Investigation of the Effects of Component Ratios on the Properties of Superhydrophobic Polyurethane/Fluorinated Acrylic Co-Polymer/SiO2 Nanocomposite Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Coating Preparation

2.3. Characterization

3. Results and Discussion

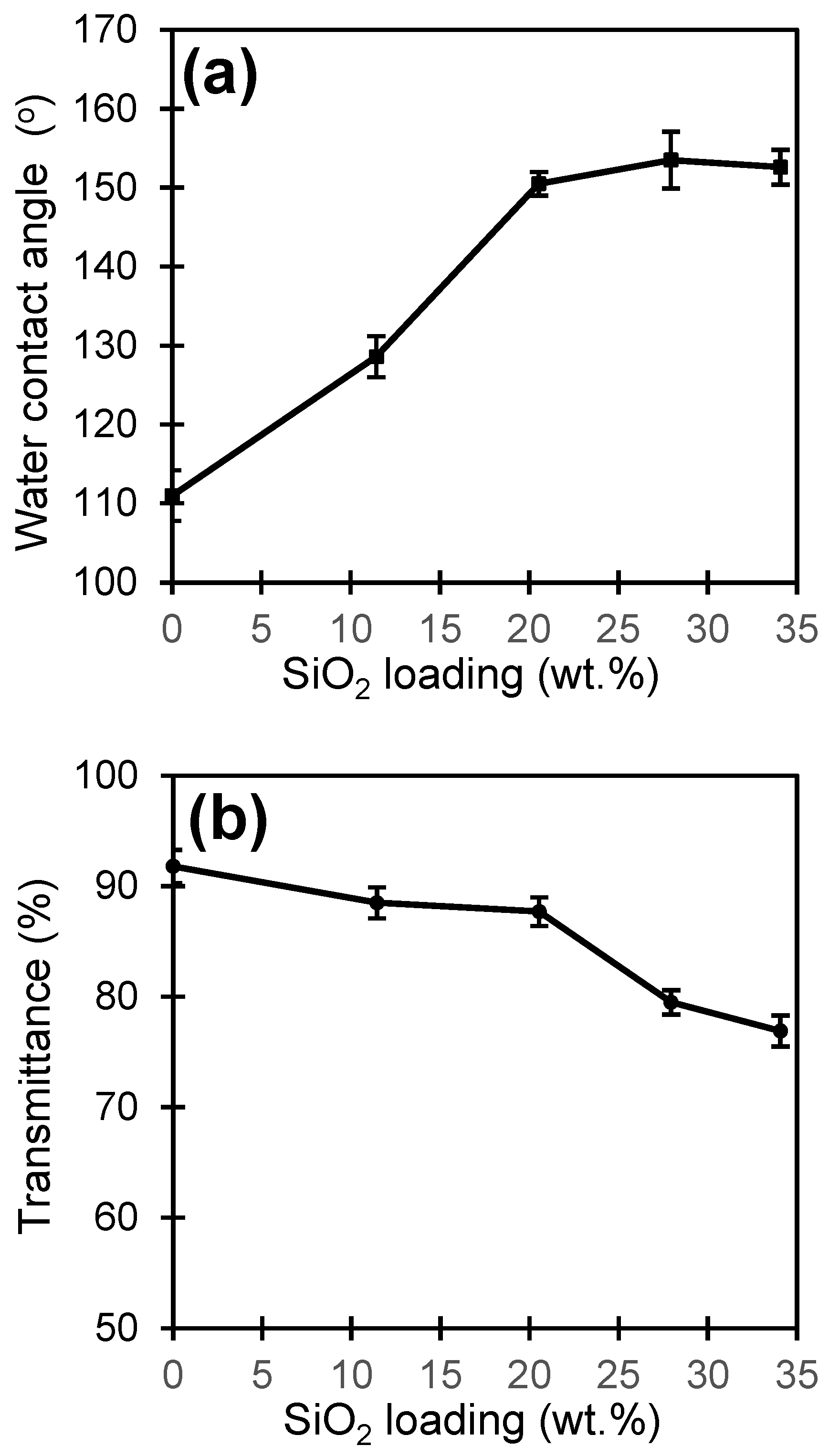

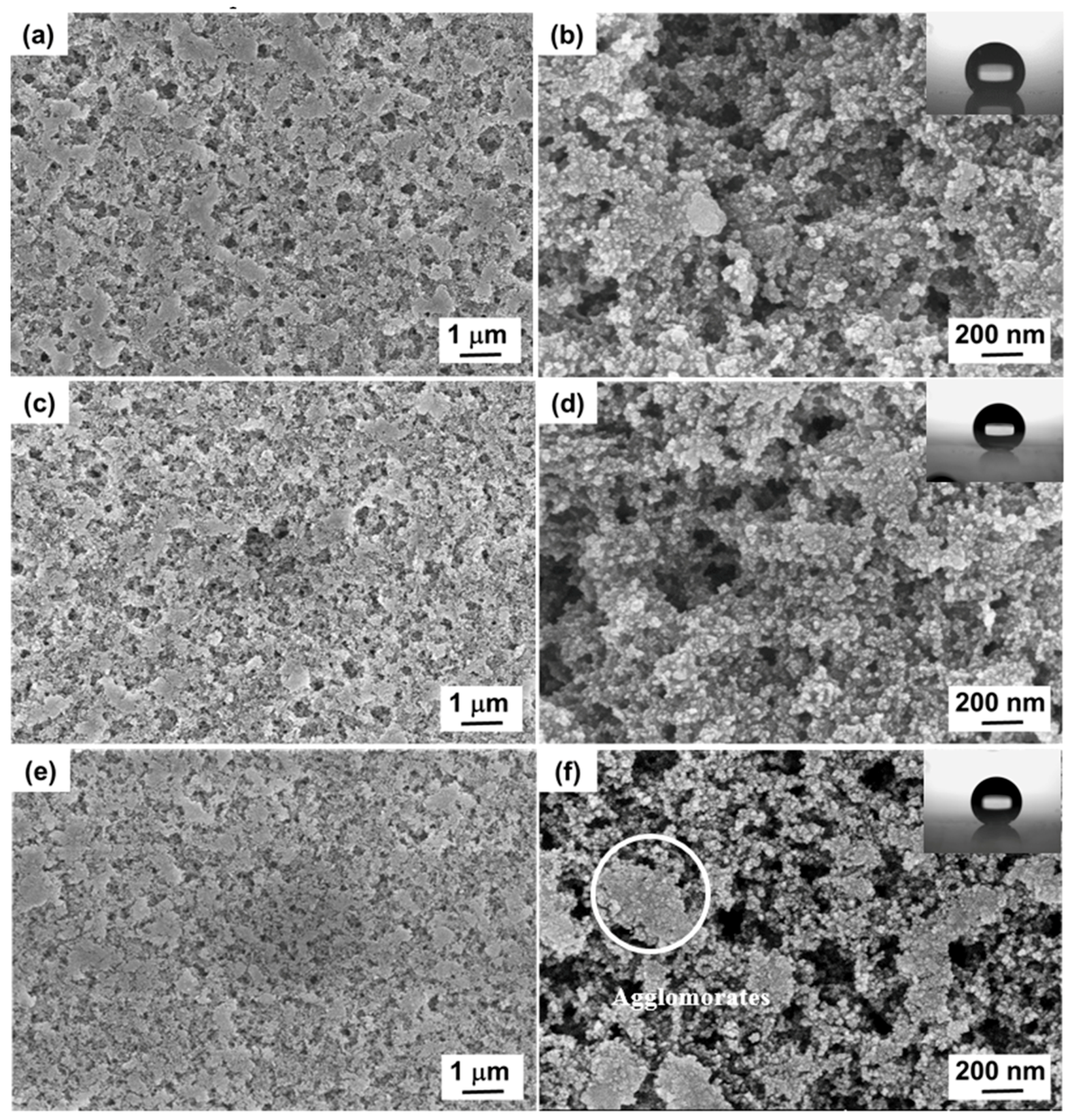

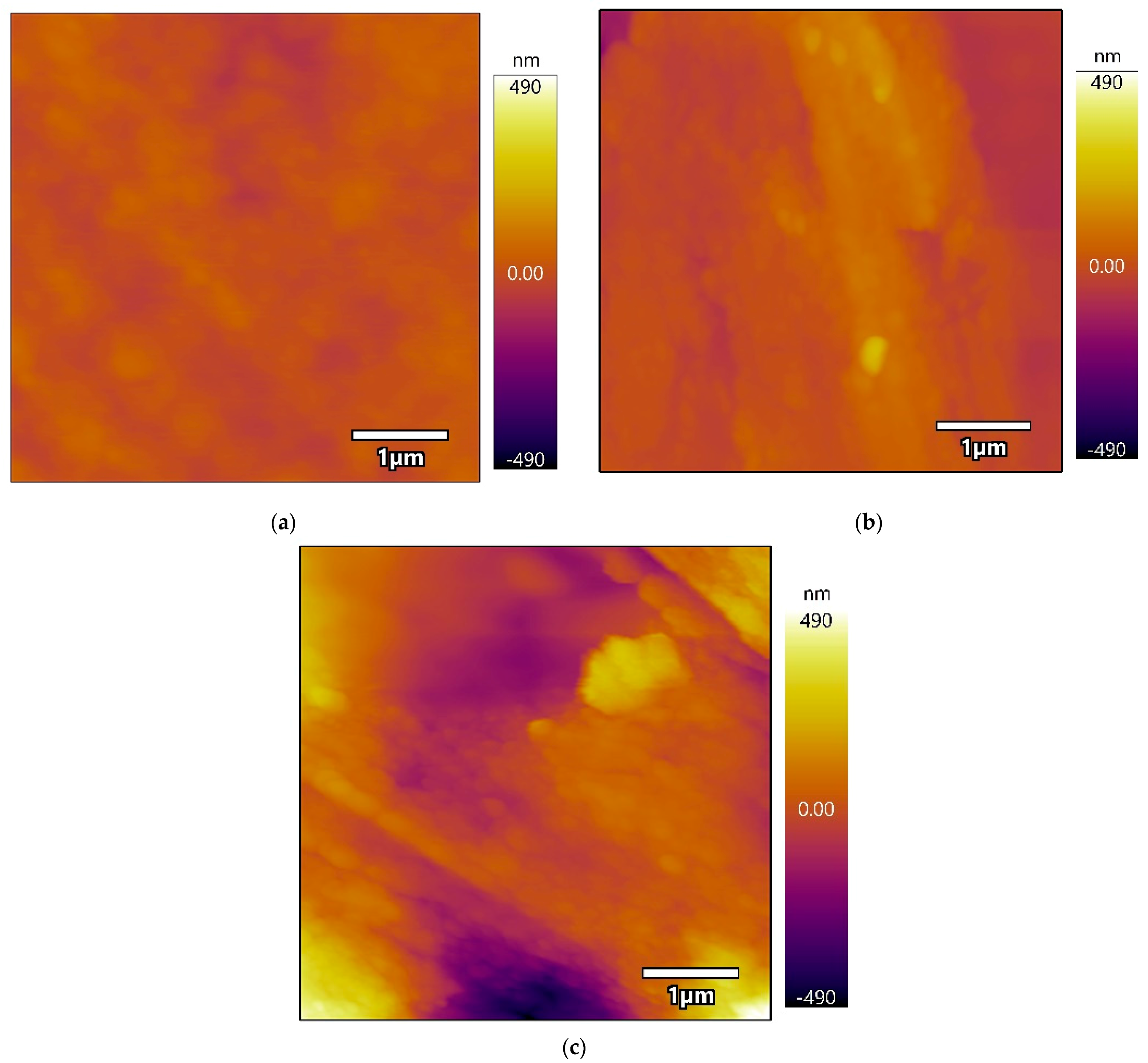

3.1. Effects of SiO2 Nanoparticle Loading

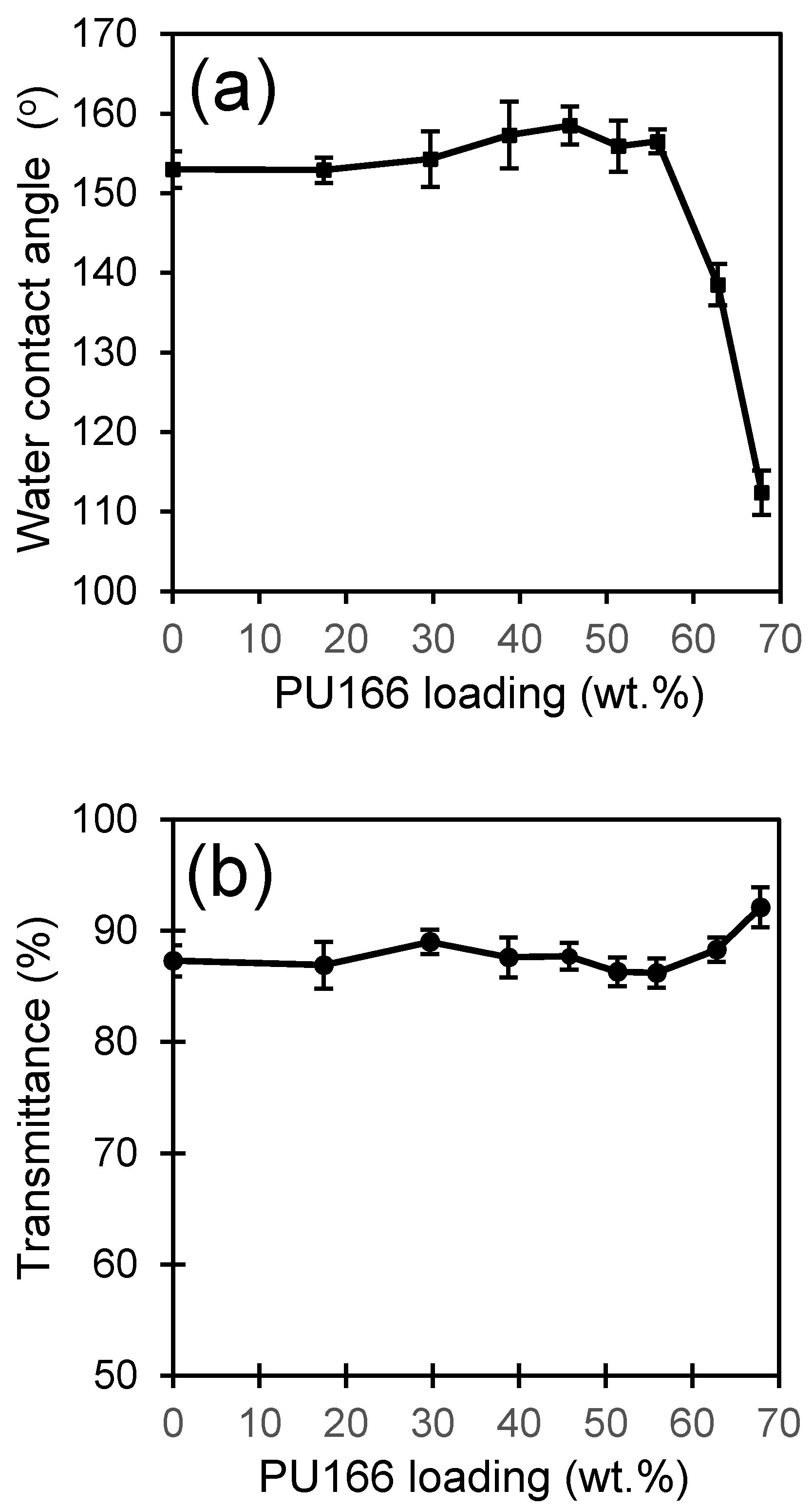

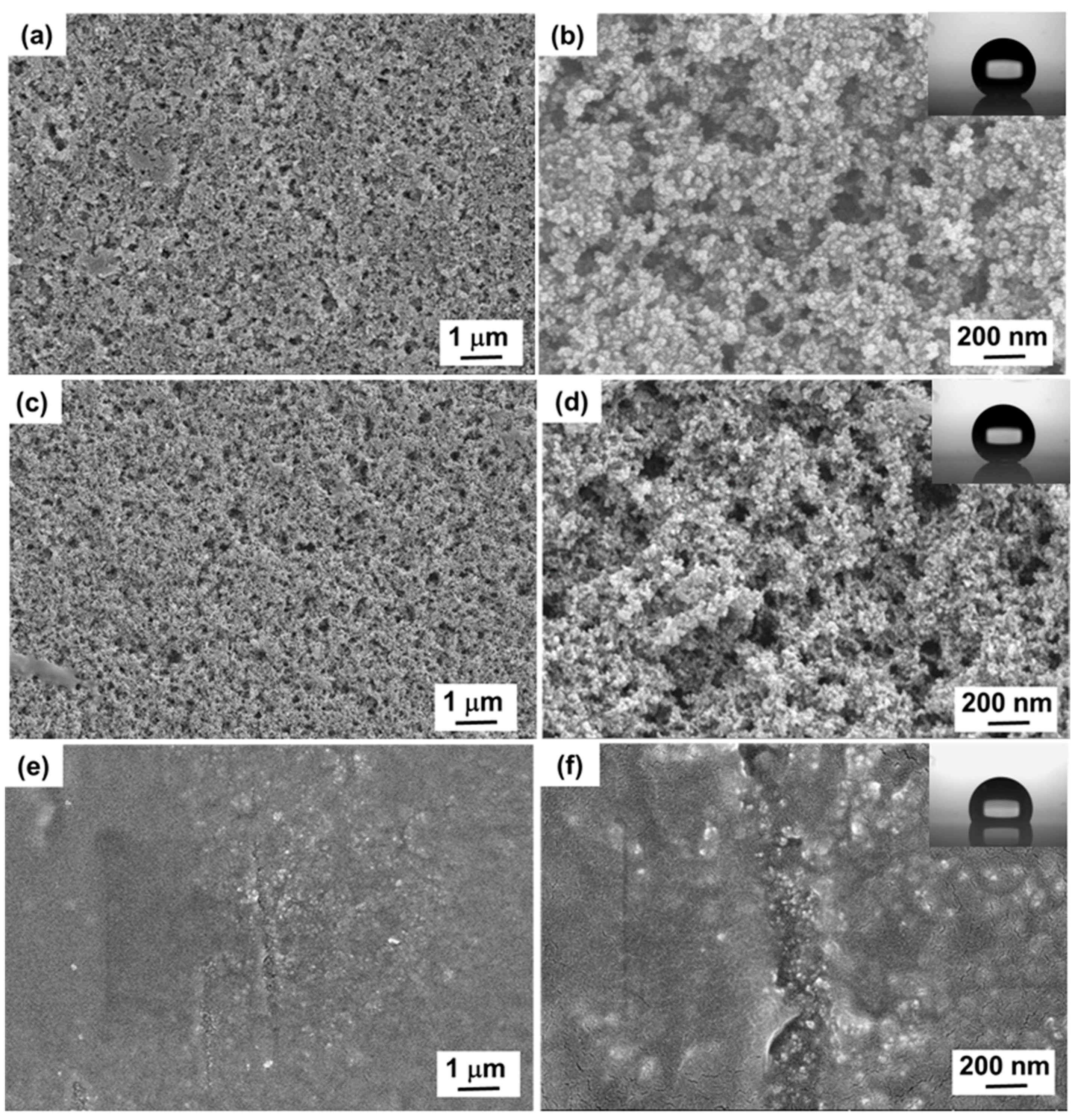

3.2. Effects of PU Loading

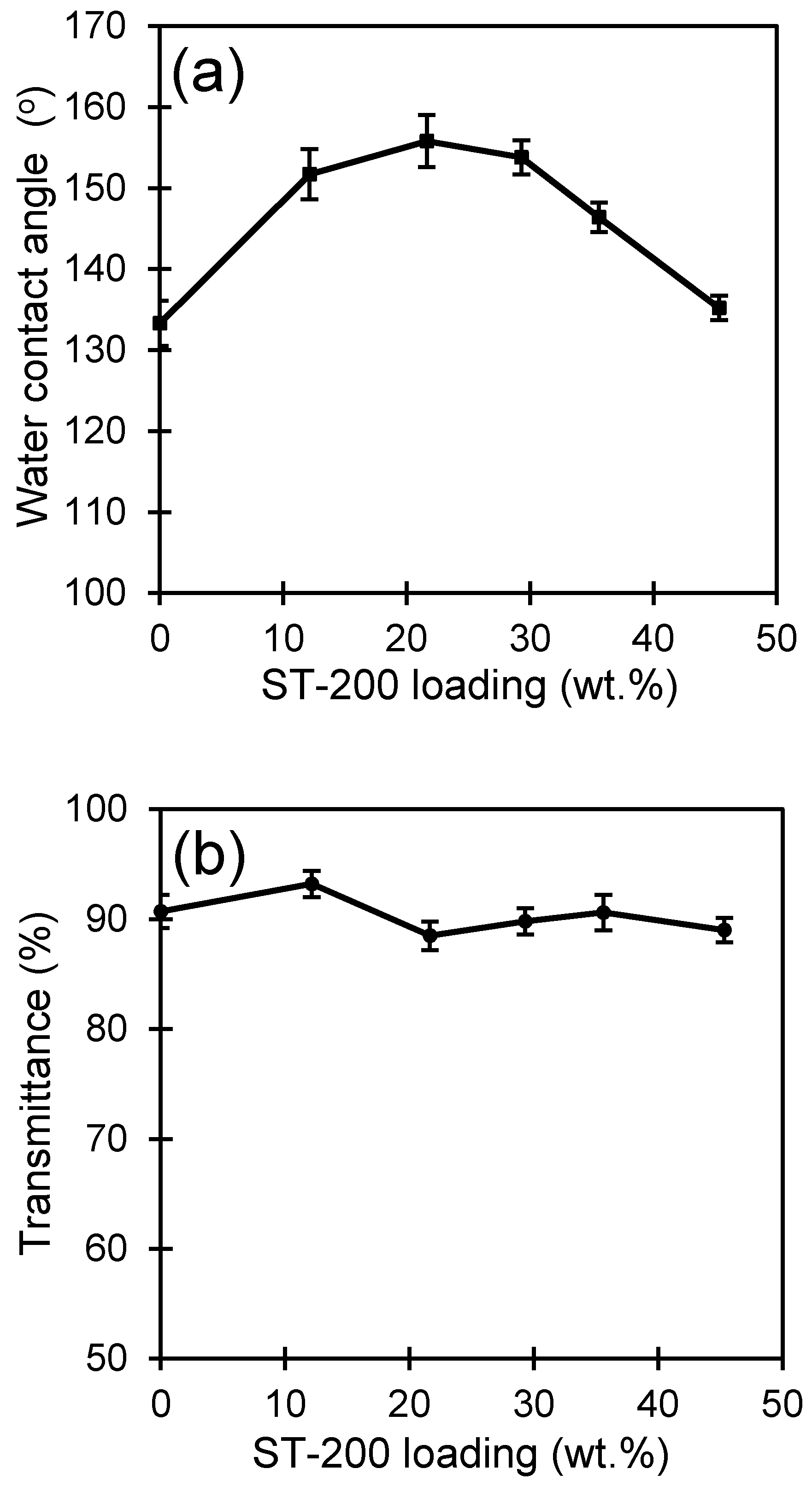

3.3. Effects of Fluorinated Acrylic Copolymer ST-200

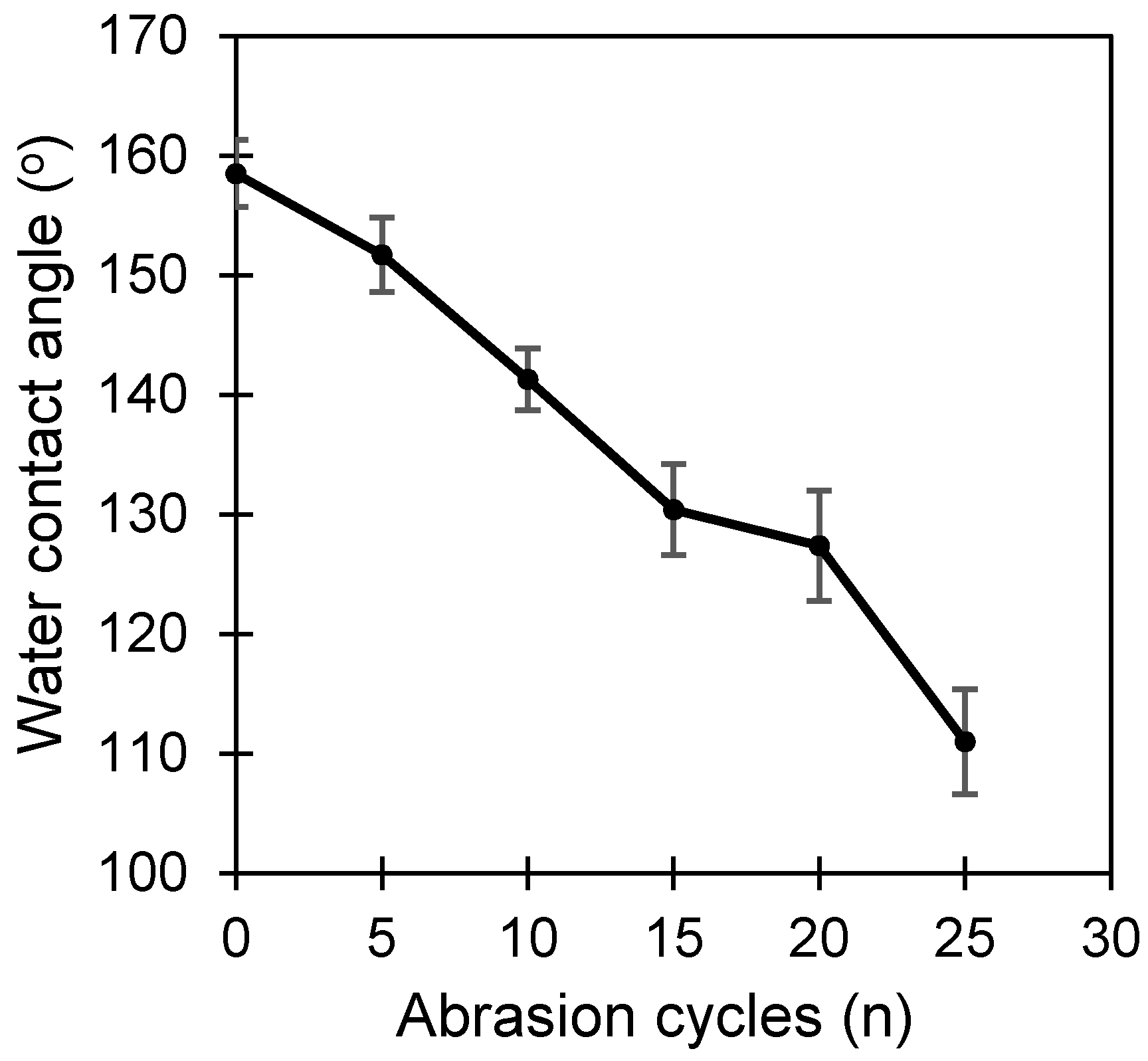

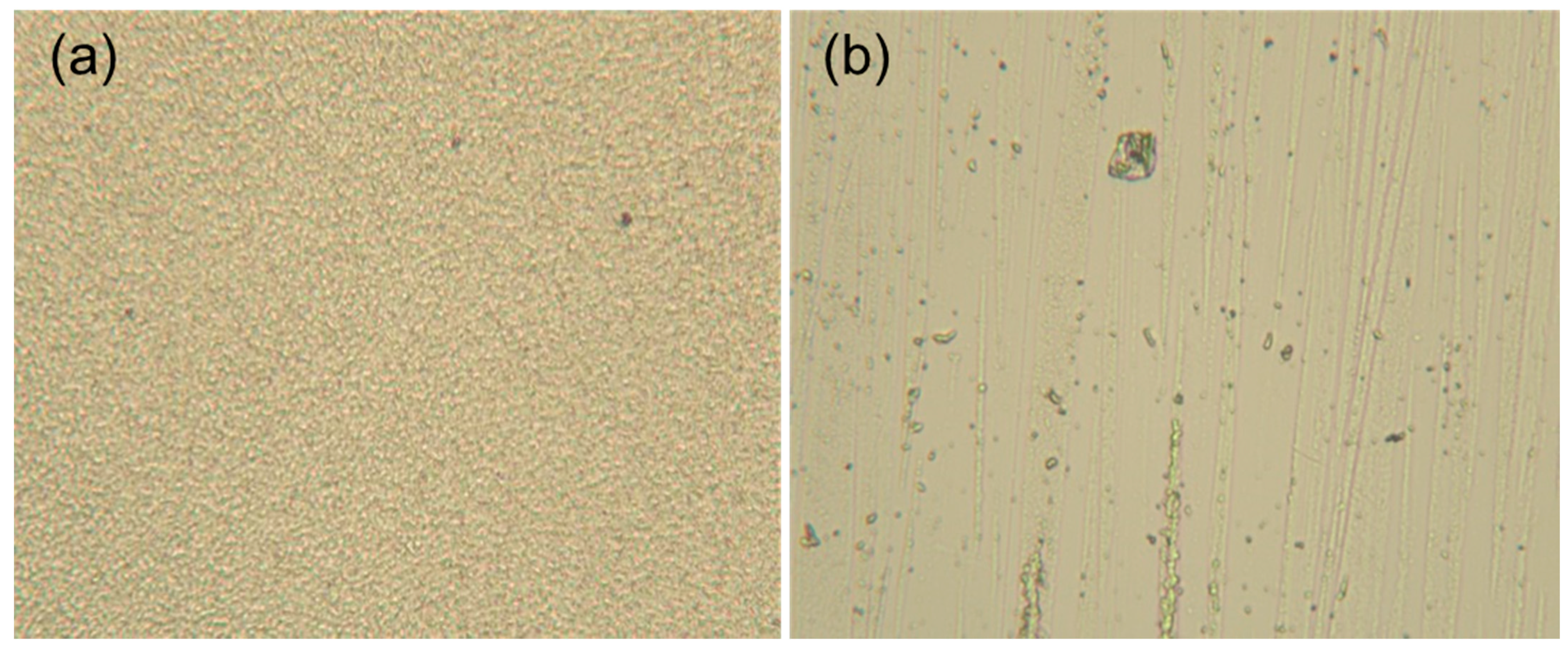

3.4. Abrasion Resistance

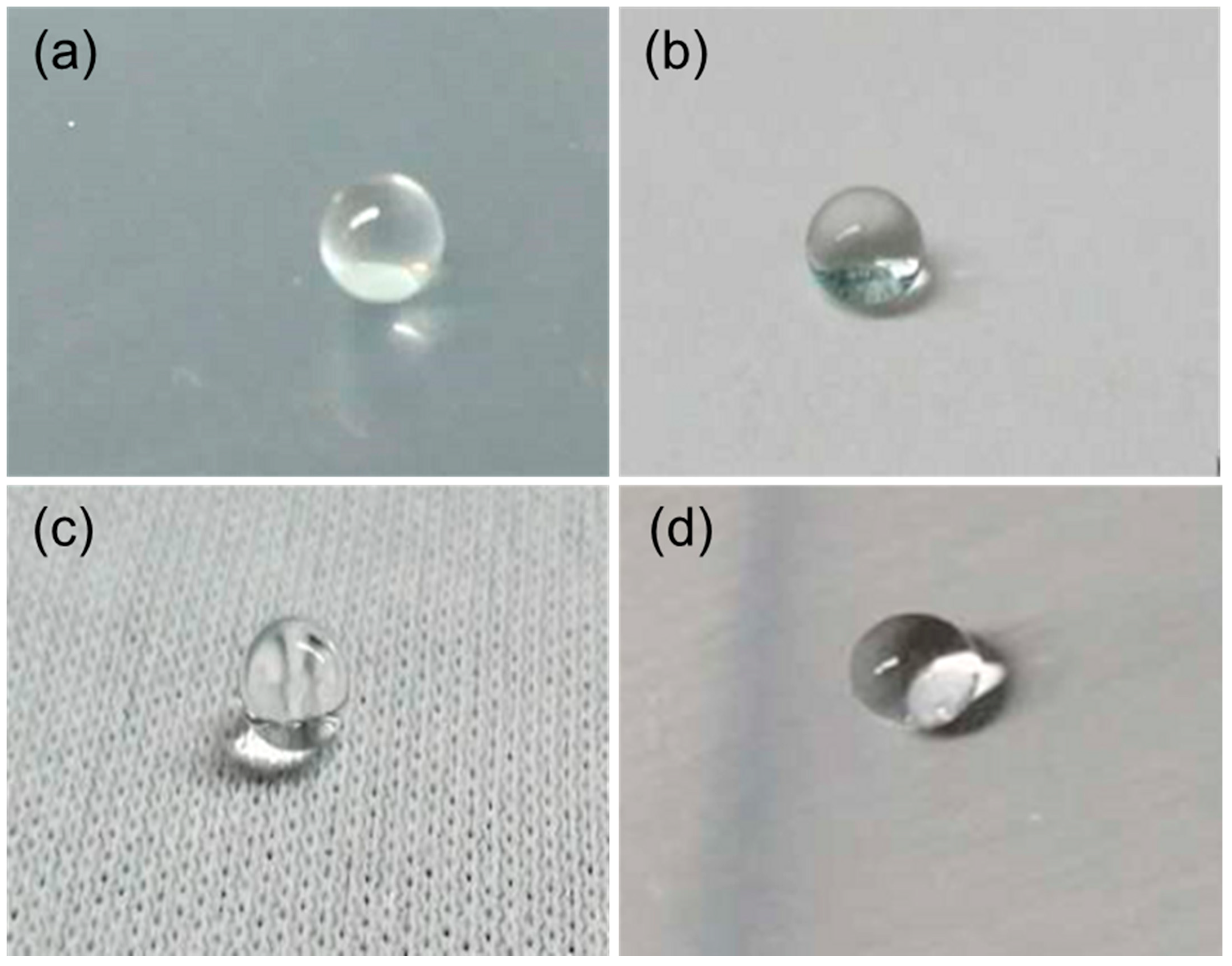

3.5. Practical Applications

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, Y.; Miao, D.; Kong, L.; Jiang, J.; Guo, Z. Preparation and Performance Test of the Super-Hydrophobic Polyurethane Coating Based on Waste Cooking Oil. Coatings 2019, 9, 861. [Google Scholar] [CrossRef]

- Safaei, M.R.; Ranjbarzadeh, R.; Hajizadeh, A.; Bahiraei, M.; Afrand, M.; Karimipour, A. Effects of cobalt ferrite coated with silica nanocomposite on the thermal conductivity of an antifreeze: New nanofluid for refrigeration condensers. Int. J. Refrig. 2019, 102, 86–95. [Google Scholar] [CrossRef]

- Agbe, H.; Sarkar, D.K.; Chen, X. Tunable Superhydrophobic Aluminum Surfaces with Anti-Biofouling and Antibacterial Properties. Coatings 2020, 10, 982. [Google Scholar] [CrossRef]

- Ghazali, N.; Basirun, W.J.; Nor, A.M.; Johan, M.R. Super-Amphiphobic Coating System Incorporating Functionalized Nano-Al2O3 in Polyvinylidene Fluoride (PVDF) with Enhanced Corrosion Resistance. Coatings 2020, 10, 387. [Google Scholar] [CrossRef]

- Jia, L.; Sun, J.; Li, X.; Zhang, X.; Chen, L.; Tian, X. Preparation and Anti-frost Performance of PDMS-SiO2/SS Superhydrophobic Coating. Coatings 2020, 10, 1051. [Google Scholar] [CrossRef]

- Qian, C.; Li, Q.; Chen, X. Droplet Impact on the Cold Elastic Superhydrophobic Membrane with Low Ice Adhesion. Coatings 2020, 10, 964. [Google Scholar] [CrossRef]

- Rasheed, T.; Shafi, S.; Bilal, M.; Hussain, T.; Sher, F.; Rizwan, K. Surfactants-based remediation as an effective approach for removal of environmental pollutants—A review. J. Mol. Liq. 2020, 113960. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, H.; Wang, G.; Liu, A. Recent progress in preparation and anti-icing applications of superhydrophobic coatings. Coatings 2018, 8, 208. [Google Scholar] [CrossRef]

- Shang, B.; Chen, M.; Wu, L. Fabrication of UV-Triggered Liquid-Repellent Coatings with Long-Term Self-Repairing Performance. ACS Appl. Mater. Interfaces 2018, 10, 31777–31783. [Google Scholar] [CrossRef]

- Fihri, A.; Bovero, E.; Al-Shahrani, A.; Al-Ghamdi, A.; Alabedi, G. Recent progress in superhydrophobic coatings used for steel protection: A review. Colloids Surf. A Physicochem. Eng. Asp. 2017, 520, 378–390. [Google Scholar] [CrossRef]

- Das, S.; Kumar, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. A Review on Superhydrophobic Polymer Nanocoatings: Recent Development and Applications. Ind. Eng. Chem. Res. 2018, 57, 2727–2745. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.; Jin, T.; He, L.; Zeng, Y.; Ma, Q.; Li, N. Fabrication of superhydrophobic coating from non-fluorine siloxanes via a one-pot sol-gel method. J. Mater. Sci. 2018, 53, 11253–11264. [Google Scholar] [CrossRef]

- Kumar, A.; Gogoi, B. Development of durable self-cleaning superhydrophobic coatings for aluminium surfaces via chemical etching method. Tribol. Int. 2018, 122, 114–118. [Google Scholar] [CrossRef]

- Ye, H.; Zhu, L.; Li, W.; Liu, H.; Chen, H. Simple spray deposition of a water-based superhydrophobic coating with high stability for flexible applications. J. Mater. Chem. A 2017, 5, 9882–9890. [Google Scholar] [CrossRef]

- Şakalak, H.; Yılmaz, K.; Gürsoy, M.; Karaman, M. Roll-to roll initiated chemical vapor deposition of super hydrophobic thin films on large-scale flexible substrates. Chem. Eng. Sci. 2020, 215, 115466. [Google Scholar] [CrossRef]

- Si, Y.; Dong, Z.; Jiang, L. Bioinspired Designs of Superhydrophobic and Superhydrophilic Materials. ACS Cent. Sci. 2018, 4, 1102–1112. [Google Scholar] [CrossRef]

- Guo, D.; Chen, J.; Wen, L.; Wang, P.; Xu, S.; Cheng, J.; Wen, X.; Wang, S.; Huang, C.; Pi, P. A superhydrophobic polyacrylate film with good durability fabricated via spray coating. J. Mater. Sci. 2018, 53, 15390–15400. [Google Scholar] [CrossRef]

- Ma, C.; Li, Y.; Zhang, J.; Ning, F.; Kang, M.; Li, H.; Qiu, Z. Preparation and characterization of polyacrylate composite and its application in superhydrophobic coating based on silicone-modified ZnO. J. Coat. Technol. Res. 2021, 1–19. [Google Scholar] [CrossRef]

- Hooda, A.; Goyat, M.S.; Kumar, A.; Gupta, R. A facile approach to develop modified nano-silica embedded polystyrene based transparent superhydrophobic coating. Mater. Lett. 2018, 233, 340–343. [Google Scholar] [CrossRef]

- Latthe, S.S.; Sutar, R.S.; Shinde, T.B.; Pawar, S.B.; Khot, T.M.; Bhosale, A.K.; Sadasivuni, K.K.; Xing, R.; Mao, L.; Liu, S. Superhydrophobic leaf mesh decorated with SiO2 nanoparticle–polystyrene nanocomposite for oil–water separation. ACS Appl. Nano Mater. 2019, 2, 799–805. [Google Scholar] [CrossRef]

- Wei, C.; Dai, F.; Lin, L.; An, Z.; He, Y.; Chen, X.; Chen, L.; Zhao, Y. Simplified and robust adhesive-free superhydrophobic SiO2-decorated PVDF membranes for efficient oil/water separation. J. Membr. Sci. 2018, 555, 220–228. [Google Scholar] [CrossRef]

- Wang, M.; Liu, G.; Yu, H.; Lee, S.-H.; Wang, L.; Zheng, J.; Wang, T.; Yun, Y.; Lee, J.K. ZnO nanorod array modified PVDF membrane with superhydrophobic surface for vacuum membrane distillation application. ACS Appl. Mater. Interfaces 2018, 10, 13452–13461. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Shen, Y.; Tao, J.; He, Z.; Xie, Y.; Chen, H.; Jin, M.; Hou, W. Facile spraying fabrication of highly flexible and mechanically robust superhydrophobic F-SiO2@ PDMS coatings for self-cleaning and drag-reduction applications. New J. Chem. 2018, 42, 18208–18216. [Google Scholar] [CrossRef]

- Deka, B.J.; Lee, E.-J.; Guo, J.; Kharraz, J.; An, A.K. Electrospun nanofiber membranes incorporating PDMS-aerogel superhydrophobic coating with enhanced flux and improved antiwettability in membrane distillation. Environ. Sci. Technol. 2019, 53, 4948–4958. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Chen, R.; Liu, Q.; Liu, J.; Yu, J.; Wang, C.; Zhang, M.; Liu, P.; Wang, J. Fabrication of ZnO/epoxy resin superhydrophobic coating on AZ31 Magnesium Alloy. Chem. Eng. J. 2019, 368, 261–272. [Google Scholar] [CrossRef]

- Ren, T.; Tang, G.; Yuan, B.; Yan, Z.; Ma, L.; Huang, X. One-step fabrication of robust superhydrophobic coatings with corrosion resistance by a self-curing epoxy-resin-based adhesive. Surf. Coat. Technol. 2019, 380, 125086. [Google Scholar] [CrossRef]

- Ghashghaee, M.; Fallah, M.; Rabiee, A. Superhydrophobic nanocomposite coatings of poly (methyl methacrylate) and stearic acid grafted CuO nanoparticles with photocatalytic activity. Prog. Org. Coat. 2019, 136, 105270. [Google Scholar] [CrossRef]

- Sutar, R.S.; Gaikwad, S.S.; Latthe, S.S.; Kodag, V.S.; Deshmukh, S.B.; Saptal, L.P.; Kulal, S.R.; Bhosale, A.K. Superhydrophobic Nanocomposite Coatings of Hydrophobic Silica NPs and Poly (methyl methacrylate) with Notable Self-Cleaning Ability. Wiley Online Libr. 2020, 393, 2000116. [Google Scholar] [CrossRef]

- Luo, G.; Jin, Z.; Dong, Y.; Huang, J.; Zhang, R.; Wang, J.; Li, M.; Shen, Q.; Zhang, L. Preparation and performance enhancements of wear-resistant, transparent PU/SiO2 superhydrophobic coating. Surf. Eng. 2018, 34, 139–145. [Google Scholar] [CrossRef]

- Yousefi, E.; Ghadimi, M.R.; Amirpoor, S.; Dolati, A. Preparation of new superhydrophobic and highly oleophobic polyurethane coating with enhanced mechanical durability. Appl. Surf. Sci. 2018, 454, 201–209. [Google Scholar] [CrossRef]

- Zheng, H.; Pan, M.; Wen, J.; Yuan, J.; Zhu, L.; Yu, H. Robust, Transparent, and Superhydrophobic Coating Fabricated with Waterborne Polyurethane and Inorganic Nanoparticle Composites. Ind. Eng. Chem. Res. 2019, 58, 8050–8060. [Google Scholar] [CrossRef]

- Yu, N.; Xiao, X.; Ye, Z.; Pan, G. Facile preparation of durable superhydrophobic coating with self-cleaning property. Surf. Coat. Technol. 2018, 347, 199–208. [Google Scholar] [CrossRef]

- Huang, J.; Lyu, S.; Chen, Z.; Wang, S.; Fu, F. A facile method for fabricating robust cellulose nanocrystal/SiO2 superhydrophobic coatings. J. Colloid Interface Sci. 2019, 536, 349–362. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Liu, W.; Jiang, C.; He, S.; Xie, Y.; Wang, Z. Fabrication of superhydrophobic cotton fabric with fluorinated TiO2 sol by a green and one-step sol-gel process. Carbohydr. Polym. 2018, 197, 75–82. [Google Scholar] [CrossRef] [PubMed]

- Kokare, A.M.; Sutar, R.S.; Deshmukh, S.G.; Xing, R.; Liu, S.; Latthe, S.S. ODS–Modified TiO2 Nanoparticles for the Preparation of Self-Cleaning Superhydrophobic Coating; AIP Publishing LLC: Melville, NY, USA, 2020; p. 100068. [Google Scholar] [CrossRef]

- Hwang, G.B.; Patir, A.; Page, K.; Lu, Y.; Allan, E.; Parkin, I.P. Buoyancy increase and drag-reduction through a simple superhydrophobic coating. Nanoscale 2017, 9, 7588–7594. [Google Scholar] [CrossRef]

- Sun, K.; Liu, H.; Wang, X.; Wu, D. Innovative design of superhydrophobic thermal energy-storage materials by microencapsulation of n-docosane with nanostructured ZnO/SiO2 shell. Appl. Energy 2019, 237, 549–565. [Google Scholar] [CrossRef]

- Satapathy, M.; Varshney, P.; Nanda, D.; Mohapatra, S.S.; Behera, A.; Kumar, A. Fabrication of durable porous and non-porous superhydrophobic LLDPE/SiO2 nanoparticles coatings with excellent self-cleaning property. Surf. Coat. Technol. 2018, 341, 31–39. [Google Scholar] [CrossRef]

- Radwan, A.B.; Abdullah, A.M.; Hassan, M.K. The missing piece of the puzzle regarding the relation between the degree of superhydrophobicity and the corrosion resistance of superhydrophobic coatings. Electrochem. Commun. 2018, 91, 41–44. [Google Scholar] [CrossRef]

- Vu, M.C.; Bach, Q.-V.; Nguyen, D.D.; Tran, T.S.; Goodarzi, M. 3D interconnected structure of poly (methyl methacrylate) microbeads coated with copper nanoparticles for highly thermal conductive epoxy composites. Compos. Part B Eng. 2019, 175, 107105. [Google Scholar] [CrossRef]

- Karimipour, A.; Bagherzadeh, S.A.; Goodarzi, M.; Alnaqi, A.A.; Bahiraei, M.; Safaei, M.R.; Shadloo, M.S. Synthesized CuFe2O4/SiO2 nanocomposites added to water/EG: Evaluation of the thermophysical properties beside sensitivity analysis & EANN. Int. J. Heat Mass Transf. 2018, 127, 1169–1179. [Google Scholar] [CrossRef]

- Alrashed, A.A.A.A.; Karimipour, A.; Bagherzadeh, S.A.; Safaei, M.R.; Afrand, M. Electro-and thermophysical properties of water-based nanofluids containing copper ferrite nanoparticles coated with silica: Experimental data, modeling through enhanced ANN and curve fitting. Int. J. Heat Mass Transf. 2018, 127, 925–935. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ke, C.; Li, Z.; Zhang, C.; Wu, X.; Zhu, Z.; Jiang, Y. Investigation of the Effects of Component Ratios on the Properties of Superhydrophobic Polyurethane/Fluorinated Acrylic Co-Polymer/SiO2 Nanocomposite Coatings. Coatings 2021, 11, 174. https://doi.org/10.3390/coatings11020174

Ke C, Li Z, Zhang C, Wu X, Zhu Z, Jiang Y. Investigation of the Effects of Component Ratios on the Properties of Superhydrophobic Polyurethane/Fluorinated Acrylic Co-Polymer/SiO2 Nanocomposite Coatings. Coatings. 2021; 11(2):174. https://doi.org/10.3390/coatings11020174

Chicago/Turabian StyleKe, Chong, Zhongfa Li, Chenhua Zhang, Xinguo Wu, Zhiping Zhu, and Yongdong Jiang. 2021. "Investigation of the Effects of Component Ratios on the Properties of Superhydrophobic Polyurethane/Fluorinated Acrylic Co-Polymer/SiO2 Nanocomposite Coatings" Coatings 11, no. 2: 174. https://doi.org/10.3390/coatings11020174

APA StyleKe, C., Li, Z., Zhang, C., Wu, X., Zhu, Z., & Jiang, Y. (2021). Investigation of the Effects of Component Ratios on the Properties of Superhydrophobic Polyurethane/Fluorinated Acrylic Co-Polymer/SiO2 Nanocomposite Coatings. Coatings, 11(2), 174. https://doi.org/10.3390/coatings11020174