Preparation, Characterization, and Terahertz Spectroscopy Characteristics of Reduced Graphene Oxide-Doped Epoxy Resin Coating

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

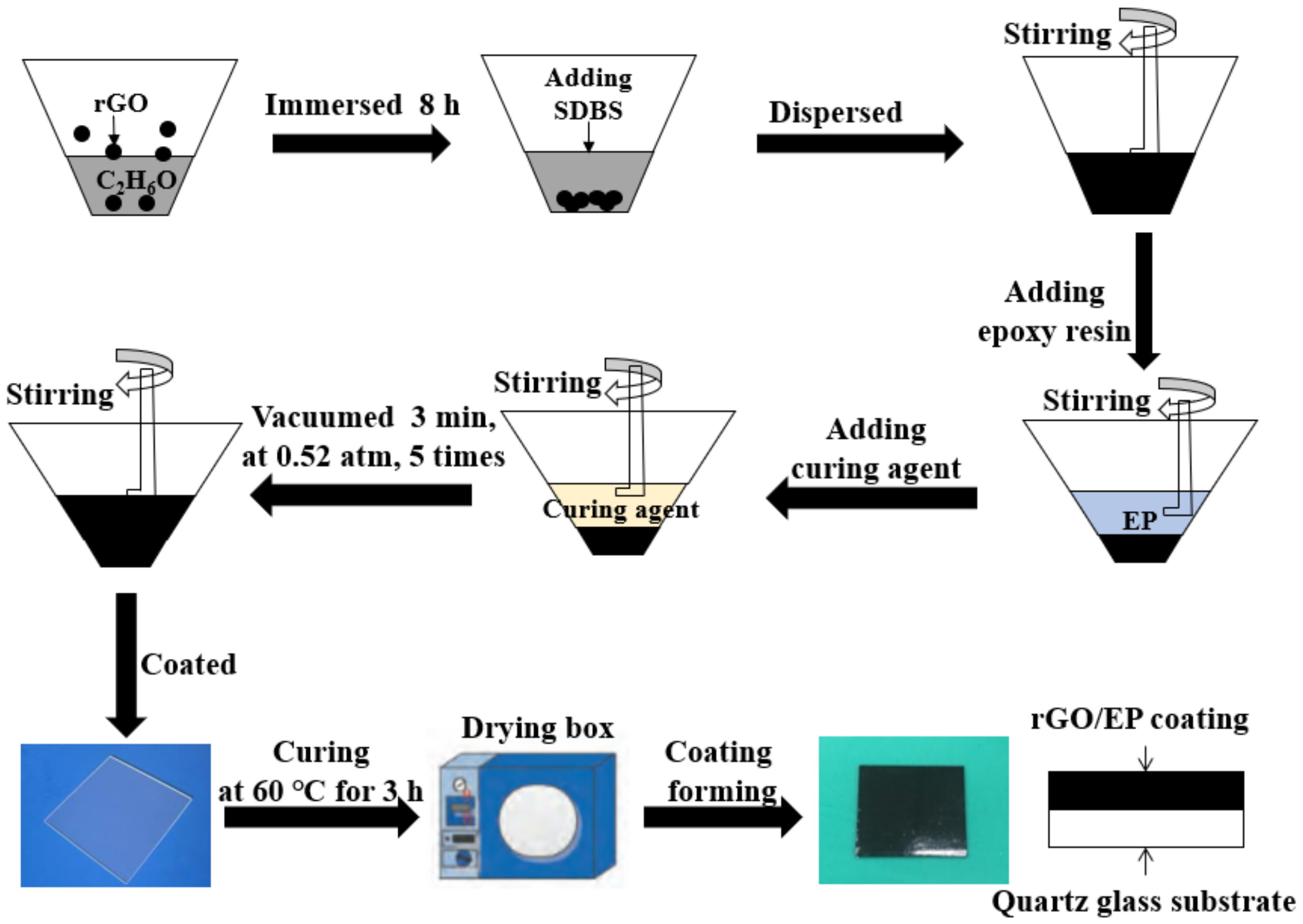

2.2. Preparation of rGO/EP

2.3. Characterization

3. Results and Discussion

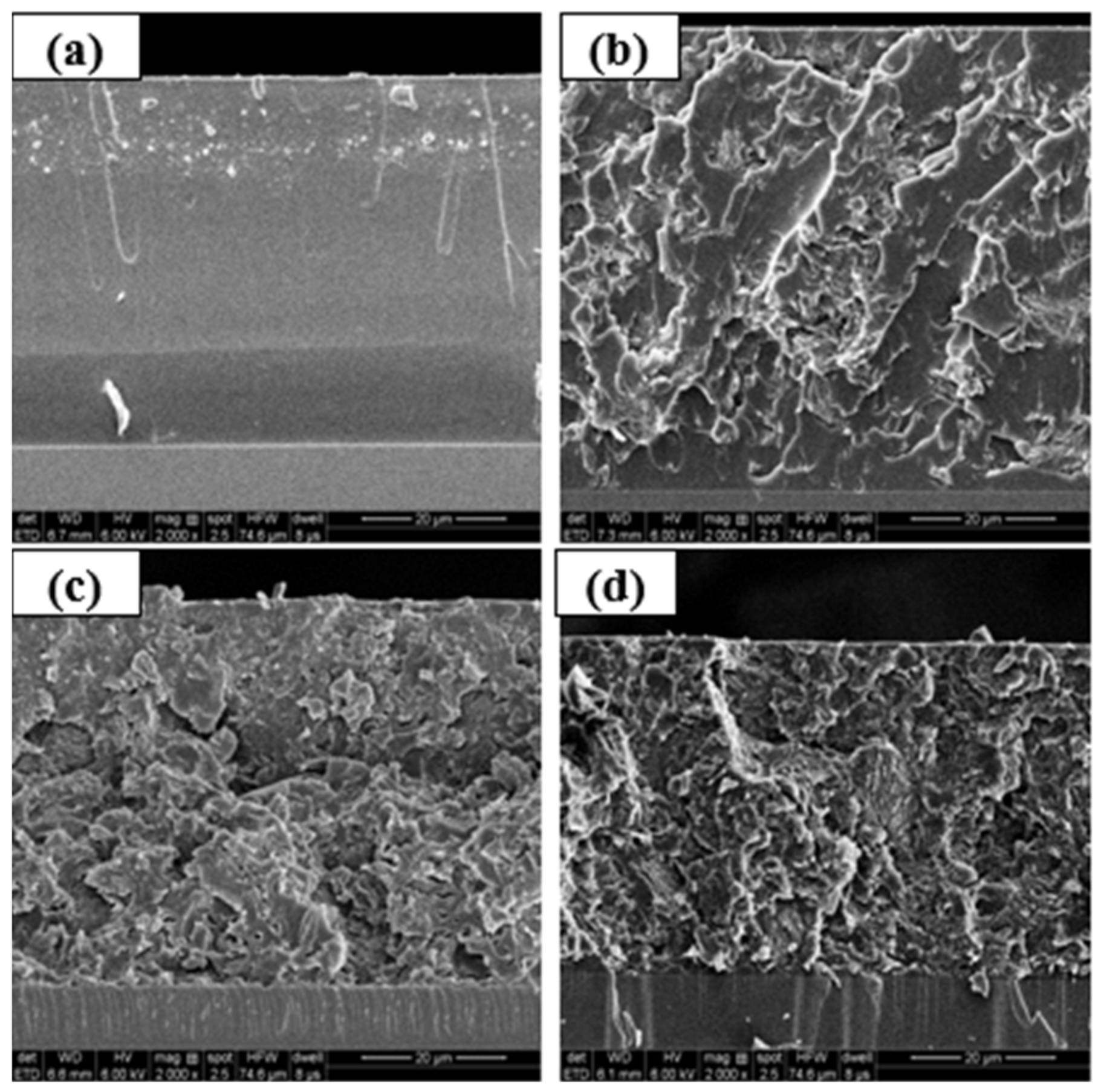

3.1. Morphology Analysis

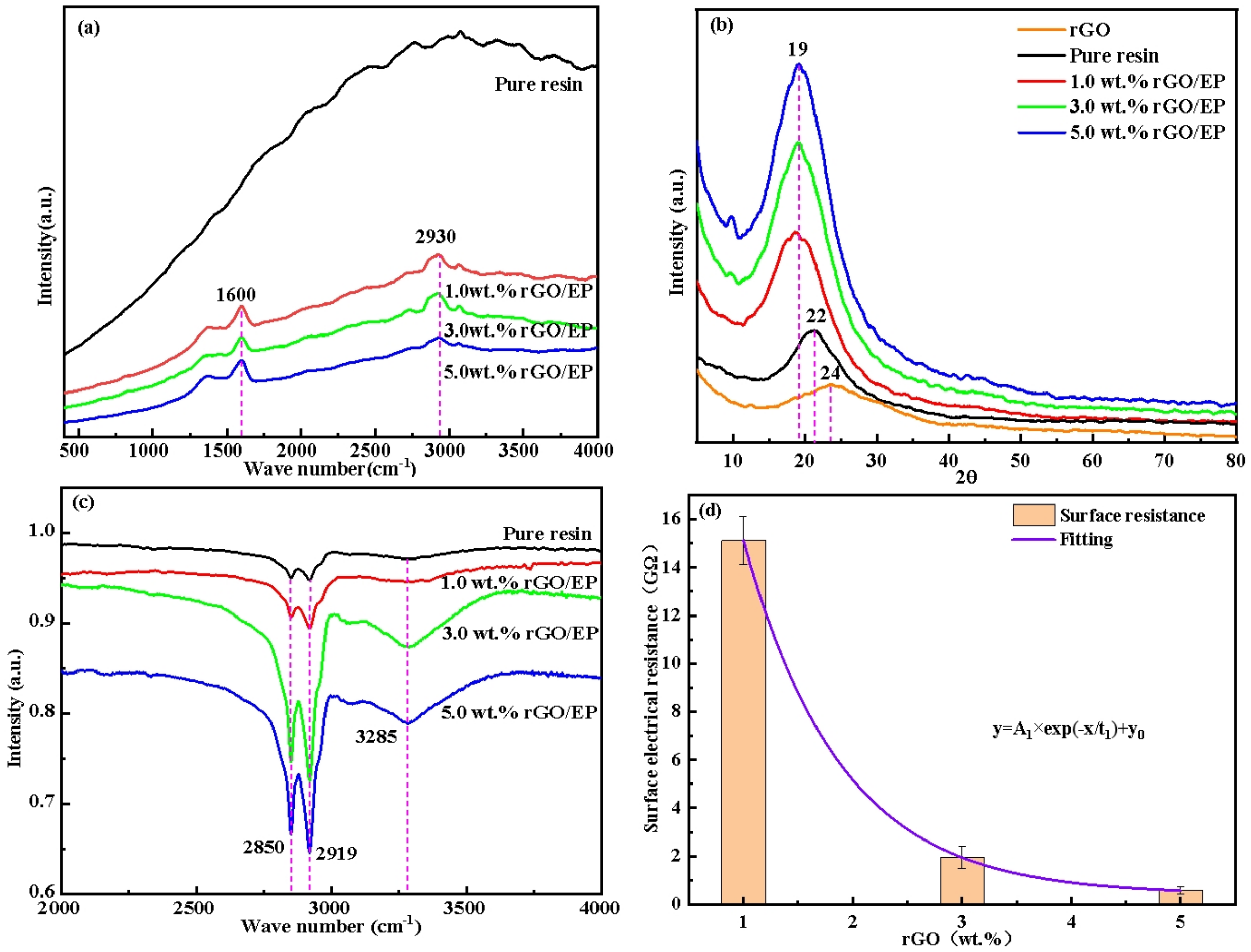

3.2. Physical and Chemical Characterizations

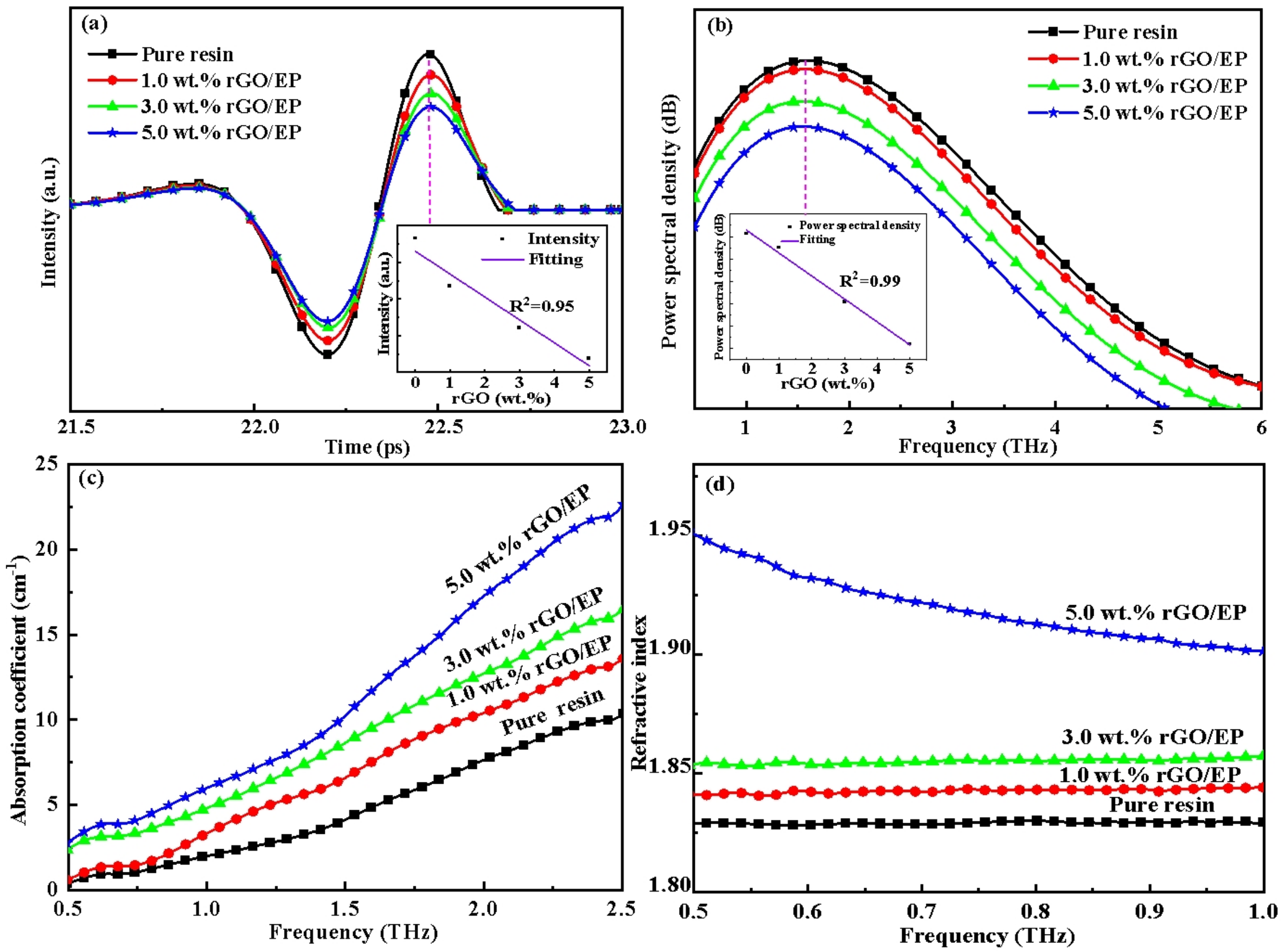

3.3. Terahertz Spectroscopy Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, C.G.; Wei, X.D.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.Z.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Cai, D.Y.; Jin, J.; Yusoh, K.; Rafiq, R.; Song, M. High performance polyurethane/functionalized graphene nanocomposites with improved mechanical and thermal properties. Compos. Sci. Technol. 2012, 72, 702–707. [Google Scholar] [CrossRef]

- Zhou, T.N.; Chen, F.; Tang, C.Y.; Bai, H.; Qin, Z.; Hua, D.; Qiang, F. The preparation of high performance and conductive poly(vinyl alcohol)/graphene nanocomposite via reducing graphite oxide with sodium hydrosulfifite. Compos. Sci. Technol. 2011, 71, 1266–1270. [Google Scholar] [CrossRef]

- Wang, X.; Yang, H.Y.; Song, L.; Yuan, H.; Lu, H. Morphology, mechanical and thermal properties of graphene-reinforced poly(butylene succinate) nanocomposites. Compos. Sci. Technol. 2011, 72, 1–6. [Google Scholar] [CrossRef]

- Campo, M.; Jiménez-Suárez, A.; Urea, A. Tribological properties of different types of graphene nanoplatelets as additives for the epoxy resin. Appl. Sci. 2020, 10, 4363. [Google Scholar] [CrossRef]

- Chen, L.; Liu, H.; Liu, Z.Q.; QSA, B. Thermal conductivity and anti-corrosion of epoxy resin based composite coatings doped with graphene and graphene oxide. Compos. Part C 2021, 5, 100–124. [Google Scholar] [CrossRef]

- Hegde, M.B.; Mohana, K.N.S.; Rajitha, K.; Madhusudhana, A.M. Reduced graphene oxide-epoxidized linseed oil nanocomposite: A highly efficient bio-based anti-corrosion coating material for mild steel. Prog. Org. Coat. 2021, 159, 106399. [Google Scholar] [CrossRef]

- Zhang, W.; Yi, M.; Shen, Z.G.; Zhao, X.; Zhang, X.; Ma, S. Graphene-reinforced epoxy resin with enhanced atomic oxygen erosion resistance. J. Mater. Sci. 2013, 48, 2416–2423. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Zhang, W.H.; Li, D.S.; Sun, Y.Y.; Wang, Z.; Hou, C.L.; Chen, L.; Cao, Y.; Liu, Y.Q. Mechanical and anticorrosive properties of graphene/epoxy resin composites coating prepared by in-situ method. Int. J. Mol. Sci. 2015, 16, 2239–2251. [Google Scholar] [CrossRef] [Green Version]

- Shen, X.J.; Pei, X.Q.; Fu, S.Y.; Friedrich, K. Significantly modified tribological performance of epoxy nanocomposites at very low graphene oxide content. Polymer 2013, 54, 1234–1242. [Google Scholar] [CrossRef]

- Wu, J.; Ye, Z.; Ge, H.; Chen, J.; Liu, W.; Liu, Z. Modified carbon fiber/magnetic graphene/epoxy composites with synergistic effect for electromagnetic interference shielding over broad frequency band. J. Colloid Interf. Sci. 2017, 506, 217–226. [Google Scholar] [CrossRef]

- Wen, B.; Cao, M.; Lu, M.; Cao, W.Q.; Shi, H.L.; Liu, J.; Wang, X.X.; Jin, H.B.; Fang, X.Y.; Wang, W.Z.; et al. Reduced graphene oxides: Light-weight and high-efficiency electromagnetic interference shielding at elevated temperatures. Adv. Mater. 2014, 21, 3484–3489. [Google Scholar] [CrossRef]

- Chen, C.; Qiu, S.H.; Cui, M.J.; Qin, S.L.; Yan, G.P.; Zhao, H.C.; Wang, L.P.; Xue, Q.J. Achieving high performance corrosion and wear resistant epoxy coatings via incorporation of noncovalent functionalized graphene. Carbon 2017, 114, 356–366. [Google Scholar] [CrossRef]

- Pan, L.; Liu, Z.H.; Kzlta, O.; Zhong, L.; Pang, X.; Wang, F.; Zhu, Y.; Ma, W.; Lv, Y. Carbon fiber/poly ether ether ketone composites modified with graphene for electro-thermal deicing applications. Compos. Sci. Technol. 2020, 192, 108–117. [Google Scholar] [CrossRef]

- Kim, D.H.; Ryu, C.H.; Park, S.H.; Kim, H.S. Nondestructive evaluation of hidden damages in glass fiber reinforced plastic by using the terahertz spectroscopy. Int. J. Pr. Eng. Manuf. GT 2017, 4, 211–219. [Google Scholar] [CrossRef]

- Taraghi, I.; Lopato, P.; Paszkiewicz, S.; Piesowicz, E. X-ray and terahertz imaging as non-destructive techniques for defects detection in nanocomposites foam-core sandwich panels containing carbon nanotubes. Polym. Test. 2019, 79, 106084. [Google Scholar] [CrossRef]

- Xu, J.; Wang, H.J.; Duan, Y.X.; He, Y.; Zhang, Z. Terahertz Imaging and vibro-thermography for impact response in carbon fiber reinforced plastics. Infrared Phys. Technol. 2020, 109, 103413. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, J.D.; Wang, J.; Lang, J.P.; Zhang, J.B.; Shen, Y.; Cui, H.L.; Shi, C.C. Nondestructive evaluation of glass fiber honeycomb sandwich panels using reflective terahertz imaging. J. Sandw. Struct. Mater. 2017, 21, 1211–1223. [Google Scholar] [CrossRef]

- Zhong, M.; Liu, B.W.; Li, C.; Wang, Z.Q.; Wei, D.S.; Zhou, B.; Dai, X.; Xu, Y.J. Terahertz spectroscopy and imaging detection of defects in civil aircraft composites. J. Spectros. 2020, 2020, 1–8. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, C.C.; Ma, Y.T.; Han, X.H.; Li, W.; Chang, T.Y.; Wei, D.S.; Du, C.L.; Cui, H.L. Spectroscopic study of terahertz reflection and transmission properties of carbon-fiber-reinforced plastic composites. Opt. Eng. 2015, 54, 054106. [Google Scholar] [CrossRef] [Green Version]

- Macutkevic, J.; Seliuta, D.; Valusis, G.; Adomavicius, R.; Kuzhir, P.; Paddubskaya, A.; Shuba, M.; Maksimenko, S.; Coderoni, L.; Micciulla, F.; et al. Terahertz time domain spectroscopy of epoxy resin composite with various carbon inclusions. Chem. Phys. 2012, 404, 129–135. [Google Scholar] [CrossRef]

- Zhao, F.Y.; Ling, L.Z.; Liu, L.Y.; Zafar, A.; Ni, Z.H. The dispersion of graphene in conductive epoxy composites investigated by Raman spectroscopy. J. Raman Spectros. 2017, 48, 432–436. [Google Scholar] [CrossRef]

- Ahmad, A.; Aziz, S.A.; Abbas, Z.; Obaiys, S.J.; Khamis, A.M.; Hussain, I.R.; Zaid, M.H.M. Preparation of a chemically reduced graphene oxide reinforced epoxy resin polymer as a composite for electromagnetic interference shielding and microwave-absorbing applications. Polymers 2018, 10, 1180. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, M.; Dai, X.; Xiang, H.; Liu, B.; Zhao, X.; Wei, D.; Tu, X.; Wang, Z.; Gong, Y.; Xu, Y.; et al. Preparation, Characterization, and Terahertz Spectroscopy Characteristics of Reduced Graphene Oxide-Doped Epoxy Resin Coating. Coatings 2021, 11, 1503. https://doi.org/10.3390/coatings11121503

Zhong M, Dai X, Xiang H, Liu B, Zhao X, Wei D, Tu X, Wang Z, Gong Y, Xu Y, et al. Preparation, Characterization, and Terahertz Spectroscopy Characteristics of Reduced Graphene Oxide-Doped Epoxy Resin Coating. Coatings. 2021; 11(12):1503. https://doi.org/10.3390/coatings11121503

Chicago/Turabian StyleZhong, Mian, Xin Dai, Hongxing Xiang, Bingwei Liu, Xin Zhao, Dongshan Wei, Xiaoguang Tu, Zhihao Wang, Yan Gong, Yajun Xu, and et al. 2021. "Preparation, Characterization, and Terahertz Spectroscopy Characteristics of Reduced Graphene Oxide-Doped Epoxy Resin Coating" Coatings 11, no. 12: 1503. https://doi.org/10.3390/coatings11121503

APA StyleZhong, M., Dai, X., Xiang, H., Liu, B., Zhao, X., Wei, D., Tu, X., Wang, Z., Gong, Y., Xu, Y., & He, M. (2021). Preparation, Characterization, and Terahertz Spectroscopy Characteristics of Reduced Graphene Oxide-Doped Epoxy Resin Coating. Coatings, 11(12), 1503. https://doi.org/10.3390/coatings11121503