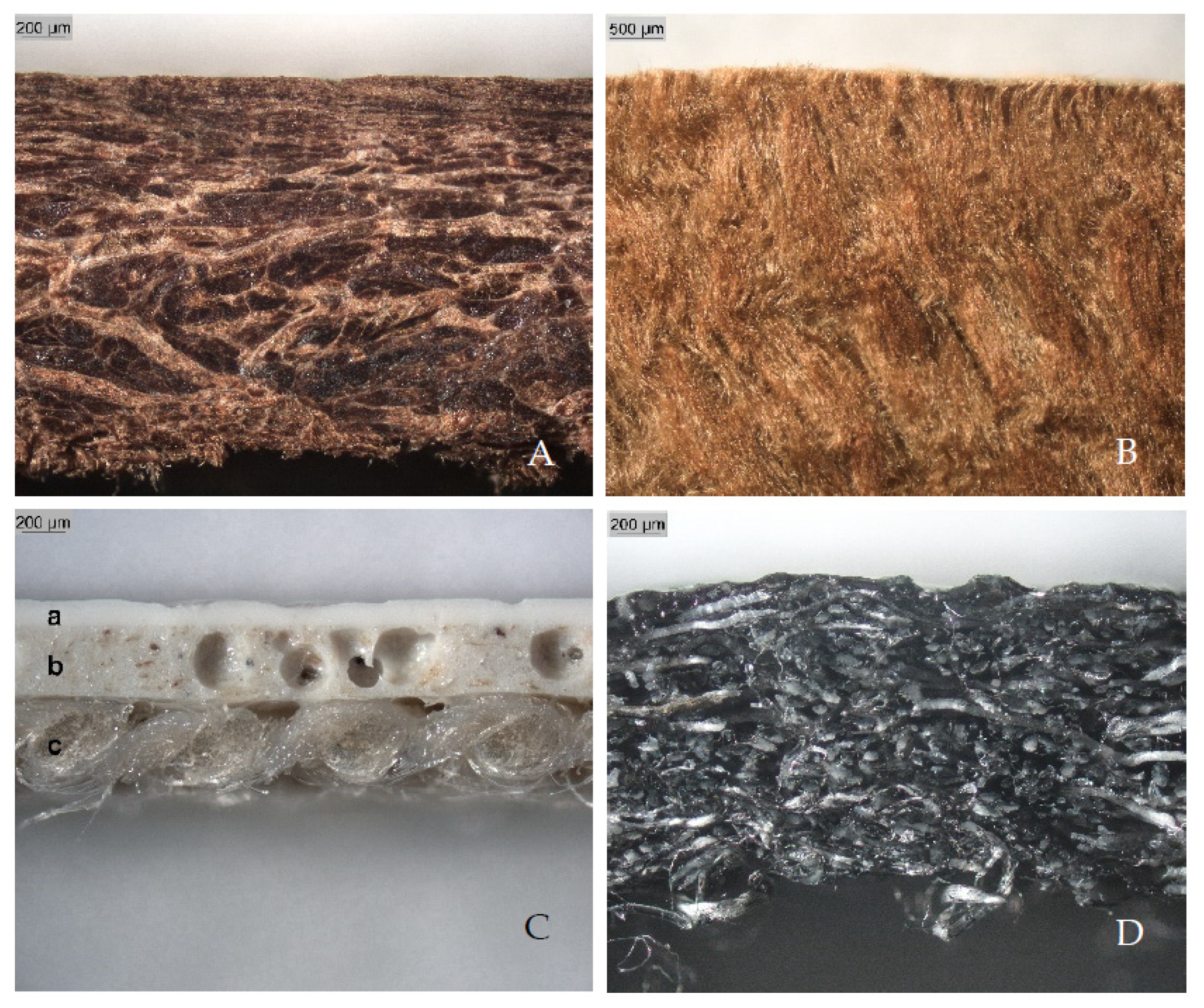

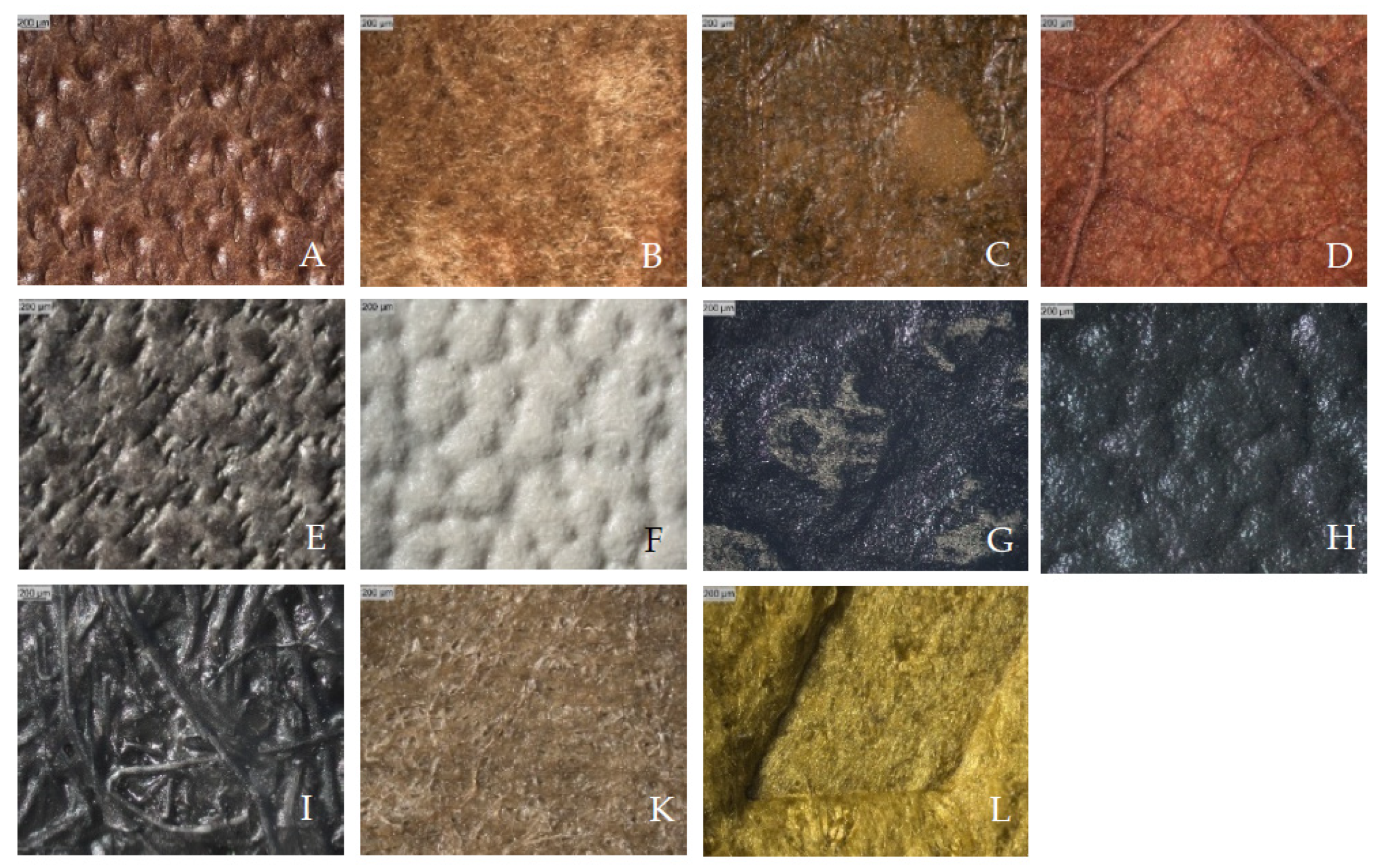

A selection of microscopic pictures of the cross sections representing the different principal structures is shown in

Figure 2, and the different surface designs are presented in

Figure 3. All microscopic pictures are added in high resolution in the supplements as well as an example of a FTIR spectrum of Desserto

®, a PUR coated material (see

Supplementary Materials).

The structures of Desserto

® (

Figure 2A), Vegea

®, and Appleskin

® reflect the typical composition of PUR-coated artificial leather used for, e.g., shoe or upholstery application. The support of the investigated samples consisted of knitted or woven polyester textiles, except that of Vegea

®, which was made of cellulose. The textiles were coated with foamed polyurethane-based middle layers containing organic fillers based on cellulose. The materials are finished with polymer-based topcoats. The surfaces of the materials were partly embossed to achieve a leather-like optic and to adjust the haptic (

Figure 3E–H). Even Teak Leaf

® falls into the structural category of a coated textile. Here, the textile support on the reverse side is built by two non-woven layers. The middle layer is cellulose-based, the fibers are stuck together with an acrylic acid-based polymeric binder, and the basic support on the reverse side is polyester-based. On the top, the Teak Leaf

® material is coated by a transparent waxy polyolefin film. The leaf of teak mainly fulfills desired optical needs (

Figure 3D).

Pinatex

® (

Figure 2D) and SnapPap

® consist of a cellulose-based fibrous non-woven. The fibers of SnapPap

® are bonded by an acrylic acid-based polymeric binder. In contrast, the investigated sample of Pinatex

® is coated with a thin polymeric layer. The fibrous structures of the non-woven fabric of both materials are visible at the surface due to the thin coating layer (

Figure 3I,K).

Muskin

® (

Figure 2B) and Kombucha are single-layer materials without any textile support and without a topcoat. Both consist of polysaccharides. Muskin

® appears very porous composed of fine brown fibers with a fiber orientation perpendicular to the surface. These fibers appear at the surface as a fine lawn without a distinct structure (

Figure 3B). In contrast, Kombucha consists of one compact layer, which contains some inclusions and talcum and shows a glossy brown surface (

Figure 3C).

It was found that Noani

® was not a single material but crafted of three distinct layers. The top is formed by an embossed microfiber material, the middle layer consists of leather board material and the backside is a PUR/PVC-coated textile that consists of three layers typical for conventional artificial leather. The use of a leather board material is surprising because Noani

® is referred to as a vegan product and the label “PETA approved” is embossed in the material. Because of this and since the Noani

® sample does not represent a single material, it will not be further discussed with respect to structural categories. Regardless of the actual composition, all engineered materials try to mimic a natural appearance (

Figure 3).

3.2. Touch and Feel Properties

The surface of Muskin® and the upper material of Noani® feel pleasant. Due to the presence of very fine fibers, both materials create a velvety feeling similar to suede leather. The materials with synthetic surfaces as in artificial leathers (Desserto®, Appleskin®, Vegea®, PUR-coated textile) show a soft feeling and can be deformed in the z-direction. However, the touch of these materials appears artificially with a sticky tendency. The surface of Pinatex® and Teak Leaf® appears synthetic, too. In addition, Desserto®, Pinatex®, and SnapPap® are evaluated to feel rough. The surface of Kombucha appeared sticky.

3.3. Thickness

The thickness of the materials was determined by surveying the prepared microscopic cross sections. The overall thickness of all materials was found to range from 0.29 mm to 6.22 mm, which also shows the variety of the material types (

Table 2). The thickness of leather, the PUR-coated textile, and the trendy alternatives Desserto

®, Appleskin

®, Vegea

®, and Pinatex

® are in a typical range for materials used for shoes, gloves, and apparel goods applications. The materials Kombucha, SnapPap

®, and Teak Leaf

® appear very thin and in contrast, Muskin

® is very thick for the mentioned applications. In consequence, already from the results of the thickness measurements, significant differences in the material properties could be expected, e.g., in deformation properties.

3.4. Tensile Strength and Tear Strength

The most important mechanical properties for materials used for shoes, gloves, and apparel goods are tensile strength and tear strength [

17,

18]. The results for both parameters vary over a very wide range, whereas the category of naturally grown tissues shows the broadest range.

Leather as the grown skin tissue shows a very high mechanical stability (tensile strength, tear strength), representing the highest value for the tensile strength and tear strength within that survey. Tensile strength exceeds the specification of >15 N/mm

2 for chrome tanned upper leather for shoes (ISO 20942) [

14]. In contrast, the values of the Muskin

® sample are extremely low.

The coated textiles show tensile strengths of 9 up to 20 N/mm2. The tensile strength of coated textiles depends mainly on the properties of the supporting fabric. The results show a reasonable choice of fabric for the intended use of these engineered materials regardless of the natural or artificial origin of the fabric fibers.

The tensile strengths of the non-woven materials made of natural plant fibers range from 4 up to 25 N/mm2. Strength depends on fiber properties and fiber bonding. Despite a satisfying tensile strength, the tear resistance of SnapPap® is low due to the short fiber length, which cannot be leveraged by the polymeric binder. Except for the non-woven materials, tear strength follows the same tendency as tensile strength.

3.5. Flex Resistance

Materials for shoes must resist intensive bending and convex and concave deformation during usage. The flexometer test is used to assess the long-time resistance against bending. Grade 0 is the best rating indicating that the material itself and the coating layers shows no cracks by flexing. A grade of ≤2 (only very small cracks in top layer of the coating) is usually accepted to pass that test. When a grade of >2 is observed, flexing has to be stopped and the number of flex cycles is noted. Leather, Pinatex®, and PUR-coated textile fulfilled the specification of >80.000 flex cycles according to ISO 20942. The flex resistance of Teak Leaf®, SnapPap®, and Muskin® material was found to be insufficient for the aimed applications.

3.6. Water Vapor Permeability and Water Vapor Absorption

A pleasant wearing comfort of shoes, gloves, or apparel is related to the water vapor permeability (WVP) of the material, which allows transporting the humidity of the body through the clothing material to its surface. The comfort is also enhanced by the ability of the materials to absorb water vapor. Comfortable water vapor permeability limits are specified in ISO 20942 to be >>0.8 mg/(cm2 × h). Leather, Muskin®, and SnapPap® exceed the water vapor permeability by far, and Pinatex® and PUR-coated textile still fulfill the ISO 20942 requirement. The WVP of all other materials is insufficient.

Water vapor absorption (WVA) of Kombucha, leather, and Muskin® is high, presumably due to their polar nature of the natural polymers. The other materials, especially those that contain a significant amount of synthetic polymer with less polarity show much lower water vapor absorption.

3.7. Harmful Substances

The materials were examined for potentially hazardous substances by means of thermal desorption analysis. In several samples (Appleskin®, Pinatex®, Desserto®, Vegea®, SnapPap®, Teak Leaf®) synthetic and biogenic raw materials had been combined. However, the processing of fossil-based raw materials often requires the application of solvents, crosslinking agents, or plasticizers to achieve suitable material properties.

All tested materials emitted volatile organic compounds when applied to the thermal desorption screening procedure. Restricted substances were identified in the samples of PUR-coated textile (reference), the similarly constructed materials Desserto®, Appleskin®, and Vegea®, but also in Pinatex®. The PUR-coated textile contained considerable amounts of dimethylformamide (DMFa) and toluene and traces of N,N-dimethylacetamide. In Appleskin®, butanone oxime and traces of DMFa were detected. Desserto® contained the five restricted substances butanone oxime, toluene, free isocyanate, folpet (an organic pesticide), and traces of the plasticizer Diisobutyl phthalate (DIBP). Toluene was detected in the sample of Vegea® and DIBP in that of Pinatex®.

4. Discussion

The materials that have been tested in this study are used to manufacture fashionable consumer goods as shoes, bags, clothes, and accessories. In this regard, aspects of (1) functional properties and (2) the appearance have to be discussed. While the construction of the material mainly influences the functional properties, the appearance is markedly a result of the surface properties. Both groups of properties varied on a very broad scale, though the materials are offered for similar final applications. Analyzing the composition, the construction, the surfaces, and the feel allowed us to compare the materials in regard to their possible performance. For this purpose, the materials were investigated by standardized testing procedures for leather since the materials are offered as a leather alternative.

4.1. Structure

Based on the structural design and with respect to functional properties, the investigated samples can be grouped into three completely different material concepts, which are (a) grown animal-free materials, (b) multi-layered coated fabrics as for artificial leather combined with plant-based additives, and (c) non-woven fabrics with or without a surface finish.

As derived from the results of the FTIR analysis, the functional layers of the coated fabrics are mainly PUR based. In contrast, fully bio-based naturally grown materials investigated in this study did not nearly fulfill the mechanical requirements expected, e.g., for shoe upper materials. The question arises, why animal-free materials (a), which are directly manufactured by preserving a grown structure combined with more or less intensive processing, show only poor mechanical resistance compared to leather.

The resulting structures of grown natural materials are intended to be an alternative for the fibrous structure of animal skin [

11,

24,

25]. A typical representative is the fungus-based material Muskin

® taken from

Phellinus ellipsoideus. The microscopic pictures show that the mycelium is composed of hyphae that represent the structure-forming component. Our measurements showed mainly polysaccharides as chemical structures. Therefore, it can be assumed that chitin forms the hyphae. The FTIR spectrum exactly fits that of other investigations [

26]. The latter interpreted the spectra in more detail and also assigned proteins, lipids, and nucleic acids. However, the mechanical stability of the mycelium is limited. This may be caused by the limited stability of the hyphae itself, and the processed mycelium as shown elsewhere [

11,

27]. The pictures of the cross section show that the fibers are oriented perpendicular to the surface. This also leads to poor mechanical stability. Presumably, the mechanical performance could be improved if the fibers were aligned along the direction of the mechanical load.

In contrast, Kombucha is a traditional Japanese beverage, which is prepared by a symbiosis of bacteria and yeasts metabolizing sugars into organic acids, ethanol, and carbon dioxide. In parallel, bacteria (e.g.,

Acetobacter xylinum) are secreting high molecular weight polysaccharides, which lead to a gel-like consistency. The intensively growing microorganisms can be harvested and the secreted polymers are used as a biogenic structure-forming material after a drying step [

10]. The mechanical stability of the Kombucha material sample was much higher than that of Muskin

® but missed the requirements for shoe upper materials as well. While Muskin

® shows a loose and open structure, which allows water vapor to diffuse through the material, Kombucha is very tight but it absorbs higher amounts of water. Both microorganism-based materials appear homogenous in their cross sections.

The raw material of leather, the animal skin is composed of collagen, a structure-forming protein. Leather is built from intertwined fibrils and fibers, which are additionally cross-linked by leather tanning. The fibrous structure of leather shows a gradient in its material density from the grain to the reverse side. The final layer on top is composed of very thin and tight collagen fibers. The grown skin tissue shows a very high mechanical stability (tensile strength, tear strength), which is by 100 to 1000 times higher than that of the microorganism-based materials [

5,

10,

11,

25,

26,

28]. The strength of leather can be related to the stability of the collagen fibers themselves and to the weaving and crosslinks between the fibers.

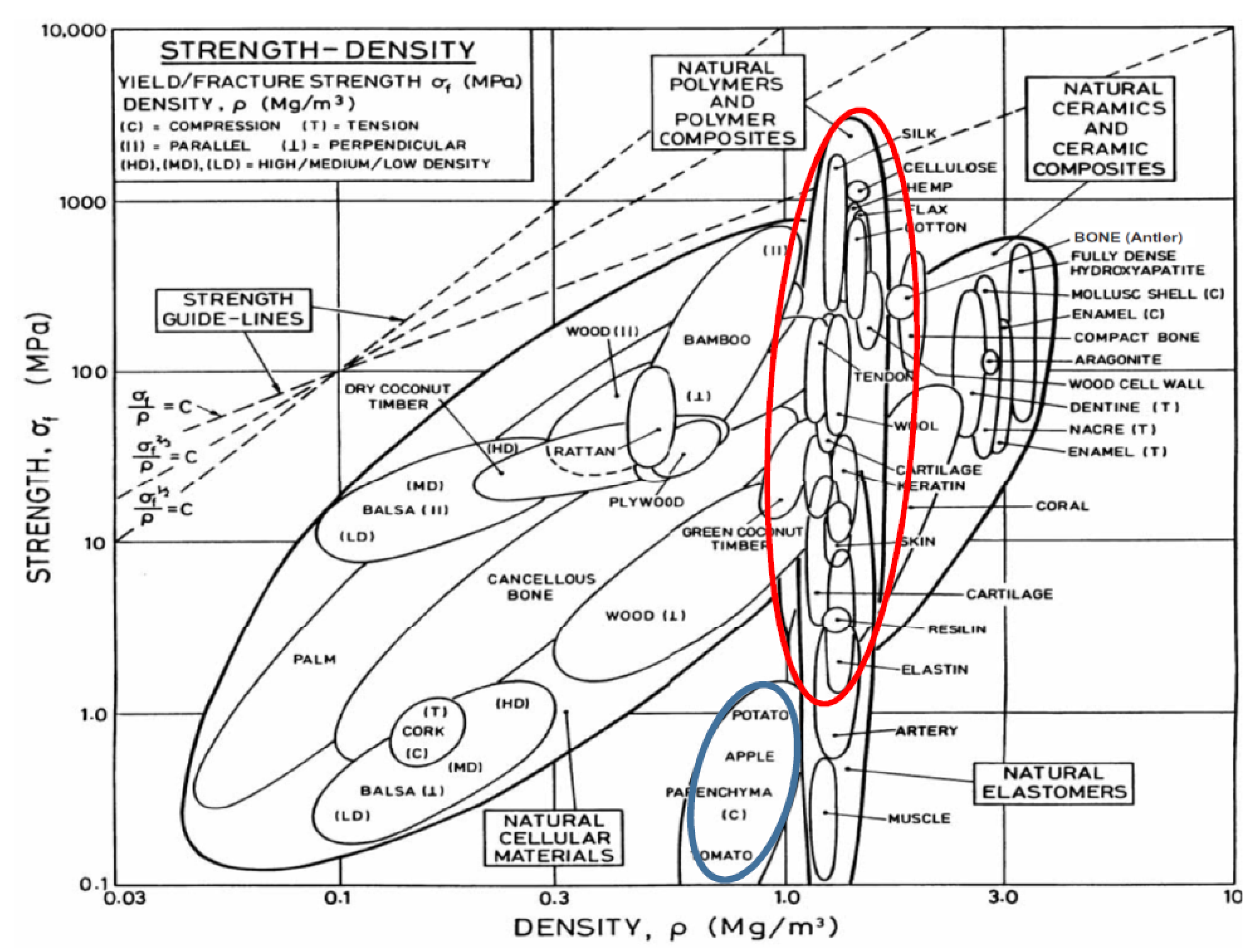

From the biological point of view, hyphae of microorganisms and the animal skin fulfill very different tasks in the respective organisms. The performance of natural materials had been summarized in the past in Ashby plots.

Figure 4 provides an impressive overview of a couple of different natural materials and their mechanical limits [

29]. Natural flexible load transferring materials appear with a density of ~1 Mg/m

3 and range from 0.1 MPa to more than 1000 MPa (marked red). The tensile strength of parenchymatous plant tissues is low (marked blue). Collagen-based materials such as skin and tendon appear to be very stable (red ellipse). High stability is also observed in structures of plants, which have to transfer load (wood, cellulose fibers).

It can be deduced from these considerations that grown natural materials will only exhibit flexible and mechanical resilience when load transferring structures are used. The animal skin covers a broad set of aimed functions. It has to protect the body for a long time against mechanical impact, it is flexible to allow mobility, and often it has to regulate the temperature and water balance. Plant fibers have to absorb the weight of the plant against gravitation and in load direction.

In contrast, the tissue-like structures of microorganisms appear as parenchymatous materials, based on fiber networks, which primarily offer active cells a matrix for metabolism (bacteria, fungi) and transportation of nutrients (hyphae). Therefore, they appear at the bottom of

Figure 4. To overcome these mechanical deficiencies, it was proposed to stabilize the fiber network of Muskin

® by crosslinking agents [

25,

26], or to adjust the softness of Kombucha materials by the addition of plasticizing agents [

10]. However, this contradicts the multiscale idea, the variation of the density and the orientation of the fibers along their load direction, which would presumably better help to overcome the observed limitations.

The second concept to achieve highly functional leather-like materials with a high content of bio-based components takes up the principle of artificial leather. These materials simulate the structure of leather as multilayer material. The functions can be separated between the textile support, which has to fulfill the mechanical function (tensile strength, tear strength), the middle layer, by which feel and softness are adjusted, and the topcoat, which takes over the final optical appearance. A grain structure similar to that of leather is mostly achieved by embossing. Therefore, to increase the biogenic part of the materials, it would be effective to replace the polyester support with natural fibers. As shown in

Figure 4, the natural fibers may show excellent mechanical stabilities. However, only Vegea

® and Teak Leaf

® use a cellulose-based fabric as support. The renewable content in these multilayer materials could also be increased by replacing synthetic polymers in the coating layers. Desserto

® and Appleskin

® adopt this principle. A part of PUR is replaced by agricultural by-products, which are used as fillers. A detailed analysis of the origin of the natural component and its content in relation to the bulk of the material was not possible, however. Nevertheless, the bulk of the materials remains to consist of polyurethane. In the case of Teak Leaf

®, a natural-appearing surface is created by imparting the natural leaf, which is covered by synthetic waxes. However, because of the missing elastic foam layer as used in artificial leather and its replacement by the plant leaf, the flex resistance is hampered and appears not adequately adjusted from a functional point of view.

As a third strategy to replace leather with animal-free materials for which plant-based non-woven fabrics are used. The fossil-based polyester textile support is exchanged by natural fiber alternatives as cotton, linen, etc. Ideally, the fabric would be finished with a biobased polymer. Pinatex

®, for example, is manufactured from pineapple leaf fibers, which are laboriously processed before they are coated by a thin polymer film that can be either fossil-based or from renewable resources to improve usability. Pinatex

® promotes its polymer finish to be polylactide, which can be produced fully bio-based [

13,

30,

31,

32]. However, our analysis showed at least a remarkable content of PUR/acrylate in the finish. The very thin surface coating does not completely cover the fibrous non-woven, which leads to a hard surface with a fibrous appearance that withstands the flex test, however. The material appears more similar to a textile non-woven and the low mechanical resistance can be correlated directly to the low binder content of the fibers of the non-woven support. SnapPap

® is based on cellulosic fibers as well, but in contrast to Pinatex

®, the matrix is bound with acrylic acid-based polymers. Both materials neither simulate a leather structure nor do they appear as a leather surface. Therefore, they should rather be estimated as coated or impregnated textile than as artificial leather or leather alternative.

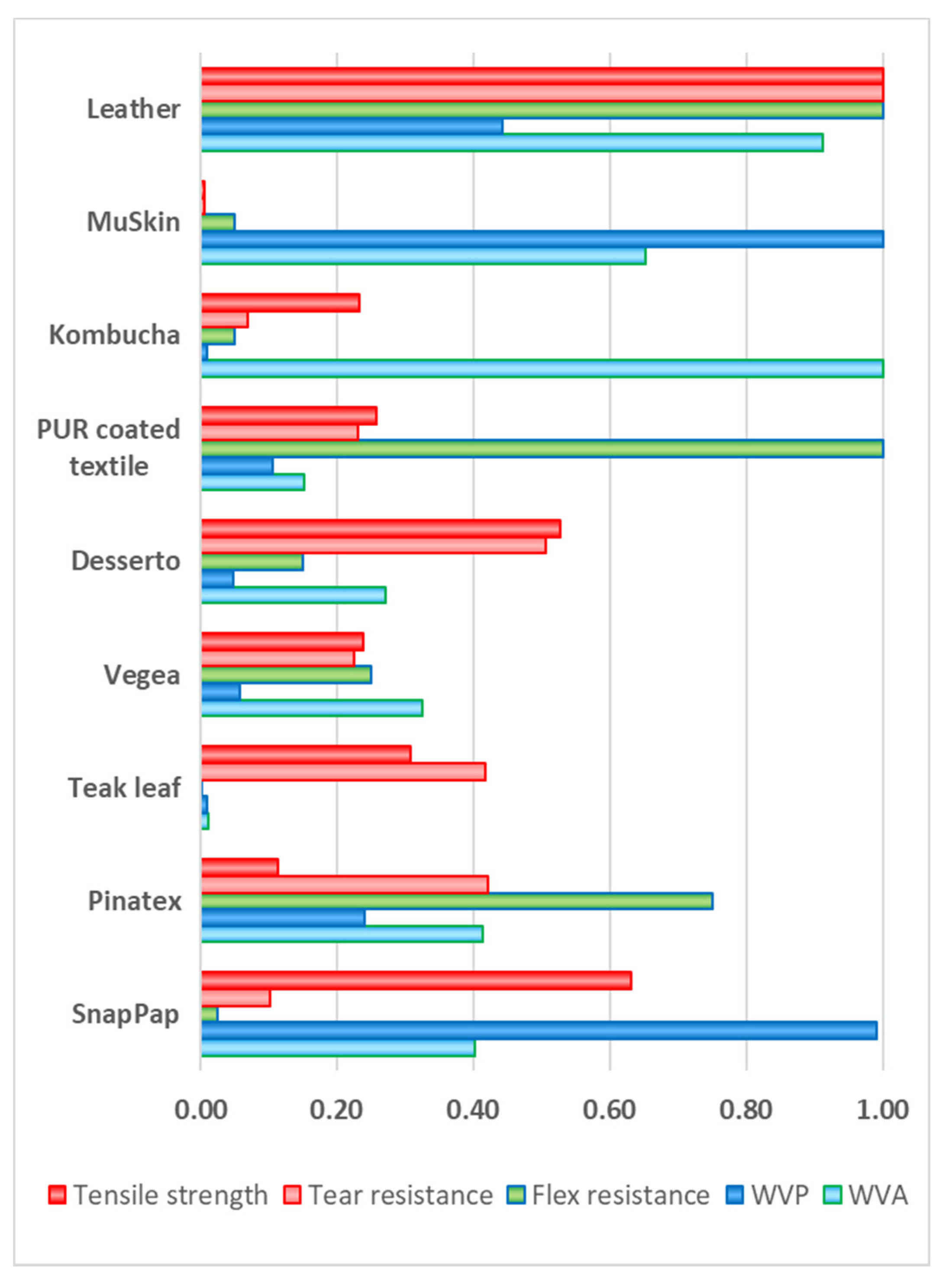

Figure 5 shows impressively the performance of the different materials in comparison to the references. Alternative materials have specific advantages, but none of the materials combines high mechanical strength and flex resistance with high water vapor permeability as in the case of leather.

4.2. Surfaces and Appearance

The surfaces of the materials are their “face.” This is impressively shown with the applied leaf in Teak Leaf

® as an eye-catcher. The resulting structures appear optically interesting but do not fulfill the same function as the foam layer in engineered coated textiles. Other plant materials, which are used in similar constructions to achieve interesting optical properties are, e.g., cork based. They have not been investigated in this study but have to be supported as well by textiles to achieve suitable physical properties [

33,

34,

35]. Therefore, the Teak Leaf

® solution appears more design-driven than it takes functional aspects into account.

To achieve sufficient functional properties of the surface of flexible materials often a final topcoat is applied, which then determines the optic and partially haptic and other useful properties of the materials, e.g., flex resistance, abrasion behavior, and soiling behavior. The water vapor permeability also depends on the tightness of the topcoat or of watertight layers in between. The thicker this layer the less the material allows vapor and gas permeation [

36].

Leather as investigated usually shows only a very thin top coat to improve the soiling behavior. The flex resistance is very high. The water vapor permeability is in an appropriate range. Muskin

® and SnapPap

® show very open structures, which allow water vapor perfectly to diffuse. However, their performance characteristics, particularly the poor flex resistance, limits the long-time use. All other investigated materials are very tight against water vapor permeation. Used as a shoe material, this would lead to sweating of the feet and would reduce the comfort [

37,

38] but the materials would be tight against rain if used as, e.g., bag or rain jacket.

The microscopic surface of SnapPap® and Pinatex® shows the fibrous non-woven fabric, which takes over the mechanical properties of the material. SnapPap® and Pinatex® do not appear leather-like. They show hard surfaces and an exposed fibrous non-woven structure. Applying a thicker polymer coating and embossing a grain structure would presumably lead to a leather-like optic. In this case, considerations regarding water vapor permeability for coated textiles have to be taken into account.