Improvement in the Figure of Merit of ITO-Metal-ITO Sandwiched Films on Poly Substrate by High-Power Impulse Magnetron Sputtering

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

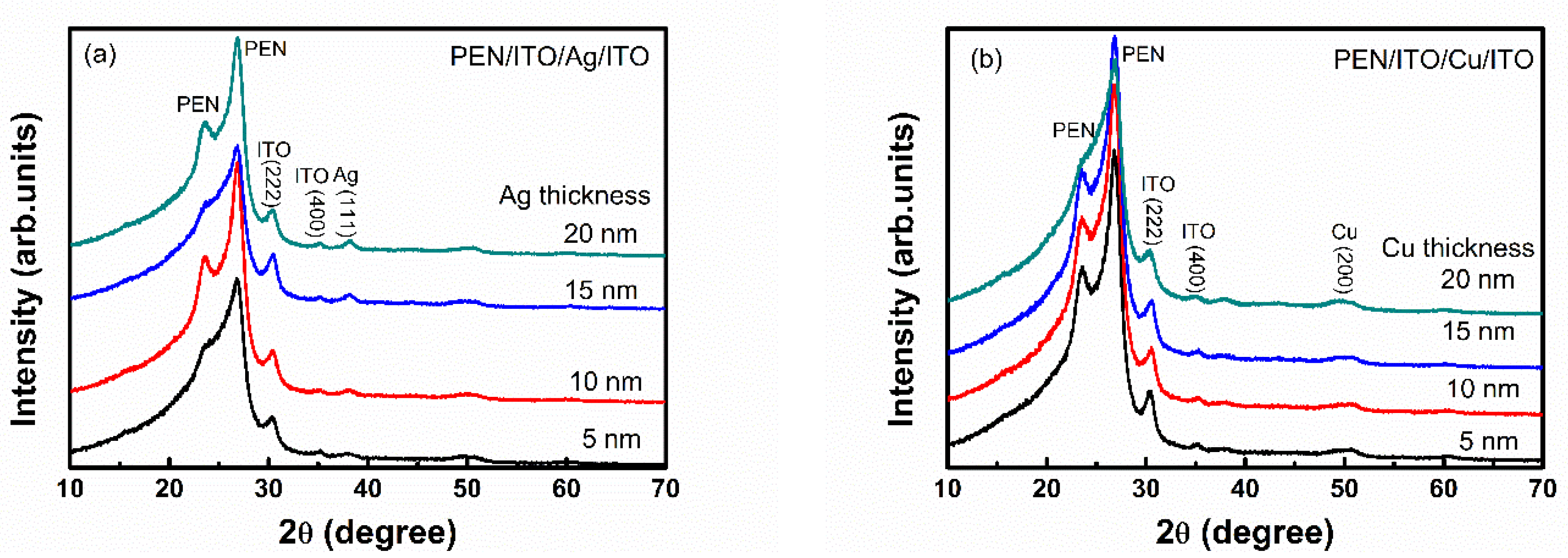

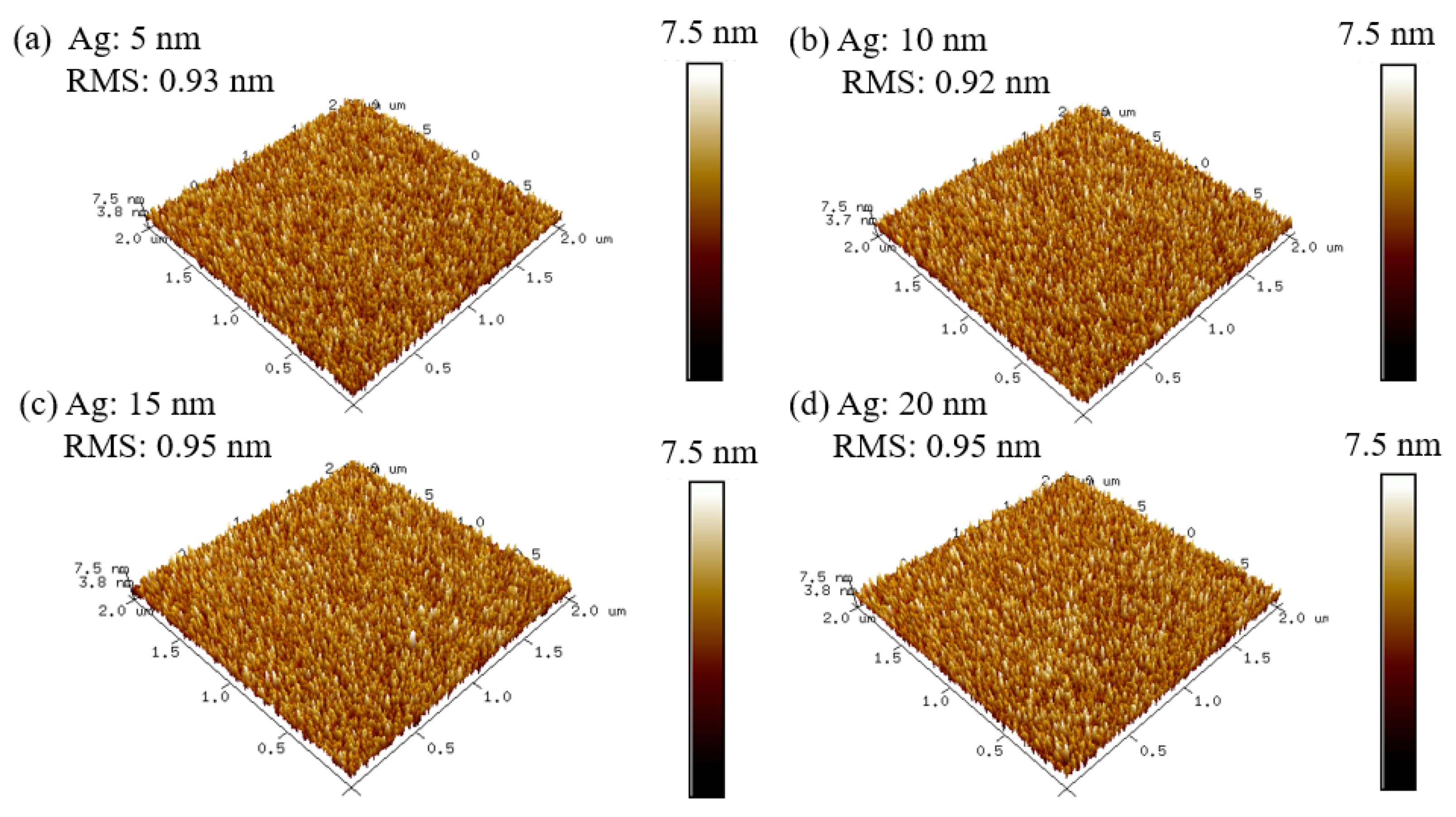

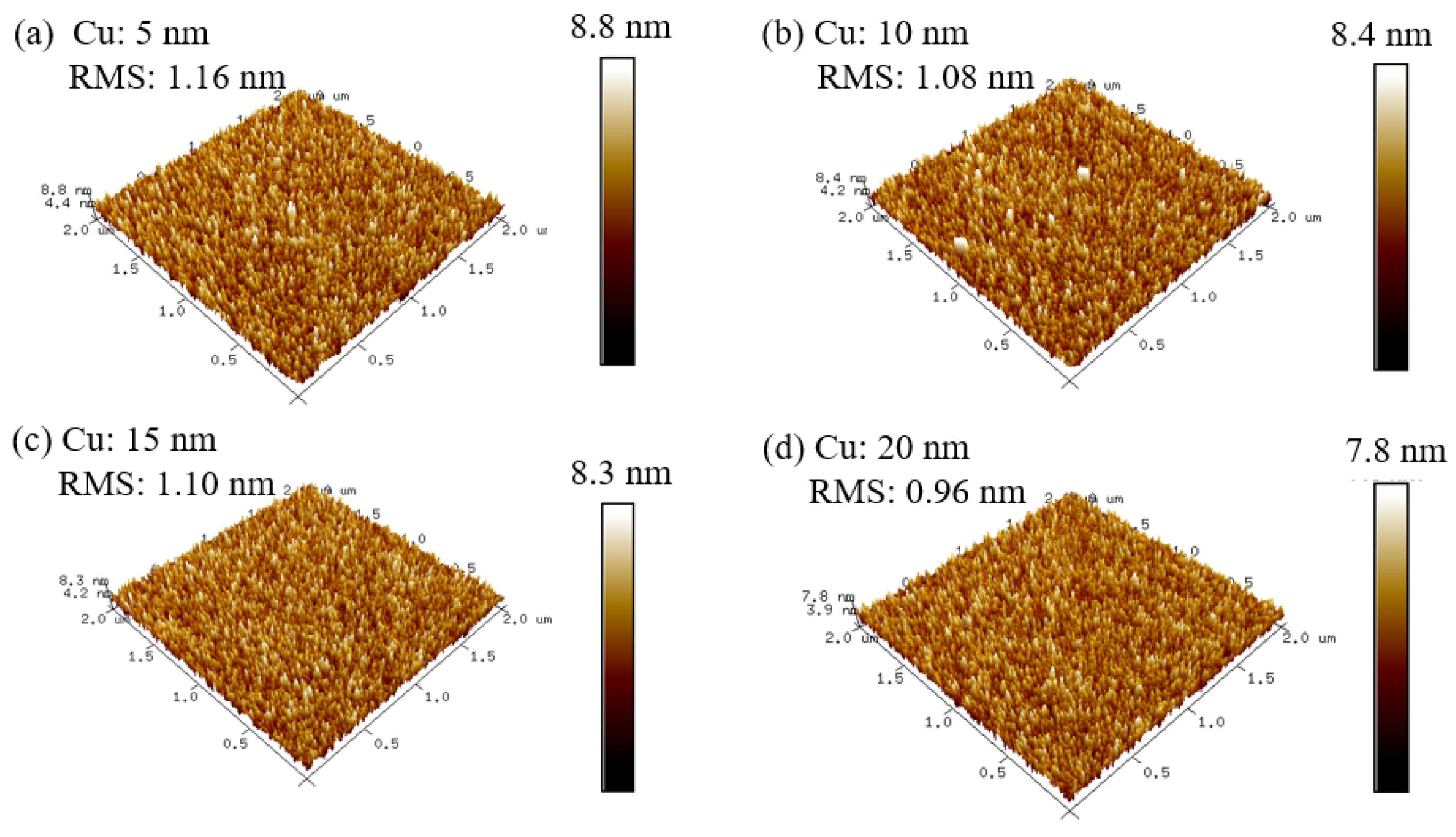

3.1. Material Properties of the Sandwiched TCO Films

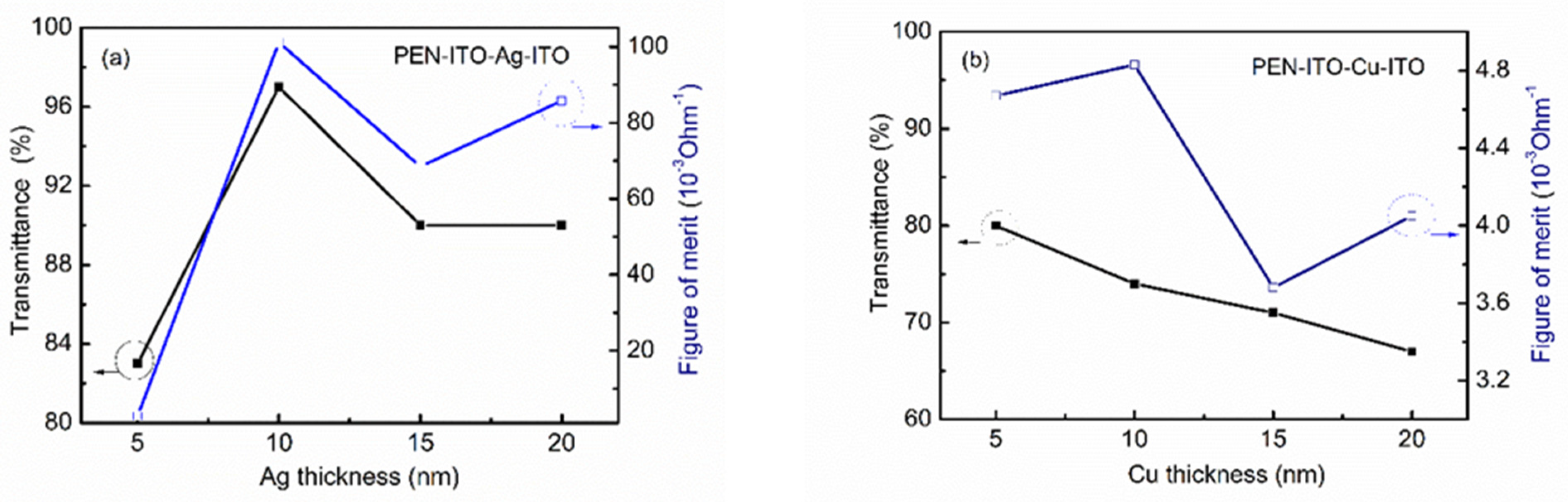

3.2. Opto-Electrical Properties of the Sandwiched TCO Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statements

Conflicts of Interest

References

- Sahu, D.R.; Lin, S.Y.; Huang, J.L. ZnO/Ag/ZnO multilayer films for the application of a very low resistance transparent electrode. Appl. Surf. Sci. 2006, 252, 7509–7514. [Google Scholar] [CrossRef]

- Meng, L.; Chai, H.; Yang, X.; Lv, Z.; Yang, T. Optically rough and physically flat TCO substrate formed by coating ZnO thin film on pyramid-patterned glass substrate. Sol. Energy Mater. Sol. Cells 2019, 191, 459–465. [Google Scholar] [CrossRef]

- Hulubei, C.; Albu, R.M.; Lisa, G.; Nicolescu, A.; Hamciuc, E.; Hamciuc, C.; Barzic, A.I. Antagonistic effects in structural design of sulfur-based polyimides as shielding layers for solar cells. Sol. Energy Mater. Sol. Cells 2019, 193, 219–230. [Google Scholar] [CrossRef]

- Cho, S.P.; Na, S.; Kim, S.S. Efficient ITO-free semitransparent perovskite solar cells with metal transparent electrodes. Sol. Energy Mater. Sol. Cells 2019, 196, 1–8. [Google Scholar] [CrossRef]

- Patel, M.; Ban, D.K.; Ray, A.; Kim, J. Transparent all-oxide photovoltaics and broadband high-speed energy-efficient optoelectronics. Sol. Energy Mater. Sol. Cells 2019, 194, 148–158. [Google Scholar] [CrossRef]

- Cho, Y.; Parmar, N.S.; Nahm, S.J.; Choi, W. Full range optical and electrical properties of Zn-doped SnO2 and oxide/metal/oxide multilayer thin films deposited on flexible PET substrate. J. Alloys Compd. 2017, 694, 217–222. [Google Scholar] [CrossRef]

- Liu, W.S.; Lin, Y.H.; Huang, C.L.; Wang, C.W. Device performance improvement of transparent thin-film transistors with a Ti-doped GaZnO/InGaZnO/Ti-Doped GaZnO sandwich composite-channel structure. IEEE Trans. Electron. Devices 2017, 64, 2533–2541. [Google Scholar] [CrossRef]

- Voggu, V.R.; Sham, J.; Pfeffer, S.; Pate, J.; Filip, L.; Harvey, T.B.; Brown, R.M., Jr.; Korgel, B.A. Flexible CuInSe2 nanocrystal solar cells on paper. ACS Energy Lett. 2017, 2, 574–581. [Google Scholar] [CrossRef]

- Pisoni, S.; Fu, F.; Feurer, T.; Makha, M.; Bissig, B.; Nishiwaki, S.; Tiwari, A.N.; Buecheler, S. Flexible NIR-transparent perovskite solar cells for all-thin-film tandem photovoltaic devices. J. Mater. Chem. A. 2017, 5, 13639–13647. [Google Scholar] [CrossRef]

- Park, S.K.; Han, J.I.; Kim, W.K.; Kwak, M.G. Deposition of indium–tin-oxide films on polymer substrates for application in plastic-based flat panel displays. Thin Solid Film. 2001, 397, 49–55. [Google Scholar] [CrossRef]

- Dehuff, N.L.; Kettenring, E.S.; Hong, D.; Chiang, H.Q.; Wager, J.F.; Hoffman, R.L.; Park, C.H.; Keszler, D.A. Transparent thin-film transistors with zinc indium oxide channel layer. J. Appl. Phys. 2005, 97, 064505-1–064505-5. [Google Scholar] [CrossRef]

- Uchida, T.; Kasahara, Y.; Otomo, T.; Seki, S.; Wang, M.; Sawada, Y. Transparent conductive electrode deposited by Cs-incorporated RF magnetron sputtering and evaluation of the damage in OLED organic layer. Thin Solid Film. 2008, 516, 5907–5910. [Google Scholar] [CrossRef]

- Kim, H.K.; Lee, S.G.; Yun, K.S. Capacitive tactile sensor array for touch screen application. Sens. Actuators A 2011, 165, 2–7. [Google Scholar] [CrossRef]

- Ahn, M.H.; Cho, E.S.; Kwon, S.J. Characteristics of ITO-resistive touch film deposited on a PET substrate by in-line DC magnetron sputtering. Vacuum 2014, 101, 221–227. [Google Scholar] [CrossRef]

- Sierros, K.A.; Morris, N.J.; Kukureka, S.N.; Cairns, D.R. Dry and wet sliding wear of ITO-coated PET components used in flexible optoelectronic applications. Wear 2009, 267, 625–631. [Google Scholar] [CrossRef]

- Lee, S.Y.; Cho, E.S.; Kwon, S.J. The optical analyses of the multilayer transparent electrode and the formation of ITO/Mesh-Ag/ITO multilayers for enhancing an optical transmittance. Appl. Surf. Sci. 2019, 487, 990–999. [Google Scholar] [CrossRef]

- Triambulo, R.E.; Cheong, H.; Cheong, G.; Lee, G.H.; Yi, I.S.; Park, J.W. A transparent conductive oxide electrode with highly enhanced flexibility achieved by controlled crystallinity by incorporating Ag nanoparticles on substrates. J. Alloys Compd. 2015, 620, 340–349. [Google Scholar] [CrossRef]

- Torrisi, G.; Crupi, I.; Mirabella, S.; Terrasi, A. Robustness and electrical reliability of AZO/Ag/AZO thin film after bending stress. Sol. Energy Mater. Sol. Cells 2017, 165, 88–93. [Google Scholar] [CrossRef]

- Cesarini, G.; Leahu, G.; Grilli, M.L.; Sytchkova, A.; Sibilia, C.; Voti, R.L. Optical and photoacoustic investigation of AZO/Ag/AZO transparent conductive coating for solar cells. Phys. Status Solidi 2016, 13, 998–1001. [Google Scholar] [CrossRef]

- Ta, H.; Zhao, L.; Pohl, D.; Pang, J.; Trzebicka, B.; Rellinghaus, B.; Pribat, D.; Gemming, T.; Liu, Z.; Bachmatiuk, A.; et al. Graphene-like ZnO: A mini review. Crystals 2016, 6, 100. [Google Scholar] [CrossRef]

- Olszowska, K.; Zhao, J.P.S.L.; Ta, H.Q.; Liu, Z.; Trzebicka, B.; Bachmatiuk, A.; Rummeli, M.H. Three-dimensional nanostructured graphene: Synthesis and energy, environmental and biomedical applications. Synth. Met. 2017, 234, 53–85. [Google Scholar] [CrossRef]

- Wang, K.; Zhou, S.; Zhou, Y.; Ren, J.; Li, L.; Lan, Y. Synthesis of porous carbon by activation method and its electrochemical performance. Int. J. Electrochem. Sci. 2018, 13, 10766–10773. [Google Scholar]

- Wang, K.; Li, L.; Xue, W.; Zhou, S.; Lan, Y.; Zhang, H.; Sui, Z. Electrodeposition synthesis of PANI/MnO2/graphene composite materials and its electrochemical performance. Int. J. Electrochem. Sci. 2017, 12, 8306–8314. [Google Scholar]

- Wang, K.; Li, L.; Lan, Y.; Dong, P.; Xia, G. Application research of chaotic carrier frequency modulation technology in two-stage matrix converter. Math. Probl. Eng. 2019, 11, 2614327. [Google Scholar] [CrossRef]

- Boscarino, S.; Crupi, I.; Mirabella, S.; Simone, F.; Terrasi, A. TCO/Ag/TCO transparent electrodes for solar cells application. Appl. Phys. A 2014, 116, 1287–1291. [Google Scholar] [CrossRef]

- Crupi, I.; Boscarino, S.; Strano, V.; Mirabella, S.; Simone, F.; Terrasi, A. Optimization of ZnO: Al/Ag/ZnO: Al structures for ultra-thin high-performance transparent conductive electrodes. Thin Solid Film. 2012, 520, 4432–4435. [Google Scholar] [CrossRef]

- Crupi, I.; Boscarino, S.; Torrisi, G.; Scapellato, G.; Mirabella, S.; Piccitto, G.; Simone, F.; Terrasi, A. Laser irradiation of ZnO:Al/Ag/ZnO:Al multilayers for electrical isolation in thin film photovoltaics. Nanoscale Res. Lett. 2013, 8, 392. [Google Scholar] [CrossRef][Green Version]

- Bingel, A.; Stenzel, O.; Naujok, P.; Müller, R.; Shestaeva, S.; Steglich, M.; Schulz, U.; Kaiser, N.; Tünnermann, A. AZO/Ag/AZO transparent conductive films: Correlation between the structural, electrical, and optical properties and development of an optical model. Opt. Mater. Express 2016, 6, 3217–3232. [Google Scholar] [CrossRef]

- Kim, D. Properties of ITO/Cu/ITO multilayer films for application as low resistance transparent electrodes. Trans. Electr. Electron. Mater. 2009, 10, 165–168. [Google Scholar] [CrossRef]

- Leterrier, Y.; Medico, L.; Demarco, F.; Manson, J.A.E.; Betz, U.; Escola, M.F.; Olsson, M.K.; Atamny, F. Mechanical integrity of transparent conductive oxide films for flexible polymer-based displays. Thin Solid Film. 2004, 460, 156–166. [Google Scholar] [CrossRef]

- Kerkache, L.; Layadi, A.; Dogheche, E.; Remiens, D. Physical properties of RF sputtered ITO thin films and annealing effect. J. Phys. D Appl. Phys. 2006, 39, 184–189. [Google Scholar] [CrossRef]

- Choi, H.J.; Yoon, S.G.; Lee, J.H.; Lee, J.Y. Crystallized Indium-Tin Oxide (ITO) thin films grown at low temperature onto flexible polymer substrates. ECS J. Solid State Sci. Technol. 2012, 1, Q106–Q109. [Google Scholar] [CrossRef]

- Wu, C.C. High flexible touch screen panel fabricated with silver-inserted transparent ITO triple-layer structures. RSC Adv. 2018, 8, 11862–11870. [Google Scholar] [CrossRef]

- Yoon, S.; Jang, G. Development of refractive-index-matched MTO/Ag/MTO multilayer film on poly (ethylene terephthalate) substrate. J. Nanosci. Nanotechnol. 2019, 19, 1485–1489. [Google Scholar] [CrossRef] [PubMed]

- Yoon, S.; Kim, T.; Jang, G. Investigation of SiO2/TiO2 index matching layer applied to MTO/Ag/MTO structured film deposited on PET substrate. Phys. Status Solidi A 2018, 215, 1700974. [Google Scholar] [CrossRef]

- Carreri, F.C.; Sabelfeld, A.; Gerdes, H.; Bandorf, R.; Vergöhl, M.; Bräuer, G. HIPIMS ITO films from a rotating cylindrical cathode. Surf. Coat. Technol. 2016, 290, 65–72. [Google Scholar] [CrossRef]

- Kurdesau, F.; Khripunov, G.; da Cunha, A.F.; Kaelin, M.; Tiwari, A.N. Comparative study of ITO layers deposited by DC and RF magnetron sputtering at room temperature. J. Non-Cryst. Solids 2006, 352, 1466–1470. [Google Scholar] [CrossRef]

- Tuna, O.; Selamet, Y.; Aygun, G.; Ozyuzer, L. High quality ITO thin films grown by DC and RF sputtering without oxygen. J. Phys. D Appl. Phys. 2010, 43, 055402. [Google Scholar] [CrossRef]

- Hong, C.S.; Kim, H.Y.; Park, S.H.; Lee, C.M. Effects of the Al interlayer thickness on the resistivity and the transmittance of GZO/Al/ZnO multilayer thin films deposited on polymer substrates. J. Korean Phys. Soc. 2008, 53, 1070–1073. [Google Scholar] [CrossRef]

- Loquai, S.; Baloukas, B.; Zabeida, O.; Klemberg-Sapieha, J.E.; Martinu, L. HiPIMS-deposited thermochromic VO2 films on polymeric substrates. Sol. Energy Mater. Sol. 2016, 155, 60–69. [Google Scholar] [CrossRef]

- Yang, Y.J.; Tsou, H.K.; Chen, Y.H.; Chung, C.J.; He, J.L. Enhancement of bioactivity on medical polymer surface using high power impulse magnetron sputtered titanium dioxide film. Mater. Sci. Eng. C 2015, 57, 58–66. [Google Scholar] [CrossRef] [PubMed]

- Kelly, P.J.; Barker, P.M.; Ostovarpour, S.; Ratova, M.; West, G.T.; Iordanova, I.; Bradley, J.W. Deposition of photocatalytic titania coatings on polymeric substrates by HiPIMS. Vacuum 2012, 86, 1880–1882. [Google Scholar] [CrossRef]

- Lundin, D.; Sarakinos, K. An introduction to thin film processing using high-power impulse magnetron sputtering. J. Mater. Res. 2012, 27, 780–792. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Chen, Y.H.; Hsu, C.C.; He, J.L. Antibacterial silver coating on poly (ethylene terephthalate) fabric by using high power impulse magnetron sputtering. Surf. Coat. Technol. 2013, 232, 868–875. [Google Scholar] [CrossRef]

- Chen, Y.H.; Wu, G.W.; He, J.L. Antimicrobial brass coatings prepared on poly (ethylene terephthalate) textile by high power impulse magnetron sputtering. Mater. Sci. Eng. C 2015, 48, 41–47. [Google Scholar] [CrossRef]

- Kouznetsov, V.; Macak, K.; Schneider, J.M.; Maca, K.; Helmersson, U.; Petrov, I. A novel pulsed magnetron sputter technique utilizing very high target power densities. Surf. Coat. Technol. 1999, 122, 290–293. [Google Scholar] [CrossRef]

- Ehiasarian, A.; Pulgarin, C.; Kiwi, J. Inactivation of bacteria under visible light and in the dark by Cu films, Advantages of Cu-HIPIMS-sputtered films. Env. Sci. Pollut. Res. 2012, 19, 3791. [Google Scholar] [CrossRef]

- Wu, W.Y.; Chan, M.Y.; Hsu, Y.H.; Chen, G.Z.; Liao, S.C.; Lee, C.H.; Lui, P.W. Bioapplication of TiN thin films deposited using high power impulse magnetron sputtering. Surf. Coat. Technol. 2019, 362, 167–175. [Google Scholar] [CrossRef]

- Hsu, Y.H.; Wu, W.Y. Antibacterial Ag-Cu coatings deposited using an asymmetric bipolar high-power impulse magnetron sputtering technique. Surf. Coat. Technol. 2019, 362, 302–310. [Google Scholar] [CrossRef]

- Liao, S.C.; Chen, C.Y.; Hsu, Y.H.; Li, C.T.; Hsieh, C.C.; Tsai, M.S.; Chan, M.Y.; Lee, C.H.; Wang, S.H.; Ng, S.K.; et al. In vitro and in vivo biocompatibility study of surface modified TiN deposited on Ti6Al4V using high-power impulse magnetron sputtering technique. Surf. Coat. Technol. 2020, 394, 125814. [Google Scholar] [CrossRef]

- Yoon, S.M.; Choi, J.W.; Jang, G.E. Highly transparent MTO/Ag/MTO multilayer film deposited on polyethylene terephthalate substrate for transparent conductive oxide. J. Nanosci. Nanotechnol. 2017, 17, 7218–7222. [Google Scholar] [CrossRef]

- Park, Y.S.; Park, H.K.; Jeong, J.A.; Kim, H.K.; Choi, K.H.; Na, S.I.; Kim, D.Y. Comparative investigation of transparent ITO/Ag/ITO and ITO/Cu/ITO electrodes grown by dual-target DC sputtering for organic photovoltaics. J. Electrochem. Soc. 2009, 156, H588–H594. [Google Scholar] [CrossRef]

- Bootharaju, M.S.; Pradeep, T. Uptake of toxic metal ions from water by naked and monolayer protected silver nanoparticles: An X-ray photoelectron spectroscopic investigation. J. Phys. Chem. C 2010, 114, 8328–8336. [Google Scholar] [CrossRef]

- National Institute of Standards and Technology. NIST X-ray Photoelectron Spectroscopy Database, Version 3.5; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2003. [Google Scholar]

- Mackova, A.; Švorčik, V.; Sajdl, P.; Strýhal, Z.; Pavlík, J.; Malinský, P.; Šlouf, M. RBS, XPS, and TEM study of metal and polymer interface modified by plasma treatment. Vacuum 2008, 82, 307–310. [Google Scholar] [CrossRef]

- Choi, K.H.; Nam, H.J.; Jeong, J.A.; Cho, S.W.; Kim, H.K.; Kang, J.W.; Kim, D.G.; Cho, W.J. Highly flexible and transparent InZnSnOx/Ag/InZnSnOx multilayer electrode for flexible organic light emitting diodes. Appl. Phys. Lett. 2008, 92, 223302. [Google Scholar] [CrossRef]

- Tachibana, Y.; Kusunoki, K.; Watanabe, T.; Hashimoto, K.; Ohsaki, H. Optical properties of multilayers composed of silver and dielectric materials. Thin Solid Film. 2003, 432, 212–216. [Google Scholar] [CrossRef]

- Shin, Y.H.; Cho, C.K.; Kim, H.K. Resistance and transparency tunable Ag-inserted transparent InZnO films for capacitive touch screen panels. Thin Solid Film. 2013, 548, 641–645. [Google Scholar] [CrossRef]

- Hong, C.H.; Shin, J.H.; Ju, B.K.; Kim, K.H.; Park, N.M.; Kim, B.S.; Cheong, W.S. Index-matched indium tin oxide electrodes for capacitive touch screen paned applications. J. Nanosci. Nanotechnol. 2013, 13, 7756–7759. [Google Scholar] [CrossRef]

- Yan, X.; Mont, F.W.; Poxson, D.J.; Schubert, M.F.; Kim, J.K.; Cho, J.; Schubert, E.F. Refractive-index-matched indium-tin-oxide electrodes for liquid crystal displays. Jpn. J. Appl. Phys. 2009, 48, 120203. [Google Scholar] [CrossRef]

- Lin, T.C.; Chang, S.C.; Chiu, C.F. Annealing effect of ITO and ITO/Cu transparent conductive films in low pressure hydrogen atmosphere. Mater. Sci. Eng. B 2006, 129, 39–42. [Google Scholar] [CrossRef]

- Kim, T.H.; Park, S.H.; Kim, D.H.; Nah, Y.C.; Kim, H.K. Roll-to-roll sputtered ITO/Ag/ITO multilayers for highly transparent and flexible electrochromic applications. Sol. Energy Mater. Sol. Cells 2017, 160, 203–210. [Google Scholar] [CrossRef]

- Kim, T.H.; Choi, B.H.; Park, J.S.; Lee, S.M.; Lee, Y.S.; Park, L.S. Transparent conductive ITO/Ag/ITO multilayer films prepared by low temperature process and physical properties. Mol. Cryst. Liq. Cryst. 2010, 520, 209–214. [Google Scholar] [CrossRef]

- Kim, T.H.; Park, K.W.; Kim, J.S. Transparent conductive AGZO/Ag/AGZO multilayers on PET substrate by roll-to-roll sputtering. J. Nanosci. Nanotechnol. 2016, 16, 1689–1692. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, S.M.; Ko, E.H.; Kim, T.H.; Nah, Y.C.; Lee, S.J.; Lee, J.H.; Kim, H.K. Roll-to-Roll sputtered ITO/Cu/ITO multilayer electrode for flexible, transparent thin film heaters and electrochromic applications. Sci. Rep. 2016, 6, 33868. [Google Scholar] [CrossRef]

- Ding, X.W.; Yan, J.L.; Li, T.; Zhang, L.Y. Effect of SiO2 buffer layer thickness on the properties of ITO/Cu/ITO multilayer films deposited on polyethylene terephthalate substrates. Vacuum 2011, 86, 443–447. [Google Scholar] [CrossRef]

| Thickness | 5 nm | 10 nm | 15 nm | 20 nm | |

|---|---|---|---|---|---|

| Sample | |||||

| Ag | 4 | 6 | 7 | 8 | |

| Cu | 1 | 1 | 1 | 2 | |

| Property | ITO/Ag/ITO | ITO/Cu/ITO | ||||||

|---|---|---|---|---|---|---|---|---|

| Metal layer thickness (nm) | 5 | 10 | 15 | 20 | 5 | 10 | 15 | 20 |

| Concentration (×1022/cm3) | 1.29 | 1.77 | 2.36 | 2.41 | 1.39 | 2.87 | 11.59 | 9.39 |

| Mobility (cm2/Vs) | 0.98 | 5.39 | 5.27 | 6.38 | 2.25 | 2.31 | 0.62 | 1.45 |

| Resistivity (×10−5 Ω/cm) | 48.85 | 6.58 | 5.03 | 4.06 | 19.96 | 9.39 | 8.65 | 4.58 |

| Sheet resistance (Ω/sq) | 57.47 | 7.29 | 5.29 | 4.06 | 23.48 | 10.43 | 9.11 | 4.58 |

| ΦTC (10−3 Ω−1) | Rs (Ω/sq) | Transmittance (%; at 550 nm) | Structure | Deposition Method | Reference |

|---|---|---|---|---|---|

| 101.16 | 7.29 | 97 | ITO/Ag (10 nm)/ITO/PEN | HiPIMS | This work |

| 4.83 | 10.43 | 74 | ITO/Cu(10 nm)/ITO/PEN | HiPIMS | This work |

| 6.66 | 8.93 | 82.4 | ITO/Ag/ITO/PET | RTR sputter | [63] |

| 64.57 | 6.4 | 91.4 | ITO/Ag/ITO/CPI | Sputter + anneal | [33] |

| 24 | 6.7 | 83.2 | ITO/Ag/ITO/PET | Sputter | [64] |

| 36.6 | 6.12 | 86.1 | MTO/Ag/MTO/PET | Sputter | [53] |

| 14 | 9.2 | 84 | AGZO/Ag/AGZO/PET | RTR sputter | [65] |

| 4.12 | 11.8 | 73.9 | ITO/Cu/ITO/PET | RTR sputter | [66] |

| 0.52 | 36 | 67 | ITO/Cu/ITO/PC | Sputter | [29] |

| 0.094 | 143 | 65 | SiO2/ITO/Cu/ITO/PET | Sputter + buffer layer | [67] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Gao, Y.-J.; Yuan, S.-H.; Wuu, D.-S.; Wu, W.-Y.; Zhang, S. Improvement in the Figure of Merit of ITO-Metal-ITO Sandwiched Films on Poly Substrate by High-Power Impulse Magnetron Sputtering. Coatings 2021, 11, 144. https://doi.org/10.3390/coatings11020144

Li H, Gao Y-J, Yuan S-H, Wuu D-S, Wu W-Y, Zhang S. Improvement in the Figure of Merit of ITO-Metal-ITO Sandwiched Films on Poly Substrate by High-Power Impulse Magnetron Sputtering. Coatings. 2021; 11(2):144. https://doi.org/10.3390/coatings11020144

Chicago/Turabian StyleLi, Hui, Ying-Jie Gao, Shuo-Huang Yuan, Dong-Sing Wuu, Wan-Yu Wu, and Sam Zhang. 2021. "Improvement in the Figure of Merit of ITO-Metal-ITO Sandwiched Films on Poly Substrate by High-Power Impulse Magnetron Sputtering" Coatings 11, no. 2: 144. https://doi.org/10.3390/coatings11020144

APA StyleLi, H., Gao, Y.-J., Yuan, S.-H., Wuu, D.-S., Wu, W.-Y., & Zhang, S. (2021). Improvement in the Figure of Merit of ITO-Metal-ITO Sandwiched Films on Poly Substrate by High-Power Impulse Magnetron Sputtering. Coatings, 11(2), 144. https://doi.org/10.3390/coatings11020144