Thermal Stability of Plasma-Sprayed Thick Thermal Barrier Coatings Using Triplex ProTM-200 Torch

Abstract

1. Introduction

2. Experimental Procedure

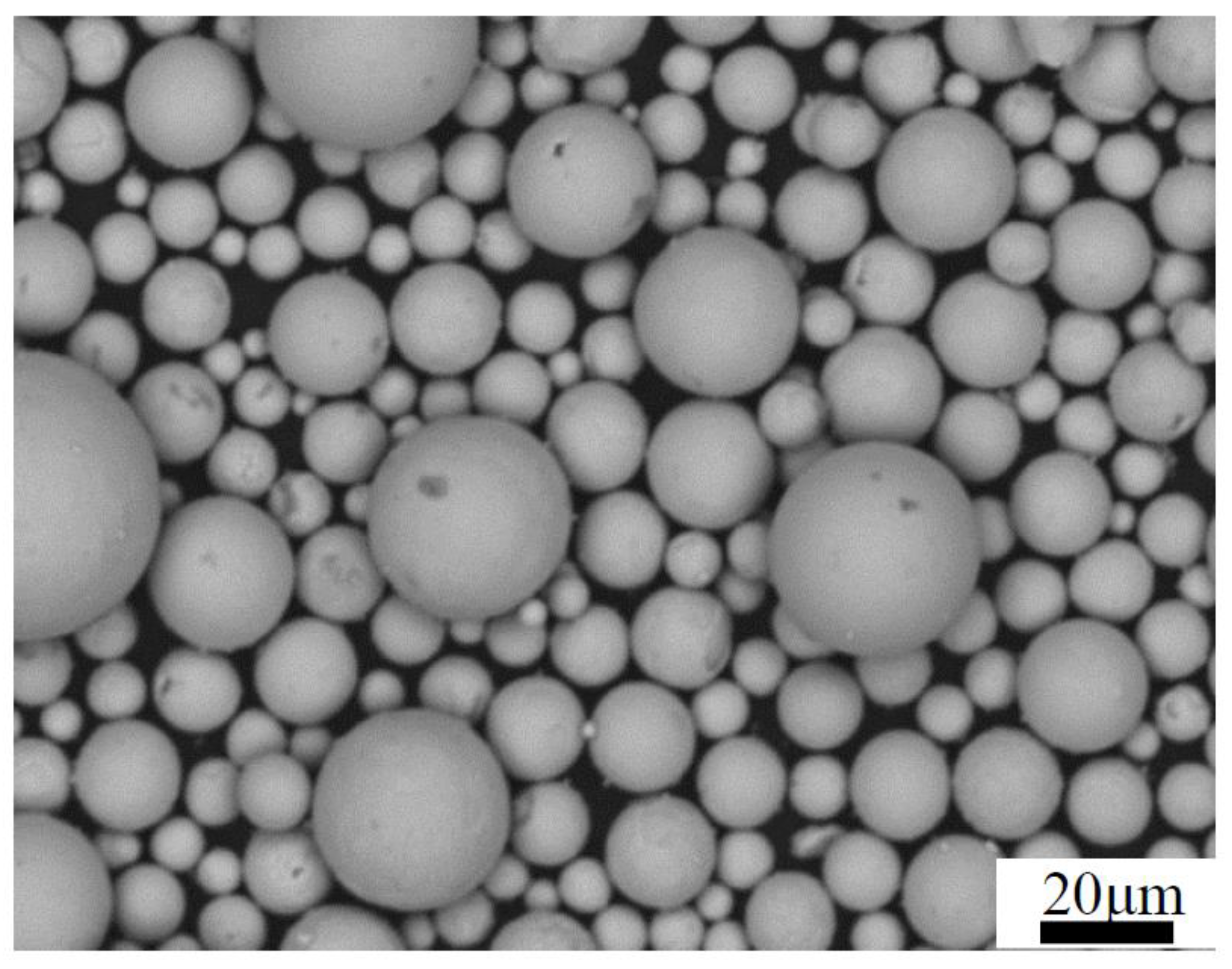

2.1. Coating Preparation

2.2. Coating Characterization

3. Results and Discussion

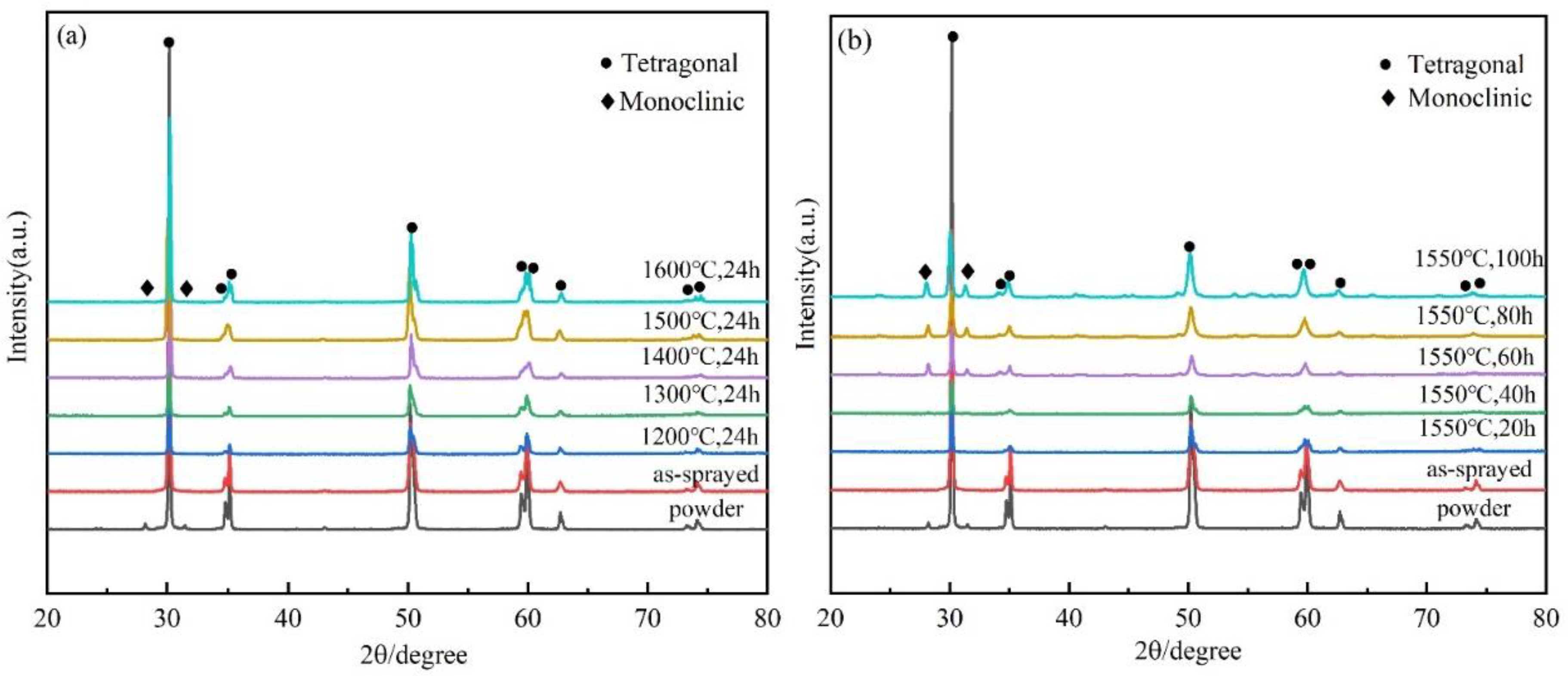

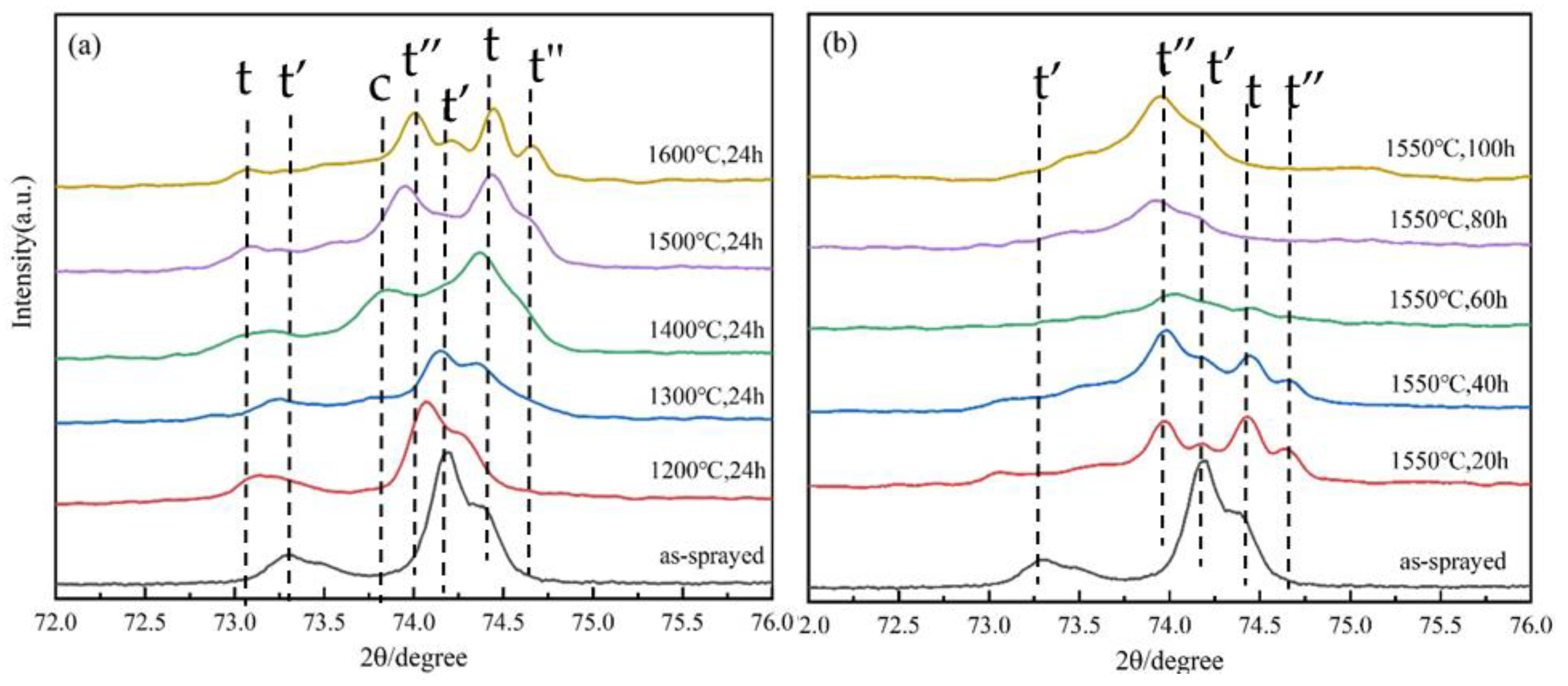

3.1. Phase Composition

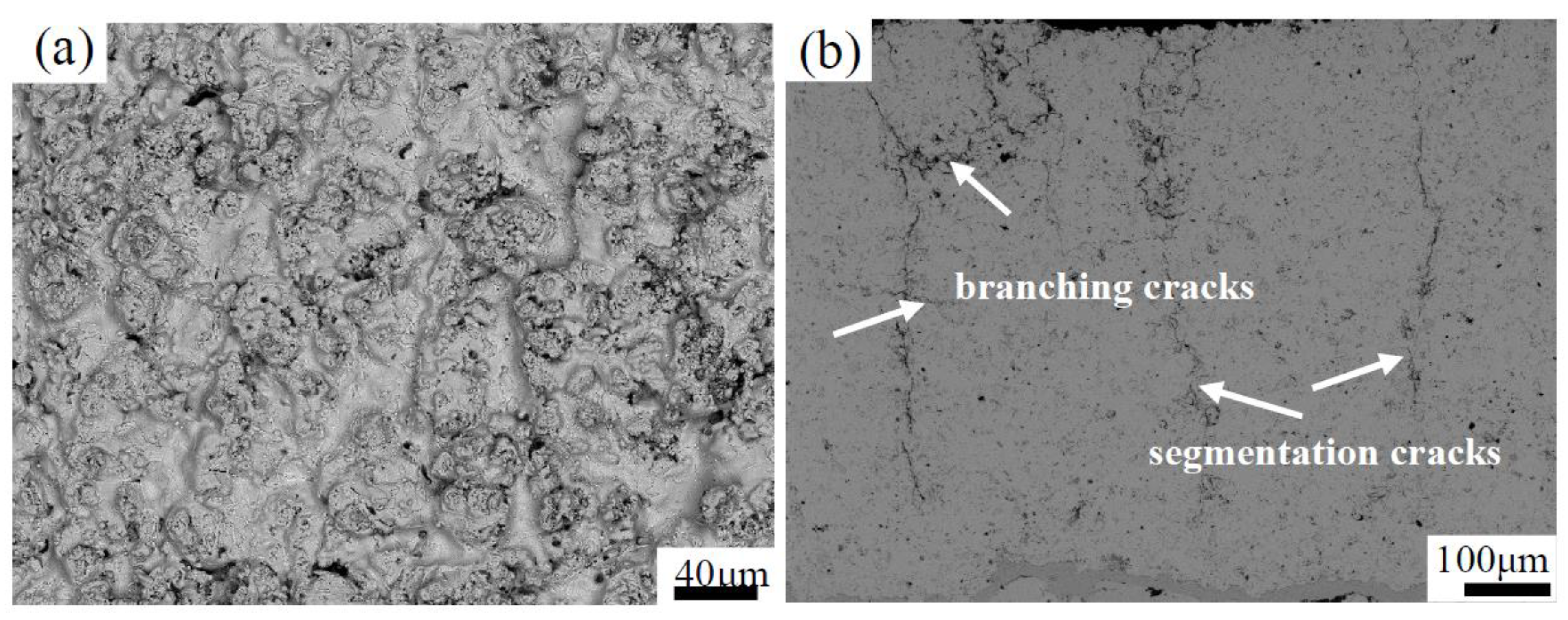

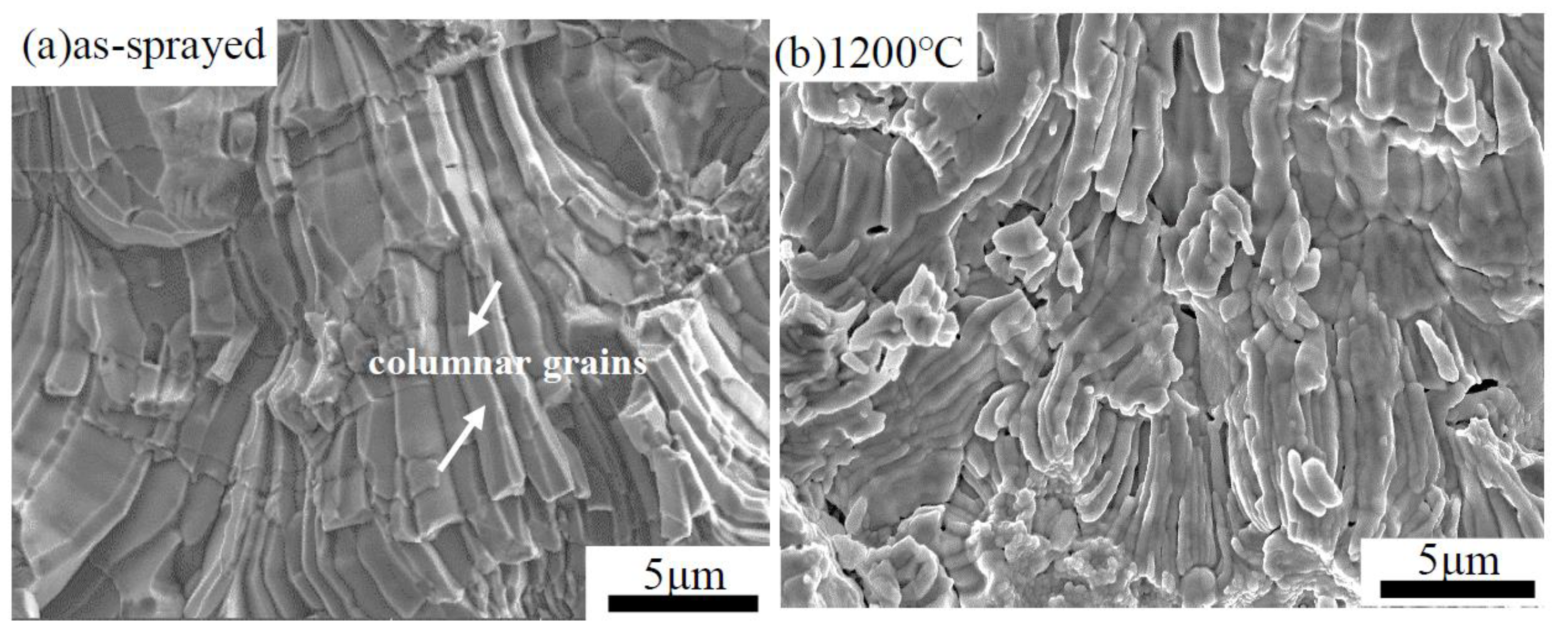

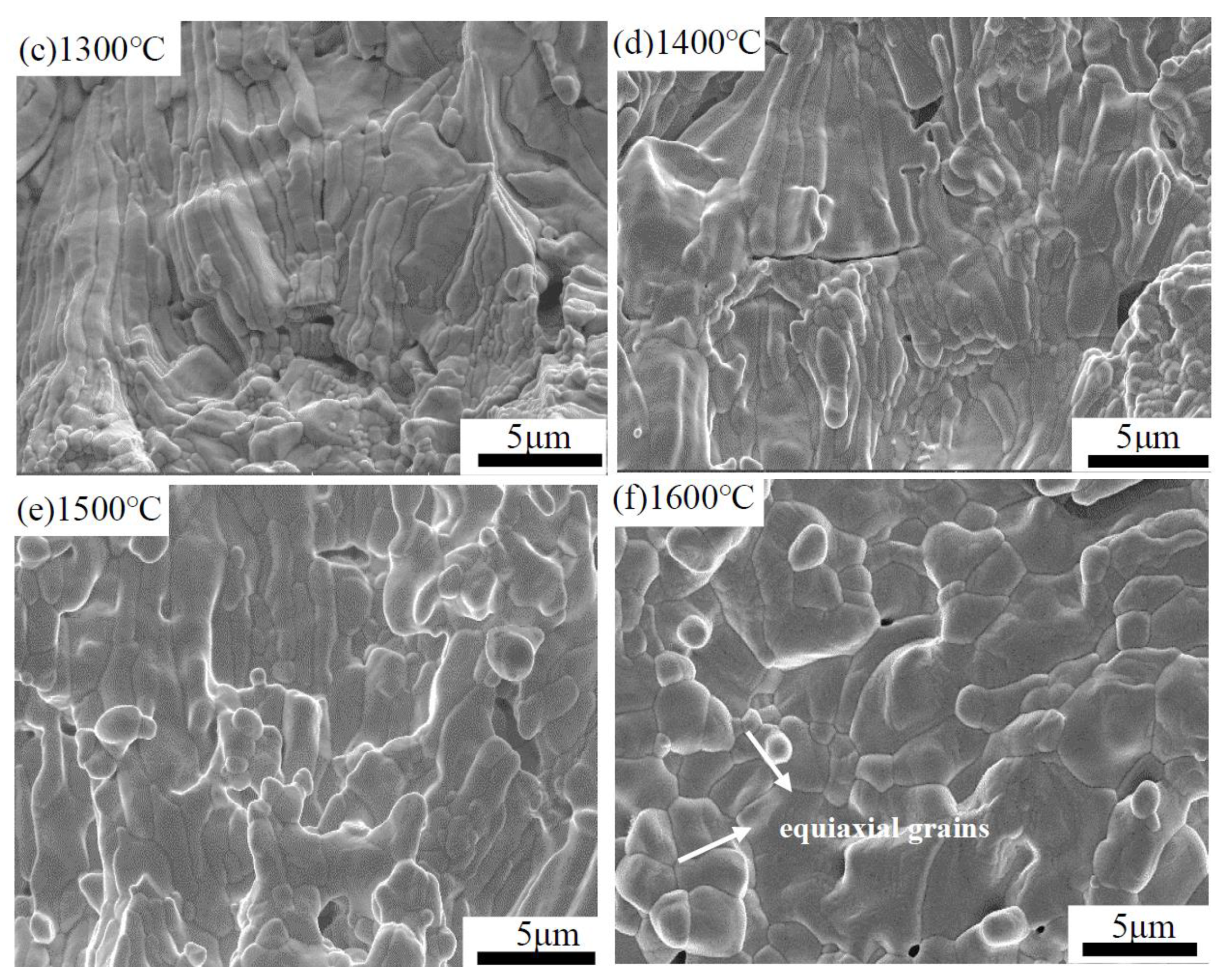

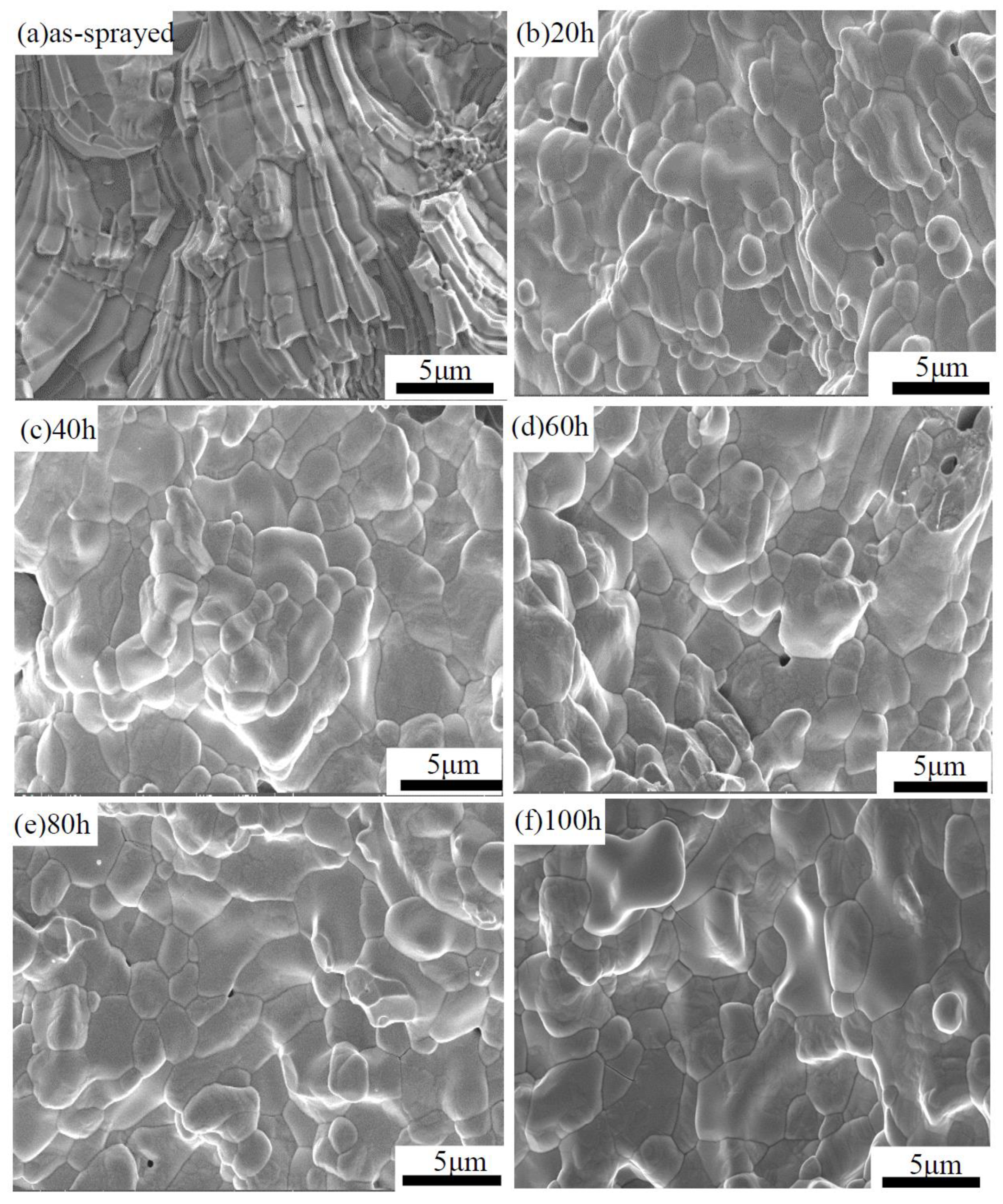

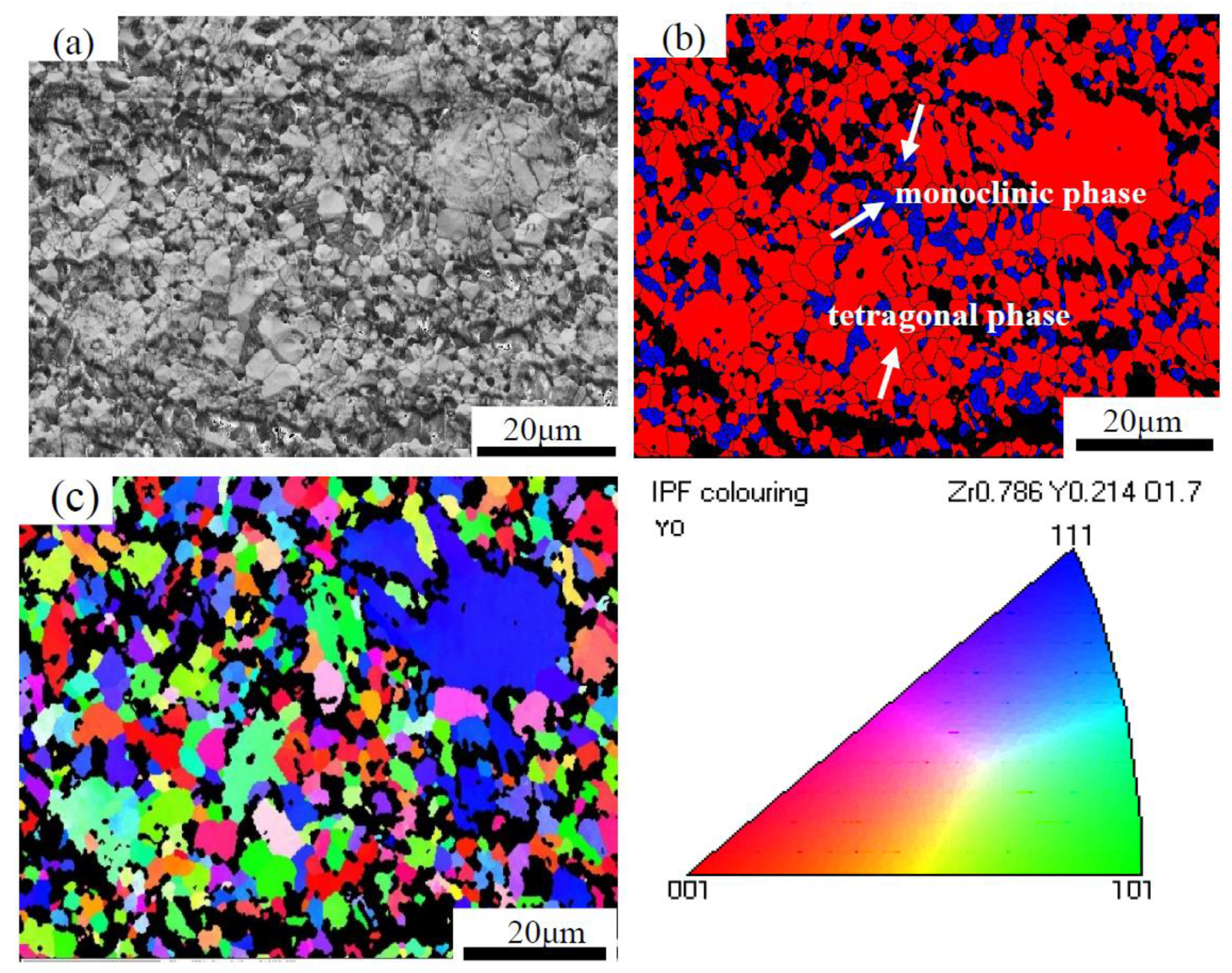

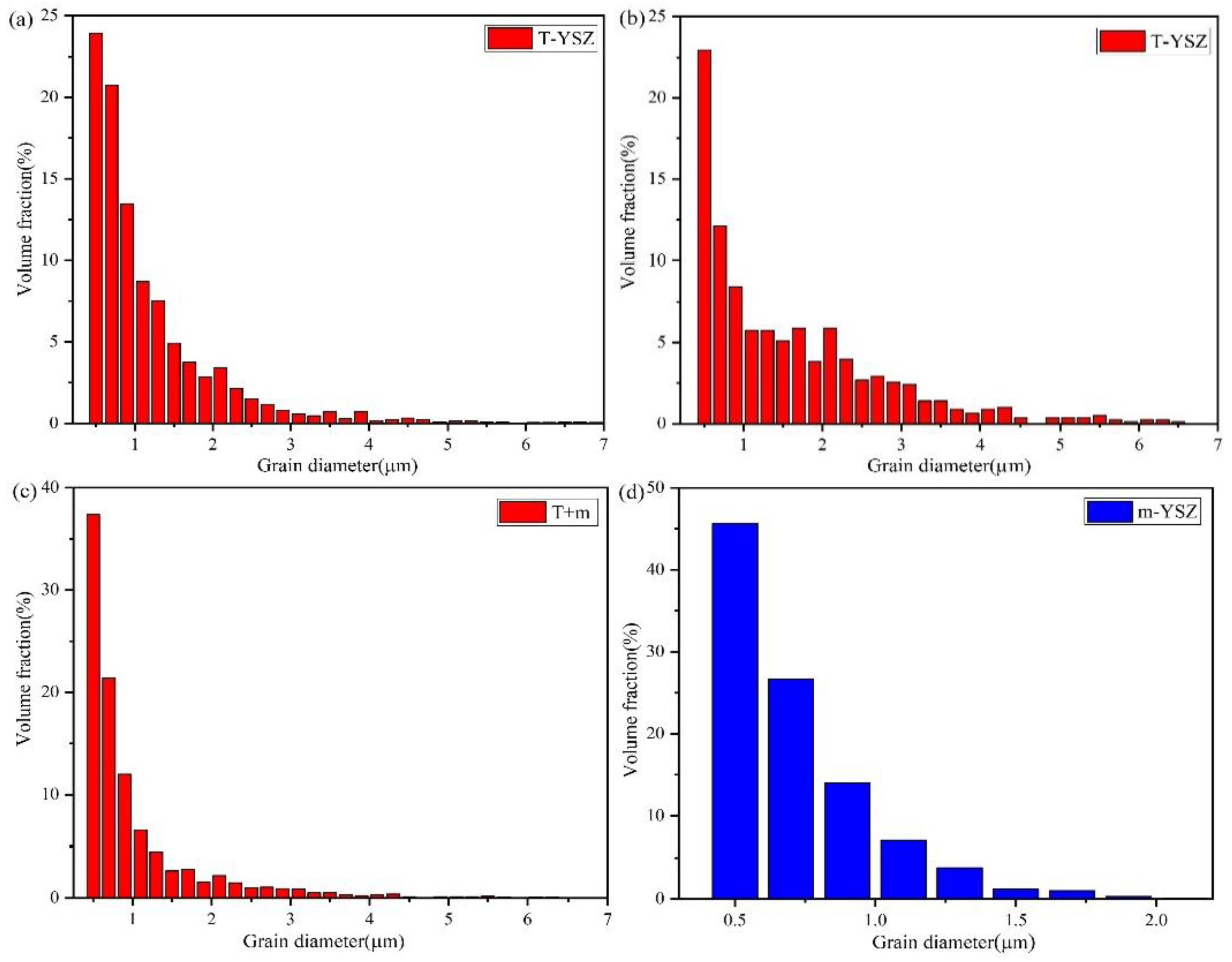

3.2. Microstructure

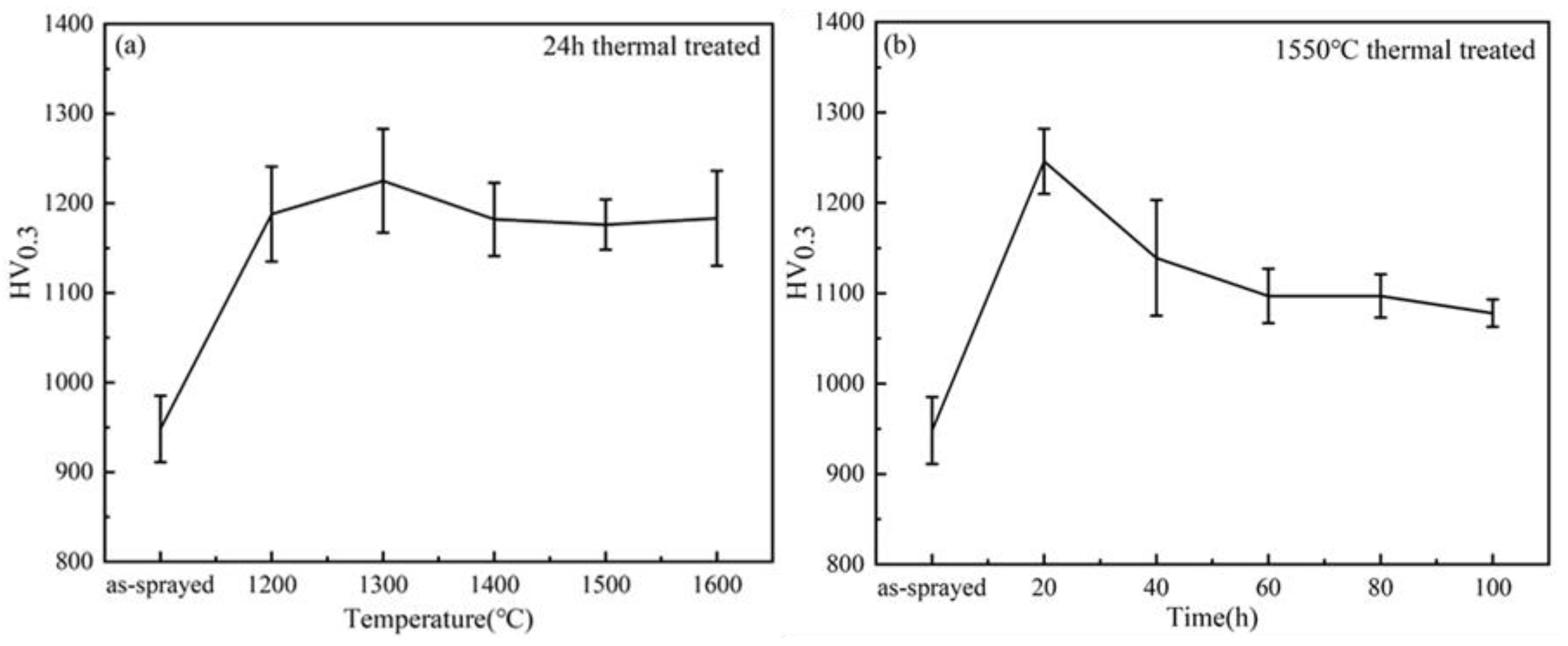

3.3. Mechanical Properties

4. Conclusions

- (1)

- The segmented APS YSZ coatings exhibited similar high-temperature phase stability to the conventional APS coating. During thermal exposure, the initial metastable tetragonal (t′-YSZ) phase of the coating gradually partitioned into equilibrium tetragonal (t-YSZ) and cubic (c-YSZ) due to yttrium diffusion, and as the temperature improved, the c-YSZ remained or transformed into another yttrium-rich tetragonal (t″-YSZ) phase. The transformation of t-YSZ to monoclinic phase (m-YSZ) occurred after 1550 °C/40 h heat treatment, and the content of the m-YSZ phase increased with the prolongation of the thermal exposure time.

- (2)

- During thermal exposure, cracks and pores proceeded along the grain boundaries, especially surrounding the small grains. In service, t-YSZ to m-YSZ phase transition easily occurred at the grain boundary because the atomic arrangement on the grain boundary is looser than in the grain.

- (3)

- The segmented APS YSZ coatings had good bonding between the lamellas, which caused the mean Vickers hardness value was higher than that of conventional APS YSZ coatings. The Vickers hardness increased apparently after thermal aging treatment due to the sintering of the coating. However, a large number of m-YSZ phases formed with the extension of thermal aging time, and the transformation of t-YSZ into m-YSZ produced irreversible volume expansion, which induced the initiation and propagation of microcracks and resulted in the decrease of the mechanical properties of the coatings.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bose, S.; DeMasi-Marcin, J. Thermal barrier coating experience in gas turbine engines at Pratt & Whitney. J. Therm. Spray Technol. 1997, 6, 99–104. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef]

- Tsipas, S.A.; Golosnoy, I. Effect of substrate temperature on the microstructure and properties of thick plasma-sprayed YSZ TBCs. J. Eur. Ceram. Soc. 2011, 31, 2923–2929. [Google Scholar] [CrossRef]

- Cai, C.; Chang, S.; Zhou, Y.; Yang, L.; Zhou, G.; Wang, Y. Microstructure characteristics of EB-PVD YSZ thermal barrier coatings corroded by molten volcanic ash. Surf. Coat. Technol. 2016, 286, 49–56. [Google Scholar] [CrossRef]

- Zheng, Z.; Luo, J.; Li, Q. Mechanism of Competitive Grain Growth in 8YSZ Splats Deposited by Plasma Spraying. J. Therm. Spray Technol. 2015, 24, 885–891. [Google Scholar] [CrossRef]

- Lee, P.-H.; Lee, S.Y.; Kwon, J.-Y.; Myoung, S.-W.; Lee, J.-H.; Jung, Y.-G.; Cho, H.; Paik, U. Thermal cycling behavior and interfacial stability in thick thermal barrier coatings. Surf. Coat. Technol. 2010, 205, 1250–1255. [Google Scholar] [CrossRef]

- Eaton, H.; Novak, R. Sintering studies of plasma-sprayed zirconia. Surf. Coat. Technol. 1987, 32, 227–236. [Google Scholar] [CrossRef]

- Steffens, H.-D.; Babiak, Z.; Gramlich, M. Some Aspects of Thick Thermal Barrier Coating Lifetime Prolongation. J. Therm. Spray Technol. 1999, 8, 517–522. [Google Scholar] [CrossRef]

- Thompson, J.A.; Clyne, T.W. The effect of heat treatment on the stiffness of zirconia top coats in plasma-sprayed TBCs. Acta Mater. 2001, 49, 1565–1575. [Google Scholar] [CrossRef]

- Karger, M.; Vaßen, R.; Stöver, D. Atmospheric plasma sprayed thermal barrier coatings with high segmentation crack densities: Spraying process, microstructure and thermal cycling behavior. Surf. Coat. Technol. 2011, 206, 16–23. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, L.; Yang, J.; Li, D.; Zhong, X.; Zhao, H.; Shao, F.; Tao, S. Thermal Aging Behavior of Axial Suspension Plasma-Sprayed Yttria-Stabilized Zirconia (YSZ) Thermal Barrier Coatings. J. Therm. Spray Technol. 2014, 24, 338–347. [Google Scholar] [CrossRef]

- Bernard, B.; Quet, A.; Bianchi, L.; Joulia, A.; Malié, A.; Schick, V.; Rémy, B. Thermal insulation properties of YSZ coatings: Suspension Plasma Spraying (SPS) versus Electron Beam Physical Vapor Deposition (EB-PVD) and Atmospheric Plasma Spraying (APS). Surf. Coat. Technol. 2017, 318, 122–128. [Google Scholar] [CrossRef]

- Fauchais, P.; Joulia, A.; Goutier, S.; Chazelas, C.; Vardelle, M.; Rossignol, S.; Vardelle, A. Suspension and solution plasma spraying. J. Phys. D Appl. Phys. 2013, 46, 224015. [Google Scholar] [CrossRef]

- Hass, D.; Slifka, A.; Wadley, H. Low thermal conductivity vapor deposited zirconia microstructures. Acta Mater. 2001, 49, 973–983. [Google Scholar] [CrossRef]

- Tian, Y.S.; Chen, C.Z.; Wang, D.Y.; Ji, Q. Recent developments in zirconia thermal barrier coatings. Surf. Rev. Lett. 2005, 12, 369–378. [Google Scholar] [CrossRef]

- Guo, H.; Murakami, H.; Kuroda, S. Thermal Cycling Behavior of Plasma Sprayed Segmented Thermal Barrier Coatings. Mater. Trans. 2006, 47, 306–309. [Google Scholar] [CrossRef][Green Version]

- Mihm, S.; Duda, T.; Gruner, H.; Thomas, G.; Dzur, B. Method and Process Development of Advanced Atmospheric Plasma Spraying for Thermal Barrier Coatings. J. Therm. Spray Technol. 2012, 21, 400–408. [Google Scholar] [CrossRef]

- Mauer, G.; Vaßen, R.; Stöver, D. Preliminary study on the TriplexPro (TM)-200 gun for atmospheric plasma spraying of yttria-stabilized zirconia. Surf. Coat. Technol. 2008, 202, 4374–4381. [Google Scholar]

- Richardt, K.; Bobzin, K.; Sporer, D.; Schläfer, T.; Fiala, P. Tailor-Made Coatings for Turbine Applications Using the Triplex Pro 200. J. Therm. Spray Technol. 2008, 17, 612–616. [Google Scholar] [CrossRef]

- Lu, Z.; Myoung, S.-W.; Kim, H.-S.; Kim, M.-S.; Lee, J.-H.; Jung, Y.-G.; Jang, J.-C.; Paik, U. Microstructure Evolution and Interface Stability of Thermal Barrier Coatings with Vertical Type Cracks in Cyclic Thermal Exposure. J. Therm. Spray Technol. 2013, 22, 671–679. [Google Scholar] [CrossRef]

- Lughi, V.; Tolpygo, V.K.; Clarke, D.R. Microstructural aspects of the sintering of thermal barrier coatings. Mater. Sci. Eng. A 2004, 368, 212–221. [Google Scholar] [CrossRef]

- Witz, G.; Shklover, V.; Steurer, W.; Bachegowda, S.; Bossmann, H.-P. Phase Evolution in Yttria-Stabilized Zirconia Thermal Barrier Coatings Studied by Rietveld Refinement of X-Ray Powder Diffraction Patterns. J. Am. Ceram. Soc. 2007, 90, 2935–2940. [Google Scholar] [CrossRef]

- Ho, C.-J.; Tuan, W.-H. Phase stability and microstructure evolution of yttria-stabilized zirconia during firing in a reducing atmosphere. Ceram. Int. 2011, 37, 1401–1407. [Google Scholar] [CrossRef]

- Krogstad, J.A.; Krämer, S.; Lipkin, D.M.; Johnson, C.A.; Mitchell, D.R.; Cairney, J.M.; Levi, C.G. Phase Stability of t′-Zirconia-Based Thermal Barrier Coatings: Mechanistic Insights. J. Am. Ceram. Soc. 2011, 94, S168–S177. [Google Scholar] [CrossRef]

- Zhai, M.; Li, D.; Zhao, Y.; Zhong, X.; Shao, F.; Zhao, H.; Liu, C.; Tao, S. Comparative study on thermal shock behavior of thick thermal barrier coatings fabricated with nano-based YSZ suspension and agglomerated particles. Ceram. Int. 2016, 42, 12172–12179. [Google Scholar] [CrossRef]

- Ganvir, A.; Markocsan, N.; Joshi, S.V. Influence of Isothermal Heat Treatment on Porosity and Crystallite Size in Axial Suspension Plasma Sprayed Thermal Barrier Coatings for Gas Turbine Applications. Coatings 2016, 7, 4. [Google Scholar] [CrossRef]

- Lughi, V.; Clarke, D.R. Transformation of Electron-Beam Physical Vapor-Deposited 8 wt% Yttria-Stabilized Zirconia Thermal Barrier Coatings. J. Am. Ceram. Soc. 2005, 88, 2552–2558. [Google Scholar] [CrossRef]

- Yashima, M.; Sasaki, S.; Kakihana, M.; Yamaguchi, Y.; Arashi, H.; Yoshimura, M. Oxygen-induced structural-change of the tetragonal phase around the tetragonal-cubic plasma-boundary in ZrO2-YO1.5 solid-solutions. Acta Cryst. Sect. B Struct. Sci. Cryst. Eng. Mater. 1994, 50, 663–672. [Google Scholar] [CrossRef]

- Lipkin, D.M.; Krogstad, J.A.; Gao, Y.; Johnson, C.A.; Nelson, W.A.; Levi, C.G. Phase Evolution upon Aging of Air-Plasma Sprayed t′-Zirconia Coatings: I-Synchrotron X-Ray Diffraction. J. Am. Ceram. Soc. 2012, 96, 290–298. [Google Scholar] [CrossRef]

- Mercer, C.; Faulhaber, S.; Evans, A.; Darolia, R. A delamination mechanism for thermal barrier coatings subject to calcium–magnesium–alumino-silicate (CMAS) infiltration. Acta Mater. 2005, 53, 1029–1039. [Google Scholar] [CrossRef]

- Dalach, P.; Ellis, D.E.; Van De Walle, A. First-principles thermodynamic modeling of atomic ordering in yttria-stabilized zirconia. Phys. Rev. B 2010, 82. [Google Scholar] [CrossRef]

- Cheng, Z.; Yang, J.; Shao, F.; Zhong, X.; Zhao, H.; Zhuang, Y.; Ni, J.; Tao, S. Thermal Stability of YSZ Coatings Deposited by Plasma Spray–Physical Vapor Deposition. Coatings 2019, 9, 464. [Google Scholar] [CrossRef]

- Huang, Y.; Hu, N.; Zeng, Y.; Song, X.; Lin, C.; Liu, Z.; Zhang, J. Effect of Different Types of Pores on Thermal Conductivity of YSZ Thermal Barrier Coatings. Coatings 2019, 9, 138. [Google Scholar] [CrossRef]

| Parameters | Top Coating |

|---|---|

| Plasma torch Plasma gas mixture | Triplex Pro™-200 He + Ar |

| Plasma gas flow rate (slpm) | He: 4–7 Ar: 40–47 |

| Carrier gas (slpm) | Ar: 2–3 |

| Current (A) | 500–530 |

| Stand-off distance (mm) | 90–110 |

| Powder feed rate (g/min) | 75–105 |

| Coating | Monoclinic Phase (%) | Tetragonal Phase (%) | Grain Size (μm) |

|---|---|---|---|

| As-sprayed | 0 | 98.1 | T: 1.22 |

| 1600 °C/24 h | 0.15 | 92.5 | T: 1.71 m: 0.55 T + m: 1.67 |

| 1550 °C/100 h | 12.4 | 63.8 | T: 1.63 |

| m: 0.72 | |||

| T + m: 1.05 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, S.; Yang, J.; Li, W.; Shao, F.; Zhong, X.; Zhao, H.; Zhuang, Y.; Ni, J.; Tao, S.; Yang, K. Thermal Stability of Plasma-Sprayed Thick Thermal Barrier Coatings Using Triplex ProTM-200 Torch. Coatings 2020, 10, 894. https://doi.org/10.3390/coatings10090894

Tao S, Yang J, Li W, Shao F, Zhong X, Zhao H, Zhuang Y, Ni J, Tao S, Yang K. Thermal Stability of Plasma-Sprayed Thick Thermal Barrier Coatings Using Triplex ProTM-200 Torch. Coatings. 2020; 10(9):894. https://doi.org/10.3390/coatings10090894

Chicago/Turabian StyleTao, Shiqian, Jiasheng Yang, Wei Li, Fang Shao, Xinghua Zhong, Huayu Zhao, Yin Zhuang, Jinxing Ni, Shunyan Tao, and Kai Yang. 2020. "Thermal Stability of Plasma-Sprayed Thick Thermal Barrier Coatings Using Triplex ProTM-200 Torch" Coatings 10, no. 9: 894. https://doi.org/10.3390/coatings10090894

APA StyleTao, S., Yang, J., Li, W., Shao, F., Zhong, X., Zhao, H., Zhuang, Y., Ni, J., Tao, S., & Yang, K. (2020). Thermal Stability of Plasma-Sprayed Thick Thermal Barrier Coatings Using Triplex ProTM-200 Torch. Coatings, 10(9), 894. https://doi.org/10.3390/coatings10090894