Novel Terahertz Nondestructive Method for Measuring the Thickness of Thin Oxide Scale Using Different Hybrid Machine Learning Models

Abstract

:1. Introduction

2. Material and Methods

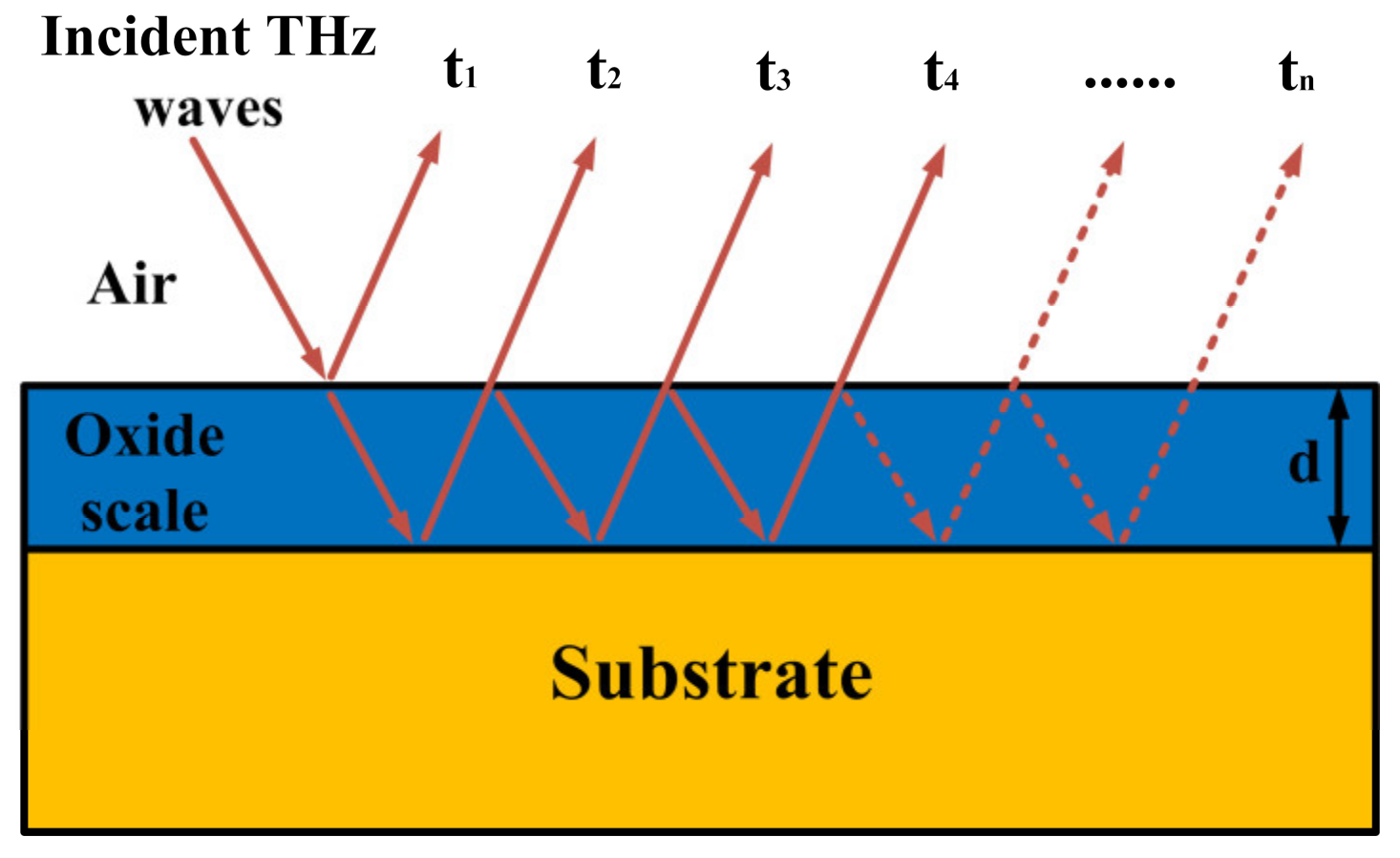

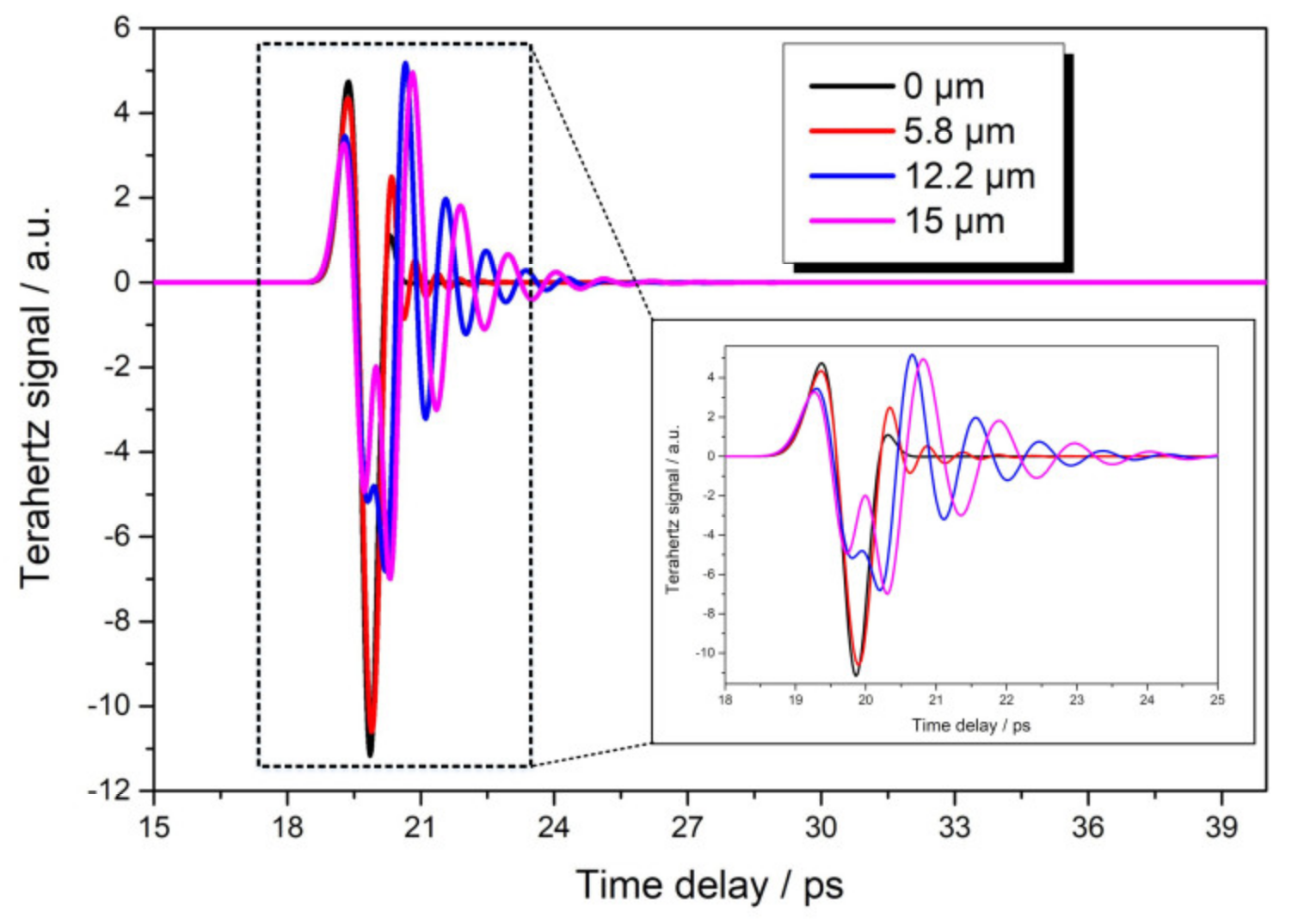

2.1. Terahertz Inspection Signal Obtained by FDTD Simulation

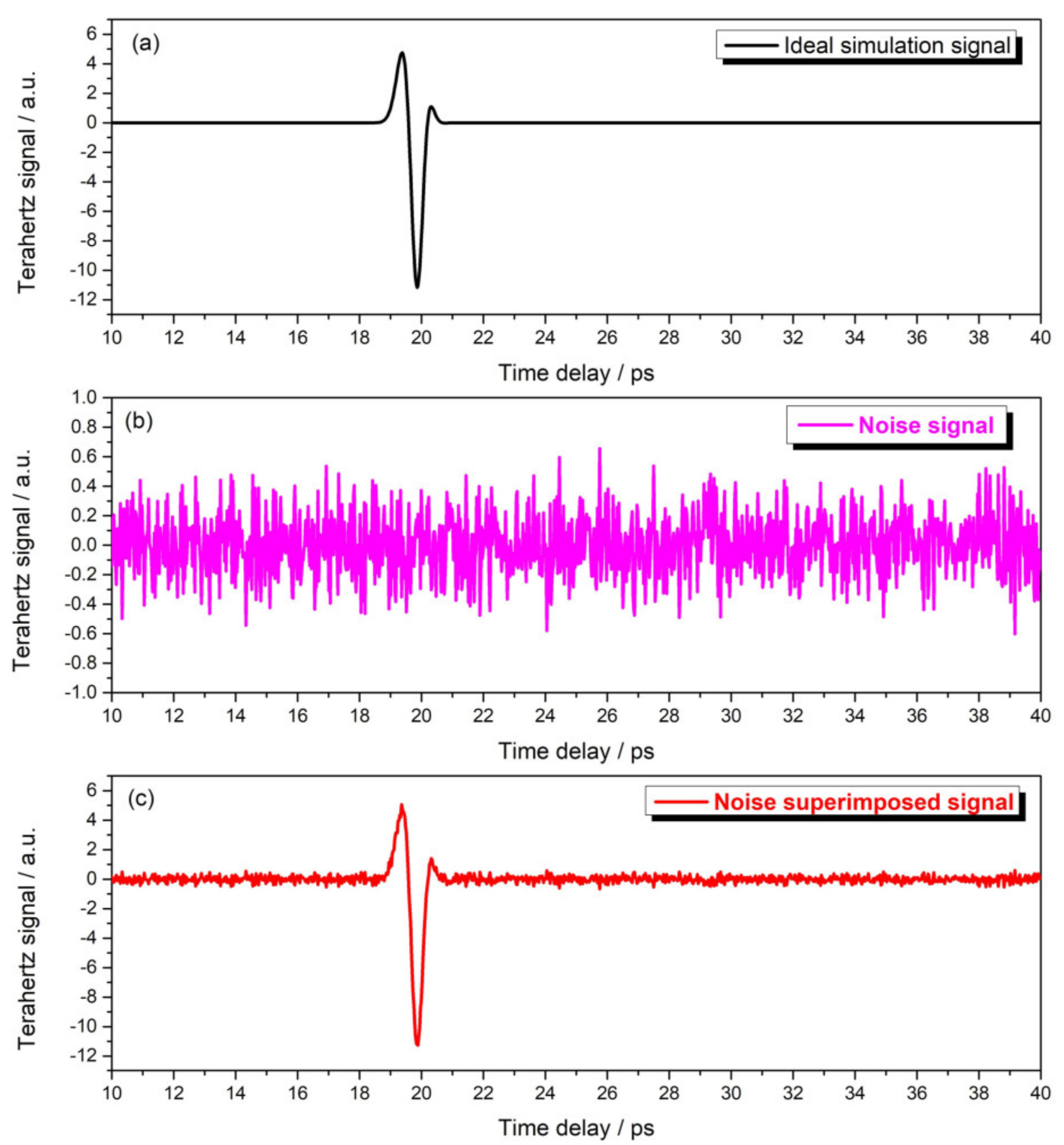

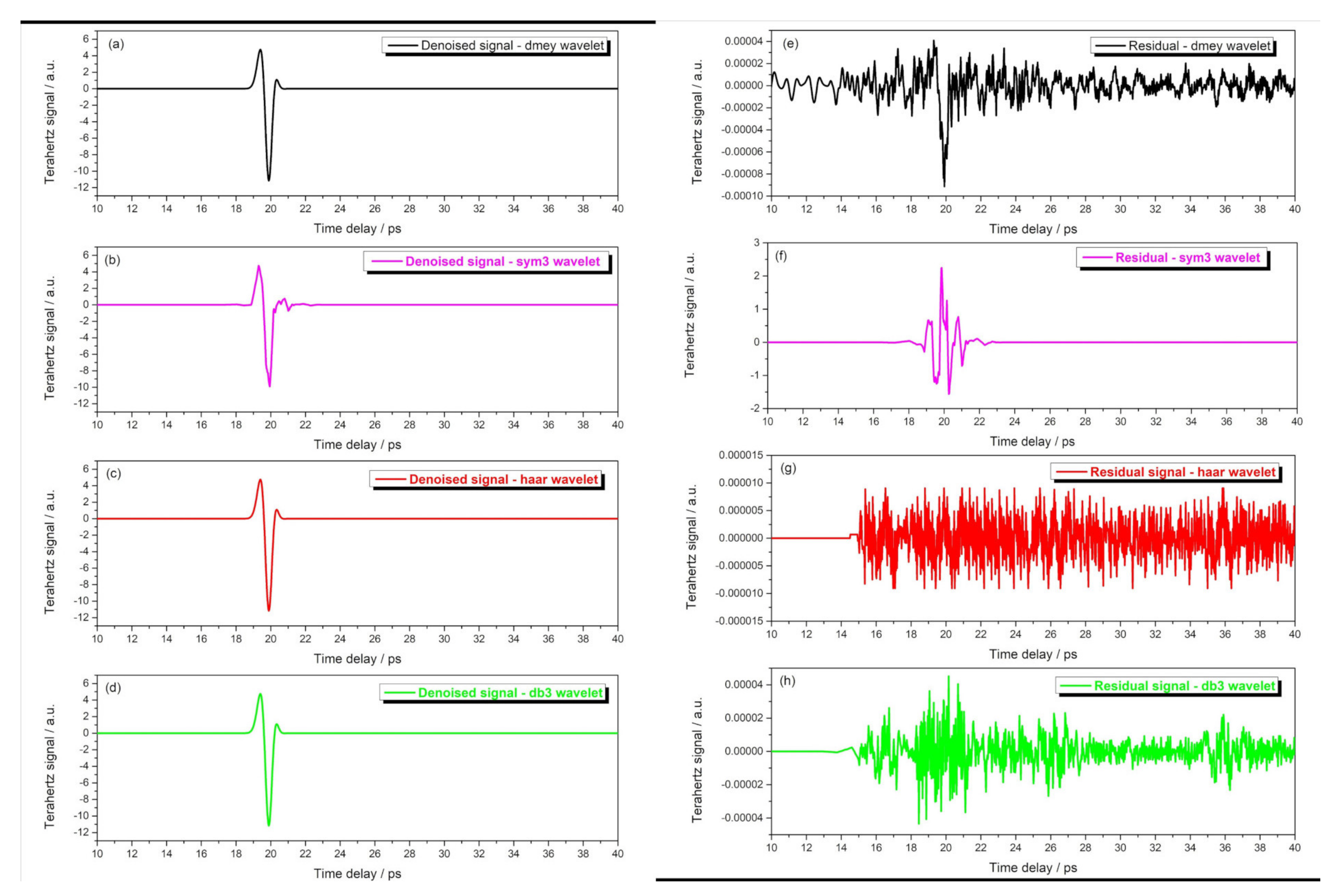

2.2. Signal Nosie Reduction Methods

2.3. Modeling Approaches

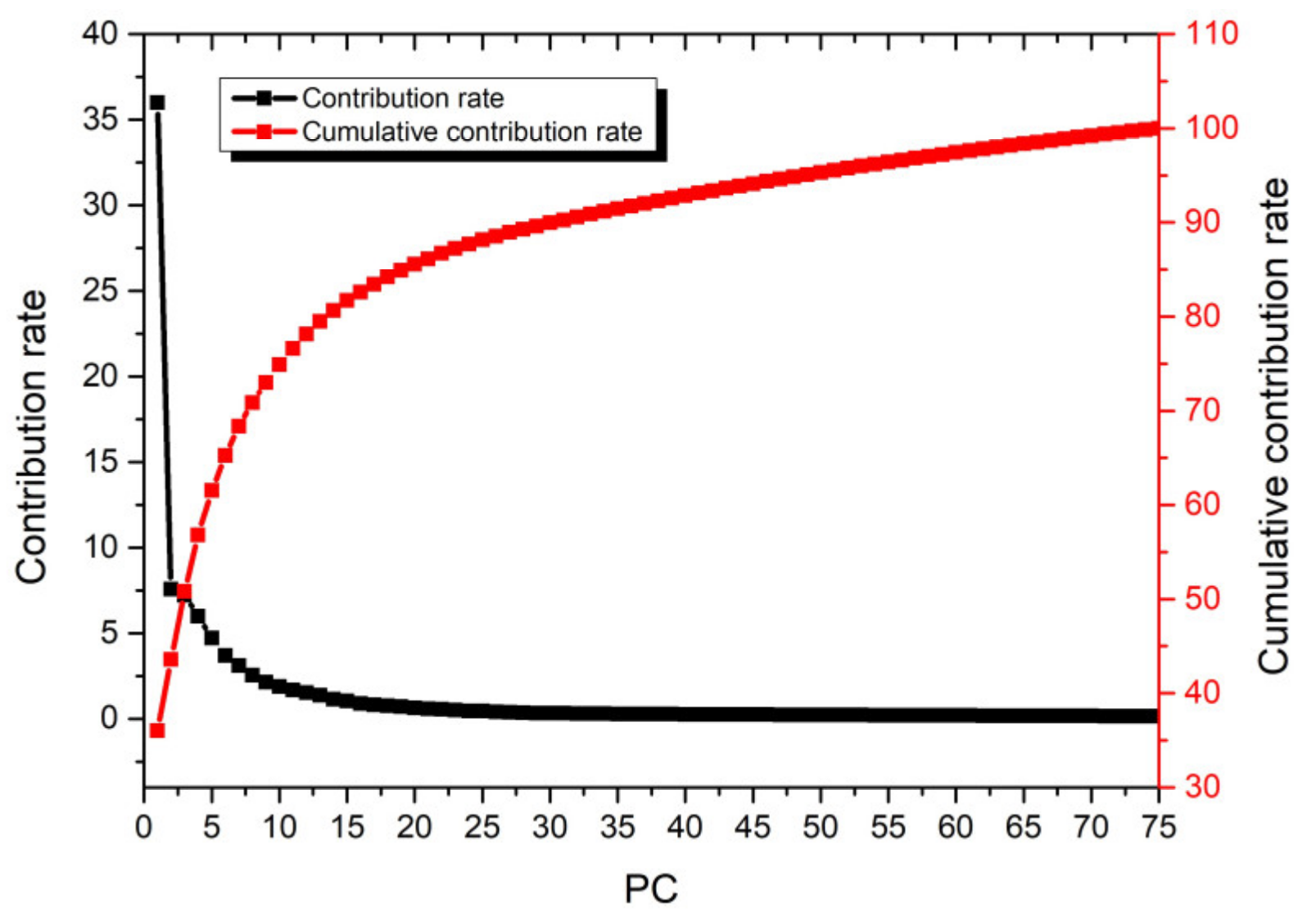

2.3.1. Principal Component Analysis

2.3.2. Back-Propagation Neural Network

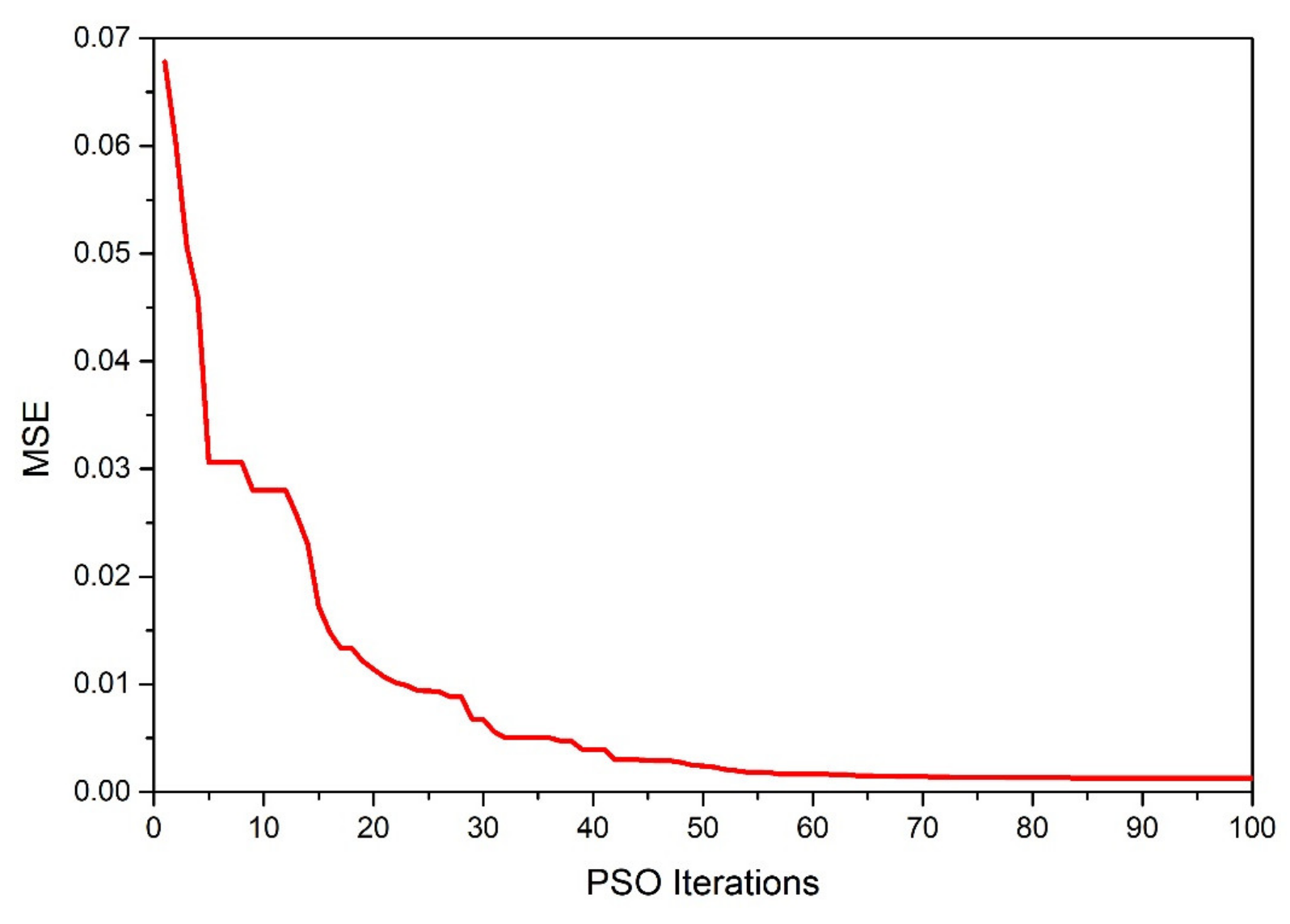

2.3.3. Extreme Learning Machine Optimized by Particle Swarm Optimization Algorithm

- Initialize the particle swarm, select the appropriate learning factors (c1 and c2), inertia weight, particle dimension D, maximum iteration number K and population size M.

- For computing the single individuals and , the ELM algorithm can calculate the output weight matrix, and use the training samples to calculate the mean square error (, n is the number of measurements, is the deviation of a set of measured values from the average) of the individual of the initial population.

- Set the PSO adaptability , compare the values of and pbest in the same iteration, when is greater than pbest, then use instead of pbest, otherwise it will remain unchanged. Then compare the values of and gbest, when is greater than gbest, then use instead of gbest, otherwise it will still remain unchanged. For three conditions: the number of running times is greater than or equal to the maximum number of iterations, the running time is greater than or equal to the longest running time, and the fitness value is less than or equal to the specified threshold. When any one of these three conditions is met, exit the program and return the current optimal individual and fitness.

- The and corresponding to the optimal fitness are obtained, and the output weight matrix H is calculated by using Equation (4).

2.3.4. Statistical Assessment of Machine Learning Models

3. Results and Discussion

3.1. Comparison of Various Denoising Methods

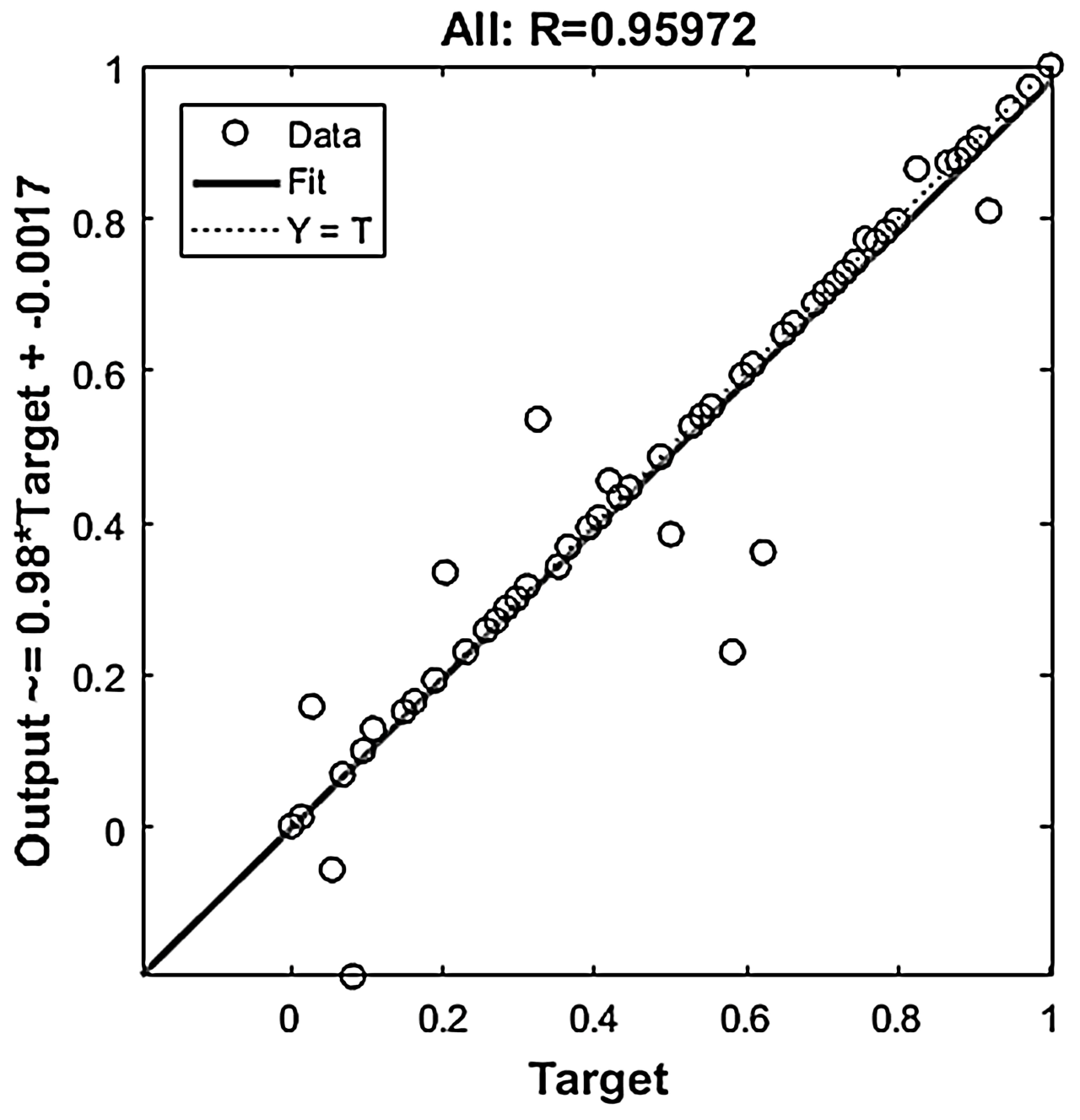

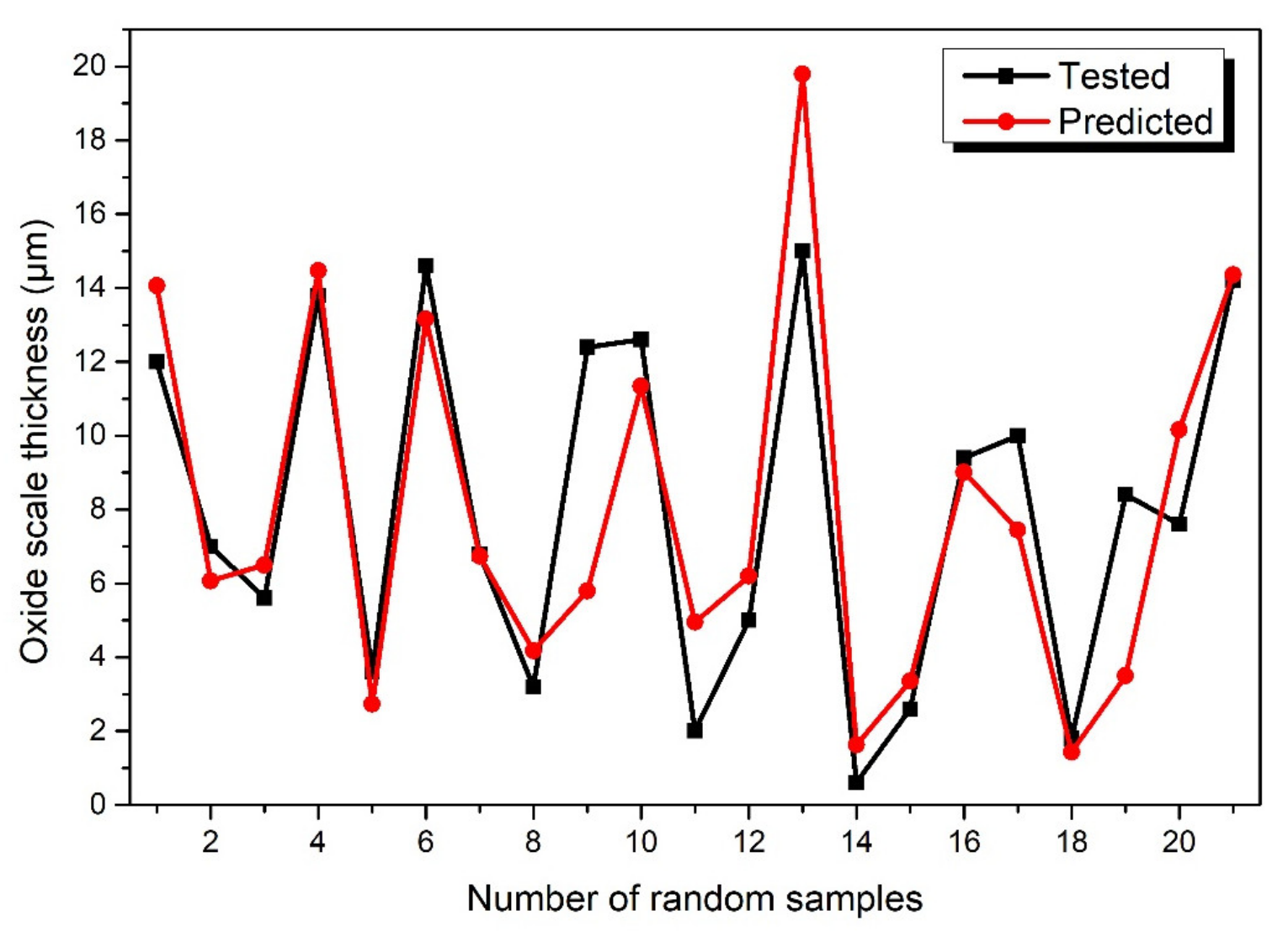

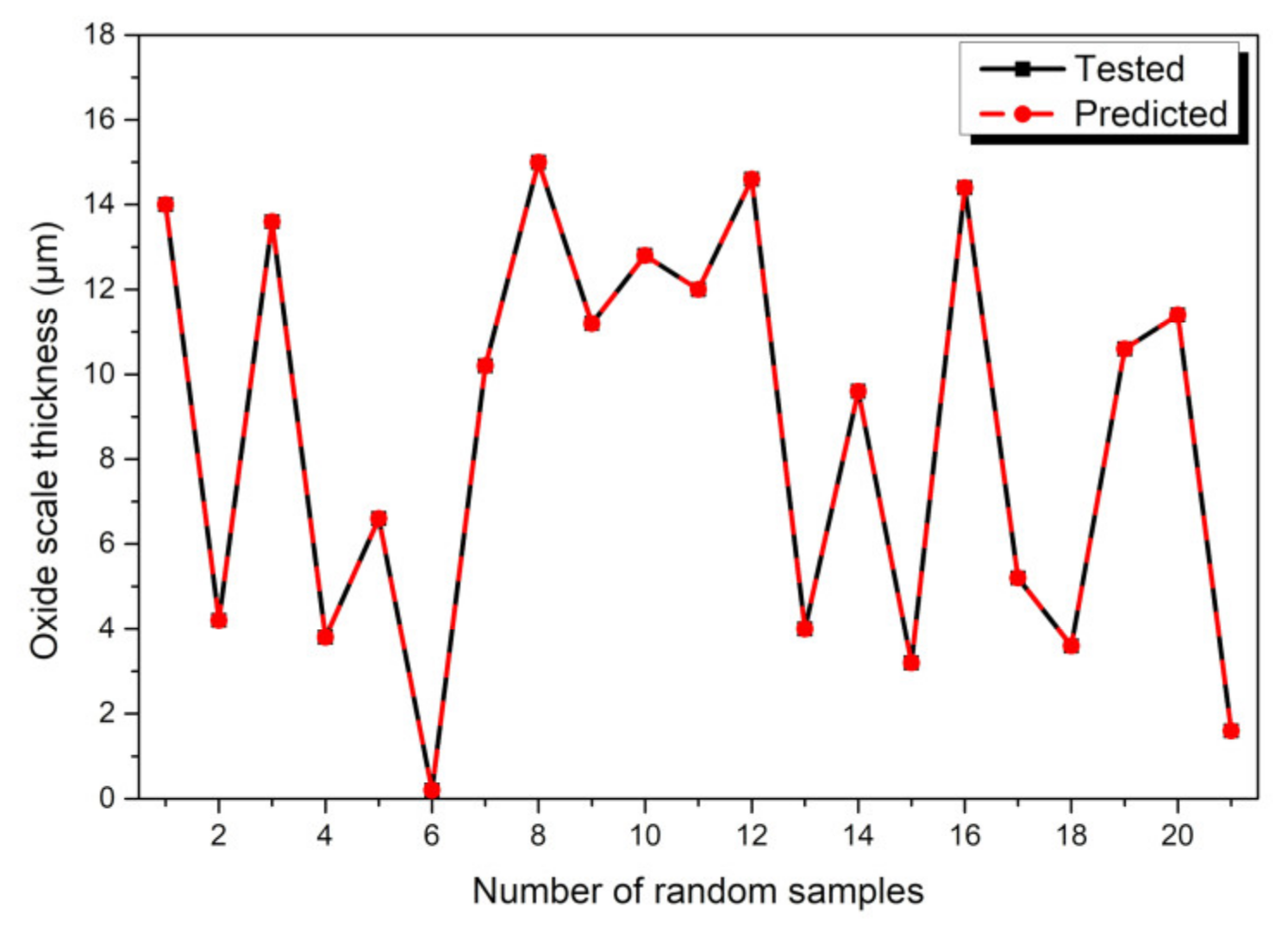

3.2. Comparison of Various Hybrid Machine Learning Approaches

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, S.R.; Lee, S.; Kang, H.G.; Park, J.W. Oxide scale on stainless steels and its effect on sticking during hot-rolling. Corros. Sci. 2019, 164, 108357. [Google Scholar] [CrossRef]

- Chen, R.Y.; Yuen, W.Y.D. Oxide-scale structures formed on commercial hot-rolled steel strip and their formation mechanisms. Oxid. Met. 2001, 56, 89–118. [Google Scholar] [CrossRef]

- Schwertmann, U.; Cornell, R.M. The Iron Oxides Iron Oxides in the Laboratory: Preparation and Characterization; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2007. [Google Scholar]

- Chen, R.Y.; Yuen, W.Y.D. Examination of oxide scales of hot rolled steel products. ISIJ Int. 2005, 45, 52–59. [Google Scholar] [CrossRef] [Green Version]

- Chattopadhyay, A.; Bandyopadhyay, N.; Das, A.K.; Panigrahi, M. Oxide scale characterization of hot rolled coils by raman spectroscopy technique. Scr. Mater. 2005, 52, 211–215. [Google Scholar] [CrossRef]

- He, Y.; Jia, T.; Liu, X.; Cao, G.; Liu, Z.; Li, J. Hot-dip galvanizing of carbon steel after cold rolling with oxide scale and hydrogen descaling. J. Iron Steel Res. Int. 2014, 21, 222–226. [Google Scholar] [CrossRef]

- Chattopadhyay, A.; Kumar, P.; Roy, D. Study on formation of “easy to remove oxide scale” during mechanical descaling of high carbon wire rods. Surf. Coat. Technol. 2009, 203, 2912–2915. [Google Scholar] [CrossRef]

- Le Guevel, Y.; Grégoire, B.; Bouchaud, B.; Bilhé, P.; Pasquet, A.; Thiercelin, M.; Pedraza, F. Influence of the oxide scale features on the electrochemical descaling and stripping of aluminide coatings. Surf. Coat. Technol. 2016, 292, 1–10. [Google Scholar] [CrossRef]

- Shi, J.; Wang, D.R.; He, Y.D.; Qi, H.B.; Wei, G. Reduction of oxide scale on hot-rolled strip steels by carbon monoxide. Mater. Lett. 2008, 62, 3500–3502. [Google Scholar]

- Eldridge, J.I.; Bencic, T.J. Monitoring delamination of plasma-sprayed thermal barrier coatings by reflectance-enhanced luminescence. Surf. Coat. Technol. 2006, 201, 3926–3930. [Google Scholar] [CrossRef] [Green Version]

- Gentleman, M.; Clarke, D. Concepts for luminescence sensing of thermal barrier coatings. Surf. Coat. Technol. 2004, 188, 93–100. [Google Scholar] [CrossRef]

- Eldridge, J.I.; Wolfe, D.E. Monitoring thermal barrier coating delamination progression by upconversion luminescence imaging. Surf. Coat. Technol. 2019, 378, 124923. [Google Scholar] [CrossRef]

- Park, H.; Lee, C.S. Quantitative elemental analysis of Fe–Zn–alloy coating by nondestructive method. X Ray Spectrom. 2008, 37, 561–564. [Google Scholar] [CrossRef]

- Queralt, I.; Ibañez, J.; Marguí, E.; Pujol, J. Thickness measurement of semiconductor thin films by energy dispersive X-ray fluorescence benchtop instrumentation: Application to GaN epilayers grown by molecular beam epitaxy. Spectrochim. Acta Part B At. Spectrosc. 2010, 65, 583–586. [Google Scholar] [CrossRef]

- Liu, Y.T.; Mu, R.D.; Guo, G.P.; Yang, G.G.; Tang, J. Infrared flash thermographic nondestructive testing of defects in thermal barrier coating. J. Aeronaut. Mater. 2015, 35, 83–90. [Google Scholar]

- Shrestha, R.; Kim, W. Evaluation of coating thickness by thermal wave imaging: A comparative study of pulsed and lock-in infrared thermography–Part II: Experimental investigation. Infrared Phys. Technol. 2018, 92, 24–29. [Google Scholar] [CrossRef]

- Hamel, M.; Addali, A.; Mba, D. Monitoring oil film regimes with acoustic emission. Proc. Inst. Mech. Eng. Part J. 2014, 228, 223–231. [Google Scholar] [CrossRef]

- Liu, G.; Toncich, D.J.; Harvey, E.C. Evaluation of excimer laser ablation of thin Cr film on glass substrate by analysing acoustic emission. Opt. Lasers Eng. 2004, 42, 639–651. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, Y.; Lai, C.; Lai, C. Thickness measurement of multi-layer conductive coatings using multifrequency eddy current techniques. Nondestr. Test. Eval. 2016, 31, 1–18. [Google Scholar] [CrossRef]

- Khan, A.N.; Khan, S.H.; Ali, F.; Iqbal, M.A. Evaluation of ZrO2–24MgO ceramic coating by eddy current method. Comput. Mater. Sci. 2009, 44, 1007–1012. [Google Scholar] [CrossRef]

- Lavrentyev, A.I.; Rokhlin, S.I. An ultrasonic method for determination of elastic moduli, density, attenuation and thickness of a polymer coating on a stiff plate. Ultrasonics 2001, 39, 211–221. [Google Scholar] [CrossRef]

- Chen, H.L.R.; Zhang, B.; Alvin, M.A.; Lin, Y. Ultrasonic detection of delamination and material characterization of thermal barrier coatings. J. Therm. Spray Technol. 2012, 21, 1184–1194. [Google Scholar] [CrossRef]

- Wang, W.; Wei, J.; Hong, H.; Xuan, F.; Shan, Y. Effect of processing and service conditions on the luminescence intensity of plasma sprayed (Tm3++Dy3+) co-doped YSZ coatings. J. Alloys Compd. 2014, 584, 136–141. [Google Scholar] [CrossRef]

- Vavilov, V.P.; Burleigh, D.D. Review of pulsed thermal NDT: Physical principles, theory and data processing. NDT E Int. 2015, 73, 28–52. [Google Scholar] [CrossRef]

- Dhillon, S.S.; Vitiello, M.S.; Linfield, E.H.; Davies, A.G.; Hoffmann, M.C.; Booske, J.; Paoloni, C.; Gensch, M.; Weightman, P.; Williams, G.P.; et al. The 2017 terahertz science and technology roadmap. J. Phys. D Appl. Phys. 2017, 50, 043001. [Google Scholar] [CrossRef]

- Zhong, S. Progress in terahertz nondestructive testing: A review. Front. Mech. Eng. 2018, 14, 273–281. [Google Scholar] [CrossRef]

- Ospald, F.; Zouaghi, W.; Beigang, R.; Matheis, C.; Jonuscheit, J.; Recur, B.; Guillet, J.P.; Mounaix, P.; Vleugels, W.; Pablo, V.; et al. Aeronautics composite material inspection with a terahertz time-domain spectroscopy system. Opt. Eng. 2013, 53, 031208. [Google Scholar] [CrossRef]

- Ye, D.; Wang, W.; Huang, J.; Lu, X.; Zhou, H. Nondestructive interface morphology characterization of thermal barrier coatings using terahertz time-domain spectroscopy. Coatings 2019, 9, 89. [Google Scholar] [CrossRef] [Green Version]

- Ye, D.; Wang, W.; Zhou, H.; Li, Y.; Fang, H.; Huang, J.; Gong, H.; Li, Z. Quantitative determination of porosity in thermal barrier coatings using terahertz reflectance spectrum: Case study of atmospheric-plasma-sprayed YSZ coatings. IEEE Trans. Terahertz Sci. Technol. 2020, 10, 383–390. [Google Scholar] [CrossRef]

- Ye, D.; Wang, W.; Zhou, H.; Huang, J.; Wu, W.; Gong, H.; Li, Z. In-situ evaluation of porosity in thermal barrier coatings based on the broadening of terahertz time-domain pulses: Simulation and experimental investigations. Opt. Express 2019, 27, 28150–28165. [Google Scholar] [CrossRef]

- Ye, D.; Wang, W.; Zhou, H.; Fang, H.; Huang, J.; Li, Y.; Gong, H.; Li, Z. Characterization of thermal barrier coatings microstructural features using terahertz spectroscopy. Surf. Coat. Technol. 2020, 394, 125836. [Google Scholar] [CrossRef]

- Wang, L.; Yuan, M.; Huang, H.; Zhu, Y. Recognition of edge object of human body in THz security inspection system. Infrared Laser Eng. 2017, 46, 1125002. [Google Scholar] [CrossRef]

- Vohra, N.; Bowman, T.; Bailey, K.; El-Shenawee, M. Terahertz Imaging and Characterization Protocol for Freshly Excised Breast Cancer Tumors. J. Vis. Exp. 2020, 2020. [Google Scholar] [CrossRef]

- Jiang, Y.; Ge, H.; Zhang, Y. Quantitative analysis of wheat maltose by combined terahertz spectroscopy and imaging based on Boosting ensemble learning. Food Chem. 2020, 307, 125533. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Zhao, P.; Wu, C.; Liu, C.; Yang, J.; Zheng, L. Rapid determination of aflatoxin B1 concentration in soybean oil using terahertz spectroscopy with chemometric methods. Food Chem. 2019, 293, 213–219. [Google Scholar] [CrossRef] [PubMed]

- Dai, X.; Fan, S.; Qian, Z.; Wang, R.; Wallace, V.P.; Sun, Y. Prediction of the terahertz absorption features with a straightforward molecular dynamics method. Spectrochim. Acta Part A 2020, 236, 118330. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Mohan, S. Application of process analytical technology for pharmaceutical coating: Challenges, pitfalls, and trends. AAPS PharmSciTech 2020, 21. [Google Scholar] [CrossRef]

- Ryu, C.H.; Park, S.H.; Kim, D.H.; Jhang, K.Y.; Kim, H.S. Nondestructive evaluation of hidden multi-delamination in a glass-fiber-reinforced plastic composite using terahertz spectroscopy. Compos. Struct. 2016, 156, 338–347. [Google Scholar] [CrossRef]

- Kim, D.H.; Ryu, C.H.; Park, S.H.; Kim, H.S. Nondestructive evaluation of hidden damages in glass fiber reinforced plastic by using the terahertz spectroscopy. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 211–219. [Google Scholar] [CrossRef]

- Park, S.H.; Jang, J.W.; Kim, H.S. Non-destructive evaluation of the hidden voids in integrated circuit packages using terahertz time-domain spectroscopy. J. Micromech. Microeng. 2015, 25, 095007. [Google Scholar] [CrossRef]

- Ahi, K.; Shahbazmohamadi, S.; Asadizanjani, N. Quality control and authentication of packaged integrated circuits using enhanced-spatial-resolution terahertz time-domain spectroscopy and imaging. Opt. Lasers Eng. 2018, 104, 274–284. [Google Scholar] [CrossRef]

- Cao, B.; Wang, M.; Li, X.; Fan, M.; Tian, G. Noncontact thickness measurement of multilayer coatings on metallic substrate using pulsed terahertz technology. IEEE Sens. J. 2020, 20, 3162–3171. [Google Scholar] [CrossRef]

- Khaliduzzaman, A.; Konagaya, K.; Suzuki, T.; Kashimori, A.; Kondo, N.; Ogawa, Y. A Nondestructive eggshell thickness measurement technique using terahertz waves. Sci. Rep. 2020, 10, 1052. [Google Scholar] [CrossRef] [PubMed]

- Tu, W.; Zhong, S.; Shen, Y.; Atilla, I.; Fu, X. Neural network-based hybrid signal processing approach for resolving thin marine protective coating by terahertz pulsed imaging. Ocean. Eng. 2019, 173, 58–67. [Google Scholar] [CrossRef]

- Tojima, Y.; Sudo, H.; Kubota, T.; Cho, K.; Nakabayashi, H.; Suizu, K. Nondestructive measurement of layer structures in dielectric substrates by collimated terahertz time domain spectroscopy. IEICE Electron. Expr. 2018, 15, 0579. [Google Scholar] [CrossRef]

- Fotovvati, B.; Namdari, N.; Dehghanghadikolaei, A. On coating techniques for surface protection: A review. J. Manuf. Mater. Process. 2019, 3, 28. [Google Scholar] [CrossRef] [Green Version]

- Birks, N.; Meier, G.H. Introduction to High-Temperature Oxidation of Metals; Edward Arnold: London, UK, 1983. [Google Scholar]

- Torrcsa, M.; Colas, R. A model for heat conduction through the oxide layer of steel during hot rolling. J. Mater. Process. Technol. 2000, 105, 258–263. [Google Scholar]

- Zhai, M.; Locquet, A.; Roquelet, C.; Alexandrec, P.; Daheronc, L.; Citrinab, D.S. Nondestructive measurement of mill-scale thickness on steel by terahertz time-of-flight tomography. Surf. Coat. Technol. 2020, 393, 125765. [Google Scholar] [CrossRef]

- Henning, T.; Il’In, V.B.; Krivova, N.A.; Michel, B.; Voshchinnikov, N.V. WWW database of optical constants for astronomy. Astron. Astrophys. Suppl. Ser. 1999, 136, 405–406. [Google Scholar] [CrossRef] [Green Version]

- Hasegawa, N.; Nagashima, T.; Hirano, K. Thickness measurement of iron-oxide layers on steel plates using terahertz reflectometry. In Proceedings of the 2011 International Conference on Infrared, Millimeter, and Terahertz Waves, Houston, TX, USA, 2–7 October 2011. [Google Scholar]

- Henning, T.; Begemann, B.; Mutschke, H.; Dorschner, J. Optical properties of oxide dust grains. Astron. Astrophys. Suppl. Ser. 1995, 136, 143–149. [Google Scholar]

- Steyer, T.R. Infrared Optical Properties of some Solids of Possible Interest in Astronomy and Atmospheric Physics. Ph.D. Thesis, University of Arizona, Tucson, AZ, USA, 1974. [Google Scholar]

- Buchenau, U.; Müller, I. Optical properties of magnetite. Solid State Commun. 1972, 11, 1291–1293. [Google Scholar] [CrossRef]

- Huffman, D.R. Interstellar grains: The interaction of light with a small particle system. Adv. Phys. 1977, 26, 129. [Google Scholar] [CrossRef]

- Sadowski, L.; Nikoo, M.; Mohammad, N. Hybrid metaheuristic-neural assessment of the adhesion in existing cement composites. Coatings 2017, 7, 49. [Google Scholar] [CrossRef] [Green Version]

- Samide, A.; Stoean, R.; Stoean, C.; Tutunaru, B.; Grecu, R.; Cioatera, N. Investigation of polymer coatings formed by polyvinyl alcohol and silver nanoparticles on copper surface in acid medium by means of deep convolutional neural networks. Coatings 2019, 9, 105. [Google Scholar] [CrossRef] [Green Version]

- Lopato, P.; Chady, T.; Sikora, R.; Gratkowski, S.; Ziolkowski, M. Full wave numerical modelling of terahertz systems for nondestructive evaluation of dielectric structures. Compel 2013, 32, 736–749. [Google Scholar] [CrossRef]

- Schneider, J.B.; Wagner, C.L.; Kruhlak, R.J. Simple conformal methods for finite-difference time-domain modeling of pressure-release surfaces. J. Acoust. Soc. Am. 1998, 104, 3219–3226. [Google Scholar] [CrossRef]

- Luo, M.; Zhong, S.; Yao, L.; Tu, W.; Nsengiyumva, W.; Chen, W. Thin thermally grown oxide thickness detection in thermal barrier coatings based on SWT-BP neural network algorithm and terahertz technology. Appl. Opt. 2020, 59, 4097–4104. [Google Scholar] [CrossRef]

- Sullivan, D.M. Electromagnetic Simulation Using the FDTD Method; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 1–19. [Google Scholar]

- Chen, Y.; Huang, S.; Pickwell-Macpherson, E. Frequency-wavelet domain deconvolution for terahertz reflection imaging and spectroscopy. Opt. Express 2010, 18, 1177–1190. [Google Scholar] [CrossRef]

- Lyui, W.; Geng, H.; Zheng, X.; Wang, Y. Noise and Echo Simulation and Removal of Terahertz Time-Domain Spectroscopy. In Proceedings of the 2018 43rd International Conference on Infrared, Millimeter, and Terahertz Waves (IRMMW-THz), Jeju, Korea, 13–18 September 2018. [Google Scholar]

- Poornachandra, S. Wavelet-based denoising using subband dependent threshold for ECG signals. Digit. Signal. Process. 2008, 18, 49–55. [Google Scholar] [CrossRef]

- Berkner, K.; Wells, R.O. Smoothness estimates for soft-threshold denoising via translation-invariant wavelet transforms. Appl. Comput. Harmon. Anal. 2002, 12, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Wold, S. Principal component analysis. Chemometr. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Chen, M. Matlab Neural Network Principle and Example Solution; Tsinghua University Press: Beijing, China, 2013. [Google Scholar]

- Figueiredo, E.M.N.; Ludermir, T.B. Investigating the use of alternative topologies on performance of the PSO-ELM. Neurocomputing 2014, 127, 4–12. [Google Scholar] [CrossRef]

- Castano, A.; Fernandez-Navarre, F.; Hervas-Martinez, C. PCA-ELM: A robust and pruned extreme learning machine approach based on principal component analysis. Neural Process. Lett. 2013, 37, 377–392. [Google Scholar] [CrossRef]

- Eberhart, R.C.; Shi, Y.H.; Kennedy, J. Swarm Intelligence; Morgan Kaufman Publishers: San Francisco, CA, USA, 2001. [Google Scholar]

| Prediction Results | RMSE | MAE | MAPE | R2 |

|---|---|---|---|---|

| BP model | 2.4641 | 1.7816 | 0.3460 | 0.7494 |

| PCA-PSO-ELM model | 2.6951 × 10−14 | 2.6232 × 10−14 | 1.3459 × 10−14 | 1.0000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Ye, D.; Chen, J.; Zhou, H. Novel Terahertz Nondestructive Method for Measuring the Thickness of Thin Oxide Scale Using Different Hybrid Machine Learning Models. Coatings 2020, 10, 805. https://doi.org/10.3390/coatings10090805

Xu Z, Ye D, Chen J, Zhou H. Novel Terahertz Nondestructive Method for Measuring the Thickness of Thin Oxide Scale Using Different Hybrid Machine Learning Models. Coatings. 2020; 10(9):805. https://doi.org/10.3390/coatings10090805

Chicago/Turabian StyleXu, Zhou, Dongdong Ye, Jianjun Chen, and Haiting Zhou. 2020. "Novel Terahertz Nondestructive Method for Measuring the Thickness of Thin Oxide Scale Using Different Hybrid Machine Learning Models" Coatings 10, no. 9: 805. https://doi.org/10.3390/coatings10090805

APA StyleXu, Z., Ye, D., Chen, J., & Zhou, H. (2020). Novel Terahertz Nondestructive Method for Measuring the Thickness of Thin Oxide Scale Using Different Hybrid Machine Learning Models. Coatings, 10(9), 805. https://doi.org/10.3390/coatings10090805