Tribology of 2D Nanomaterials: A Review

Abstract

1. Introduction

2. Characteristics of 2D Materials

3. Synthesis of 2D Materials

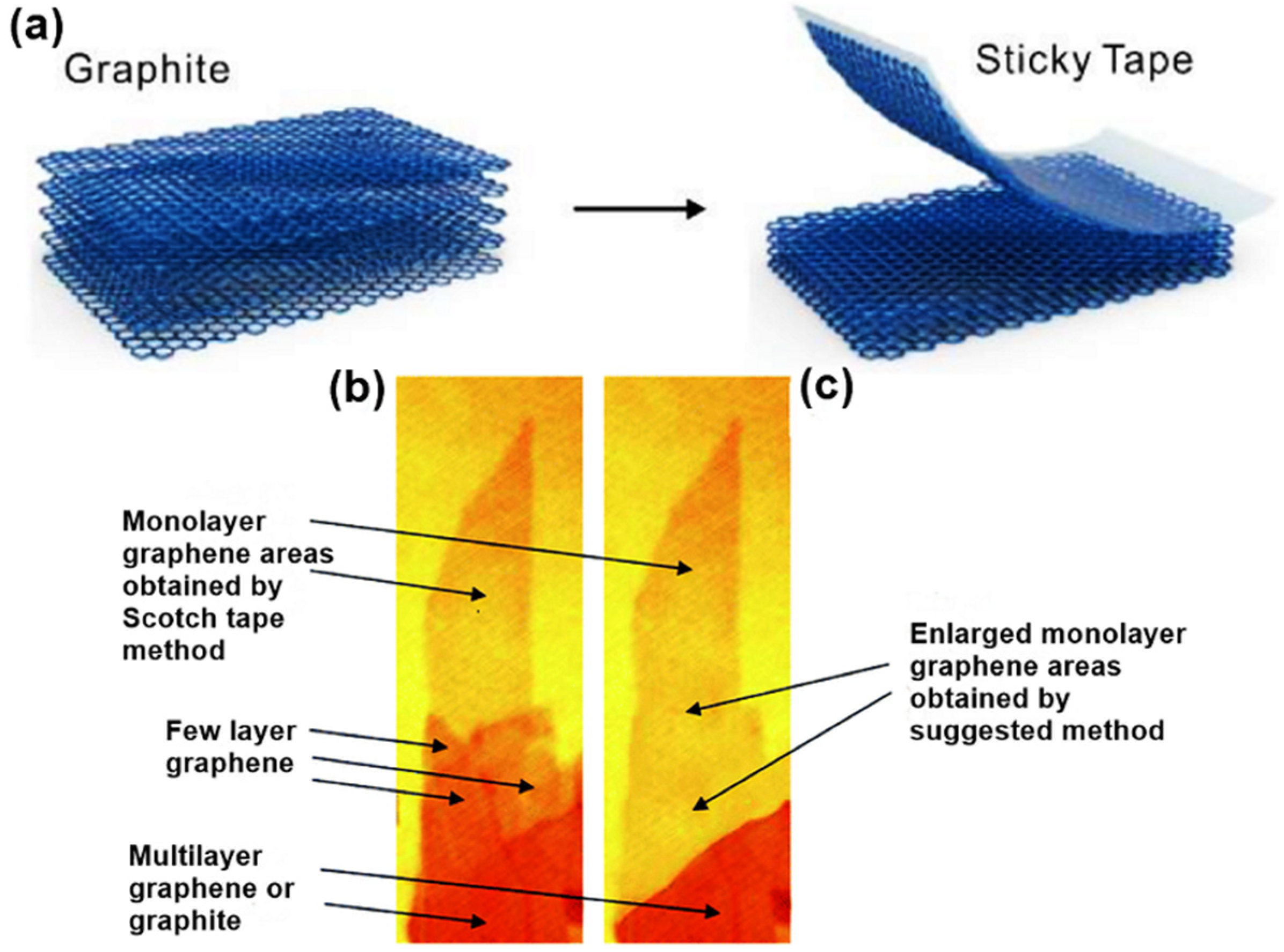

3.1. Mechanical Exfoliation

3.2. Liquid-Phase Exfoliation (LPE)

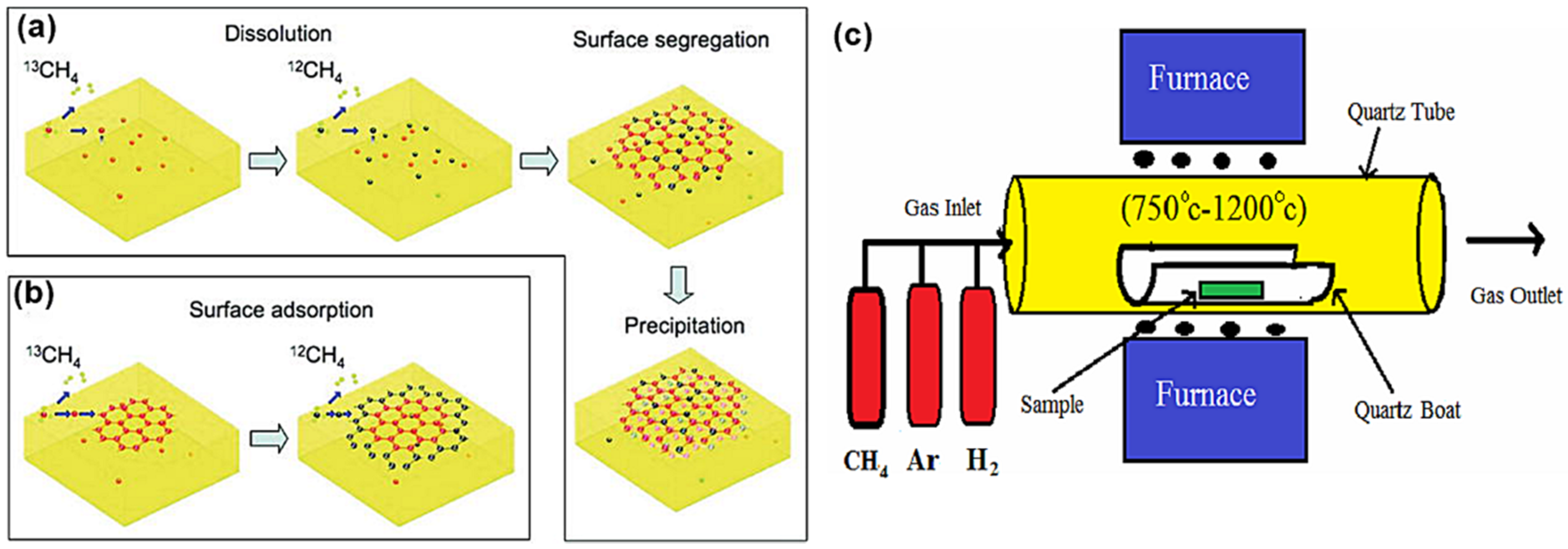

3.3. Chemical Vapor Deposition (CVD)

4. Tribology of 2D Materials

4.1. Graphene and Graphene-Family

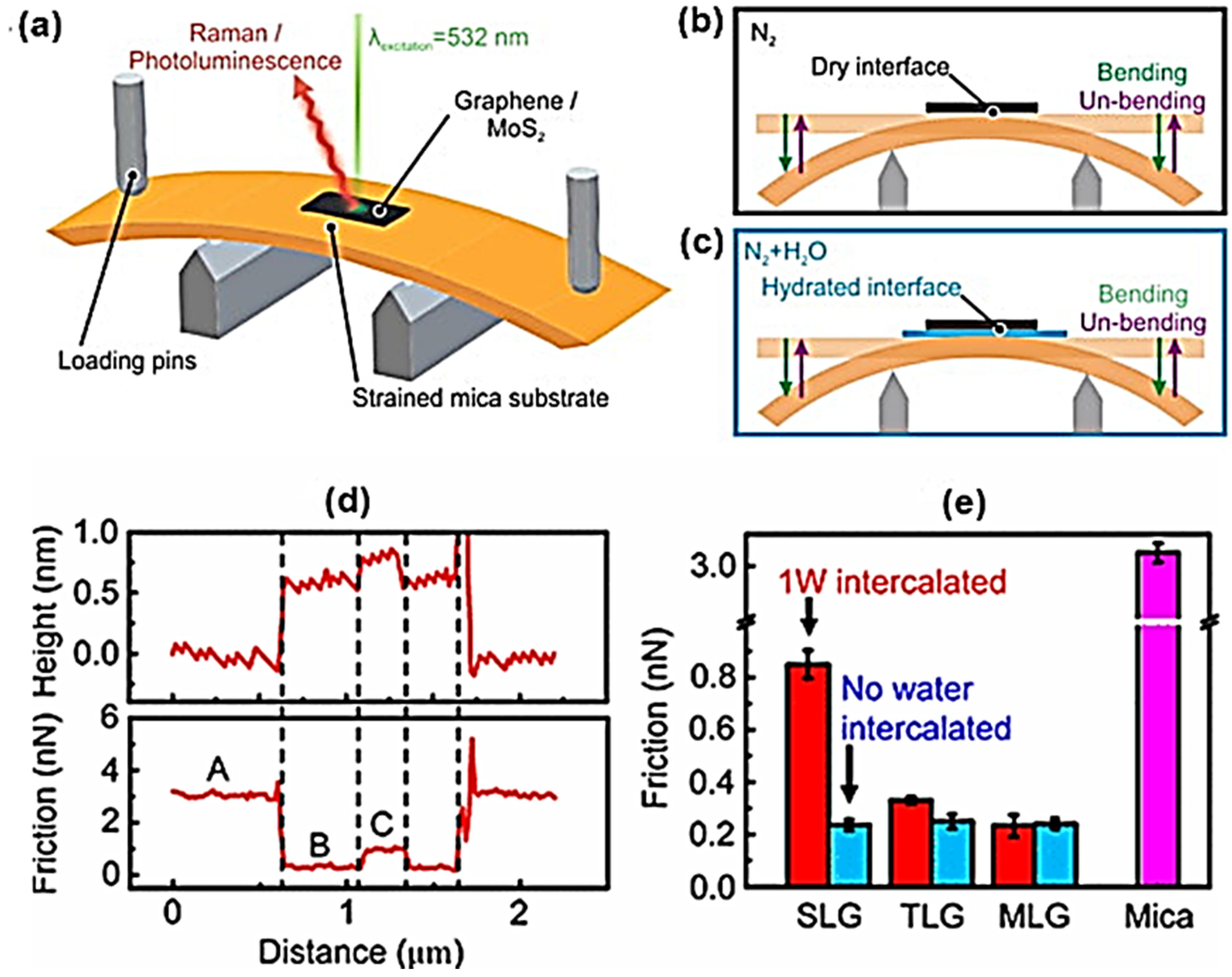

4.1.1. Influence of Solvent

4.1.2. Applications as Lubricant Nano-Additives

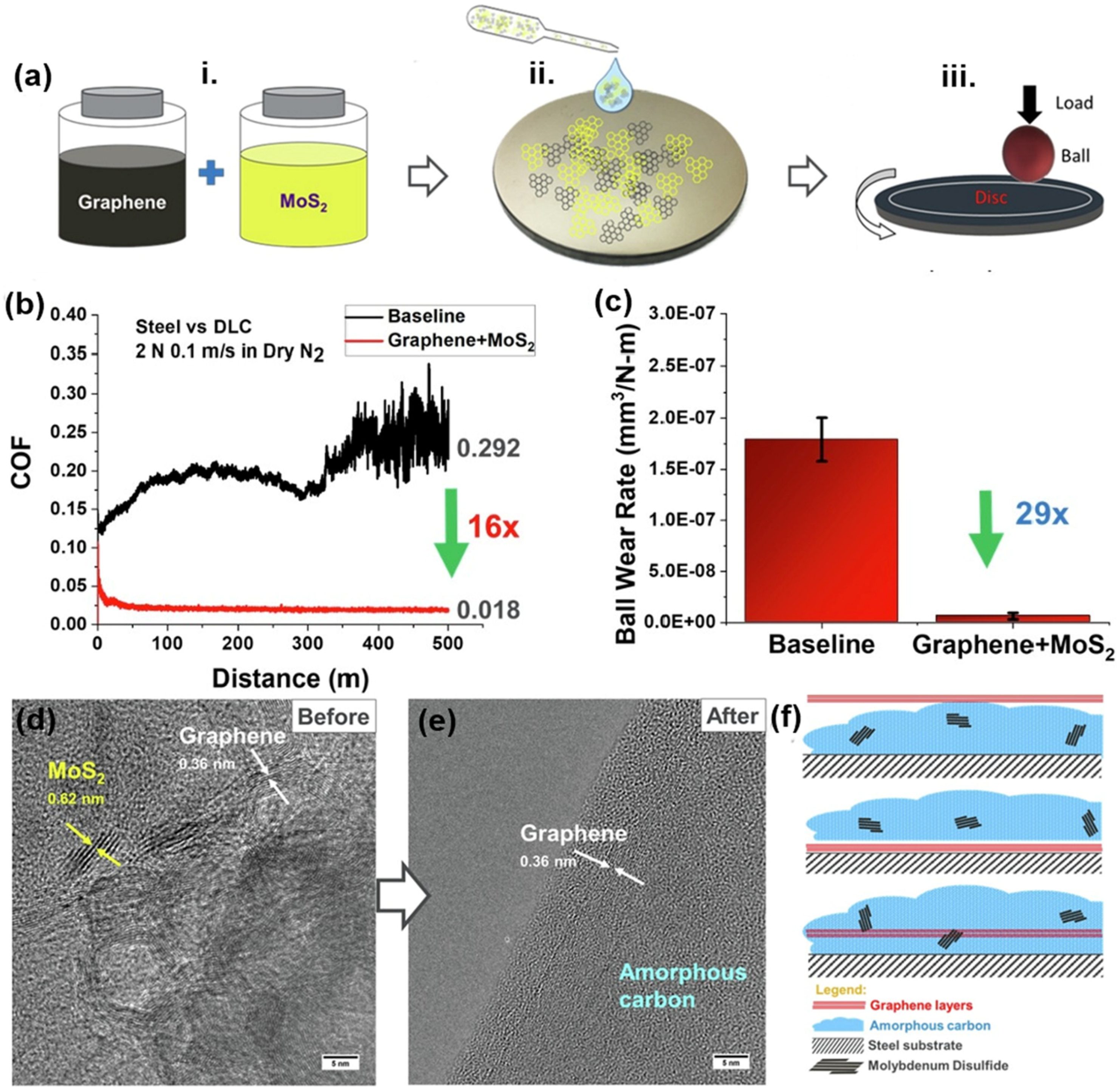

4.1.3. In Combination with Non-2D Materials

4.1.4. Biomedical Application

4.2. Transition Metal Dichalcogenides (TMDCs)

4.2.1. Molybdenum Disulfide (MoS2)

4.2.2. Tungsten Disulfide (WS2)

Application in Low Earth Orbits (LEO)

4.3. Other 2D Layered Materials

4.3.1. Zirconium Phosphate

4.3.2. Hexagonal Boron Nitride (h-BN)

4.3.3. Black Phosphorus

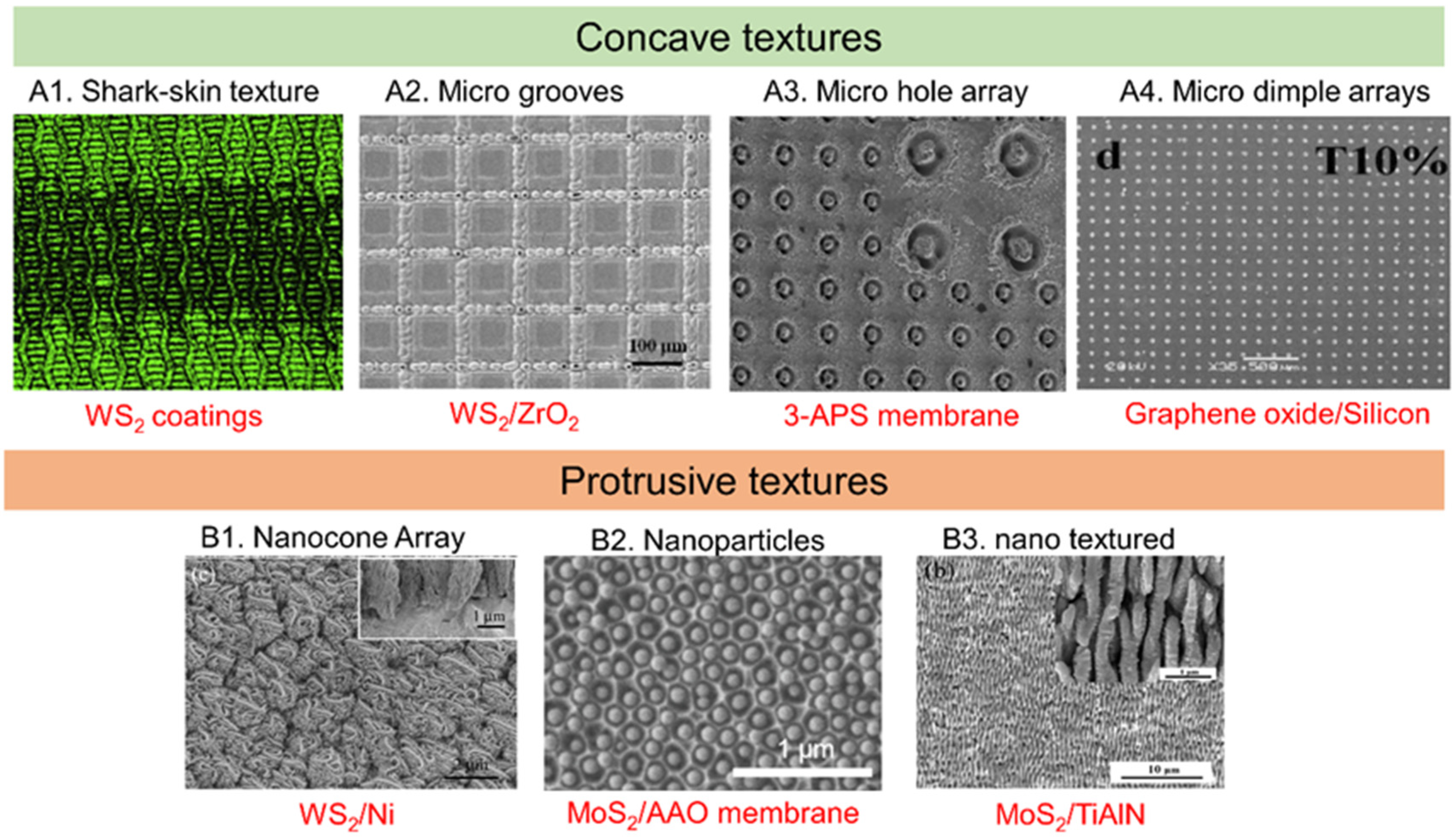

5. Micro-Nano Patterns

6. Conclusions and Prospects

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Luo, J.; Zhou, X. Superlubricitive engineering—Future industry nearly getting rid of wear and frictional energy consumption. Friction 2020, 8, 643–665. [Google Scholar] [CrossRef]

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, S. 2D nanomaterials as lubricant additive: A review. Mater. Des. 2017, 135, 319–332. [Google Scholar] [CrossRef]

- Penkov, O.; Kim, H.-J.; Kim, H.-J.; Kim, D.-E. Tribology of Graphene: A Review. Int. J. Precis. Eng. Manuf. 2014, 15, 577–585. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Cesano, F.; Scarano, D. Graphene and Other 2D Layered Hybrid Nanomaterial-Based Films: Synthesis, Properties, and Applications. Coatings 2018, 8, 419. [Google Scholar] [CrossRef]

- Tanjil, M.R.-E.; Jeong, Y.; Yin, Z.; Panaccione, W.; Wang, C.M. Angstrom-Scale, Atomically Thin 2D Materials for Corrosion Mitigation and Passivation. Coatings 2019, 9, 133. [Google Scholar] [CrossRef]

- Xia, M. 2D Materials-Coated Plasmonic Structures for SERS Applications. Coatings 2018, 8, 137. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Kan, Y.; Liang, H. Formation of Anti-Wear Tribofilms via α-ZrP Nanoplatelet as Lubricant Additives. Lubricants 2016, 4, 28. [Google Scholar] [CrossRef]

- Meng, Y.; Su, F.; Chen, Y. Supercritical Fluid Synthesis and Tribological Applications of Silver Nanoparticle-decorated Graphene in Engine Oil Nanofluid. Sci. Rep. 2016, 6, 31246. [Google Scholar] [CrossRef] [PubMed]

- Njiwa, P.; Hadj-Aïssa, A.; Afanasiev, P.; Geantet, C.; Bosselet, F.; Vacher, B.; Belin, M.; Le Mogne, T.; Dassenoy, F. Tribological Properties of New MoS2 Nanoparticles Prepared by Seed-Assisted Solution Technique. Tribol. Lett. 2014, 55, 473–481. [Google Scholar] [CrossRef]

- Grossiord, C.; Varlot, K.; Martin, J.M.; Le Mogne, T.; Esnouf, C.; Inoue, K. MoS2 single sheet lubrication by molybdenum dithiocarbamate. Tribol. Int. 1998, 31, 737–743. [Google Scholar] [CrossRef]

- Joly-Pottuz, L.; Dassenoy, F.; Belin, M.; Vacher, B.; Martin, J.M.; Fleischer, N. Ultralow-friction and wear properties of IF-WS2 under boundary lubrication. Tribol. Lett. 2005, 18, 477–485. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, M.; Li, X.; Jin, L.; Su, G.; Mo, Y.; Li, L.; Zhu, H.; Tian, Y. Research Progress in Application of 2D Materials in Liquid-Phase Lubrication System. Materials 2018, 11, 1314. [Google Scholar] [CrossRef] [PubMed]

- Late, D.J.; Bhat, A.; Rout, C.S. Chapter 2—Fundamentals and Properties of 2D Materials in General and Sensing Applications. In Fundamentals and Sensing Applications of 2D Materials; Hywel, M., Rout, C.S., Late, D.J., Eds.; Woodhead Publishing: Sawston/Cambridge, UK, 2019; pp. 5–24. [Google Scholar]

- Geim, A.K.; Novoselov, K.S. Nanoscience and Technology: A Collection of Reviews from Nature Journals; Rogers, P., Ed.; World Scientific: Singapore, 2010; p. 11. [Google Scholar]

- Fiori, G.; Bonaccorso, F.; Iannaccone, G.; Palacios, T.; Neumaier, D.; Seabaugh, A.; Banerjee, S.K.; Colombo, L. Electronics based on two-dimensional materials. Nat. Nanotechnol. 2014, 9, 768–779. [Google Scholar] [CrossRef]

- Choi, J.S.; Kim, J.-S.; Byun, I.-S.; Lee, D.H.; Lee, M.J.; Park, B.H.; Lee, C.; Yoon, D.; Cheong, H.; Lee, K.H.; et al. Friction Anisotropy–Driven Domain Imaging on Exfoliated Monolayer Graphene. Science 2011, 333, 607–610. [Google Scholar] [CrossRef]

- Filleter, T.; McChesney, J.L.; Bostwick, A.; Rotenberg, E.; Emtsev, K.V.; Seyller, T.; Horn, K.; Bennewitz, R. Friction and Dissipation in Epitaxial Graphene Films. Phys. Rev. Lett. 2009, 102, 086102. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, T.; Erdemir, A.; Li, Q. Tribology of two-dimensional materials: From mechanisms to modulating strategies. Mater. Today 2019, 26, 67–86. [Google Scholar] [CrossRef]

- Li, S.; Li, Q.; Carpick, R.W.; Gumbsch, P.; Liu, X.Z.; Ding, X.; Sun, J.; Li, J. The evolving quality of frictional contact with grapheme. Nature 2016, 539, 541–545. [Google Scholar] [CrossRef] [PubMed]

- Mendoza-Sánchez, B.; Gogotsi, Y. Synthesis of Two-Dimensional Materials for Capacitive Energy Storage. Adv. Mater. 2016, 28, 6104–6135. [Google Scholar] [CrossRef] [PubMed]

- Timmerman, M.A.; Xia, R.; Le, P.T.P.; Wang, Y.; ten Elshof, J.E. Metal Oxide Nanosheets as 2D Building Blocks for the Design of Novel Materials. Chem.-A Eur. J. 2020, 26, 9084–9098. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xie, Y. Recent advances in free-standing two-dimensional crystals with atomic thickness: Design, assembly and transfer strategies. Chem. Soc. Rev. 2013, 42, 8187–8199. [Google Scholar] [CrossRef]

- Koren, E.; Lörtscher, E.; Rawlings, C.; Knoll, A.W.; Duerig, U. Adhesion and friction in mesoscopic graphite contacts. Science 2015, 348, 679–683. [Google Scholar] [CrossRef]

- Liechti, K.M. Understanding friction in layered materials. Science 2015, 348, 632–633. [Google Scholar] [CrossRef]

- Shinjo, K.; Hirano, M. Dynamics of friction: Superlubric State. Surf. Sci. 1993, 283, 473–478. [Google Scholar] [CrossRef]

- Ky, D.L.C.; Bien-Cuong Tran, K.; Le, C.T.; Kim, Y.S.; Chung, K.-H. Friction characteristics of mechanically exfoliated and CVD-grown single-layer MoS2. Friction 2018, 6, 395–406. [Google Scholar] [CrossRef]

- Lee, C.; Li, Q.; Kalb, W.; Liu, X.-Z.; Berger, H.; Carpick, R.W.; Hone, J. Frictional Characteristics of Atomically Thin Sheets. Science 2010, 328, 76–80. [Google Scholar] [CrossRef]

- Shull, K.R. Contact mechanics and the adhesion of soft solids. Mater. Sci. Eng. R Rep. 2002, 36, 1–45. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, Y.; Hu, X.; Fang, L.; Song, Y.; Liu, D.; Luo, J. Influence of elastic property on the friction between atomic force microscope tips and 2D materials. Nanotechnology 2020, 31, 285710. [Google Scholar] [CrossRef] [PubMed]

- Park, J.Y.; Ogletree, D.F.; Thiel, P.A.; Salmeron, M. Electronic Control of Friction in Silicon pn Junctions. Science 2006, 313, 186. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Park, J.Y.; Hendriksen, B.L.M.; Ogletree, D.F.; Salmeron, M. Electronic contribution to friction on GaAs: An atomic force microscope study. Phys. Rev. B 2008, 77, 184105. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Hilton, M.R.; Bauer, R.; Didziulis, S.V.; Dugger, M.T.; Keem, J.M.; Scholhamer, J. Structural and tribological studies of MoS2 solid lubricant films having tailored metal-multilayer nanostructures. Surf. Coat. Technol. 1992, 53, 13–23. [Google Scholar] [CrossRef]

- Ratoi, M.; Niste, V.B.; Walker, J.; Zekonyte, J. Mechanism of Action of WS2 Lubricant Nanoadditives in High-Pressure Contacts. Tribol. Lett. 2013, 52, 81–91. [Google Scholar] [CrossRef]

- Shi, Q.; Tang, H.; Zhu, H.; Tang, G.; Zhang, K.; Zhang, H.; Li, C. Synthesis and tribological properties of ti-doped NbSe2 nanoparticles. Chalcogenide Lett. 2014, 11, 199–207. [Google Scholar]

- Parvez, K. Chapter 1—Two-Dimensional Nanomaterials: Crystal Structure and Synthesis. In Biomedical Applications of Graphene and 2D Nanomaterials; Nurunnabi, M., McCarthy, J.R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–25. [Google Scholar]

- Yi, M.; Shen, Z. A review on mechanical exfoliation for the scalable production of graphene. J. Mater. Chem. A 2015, 3, 11700–11715. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Jiang, D.; Schedin, F.; Booth, T.J.; Khotkevich, V.V.; Morozov, S.V.; Geim, A.K. Two-dimensional atomic crystals. Proc. Natl. Acad. Sci. USA 2005, 102, 10451–10453. [Google Scholar] [CrossRef]

- Li, H.; Wu, J.; Yin, Z.; Zhang, H. Preparation and Applications of Mechanically Exfoliated Single-Layer and Multilayer MoS2 and WSe2 Nanosheets. Acc. Chem. Res. 2014, 47, 1067–1075. [Google Scholar] [CrossRef]

- Li, H.; Lu, G.; Wang, Y.; Yin, Z.; Cong, C.; He, Q.; Wang, L.; Ding, F.; Yu, T.; Zhang, H. Mechanical Exfoliation and Characterization of Single- and Few-Layer Nanosheets of WSe2, TaS2, and TaSe2. Small 2013, 9, 1974–1981. [Google Scholar] [CrossRef] [PubMed]

- Late, D.J.; Doneux, T.; Bougouma, M. Single-layer MoSe2 based NH3 gas sensor. Appl. Phys. Lett. 2014, 105, 233103. [Google Scholar] [CrossRef]

- Shmavonyan, G.S.; Sevoyan, G.; Aroutiounian, V.M. Enlarging the surface area of monolayer graphene synthesized by mechanical exfoliation. Armen. J. Phys. 2013, 6, 1–6. [Google Scholar]

- Peng, Y.; Wang, Z.; Zou, K. Friction and Wear Properties of Different Types of Graphene Nanosheets as Effective Solid Lubricants. Langmuir 2015, 31, 7782–7791. [Google Scholar] [CrossRef]

- Zhang, Y.; Small, J.P.; Pontius, W.V.; Kim, P. Fabrication and electric-field-dependent transport measurements of mesoscopic graphite devices. Appl. Phys. Lett. 2005, 86, 073104. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, S.J.; Choi, J.W. Electrical Property of Graphene and Its Application to Electrochemical Biosensing. Nanomaterials 2019, 9, 297. [Google Scholar] [CrossRef]

- Hernandez, Y.; Nicolosi, V.; Lotya, M.; Blighe, F.M.; Sun, Z.; De, S.; McGovern, I.T.; Holland, B.; Byrne, M.; Gun’Ko, Y.K.; et al. High-yield production of graphene by liquid-phase exfoliation of graphite. Nat. Nanotechnol. 2008, 3, 563–568. [Google Scholar] [CrossRef]

- Coleman, J.N.; Lotya, M.; O’Neill, A.; Bergin, S.D.; King, P.J.; Khan, U.; Young, K.; Gaucher, A.; De, S.; Smith, R.J.; et al. Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 2011, 331, 568–571. [Google Scholar] [CrossRef]

- Singh, V.; Joung, D.; Zhai, L.; Das, S.; Khondaker, S.I.; Seal, S. Graphene based materials: Past, present and future. Prog. Mater. Sci. 2011, 56, 1178–1271. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Zhou, C. Review of Chemical Vapor Deposition of Graphene and Related Applications. Acc. Chem. Res. 2013, 46, 2329–2339. [Google Scholar] [CrossRef]

- Somani, P.R.; Somani, S.P.; Umeno, M. Planer nano-graphenes from camphor by CVD. Chem. Phys. Lett. 2006, 430, 56–59. [Google Scholar] [CrossRef]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E.; et al. Large-Area Synthesis of High-Quality and Uniform Graphene Films on Copper Foils. Science 2009, 324, 1312–1314. [Google Scholar] [CrossRef] [PubMed]

- Zhan, Y.; Liu, Z.; Najmaei, S.; Ajayan, P.M.; Lou, J. Large-Area Vapor-Phase Growth and Characterization of MoS2 Atomic Layers on a SiO2 Substrate. Small 2012, 8, 966–971. [Google Scholar] [CrossRef]

- Li, X.; Cai, W.; Colombo, L.; Ruoff, R.S. Evolution of Graphene Growth on Ni and Cu by Carbon Isotope Labeling. Nano Lett. 2009, 9, 4268–4272. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, D.; Tripathi, C.C. Graphene: Potential material for nanoelectric applications, India. J. Pure Appl. Phys. 2015, 53, 501–513. [Google Scholar]

- Jia, G.; Plentz, J.; Dellith, J.; Dellith, A.; Wahyuono, R.A.; Andrae, G. Large Area Graphene Deposition on Hydrophobic Surfaces, Flexible Textiles, Glass Fibers and 3D Structures. Coatings 2019, 9, 183. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

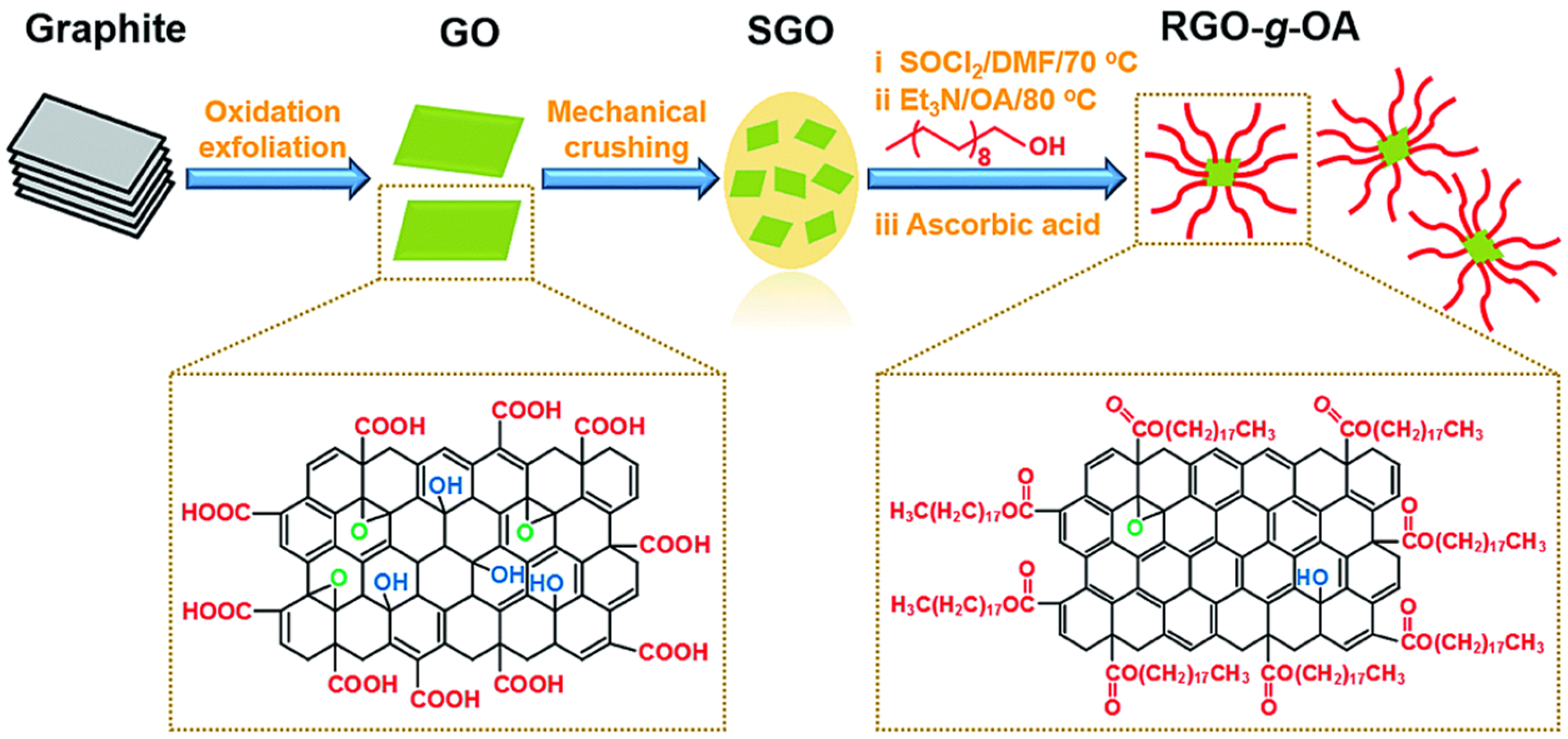

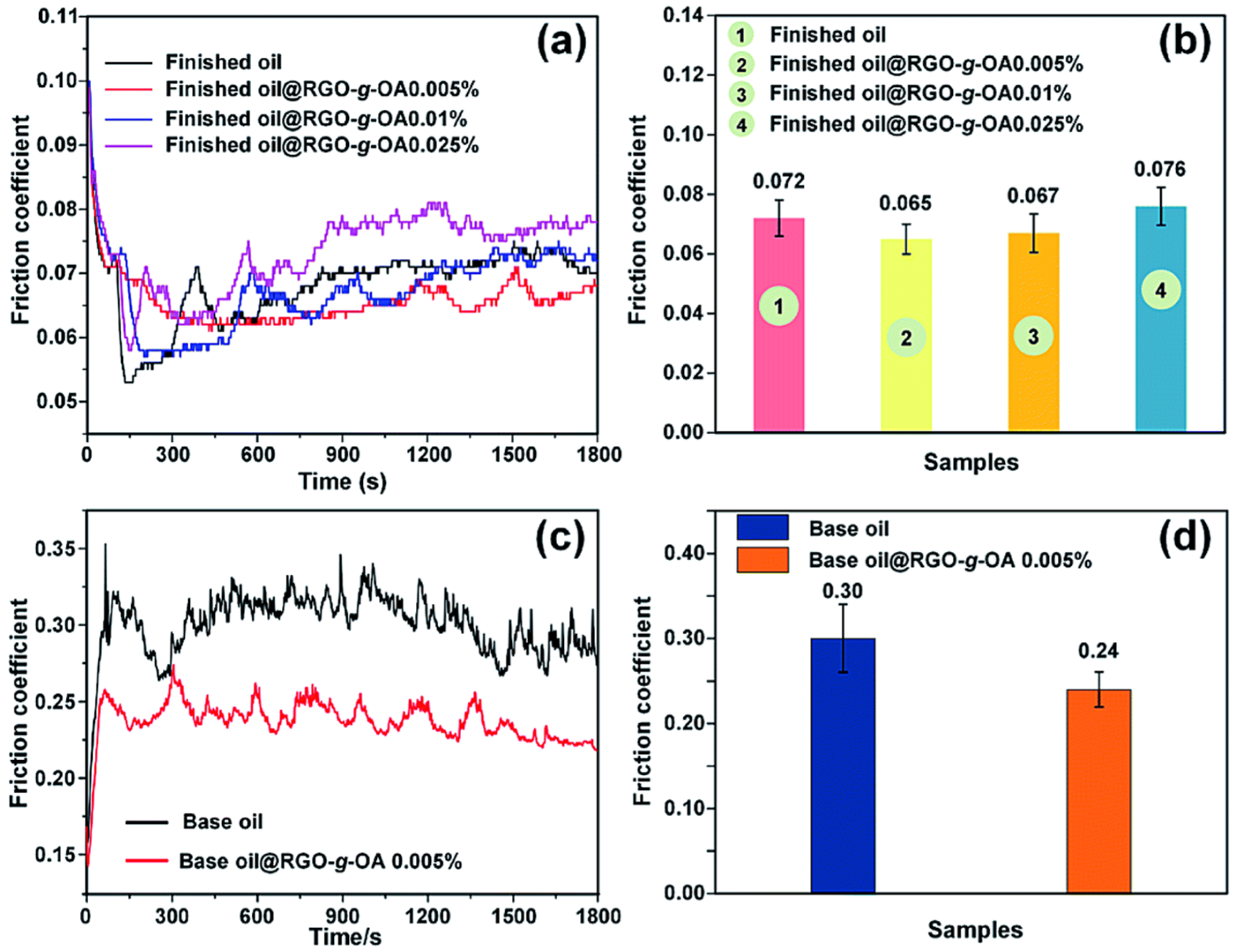

- Zhu, C.; Yan, Y.; Wang, F.; Cui, J.; Zhao, S.; Gao, A.; Zhang, G. Facile fabrication of long-chain alkyl functionalized ultrafine reduced graphene oxide nanocomposites for enhanced tribological performance. RSC Adv. 2019, 9, 7324–7333. [Google Scholar] [CrossRef]

- Bunch, J.S.; Verbridge, S.S.; Alden, J.S.; van der Zande, A.M.; Parpia, J.M.; Craighead, H.G.; McEuen, P.L. Impermeable Atomic Membranes from Graphene Sheets. Nano Lett. 2008, 8, 2458–2462. [Google Scholar] [CrossRef]

- Blau, P.J. Four great challenges confronting our understanding and modeling of sliding friction**Research sponsored by the U.S. Department of Energy, Assistant Secretary for Energy Efficiency and Renewable Energy, office of Transportation Technologies, as part of the Heavy Vehicle Propulsion System Materials Program, under contract DE-AC05-960R22464 with Lockheed Martin Energy Research Corporation. In Tribology Series; Dowson, D., Taylor, C.M., Childs, T.H.C., Dalmaz, G., Berthier, Y., Flamand, L., Georges, J.M., Lubrecht, A.A., Eds.; Elsevier: Amsterdam, The Netherlands, 1998; pp. 117–128. [Google Scholar]

- Shakhvorostov, D.; Pöhlmann, K.; Scherge, M. An energetic approach to friction, wear and temperature. Wear 2004, 257, 124–130. [Google Scholar] [CrossRef]

- Blau, P.J. On the nature of running-in. Tribol. Int. 2005, 38, 1007–1012. [Google Scholar] [CrossRef]

- Zhao, S.; Shi, S.; Xia, K.; Wang, T.; Chai, M.; Zhang, Y.; Qu, C.; Zheng, Q. Scratching of Graphene-Coated Cu Substrates Leads to Hardened Cu Interfaces with Enhanced Lubricity. ACS Appl. Nano Mater. 2020, 3, 1992–1998. [Google Scholar] [CrossRef]

- Yao, Q.; Qi, Y.; Zhang, J.; Zhang, S.; Zhao, P.; Wang, H.; Feng, X.-Q.; Li, Q. Impacts of the substrate stiffness on the anti-wear performance of grapheme. AIP Adv. 2019, 9, 075317. [Google Scholar] [CrossRef]

- Savage, R.H. Graphite Lubrication. J. Appl. Phys. 1948, 19, 1–10. [Google Scholar] [CrossRef]

- Lancaster, J.K.; Pritchard, J.R. The influence of environment and pressure on the transition to dusting wear of graphite. J. Phys. D Appl. Phys. 1981, 14, 747–762. [Google Scholar] [CrossRef]

- Nair, R.R.; Wu, H.A.; Jayaram, P.N.; Grigorieva, I.V.; Geim, A.K. Unimpeded Permeation of Water through Helium-Leak–Tight Graphene-Based Membranes. Science 2012, 335, 442–444. [Google Scholar] [CrossRef] [PubMed]

- Tocci, G.; Joly, L.; Michaelides, A. Friction of Water on Graphene and Hexagonal Boron Nitride from Ab Initio Methods: Very Different Slippage Despite Very Similar Interface Structures. Nano Lett. 2014, 14, 6872–6877. [Google Scholar] [CrossRef]

- Chen, W.; Foster, A.S.; Alava, M.J.; Laurson, L. Stick-Slip Control in Nanoscale Boundary Lubrication by Surface Wettability. Phys. Rev. Lett. 2015, 114, 095502. [Google Scholar] [CrossRef]

- Lin, H.; Rauf, A.; Severin, N.; Sokolov, I.M.; Rabe, J.P. Influence of interface hydration on sliding of graphene and molybdenum-disulfide single-layers. J. Colloid Interface Sci. 2019, 540, 142–147. [Google Scholar] [CrossRef]

- Lee, H.; Ko, J.-H.; Choi, J.S.; Hwang, J.H.; Kim, Y.-H.; Salmeron, M.; Park, J.Y. Enhancement of Friction by Water Intercalated between Graphene and Mica. J. Phys. Chem. Lett. 2017, 8, 3482–3487. [Google Scholar] [CrossRef]

- Xu, K.; Cao, P.; Heath, J.R. Graphene Visualizes the First Water Adlayers on Mica at Ambient Conditions. Science 2010, 329, 1188–1191. [Google Scholar] [CrossRef]

- Severin, N.; Lange, P.; Sokolov, I.M.; Rabe, J.P. Reversible Dewetting of a Molecularly Thin Fluid Water Film in a Soft Graphene–Mica Slit Pore. Nano Lett. 2012, 12, 774–779. [Google Scholar] [CrossRef]

- Li, Q.; Song, J.; Besenbacher, F.; Dong, M. Two-Dimensional Material Confined Water. Acc. Chem. Res. 2015, 48, 119–127. [Google Scholar] [CrossRef]

- Lee, M.J.; Choi, J.S.; Kim, J.-S.; Byun, I.-S.; Lee, D.H.; Ryu, S.; Lee, C.; Park, B.H. Characteristics and effects of diffused water between graphene and a SiO2 substrate. Nano Res. 2012, 5, 710–717. [Google Scholar] [CrossRef]

- Dou, X.; Koltonow, A.R.; He, X.; Jang, H.D.; Wang, Q.; Chung, Y.-W.; Huang, J. Self-dispersed crumpled graphene balls in oil for friction and wear reduction. Proc. Natl. Acad. Sci. USA 2016, 113, 1528–1533. [Google Scholar] [CrossRef]

- Mutyala, K.C.; Wu, Y.A.; Erdemir, A.; Sumant, A.V. Graphene—MoS2 ensembles to reduce friction and wear in DLC-Steel contacts. Carbon 2019, 146, 524–527. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen. Carbon 2013, 59, 167–175. [Google Scholar] [CrossRef]

- Qi, W.; Huang, P.; Chen, X.; Jin, J.; Luo, J. Achieving controllable friction of ultrafine-grained graphite HPG510 by tailoring the interfacial nanostructures. Appl. Surf. Sci. 2020, 512, 145731. [Google Scholar] [CrossRef]

- Han, J.-S.; Choi, J.-Y.; Yoo, M.; Lee, C.-S. Synthesis, Dispersion, and Tribological Performance of Alkyl-functionalized Graphene Oxide as an Oil Lubricant Additive and Synergistic Interaction with IF-WS2. Bull. Korean Chem. Soc. 2020, 41, 518–529. [Google Scholar] [CrossRef]

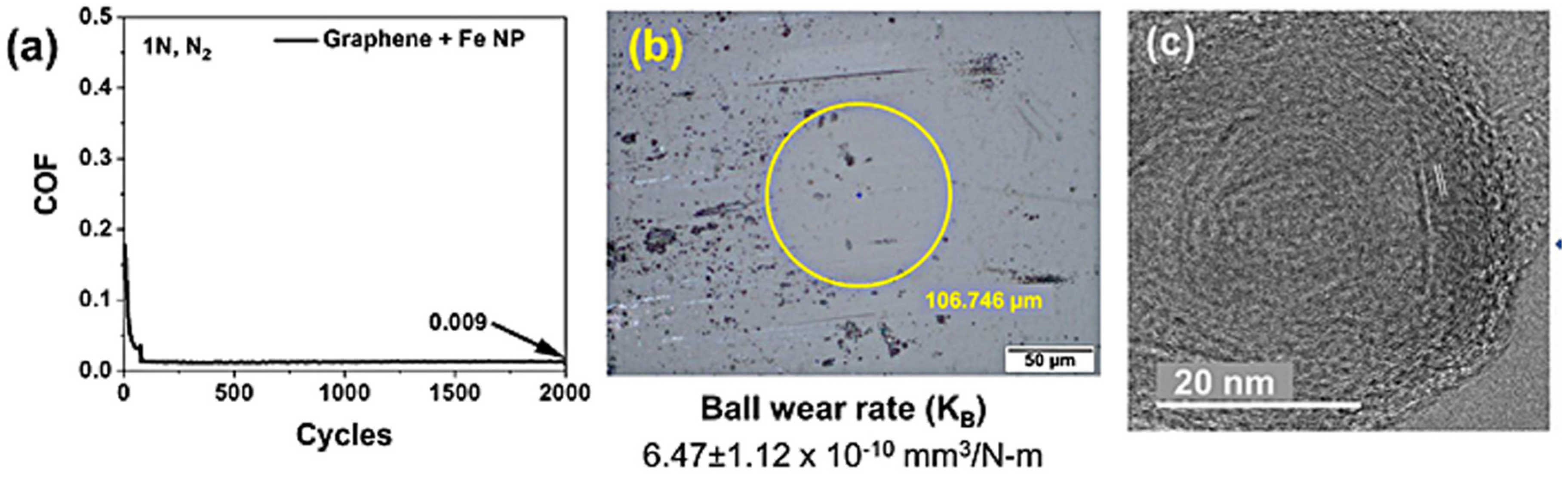

- Berman, D.; Mutyala, K.C.; Srinivasan, S.; Sankaranarayanan, S.K.R.S.; Erdemir, A.; Shevchenko, E.V.; Sumant, A.V. Iron-Nanoparticle Driven Tribochemistry Leading to Superlubric Sliding Interfaces. Adv. Mater. Interfaces 2019, 6, 1901416. [Google Scholar] [CrossRef]

- Uzoma, P.C.; Liu, F.; Xu, L.; Zhang, Z.; Han, E.-H.; Ke, W.; Arukalam, I.O. Superhydrophobicity, conductivity and anticorrosion of robust siloxane-acrylic coatings modified with graphene nanosheets. Prog. Org. Coat. 2019, 127, 239–251. [Google Scholar] [CrossRef]

- Ge, X.; Li, J.; Wang, H.; Zhang, C.; Liu, Y.; Luo, J. Macroscale superlubricity under extreme pressure enabled by the combination of graphene-oxide nanosheets with ionic liquid. Carbon 2019, 151, 76–83. [Google Scholar] [CrossRef]

- Dev Srivyas, P.; Charoo, M.S. Tribological characterization of hybrid aluminum composite under boundary lubricating sliding conditions. Mater. Today: Proc. 2020, 26, 492–500. [Google Scholar] [CrossRef]

- Mohseni Taromsari, S.; Salari, M.; Bagheri, R.; Faghihi Sani, M.A. Optimizing tribological, tensile & in-vitro biofunctional properties of UHMWPE based nanocomposites with simultaneous incorporation of graphene nanoplatelets (GNP) & hydroxyapatite (HAp) via a facile approach for biomedical applications. Compos. Part B Eng. 2019, 175, 107181. [Google Scholar]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Tai, Z.; Chen, Y.; An, Y.; Yan, X.; Xue, Q. Tribological Behavior of UHMWPE Reinforced with Graphene Oxide Nanosheets. Tribol. Lett. 2012, 46, 55–63. [Google Scholar] [CrossRef]

- Das, B.; Eswar Prasad, K.; Ramamurty, U.; Rao, C.N.R. Nano-indentation studies on polymer matrix composites reinforced by few-layer graphene. Nanotechnology 2009, 20, 125705. [Google Scholar] [CrossRef]

- Castellanos-Gomez, A.; Poot, M.; Steele, G.A.; van der Zant, H.S.J.; Agraït, N.; Rubio-Bollinger, G. Elastic Properties of Freely Suspended MoS2 Nanosheets. Adv. Mater. 2012, 24, 772–775. [Google Scholar] [CrossRef]

- Bertolazzi, S.; Brivio, J.; Kis, A. Stretching and Breaking of Ultrathin MoS2. ACS Nano 2011, 5, 9703–9709. [Google Scholar] [CrossRef]

- Serpini, E.; Rota, A.; Valeri, S.; Ukraintsev, E.; Rezek, B.; Polcar, T.; Nicolini, P. Nanoscale frictional properties of ordered and disordered MoS2. Tribol. Int. 2019, 136, 67–74. [Google Scholar] [CrossRef]

- Bui, H.S. Influence of Different Environement on the Tribological Behavior of Molybdenum Disulfide MoS2. Int. J. Innov. Sci. Res. Technol. 2020, 5, 478–481. [Google Scholar]

- Clauss, F.J. Chapter 4—Molybdenum Disulfide. In Solid Lubricants and Self-Lubricating Solids; Clauss, F.J., Ed.; Academic Press: Cambridge, MA, USA, 1972; pp. 75–112. [Google Scholar]

- Cao, X.A.; Gan, X.; Lang, H.; Yu, K.; Ding, S.; Peng, Y.; Yi, W. Anisotropic nanofriction on MoS2 with different thicknesses. Tribol. Int. 2019, 134, 308–316. [Google Scholar] [CrossRef]

- Chhowalla, M.; Shin, H.S.; Eda, G.; Li, L.-J.; Loh, K.P.; Zhang, H. The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat. Chem. 2013, 5, 263–275. [Google Scholar] [CrossRef] [PubMed]

- Acikgoz, O.; Baykara, M.Z. Speed dependence of friction on single-layer and bulk MoS2 measured by atomic force microscopy. Appl. Phys. Lett. 2020, 116, 071603. [Google Scholar] [CrossRef]

- Wu, P.-R.; Li, W.; Ge, T.; Feng, Y.-M.; Liu, Z.; Cheng, Z.-L. Preparation and tribological properties of chemically decorated MoS2 nanosheets with oleic diethanolamide. Lubr. Sci. 2019, 31, 41–50. [Google Scholar]

- Li, Y.; Xie, M.; Sun, Q.; Xu, X.; Fan, X.; Zhang, G.; Li, H.; Zhu, M. The effect of atmosphere on the tribological behavior of magnetron sputtered MoS2 coatings. Surf. Coat. Technol. 2019, 378, 125081. [Google Scholar] [CrossRef]

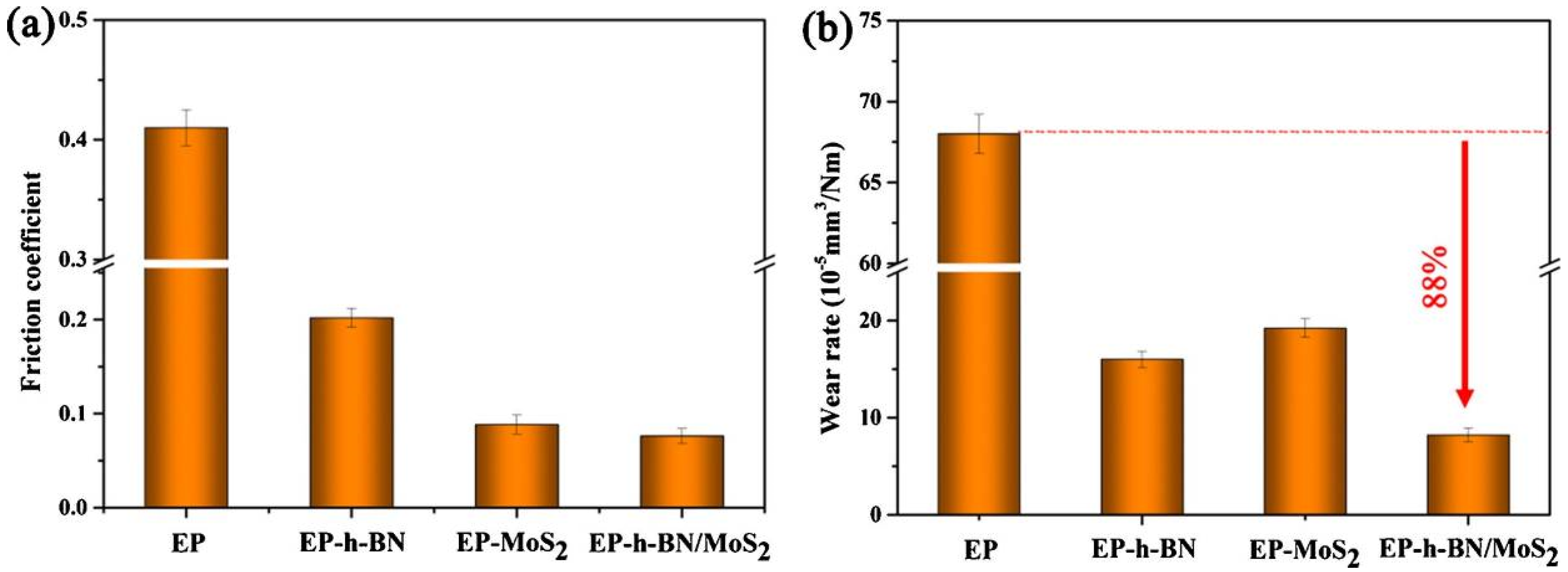

- Chen, B.; Zhang, M.; Li, X.; Dong, Z.; Jia, Y.; Li, C. Tribological properties of epoxy-based self-lubricating composite coating enhanced by 2D/2D h-BN/ MoS2 hybrid. Prog. Org. Coat. 2020, 147, 105767. [Google Scholar] [CrossRef]

- Yu, G.; Gong, Z.; Jiang, B.; Wang, D.; Bai, C.; Zhang, J. Superlubricity for hydrogenated diamond like carbon induced by thin MoS2 and DLC layer in moist air. Diam. Relat. Mater. 2020, 102, 107668. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, Y.; Yang, G.; Yang, K.; Zhang, S.; Yu, L.; Zhang, P. Tribological Properties of Oleylamine-Modified Ultrathin WS2 Nanosheets as the Additive in Polyalpha Olefin Over a Wide Temperature Range. Tribol. Lett. 2016, 61, 24. [Google Scholar] [CrossRef]

- Evaristo, M.; Fernandes, F.; Cavaleiro, A. Room and High Temperature Tribological Behaviour of W-DLC Coatings Produced by DCMS and Hybrid DCMS-HiPIMS Configuration. Coatings 2020, 10, 319. [Google Scholar] [CrossRef]

- Aldana, P.U.; Vacher, B.; Le Mogne, T.; Belin, M.; Thiebaut, B.; Dassenoy, F. Action Mechanism of WS2 Nanoparticles with ZDDP Additive in Boundary Lubrication Regime. Tribol. Lett. 2014, 56, 249–258. [Google Scholar] [CrossRef]

- An, V.; Irtegov, Y.; de Izarra, C. Study of Tribological Properties of Nanolamellar WS2 and MoS2 as Additives to Lubricants. J. Nanomater. 2014, 2014, 1–8. [Google Scholar]

- Ma, L.; Liu, Z.; Cheng, Z.-L. Scalable exfoliation and friction performance of few-layered WS2 nanosheets by microwave-assisted liquid-phase sonication. Ceram. Int. 2020, 46, 3786–3792. [Google Scholar] [CrossRef]

- Hu, N.; Zhang, X.; Wang, X.; Wu, N.; Wang, S. Study on Tribological Properties and Mechanisms of Different Morphology WS2 as Lubricant Additives. Materials 2020, 13, 1522. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Sun, J.; Weng, L.; Hua, Y.; Liu, W.; Neville, A.; Hu, M.; Gao, X. In-situ friction and wear responses of WS2 films to space environment: Vacuum and atomic oxygen. Appl. Surf. Sci. 2018, 447, 368–373. [Google Scholar] [CrossRef]

- Fu, Y.; Jiang, D.; Wang, D.; Gao, X.; Hu, M.; Yang, W. Tribological Performance of MoS2- WS2 Composite Film under the Atomic Oxygen Irradiation Conditions. Materials 2020, 13, 1407. [Google Scholar] [CrossRef]

- Gao, X.; Fu, Y.; Jiang, D.; Wang, D.; Xu, S.; Liu, W.; Weng, L.; Yang, J.; Sun, J.; Hu, M. Constructing WS2/MoS2 nano-scale multilayer film and understanding its positive response to space environment. Surf. Coat. Technol. 2018, 353, 8–17. [Google Scholar] [CrossRef]

- He, X.; Xiao, H.; Choi, H.; Díaz, A.; Mosby, B.; Clearfield, A.; Liang, H. α-Zirconium phosphate nanoplatelets as lubricant additives. Colloids Surf. A Physicochem. Eng. Asp. 2014, 452, 32–38. [Google Scholar] [CrossRef]

- Bondarev, A.V.; Kovalskii, A.M.; Firestein, K.L.; Loginov, P.A.; Sidorenko, D.A.; Shvindina, N.V.; Sukhorukova, I.V.; Shtansky, D.V. Hollow spherical and nanosheet-base BN nanoparticles as perspective additives to oil lubricants: Correlation between large-scale friction behavior and in situ TEM compression testing. Ceram. Int. 2018, 44, 6801–6809. [Google Scholar] [CrossRef]

- Ma, Z.-S.; Ding, H.-L.; Liu, Z.; Cheng, Z.-L. Preparation and tribological properties of hydrothermally exfoliated ultrathin hexagonal boron nitride nanosheets (BNNSs) in mixed NaOH/KOH solution. J. Alloy. Compd. 2019, 784, 807–815. [Google Scholar] [CrossRef]

- Sagbas, B. Tribological performance of PEEK with green lubricant enhanced by nano hexagonal boron nitride powder. Ind. Lubr. Tribol. 2020, 72, 203–210. [Google Scholar] [CrossRef]

- Song, J.; Dai, Z.D.; Li, J.Y.; Tong, X.; Zhao, H.C. Polydopamine-decorated boron nitride as nano-reinforcing fillers for epoxy resin with enhanced thermomechanical and tribological properties. Mater. Res. Express 2018, 5, 075029. [Google Scholar] [CrossRef]

- Bondarev, A.V.; Fraile, A.; Polcar, T.; Shtansky, D.V. Mechanisms of friction and wear reduction by h-BN nanosheet and spherical W nanoparticle additives to base oil: Experimental study and molecular dynamics simulation. Tribol. Int. 2020, 151, 106493. [Google Scholar] [CrossRef]

- Wang, W.; Xie, G.; Luo, J. Superlubricity of Black Phosphorus as Lubricant Additive. ACS Appl. Mater. Interfaces 2018, 10, 43203–43210. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Huang, P.; Guo, D.; Xie, G. Anisotropic Mechanical Properties of Black Phosphorus Nanoribbons. J. Phys. Chem. C 2016, 120, 29491–29497. [Google Scholar] [CrossRef]

- Zhou, Q.; Chen, Q.; Tong, Y.; Wang, J. Light-Induced Ambient Degradation of Few-Layer Black Phosphorus: Mechanism and Protection. Angew. Chem. Int. Ed. 2016, 55, 11437–11441. [Google Scholar] [CrossRef]

- Wu, S.; He, F.; Xie, G.; Bian, Z.; Luo, J.; Wen, S. Black Phosphorus: Degradation Favors Lubrication. Nano Lett. 2018, 18, 5618–5627. [Google Scholar] [CrossRef] [PubMed]

- Cui, Z.; Xie, G.; He, F.; Wang, W.; Guo, D.; Wang, W. Atomic-Scale Friction of Black Phosphorus: Effect of Thickness and Anisotropic Behavior. Adv. Mater. Interfaces 2017, 4, 1700998. [Google Scholar] [CrossRef]

- Bai, L.; Liu, B.; Srikanth, N.; Tian, Y.; Zhou, K. Nano-friction behavior of phosphorene. Nanotechnology 2017, 28, 355704. [Google Scholar] [CrossRef]

- Lee, H.G.; Yoon, H.M.; Lee, J.S. Anisotropic nanoscale and sub-nanoscale friction behaviors between phosphorene and silicon tip. Appl. Surf. Sci. 2019, 481, 1573–1584. [Google Scholar] [CrossRef]

- Sha, Z.-D.; Pei, Q.-X.; Ding, Z.; Jiang, J.-W.; Zhang, Y.-W. Mechanical properties and fracture behavior of single-layer phosphorene at finite temperatures. J. Phys. D Appl. Phys. 2015, 48, 395303. [Google Scholar] [CrossRef]

- Jiang, J.-W.; Park, H.S. Mechanical properties of single-layer black phosphorus. J. Phys. D Appl. Phys. 2014, 47, 385304. [Google Scholar] [CrossRef]

- Losi, G.; Restuccia, P.; Righi, M.C. Superlubricity in phosphorene identified by means of ab initio calculations. 2D Mater. 2020, 7, 025033. [Google Scholar] [CrossRef]

- Ishikawa, Y.; Hiratsuka, K.-I.; Sasada, T. Role of water in the lubrication of hydrogel. Wear 2006, 261, 500–504. [Google Scholar] [CrossRef]

- Han, J.; Sun, J.P.; Xu, S.; Song, D.; Han, Y.; Zhu, H.; Fang, L. Tuning the Friction of Silicon Surfaces Using Nanopatterns at the Nanoscale. Coatings 2018, 8, 7. [Google Scholar] [CrossRef]

- Hu, H.; Shi, B.; Breslin, C.M.; Gignac, L.; Peng, Y. A Sub-Micron Spherical Atomic Force Microscopic Tip for Surface Measurements. Langmuir 2020, 36, 7861–7867. [Google Scholar] [CrossRef]

- Li, X.; Deng, J.; Yue, H.; Ge, D.; Zou, X. Wear performance of electrohydrodynamically atomized WS2 coatings deposited on biomimetic shark-skin textured surfaces. Tribol. Int. 2019, 134, 240–251. [Google Scholar] [CrossRef]

- Li, X.; Deng, J.; Zhang, L.; Liu, Y.; Yue, H.; Duan, R.; Ge, D. Effect of surface textures and electrohydrodynamically atomized WS2 films on the friction and wear properties of ZrO2 coatings. Ceram. Int. 2019, 45, 1020–1030. [Google Scholar] [CrossRef]

- Li, X.; Liu, Q.; Dong, G. Self-assembly membrane on textured surface for enhancing lubricity of graphene oxide nano-additive. Appl. Surf. Sci. 2020, 505, 144572. [Google Scholar] [CrossRef]

- Jia, X.; Wang, C.; Xiong, G.; Zhu, F. Surface micro-texturing design for improving tribological behaviour of graphene oxide thin films. Bull. Mater. Sci. 2019, 42, 236. [Google Scholar] [CrossRef]

- Wang, D.; Hu, M.; Jiang, D.; Gao, X.; Fu, Y.; Sun, J.; Weng, L. Cabbage-like WS2/Ni bilayer thin film for improved tribological property. Surf. Coat. Technol. 2019, 358, 50–56. [Google Scholar] [CrossRef]

- Sekiguchi, K.; Katsumata, K.-I.; Segawa, H.; Nakanishi, T.; Yasumori, A. Fabrication of a Silica–Silica Nanoparticle Monolayer Array Nanocomposite Film on an Anodic Aluminum Oxide Substrate and Its Optical and Tribological Properties. ACS Appl. Mater. Interfaces 2020, 12, 27672–27681. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Deng, J.; Lei, S.; Yu, X. Effect of micro/nano-textures and burnished MoS2 addition on the tribological properties of PVD TiAlN coatings against AISI 316 stainless steel. Surf. Coat. Technol. 2016, 291, 382–395. [Google Scholar] [CrossRef]

- Meng, R.; Deng, J.; Duan, R.; Liu, Y.; Zhang, G. Modifying tribological performances of AISI 316 stainless steel surfaces by laser surface texturing and various solid lubricants. Opt. Laser Technol. 2019, 109, 401–411. [Google Scholar] [CrossRef]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Cannon, A.H.; King, W.P. Casting metal microstructures from a flexible and reusable mold. J. Micromech. Microeng. 2009, 19, 095016. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, Q.Z.; Wang, C.W.; Zhang, Y. Modulation of dry tribological property of stainless steel by femtosecond laser surface texturing. Appl. Phys. A-Mater. 2015, 119, 1155–1163. [Google Scholar] [CrossRef]

- Yilbas, B.S. Laser treatment of zirconia surface for improved surface hydrophobicity. J. Alloy. Compd. 2015, 625, 208–215. [Google Scholar] [CrossRef]

- Wahab, J.A.; Ghazali, M.J.; Sajuri, Z.; Otsuka, Y.; Jayaprakash, M.; Nakamura, S.; Baharin, A.F.S. Effects of micro-grooves on tribological behaviour of plasma-sprayed alumina-13%titania coatings. Ceram. Int. 2017, 43, 6410–6416. [Google Scholar] [CrossRef]

- Xing, Y.Q.; Deng, J.X.; Wu, Z.; Cheng, H.W. Effect of regular surface textures generated by laser on tribological behavior of Si3N4/TiC ceramic. Appl. Surf. Sci. 2013, 265, 823–832. [Google Scholar] [CrossRef]

- Ramesh, A.; Akram, W.; Mishra, S.P.; Cannon, A.H.; Polycarpou, A.A.; King, W.P. Friction characteristics of microtextured surfaces under mixed and hydrodynamic lubrication. Tribol. Int. 2013, 57, 170–176. [Google Scholar] [CrossRef]

- Song, H.-J.; Jia, X.-H.; Li, N.; Yang, X.-F.; Tang, H. Synthesis of α-Fe2O3 nanorod/graphene oxide composites and their tribological properties. J. Mater. Chem. 2012, 22, 895–902. [Google Scholar] [CrossRef]

- Zhou, Q.; Huang, J.; Wang, J.; Yang, Z.; Liu, S.; Wang, Z.; Yang, S. Preparation of a reduced graphene oxide/zirconia nanocomposite and its application as a novel lubricant oil additive. RSC Adv. 2015, 5, 91802–91812. [Google Scholar] [CrossRef]

- Meng, Y.; Su, F.; Chen, Y. A Novel Nanomaterial of Graphene Oxide Dotted with Ni Nanoparticles Produced by Supercritical CO2-Assisted Deposition for Reducing Friction and Wear. ACS Appl. Mater. Interfaces 2015, 7, 11604–11612. [Google Scholar] [CrossRef] [PubMed]

- Mungse, H.P.; Khatri, O.P. Chemically Functionalized Reduced Graphene Oxide as a Novel Material for Reduction of Friction and Wear. J. Phys. Chem. C 2014, 118, 14394–14402. [Google Scholar] [CrossRef]

- Zhang, W.; Zhou, M.; Zhu, H.; Tian, Y.; Wang, K.; Wei, J.; Ji, F.; Li, X.; Li, Z.; Zhang, P.; et al. Tribological properties of oleic acid-modified graphene as lubricant oil additives. J. Phys. D Appl. Phys. 2011, 44, 205303. [Google Scholar] [CrossRef]

- Liang, S.; Shen, Z.; Yi, M.; Liu, L.; Zhang, X.; Ma, S. In-situ exfoliated graphene for high-performance water-based lubricants. Carbon 2016, 96, 1181–1190. [Google Scholar] [CrossRef]

- Uddin, M.E.; Kuila, T.; Nayak, G.C.; Kim, N.H.; Ku, B.-C.; Lee, J.H. Effects of various surfactants on the dispersion stability and electrical conductivity of surface modified graphene. J. Alloy. Compd. 2013, 562, 134–142. [Google Scholar] [CrossRef]

- Lu, S.; Qi, X.; Hu, Y.; Li, B.; Zhang, J. Deployment Dynamics of Large Space Antenna and Supporting Arms. IEEE Access 2019, 7, 69922–69935. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uzoma, P.C.; Hu, H.; Khadem, M.; Penkov, O.V. Tribology of 2D Nanomaterials: A Review. Coatings 2020, 10, 897. https://doi.org/10.3390/coatings10090897

Uzoma PC, Hu H, Khadem M, Penkov OV. Tribology of 2D Nanomaterials: A Review. Coatings. 2020; 10(9):897. https://doi.org/10.3390/coatings10090897

Chicago/Turabian StyleUzoma, Paul C., Huan Hu, Mahdi Khadem, and Oleksiy V. Penkov. 2020. "Tribology of 2D Nanomaterials: A Review" Coatings 10, no. 9: 897. https://doi.org/10.3390/coatings10090897

APA StyleUzoma, P. C., Hu, H., Khadem, M., & Penkov, O. V. (2020). Tribology of 2D Nanomaterials: A Review. Coatings, 10(9), 897. https://doi.org/10.3390/coatings10090897