Microring Zone Structure for Near-Field Probes

Abstract

:1. Introduction

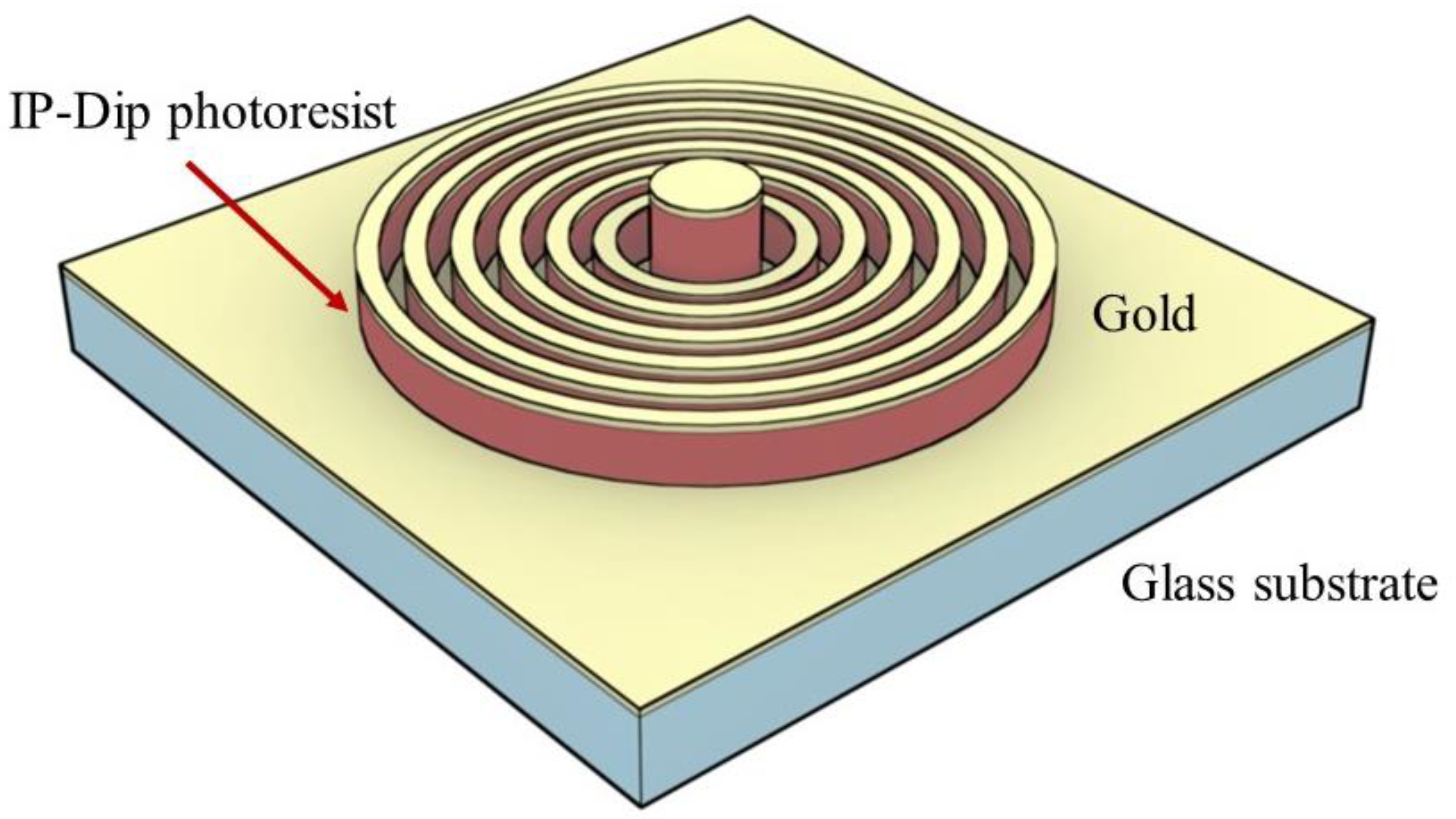

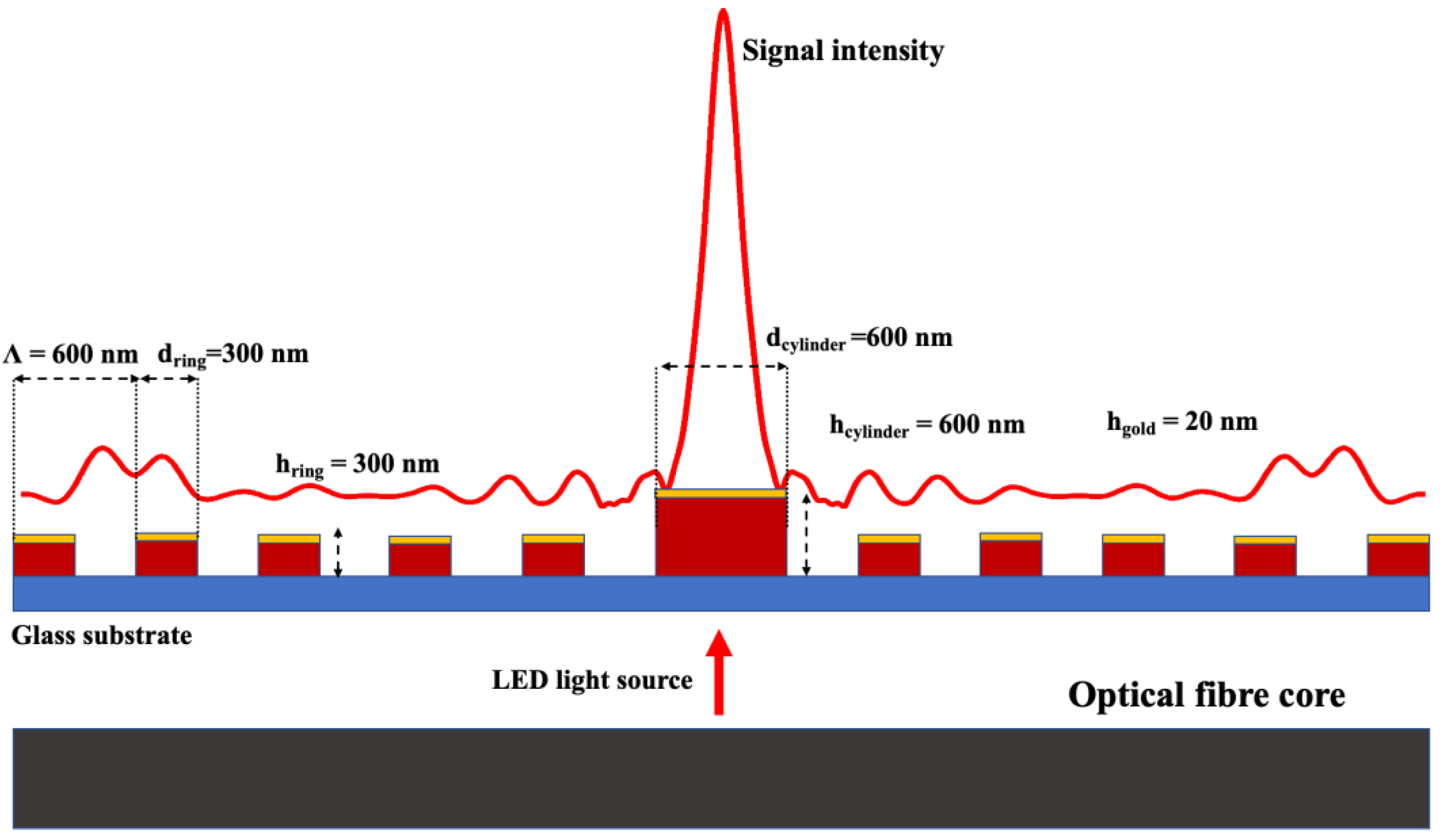

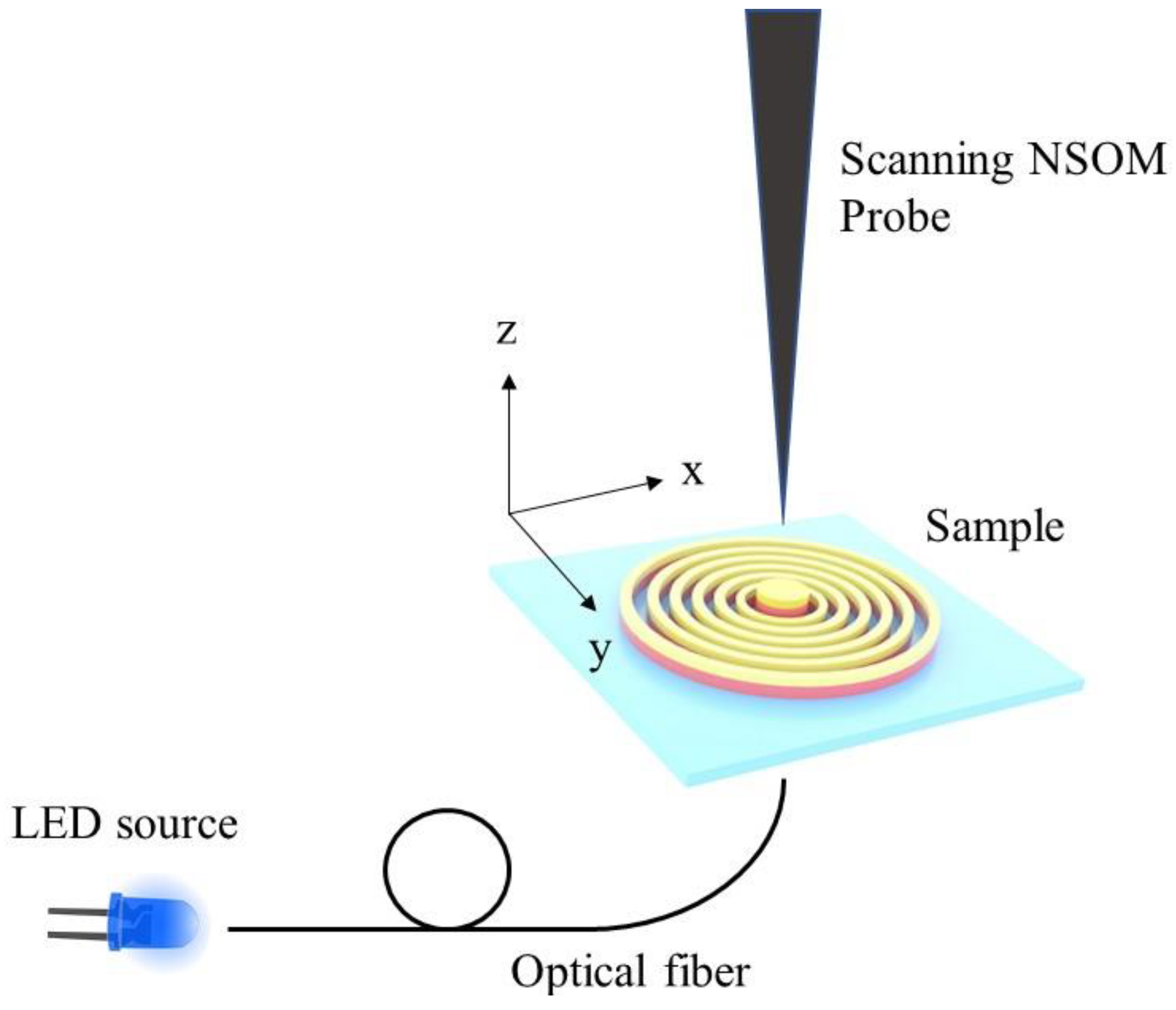

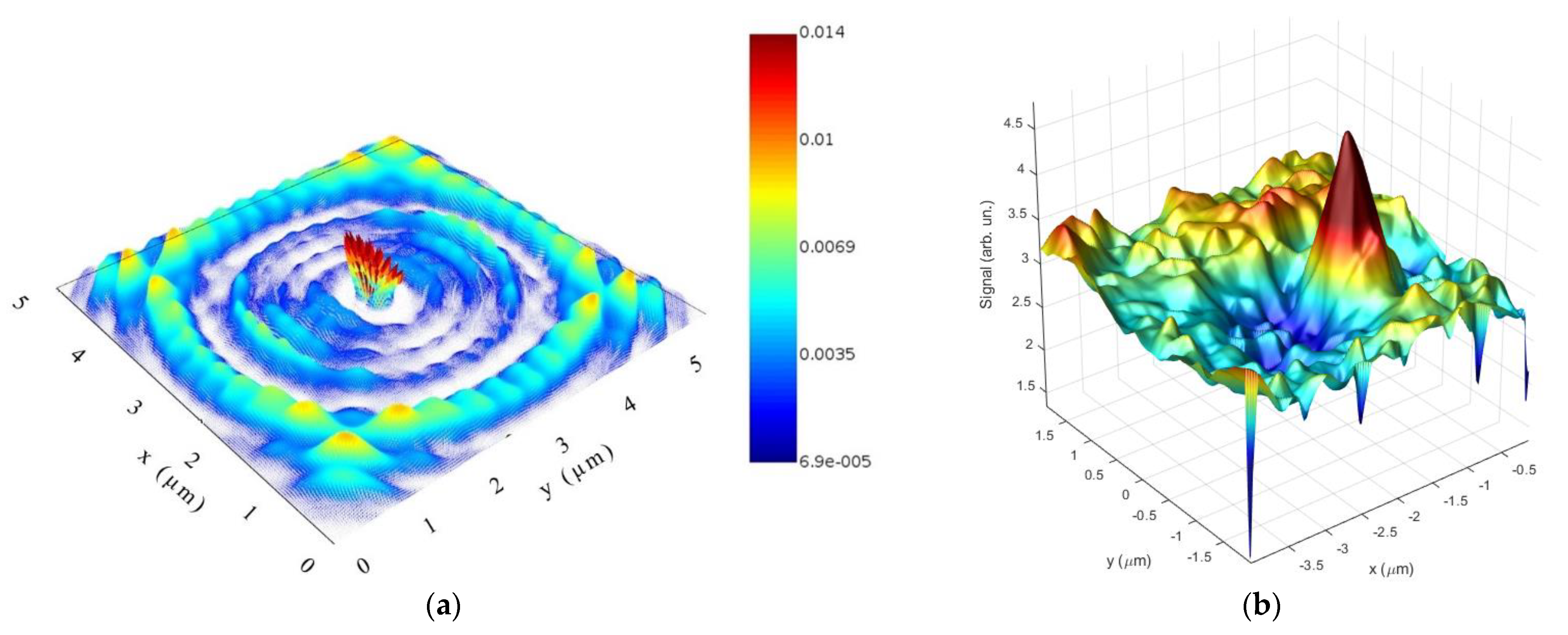

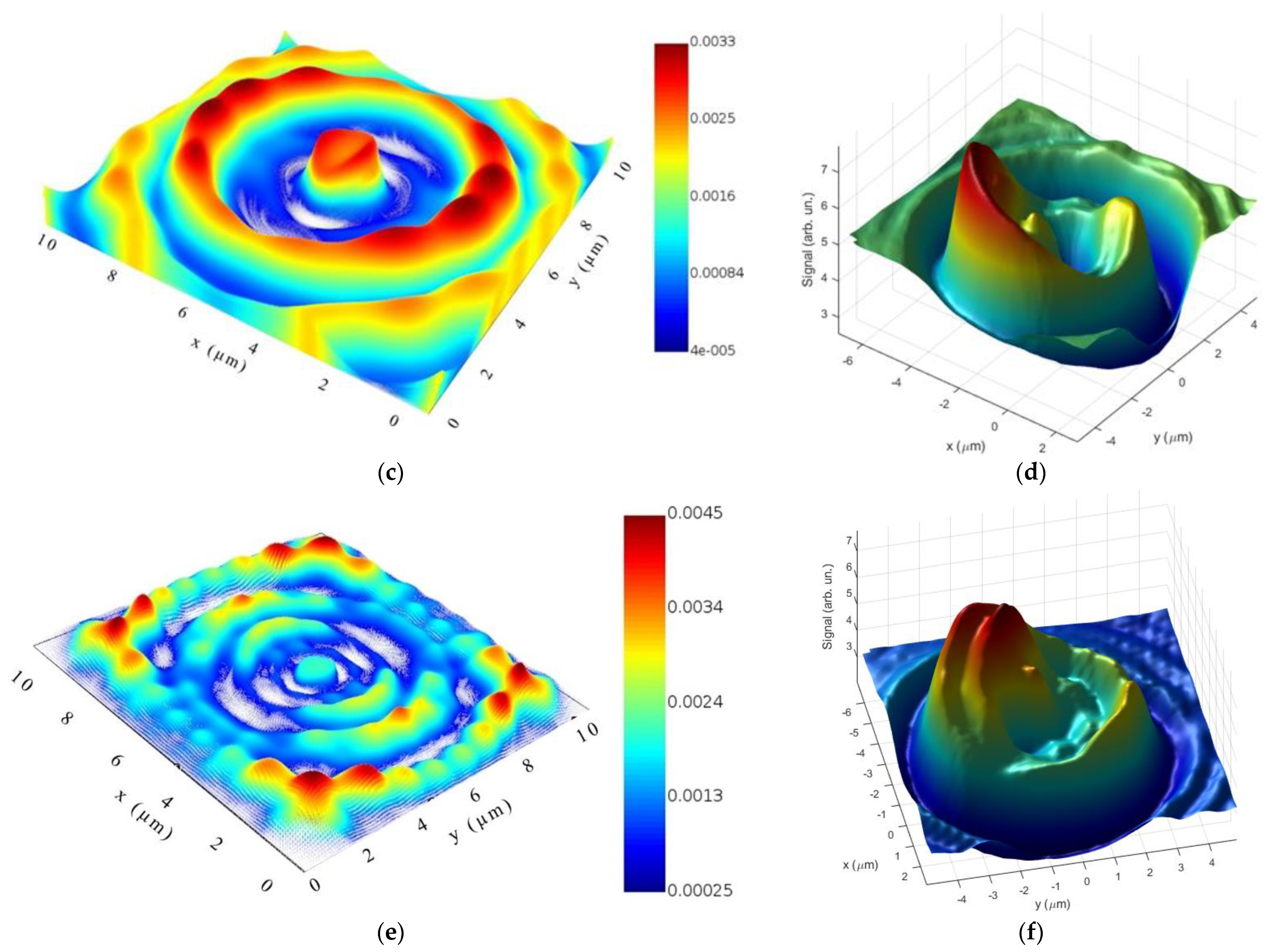

2. Design and Simulation of Microring-Zone Structure

3. Fabrication and Structure Analysis

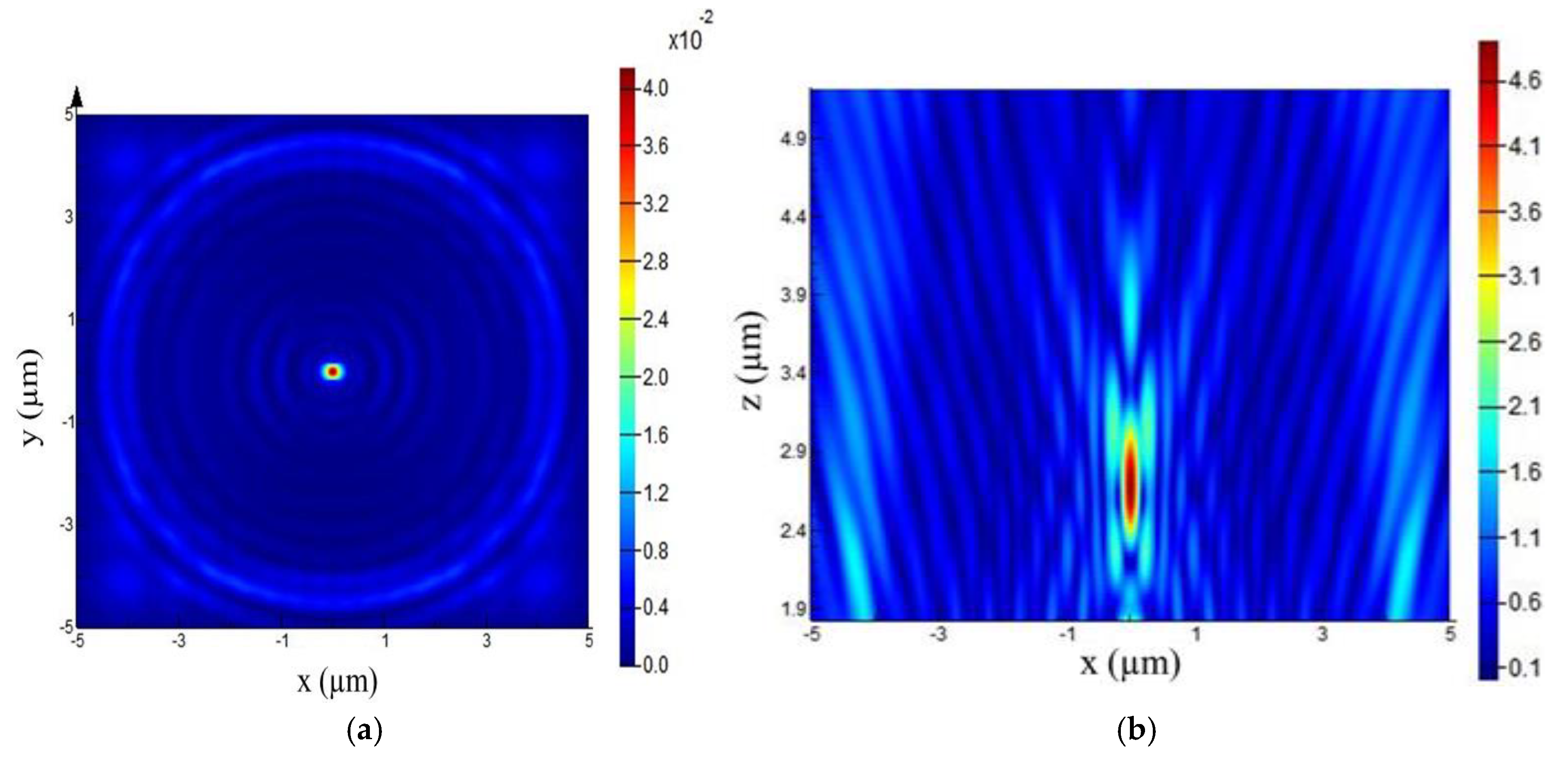

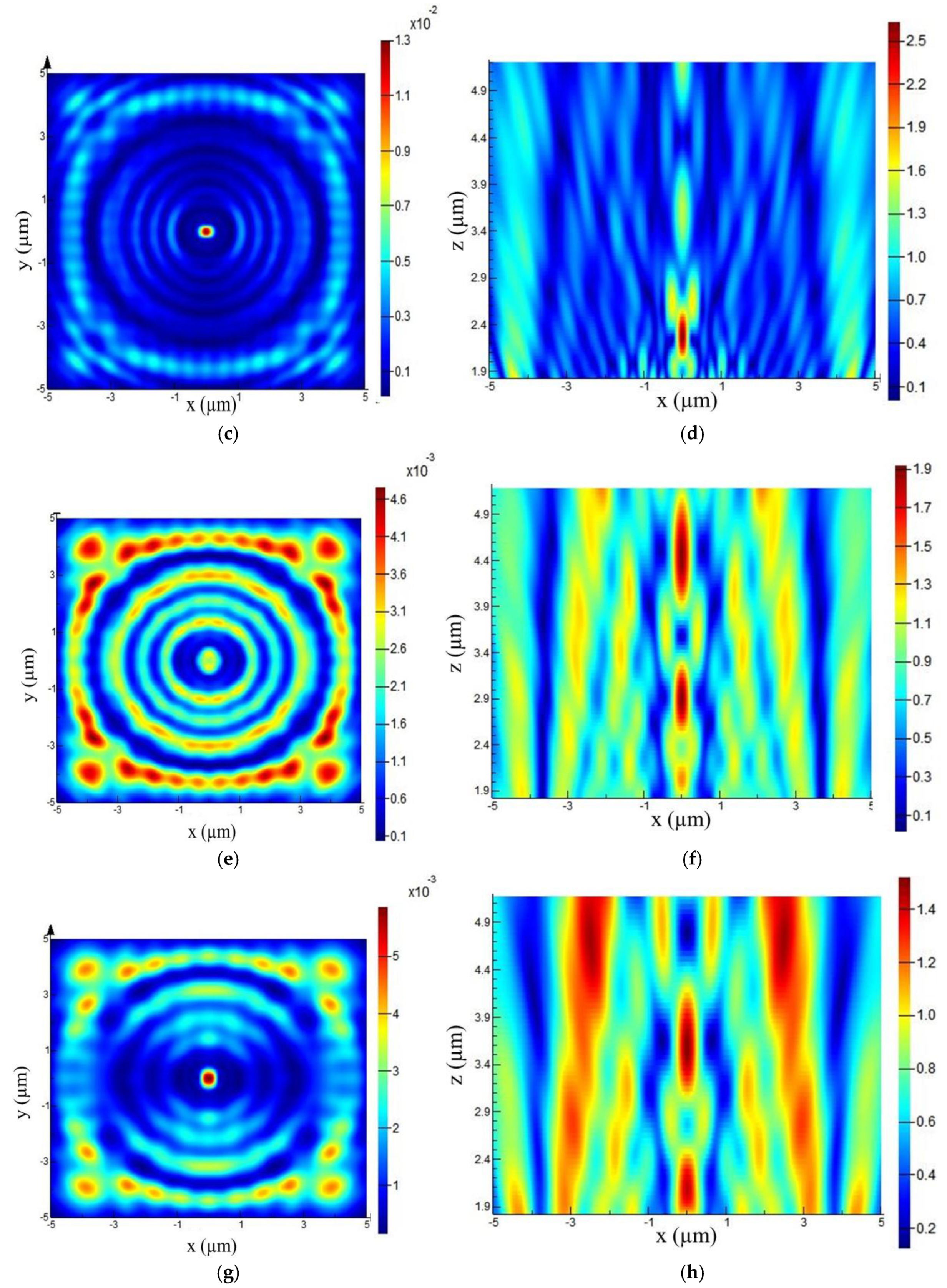

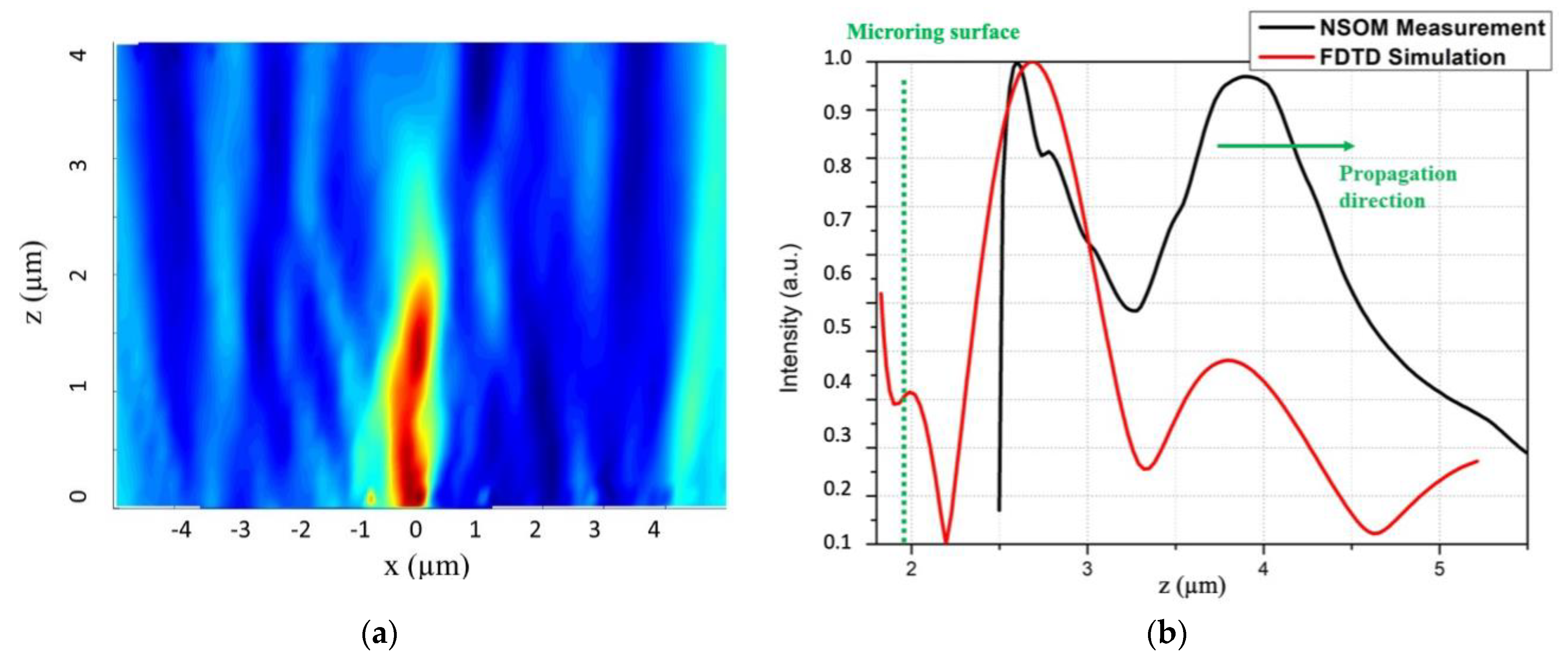

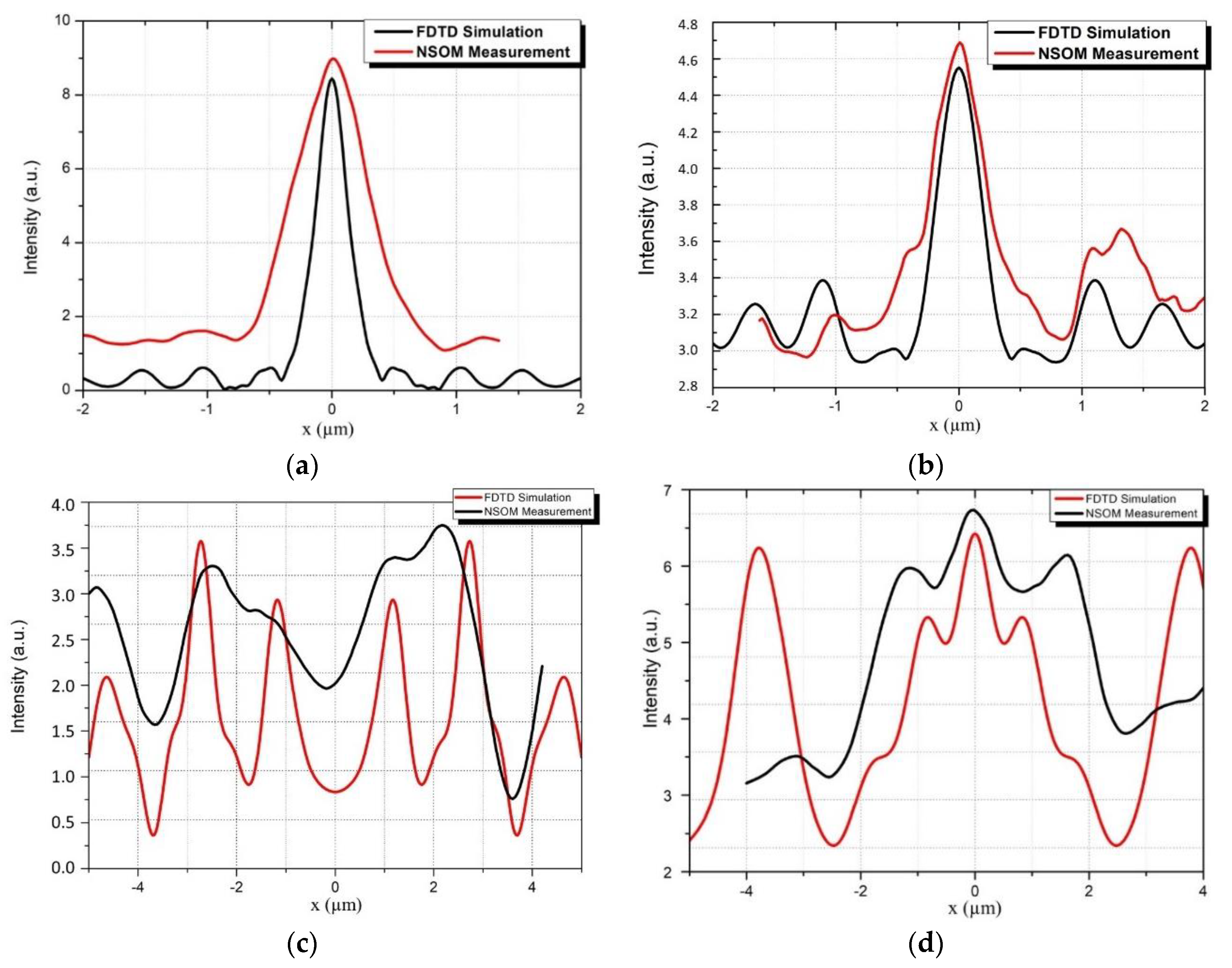

4. Results—Near-Field Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Novotny, L.H.B. Principles of Nano-Optics, 2nd ed.; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Nickelson, L. Electromagnetic Theory and Plasmonics for Engineers; Springer: Vilnius, Lithuania, 2019. [Google Scholar] [CrossRef]

- Krenn, J.R.; Weeber, J.-C. Surface plasmon polaritons in metal stripes and wires. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2004, 362, 739–756. [Google Scholar] [CrossRef] [PubMed]

- Raether, H. Surface Plasmons on Smooth and Rough Surfaces and on Gratings; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar] [CrossRef]

- Ditlbacher, H.; Krenn, J.; Schider, G.; Leitner, A.; Aussenegg, F.R. Two-dimensional optics with surface plasmon polaritons. Appl. Phys. Lett. 2002, 81, 1762–1764. [Google Scholar] [CrossRef]

- Liu, Z.; Steele, J.M.; Srituravanich, W.; Pikus, Y.; Sun, A.C.; Zhang, X. Focusing Surface Plasmons with a Plasmonic Lens. Nano Lett. 2005, 5, 1726–1729. [Google Scholar] [CrossRef] [PubMed]

- Ogut, E.; Yanik, C.; Kaya, I.I.; Ow-Yang, C.; Sendur, K. Focusing short-wavelength surface plasmons by a plasmonic mirror. Opt. Lett. 2018, 43, 2208–2211. [Google Scholar] [CrossRef] [PubMed]

- Mote, R.G.; Yu, S.F.; Ng, B.K.; Zhou, W.; Lau, S.P. Near-field focusing properties of zone plates in visible regime—New insights. Opt. Express 2008, 16, 9554–9564. [Google Scholar] [CrossRef] [PubMed]

- Mote, R.G.; Minin, O.V.; Minin, I.V. Focusing behavior of 2-dimensional plasmonic conical zone plate. Opt. Quantum Electron. 2017, 49, 271. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, W. Subwavelength beaming using depth-tuned annular nanostructures. J. Mod. Opt. 2009, 56, 919–926. [Google Scholar] [CrossRef]

- Johnson, P.B.; Christy, R.W. Optical Constanst of the Noble Metals. Phys. Rev. B 1972, 6, 4370. [Google Scholar] [CrossRef]

- Dryakhlushin, V.F.; Klimov, A.Y. Near-field optical lithography method for fabrication of the nano dimensional objects. Appl. Surf. Sci. 2005, 248, 200–203. [Google Scholar] [CrossRef]

- Huang, J.-S.; Yang, Y.-T. Origin and Future of Plasmonic Optical Tweezers. Nanomaterials 2015, 5, 1048–1065. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yongqi, X.Z.; Zhou, X. Plasmonic Lenses: A Review. Plasmonics 2010, 5, 287–310. [Google Scholar]

- Shi, H.; Wang, C. Beam manipulating by metallic nano-slits with variant widths. Opt. Express 2005, 13, 6815–6820. [Google Scholar] [CrossRef] [PubMed]

- Maier, S.A. Plasmonics: Applications and Fundamentals; Springer: New York, NY, USA, 2007. [Google Scholar]

- Rosenblatt, G.; Simkhovich, B.; Bartal, G.; Orenstein, M. Nonmodal Plasmonics: Controlling the Forced Optical Response of Nanostructures. Phys. Rev. X 2020, 10, 011071. [Google Scholar] [CrossRef] [Green Version]

- Schuller, J.A.; Barnard, E.; Cai, W.; Jun, Y.C.; White, J.S.; Brongersma, M.L. Plasmonics for extreme light concentration and manipulation. Nat. Mater. 2010, 9, 193–204. [Google Scholar] [CrossRef] [PubMed]

- Beynon, T.D.; Strange, R.M.R. Computational study of diffraction patterns for near-field Fresnel and Gabor zone plates. J. Opt. Soc. Am. A 2000, 17, 101–106. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Luo, Y.; Yao, N.; Zhang, W.; Wang, C.; Gao, P.; Zhao, C.; Pu, M.; Luo, X. Modeling and experimental study of plasmonic lens imaging with resolution enhanced methods. Opt. Express 2016, 24, 27115–27126. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.; Zhou, W.; Lim, L.E.N. Near-field behavior of zone-plate-like plasmonic nanostructures. J. Opt. Soc. Am. A 2007, 25, 238–249. [Google Scholar] [CrossRef] [PubMed]

| Wavelength (nm) | εAu (20 nm Layer) | εIP-dip |

|---|---|---|

| 420 | −2.462 | 2.396 |

| 490 | −1.137 | 2.387 |

| 625 | −0.05137 | 2.368 |

| 780 | −0.0342 | 2.348 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Micek, P.; Pudis, D.; Gaso, P.; Durisova, J.; Jandura, D. Microring Zone Structure for Near-Field Probes. Coatings 2021, 11, 1363. https://doi.org/10.3390/coatings11111363

Micek P, Pudis D, Gaso P, Durisova J, Jandura D. Microring Zone Structure for Near-Field Probes. Coatings. 2021; 11(11):1363. https://doi.org/10.3390/coatings11111363

Chicago/Turabian StyleMicek, Patrik, Dusan Pudis, Peter Gaso, Jana Durisova, and Daniel Jandura. 2021. "Microring Zone Structure for Near-Field Probes" Coatings 11, no. 11: 1363. https://doi.org/10.3390/coatings11111363

APA StyleMicek, P., Pudis, D., Gaso, P., Durisova, J., & Jandura, D. (2021). Microring Zone Structure for Near-Field Probes. Coatings, 11(11), 1363. https://doi.org/10.3390/coatings11111363