A Bio-Based Render for Insulating Agglomerated Cork Panels

Abstract

:1. Introduction

- (1)

- to construct safer buildings and make interior environments healthier for humans to live in;

- (2)

- to limit the amount of landfill created by demolished buildings, since bio-based materials are often biodegradable;

- (3)

- to develop agricultural and ecological production, both of which create income for farmers and increase the amount of CO2 absorbed, since most bio-based materials are derived from agricultural residuals.

2. Materials and Methods

2.1. Lime Render

2.2. Beeswax-Rosin Coating

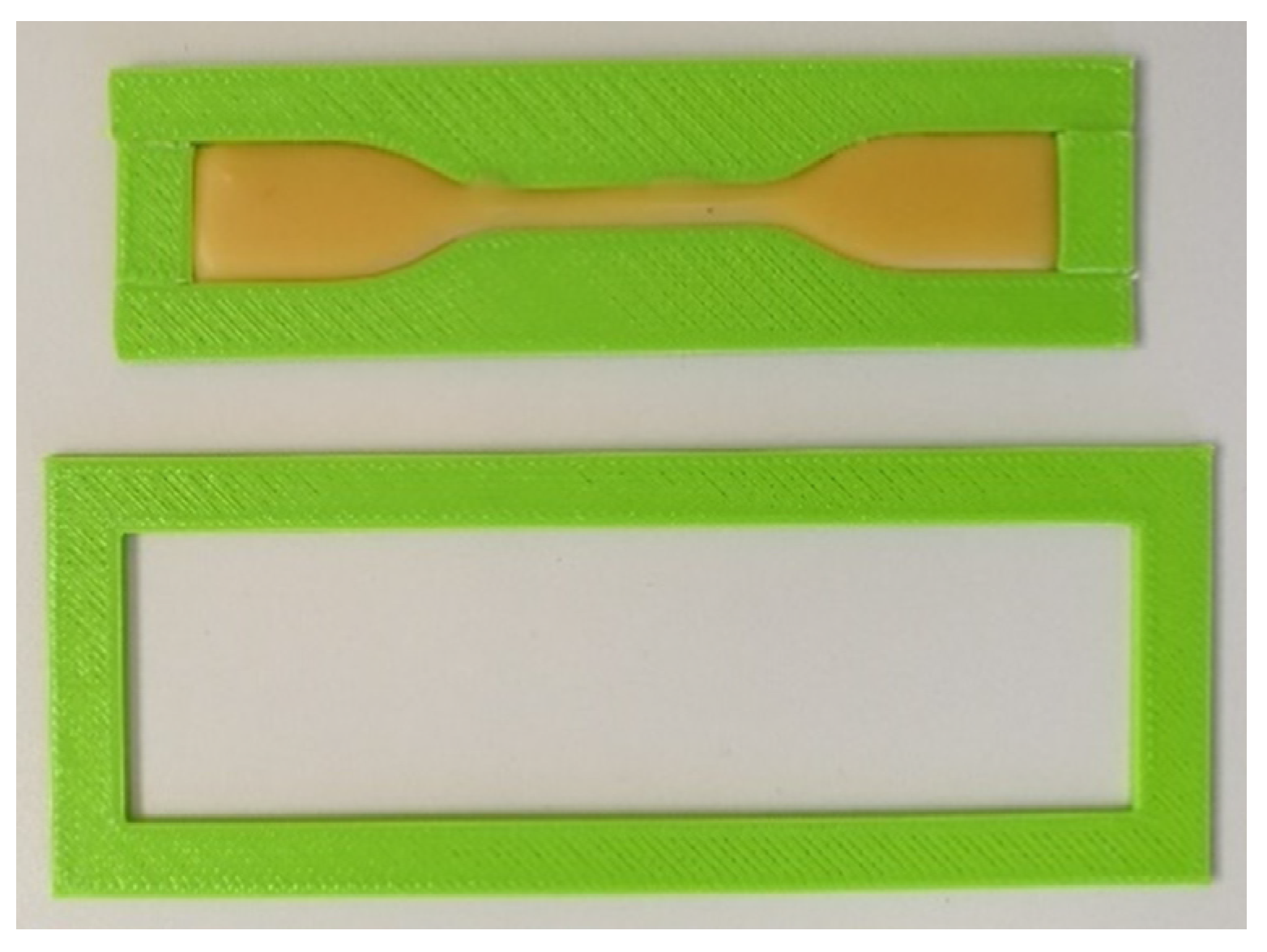

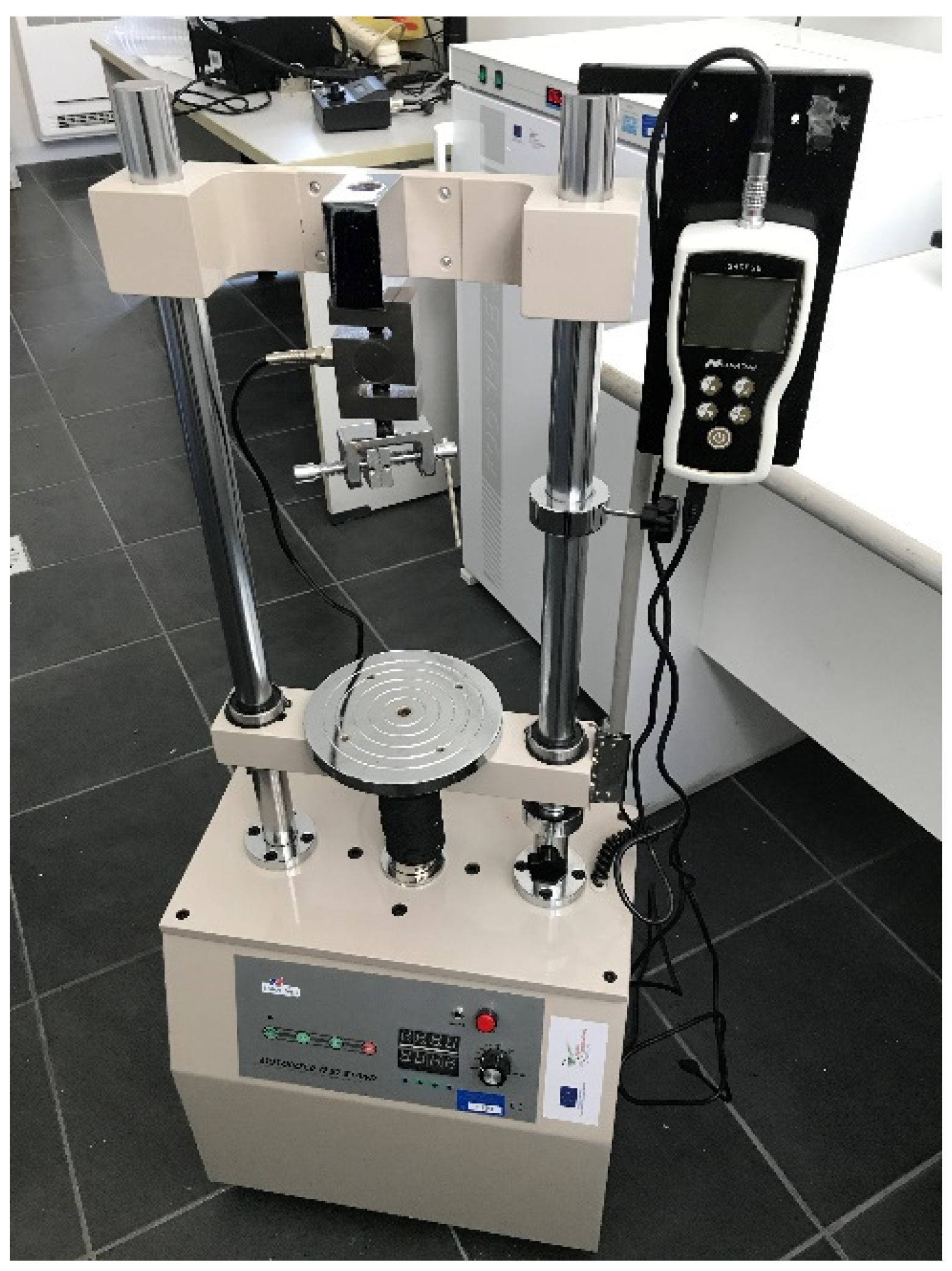

2.2.1. Tensile Strength Test

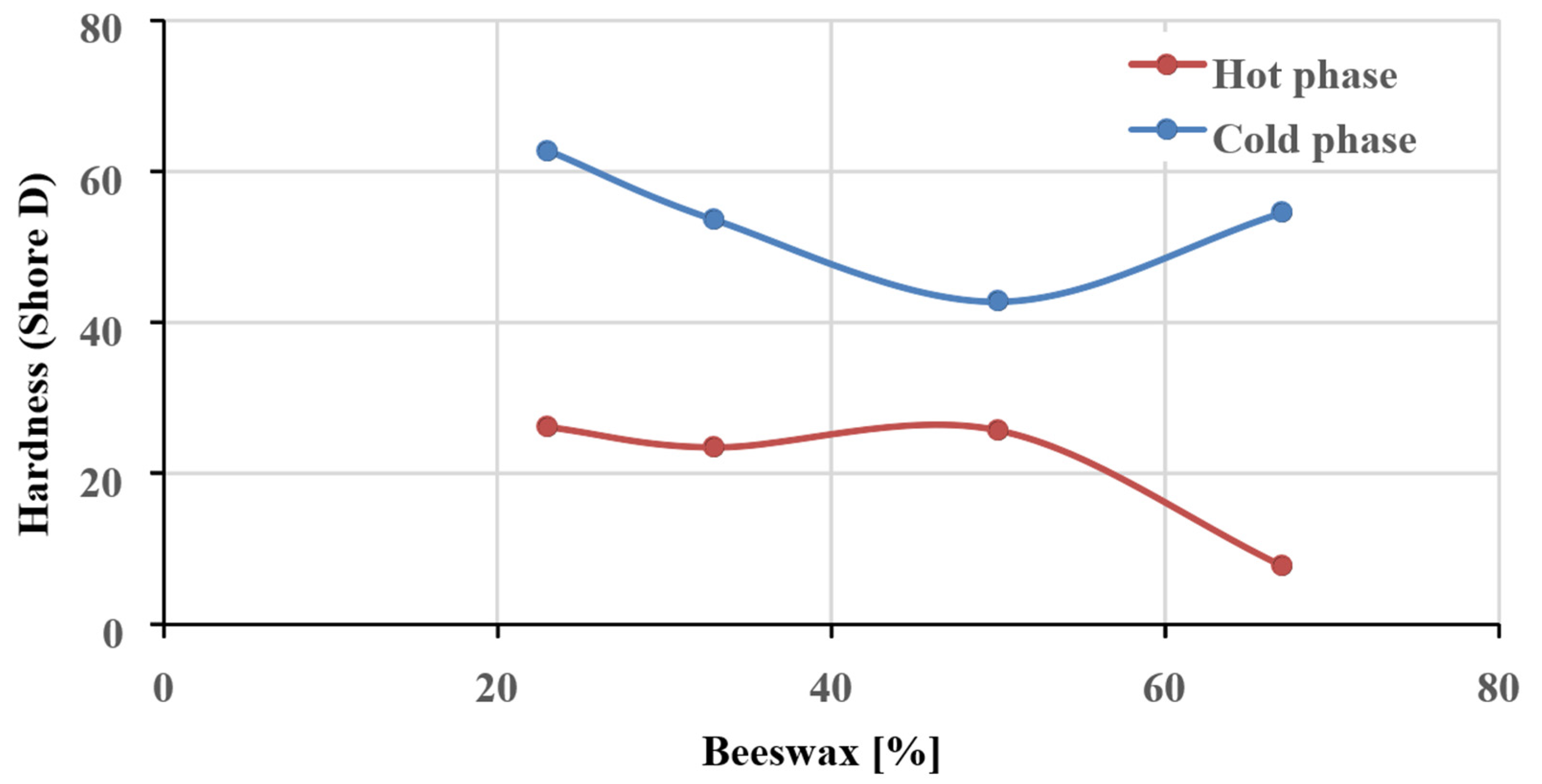

2.2.2. Hardness

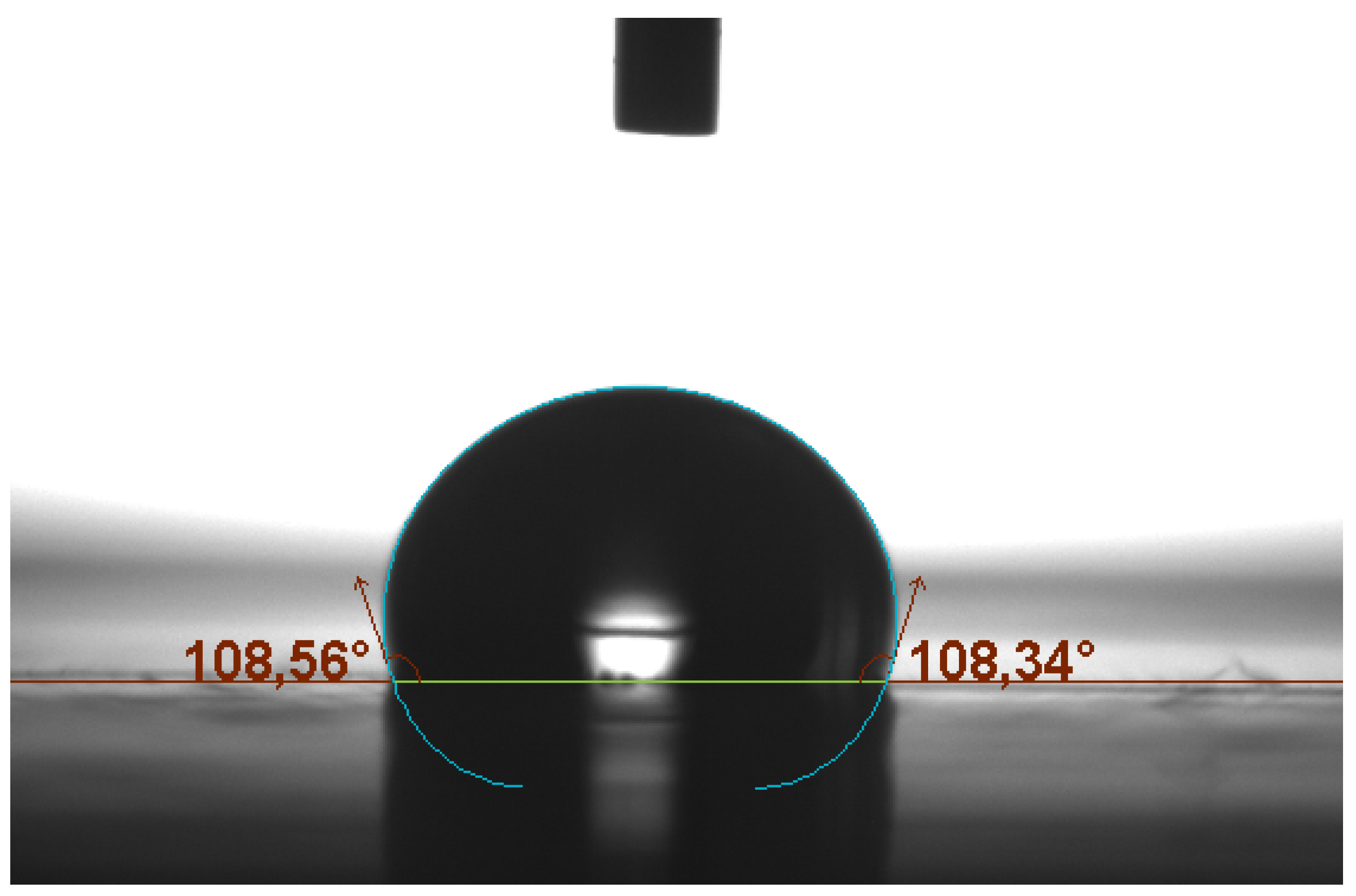

2.2.3. Hydrophobicity

2.2.4. Fracture Density

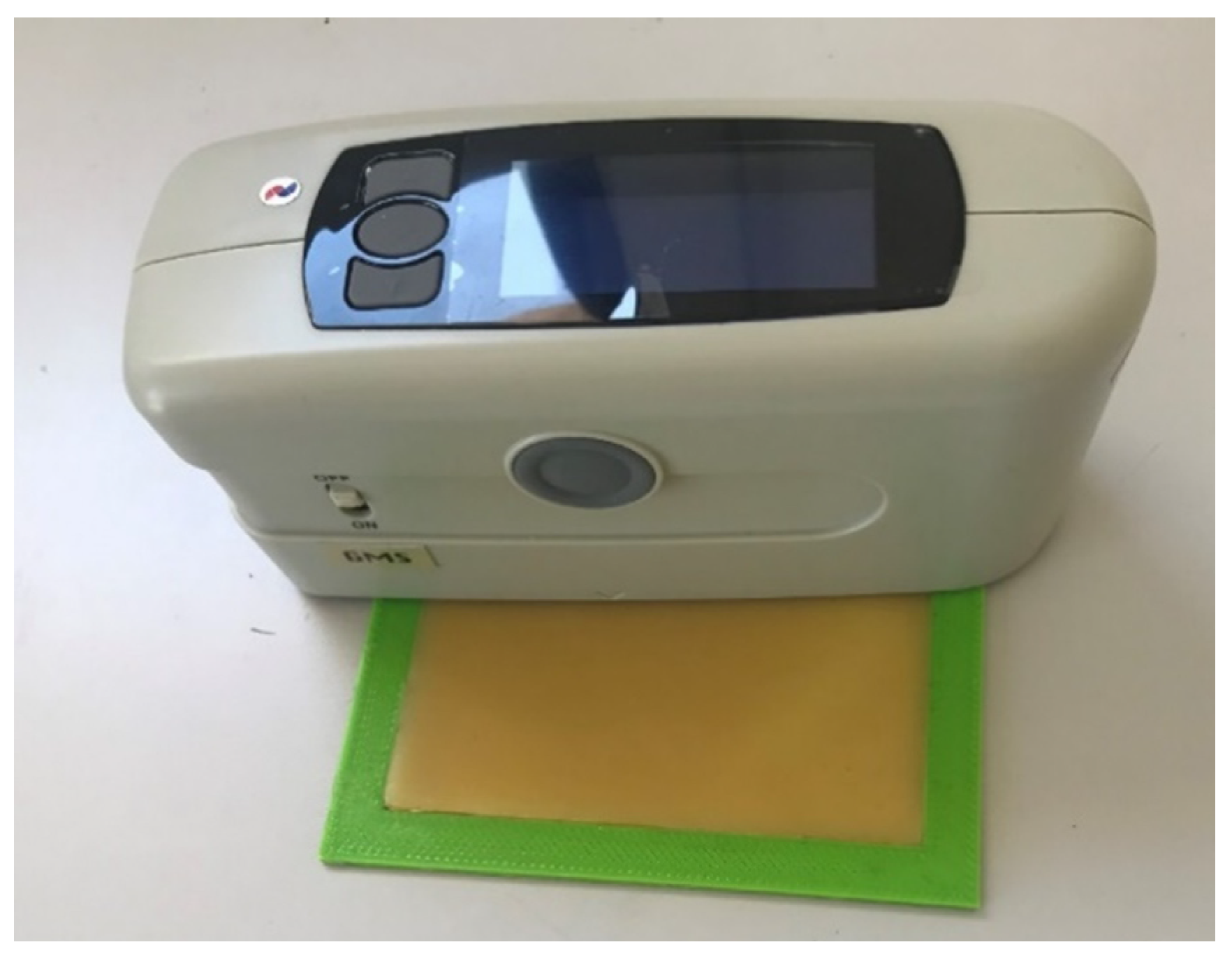

2.2.5. Glossiness

3. Results

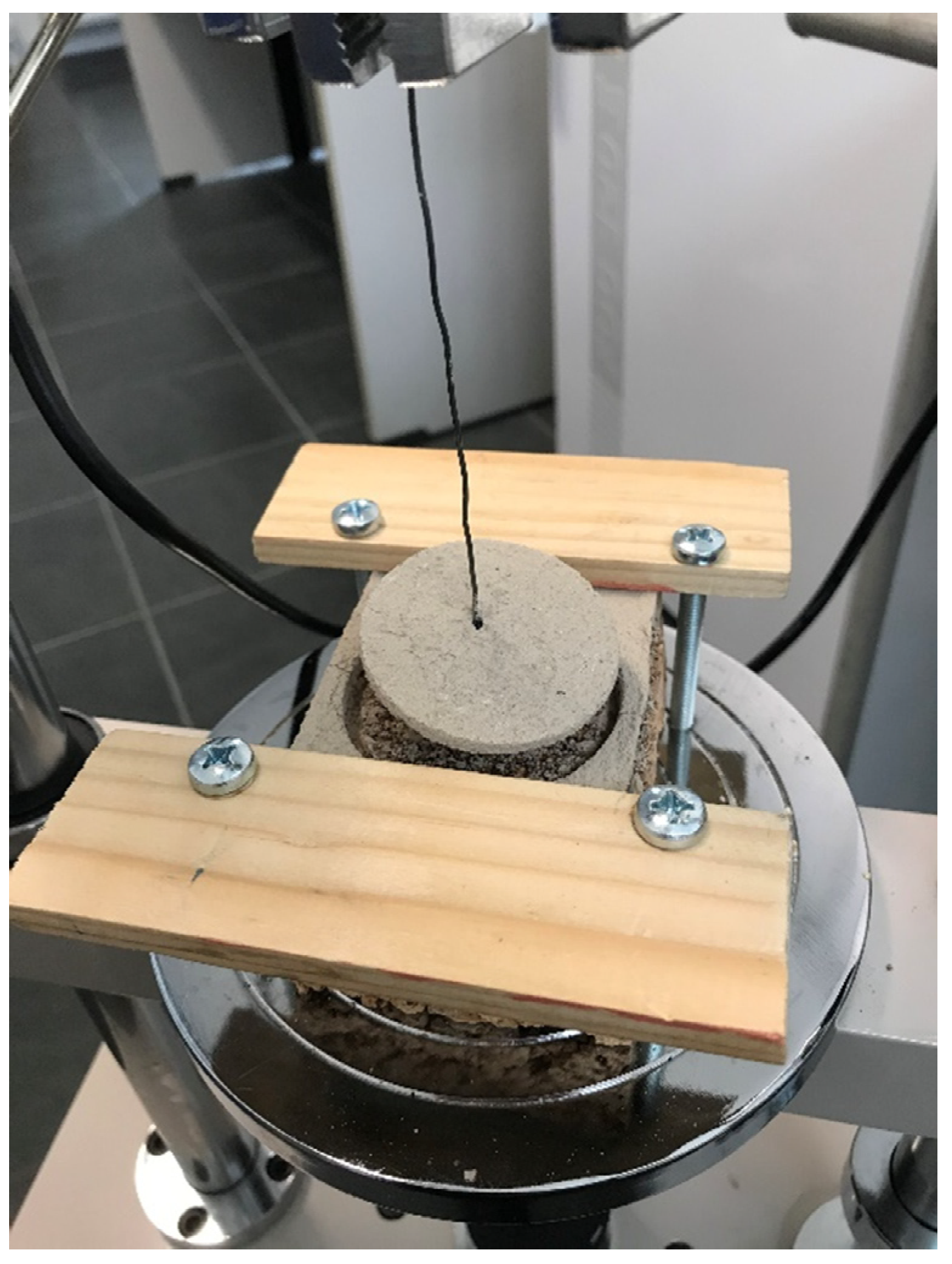

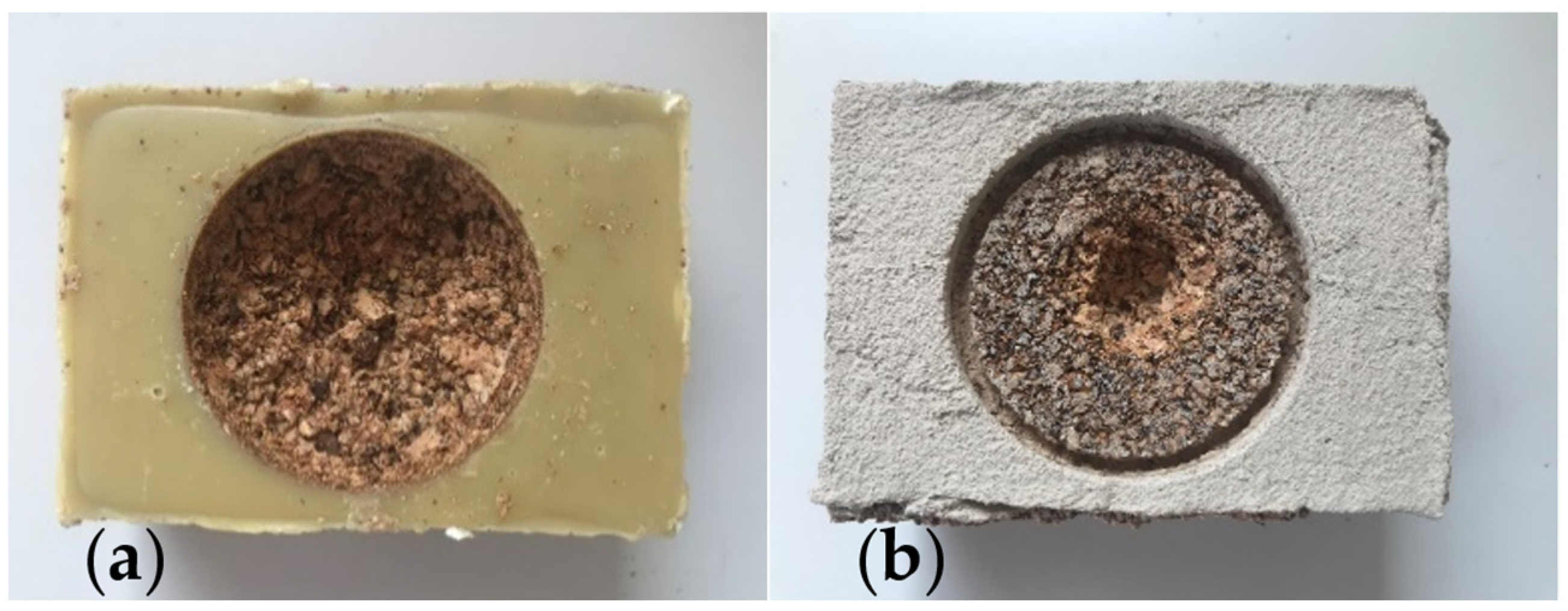

3.1. Coating Detachment Strength

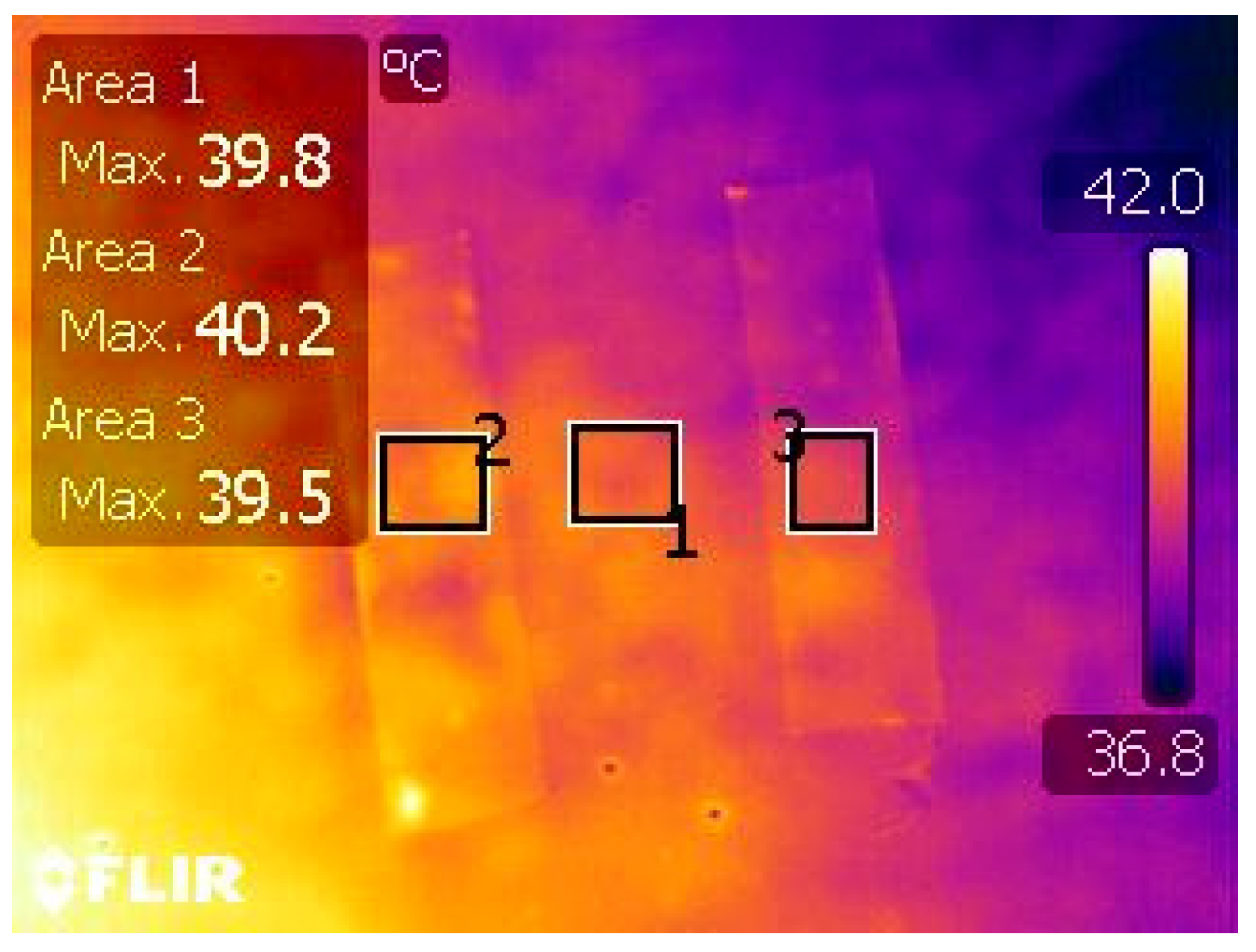

3.2. Emissivity Properties

4. Discussion

5. Conclusions

- A coating with a BR layer creates a more hydrophobic surface of cork panel insulation and also allows it to maintain the same insulation property in a wet environment.

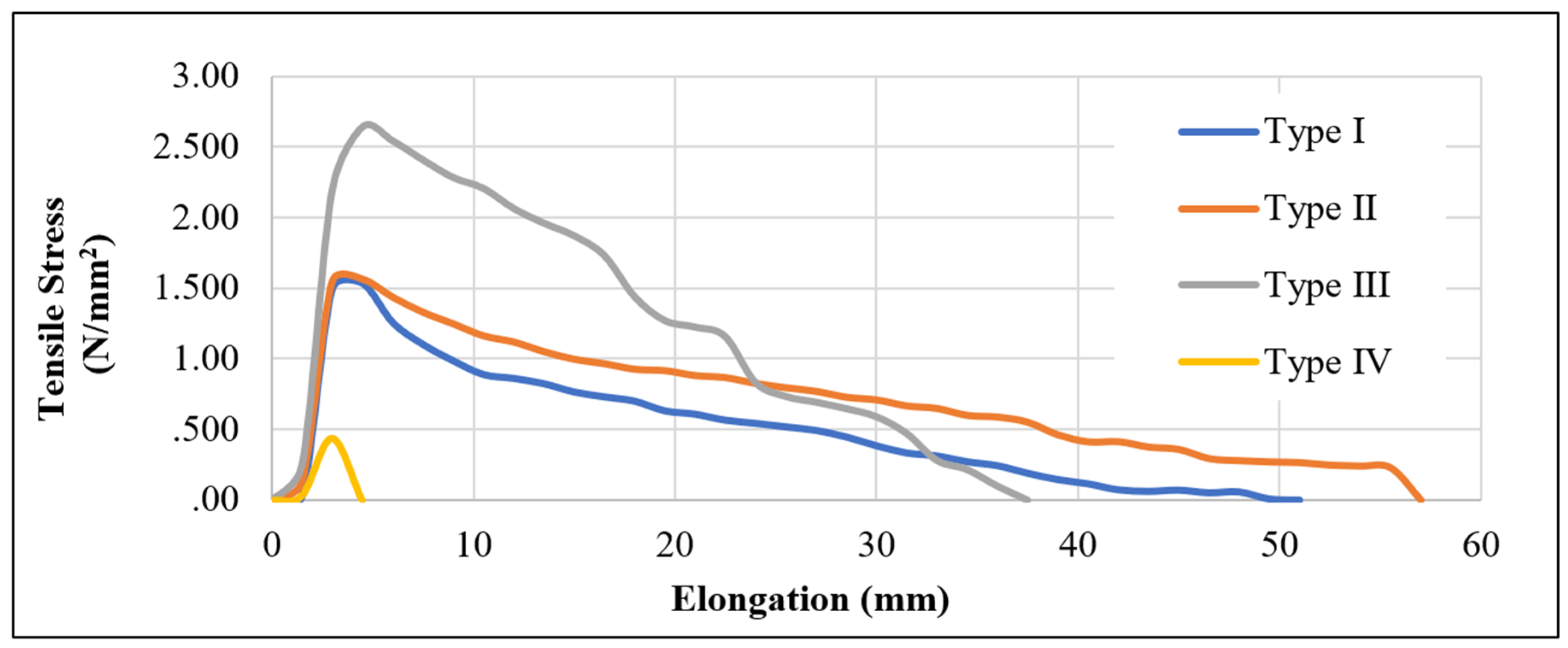

- BR coating demonstrates good elongation and allows for the deformation of the substrate without it breaking.

- The BR layer features a high adhesion strength with the cork substrate because the composite penetrates inside the cork matrix.

- The BR layer demonstrates a high level of hardness and low brittle behavior in the context of high environmental temperature excursions.

- The BR coating diminishes the surface emissivity of the substrate, raising the reflectivity of the sun radiation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fetting, C. The European Green Deal; ESDN Office: Vienna, Austria, 2020. [Google Scholar]

- López-Ochoa, L.M.; Las-Heras-Casas, J.; Olasolo-Alonso, P.; López-González, L.M. Towards nearly zero-energy buildings in Mediterranean countries: Fifteen years of implementing the Energy Performance of Buildings Directive in Spain (2006–2020). J. Build. Eng. 2021, 44, 102962. [Google Scholar] [CrossRef]

- Barreca, F.; Modica, G.; Di Fazio, S.; Tirella, V.; Tripodi, R.; Fichera, C.R. Improving building energy modelling by applying advanced 3D surveying techniques on agri-food facilities. J. Agric. Eng. 2017, 48, 203–208. [Google Scholar] [CrossRef] [Green Version]

- Mitter, H.; Techen, A.-K.; Sinabell, F.; Helming, K.; Schmid, E.; Bodirsky, B.L.; Holman, I.; Kok, K.; Lehtonen, H.; Leip, A.; et al. Shared Socio-economic Pathways for European agriculture and food systems: The Eur-Agri-SSPs. Glob. Environ. Chang. 2020, 65, 102159. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Barreca, F.; Praticò, P. Environmental indoor thermal control of extra virgin olive oil storage room with phase change materials. J. Agric. Eng. 2019, 50, 208–214. [Google Scholar] [CrossRef]

- Khoukhi, M.; Abdelbaqi, S.; Hassan, A.; Darsaleh, A. Impact of dynamic thermal conductivity change of EPS insulation on temperature variation through a wall assembly. Case Stud. Therm. Eng. 2021, 25, 100917. [Google Scholar] [CrossRef]

- Boussaba, L.; Lefebvre, G.; Makhlouf, S.; Grados, A.; Royon, L. Investigation and properties of a novel composite bio-PCM to reduce summer energy consumptions in buildings of hot and dry climates. Sol. Energy 2021, 214, 119–130. [Google Scholar] [CrossRef]

- Parlato, M.C.M.; Porto, S.M.C. Organized framework of main possible applications of sheep wool fibers in building components. Sustainability 2020, 12, 761. [Google Scholar] [CrossRef] [Green Version]

- Evola, G.; Cascone, S.; Sciuto, G.; Parisi, C.B. Performance comparison between building insulating materials made of straw bales and EPS for timber walls. IOP Conf. Ser. Mater. Sci. Eng. 2019, 609, 072020. [Google Scholar] [CrossRef] [Green Version]

- Cascone, S.; Cascone, S.; Vitale, M. Building Insulating Materials from Agricultural By-Products: A Review. In Sustainability in Energy and Buildings; Littlewood, J., Howlett, R.J., Jain, L.C., Eds.; Springer: Singapore, 2019; pp. 309–318. ISBN 978-981-32-9867-5. [Google Scholar]

- Ferraz, P.F.P.; Mendes, R.F.; Marin, D.B.; Paes, J.L.; Cecchin, D.; Barbari, M. Agricultural residues of lignocellulosic materials in cement composites. Appl. Sci. 2020, 10, 8019. [Google Scholar] [CrossRef]

- Gil, L. Insulation corkboard for sustainable energy and environmental protection. Ciência Tecnol. Mater. 2013, 25, 38–41. [Google Scholar] [CrossRef]

- Tártaro, A.S.; Mata, T.M.; Martins, A.A.; Esteves da Silva, J.C.G. Carbon footprint of the insulation cork board. J. Clean. Prod. 2017, 143, 925–932. [Google Scholar] [CrossRef]

- Sierra-Pérez, J.; Boschmonart-Rives, J.; Guillén-Lambea, S.; Rodriguez-Soria, B.; Gabarrell, X. Environmental Implications of Cork as Thermal Insulation in Façade Retrofits. In Proceedings of the 10th Conference Advanced Building Skins Conference, Bern, Switzerland, 3 November 2015. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative analysis of building insulation material properties and performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Silva, S.P.; Sabino, M.A.; Fernandes, E.M.; Correlo, V.M.; Boesel, L.F.; Reis, R.L. Cork: Properties, capabilities and applications. Int. Mater. Rev. 2008, 53, 256. [Google Scholar] [CrossRef] [Green Version]

- Gil, L. Cork Composites: A Review. Materials 2009, 2, 776–789. [Google Scholar] [CrossRef] [Green Version]

- Rives, J.; Fernandez-Rodriguez, I.; Gabarrell, X.; Rieradevall, J. Environmental analysis of cork granulate production in Catalonia—Northern Spain. Resour. Conserv. Recycl. 2012, 58, 132–142. [Google Scholar] [CrossRef]

- Franke, R.; Schreiber, L. Suberin—A biopolyester forming apoplastic plant interfaces. Curr. Opin. Plant Biol. 2007, 10, 252–259. [Google Scholar] [CrossRef]

- Barreca, F.; Cardinali, G.D.; Fichera, C.R.; Praticò, P. Utilization of cork residues for high performance walls in green buildings. Agric. Eng. Int. CIGR J. 2018, 20, 47–55. [Google Scholar]

- Matias, L.; Santos, C.; Reis, M.; Gil, L. Declared value for the thermal conductivity coefficient of insulation corkboard. Wood Sci. Technol. 1997, 31, 355–365. [Google Scholar] [CrossRef]

- Santamouris, M. Cooling the buildings—past, present and future. Energy Build. 2016, 128, 617–638. [Google Scholar] [CrossRef]

- Librelotto, L.I.; Kekez, M. The environmental impact of a lime mortar layer of the ETICs insulation: A case of study with Life Cycle Assessment (LCA) from Environmental Product Declaration (EPD) in Portugal the environmental impact of a lime mortar layer of the ETICs insulation. MIX Sustent. 2020, 6, 139–148. [Google Scholar] [CrossRef]

- Perilli, S.; Sfarra, S.; Guerrini, M.; Bisegna, F.; Ambrosini, D. The thermophysical behaviour of cork supports doped with an innovative thermal insulation and protective coating: A numerical analysis based on in situ experimental data. Energy Build. 2018, 159, 508–528. [Google Scholar] [CrossRef]

- Cherki, A.; Remy, B.; Khabbazi, A.; Jannot, Y.; Baillis, D. Experimental thermal properties characterization of insulating cork–gypsum composite. Constr. Build. Mater. 2014, 54, 202–209. [Google Scholar] [CrossRef]

- Jerónimo, A.; Soares, C.; Aguiar, B.; Lima, N. Hydraulic lime mortars incorporating micro cork granules with antifungal properties. Constr. Build. Mater. 2020, 255, 119368. [Google Scholar] [CrossRef]

- Mitchell, G.R.; Mahendra, V.; Sousa, D. Biopolymers Based on Rosin. Curr. Res. Biopolym. 2018, 2018, 1–6. [Google Scholar] [CrossRef]

- Michel, B.; Forchem, O. Pine Chemicals Industry Global Overview and Trends. In Proceedings of the 2019 PCA International Conference, Vancouver, BC, Canada, 22–24 September 2019. [Google Scholar]

- Karlberg, A.T. Chemical Modifications of Colophony. In Handbook of Occupational Dermatology; Springer: Berlin, Germany, 2000; pp. 506–516. [Google Scholar]

- Derdar, H.; Mitchell, G.R.; Mahendra, V.S.; Benachour, M.; Haoue, S.; Cherifi, Z.; Bachari, K.; Harrane, A.; Meghabar, R. Green Nanocomposites from Rosin-Limonene Copolymer and Algerian Clay. Polymers 2020, 12, 1971. [Google Scholar] [CrossRef] [PubMed]

- Eshetie, T. A review on crude beeswax mismanagement and lose: Opportunities for collection, processing and marketing in Ethiopia. J. Nutr. Health Food Eng. 2018, 8, 384–389. [Google Scholar] [CrossRef] [Green Version]

- Svečnjak, L.; Chesson, L.A.; Gallina, A.; Maia, M.; Martinello, M.; Mutinelli, F.; Muz, M.N.; Nunes, F.M.; Saucy, F.; Tipple, B.J.; et al. Standard methods for Apis mellifera beeswax research. J. Apic. Res. 2019, 58, 1–108. [Google Scholar] [CrossRef] [Green Version]

- Comparini, A.; Biasiolo, A. Genetic discrimination of Italian bee, Apis mellifera ligustica versus Carniolan bee, Apis mellifera carnica by allozyme variability analysis. Biochem. Syst. Ecol. 1991, 19, 189–194. [Google Scholar] [CrossRef]

- Naderizadeh, S.; Heredia-Guerrero, J.A.; Caputo, G.; Grasselli, S.; Malchiodi, A.; Athanassiou, A.; Bayer, I.S. Superhydrophobic Coatings from Beeswax-in-Water Emulsions with Latent Heat Storage Capability. Adv. Mater. Interfaces 2019, 6, 1970036. [Google Scholar] [CrossRef] [Green Version]

- Gaillard, Y.; Mija, A.; Burr, A.; Darque-Ceretti, E.; Felder, E.; Sbirrazzuoli, N. Green material composites from renewable resources: Polymorphic transitions and phase diagram of beeswax/rosin resin. Thermochim. Acta 2011, 521, 90–97. [Google Scholar] [CrossRef]

- Zelany, M. A concept of compromise solutions and the method of the displaced ideal. Comput. Oper. Res. 1974, 1, 479–496. [Google Scholar] [CrossRef]

- Dessi, P.; Fantuccil, A.; Galimbert, V.; Nironi, L. Performance and Durabllity Tests for Plastering Mortars. In Proceedings of the 12th International Brick and Block Masonry Conference, Madrid, Spain, 25–28 June 2000; pp. 2067–2082. [Google Scholar]

- Abdikheibari, S.; Parvizi, R.; Hadi Moayed, M.; Zebarjad, S.M.; Abdolkarim Sajjadi, S. Beeswax-colophony blend: A novel green organic coating for protection of steel drinking water storage tanks. Metals 2015, 5, 1645–1664. [Google Scholar] [CrossRef] [Green Version]

- Qi, H.J.; Joyce, K.; Boyce, M.C. Durometer hardness and the stress-strain behavior of elastomeric materials. Rubber Chem. Technol. 2003, 76, 419–435. [Google Scholar] [CrossRef]

- Mates, J.E.; Schutzius, T.M.; Bayer, I.S.; Qin, J.; Waldroup, D.E.; Megaridis, C.M. Water-based superhydrophobic coatings for nonwoven and cellulosic substrates. Ind. Eng. Chem. Res. 2014, 53, 222–227. [Google Scholar] [CrossRef]

- Ding, X.; Ma, T.; Gu, L.; Zhang, Y. Investigation of surface micro-crack growth behavior of asphalt mortar based on the designed innovative mesoscopic test. Mater. Des. 2020, 185, 108238. [Google Scholar] [CrossRef]

- Alonso, C.; Martín-Consuegra, F.; Oteiza, I.; Asensio, E.; Pérez, G.; Martínez, I.; Frutos, B. Effect of façade surface finish on building energy rehabilitation. Sol. Energy 2017, 146, 470–483. [Google Scholar] [CrossRef]

- Zinzi, M. Exploring the potentialities of cool facades to improve the thermal response of Mediterranean residential buildings. Sol. Energy 2016, 135, 386–397. [Google Scholar] [CrossRef]

- Barreca, F.; Fichera, C.R. Thermal insulation performance assessment of agglomerated cork boards. Wood Fiber Sci. 2016, 48, 96–103. [Google Scholar]

- Kingdom, U.; Bosiljkov, V.; Bright, N.J.; Edgell, G.; Forde, M.; Groot, C.; Maierhofer, C.; Maurenbrecher, P.; Modena, C.; Page, A.; et al. RILEM recommendation MDT. D.3—Determination “In Situ” of the adhesive strength of rendering and plastering mortars to their substrate. Mater. Struct. 2004, 37, 488–490. [Google Scholar] [CrossRef]

- Santamaría-Vicario, I.; Rodríguez, A.; Junco, C.; Gutiérrez-González, S.; Calderón, V. Durability behavior of steelmaking slag masonry mortars. Mater. Des. 2016, 97, 307–315. [Google Scholar] [CrossRef]

- Bruno, R.; Bevilacqua, P.; Ferraro, V.; Arcuri, N. Reflective thermal insulation in non-ventilated air-gaps: Experimental and theoretical evaluations on the global heat transfer coefficient. Energy Build. 2021, 236, 110769. [Google Scholar] [CrossRef]

- Clarke, F.J.J.; Larkin, J.A. Measurement of total reflectance, transmittance and emissivity over the thermal IR spectrum. Infrared Phys. 1985, 25, 359–367. [Google Scholar] [CrossRef]

- Chen, C. Determining the leaf emissivity of three crops by infrared thermometry. Sensors 2015, 15, 11387–11401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jelle, B.P.; Kalnæs, S.E.; Gao, T. Low-emissivity materials for building applications: A state-of-the-art review and future research perspectives. Energy Build. 2015, 96, 329–356. [Google Scholar] [CrossRef] [Green Version]

- Shi, Z.; Zhang, X. Analyzing the effect of the longwave emissivity and solar reflectance of building envelopes on energy-saving in buildings in various climates. Sol. Energy 2011, 85, 28–37. [Google Scholar] [CrossRef]

- Sabuga, W.; Todtenhaupt, R. Effect of roughness on the emissivity of the precious metals silver, gold, palladium, platinum, rhodium, and iridium. High Temp. High Press. 2001, 33, 261–269. [Google Scholar] [CrossRef]

- Wen, C.D.; Mudawar, I. Modeling the effects of surface roughness on the emissivity of aluminum alloys. Int. J. Heat Mass Transf. 2006, 49, 4279–4289. [Google Scholar] [CrossRef]

- Barbaresi, A.; Bovo, M.; Santolini, E.; Barbaresi, L.; Torreggiani, D.; Tassinari, P. Development of a low-cost movable hot box for a preliminary definition of the thermal conductance of building envelopes. Build. Environ. 2020, 180, 107034. [Google Scholar] [CrossRef]

- Barreca, F.; Praticò, P. Post-Occupancy Evaluation of Buildings for Sustainable Agri-Food Production—A Method Applied to an Olive Oil Mill. Buildings 2018, 8, 83. [Google Scholar] [CrossRef] [Green Version]

- Valenti, F.; Porto, S.; Cascone, G.; Arcidiacono, C. Potential biogas production from agricultural by-products in Sicily: A case study of citrus pulp and olive pomace. J. Agric. Eng. 2017, 48, 196–202. [Google Scholar] [CrossRef] [Green Version]

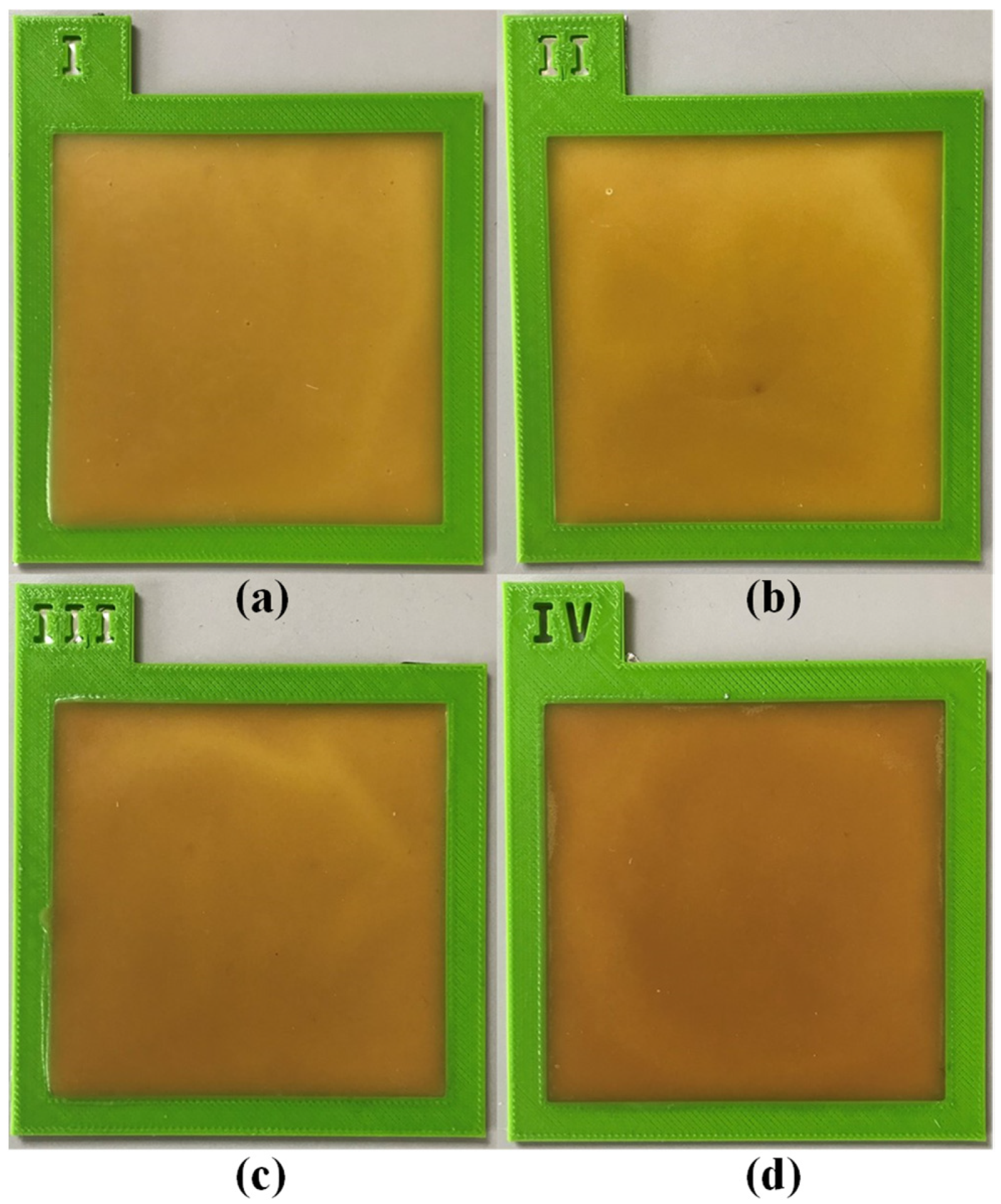

| Blending Type | Beeswax (%) | Rosin (%) |

|---|---|---|

| I | 67 | 33 |

| II | 50 | 50 |

| III | 33 | 67 |

| IV | 23 | 77 |

| Yield Tensile Strength (N/mm2) | Type I | Type II | Type III | Type IV |

| 1.54 ± 0.22 | 1.55 ± 0.33 | 2.64 ± 0.49 | 0.44 ± 0.09 |

| Hardness (Shore D) | Type I | Type II | Type III | Type IV |

| 30.91 ± 1.46 | 25.81 ± 1.83 | 33.37 ± 2.49 | 42.63 ± 2.29 |

| CYCLE | Type I | Type II | Type III | Type IV |

|---|---|---|---|---|

| Hot (Shore D) | 7.41 ± 0.76 | 25.21 ± 2.93 | 23.16 ± 1.96 | 26.03 ± 2.04 |

| Cold (Shore D) | 54.5 ± 2.33 | 42.77 ± 4.83 | 53.52 ± 4.41 | 62.64 ± 1.85 |

| Hydrophobicity (°) | Type I | Type II | Type III | Type IV |

| 88.42 ± 5.94 | 107.31 ± 4.64 | 98.69 ± 4.81 | 96.44 ± 8.37 |

| Fracture Density (mm∙mm−2∙10−4) | Type I | Type II | Type III | Type IV |

| 5.21 ± 0.12 | 2.10 ± 0.13 | 43.29 ± 0.24 | 59.89 ± 0.24 |

| Glossiness (GU) | Type I | Type II | Type III | Type IV |

| 7.18 ± 0.45 | 6.01 ± 0.45 | 14.52 ± 0.64 | 44.72 ± 4.25 |

| Specimen | TYPE I | TYPE II | TYPE III | TYPE IV |

|---|---|---|---|---|

| Ultimate tensile strength | 0.58 | 0.59 | 1.00 | 0.17 |

| Elongation max | 0.70 | 1.00 | 0.39 | 0.00 |

| Hardness | 0.87 | 0.71 | 0.87 | 1.00 |

| Hardness frost-defrost—COLD (−17 C) | 0.87 | 0.68 | 0.85 | 1.00 |

| Hardness frost-defrost—HOT (+40 C) | 0.29 | 0.98 | 0.90 | 1.00 |

| Hydrophobicity | 0.89 | 1.00 | 0.96 | 0.87 |

| Glossiness | 0.16 | 0.13 | 0.32 | 1.00 |

| Fracture density | 2.46 | 1.00 | 20.52 | 28.40 |

| E | 0.73 | 0.49 | 0.73 | 1.00 |

| Ideal point’s distance | 1.93 | 1.17 | 19.54 | 27.43 |

| Coating | Tensile Stress Peak (N) |

|---|---|

| Lime plaster on fine cork granules | 145 ± 1.78 |

| Lime plaster on large cork granules | 130 ± 1.23 |

| Beeswax/rosin on large cork granules | 463 ± 0.97 |

| Beeswax/rosin on fine cork granules | 323 ± 1.12 |

| Panel Surface | Emissivity Value (ε) |

|---|---|

| Side with fine cork granules | 0.62 ± 0.03 |

| Side with large cork granules | 0.93 ± 0.02 |

| Dark brown cork panel | 0.86 ± 0.03 |

| Coating of BR | 0.73 ± 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barreca, F.; Arcuri, N.; Cardinali, G.D.; Di Fazio, S. A Bio-Based Render for Insulating Agglomerated Cork Panels. Coatings 2021, 11, 1478. https://doi.org/10.3390/coatings11121478

Barreca F, Arcuri N, Cardinali GD, Di Fazio S. A Bio-Based Render for Insulating Agglomerated Cork Panels. Coatings. 2021; 11(12):1478. https://doi.org/10.3390/coatings11121478

Chicago/Turabian StyleBarreca, Francesco, Natale Arcuri, Giuseppe Davide Cardinali, and Salvatore Di Fazio. 2021. "A Bio-Based Render for Insulating Agglomerated Cork Panels" Coatings 11, no. 12: 1478. https://doi.org/10.3390/coatings11121478

APA StyleBarreca, F., Arcuri, N., Cardinali, G. D., & Di Fazio, S. (2021). A Bio-Based Render for Insulating Agglomerated Cork Panels. Coatings, 11(12), 1478. https://doi.org/10.3390/coatings11121478