Formation of Tribofilm in the Friction of Fluorinated Diamond-Like Carbon (FDLC) Film against Ti6Al4V in Bovine Serum Albumin (BSA) Solution

Abstract

1. Introduction

2. Experiment

2.1. Film Preparation

2.2. Friction and Wear

3. Results

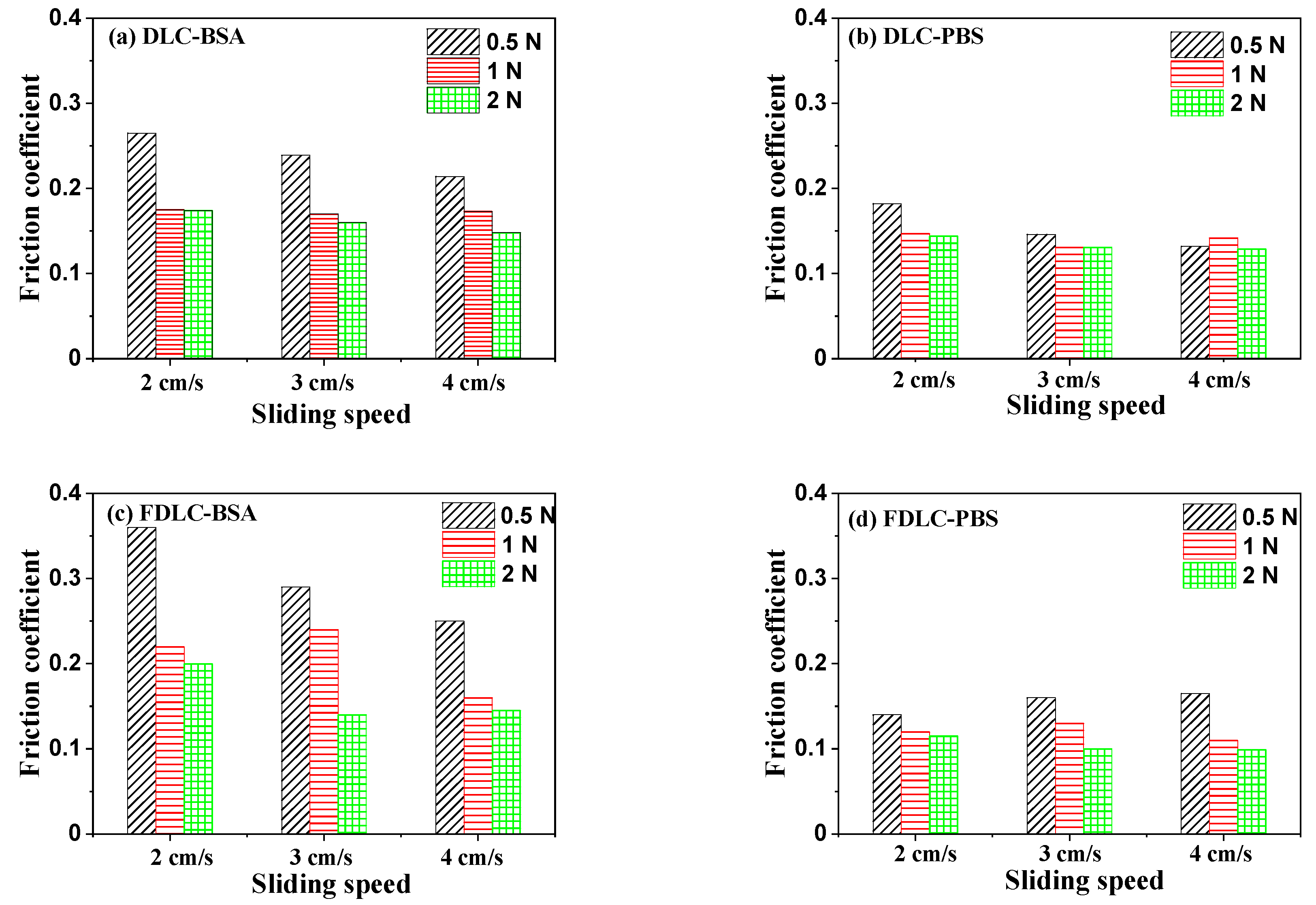

3.1. Friction

3.2. Wear of Ti6Al4V Counterfaces

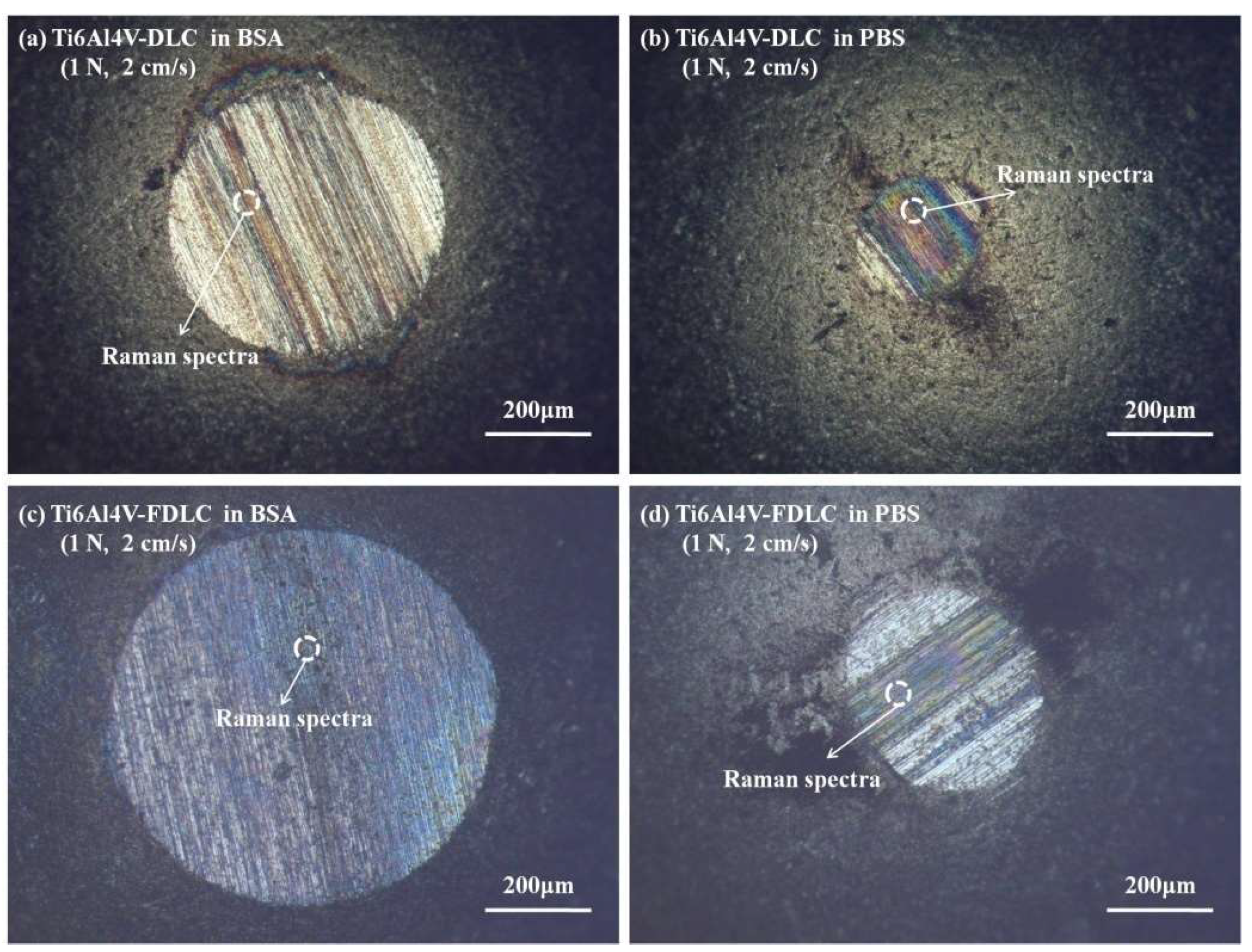

3.2.1. Morphology of the Counterfaces

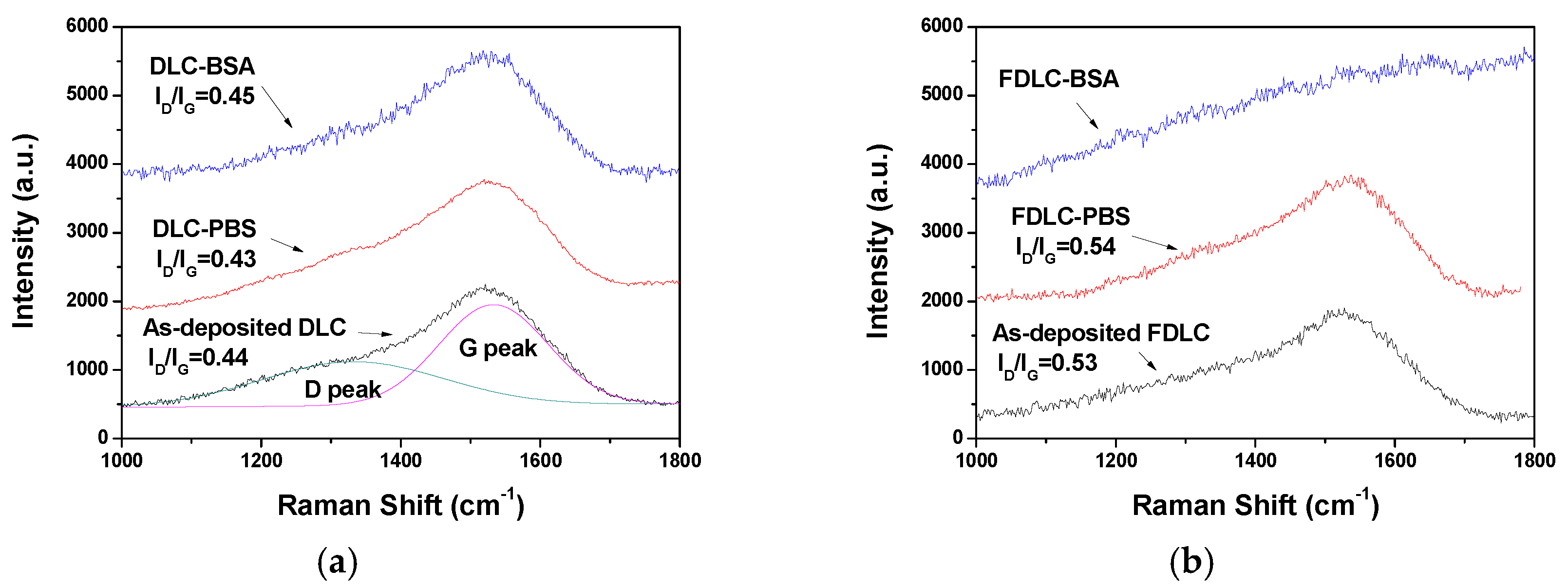

3.2.2. Structure of Tribofilms

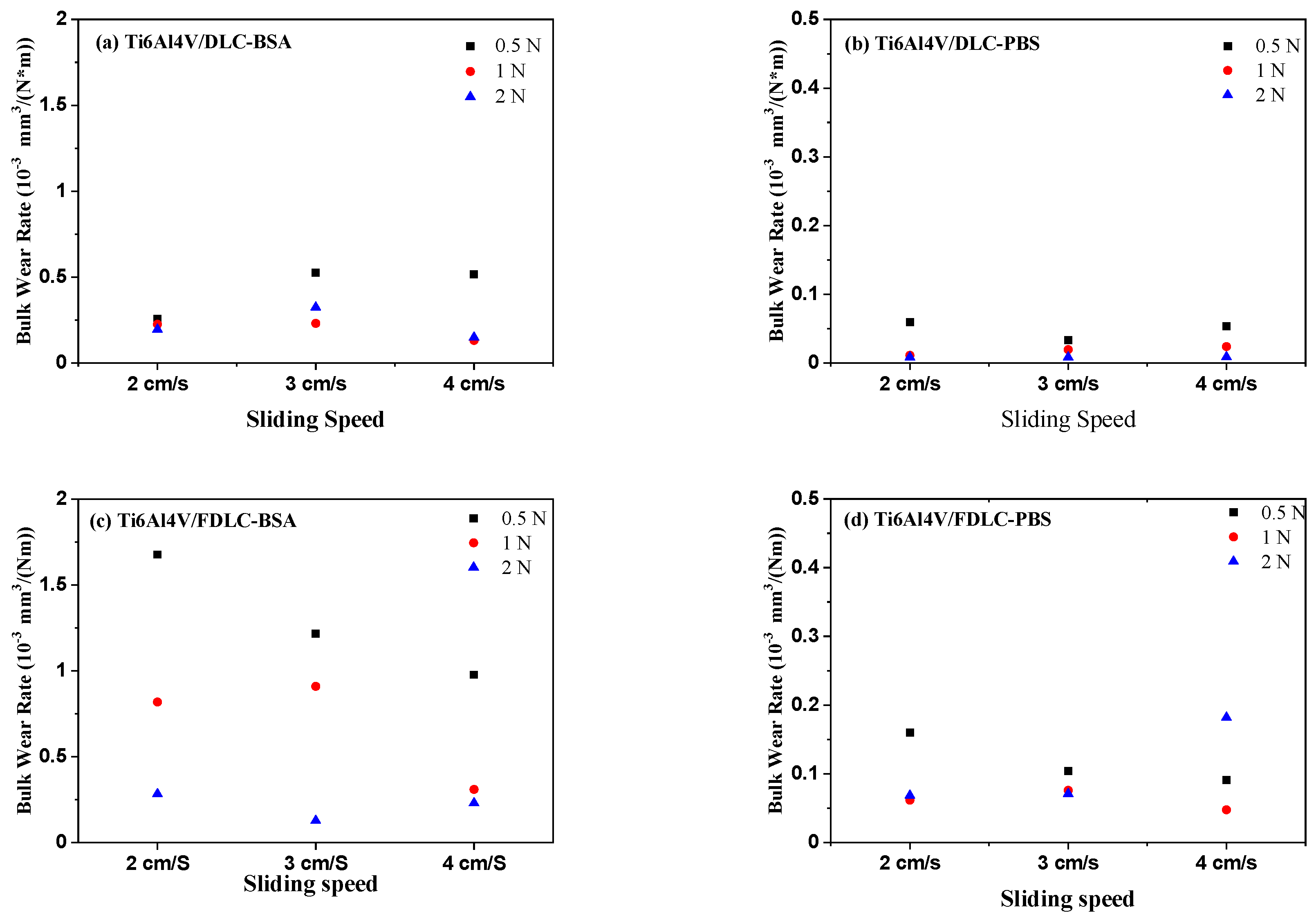

3.2.3. Bulk Wear Rates of Ti6Al4V Counter Balls

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liao, Y.; Pourzal, R.; Wimmer, M.A.; Jacobs, J.J.; Fischer, A.; Marks, L.D. Graphitic Tribological Layers in Metal-on-Metal Hip Replacements. Science 2011, 334, 1687–1690. [Google Scholar] [CrossRef]

- Erdemir, A.; Ramirez, G.; Eryilmaz, O.L.; Narayanan, B.; Liao, Y.; Kamath, G.; Sankaranarayanan, S.K. Carbon-based tribofilms from lubricating oils. Nature 2016, 536, 67–71. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.C.; Li, J.J. Superlubricity of carbon nanostructures. Carbon 2020, 158, 1–23. [Google Scholar] [CrossRef]

- Zhang, T.F.; Jiang, F.; Liao, T.T.; Deng, Q.Y.; Li, S.S.; Wang, Y.; Leng, Y.X. Tribological behavior of diamond like carbon film sliding against CoCrMo or Al2O3 in air and water environment. Tribol. Int. 2016, 95, 456–461. [Google Scholar] [CrossRef]

- Lafon-Placette, S.; Fontaine, J.; Bouchet, M.I.D.B.; Heau, C. Critical role of a metallic counterpart on the tribochemical wear of ta-C coatings in base oil. Wear 2018, 402–403, 91–99. [Google Scholar] [CrossRef]

- Tanaka, A.; Nishibori, T.; Suzuki, M.; Maekawa, K. Characteristics of friction surfaces with DLC films in low and high humidity air. Wear 2004, 257, 297–303. [Google Scholar] [CrossRef]

- Guo, P.; Geng, Z.; Lu, Z.; Zhang, G.; Wu, Z. Probing the lubrication mechanism of rough diamond-like carbon films against silicon nitride under water. Tribol. Int. 2018, 128, 248–259. [Google Scholar] [CrossRef]

- Suzuki, M.; Tanaka, A.; Ohana, T.; Zhang, W. Frictional behavior of DLC films in a water environment. Diam. Relat. Mater. 2004, 13, 1464–1468. [Google Scholar] [CrossRef]

- Hatem, A.; Lin, J.; Wei, R.; Torres, R.D.; Laurindo, C.; Soares, P. Tribocorrosion behavior of DLC-coated Ti-6Al-4V alloy deposited by PIID and PEMS + PIID techniques for biomedical applications. Surf. Coat. Technol. 2017, 332, 223–232. [Google Scholar] [CrossRef]

- Escudeiro, A.; Wimmer, M.A.; Polcar, T.; Cavaleiro, A. Tribological behavior of uncoated and DLC-coated CoCr and Ti-alloys in contact with UHMWPE and PEEK counterbodies. Tribol. Int. 2015, 89, 97–104. [Google Scholar] [CrossRef]

- Talha, M.; Ma, Y.; Kumar, P.; Lin, Y.; Singh, A. Role of protein adsorption in the bio corrosion of metallic implants—A review. Colloids Surf. B Biointerfaces 2019, 176, 494–506. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.J.; Deng, Q.Y.; Leng, Y.X.; Wang, C.M.; Huang, N. Characterization of adsorption and lubrication of synovial fluid proteins and HA on DLC joint bearings surface. Surf. Coat. Technol. 2017, 320, 320–332. [Google Scholar] [CrossRef]

- Hang, R.; Qi, Y. A study of biotribological behavior of DLC coatings and its influence to human serum albumin. Diam. Relat. Mater. 2010, 19, 62–66. [Google Scholar] [CrossRef]

- Guo, F.; Zhou, Z.; Hua, M.; Dong, G. Effect of aqueous solution and load on the formation of DLC transfer film against Co-Cr-Mo for joint prosthesis. J. Mech. Behav. Biomed. Mater. 2015, 49, 12–22. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Qing, Y.A.; Xiao, L.G.; Wang, Y.G.; Bao, X.F.; Qin, Y.G.; Zhang, J.Y.; Zhang, K. Design of new-type F-FLC artificial joint coatings via fluorine incorporation and fullerene-like structure construction. Surf. Coat. Technol. 2020, 385, 125419. [Google Scholar] [CrossRef]

- Imbeni, V.; Martini, C.; Prandstraller, D.; Poli, G.; Trepanier, C.; Duerig, T.W. Preliminary study of micro-scale abrasive wear of a NiTi shape memory alloy. Wear 2003, 254, 1299–1306. [Google Scholar] [CrossRef]

- Kim, D.W.; Kim, K.W. Effects of sliding velocity and normal load on friction and wear characteristics of multi-layered diamond-like carbon (DLC) coating prepared by reactive sputtering. Wear 2013, 297, 722–730. [Google Scholar] [CrossRef]

- Wu, B.; Zhang, T.; Deng, Q.; Leng, Y.; Huang, N. Effects of Adsorption of Albumin and Gamma-Globulin on the Tribological Performance of a Diamond-Like Carbon Film. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2019, 34, 1103–1108. [Google Scholar] [CrossRef]

- Ahmed, M.H.; Byrne, J.A.; McLaughlin, J. Evaluation of glycine adsorption on diamond like carbon (DLC) and fluorinated DLC deposited by plasma-enhanced chemical vapor deposition (PECVD). Surf. Coat. Technol. 2012, 209, 8–14. [Google Scholar] [CrossRef]

- Nečas, D.; Vrbka, M.; Gallo, J.; Křupka, I.; Hartl, M. On the Observation of Lubrication Mechanisms within Hip Joint Replacements. Part II: Hard-on-hard Bearing Pairs. J. Mech. Behav. Biomed. Mater. 2019, 89, 249–259. [Google Scholar] [CrossRef]

- Liub, H.C.; Guo, F.; Wong, P.L.; Li, X. Investigation of adsorbed protein and passive films on hydrodynamic lubricated steel slider surface. Tribol. Int. 2017, 109, 133–139. [Google Scholar]

- Kanda, K.; Yamada, N.; Yokota, K.; Tagawa, M.; Niibe, M.; Okada, M.; Haruyama, Y.; Matsui, S. Fabrication of fluorine-terminated diamond-like carbon thin film using ahyperthermal atomic fluorine beam. Diam. Relat. Mater. 2011, 20, 703–706. [Google Scholar] [CrossRef]

- Liu, Z.; Zheng, S.; Lu, Z.; Pu, J.; Zhang, G. Adhesive transfer at copper/diamond interface and adhesion reduction mechanism with fluorine passivation: A first-principles study. Carbon 2018, 127, 548–556. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Xu, Z.; Su, Y.; Wang, J.; Li, L.; Chong, K.B.; Hou, X.; Paddea, S. Formation of Tribofilm in the Friction of Fluorinated Diamond-Like Carbon (FDLC) Film against Ti6Al4V in Bovine Serum Albumin (BSA) Solution. Coatings 2020, 10, 903. https://doi.org/10.3390/coatings10090903

Zhang T, Xu Z, Su Y, Wang J, Li L, Chong KB, Hou X, Paddea S. Formation of Tribofilm in the Friction of Fluorinated Diamond-Like Carbon (FDLC) Film against Ti6Al4V in Bovine Serum Albumin (BSA) Solution. Coatings. 2020; 10(9):903. https://doi.org/10.3390/coatings10090903

Chicago/Turabian StyleZhang, Tengfei, Zhaoying Xu, Yongyao Su, Jinbiao Wang, Lu Li, Kok Boon Chong, Xiaodong Hou, and Sanjooram Paddea. 2020. "Formation of Tribofilm in the Friction of Fluorinated Diamond-Like Carbon (FDLC) Film against Ti6Al4V in Bovine Serum Albumin (BSA) Solution" Coatings 10, no. 9: 903. https://doi.org/10.3390/coatings10090903

APA StyleZhang, T., Xu, Z., Su, Y., Wang, J., Li, L., Chong, K. B., Hou, X., & Paddea, S. (2020). Formation of Tribofilm in the Friction of Fluorinated Diamond-Like Carbon (FDLC) Film against Ti6Al4V in Bovine Serum Albumin (BSA) Solution. Coatings, 10(9), 903. https://doi.org/10.3390/coatings10090903