Abstract

Pt coatings on NiTi film micro-actuators and/or sensors can add some useful properties, e.g., they may improve the NiTi anticorrosion and thermomechanical characteristics or activate surface properties beneficial for a specific application (e.g., functionalized surfaces for biomedical applications). Pt coatings prepared via atomic layer deposition (ALD) may help reduce cost due to the nanometric thickness. However, no authors have reported preparation of Pt ALD coatings on NiTi films, perhaps due to the challenge of the concurrent NiTi film oxidation during the Pt ALD process. In the present study, Al2O3 and Pt ALD coatings were applied to NiTi thin films. The ALD coating properties were studied using electron and atomic force microscopies and X-ray photoelectron spectroscopy (XPS). Potential structural changes of NiTi due to the ALD process were evaluated using electron microscopy and X-ray diffraction. The presented ALD process resulted in well-controllable preparation of Pt nanoparticles on ultrathin Al2O3 seed layer and a change of the transformation temperatures of the NiTi films.

1. Introduction

Atomic layer deposition (ALD) is a kind of chemical vapor deposition (CVD) technique that typically uses two precursor gas reactants sent into the reaction zone in an alternating sequence of precisely controlled pulses. Any excessive amount of unreacted precursors in the deposition chamber is purged with an inert gas. This purging results in the self-limiting character of the surface chemical reactions on the substrate and in this way not more than one precursor monolayer is left on the surface after purging. In ideal cases, the ALD may provide researchers with an excellent thickness control at the Angstrom level, and it forms conformal coating on complex 3D shapes [1,2,3,4]. It is worth mentioning that an additional advantage of the ALD is also compositional control demonstrated, e.g., in references [5,6,7,8,9]. Due to low deposition rates (100–300 nm/h [1,10] depending on the size of the deposition chamber and the aspect ratio of the substrate), the ALD is suitable mainly for nanometric coatings. However, successful attempts have been made to increase the deposition rate significantly [11]. When the ALD is applied to coat NiTi alloys, then the deposition temperature (substrate temperature, or specifically, temperature at the NiTi surface) is a concern. High deposition temperature may result in unwanted NiTi grain growth and/or NiTi surface oxidation. Although some ALD processes can take place at low deposition temperatures [12,13,14], unfortunately this is not the case for any Pt ALD process applied to NiTi.

Since ALD was introduced as a deposition technique in 1977, a variety of ALD coating types (oxides, nitrides, sulfides, individual chemical elements, etc.) have been prepared. However, for some coatings no suitable precursors have been found, so far. Furthermore, some ALD coatings may be prone to containing organic impurities from precursors [4]. Therefore, for each ALD coating and type of substrate, the ALD process parameters such as growth temperature, pulse duration, precursor pressures, etc., have to be carefully adjusted [15].

The equiatomic NiTi alloy is a thermomechanical transducer material with the ability to convert thermal energy to mechanical energy (and vice versa, when the heat energy is generated in NiTi upon loading in the form of the latent heat of the forward martensitic transformation [16]). This ability is utilized in NiTi actuators whose actuation frequency is usually limited by the slow cooling times of NiTi material [17]. During cooling, the martensitic transformation from B2 to B19′ structure proceeds in NiTi in temperature interval from Ms (martensite start) to Mf (martensite finish) [18]. In order to make the cooling time shorter, NiTi thin films and/or thin wires (both have a high surface-to-volume ratio) have often been employed in NiTi actuators. Besides the relatively fast heat exchange between NiTi films and their surrounding environment, NiTi films may attract interest due to the possibility of incorporating NiTi films in micro-electro-mechanical systems (MEMS) [19,20,21,22,23]. Due to confirmed acceptable biotolerance [24], NiTi films may be also used (with certain limitations) in bio-MEMS. Generally, NiTi and other shape memory alloy (SMA) actuators have high output work (force × stroke) per weight and power density compared to other actuator materials/other types of actuator transducers [22,25], (see also Figure 26 in reference [26]). For instance, microvalves containing NiTi films are capable of generating large work outputs and power densities in the order of 50 mJ/g and 1 W/g, respectively [26]. When pointing out the advantages of using NiTi films in various applications, it is worth mentioning that NiTi sputtered films, unlike NiTi wires, have excellent fatigue resistance [27,28].

The idea to apply thin ALD coatings on NiTi alloys first appeared in the previous study [29]. The authors used an Al2O3 ALD layer on NiTi to improve the anticorrosive properties of NiTi alloys. Later, Wang et al. [30] presented work on an Al2O3 ALD layer deposited on a superelastic NiTi carotid stent, where the Al2O3 layer sufficed for further surface modification with the top heparin layer used as a blood anticoagulant. Anticorrosive and mechanical characteristics of a thin Al2O3 ALD layer on NiTi were studied by Lin et al. [31]. Piltaver et al. [32] grew TiO2/Al2O3 ALD composite films on NiTi and other substrates in order to control the grain size of TiO2. Muralidharan et al. [33] used a V2O5 ALD layer deposited on the NiTi electrode to control electrochemical reactions in lithium batteries through strains on the NiTi/V2O5 interface.

In our previous work [29,34,35], Al2O3, TiO2 and Pt ALD coatings were deposited on NiTi samples and tested for anticorrosive and mechanical properties. Our work related to the ALD coatings on NiTi was motivated by the fact that the ALD is considered an attractive method to grow protective (anticorrosive coatings or diffusion barriers [36]) and biocompatible coatings due to excellent coating conformity, sound adhesion and low-temperature compatibility. Besides that, ALD coatings can also serve when forming 3D nanostructures [37] as a part of MEMS.

ALD Pt coating has some advantages over Al2O3 and TiO2 ALD coatings as follows. First of all, Pt coating has the potential to withstand deformations larger than the deformation allowable for ceramic coatings. Pt coating may increase radio-opacity of NiTi stents (in order to increase radio-opacity of biomedical grade NiTi wires, NiTi–Pt wires with a Pt core were proposed in 2004 and subsequently have been produced on a commercial basis [38]). Furthermore, it can form an interlayer for further surface modifications. Pt coating increases surface electrical conductivity and surface energy [39,40]. In addition to Pt prepared as a continuous layer, Pt nanoparticles (NPs) can also be prepared on various surfaces using the ALD process [41]. Pt NPs on TiO2 surfaces can have several applications, such as an efficient water-splitter [42] or an efficient electro-catalyst for methanol oxidation [41].

The ALD process for Pt on NiTi is not straightforward. The usually used precursors are (trimethyl)-methylcyclopentadienyl-platinum (IV) (MeCpPtMe3) [43,44,45,46] or Pt(acac)2 (acac = acetylacetonate) [47,48]. Precursor dimethyl(N,N-dimethyl-3-butene-1-amine-N)platinum (DDAP, C8H19NPt) has also been previously explored in some detail [49].

The co-reacting precursor is usually oxygen or dry air. The temperature window in the case of the MeCpPtMe3 precursor is 200–300 °C [47]. The Pt ALD deposition rate is low on TiO2 [50] and TiO2 is regularly present on the NiTi alloy surface because of NiTi oxidation, even at room temperature [51]. In addition, the Pt ALD process (about 100 ALD cycles) on TiO2 results in a low spreading density of Pt NPs [50]. The deposition rate of Pt on Al2O3 is superior to the rate of Pt on TiO2. Therefore, it is suggested that an Al2O3 underlayer may facilitate initial ALD growth better than the original TiO2 on NiTi. It is worth mentioning that the authors of reference [39] (also reference [52]) achieved a thin ALD Pt compact layer by depositing an additional W ALD layer on Al2O3 as an adhesion layer.

In the present study, the growth of Pt coating on an Al2O3 underlayer is evaluated using various techniques such as transmission electron microscopy (TEM), X-ray photoelectron spectroscopy (XPS) and atomic force microscope (AFM). The thermal influence of the ALD processes on the grain size and transformation temperatures of NiTi films is examined as well.

2. Materials and Methods

2.1. Samples

Transforming NiTi films with a thickness of about 1 μm deposited on Si substrates (5 × 10 mm2) were obtained from Acquandas GmbH. In reference [53], experimental work showing determination of the transformation temperatures of the as-purchased NiTi films was described. Before the ALD, the as-purchased NiTi samples were cleaned in ethanol and deionized water and finally dried using N2 gas.

2.2. ALD

The deposition was performed in a home-built ALD reactor assembled (including all accessory parts) in Taiwan Instrument Research Institute (TIRI). The precursors used for the Al2O3 (or Pt) ALD process were trimethyl-aluminum (TMA) and water vapor (or (methylcyclopentadienyl)trimethyl- platinum (MeCpPtMe3), a product of Strem Chemicals and dry air as a source of O2). First, Al2O3/NiTi/Si samples with 10 Al2O3 ALD cycles and subsequently Pt/Al2O3/NiTi/Si samples with 100 and 200 Pt ALD cycles were prepared. The substrate temperature during the Al2O3 (or Pt) ALD process was 100 °C (or 300 °C). N2 gas was exclusively used for purging. The base pressure was about 3.33 Pa. The typical cycle times for Al2O3 (or Pt) ALD growth experiment were as follows: 0.2 s TMA pulse, 10 s N2 purge, 0.2 s water vapor pulse, and 10 s N2 purge (or 0.5 s MeCpPtMe3 pulse, 10 s N2 purge, 0.5 s air pulse, and 10 s N2 purge). Hence, the Pt ALD process took about 35 min (Pt 100 ALD cycles) and 70 min (Pt 200 ALD cycles). In the initial Pt ALD cycle, hydrogen plasma was used (power output 300 W, deposition temperature 200 °C, H2 pulse duration 5 s) instead of dry air [39]. Finally, Table 1 lists all the used film samples with their names.

Table 1.

A list of the film samples and their short names used in the further text.

2.3. Microscopic Observations

Surface observations of samples Pt100 and Pt200 were made using a scanning electron microscope (SEM) TESCAN, FERA3 GM (Brno, Czech Republic). The NiTi grain size distributions in samples NiTi and Pt100 were obtained based on electron backscattering diffraction (EBSD) method using the EDAX system (EDAX, Mahwah, NJ, USA) with DigiView IV camera. It was possible to get the EBSD signal in NiTi and Pt100 samples, whereas no signal was obtained in sample Pt200, because the layer covering the NiTi layer was too thick.

A thin cross-sectional lamella was cut out from sample Pt100 (using a Ga focused ion beam in an FEI Quanta 3D Dual-Beam SEM, FEI, Hillsboro, OR, USA) and observed with a Fei Tecnai F20 field emission gun transmission electron microscope (TEM, FEI, Hillsboro, OR, USA) operated at 200 kV. Selected area electron diffraction and energy dispersive X-ray spectroscopy (EDS) were performed to identify phases and chemical elements, respectively.

Surface morphology and local conductivity of samples NiTi, Alu10 and Pt100 were investigated using Dimension Icon AFM (Bruker, Billerica, MA, USA) with an SCM-PTSI platinum silicide coated probe with a tip radius of ca. 15 nm. All the measurements were performed at room temperature under ambient conditions. The topography images were measured in PeakForce mode whereas the maps of local current were measured either in contact mode or PeakForce mode (PeakForce mode was used in the case of the simultaneous measurement of topography and local conductivity). The velocity of scanning varied from 250 to 1000 nm/s. The cantilever deflection was detected by a red laser diode (685 nm).

2.4. XPS and XRD (X-ray Diffraction) Measurements

The XPS spectra were obtained on a Kratos Axis Supra spectrometer (Kratos Analytical, Manchester, UK) with monochromatic Al Kα (1486.6 eV) X-ray radiation. The pressure in the analysis chamber was maintained near 10−9 Pa. For surface cleaning and depth profiling, a multi-mode Ar gas cluster ion source (GCIS) was used with an acceleration voltage of 5 keV and the beam current about 5.8 nA. The scanned area, dwell time in one step and number of steps were 2 × 2 mm2, 10 min and 6 steps, respectively. The mean cluster size was around 2000 (or 1000) argon atoms/cluster in the first four steps (or in the last two steps). It was estimated that 10 min of Ar ion bombardment corresponds to the depth ranging from few to several nm in the ALD layers. The signal was taken from a circular area with a diameter of 100 μm on sample Pt200. The XPS input data were compiled and analyzed using Gaussian–Lorentzian functions and Shirley background implemented in CasaXPS software (version 2.3) [54].

In the present study, the Ms transformation temperatures of samples Pt100 and Pt200 were determined using XRD in order to find out any effect of the Pt and Al2O3 ALD processes applied on NiTi/Si samples. The XRD signal was registered from the film surface using an X-ray diffractometer (X’Pert PRO from PANalytical, Malvern, UK) with a thermal chamber. Before any XRD measurement, either the NiTi film was first heated above the Af (austenite finish) temperature and then cooled down to a test temperature. The XRD patterns were registered at various test temperatures, which were kept constant throughout each XRD measurement. The X-ray source was Co Kα radiation (λKα1 = 0.178901 nm, λKα2 = 0.17929 nm). The Ms temperature was determined based on the change of the full width at half maximum of (110)B2 peak, using the fact that during the martensitic transformation, peak (110)B2 splits into two, or more neighboring peaks. Determination of the Ms temperature (of the as-purchased NiTi film) was shown in reference [53].

3. Results

3.1. Microscopic Observations

The microscopy results are expected to reveal (i) whether the Al2O3 ALD layer in samples Alu10, Pt100 and Pt200 is continuous and (ii) whether Pt in samples Pt100 and Pt200 forms nanoparticles (NPs) or a continuous layer and, finally, (iii) whether the grain size distribution in the NiTi layer changes after the Al2O3 and Pt ALD processes.

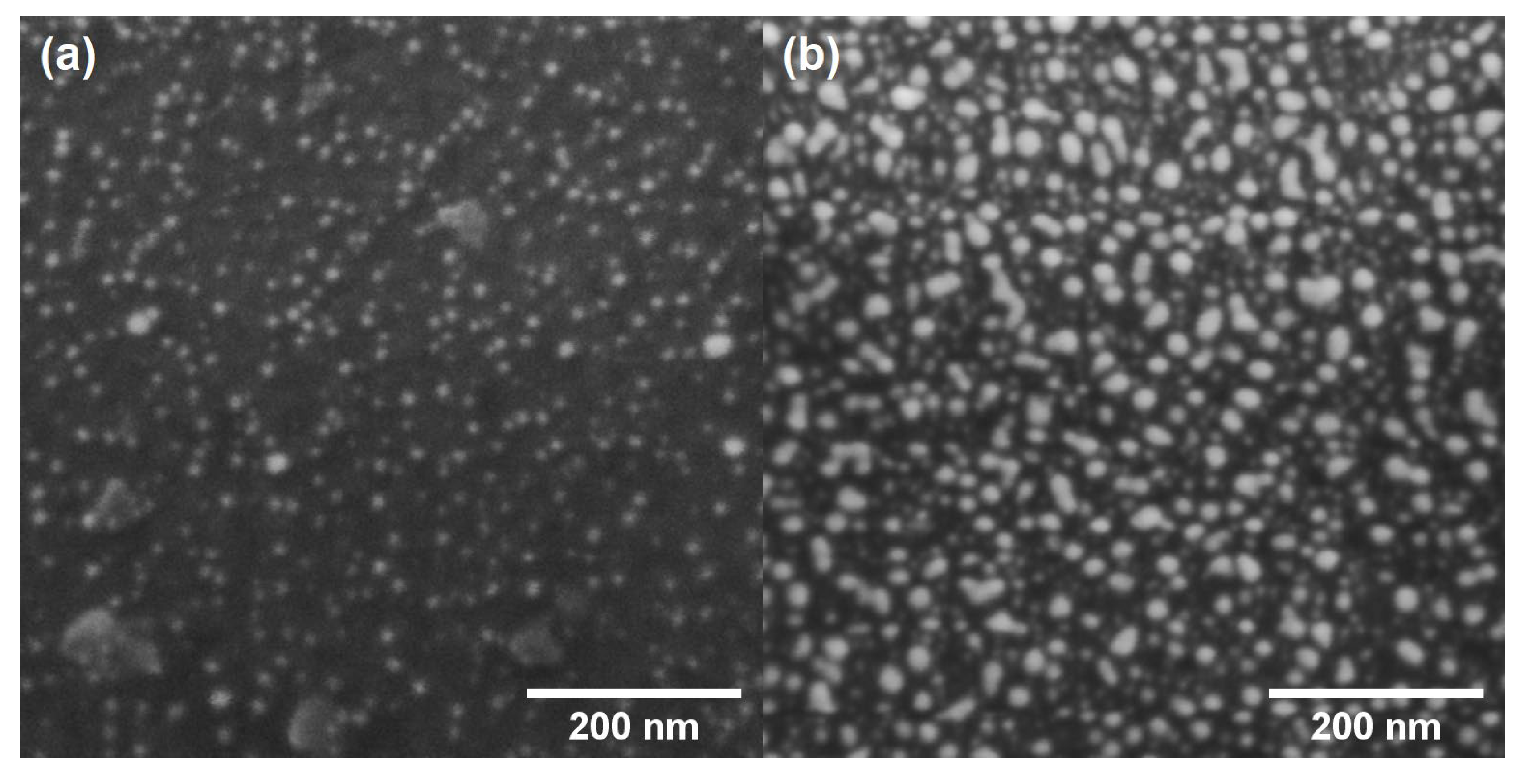

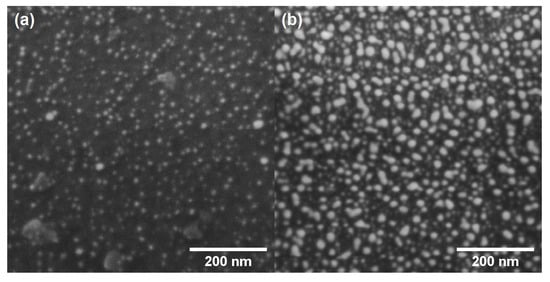

Figure 1a,b shows tiny Pt NPs, at the limit of SEM resolution, on the surfaces of samples Pt100 (a) and Pt200 (b). The areal density and mean size of the Pt NPs in Pt200 (Figure 1b) were higher than those in Pt100 (Figure 1a). The sizes of the Pt NPs in Figure 1a,b were 9–17 and 12–20 nm, respectively.

Figure 1.

The SEM micrographs of the surfaces of samples Pt100 (a) and Pt200 (b).

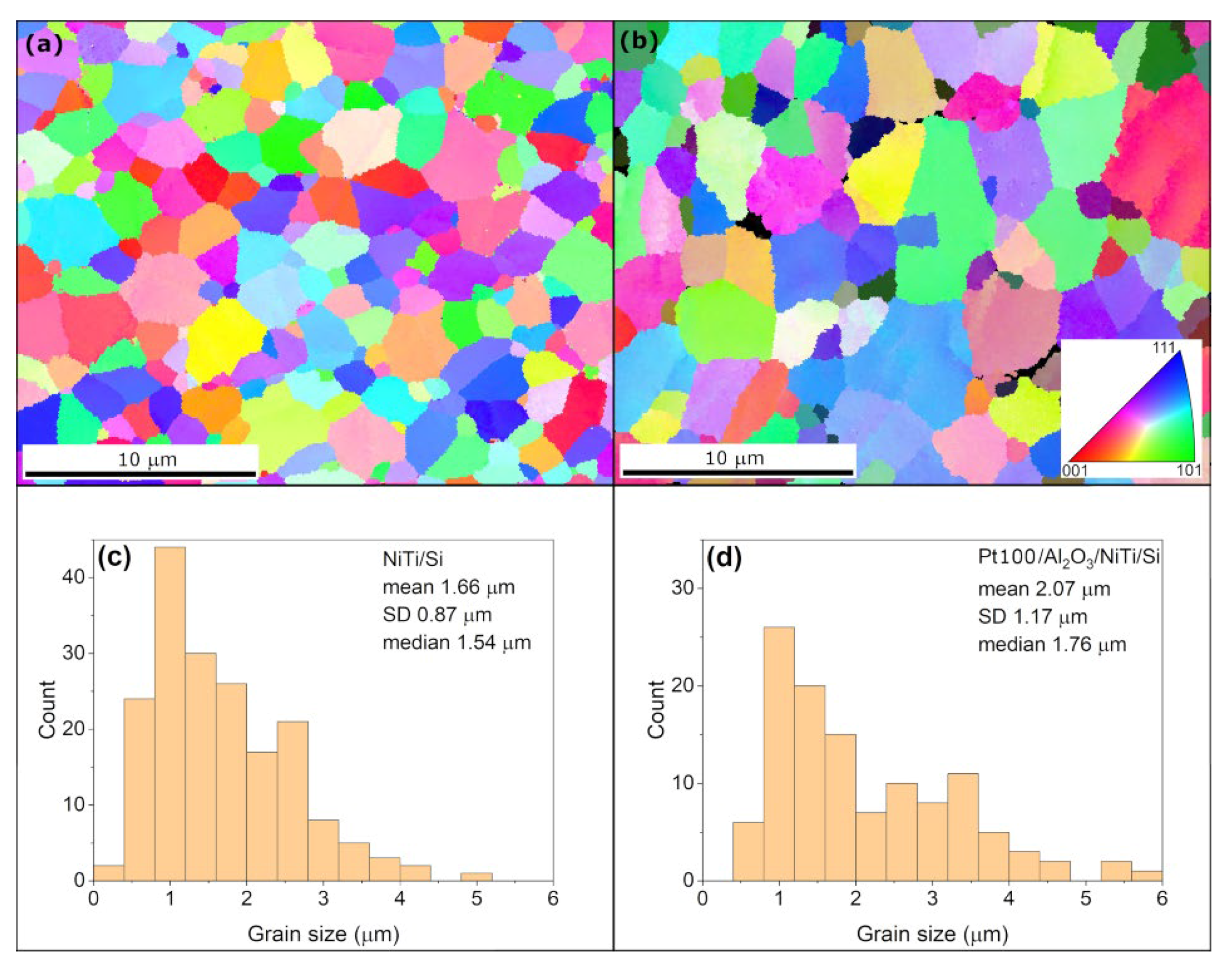

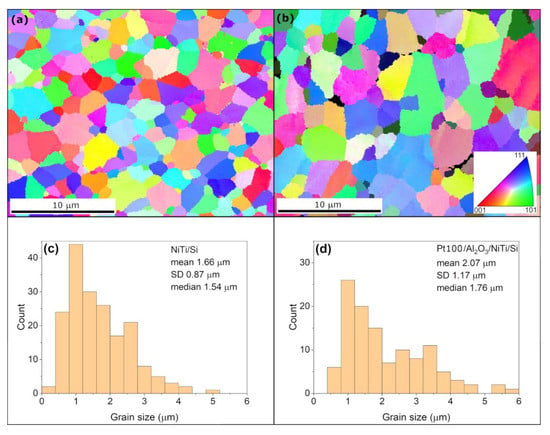

After the Al2O3 and Pt ALD processes, the grain size and grain distribution in the NiTi layer changed (due to the Pt deposition temperature up to 300 °C) as shown in Figure 2. Figure 2 compares grain distributions in the NiTi layers of samples NiTi (before the ALD depositions) and Pt100 (after the ALD depositions).

Figure 2.

The color electron backscattering diffraction (EBSD) maps representing the orientation of the grains through inverse pole figure (IPF) color-coding in selected surface areas of NiTi (a) and Pt100 (b) samples and the corresponding grain size distributions in NiTi (c) and Pt100 (d) samples. The color code for IPF orientation is given in the inset of part (b).

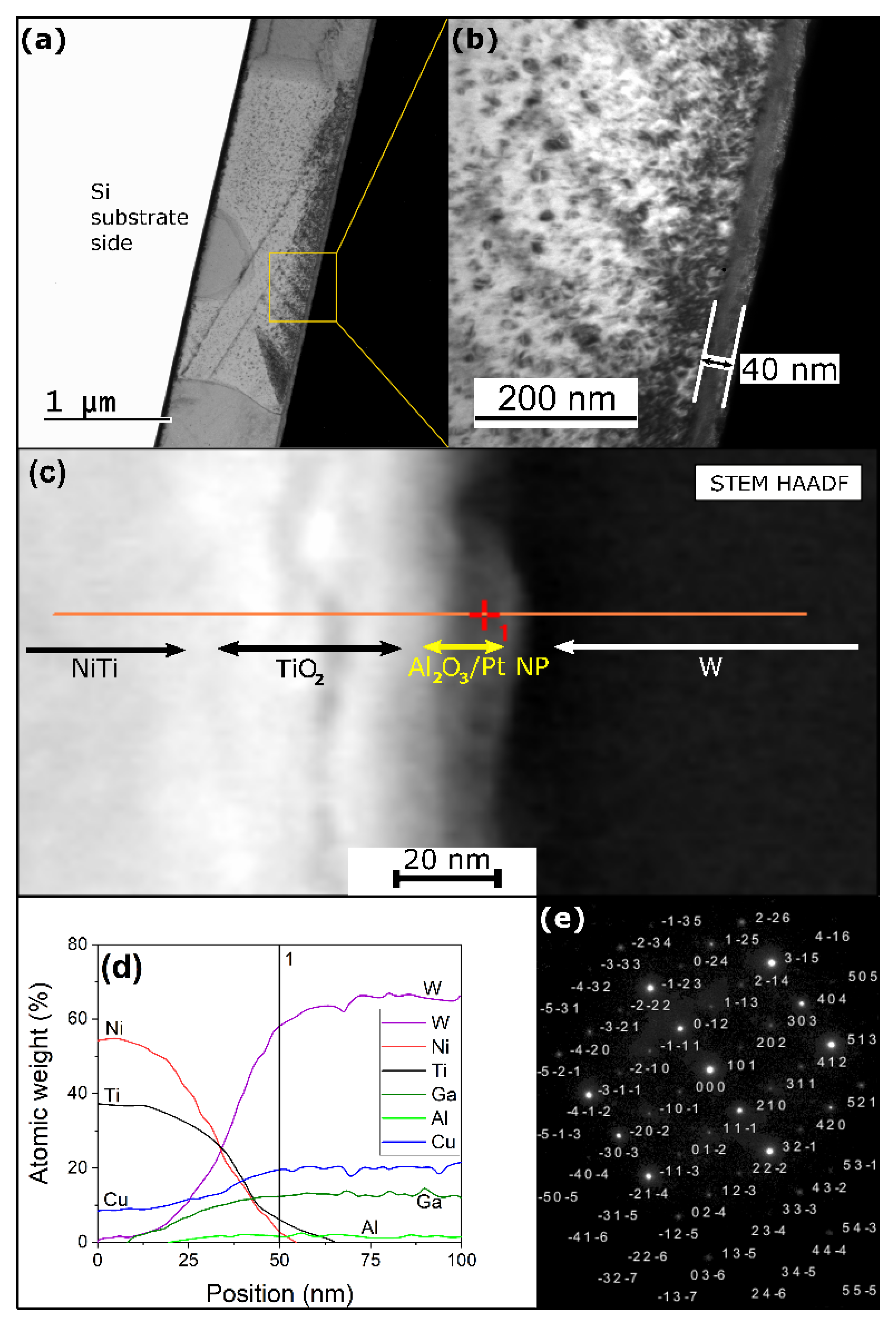

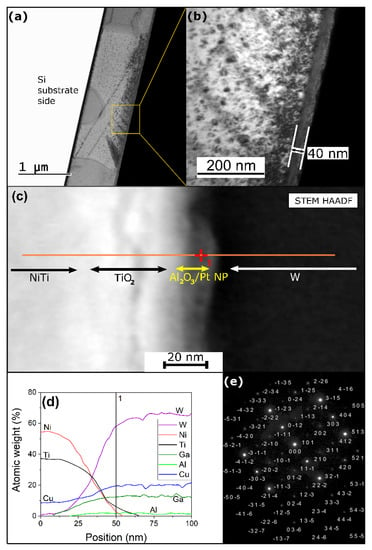

Figure 3a,b shows the TEM cross-sectional micrographs of sample Pt100, with low (a) and high magnification (b). The Si substrate in the low-magnification image is seen in a light color whereas the W layer (deposited via gas injection system (GIS) to manipulate Pt100 lamella) is seen in a dark color. The high-angle annular dark-field scanning transmission electron microscopy (HAADF STEM) image shows the upper layers in the cross-section (Figure 3c). The path of the line scan with a fixed point denoted as point 1 are shown in the image whereas the results of the EDS analysis along the line are shown in Figure 3d. The presence of Ga, Cu and W elements originates from Ga focused ion beam used to cut out the examined lamella, a Cu ring used as a support for the lamella and GIS material, respectively. The electron diffraction pattern taken from the SAED (selected area electron diffraction) inside of a NiTi grain is shown in Figure 3e. The pattern corresponds to the R-phase (the rhombohedral structure); the zone axis was [−121].

Figure 3.

The TEM cross-sectional micrograph of sample Pt100 taken in the bright field (BF) TEM mode (a,b), high-angle annular dark-field scanning transmission electron microscopy (HAADF STEM) mode (c), EDS line scans close to the NiTi top surface, however the tungsten layer is not a part of the sample (d), and the diffraction pattern (corresponding to the R-phase) taken from the SAED (selected area electron diffraction) inside of a NiTi grain (e).

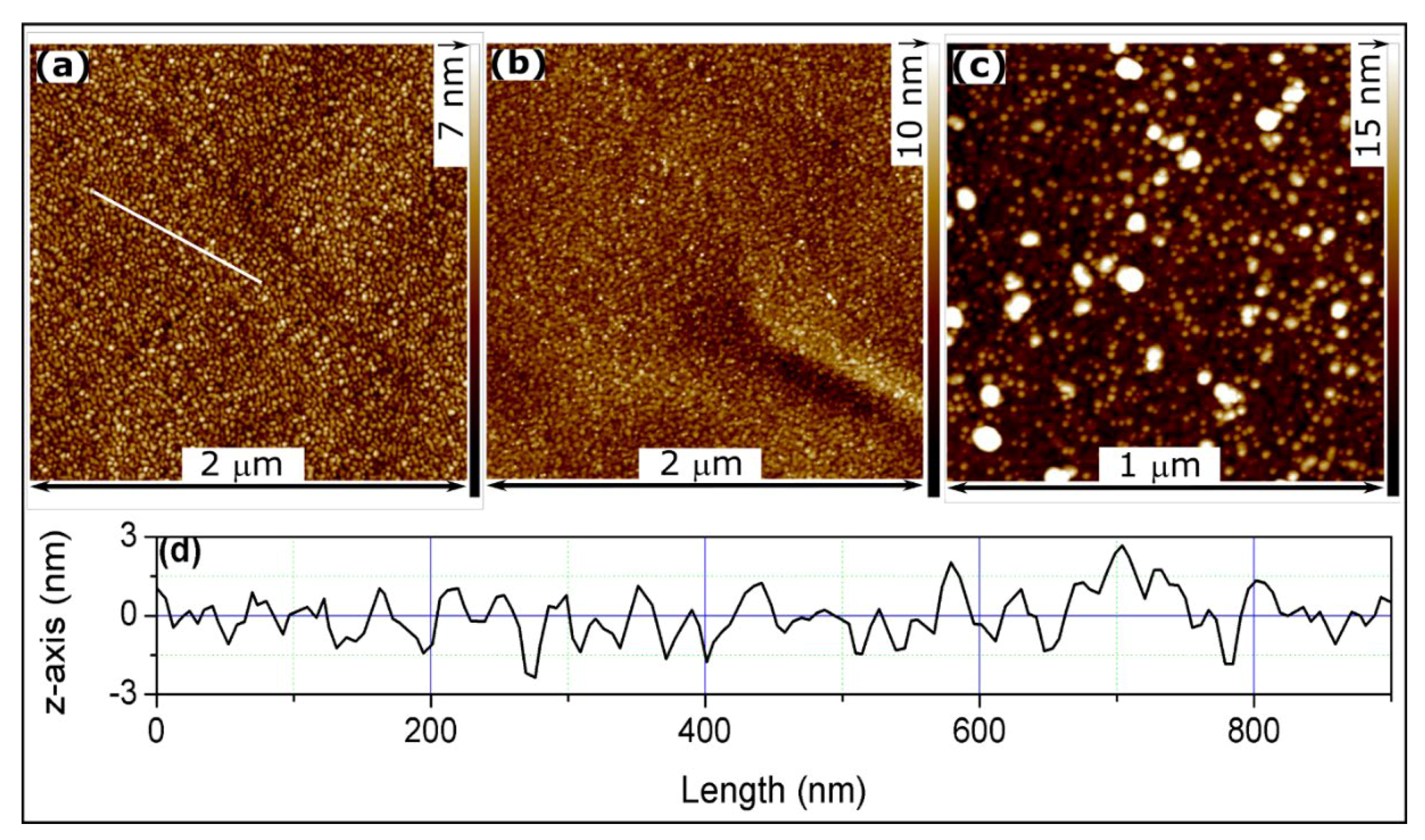

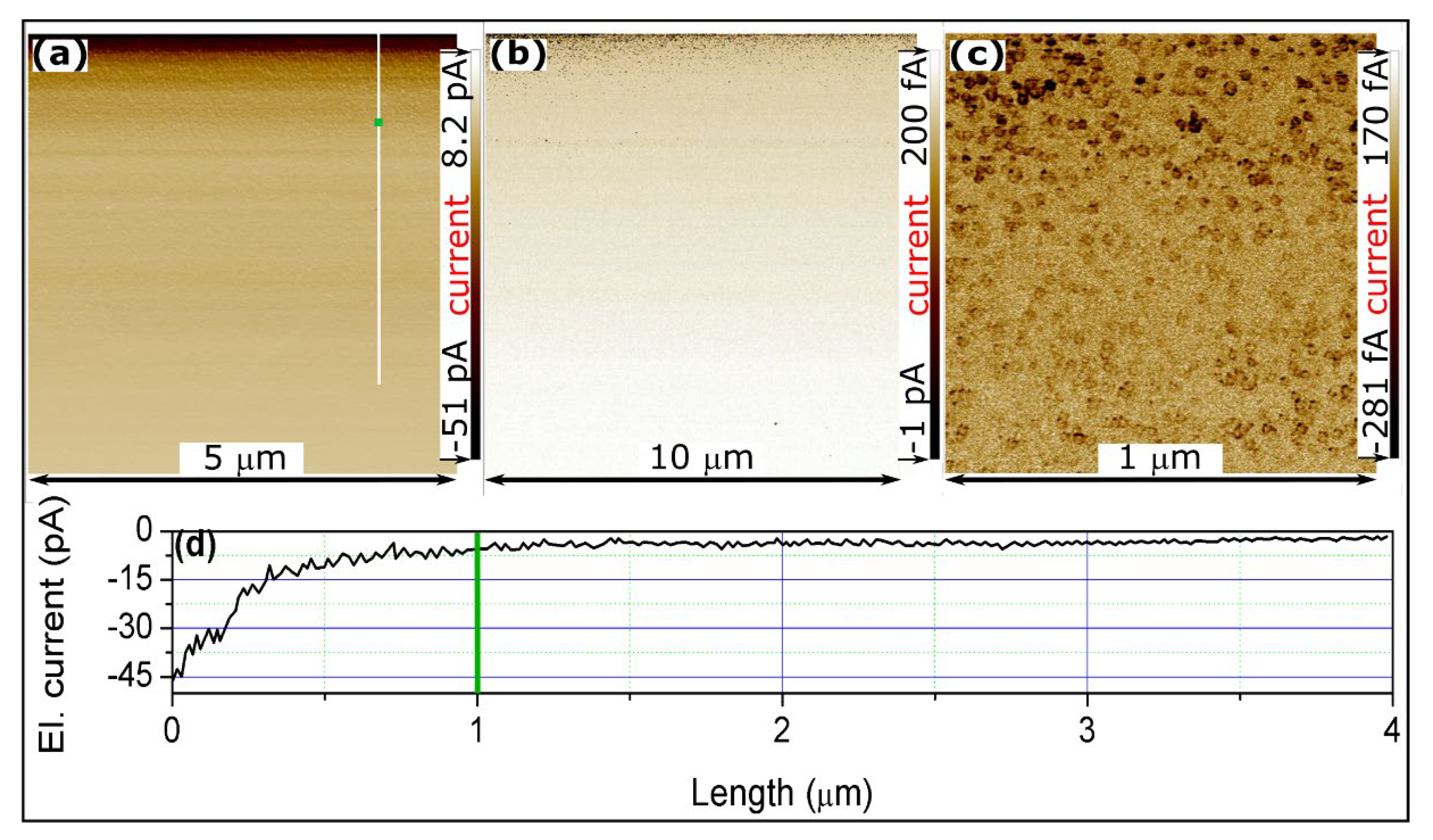

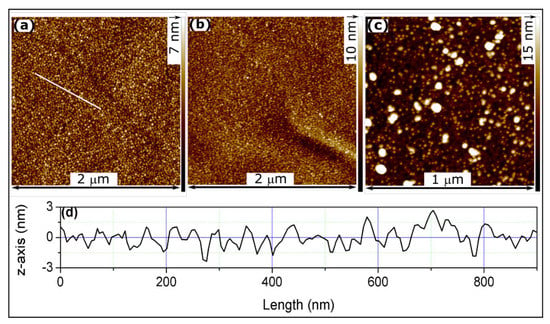

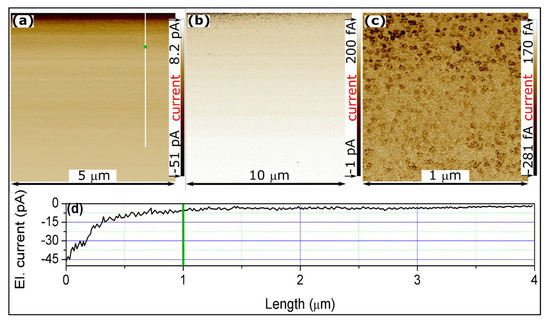

Figure 4a–c shows AFM topography images of samples NiTi (a), Alu10 (b) and Pt100 (c). The surface patterns in Figure 4a,b (belonging to samples NiTi and Alu10) are regular. The round objects in Figure 4a,b are 10–30 nm in size. Figure 4c shows surface of sample Pt100 containing two kinds of round objects—the small object (with high occurrence) and the large objects (with low occurrence) with diameters 10–17 and 30–50 nm, respectively. The cross section analysis in Figure 4d corresponds to the white line in Figure 4a. The maps of local current obtained by conductive AFM (C-AFM) for samples NiTi (a), Alu10 (b) and Pt100 (c) are shown in Figure 5a–c. The scan direction is from the top downward. Figure 5a shows high currents about −40 pA at the top and currents of few pA at the bottom. A similar distribution of local currents is shown in Figure 5b but with much lower values of local currents. Figure 5c shows some conductive round objects with diameters ranging 10–17 nm. The cross section analysis in Figure 5d corresponds to the white line in Figure 5a.

Figure 4.

The atomic force microscope (AFM) topography images of NiTi sample’s surface (forces 500 pN) (a), Alu10 sample’s surface (forces 500 pN) (b) and Pt100 sample’s surface (the maximum interaction force was 5 nN; measured simultaneously with local conductivity (Figure 5c)) (c). The white line in subfigure (a) indicates positions of the cross section analysis (d).

Figure 5.

The maps of local current obtained by C-AFM for samples NiTi (forces 100 nN, sample bias −8 V) (a), Alu10 (forces 100 nN, sample bias −4 V) (b) and Pt100 (the maximum interaction force was 5 nN, sample bias −5V, measured simultaneously with topography (Figure 4c)) (c). The white line in subfigure (a) indicates positions of the cross section analysis (d).

3.2. XPS and XRD Measurements

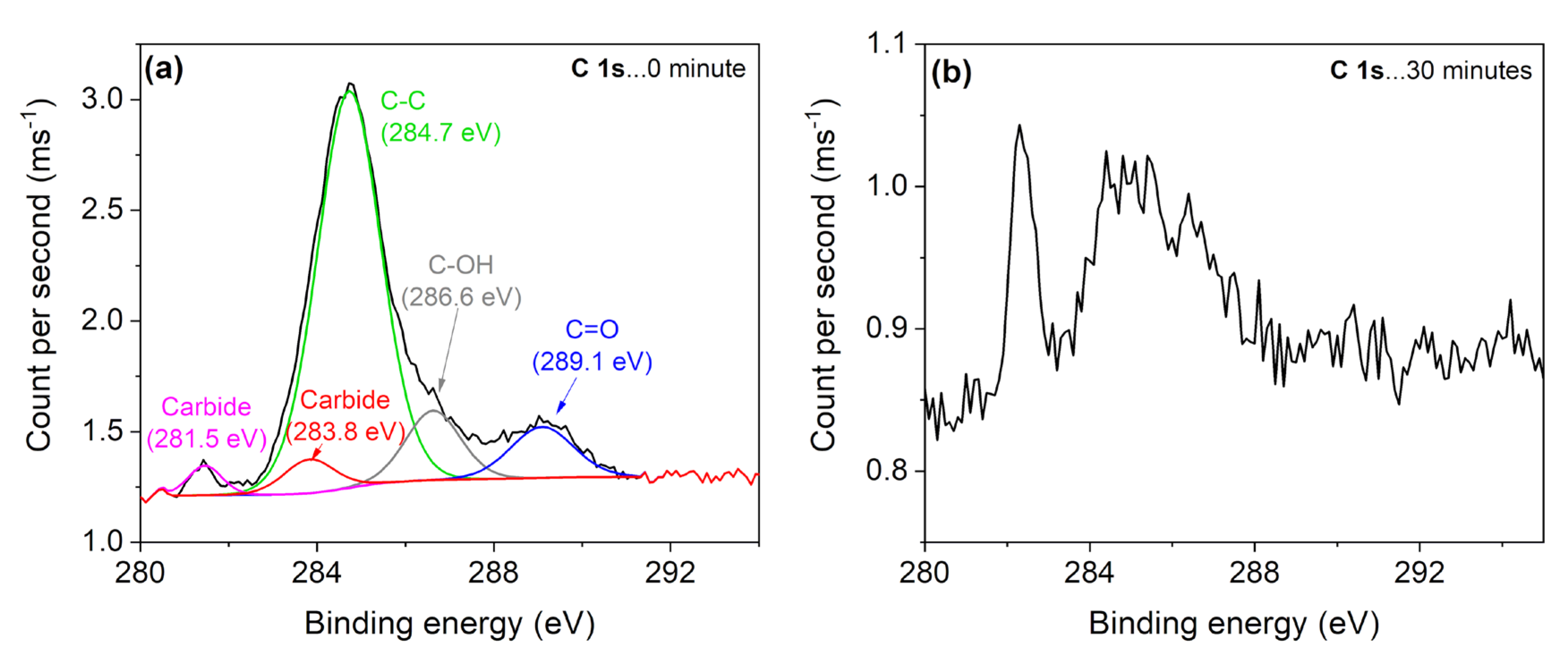

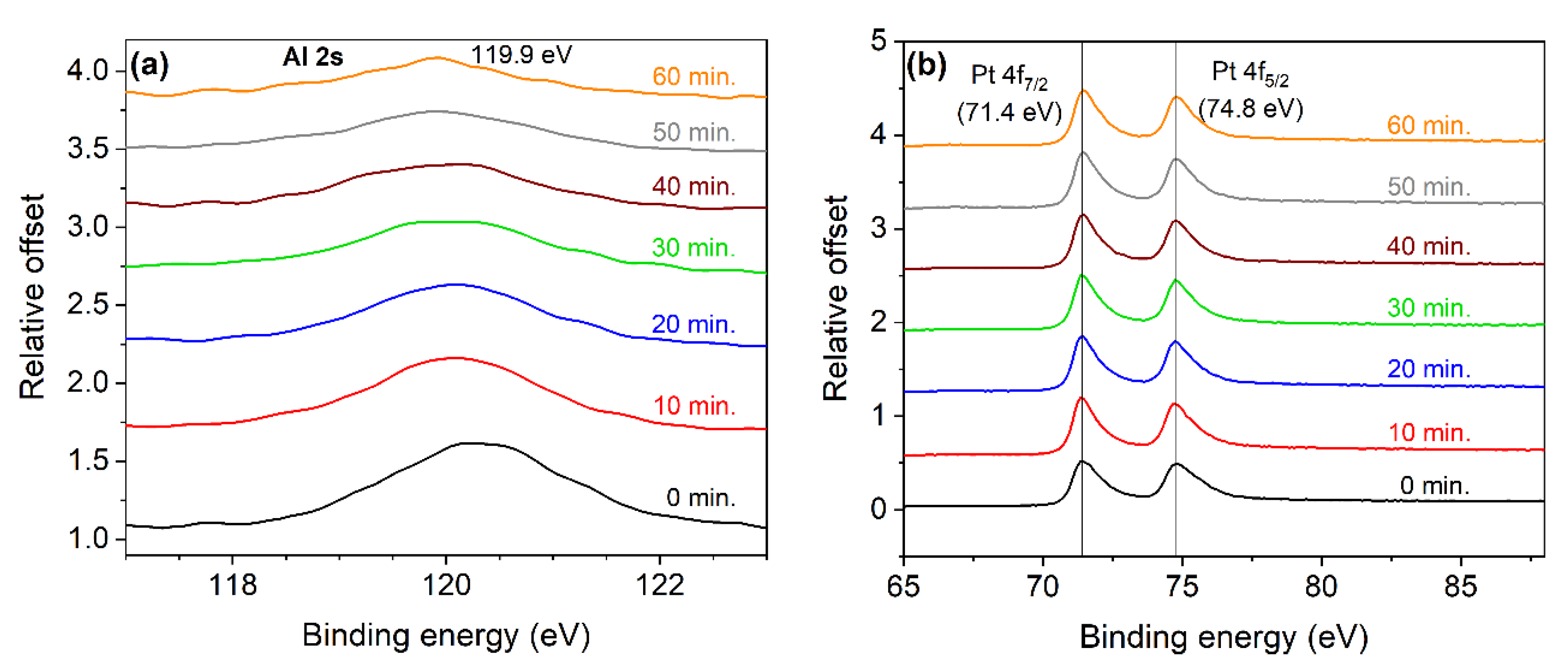

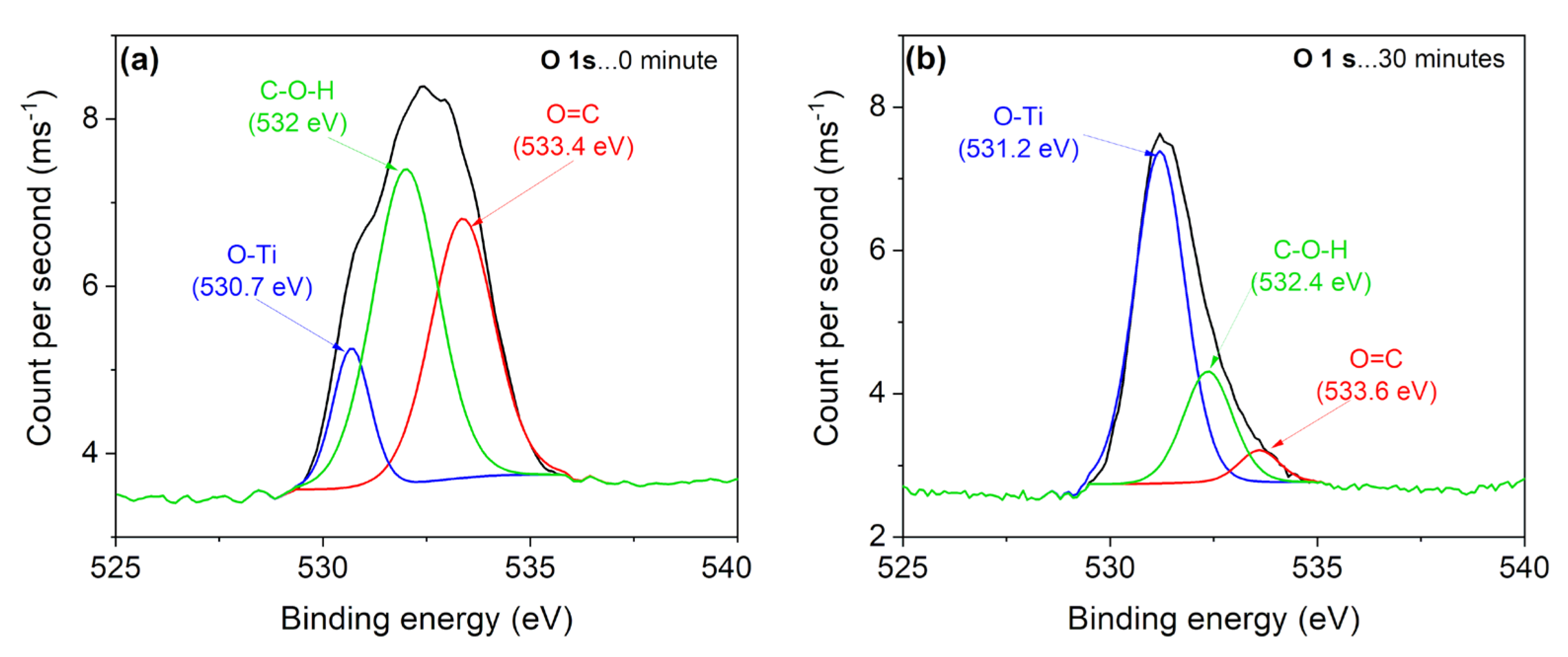

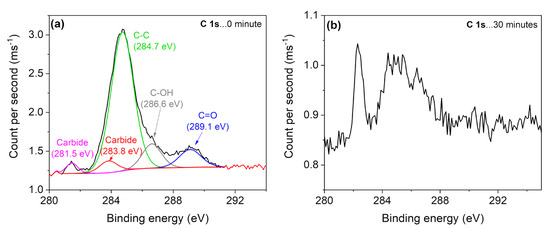

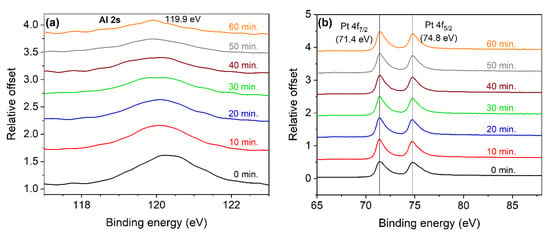

The diagrams of measured and fitted XPS spectra expressed as counts per second (CPS) versus binding energy (BE) for several individual elements after various Arn+ etching times are shown in Figure 6, Figure 7 and Figure 8.

Figure 6.

The measured and fitted XPS spectra attributed to C before etching (a) and the measured XPS spectrum after 30 min of Arn+ etching (b).

Figure 7.

The measured XPS spectra attributed to Al (a) and Pt (b) after various etching times.

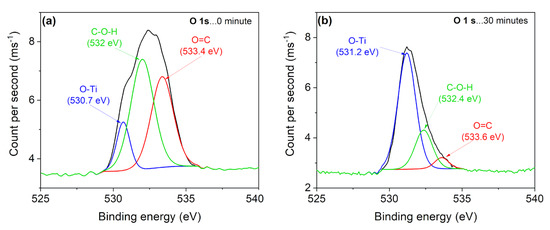

Figure 8.

The measured and fitted XPS spectra attributed to O before etching (a) and after 30 min of Arn+ etching (b).

Specifically, Figure 6a,b shows the diagrams of CPS versus BE attributed to C before Arn+ etching (0 min) and after 30 min of Arn+ etching, respectively. The diagrams of CPS versus BE, attributed to C, after etching times 10, 20, 40, 50, and 60 min (not shown here) are similar to the diagram in Figure 6b. Figure 6b does not contain any fitted XPS spectra because the measured XPS data are too noisy due to a relatively small amount of C, in various forms. Figure 7a,b shows the diagrams of CPS (relative offset) versus BE attributed to Al and Pt after various Arn+ etching times, respectively. Figure 8a,b shows the diagrams of CPS versus BE attributed to O before Arn+ etching (0 min) and after 30 min of Arn+ etching, respectively. Again, the diagrams of CPS versus BE, attributed to O, after the other etching times (not shown here) are similar to the diagram in Figure 8b. Atomic percentages of the elements at the surface of sample Pt200 determined from the XPS after various times of Arn+ etch are summarized in Table 2.

Table 2.

Atomic percentages of the elements at the surface of sample Pt200 determined from the XPS after various times of Arn+ etch.

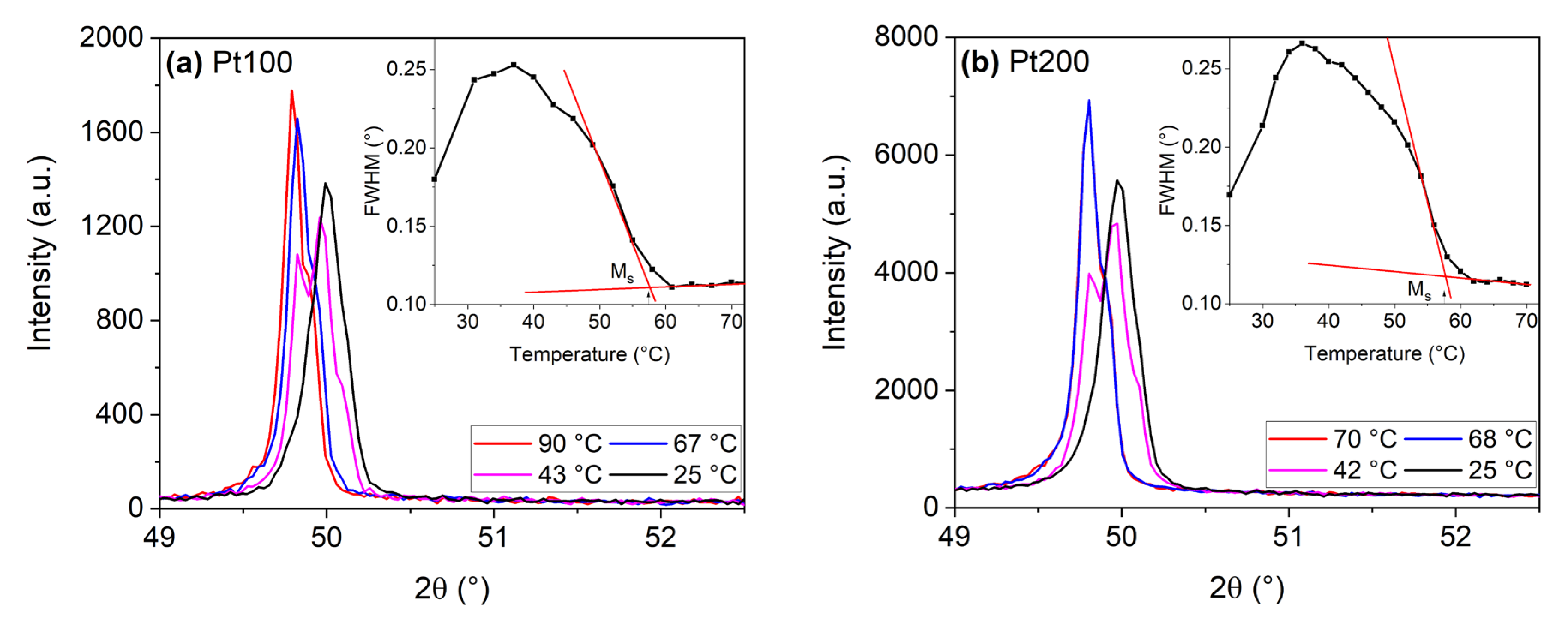

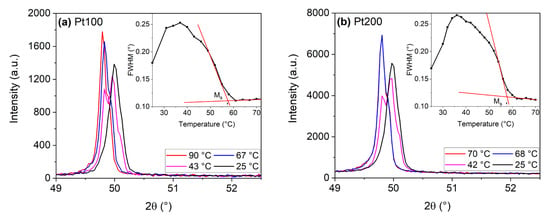

The transformation temperatures of sample NiTi and the Ms temperatures of samples Pt100 and Pt200 are summarized in Table 3. At room temperature each sample may contain both phases, austenite and martensite with crystal structures B19′ and B2, respectively. The diffractograms for the as-purchased NiTi film measured at various temperatures are shown in reference [53]. The diffractograms for samples Pt100 and Pt200 measured in the (110)B2 neighborhood at various temperatures between 25 and 90 °C are shown in Figure 9. Diffraction peaks (110)B2 are not shown for all the test temperatures but only for few selected temperatures in order to avoid accumulating too much data. The Ms temperatures for samples Pt100 and Pt200 are determined from the diagrams of FWHM (full width at half maximum) versus temperature (see the insets of Figure 9)

Table 3.

The transformation temperatures of the NiTi sample determined with AFM, from XRD patterns and shifts of resonant frequency peaks (results taken from reference [53]) and the Ms temperatures attributed to samples Pt100 and Pt200 and determined from the XRD patterns registered at various temperatures.

Figure 9.

The diffractograms for samples Pt100 (a) and Pt200 (b) measured in the (110)B2 neighborhood at various temperatures between 25 and 90 °C. The insets show the corresponding FWHM (full width at half maximum) of the (110)B2 peaks in dependence on temperature.

4. Discussion

The discussion is separated into three parts related to (i) properties of Pt coating on samples Pt100 and Pt200, (ii) properties of Al2O3 coating on samples Alu10, Pt100, Pt200 and (iii) the effect of the Pt and Al2O3 ALD processes on the properties of the NiTi layer.

4.1. Pt Phase

Pt in samples Pt100 and Pt200 did not form a continuous layer but NPs. The sizes of the Pt NPs on the surfaces of samples Pt100 and Pt200 were 9–17 nm (determined from Figures Figure 1a and Figure 4c) and 12–21 nm (determined from Figure 1b), respectively. The areal densities of Pt NPs in samples Pt100 and Pt200 were about 800–1000 NPs per 1 µm2 (determined from Figures Figure 1a and Figure 4c) and about 1700 NPs per 1 µm2 (determined from Figure 1b), respectively. As for the Pt NP size range and the Pt NP areal density on sample Pt100, there is a fair agreement between the results obtained from the SEM (Figure 1) and AFM images (Figure 5c). Due to the relatively low density of Pt NPs on sample Pt100, the EDS elemental analysis (in the chamber of TEM) along a line across the top surface did not show any presence of Pt (Figure 3d). There is no clear interface between the individual deposited layers in Figure 3c. Therefore, the locations of the individual layers were hinted at in Figure 3c. The Pt NPs are conductive (Figure 5c) and do not contain any significant amount of PtO or PtO2 phases as implied from the values of XPS binding energies corresponding to the peaks in Figure 7b. Specifically, according to reference [55], binding energies corresponding to Pt 4f7/2 for Pt, PtO and PtO2 are 71.1 ± 0.3, 72.2 ± 0.3, and 74.2 ± 0.3 eV, respectively. The XPS binding energy registered from sample Pt200 and corresponding to Pt 4f7/2 was 71.4 eV (Figure 7b), a value close to 71.1 eV (a BE value characteristic for Pt) measured in [55]. Some organic residua may remain on the surfaces of samples Pt100 and Pt200 as seen from Figure 6a. Specifically, Figure 6a shows carbon peaks with BE corresponding to C–C, C–OH and C=O bounds (the bounds characteristic for organic material). In addition, Table 2 shows that the non-etched surface of Pt200 contains about 38 at.% of carbon. After the Arn+ etch, the content of carbon significantly dropped to values around 10 at.%. The origin of the organic residua is likely in the Pt organic precursor. However, the distinct advantage of the Pt ALD process is the controllability of Pt NP size and the areal density of Pt NPs by controlling the number of Pt ALD cycles (as shown also in reference [56]).

4.2. Al2O3 Phase

In general, Al2O3 ALD processes and properties of Al2O3 ALD layers are discussed in references [57,58,59]. Thin Al2O3 ALD layers grown below 600 °C are amorphous regardless of the type of the used substrate [58]. Hence, the Al2O3 coating in the present study was amorphous. In our previous study [29], an almost identical Al2O3 ALD process applied to NiTi plate samples resulted in the deposition rate of the 0.1 nm per ALD cycle. Therefore, it is assumed that if the Al2O3 coating in samples Alu10, Pt100 and Pt200 is continuous then its thickness is about 1 nm.

After comparing Figure 5a,b one can see that the surface of sample NiTi is much more conductive than the surface of sample Alu10. Since the map of the local current in Figure 5b is quite uniform (no islands are obvious), it can be deduced that the Al2O3 coating (10 ALD cycles) in sample Alu10 forms an insulating and continuous layer. It is assumed that the Al2O3 layers in samples Pt100 and Pt200 are also insulating and continuous. Some other properties of the Al2O3 layer can be found from the XPS measurement (Figure 7a). Figure 7a shows that the individual Al 2s peaks shift with the changing Arn+ etch time. This effect may be an artifact from the Ar-etch.

Here, the Al2O3 layer has a double function: (i) Al2O3 as a barrier of further oxidation of NiTi at higher temperatures (the Pt ALD process requires high temperatures on the samples’ surfaces, about 300 °C) and (ii) Al2O3 as a layer allowing the Pt growth rate to be higher than that on TiO2.

Apart from the properties of the Pt and Al2O3 ALD coatings, it is worth mentioning the absence of Ni (in any form) on the top surface of sample Pt200 (Table 2). Generally, Ni from a NiTi alloy may be released in a corrosive environment in the form of Ni ions, which is of concern when the NiTi alloy is used as an implant in the human body. Furthermore, as the content of TiO2 is concerned, Table 2 and Figure 8a,b show the difference between the surface of sample Pt200 before and after the Arn+ etch. There is less TiO2 before the Arn+ etch than after the etch. The presence of TiO2 is due to the oxidation of NiTi layer at room temperature and during the Pt and Al2O3 ALD processes.

4.3. The Effect of the Pt and Al2O3 ALD Processes on Properties of the NiTi Layer

The deposition temperatures of the Pt and Al2O3 ALD processes were 300 and 100 °C, respectively. The Al2O3 ALD process was relatively short (only 10 ALD cycles) with the relatively low deposition temperature. Therefore, the Pt ALD process predominantly influenced the properties of the NiTi layer in samples Pt100 and Pt200. Properties of NiTi alloys and other SMAs depend to a large extent on the following factors: (i) chemical composition, (ii) grain size, (iii) texture, (iv) internal stresses, etc. Each factor (of factors (i)–(iv)) may change due to annealing of an SMA in question. The effects of factors (i)–(iv) may be inter-related and/or unevenly distributed in an SMA sample and it may be hard to discriminate contributions of the individual factors as, e.g., in the case of Fe-30 at.% Pd SMA melt-spun ribbons [60]. Since the NiTi layers in samples Pt100 and Pt200 were firmly attached to the substrate it was not easy to study mechanical properties of the NiTi layers but it was convenient to determine the Ms transformation temperatures (an important parameter of SMAs). Table 3 indicates an increase of the Ms temperature of the NiTi layers in samples Pt100 and Pt200 by 14 °C, due mainly to the Pt ALD process. Both the Pt (100 ALD cycles) and Pt (200 ALD cycles) processes resulted in the identical shift of the Ms temperature implying that in samples Pt100 and Pt200, the exposure time (about 35 and 70 min) did not matter as much as the exposure temperature (300 °C). In our previous work, a similar effect on the transformation temperatures was observed when exposing a thin NiTi plate to a polymerization temperature of 200 °C for 2 h during manufacturing the NiTi-PI composite. The PI polymerization process in the NiTi-PI composite resulted in the drop of the Ms temperature by about 3 °C [61]. In both cases (NiTi-PI and Pt100/200 samples) it is hard to find the exact cause of the Ms shift. In the case of Pt100/200 samples, oxidation of NiTi, precipitation (Ni4Ti3), stress due to the difference in the coefficients of thermal expansion of the substrate and the NiTi alloy might play a certain role in the increase of Ms.

As for the grain size distribution change due to the Pt and Al2O3 ALD processes, there was a minor increase of NiTi grains in sample Pt100 (Figure 2a–d). However, the examined areas in samples NiTi and Pt100 were too small to be statistically significant. The main purpose of the EBSD measurements was to make sure that the exposure of the NiTi film to temperatures as high as 300 °C did not result in a remarkable change of the grain size distribution.

5. Conclusions

The Al2O3 ALD process consisting of ten ALD cycles and applied to NiTi films results in a continuous and insulating layer. The following Pt ALD coating is not continuous but forms NPs with sizes 9–17 nm (Pt100) and 12–21 nm (Pt200). The areal densities of Pt NPs are about 800–1000 NPs per 1 µm2 (Pt100) and about 1700 NPs per 1 µm2 (Pt200). The Pt NPs are conductive and do not contain any significant amount of PtO or PtO2 phases. The distinct advantage of the Pt ALD is the controllability of Pt NP size and the areal density of Pt NPs by controlling the number of Pt ALD cycles.

The Al2O3 and Pt ALD processes cause non-significant grain size growth and an increase of the Ms transformation temperature by 14 °C.

Author Contributions

Conceptualization, D.V. and C.-C.K.; methodology, L.K., A.V., J.D. (Jan Duchoň), J.D. (Jan Drahokoupil), Y.-S.Y., N.K., and C.-C.K.; formal analysis, A.V., J.D. (Jan Duchoň), and J.D. (Jan Drahokoupil); investigation, J.D. (Jan Drahokoupil) and D.V.; data curation, J.R.; writing—original draft preparation, D.V.; writing—review and editing, D.V.; visualization, D.V., A.V., J.R., and L.K.; Supervision, J.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Czech Academy of Sciences and the Ministry of Science and Technology, R.O.C. within a Czech-Taiwanese Joint Research Project No. MOST-20–11. Furthermore, the work was supported by Operational Program Research, Development and Education financed by European Structural and Investment Funds and the Czech Ministry of Education, Youth and Sports (Project No. SOLID21-CZ.02.1.01/0.0/0.0/16_019/0000760).

Acknowledgments

We thank Jiříček from Institute of Physics, ASCR for carrying out the XPS measurement.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Leskelä, M.; Ritala, M. Atomic layer deposition chemistry: Recent developments and future challenges. Angew. Chem. Int. Ed. 2003, 42, 5548–5554. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.W.; Park, J.Y.; Kim, S.S. Synthesis of SnO2–ZnO core-shell nanofibers via a novel two-step process and their gas sensing properties. Nanotechnology 2009, 20, 465603. [Google Scholar] [CrossRef] [PubMed]

- Johnson, R.W.; Hultqvist, A.; Bent, S.F. A brief review of atomic layer deposition: From fundamentals to applications. Mater. Today 2014, 17, 236–246. [Google Scholar] [CrossRef]

- Leskelä, M.; Ritala, M. Atomic layer deposition (ALD): From precursors to thin film structures. Thin Solid Films 2002, 409, 138–146. [Google Scholar] [CrossRef]

- Mackus, A.J.; Schneider, J.R.; MacIsaac, C.; Baker, J.G.; Bent, S.F. Synthesis of doped, ternary, and quaternary materials by atomic layer deposition: A review. Chem. Mater. 2018, 31, 1142–1183. [Google Scholar] [CrossRef]

- Sønsteby, H.H.; Fjellvåg, H.; Nilsen, O. Functional perovskites by atomic layer deposition—An overview. Adv. Mater. Interfaces 2017, 4, 1600903. [Google Scholar] [CrossRef]

- Hultqvist, A.; Edoff, M.; Törndahl, T. Evaluation of Zn–Sn–O buffer layers for CuIn0.5Ga0.5Se2 solar cells. Prog. Photovolt. Res. Appl. 2011, 19, 478–481. [Google Scholar] [CrossRef]

- Putkonen, M.; Sajavaara, T.; Rahkila, P.; Xu, L.; Cheng, S.; Niinistö, L.; Whitlow, H.J. Atomic layer deposition and characterization of biocompatible hydroxyapatite thin films. Thin Solid Films 2009, 517, 5819–5824. [Google Scholar] [CrossRef]

- Kosola, A.; Putkonen, M.; Johansson, L.S.; Niinistö, L. Effect of annealing in processing of strontium titanate thin films by ALD. Appl. Surf. Sci. 2003, 211, 102–112. [Google Scholar] [CrossRef]

- Ritala, M.; Niinisto, J. Chemical Vapour Deposition: Precursors, Processes and Applications; Royal Society of Chemistry: London, UK, 2009. [Google Scholar]

- Poodt, P.; Lankhorst, A.; Roozeboom, F.; Spee, K.; Maas, D.; Vermeer, A. High-speed spatial atomic-layer deposition of aluminum oxide layers for solar cell passivation. Adv. Mater. 2010, 22, 3564–3567. [Google Scholar] [CrossRef]

- Won, S.J.; Suh, S.; Huh, M.S.; Kim, H.J. High-quality low-temperature silicon oxide by plasma-enhanced atomic layer deposition using a metal–organic silicon precursor and oxygen radical. IEEE Electron Device Lett. 2010, 31, 857–859. [Google Scholar]

- Groner, M.D.; Fabreguette, F.H.; Elam, J.W.; George, S.M. Low-temperature Al2O3 atomic layer deposition. Chem. Mater. 2004, 16, 639–645. [Google Scholar] [CrossRef]

- King, J.S.; Graugnard, E.; Summers, C.J. TiO2 inverse opals fabricated using low-temperature atomic layer deposition. Adv. Mater. 2005, 17, 1010–1013. [Google Scholar] [CrossRef]

- Sønsteby, H.H.; Yanguas-Gil, A.; Elam, J.W. Consistency and reproducibility in atomic layer deposition. J. Vac. Sci. Technol. A Vac. Surf. Films 2020, 38, 020804. [Google Scholar] [CrossRef]

- He, Y.; Yin, H.; Zhou, R.; Sun, Q. Ambient effect on damping peak of NiTi shape memory alloy. Mater. Lett. 2010, 64, 1483–1486. [Google Scholar] [CrossRef]

- Heller, L.; Vokoun, D.; Šittner, P.; Finckh, H. 3D flexible NiTi-braided elastomer composites for smart structure applications. Smart Mater. Struct. 2012, 21, 045016. [Google Scholar] [CrossRef]

- Van Humbeeck, J.; Stalmans, R. Thermomechanical Properties of SMA: Shape Memory Materials; Otsuka, K., Wayman, C.M., Eds.; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Fu, Y.Q.; Huang, W.M.; Du, H.J.; Huang, X.; Tan, J.P.; Gao, X.Y. Characterization of TiNi shape-memory alloy thin films for MEMS applications. Surf. Coat. Technol. 2001, 145, 107–112. [Google Scholar] [CrossRef]

- Gill, J.J.; Chang, D.T.; Momoda, L.A.; Carman, G.P. Manufacturing issues of thin film NiTi microwrapper. Sens. Actuators A 2001, 93, 148–156. [Google Scholar] [CrossRef]

- Kahn, H.; Huff, M.A.; Heuer, A.H. The TiNi shape-memory alloy and its applications for MEMS. J. Micromech. Microeng. 1998, 8, 213–221. [Google Scholar] [CrossRef]

- Xu, D.; Wang, L.; Ding, G.F.; Zhou, Y.; Yu, A.B.; Cai, B.C. Characteristics and fabrication of NiTi/Si diaphragm micropump. Sens. Actuators A 2001, 93, 87–92. [Google Scholar] [CrossRef]

- Choudhary, N.; Kaur, D. Shape memory alloy thin films and heterostructures for MEMS applications: A review. Sens. Actuators A 2016, 242, 162–181. [Google Scholar] [CrossRef]

- Es-Souni, M.; Es-Souni, M.; Fischer-Brandies, H. Assessing the biocompatibility of NiTi shape memory alloys used for medical applications. Anal. Bioanal. Chem. 2005, 381, 557–567. [Google Scholar] [CrossRef]

- Huang, W. On the selection of shape memory alloys for actuators. Mater. Des. 2002, 23, 11–19. [Google Scholar] [CrossRef]

- Wilson, S.A.; Jourdain, R.P.J.; Zhang, Q.; Dorey, R.A.; Bowen, C.R.; Willander, M.; Wahab, Q.U.; Willander, M.; Al-hilli, S.M.; Nur, O.; et al. New materials for micro-scale sensors and actuators: An engineering review. Mater. Sci. Eng. R Rep. 2007, 56, 1–129. [Google Scholar] [CrossRef]

- Chluba, C.; Ge, W.; de Miranda, R.L.; Strobel, J.; Kienle, L.; Quandt, E.; Wuttig, M. Ultralow-fatigue shape memory alloy films. Science 2015, 348, 1004–1007. [Google Scholar] [CrossRef]

- Eggeler, G.; Hornbogen, E.; Yawny, A.; Heckmann, A.; Wagner, M. Structural and functional fatigue of NiTi shape memory alloys. Mater. Sci. Eng. A 2004, 378, 24–33. [Google Scholar] [CrossRef]

- Kei, C.C.; Yu, Y.S.; Racek, J.; Vokoun, D.; Šittner, P. Atomic layer-deposited Al2O3 coatings on NiTi alloy. J. Mater. Eng. Perform. 2014, 23, 2641–2649. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Y.; Chen, X.; Leng, B.; Guo, X.; Zhang, T. ALD mediated heparin grafting on nitinol for self-expanded carotid stents. Colloids Surf. B Biointerfaces 2016, 143, 390–398. [Google Scholar] [CrossRef]

- Lin, H.C.; Chang, Y.L.; Han, Y.Y.; Yang, K.C.; Chen, M.C. Atomic layer deposited Al2O3 films on NiTi shape memory alloys for biomedical applications. Procedia Manuf. 2019, 37, 431–437. [Google Scholar] [CrossRef]

- Piltaver, I.K.; Peter, R.; Šarić, I.; Salamon, K.; Badovinac, I.J.; Koshmak, K.; Nannarone, S.; Marion, I.D.; Petravić, M. Controlling the grain size of polycrystalline TiO2 films grown by atomic layer deposition. Appl. Surf. Sci. 2017, 419, 564–572. [Google Scholar] [CrossRef]

- Muralidharan, N.; Brock, C.N.; Cohn, A.P.; Schauben, D.; Carter, R.E.; Oakes, L.; Walker, D.G.; Pint, C.L. Tunable mechanochemistry of lithium battery electrodes. ACS Nano 2017, 11, 6243–6251. [Google Scholar] [CrossRef] [PubMed]

- Vokoun, D.; Racek, J.; Kadeřávek, L.; Kei, C.C.; Yu, Y.S.; Klimša, L.; Šittner, P. Atomic layer-deposited TiO2 coatings on NiTi surface. J. Mater. Eng. Perform. 2018, 27, 572–579. [Google Scholar] [CrossRef]

- Vokoun, D.; Kadeřávek, L.; Kei, C.C.; Yu, Y.S.; Koothan, N. Atomic layer deposited Pt coatings on NiTi thin films. In Proceedings of the International Conference on Shape Memory and Superelastic Technologies SMST 2019, Konstanz, Germany, 13–17 May 2019. [Google Scholar]

- Elers, K.E.; Saanila, V.; Soininen, P.J.; Li, W.M.; Kostamo, J.T.; Haukka, S.; Juhanoja, J.; Besling, W.F. Diffusion barrier deposition on a copper surface by atomic layer deposition. Chem. Vap. Depos. 2002, 8, 149–153. [Google Scholar] [CrossRef]

- Jiang, X.; Bent, S.F. Area-selective ALD with soft lithographic methods: Using self-assembled monolayers to direct film deposition. J. Phys. Chem. C 2009, 113, 17613–17625. [Google Scholar] [CrossRef]

- Schaffer, J.E.; Gordon, R. Engineering characteristics of drawn filled nitinol tube. In SMST-2003, Proceedings of the International Conference on Shape Memory and Superelastic Technologies; ASM International: Cleveland, OH, USA, 2004; pp. 109–118. [Google Scholar]

- Baker, L.; Cavanagh, A.S.; Yin, J.; George, S.M.; Kongkanand, A.; Wagner, F.T. Growth of continuous and ultrathin platinum films on tungsten adhesion layers using atomic layer deposition techniques. Appl. Phys. Lett. 2012, 101, 111601. [Google Scholar] [CrossRef]

- Bondi, A. The spreading of liquid metals on solid surfaces. Surface chemistry of high-energy substances. Chem. Rev. 1953, 52, 417–458. [Google Scholar] [CrossRef]

- Anitha, V.C.; Zazpe, R.; Krbal, M.; Yoo, J.; Sopha, H.; Prikryl, J.; Macak, J.M. Anodic TiO2 nanotubes decorated by Pt nanoparticles using ALD: An efficient electrocatalyst for methanol oxidation. J. Catal. 2018, 365, 86–93. [Google Scholar] [CrossRef]

- Lai, Y.; Gong, J.; Lin, C. Self-organized TiO2 nanotube arrays with uniform platinum nanoparticles for highly efficient water splitting. Int. J. Hydrog. Energy 2012, 37, 6438–6446. [Google Scholar] [CrossRef]

- Yoo, J.; Zazpe, R.; Cha, G.; Prikryl, J.; Hwang, I.; Macak, J.M.; Schmuki, P. Uniform ALD deposition of Pt nanoparticles within 1D anodic TiO2 nanotubes for photocatalytic H2 generation. Electrochem. Commun. 2018, 86, 6–11. [Google Scholar] [CrossRef]

- Hsu, I.J.; Hansgen, D.A.; McCandless, B.E.; Willis, B.G.; Chen, J.G. Atomic layer deposition of Pt on tungsten monocarbide (WC) for the oxygen reduction reaction. J. Phys. Chem. C 2011, 115, 3709–3715. [Google Scholar] [CrossRef]

- Comstock, D.J.; Christensen, S.T.; Elam, J.W.; Pellin, M.J.; Hersam, M.C. Tuning the composition and nanostructure of Pt/Ir films via anodized aluminum oxide templated atomic layer deposition. Adv. Funct. Mater. 2010, 20, 3099–3105. [Google Scholar] [CrossRef]

- Lee, H.B.R.; Bent, S.F. Microstructure-dependent nucleation in atomic layer deposition of Pt on TiO2. Chem. Mater. 2012, 24, 279–286. [Google Scholar] [CrossRef]

- Mackus, A.J.; Garcia-Alonso, D.; Knoops, H.C.; Bol, A.A.; Kessels, W.M. Room-temperature atomic layer deposition of platinum. Chem. Mater. 2013, 25, 1769–1774. [Google Scholar] [CrossRef]

- Hämäläinen, J.; Munnik, F.; Ritala, M.; Leskela, M. Atomic layer deposition of platinum oxide and metallic platinum thin films from Pt (acac) 2 and ozone. Chem. Mater. 2008, 20, 6840–6846. [Google Scholar] [CrossRef]

- Lee, W.J.; Wan, Z.; Kim, C.M.; Oh, I.K.; Harada, R.; Suzuki, K.; Choi, E.A.; Kwon, S.H. Atomic layer deposition of Pt thin films using Dimethyl (N, N-Dimethyl-3-Butene-1-Amine-N) Platinum and O2 reactant. Chem. Mater. 2019, 31, 5056–5064. [Google Scholar] [CrossRef]

- Elam, J.W.; Zinovev, A.V.V.; Pellin, M.J.; Comstock, D.J.; Hersam, M.C. Nucleation and growth of noble metals on oxide surfaces using atomic layer deposition. ECS Trans. 2007, 3, 271–278. [Google Scholar] [CrossRef]

- Chan, C.M.; Trigwell, S.; Duerig, T. Oxidation of an NiTi Alloy. Surf. Interface Anal. 1990, 15, 349–354. [Google Scholar] [CrossRef]

- Cavanagh, A.S.; Baker, L.; Clancey, J.W.; Yin, J.; Kongkanand, A.; Wagner, F.T.; George, S.M. In situ characterization of plasma-assisted Pt ALD on W ALD adhesion layers with spectroscopic ellipsometry. ECS Trans. 2013, 58, 19–26. [Google Scholar] [CrossRef]

- Vokoun, D.; Kadeřávek, L.; Balogová, J.; Fekete, L.; Landa, M.; Drahokoupil, J.; Němeček, J.; Heller, L. Effect of FIB milling on NiTi films and NiTi/Si micro-bridge sensor. Smart Mater. Struct. 2019, 29, 015001. [Google Scholar] [CrossRef]

- Fairley, N. CasaXPS Manual 2.3. 15: Introduction to XPS and AES; Casa Software: Ltd, Teignmouth, UK, 2009. [Google Scholar]

- Shyu, J.Z.; Otto, K. Identification of platinum phases on γ-alumina by XPS. Appl. Surf. Sci. 1988, 32, 246–252. [Google Scholar] [CrossRef]

- Ding, S.J.; Chen, H.B.; Cui, X.M.; Chen, S.; Sun, Q.Q.; Zhou, P.; Lu, H.L.; Zhang, D.W.; Shen, C. Atomic layer deposition of high-density Pt nanodots on Al2O3 film using (MeCp)Pt(Me)3 and O2 precursors for nonvolatile memory applications. Nanoscale Res. Lett. 2013, 8, 80. [Google Scholar] [CrossRef] [PubMed]

- Mitchell, D.R.G.; Triani, G.; Attard, D.J.; Finnie, K.S.; Evans, P.J.; Barbé, C.J.; Bartlett, J.R. Atomic layer deposition of TiO2 and Al2O3 thin films and nanolaminates. Smart Mater. Struct. 2005, 15, S57. [Google Scholar] [CrossRef]

- Miikkulainen, V.; Leskelä, M.; Ritala, M.; Puurunen, R.L. Crystallinity of inorganic films grown by atomic layer deposition: Overview and general trends. J. Appl. Phys. 2013, 113, 2. [Google Scholar] [CrossRef]

- Puurunen, R.L. Surface chemistry of atomic layer deposition: A case study for the trimethylaluminum/water process. J. Appl. Phys. 2005, 97, 9. [Google Scholar] [CrossRef]

- Vokoun, D.; Hu, C.T. Two-way shape memory effect in Fe-28.8 at.% Pd melt-spun ribbons. Scr. Mater. 2002, 47, 453–457. [Google Scholar] [CrossRef]

- Vokoun, D.; Sysel, P.; Heller, L.; Kadeřávek, L.; Svatuška, M.; Goryczka, T.; Kafka, V.; Šittner, P. NiTi-Polyimide composites prepared using thermal imidization process. J. Mater. Eng. Perform. 2016, 25, 1993–1999. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).