Abstract

The performance of a skid resistance fog seal is studied to develop a high bond performance road skid resistance fog seal. Accordingly, a fog seal is developed based on the bond strength, permeability, and aging resistance. To develop the skid resistance fog seal herein, the skid resistance particle types and dosages are optimized according to the skid and wear resistance properties. The fog seal performance is then verified. Furthermore, the road performance of the skid resistance fog seal is studied, and the optimal amount of the skid resistance fog seal is proposed. Finally, the influence of the construction process on the skid and wear resistance is investigated. The results show that the self-made skid resistance fog seal has better bond strength, permeability, and aging resistance. The 0.6 kg/m2 skid resistance fog seal exhibits the best skid and wear resistance and water penetration performance, while the skid resistance fog seal constructed by the premix process has the best skid and wear resistance properties.

1. Introduction

Asphalt pavements deteriorate over time due to various factors, such as, material aging, traffic loading or environmental factors [1,2]. Some of the most usual defects are rutting, cracking, roughness and slippery pavements [3,4], rutting and cracking are the most common early diseases of asphalt pavements [5,6,7]. The preventive maintenance of asphalt pavements alleviates pavement diseases. A fog seal is widely used as an effective measure for the preventive maintenance of pavements [8,9], the application of fog seal on pavement is shown in Figure 1. Most studies on fog seals focused on development and road performance. Modified emulsified asphalt and water-based epoxy resin emulsion are often studied as the constituent materials of a fog seal [10,11,12,13]. Research on the road performance of a fog seal mainly focuses on the four aspects of skid resistance, permeability, wear resistance, and aging resistance. Fog seal will fill a part of the gap after it is used on the pavements surface, thus reducing the skid resistance of the pavements surface [14]. The skid resistance in pavements is a vital factor for any road administration because with higher friction available, drivers can better control their vehicles [15,16], the decrease of skid resistance will lead to the decrease of road safety. A fog seal negatively affects the skid resistance of an asphalt pavement, but the skid resistance is greatly improved after adding skid resistance particles [12,17,18]. The fog seal permeability is the basis for ensuring that the fog seal layer fully penetrates and fills the gaps in a pavement [19,20,21]. Previous studies showed that the fog seal permeability is related to the material composition [11,12,22]. That is, as the number of wear times increases, the mass loss rate of a fog seal gradually increases, and the skid resistance decreases [12,18,23]. A fog seal can easily age under the action of ultraviolet rays because its materials are all organic matter. Therefore, many studies have focused on the aging resistance of fog seals [11,12,24]. In addition, studies on the bond performance of fog seals have also been performed [11,25].

Figure 1.

The application of fog seal on pavement.

However, a fog seal still has deficiencies upon usage. Slippage occurs because of wheel wear. Its skid resistance particles fall off, resulting in insufficient skid resistance and bond performance, which causes it to peel off. Furthermore, a fog seal has insufficient aging resistance, which leads to brittle cracking that may be caused by the influence of the bond performance. The influence of material aging resistance was not considered in the development of fog seals.

In this study, the effects of the bonding performance, permeability, and aging resistance are comprehensively considered to develop a fog seal with high bonding performance and permeability and good aging resistance. The skid and wear resistance are also considered to develop the skid resistance fog seal. The road performance of the skid resistance fog seal is investigated. Moreover, the skid and wear resistance of the fog seal formed through different construction processes are studied. Importantly, a basis for the promotion and application of the skid resistance fog seal is provided.

2. Materials and Test Plan

2.1. Raw Materials

2.1.1. Skid Resistance Fog Seal Material

The skid resistance fog seal was composed of water-based epoxy emulsified asphalt and skid resistance particles:

- Water-Based Epoxy Emulsified Asphalt

The water-based epoxy emulsified asphalt was mainly composed of water-based epoxy resin emulsion, emulsified asphalt, and water-based curing agent. The water-based epoxy resin emulsion was made of epoxy resin and emulsion. A self-made fatty amide emulsifier (BE-4) and an SK90 base asphalt were used to prepare emulsified asphalt (i.e., BE-4 emulsified asphalt). Figure 2 presents the BE-4 emulsifier and aqueous solution. A commercially available water-based curing agent was used as the water-based epoxy emulsified asphalt curing agent. Table 1 lists the technical properties of the components of the waterborne epoxy emulsified asphalt [26,27,28].

Figure 2.

BE-4 emulsifier and aqueous solution: (a) BE-4 emulsifier; (b) BE-4 emulsifier aqueous solution.

Table 1.

Technical properties of the components of the waterborne epoxy emulsified asphalt.

- Skid Resistance Particles

Three kinds of hard particles (i.e., basalt sand, river sand, and emery sand) were selected as the skid resistance particles to improve the skid resistance of the fog seal. Table 2 summarizes the technical properties of the three kinds of skid resistance particles [29].

Table 2.

Technical properties of skid resistance particles.

2.1.2. Asphalt Mixture Asphalt Content: 4.9%

The Asphalt Concrete which nominal maximum size of aggregate is 13 mm (AC-13), and Stone Mastic Asphalt which nominal maximum size of aggregate is 13 mm (SMA-13) were used to simulate the actual asphalt pavement [26]. The bitumen content of AC-13 and SMA-13 are 4.6% and 4.8%, respectively. The fog seal layer was painted on an AC-13 test piece for the performance testing. Table 3 lists the AC-13 asphalt mixture gradation.

Table 3.

Asphalt mixture gradation.

2.2. Experiment Method

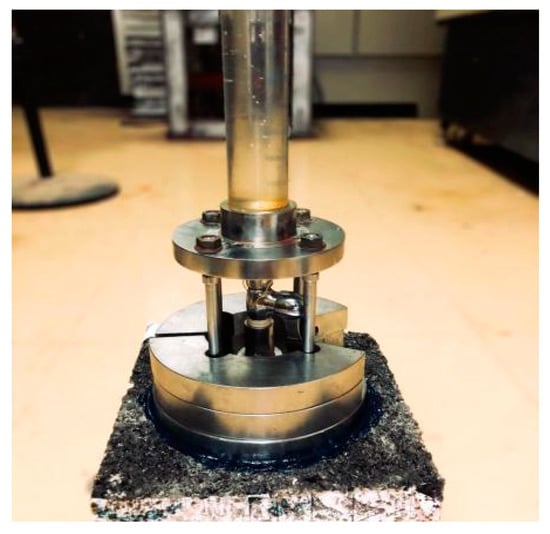

2.2.1. Bonding Performance Test

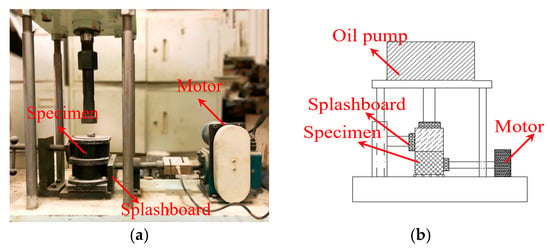

An interlayer material shear tester [30] was used to measure the shear strength of the fog seal. The normal stress of the interlayer material shear tester was 0.7 MPa. The loading rate was 10 mm/min. The test temperature was 20 °C. Figure 3 depicts the appearance and working principle of the instrument. The test piece was placed in the two hollow sleeves of the instrument. Each sleeve was a cylinder with 50 mm height and 105 mm bottom-surface diameter. Figure 4 illustrates the failure mode of the test piece in the test. The bonding performance test steps are as follows: (1) Core drilling machine was used to sample the rut board and cement board, and the height of the test piece was 5 cm, and the diameter of the bottom surface was 100 mm. (2) Apply a fixed amount of mist sealant on the surface of the same two core samples, bond the two core samples after the surface is dry, and place them in a 30 °C curing box for curing until the test piece is completely cured. (3) After the specimen is cured, place the sleeve and the test piece in the slidable track of the instrument, and start the test device to start the shear test.

Figure 3.

Interlayer material shear tester: (a) entity diagram; (b) structure diagram.

Figure 4.

Fog seal specimen.

2.2.2. Penetration Test

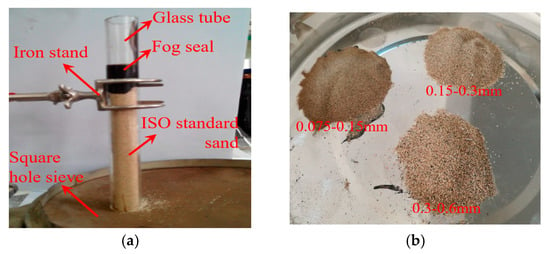

The penetration test [31] equipment included permeable glass tubes with upper and lower openings, an iron stand, a lower sealing screen, a funnel, and International Organization for Standardization standard sand. The permeable glass tube was filled with standard sand of a certain quality as the permeability channel of the fog seal. The iron stand was used to fix the permeable glass tube and funnel. Meanwhile, the lower seal screen was placed under the permeable glass tube. Figure 5 displays the permeate test device.

Figure 5.

Penetration test: (a) device; (b) ISO standard sand.

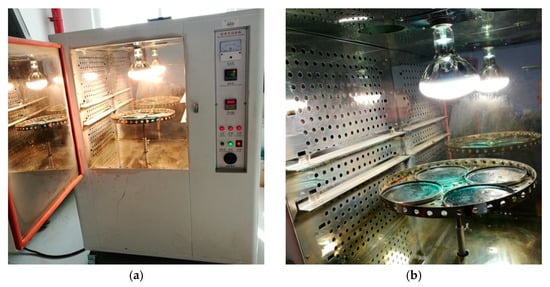

2.2.3. Aging Resistance Test

As a kind of pavement material, fog seals are mainly subjected to aging effects, such as ultraviolet radiation. Based on this, the test performed herein intends to use a yellowing-resistant aging box to simulate the role of ultraviolet light and evaluate the anti-aging properties of the fog seal. The yellowing-resistant aging box independently developed by Chang’an University (Xi’an, China) was used herein to simulate the actual ultraviolet radiation process [32]. The UV aging box is divided into two parts: illumination and heating. The short-term indoor test is realized by the combined action of heating and illumination to simulate long-term outdoor UV aging. The aging resistance test steps are as follows: (1) Weigh the aging test mold mass m0, pour in 50 g of the formulated mist-seal cementitious, and place it in a thermostat not higher than 40 °C for curing. (2) When the mass of the sample is constant, weigh the sample mass m1 at this time, open the yellowing-resistant ultraviolet aging box, set the temperature in the box to 60 °C, and place four samples for rotating ultraviolet aging. (3) Take out the sample after 48 h, weigh the sample mass m2 after aging, and convert the mass loss rate of the cured product before and after UV aging. Figure 6 illustrates the test device. The irradiation intensity was set to 250 W/m2. The irradiation height was set to 30 cm. The aging temperature and the time were 60 °C and 48 h, respectively. During the test, the ultraviolet irradiation acceleration factor N can be used to evaluate the ultraviolet aging strength. Equation (1) presents the calculation formula.

where N stands for the acceleration times of the ultraviolet irradiation; UX is the aging box radiation intensity; and U is the average value of the outdoor average daily ultraviolet radiation, usually the value is 168.6 W/m2 in Xi’an, China.

Figure 6.

Yellowing-resistant aging box: (a) overall diagram; (b) detail.

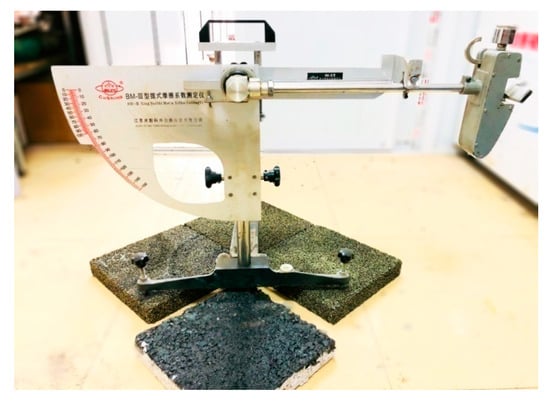

2.2.4. Skid Resistance Test

The British Pendulum Number value was used to evaluate the skid resistance of the pavement covered with the fog seal according to the Field Test Methods of Highway Subgrade and Pavement (JTG 3450-2019) [33]. Figure 7 depicts the skid resistance test.

Figure 7.

The test of skid resistance.

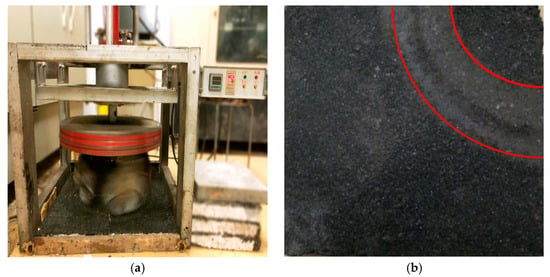

2.2.5. Wear Resistance Test

The accelerated wear tester [6] developed by Chang’an University (Figure 8a) was used to simulate the vehicle abrasion during the fog seal use. The instrument contained four 45 mm-wide polyurethane tires. Figure 8b shows the tire trajectory after wear. The rotation frequency was 5000 rpm/h. The calculated linear speed was 84.78 km/h, which was close to the design speed of high-grade highways. The test adjusted the bottom tire load by loading the disk. The vertical load was set to 1.4 MPa. The quality loss rate of the specimen after 100,000 instances of abrasion was used to evaluate the abrasion resistance of the anti-slip fog sealing layer. Equation (2) shows the mass loss rate calculation. The smaller the mass loss rate, the better the adhesion durability of the anti-slide fog sealing layer.

where V1 is the specimen mass loss rate; m0 and m1 are the specimen mass before and after wear, respectively; ma and mb are the specimen mass without spraying and after spraying, respectively; A is the specimen area; and A1 is the specimen wear area.

Figure 8.

Wear resistance test: (a) accelerated wear tester; (b) tire trajectory after wear.

2.2.6. Water Seepage Test

The water seepage test [33] was used to measure the water seepage performance coefficient of the AC-13 asphalt mixture rut boards after adjustment and gradation and the rut boards coated with the fog seal. The reduction ratios of the water seepage coefficients of the rut boards after the fog seal binder application were compared to evaluate the water seepage performance of the mist sealant. Figure 9 shows the device used in the water seepage test.

Figure 9.

Device of water seepage test.

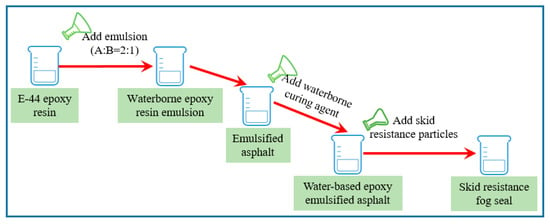

2.3. Development Process

The development process involved the following steps:

- Preparation process of the skid resistance fog seal: the skid resistance fog seal was prepared after a certain process (Figure 10).

Figure 10. Preparation process of skid resistance fog seal.

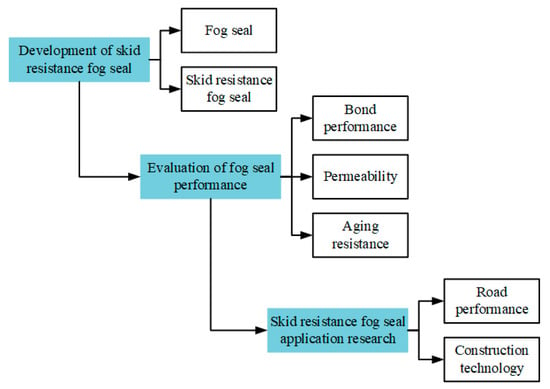

Figure 10. Preparation process of skid resistance fog seal. - Skid resistance fog seal development and performance verification process: this research focuses on the development and application of a skid resistance fog seal. First, a skid resistance fog seal with water-based epoxy emulsified asphalt and anti-slip particles is preferable. Second, the performance of the fog seal from the aspects of bond performance, permeability, and aging resistance was verified. Finally, the application research of the skid resistance fog seal was conducted from the two aspects of road performance and construction technology. Figure 11 illustrates the relevant flow chart. The preparation process of the skid resistance fog seal are as follows: (1) Add emulsion (Emulsion A:Emulsion B = 2:1) into E-44 epoxy resin to get waterborne epoxy resin emulsion. (2) Add waterborne curing agent waterborne epoxy resin emulsion and into emulsified asphalt to get water-based epoxy emulsified asphalt. (3) Add skid resistance particles into water-based epoxy emulsified asphalt to get skid resistance fog seal.

Figure 11. Skid resistance fog seal development and performance verification process.

Figure 11. Skid resistance fog seal development and performance verification process.

3. Results and Discussion

3.1. Development of the Skid Resistance Fog Seal

3.1.1. Fog Seal

The fog seal was composed of water-based epoxy resin emulsion (E), epoxy emulsified asphalt (H), and a water-based curing agent (C). The fog seal layer composed of different material proportions is referred to herein as HxEx. For example, H80E3 represents a combination of 80% epoxy emulsified asphalt and 20% aqueous emulsified epoxy resin and an aqueous curing agent (the ratio of aqueous emulsified epoxy resin and an aqueous curing agent is 3:1). The best fog seal formulation was selected by studying the permeability, adhesion, and aging properties of different-formula fog seal layers:

- Permeability

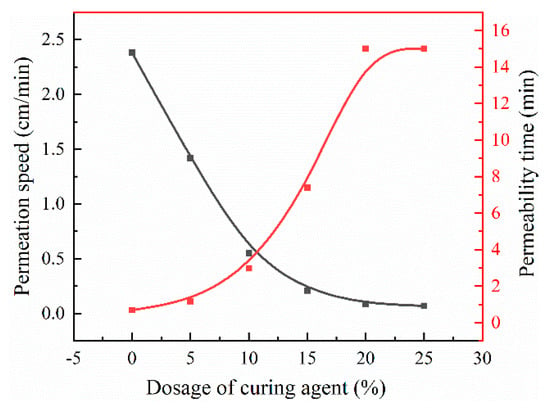

Table 4 and Figure 12 present the permeability of the epoxy emulsified asphalt under different curing agent dosages [31].

Table 4.

Permeability under different dosages of curing agent.

Figure 12.

Relationship between curing agent dosage and penetration rate.

The penetration of the epoxy emulsified asphalt was better when the amount of the curing agent was small. The amount of the curing agent of H90E2 was the smallest, exhibiting the best penetration. In contrast, the H50E2 penetration was the worst. Based on the penetration, the epoxy emulsified asphalt had a better penetration when the amount of curing agent was less than 10%, i.e., when the amount of asphalt component was more than 70%.

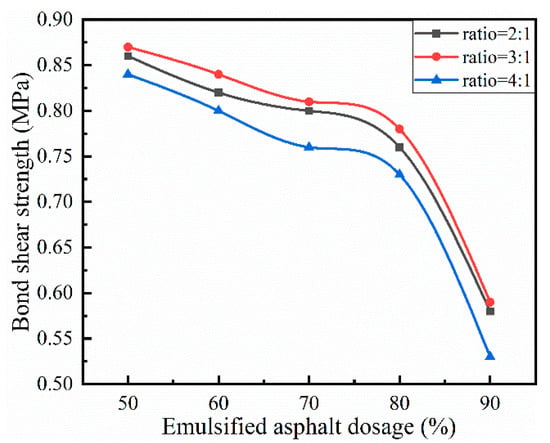

- Bond Performance

The bond shear strengths of the combined water-based epoxy resin emulsion and curing agent (referred to as the ratio) of 2:1, 3:1, and 4:1 were tested under different emulsified asphalt contents. Figure 13 shows the bond shear strength test results of the different ratios of epoxy emulsified asphalt.

Figure 13.

Bond shear strength of different dosage of epoxy emulsified asphalt.

Figure 13 shows that for a fixed ratio, the bonding shear strength continued to decrease as the amount of asphalt component increased. The decrease rate was slow when the asphalt content was not more than 80%. In other words, the bonding shear strength of the fog seal was greatly affected by the epoxy component. The greater the proportion of the epoxy component, the greater the bonding strength. The bond shear strength of the fog seal with different water-based epoxy resin emulsion to water-based curing agent ratios greatly varied. The fog seal layer with a 3:1 ratio showed the best bond performance. The bond performance of the fog seal with a 2:1 ratio was slightly lower than that of the 3:1 ratio layer; however, the difference gradually decreased as the amount of emulsified asphalt increased.

- Aging Resistance

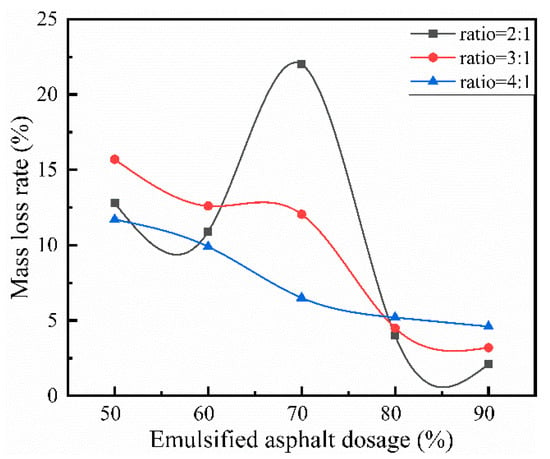

Figure 14 shows the mass loss rate of the epoxy emulsified asphalt-cured products with different ratios after 48 h of UV aging.

Figure 14.

Mass loss rate after UV aging.

The figure shows that in an asphalt component content greater than 80%, the mass loss rate of the specimen after aging decreases with the increase of the proportion of the curing agent if the asphalt component remains unchanged. This result indicates that adding a curing agent when the asphalt content is large can improve the epoxy aging resistance of the emulsified asphalt. The mass loss rate of the cured product was relatively large when the bitumen component content was less than 80%. The mass loss rate of the cured product decreased with the increase of the bitumen component content, except for the mix ratio H70E2.

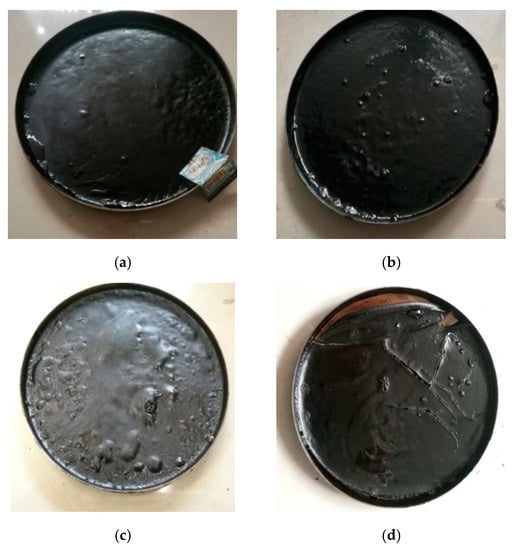

The aging resistance of the epoxy emulsified asphalt-cured product after 48 h of UV aging was divided into four levels according to the change of its appearance:

- Level I: no changes are found on the surface of the cured product. Only small bubbles appear;

- Level II: aging refers to the occurrence of surface sagging and appearance of small folds or bubbles;

- Level III: more bubbles appear on the surface of the cured product, and creases occur;

- Level IV: the surface of the cured product develops folds into larger cracks, local fractures, etc.

Figure 15 depicts all levels of aging appearance. The larger the aging appearance grade of the cured product, the worse its aging resistance. Table 5 presents the aging classification results of the epoxy resin emulsified asphalt-cured products with different ratios.

Figure 15.

All levels of aging appearance: (a) level-I; (b) level-II; (c) level-III; (d) level-IV.

Table 5.

UV aging test results.

The mass loss rate of the cured product after UV aging was large when the emulsified asphalt content was less than 80%. Many phenomena, such as wrinkles and fractures, were observed after aging. H90E2, H90E3, H90E4, and H80E2 had better resistance to ultraviolet aging when the aging rating was high.

In summary, the water-based epoxy resin emulsion with 9% mixed emulsifier (emulsifier D and E ratio of 2:1), B-44 emulsified asphalt, and water-based curing agent were used herein as the materials for the fog seal. The best combination was found to be H80E2.

3.1.2. Skid Resistance Fog Seal

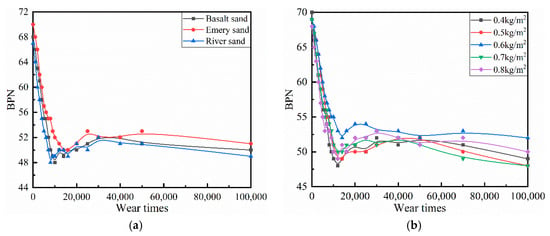

The development of the skid resistance fog seal refers to the addition of skid resistance particles to the fog seal used on a pavement to ensure pavement skid resistance. This study was conducted with respect to the type and amount of skid resistance particles. Figure 16 shows the test results.

Figure 16.

Test results of skid resistance fog seal development: (a) skid resistance particle type; (b) skid resistance particle dosage.

Figure 16a depicts that among the three types of skid resistance particles, emery provided the highest initial BPN (skid resistance) for the asphalt pavement. Its BPN curve was above the other two curves during the wear process, indicating that the BPN was higher than the other two. The BPN of the three specimens decreased by 32.5%, 32.8%, and 32.4%, respectively, after 100,000 instances of abrasion. The reduction ratio of the emery specimens was smaller with better skid resistance because of the inconsistent edges and corners of the skid resistance particles. The emery sand mostly had a cubic shape, with sharp edges and corners, a rough surface, and a uniform particle size distribution. In contrast, basalt and natural river sands were mostly spherical or ellipsoid in shape, with a smooth surface and a limited friction.

Figure 16b illustrates that when the amount of emery sand was 0.6 kg/m2, the BPN curve of the skid resistance seal specimen was located above, and the skid resistance was better. The surface roughness of the test piece can be significantly improved when the dosage is small; however, it can easily be worn away during the wear process because of the small mutual intercalation. The BPN also rapidly decreases. The surface structure was gradually filled when the dosage was close to 0.6 kg/m2. At this time, the fog seal specimen showed better skid resistance and wear resistance performance. When the content was large, the skid resistance fog seal had floating sand, and no fog sealant on the surface provided sufficient adhesion. Therefore, it can easily be abraded to reduce the skid resistance performance.

3.2. Evaluation of the Fog Seal Performance

The fog seal developed in Section 2.1 is referred to herein as the HPFA. The HPFA fog seal performance was verified by the bonding, penetration, and aging tests.

3.2.1. Evaluation of the Bond Performance

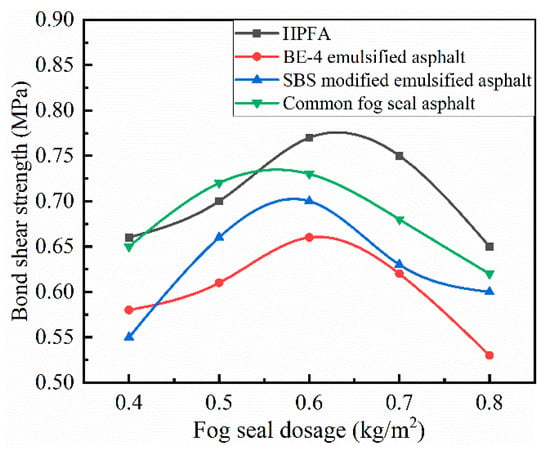

Figure 17 illustrates the results of the shear strength of the fog seal with different dosages.

Figure 17.

Bond performance of different amounts of fog seal.

The bond shear strength of the fog seal first increased and then decreased with the dosage increase, and the optimal dosage was 0.55–0.65 kg/m2. This is because the amount of fog seal is small, fog seal cannot completely cover the specimen. Therefore, the bond shear strength increased with the increase of the amount of the fog seal. The excess fog sealant formed a sliding surface when the amount exceeded the optimal amount, thereby reducing the shear strength. The bond performance of the HPFA fog seal was better than those of the other three materials.

3.2.2. Evaluation of the Permeability

Table 6 presents the permeability test results of the HPFA and three other types of fog seal binders.

Table 6.

Permeability of different fog seal.

Table 6 shows that the developed HPFA had a permeability rate of 1.29 cm/min and a penetration rate of 0.54 times that of the BE-4 emulsified asphalt, which was slightly lower than that of the emulsified asphalt. However, its penetration speed was higher than that of the SBS-modified emulsified asphalt and the commonly used asphalt in the fog seal layer. The permeability speed was 8.06 times of the SBS-modified emulsified asphalt and 3.69 times of the commonly used asphalt in the fog seal. The HPFA permeability had advantages.

3.2.3. Evaluation of the Aging Resistance

Table 7 presents the cured products of different types of fog sealants in terms of their mass loss rate, aging classification, and appearance after 48 h of UV aging.

Table 7.

Aging test results of different types of fog seal.

Table 7 shows that the mass loss rate of the HPFA-cured products after aging was low. Compared with the BE-4 emulsified asphalt, SBS-modified emulsified asphalt, and commonly used asphalt for the fog seal layer, the mass loss rate was reduced by 9.7%, 31.1%, and 40.0%, respectively. The aging classification of the HPFA was Level I, and the aging performance was better. The BE-4 emulsified asphalt-cured product exhibited slight wrinkles on the surface after aging, with a Level II aging rating. The surface of the SBS-modified emulsified asphalt produced a large number of small bubbles and fine depressions, with a Level II aging grade. The surface of the commonly used asphalt on the fog seal layer had wrinkles, with an aging rating of Level III. The HPFA-cured product surface showed a few bubbles, but no wrinkles. In summary, the HPFA-cured product had the lowest mass loss rate after the UV aging, with an aging rating of Level I. The aging performance was optimal.

3.3. Application Research of the Skid Resistance Fog Seal

The application research of the skid resistance fog seal was performed from the aspects of the road performance and the construction technology of the skid resistance fog seal. The skid resistance, wear, and water seepage performance of the skid resistance fog seal were studied. The skid and wear resistance of the fog seal under different construction processes were also investigated.

3.3.1. Road Performance of the Skid Resistance Fog Seal

- Skid Resistance

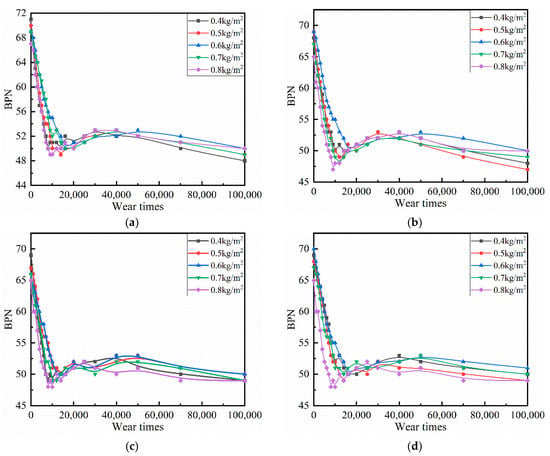

Figure 18 illustrates the skid resistance performance results of the skid resistance fog seal with different dosages.

Figure 18.

Skid resistance performance of different fog seals: (a) HPFA; (b) SBS-modified emulsified asphalt; (c) common fog seal; (d) BE-4 emulsified asphalt.

The amount of skid resistance fog seal had a better skid resistance performance at 0.5–0.7 kg/m2. The skid resistance performance was still better than that of the other fog seals as the number of wear times increased. After 100,000 instances of abrasion, the skid resistance was greater than 50 BPN when the amount of the HPFA skid resistance seal was 0.6 kg/m2. This result indicated a good skid resistance performance.

- Wear Resistance

Table 8 depicts the mass loss rate after 100,000 instances of abrasion.

Table 8.

Mass loss rate after 100,000 wears.

After 10,000 instances of abrasion, the mass loss rate of the skid resistance fog seal was the lowest when the dosage was 0.6–0.7 kg/m2, indicating a good wear resistance. The difference in the wear resistance of the three types of fog seals was small. Moreover, the mass loss rate after 100,000 wears was close when the dosage was 0.6 kg/m2.

- Water Sealing Performance

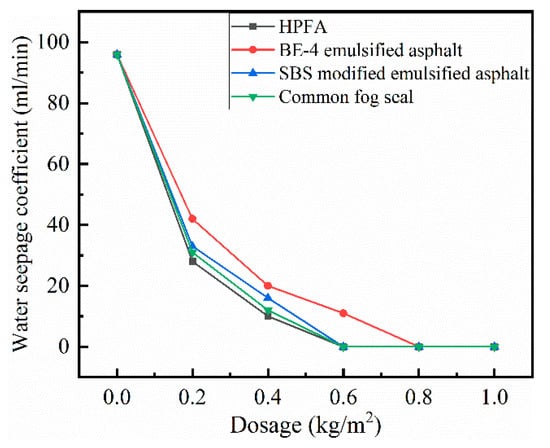

Table 9 and Figure 19 show the water sealing performance results of the skid resistance fog seal with different dosages.

Table 9.

Water seepage coefficient of fog seal with different dosage.

Figure 19.

Water seepage coefficient of fog seal with different dosage.

The reduction ratio of the water permeability coefficient was more than 50% when different amounts of fog sealant were applied on the rutting board. This result indicates that the fog seal layer material can effectively improve the road surface anti-seepage ability. The fog seal layer commonly used asphalt, SBS-modified emulsified asphalt, and HPFA when the dosage was close to 0.6 kg/m2. The rut board can be completely impermeable to water. Meanwhile, the BE-4 type emulsified asphalt can be completely sealed when the dosage was close to 0.8 kg/m2. The critical dosage when the fog sealant was completely sealed with water was taken as the optimal amount of fog sealant for the road surface, i.e., the minimum amount when the road surface is completely impervious to water.

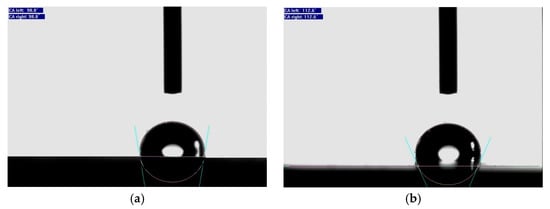

The OCA-20 video optical contact angle measuring instrument was used to measure the contact angle between the evaporation residue of the BE-4 emulsified asphalt and the cured product of the HPFA. SCA-20 software was used to analyze and calculate the contact angle. Figure 20 presents the test results.

Figure 20.

Contact angle measurement image: (a) BE-4 modified emulsified asphalt; (b) HPFA.

The calculation results of Figure 20 and SCA-20 software indicate that the contact angles of the evaporation residue of the BE-4 emulsified asphalt and the cured product of the HPFA were 98.8° and 112.6°, respectively. The material surface was hydrophilic and easily wet by liquid when the contact angle was θ < 90°. For the contact angle θ > 90°, the material surface was hydrophobic. The greater the contact angle, the better the hydrophobic performance. The surfaces of the two materials were hydrophobic. The contact angle of the HPFA was larger. In other words, it had better water sealing and hydrophobic performance and penetration adhesion when used as a fog seal binder.

3.3.2. Influence of the Construction Technology on the Fog Seal

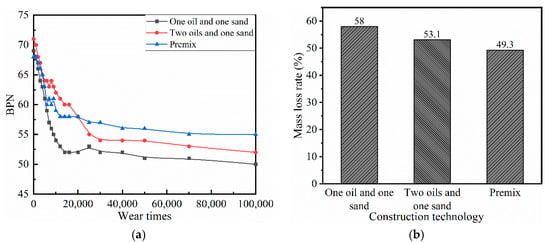

Figure 21 depicts the three construction processes, namely the “one oil and one sand,” “two oil and one sand,” and premix processes. Figure 22 shows the performance test results. The “one oil and one sand” process refers to spreading skid resistance particles after smearing the fog seal on the substrate. The “two oils and one sand” process means applying apply another layer of fog seal on the basis of the “one oil and one sand” process. Meanwhile, the premix process refers to premixing the fog seal and the skid resistance particles and painting on the substrate.

Figure 21.

Construction technology: (a) one oil and one sand; (b) two oils and one sand; (c) premix.

Figure 22.

Performance of skid resistance fog seal under different construction techniques: (a) skid resistance; (b) wear resistance.

Figure 22a depicts that the initial BPN of the premix process specimen was the smallest, while that of the “one oil and one sand” process specimen was the largest. This result can be attributed to the premix process fully covering the skid resistance particles with the mist-sealing binder, such that the anti-slip particles lost angularity, and the surface roughness was reduced. After 100,000 instances of abrasion, the BPN of the three kinds of test pieces decreased by 25.0%, 20.0%, and 13.2%, respectively. The BPN of the test pieces formed by the premix process had the smallest reduction and a better wear resistance performance. This result is attributed to the premix process being able to fully cover the fog seal binder and skid resistance particles, which increased the adhesion area of the skid resistance particles and the fog seal binder and further improved the adhesion, making the skid resistance particles not easily worn away. Better anti-slip performance and wear resistance were observed.

Figure 22b shows that compared to the “one oil and one sand”—and “two oil and one sand”—shaped test pieces, the mass loss rates after 100,000 instances of wear of the test pieces formed by the three processes were 58.0%, 53.1%, and 49.3%, respectively. The quality loss rates of the process specimens were reduced by 15.0% and 7.2%, respectively, with better wear resistance.

4. Conclusions

The following conclusions were obtained from the results of this study:

- The fog seal layer (A80E2) was developed by studying the permeability, bond performance, and aging resistance of the fog seal. The effect of the type and amount of skid resistance particles on the skid and wear resistance of the fog seal was studied to develop the skid resistance fog seal in this work;

- The self-made fog seal (i.e., HPFA) was compared with the remaining three fog seals in terms of the bond performance, permeability, and aging resistance. The results showed that the HPFA had the best bonding strength of up to 0.77 MPa, an excellent permeability (permeability rate: up to 1.29 cm/min), and a good aging resistance (mass loss rate after 48 h UV aging: 3.93%; aging level: Level I);

- The skid resistance fog seal showed an excellent road performance. After 100,000 instances of abrasion, the fog seal exhibited excellent skid resistance (54 BPN), good wear resistance (mass loss rate: 58.8%), and good water sealing capability (i.e., 0.6 kg/m2 can completely seal the water);

- The skid resistance fog seal constructed by the premix process demonstrated the best skid resistance performance and wear resistance, providing a reference for the fog seal construction.

Author Contributions

Conceptualization, Y.J. and Y.Y.; methodology, Y.Y.; software, T.T.; validation, C.D., K.Y., and Y.J.; formal analysis, Y.Y.; investigation, J.F.; resources, Y.J.; data curation, J.X.; writing—original draft preparation, T.T.; writing—review and editing, Y.Y.; visualization, J.X.; supervision, Y.J.; project administration, Y.Y.; funding acquisition, Y.J. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the scientific project from Shaanxi Provincial Communication (No. 16-17k), the scientific Research of Central Colleges of China for Chang’an University (Grant No. 300102218212), and the scientific project from Henan Provincial Communication (No. 2020J-2-2 95)

Acknowledgments

This work was supported by the scientific project from Shaanxi Provincial Communication (No. 16-17k), furthermore, we are grateful for Shaanxi Communications Construction Group Co. LTD.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Perez-Acebo, H.; Mindra, N.; Railean, A.; Roji, E. Rigid pavement performance models by means of markov chains with half-year step time. Int. J. Pavement Eng. 2019, 20, 830–843. [Google Scholar] [CrossRef]

- Elhadidy, A.A.; El-Badawy, S.M.; Elbeltagi, E.E. A simplified pavement condition index regression model for pavement evaluation. Int. J. Pavement Eng. 2019, 10. [Google Scholar] [CrossRef]

- Marcelino, P.; Antunes, M.D.; Fortunato, E. Comprehensive performance indicators for road pavement condition assessment. Struct. Infrastruct. Eng. 2018, 14, 1433–1445. [Google Scholar] [CrossRef]

- Jiang, Y.J.; Deng, C.Q.; Xue, J.S.; Liu, H.P.; Chen, Z.J. Investigation of the fatigue properties of asphalt mixture designed using vertical vibration method. Road Mater. Pavement Des. 2020, 21, 1454–1469. [Google Scholar] [CrossRef]

- Yi, Y.; Jiang, Y.J.; Li, Q.L.; Deng, C.Q.; Ji, X.P.; Xue, J.S. Development of super road heat-reflective coating and its field application. Coatings 2019, 9, 802. [Google Scholar] [CrossRef]

- Jiang, Y.; Deng, C.; Chen, Z.; Tian, Y. Evaluation of the cooling effect and anti-rutting performance of thermally resistant and heat-reflective pavement. Int. J. Pavement Eng. 2018, 21, 1–10. [Google Scholar] [CrossRef]

- Ji, X.P.; Jiang, Y.J.; Zou, H.W.; Cao, F.; Hou, Y.Q. Application of numerical simulation method to improve shear strength and rutting resistance of asphalt mixture. Int. J. Pavement Eng. 2020, 21, 112–121. [Google Scholar] [CrossRef]

- Yao, L.Y.; Dong, Q.; Ni, F.J.; Jiang, J.W.; Lu, X.R.; Du, Y.G. Effectiveness and cost-effectiveness evaluation of pavement treatments using life-cycle cost analysis. J. Transp. Eng. Part B Pavements 2019, 145, 04019006. [Google Scholar] [CrossRef]

- Chen, X.Q.; Dong, Q.; Gu, X.Y.; Mao, Q. Bayesian analysis of pavement maintenance failure probability with markov chain monte carlo simulation. J. Transp. Eng. Part B Pavements 2019, 145, 9. [Google Scholar] [CrossRef]

- Prapaitrakul, N.; Freeman, T.; Glover, C. Fog seal treatment effectiveness analysis of pavement binders using the t-test statistical approach. Pet. Sci. Technol. 2010, 28, 1895–1905. [Google Scholar] [CrossRef]

- Yunlong, L.; Yuanquan, Y. Study on Preparation and thermal reflective properties of energy saving pigments with selective solar reflection. IOP Conf. Ser. Mater. Sci. Eng. 2019, 544, 012010. [Google Scholar] [CrossRef]

- Li, X.L.; Ye, J.H.; Badjona, Y.; Chen, Y.L.; Luo, S.; Song, X.J.; Zhang, H.R.; Yao, H.; Yang, L.; You, L.Y.; et al. Preparation and performance of colored ultra-thin overlay for preventive maintenance. Constr. Build. Mater. 2020, 249, 118619. [Google Scholar] [CrossRef]

- Hamdia, K.M.; Rabczuk, T. Key parameters for fracture toughness of particle/polymer nanocomposites; sensitivity analysis via xfem modeling approach. In Proceedings of the 7th International Conference on Fracture Fatigue and Wear, FFW 2018, Ghent, Belgium, 9–10 July 2018; pp. 41–51. [Google Scholar] [CrossRef]

- Feng, P.N.; Wang, H.N.; Zhang, X.; Hasan, M.R.M.; You, Z.P.; Gao, J.F. Study on workability and skid resistance of bio-oil-modified fog seal with sand. J. Test. Eval. 2020, 48, 2072–2092. [Google Scholar] [CrossRef]

- Li, Q.J.; Zhan, Y.; Yang, G.; Wang, K.C.P. Pavement skid resistance as a function of pavement surface and aggregate texture properties. Int. J. Pavement Eng. 2018, 21, 1–11. [Google Scholar] [CrossRef]

- Pérez-Acebo, H.; Gonzalo-Orden, H.; Findley, D.J.; Rojí, E. A skid resistance prediction model for an entire road network. Constr. Build. Mater. 2020, 262, 120041. [Google Scholar] [CrossRef]

- Im, J.H.; Kim, Y.R. Performance evaluation of fog seals on chip seals and verification of fog seal field tests. Can. J. Civ. Eng. 2015, 42, 872–880. [Google Scholar] [CrossRef]

- Hu, C.C.; Zhao, J.Y.; Leng, Z.; Partl, M.N.; Li, R. Laboratory evaluation of waterborne epoxy bitumen emulsion for pavement preventative maintenance application. Constr. Build. Mater. 2019, 197, 220–227. [Google Scholar] [CrossRef]

- Islam, R.M.; Arafat, S.; Wasiuddin, N.M. Quantification of reduction in hydraulic conductivity and skid resistance caused by fog seal in low-volume roads. Transp. Res. Rec. 2017, 2657, 99–108. [Google Scholar] [CrossRef]

- Liang, H.H.; Wang, D.Y.; Wang, G.; Li, D.N.; Xu, C.; Liang, X.Y. Numerical simulation and laboratory testing verification on the performance of an asphalt pavement seal coat with superficially permeating and solidifying properties. J. Test. Eval. 2019, 47, 4427–4451. [Google Scholar] [CrossRef]

- Yang, G.L.; Wang, C.H.; Fu, H.; Yan, Z.B.; Yin, W.Y. Waterborne epoxy resin-polyurethane-emulsified asphalt: Preparation and properties. J. Mater. Civ. Eng. 2019, 31, 11. [Google Scholar] [CrossRef]

- Cui, P.D.; Wu, S.P.; Xu, H.Q.; Lv, Y. Silicone resin polymer used in preventive maintenance of asphalt mixture based on fog seal. Polymers 2019, 11, 1814. [Google Scholar] [CrossRef] [PubMed]

- Im, J.H.; Kim, Y.R. Methods for fog seal field test with polymer-modified emulsions development and performance evaluation. Transp. Res. Rec. 2013, 2361, 88–97. [Google Scholar] [CrossRef]

- Zhao, H.; Li, H.P.; Liao, K.J.; Li, Y.G. The anti-aging performance of emulsified asphalt. Pet. Sci. Technol. 2012, 30, 193–200. [Google Scholar] [CrossRef]

- Xu, B.; Li, M.L.; Liu, S.H.; Fang, J.; Ding, R.D.; Cao, D.W. Performance analysis of different type preventive maintenance materials for porous asphalt based on high viscosity modified asphalt. Constr. Build. Mater. 2018, 191, 320–329. [Google Scholar] [CrossRef]

- Synthetic Cutting Fluids (GB/T 6144-2010) National Petroleum Products and Lubricants Standardization Technical Committee Petroleum Fuels and Lubricants Sub-Technical Committee; China Standard Press: Beijing, China, 2010. (In Chinese)

- Epoxy Resin Flooring Coating (JCT 1015-2006) National Standardization Technical Committee of Lightweight and Decorative Building Materials; China Standard Press: Beijing, China, 2006. (In Chinese)

- Technical Specification for Highway Asphalt Pavement Construction (JTG F40-2004) Highway Research Institute of the Ministry of Communications; China Communications Press: Beijing, China, 2004. (In Chinese)

- Sand for Construction (GB/T 14684-2011) China Building Materials Federation; China Standard Press: Beijing, China, 2011. (In Chinese)

- Zhu, J.; Lei, M.-J.; Zhang, H.; Zhu, Y.T. Research on the mechanical properties of asphalt pavement adhesive layer based on the interlayer shear tests. J. Wuhan Univ. Technol Transp. Sci. Eng. 2013, 37, 775–779. (In Chinese) [Google Scholar]

- Song, X.H. Research on Evaluation Method and Index of Connection State between Base and Surface of Asphalt Pavement. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 6 June 2008. [Google Scholar]

- Jin, J.; Chen, S.J.; Zhang, J. UV aging behaviour of ethylene-vinyl acetate copolymers (EVA) with different vinyl acetate contents. Polym. Degrad. Stabil. 2010, 95, 725–732. [Google Scholar] [CrossRef]

- Field Test Methods of Highway Subgrade and Pavement (JTG 3450-2019) Research Institute of Highway Ministry of Transport; China Communications Press: Beijing, China, 2019. (In Chinese)

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).