Micro and Macro-Tribology Behavior of a Hierarchical Architecture of a Multilayer TaN/Ta Hard Coating

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

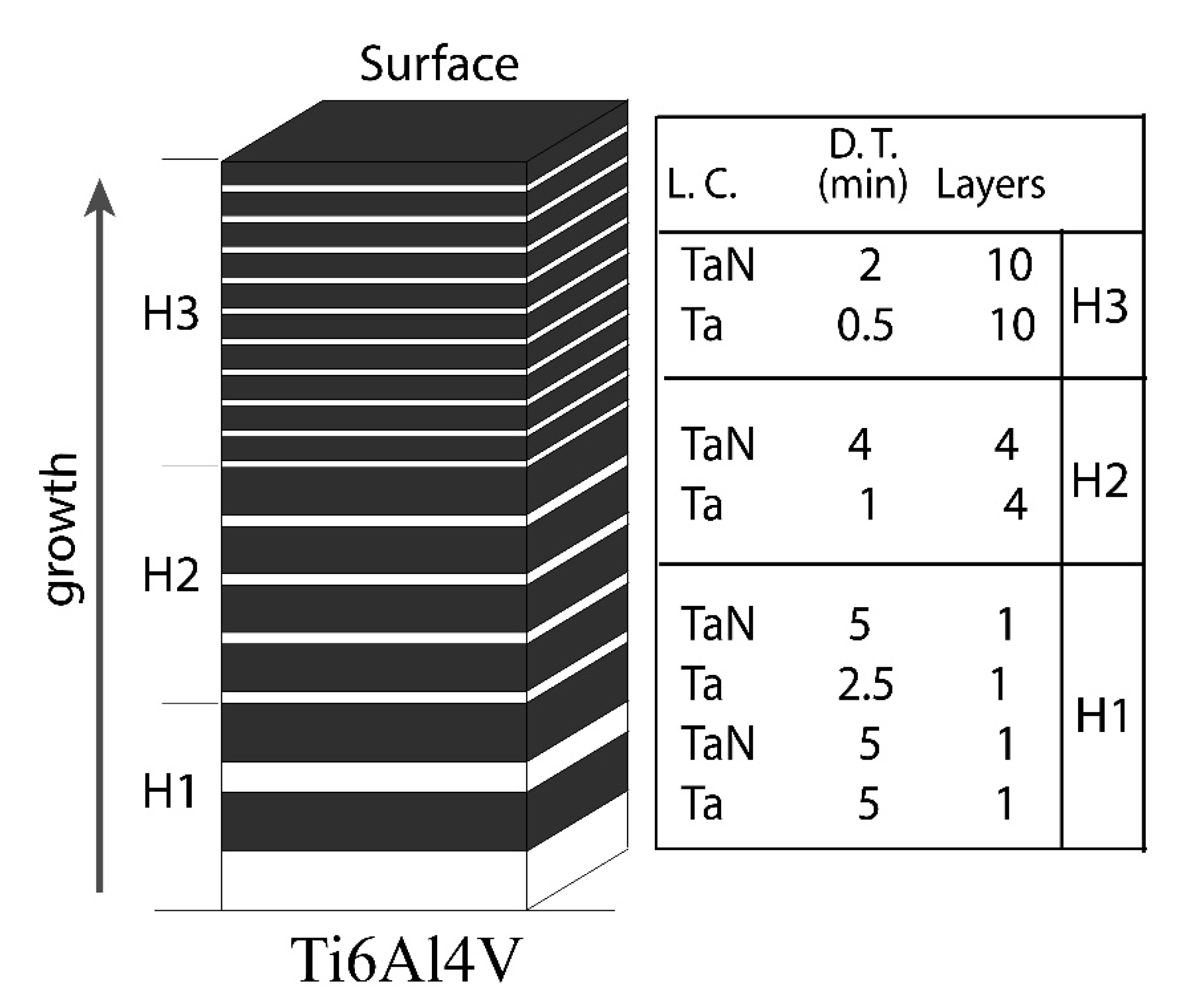

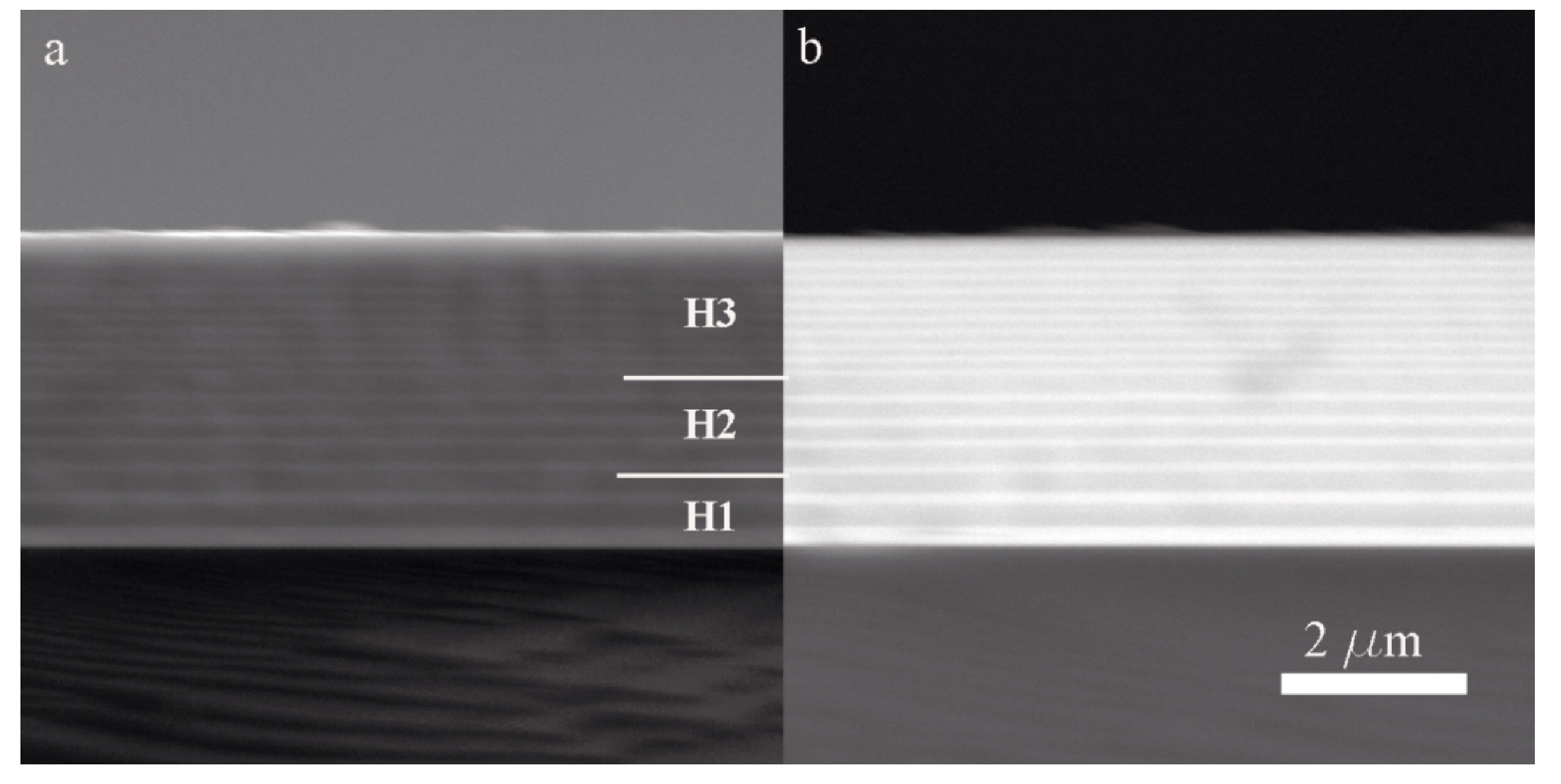

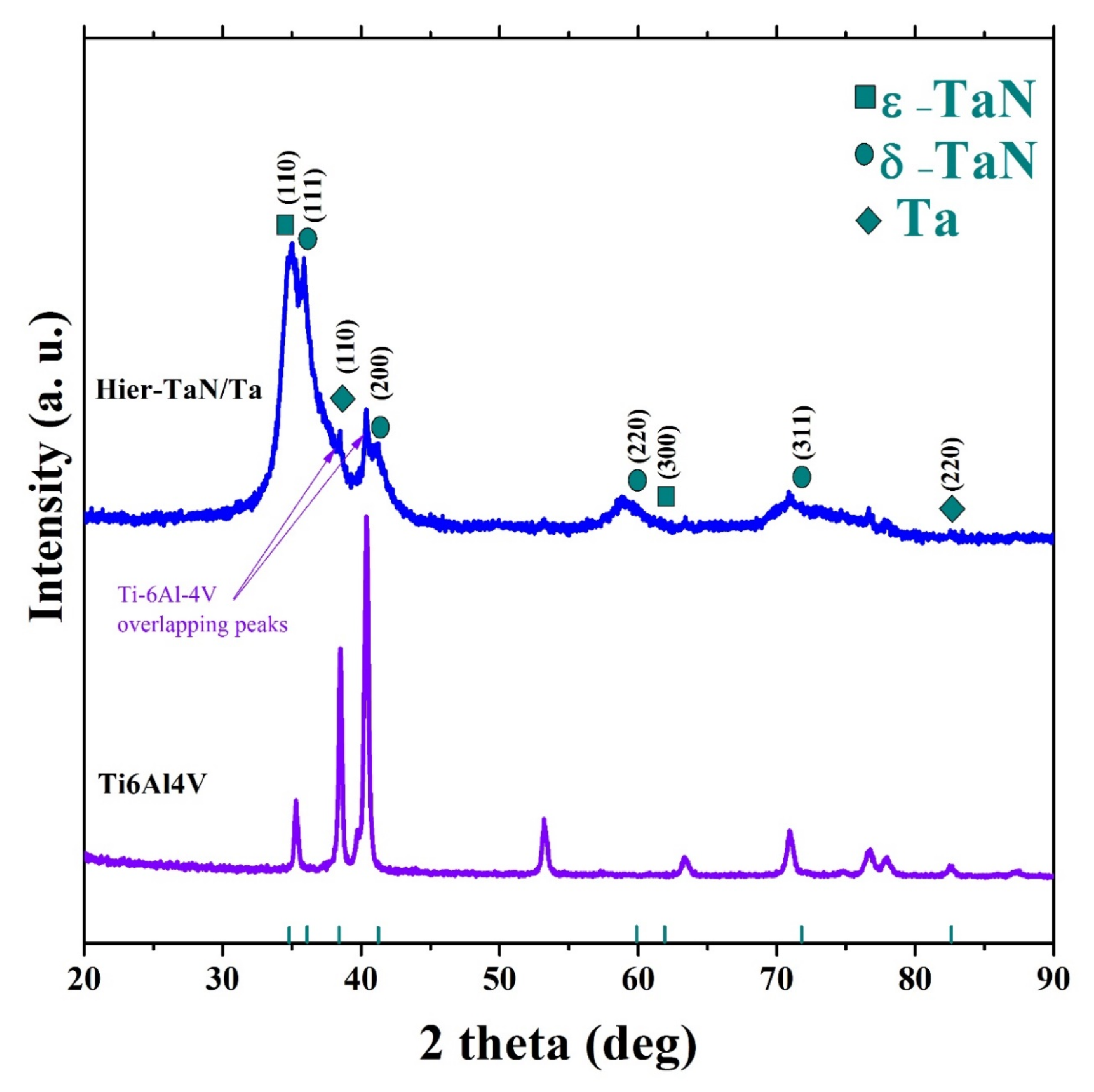

3.1. Morphological, Structural, and Mechanical Characterization

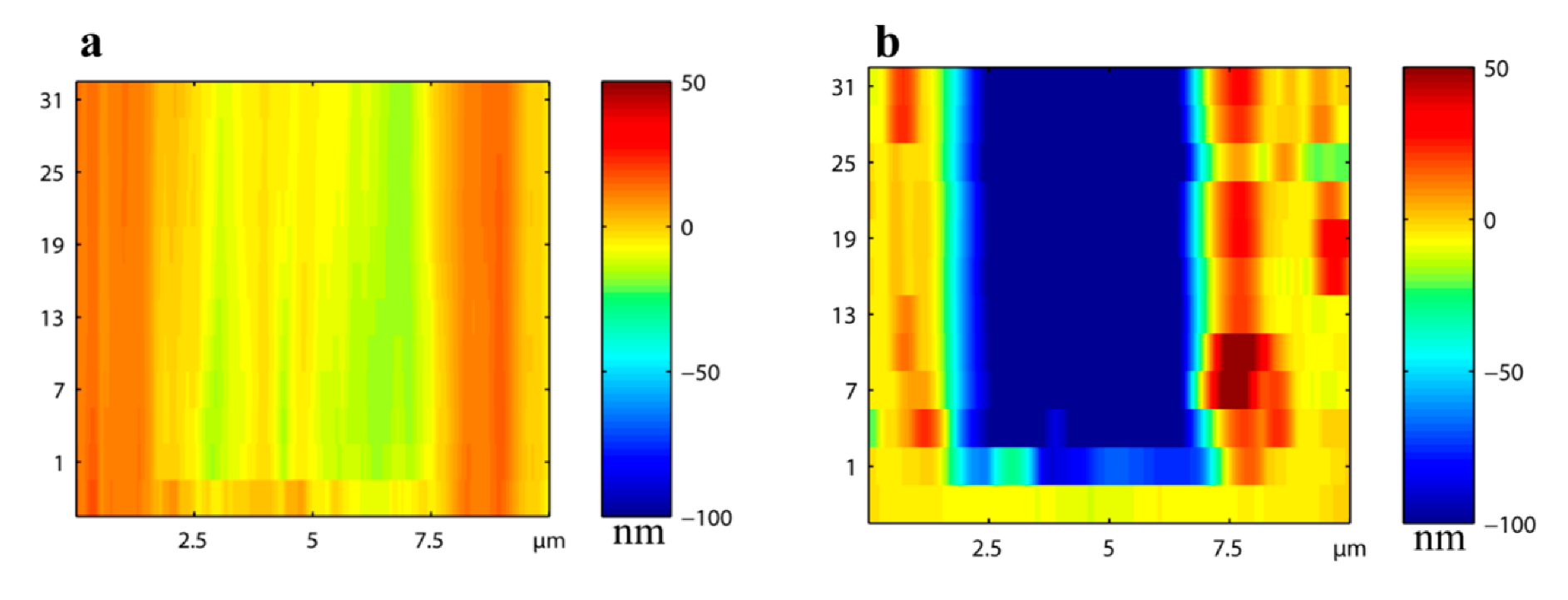

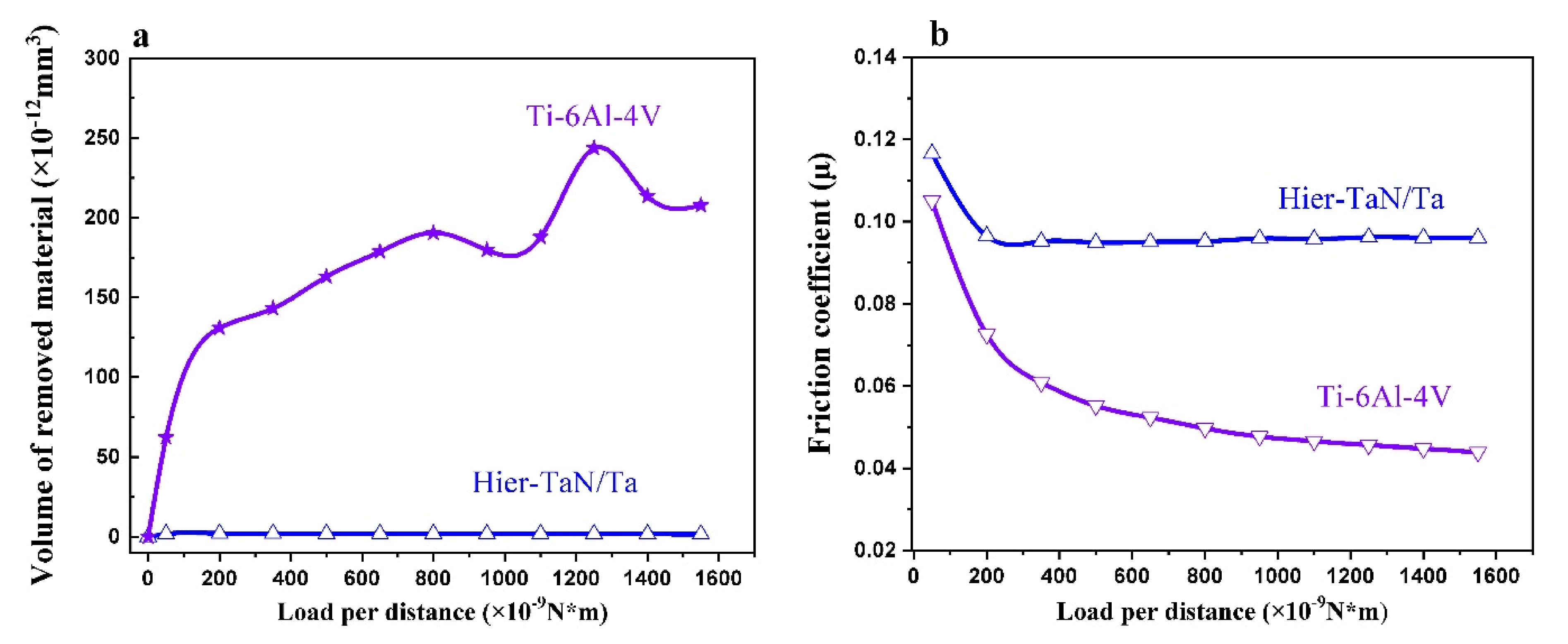

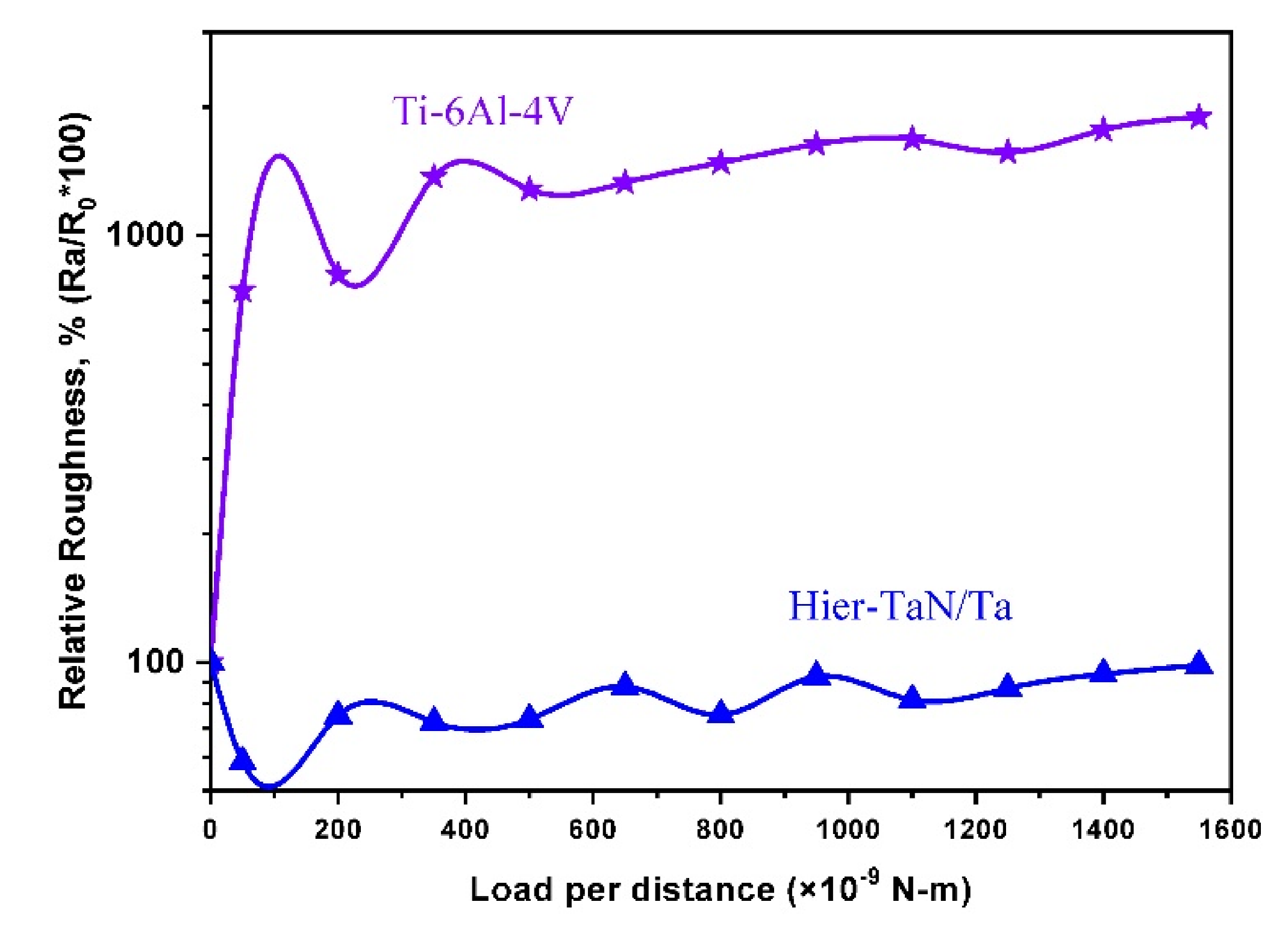

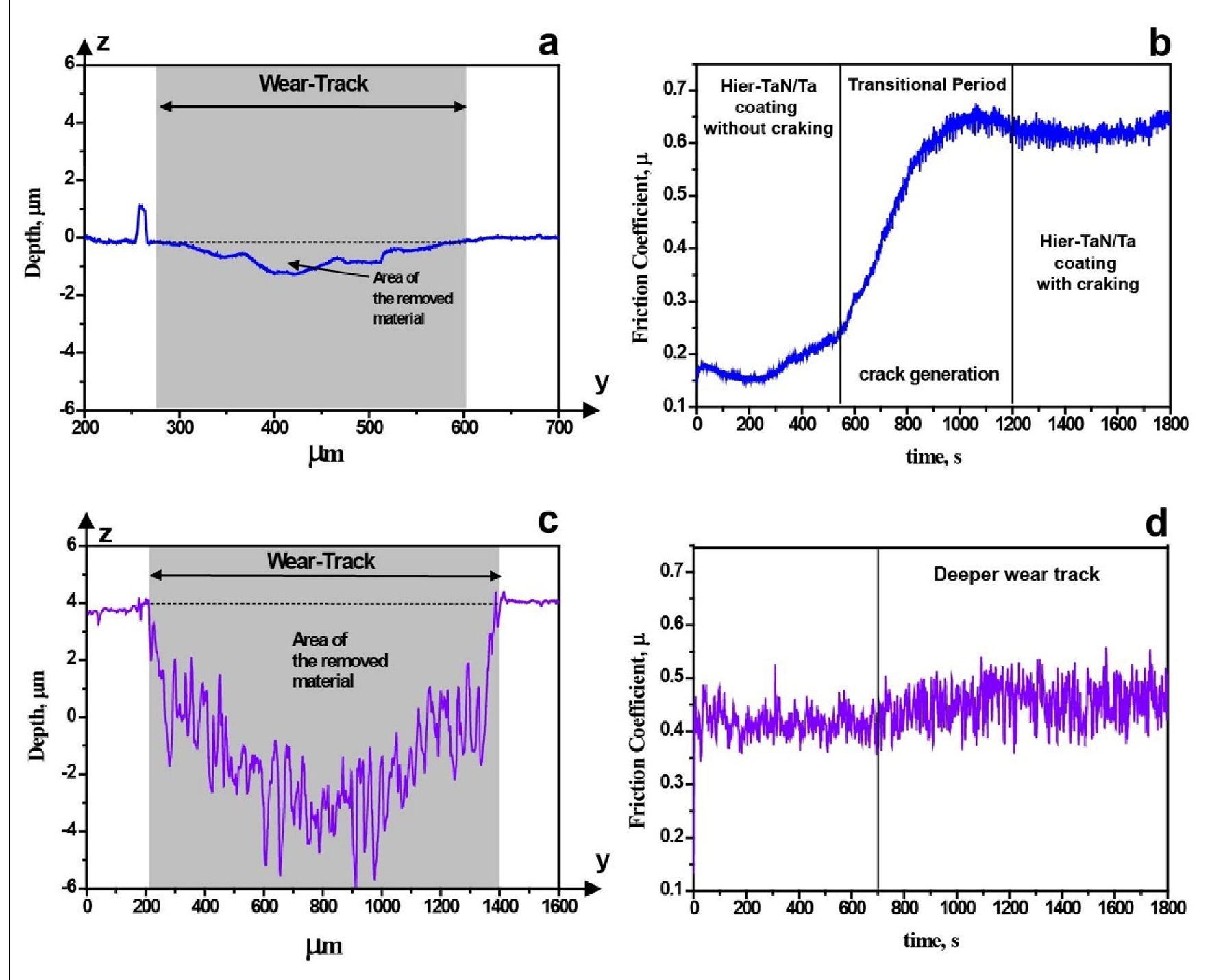

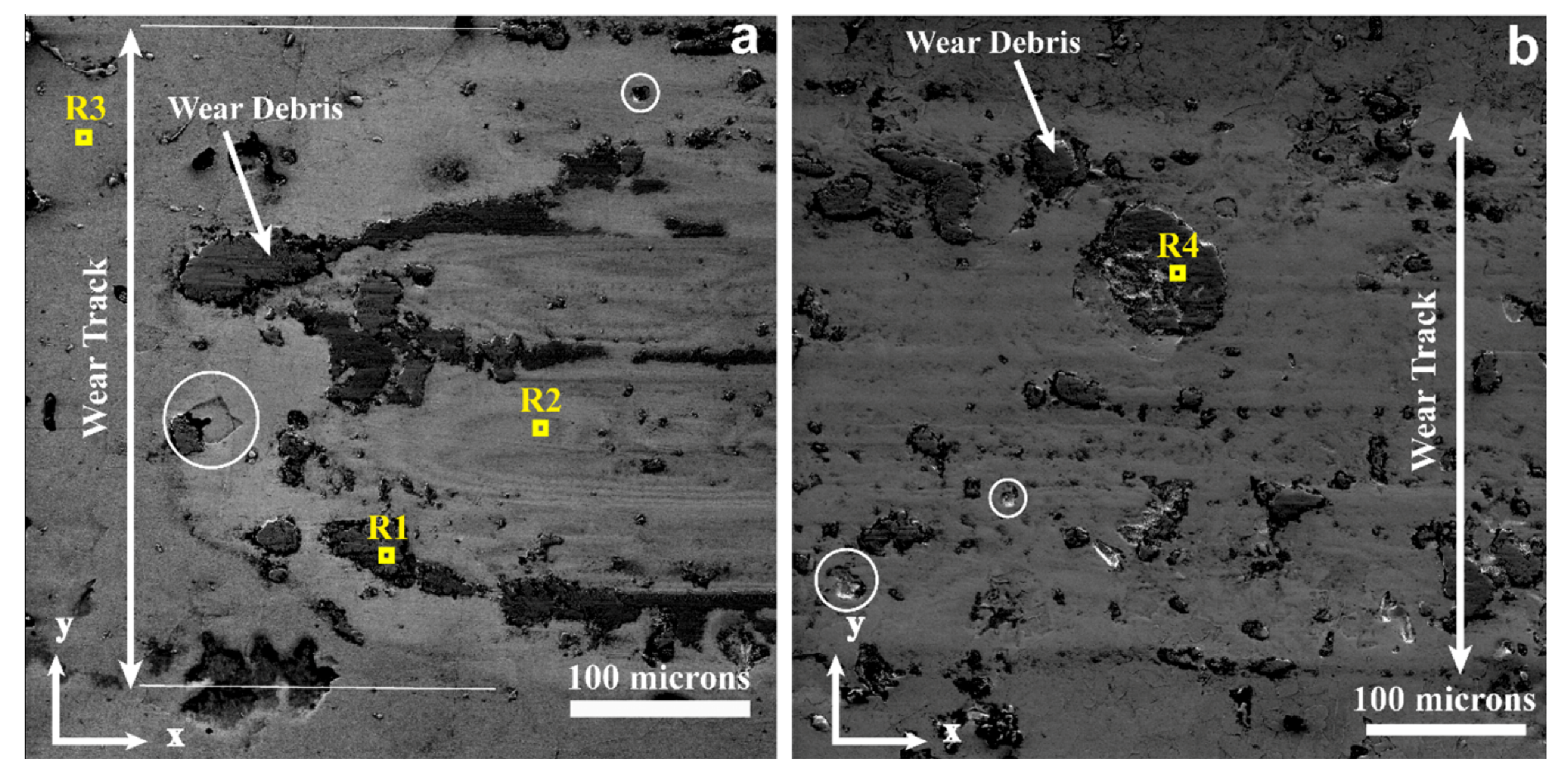

3.2. Micro and Macro-Tribological Behavior

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kang, Y.; Lee, C.; Lee, J. Effects of processing variables on the mechanical properties of Ta/TaN multilayer coatings. Mater. Sci. Eng. B 2000, 75, 17–23. [Google Scholar] [CrossRef]

- Burke, G.L. the Corrosion of Metals in Tissues; and an Introduction To Tantalum. Can. Med. Assoc. J. 1940, 43, 125–128. [Google Scholar] [PubMed]

- Gladczuk, L.; Patel, A.; Singh Paur, C.; Sosnowski, M. Tantalum films for protective coatings of steel. Thin Solid Films 2004, 467, 150–157. [Google Scholar] [CrossRef]

- Westergård, R.; Bromark, M.; Larsson, M.; Hedenqvist, P.; Hogmark, S. Mechanical and tribological characterization of DC magnetron sputtered tantalum nitride thin films. Surf. Coat. Technol. 1997, 97, 779–784. [Google Scholar] [CrossRef]

- Bahr, H.-A.; Balke, H.; Fett, T.; Hofinger, I.; Kirchhoff, G.; Munz, D.; Neubrand, A.; Semenov, A.; Weiss, H.-J.; Yang, Y. Cracks in functionally graded materials. Mater. Sci. Eng. A 2003, 362, 2–16. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, M.-J.; Zhang, D. Designing functionally graded materials with superior load-bearing properties. Acta Biomater. 2012, 8, 1101–1108. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Yamamoto, K.; DBeake, B.S.; Gershman, I.; IKovalev, A.C.; Veldhuis, S.H.; Aguirre, M.; Dosbaeva, G.L.; Endrino, J. Hierarchical adaptive nanostructured PVD coatings for extreme tribological applications: The quest for nonequilibrium states and emergent behavior. Sci. Technol. Adv. Mater. 2012, 13, 043001. [Google Scholar] [CrossRef]

- Erdemir, A.; Donnet, C. Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. D Appl. Phys. 2006, 39, 311–327. [Google Scholar] [CrossRef]

- Schmidt, D.F. Nanolaminates—Bioinspired and beyond. Mater. Lett. 2013, 108, 328–335. [Google Scholar] [CrossRef]

- Rivera-Tello, C.D.; Broitman, E.; Flores-Ruiz, F.J.; Jiménez, O.; Flores, M. Mechanical Properties and Tribological Behavior at Micro and Macro-Scale of WC/WCN/W Hierarchical Multilayer Coatings. Tribol. Int. 2016, 101, 194–203. [Google Scholar] [CrossRef]

- Maksakova, O.; Simoẽs, S.; Pogrebnjak, A.; Bondar, O.; Kravchenko, Y.; Beresnev, V.; Erdybaeva, N. The influence of deposition conditions and bilayer thickness on physical-mechanical properties of CA-PVD multilayer ZrN/CrN coatings. Mater. Charact. 2018, 140, 189–196. [Google Scholar] [CrossRef]

- Yousaf, M.I.; Pelenovich, V.O.; Yang, B.; Liu, C.S.; Fu, D.J. Effect of bilayer period on structural and mechanical properties of nanocomposite TiAlN/MoN multilayer films synthesized by cathodic arc ion-plating. Surf. Coat. Technol. 2015, 282, 94–102. [Google Scholar] [CrossRef]

- Flores, M.; Muhl, S.; Huerta, L.; Andrade, E. The influence of the period size on the corrosion and the wear abrasion resistance of TiN/Ti multilayers. Surf. Coat. Technol. 2005, 200, 1315–1319. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, L.; Karlsson, A.M. Mechanics-based analysis of selected features of the exoskeletal microstructure of Popillia japonica. J. Mater. Res. 2011, 24, 3253–3267. [Google Scholar] [CrossRef]

- Alemón, B.; Flores, M.; Ramírez, W.; Huegel, J.C.; Broitman, E. Tribocorrosion behavior and ions release of CoCrMo alloy coated with a TiAlVCN/CNx multilayer in simulated body fluid plus bovine serum albumin. Tribol. Int. 2015, 81, 159–168. [Google Scholar] [CrossRef]

- Mischler, S.; Muñoz, A.I. Wear of CoCrMo alloys used in metal-on-metal hip joints: A tribocorrosion appraisal. Wear 2013, 297, 1081–1094. [Google Scholar] [CrossRef]

- Fedrizzi, L.; Rossi, S.; Bellei, F.; Deflorian, F. Wear–corrosion mechanism of hard chromium coatings. Wear 2002, 253, 1173–1181. [Google Scholar] [CrossRef]

- An, K.; Ravichandran, K.S.; Dutton, R.E.; Semiatin, S.L. Microstructure, Texture, and Thermal Conductivity of Single-Layer and Multilayer TBC by PVD. J. Am. Ceram. Soc. 1999, 82, 399. [Google Scholar] [CrossRef]

- Khajezadeh, M.H.; Mohammadi, M.; Ghatee, M. Hot corrosion performance and electrochemical study of CoNiCrAlY/YSZ/YSZ-La2O3 multilayer thermal barrier coatings in the presence of molten salt. Mater. Chem. Phys. 2018, 220, 23–34. [Google Scholar] [CrossRef]

- Srivastava, A.; Joshi, V.; Shivpuri, R.; Bhattacharya, R.R.; Dixit, S. A multilayer coating architecture to reduce heat checking of die surfaces. Surf. Coat. Technol. 2003, 163–164, 631–636. [Google Scholar] [CrossRef]

- Culebras, M.; Igual-Muñoz, A.M.; Rodríguez-Fernández, C.; Gómez-Gómez, M.I.; Gómez, C.; Cantarero, A. Manufacturing Te/PEDOT Films for Thermoelectric Applications. ACS Appl. Mater. Interfaces 2017, 9, 20826–20832. [Google Scholar] [CrossRef] [PubMed]

- Culebras, M.; Cho, C.; Krecker, M.; Smith, R.; Song, Y.; Gómez, C.M.; Cantarero, A.; Grunlan, J.C. High Thermoelectric Power Factor Organic Thin Films through Combination of Nanotube Multilayer Assembly and Electrochemical Polymerization. ACS Appl. Mater. Interfaces 2017, 9, 6306–6313. [Google Scholar] [CrossRef] [PubMed]

- Cho, C.; Culebras, M.; Wallace, K.L.; Song, Y.; Holder, K.; Hsu, J.H.; Yu, C.; Grunlan, J.C. Stable n-type thermoelectric multilayer thin films with high power factor from carbonaceous nanofillers. Nano Energy 2016, 28, 426–432. [Google Scholar] [CrossRef]

- Mendizabal, L.; Lopez, A.; Bayón, R.; Herrero-Fernandez, P.; Barriga, J.; Gonzalez, J.J. Tribocorrosion response in biological environments of multilayer TaN films deposited by HPPMS. Surf. Coat. Technol. 2016, 295, 60–69. [Google Scholar] [CrossRef]

- Kim, S.K.; Cha, B.C. Deposition of tantalum nitride thin films by D.C. magnetron sputtering. Thin Solid Films 2005, 475, 202–207. [Google Scholar] [CrossRef]

- An, J.; Zhang, Q.Y. Structure, hardness and tribological properties of nanolayered TiN/TaN multilayer coatings. Mater. Charact. 2007, 58, 439–446. [Google Scholar] [CrossRef]

- Balagna, C.; Faga, M.G.; Spriano, S. Tantalum-based multilayer coating on cobalt alloys in total hip and knee replacement. Mater. Sci. Eng. C 2012, 32, 887–895. [Google Scholar] [CrossRef][Green Version]

- Wo, P.C.; Zhao, X.L.; Munroe, P.R.; Zhou, Z.F.; Li, K.Y.; Habibi, D.; Xie, Z.H. Extremely hard, damage-tolerant ceramic coatings with functionally graded, periodically varying architecture. Acta Mater. 2013, 61, 193–204. [Google Scholar] [CrossRef]

- Sun, J.; Bhushan, B. Hierarchical structure and mechanical properties of nacre: A review. RSC Adv. 2012, 2, 7617. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2011, 19, 3–20. [Google Scholar] [CrossRef]

- Broitman, E.; Flores-Ruiz, F.J. Novel method for in-situ and simultaneous nanofriction and nanowear characterization of materials. J. Vac. Sci. Technol. A Vacuum Surf. Film. 2015, 33, 043201. [Google Scholar] [CrossRef]

- Burris, D.L.; Sawyer, W.G. Measurement uncertainties in wear rates. Tribol. Lett. 2009, 36, 81–87. [Google Scholar] [CrossRef]

- Chen, Y.-I.; Lin, B.-L.; Kuo, Y.-C.; Huang, J.-C.; Chang, L.-C.; Lin, Y.-T. Preparation and annealing study of TaNx coatings on WC-Co substrates. Appl. Surf. Sci. 2011, 257, 6741–6749. [Google Scholar] [CrossRef]

- Zhang, G.A.; Wu, Z.G.; Wang, M.X.; Fan, X.Y.; Wang, J.; Yan, P.X. Structure evolution and mechanical properties enhancement of Al/AlN multilayer. Appl. Surf. Sci. 2007, 253, 8835–8840. [Google Scholar] [CrossRef]

- Zhao, X.; Xie, Z.; Munroe, P. Nanoindentation of hard multilayer coatings: Finite element modelling. Mater. Sci. Eng. A 2011, 528, 1111–1116. [Google Scholar] [CrossRef]

- Clevenger, L.A.; Mutscheller, A.; Harper, J.M.E.; Cabral, C.; Barmak, K. The relationship between deposition conditions, the beta to alpha phase transformation, and stress relaxation in tantalum thin films. J. Appl. Phys. 1992, 72, 4918. [Google Scholar] [CrossRef]

- Broitman, E. Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical Overview. Tribol. Lett. 2017, 65, 23. [Google Scholar] [CrossRef]

- International Organization For Standardization. ISO 14577: 2002-Metallic Materials-Intrumented Indentation Test for Hardness and Materials Parameters; IOS: Geneva, Switzerland, 2002. [Google Scholar]

- Leng, Y.; Sun, H.; Yang, P.; Chen, J.; Wang, J.; Wan, G.; Huang, N.; Tian, X.; Wang, L.; Chu, P. Biomedical properties of tantalum nitride films synthesized by reactive magnetron sputtering. Thin Solid Films 2001, 398–399, 471–475. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: Discussion of Results. Proc. Phys. Soc. B 1952, 64, 747–753. [Google Scholar] [CrossRef]

- Wang, J.; Misra, A. An overview of interface-dominated deformation mechanisms in metallic multilayers. Curr. Opin. Solid State Mater. Sci. 2011, 15, 20–28. [Google Scholar] [CrossRef]

- Munch, E.; Launey, M.E.; Alsem, D.H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Tough, bio-inspired hybrid materials. Science 2008, 322, 1516–1520. [Google Scholar] [CrossRef] [PubMed]

- Broitman, E. Tribological Testing and Standardization at the Micro-and Nanoscale. In Metrology and Standardization of Nanotechnology: Protocols and Industrial Innovations; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Broitman, E. The nature of the frictional force at the macro-, micro-, and nano-scales. Friction 2014, 2, 40–46. [Google Scholar] [CrossRef]

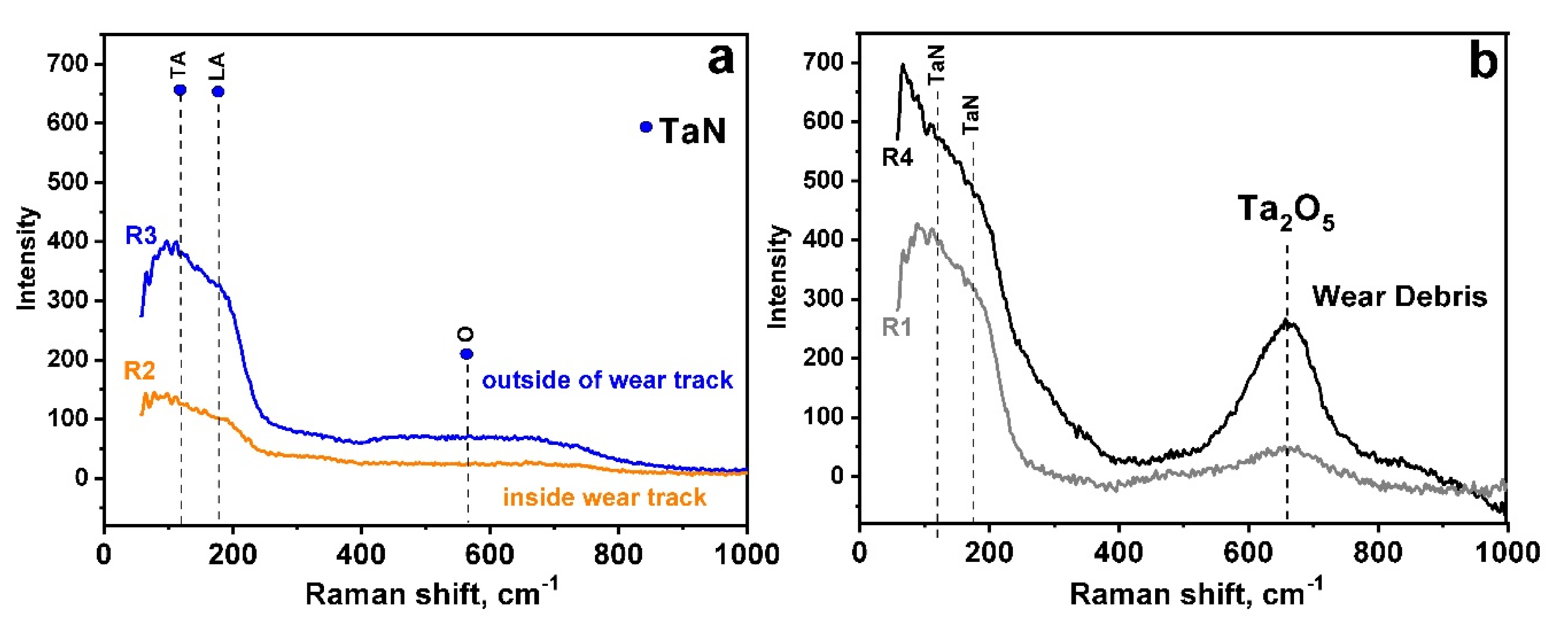

- Stoehr, M.; Shin, C.S.; Petrov, I.; Greene, J.E. Raman scattering from epitaxial TaNx (0.94 ≤ x ≤ 1.37) layers grown on MgO(001). J. Appl. Phys. 2007, 101, 123509. [Google Scholar] [CrossRef]

- Chen, Y.; Fierro, J.L.G.; Tanaka, T.; Wachs, I.E. Supported tantalum oxide catalysts: Synthesis, physical characterization, and methanol oxidation chemical probe reaction. J. Phys. Chem. B 2003, 107, 5243–5250. [Google Scholar] [CrossRef]

| Samples | Hardness, H (GPa) | Reduced Elastic Modulus, Er (GPa) | Elastic Recovery (%) | Creep (nm/s) |

|---|---|---|---|---|

| Hier-TaN/Ta | 31.4 ± 2.8 | 310 ± 20 | 64.8 | 0.2 |

| Ti6Al4V substrate | 5.3 ± 1.9 | 152 ± 12 | 27.3 | 5.9 |

| Sample | Micro Wear Volume × 10−12 mm3 | Macro Wear Volume × 10−3 mm3 | Micro CoF | Macro CoF |

|---|---|---|---|---|

| Hier-TaN/Ta | 1.6 | 2.1 | 0.088 | *0.18 |

| Ti6Al4V | 207 | 51 | 0.044 | 0.44 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rivera-Tello, C.D.; Broitman, E.; Flores-Ruiz, F.J.; Perez-Alvarez, J.; Flores-Jiménez, M.; Jiménez, O.; Flores, M. Micro and Macro-Tribology Behavior of a Hierarchical Architecture of a Multilayer TaN/Ta Hard Coating. Coatings 2020, 10, 263. https://doi.org/10.3390/coatings10030263

Rivera-Tello CD, Broitman E, Flores-Ruiz FJ, Perez-Alvarez J, Flores-Jiménez M, Jiménez O, Flores M. Micro and Macro-Tribology Behavior of a Hierarchical Architecture of a Multilayer TaN/Ta Hard Coating. Coatings. 2020; 10(3):263. https://doi.org/10.3390/coatings10030263

Chicago/Turabian StyleRivera-Tello, César D., E. Broitman, Francisco Javier Flores-Ruiz, J. Perez-Alvarez, M. Flores-Jiménez, O. Jiménez, and M. Flores. 2020. "Micro and Macro-Tribology Behavior of a Hierarchical Architecture of a Multilayer TaN/Ta Hard Coating" Coatings 10, no. 3: 263. https://doi.org/10.3390/coatings10030263

APA StyleRivera-Tello, C. D., Broitman, E., Flores-Ruiz, F. J., Perez-Alvarez, J., Flores-Jiménez, M., Jiménez, O., & Flores, M. (2020). Micro and Macro-Tribology Behavior of a Hierarchical Architecture of a Multilayer TaN/Ta Hard Coating. Coatings, 10(3), 263. https://doi.org/10.3390/coatings10030263