Fabrication of Ultralow Stress TiO2/SiO2 Optical Coatings by Plasma Ion-Assisted Deposition

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

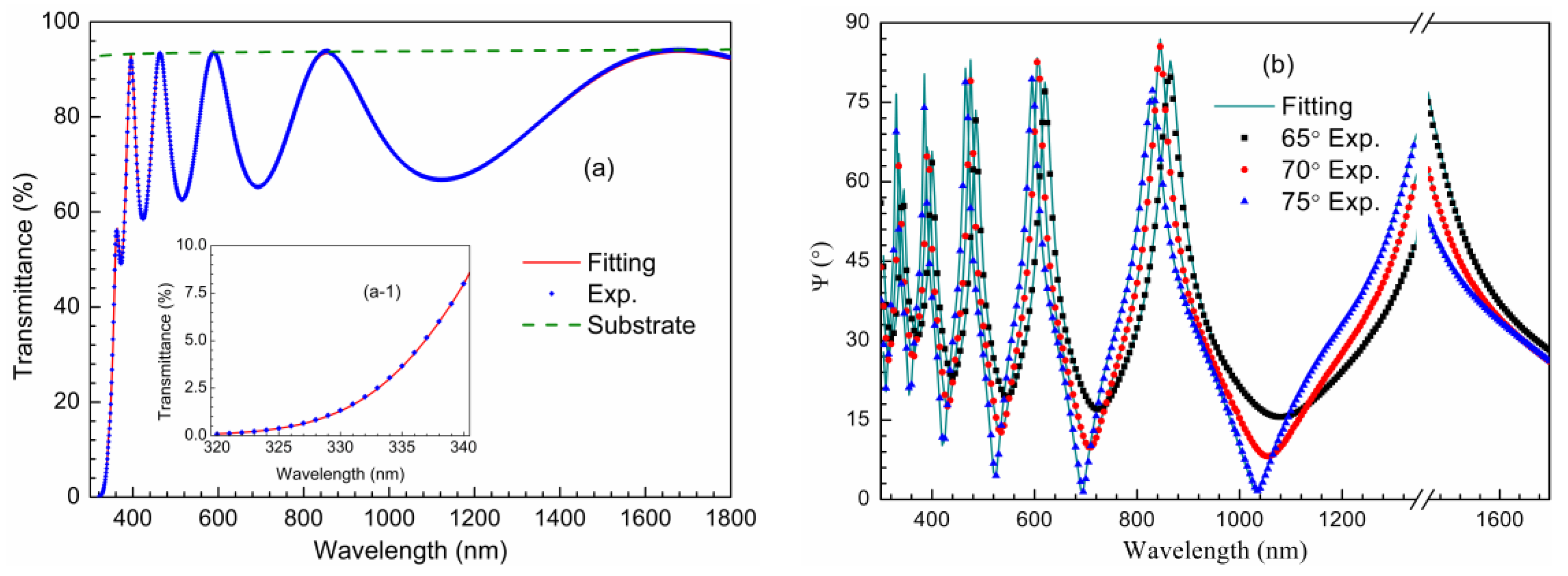

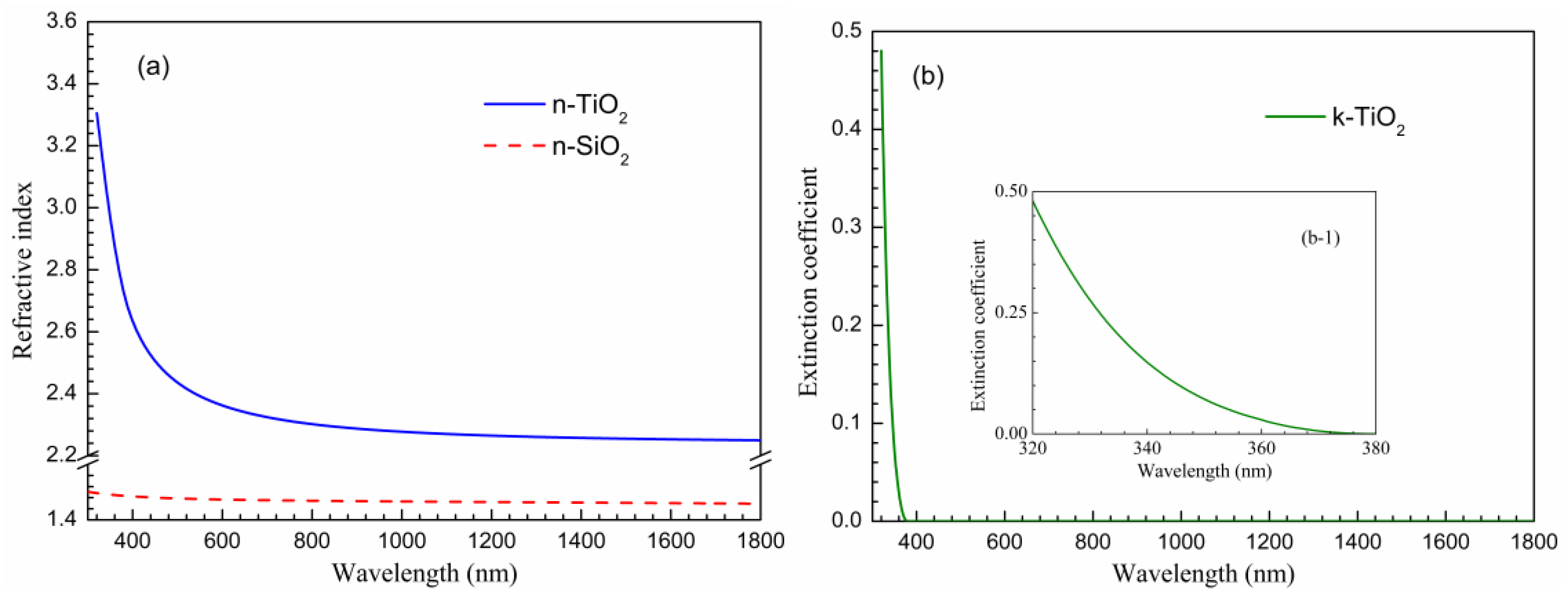

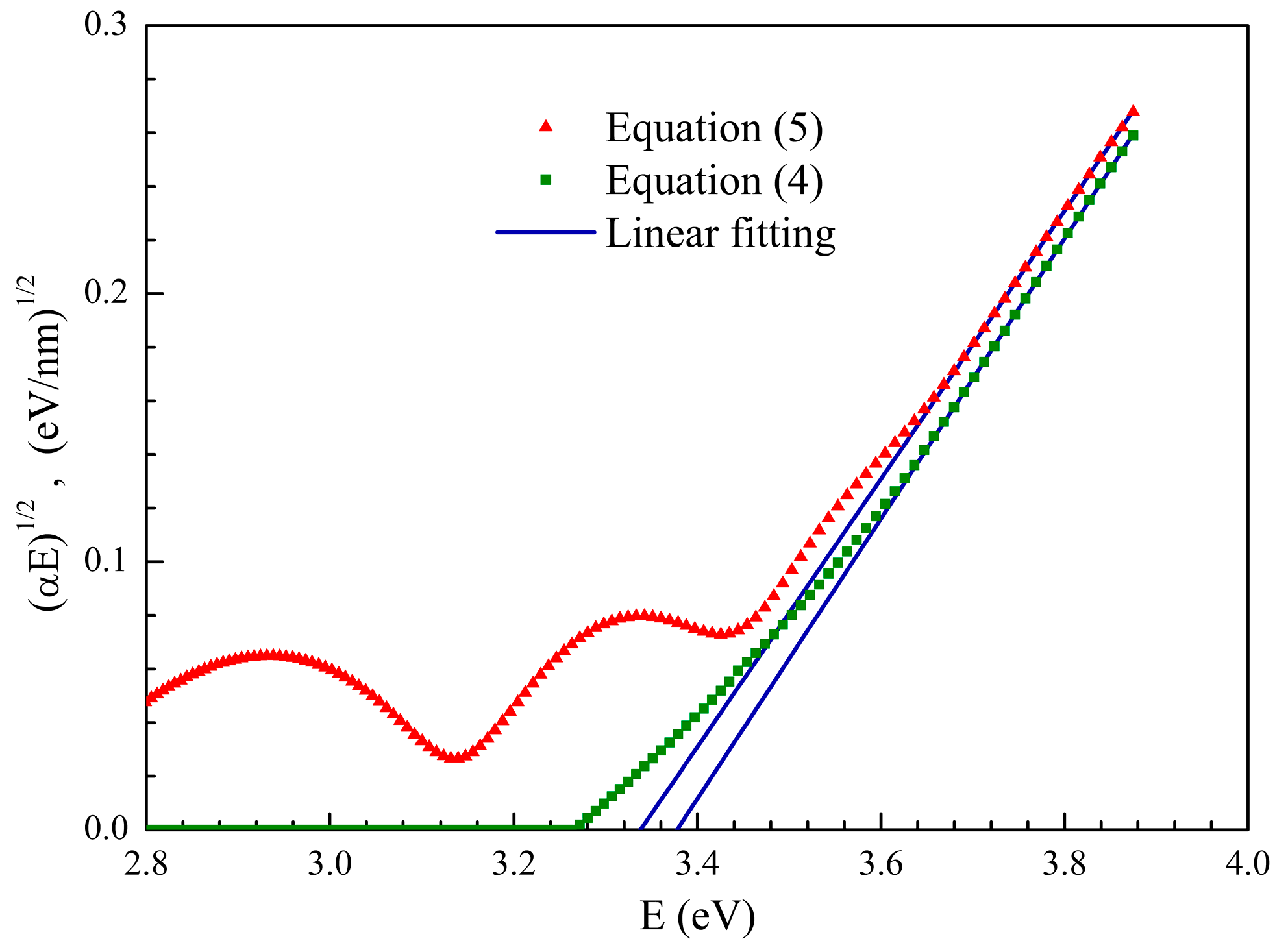

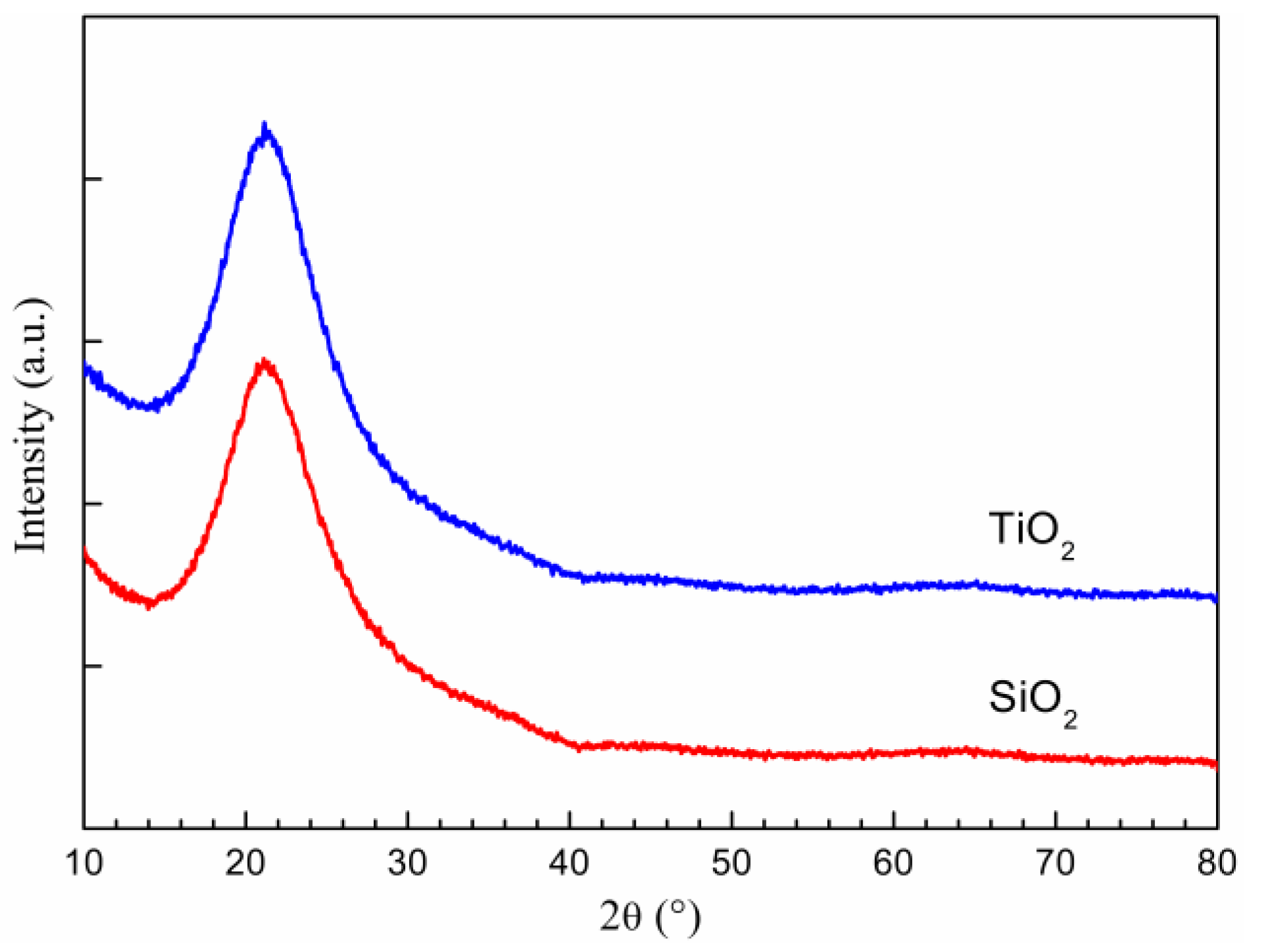

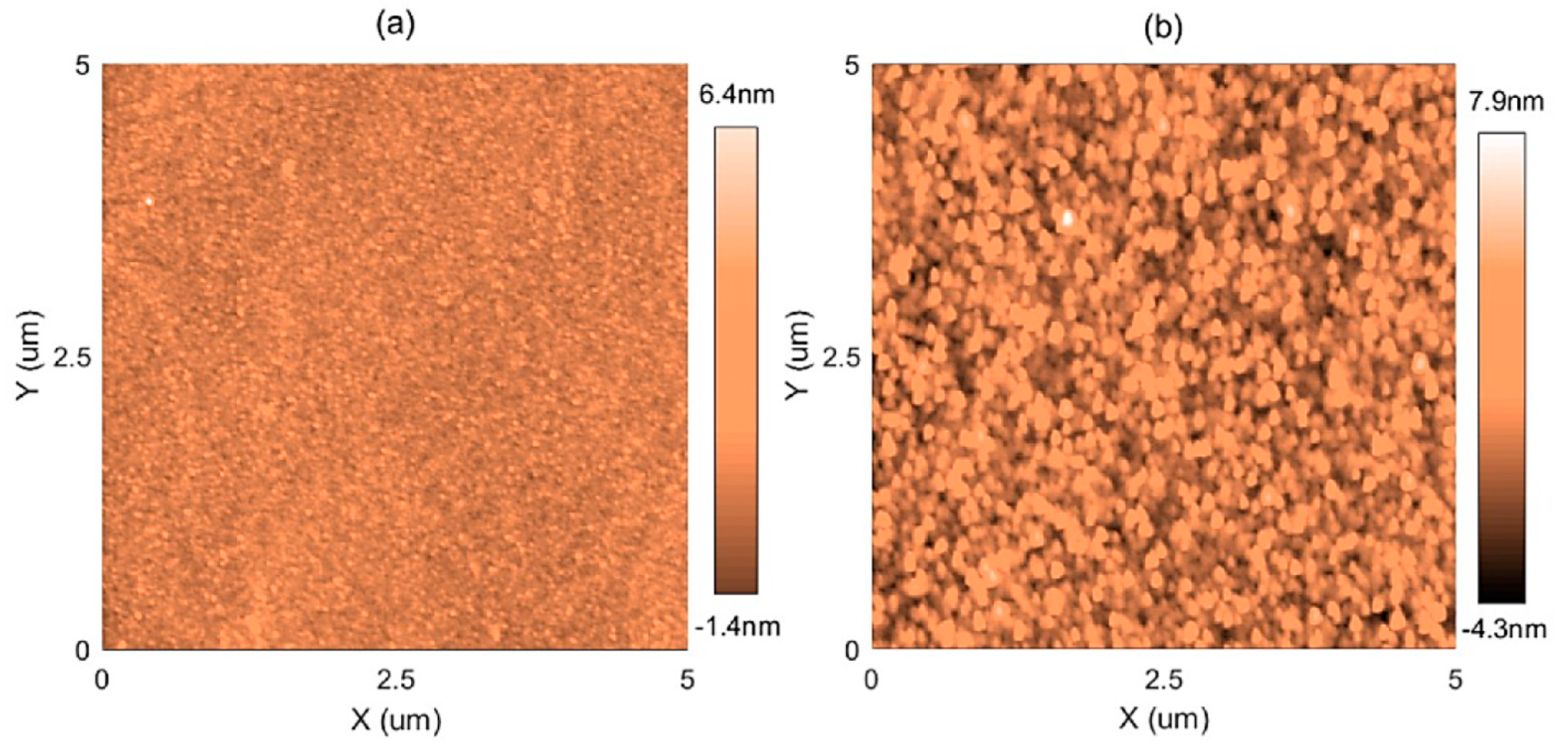

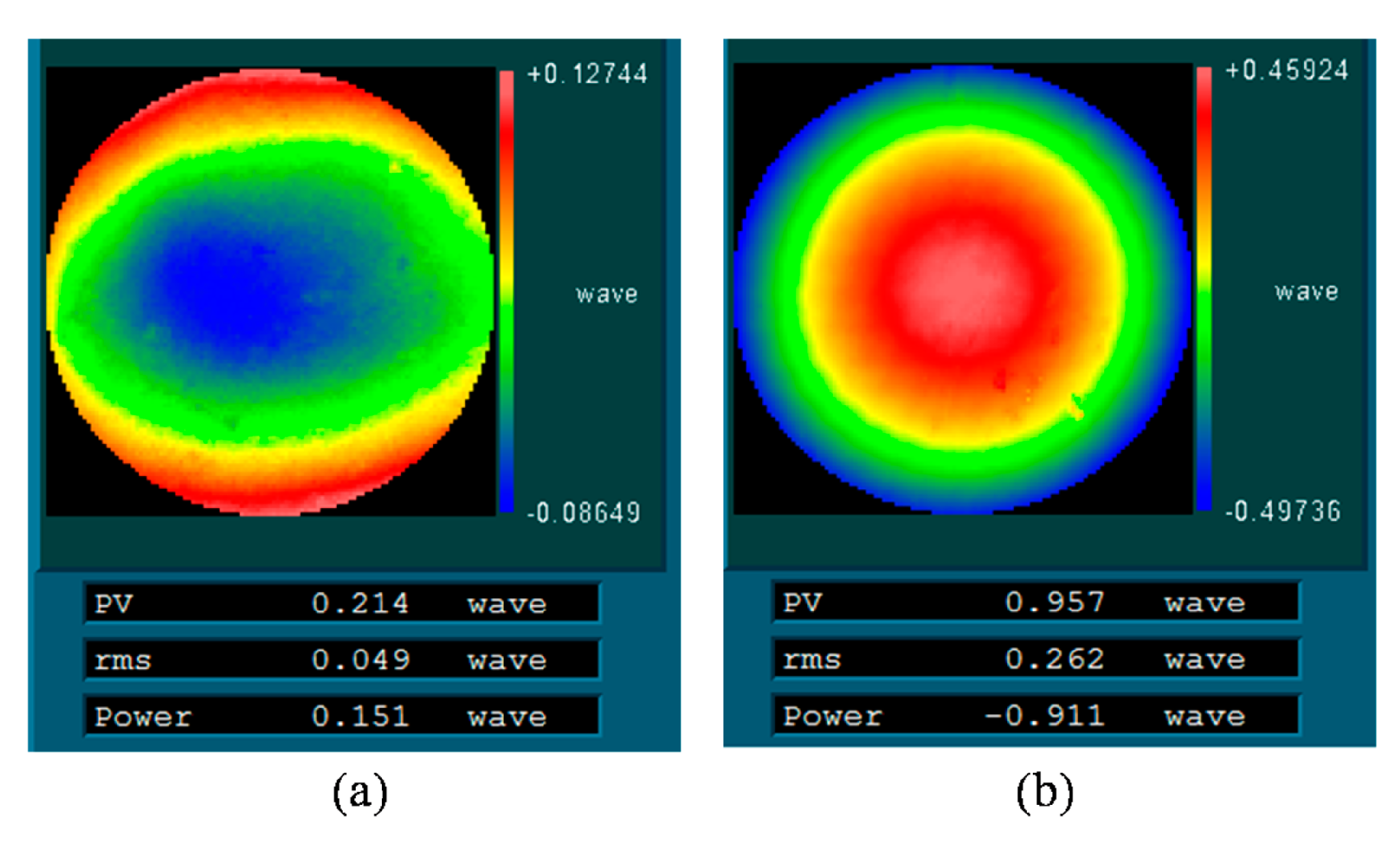

3.1. Single-Layer Coatings

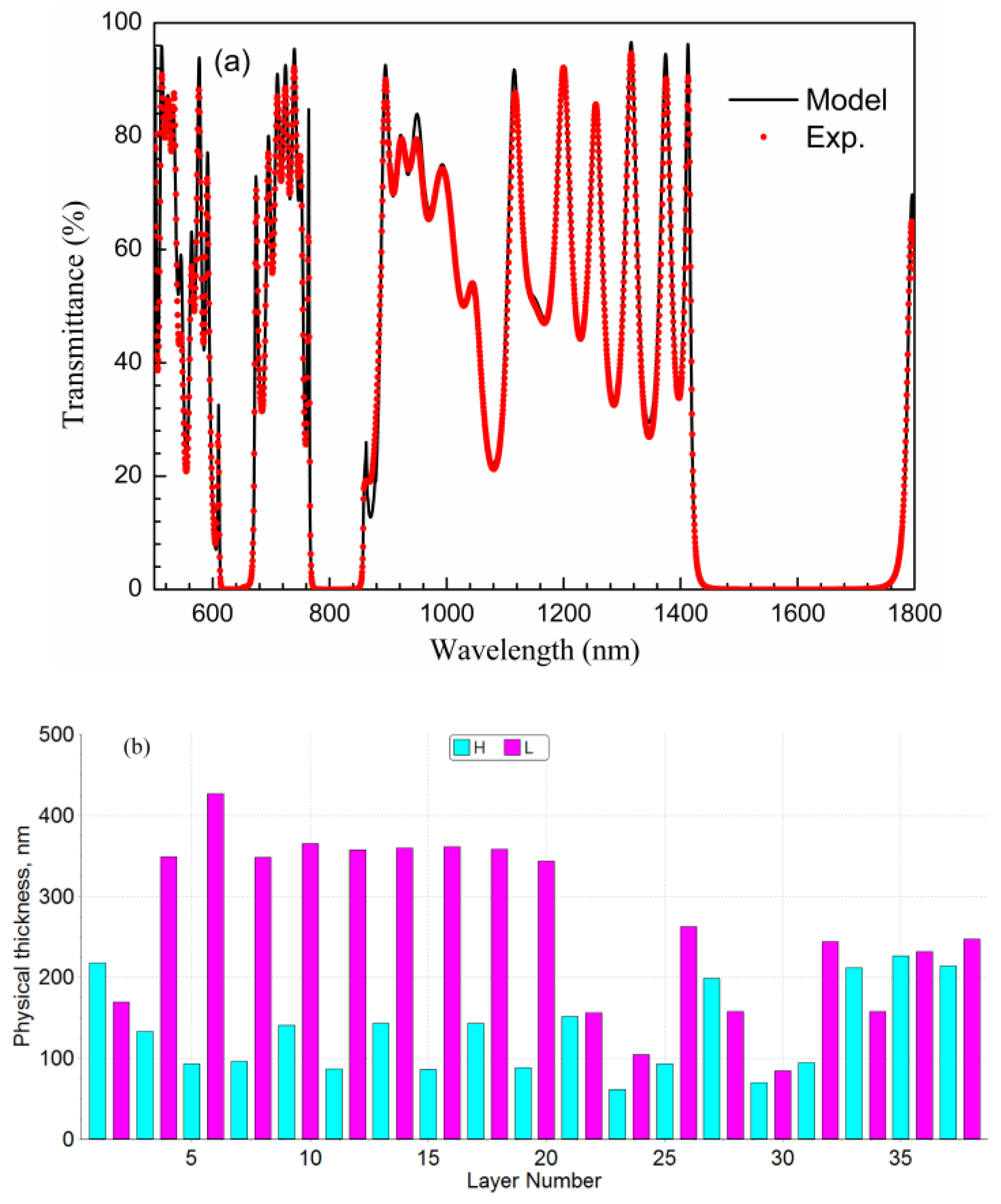

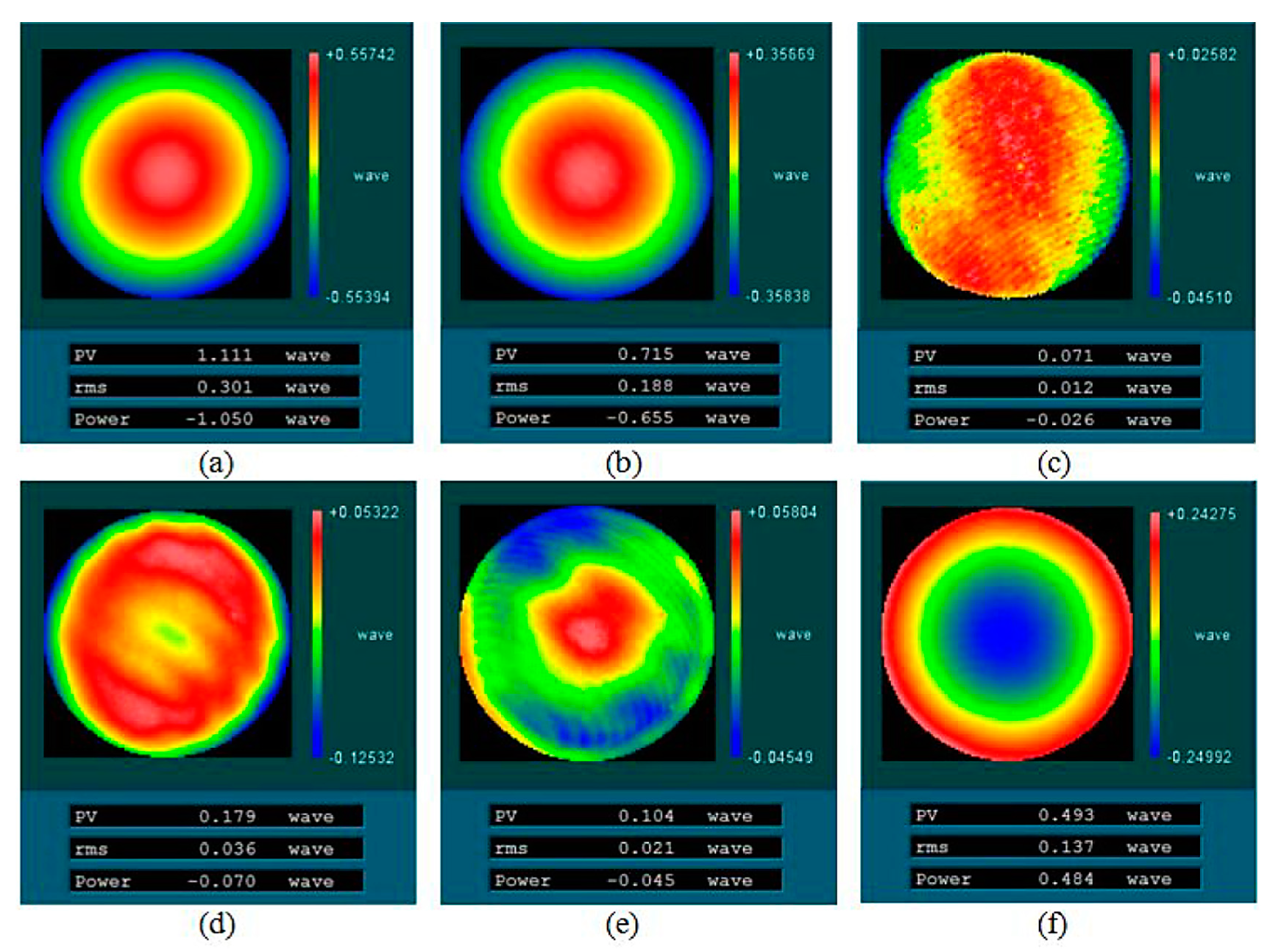

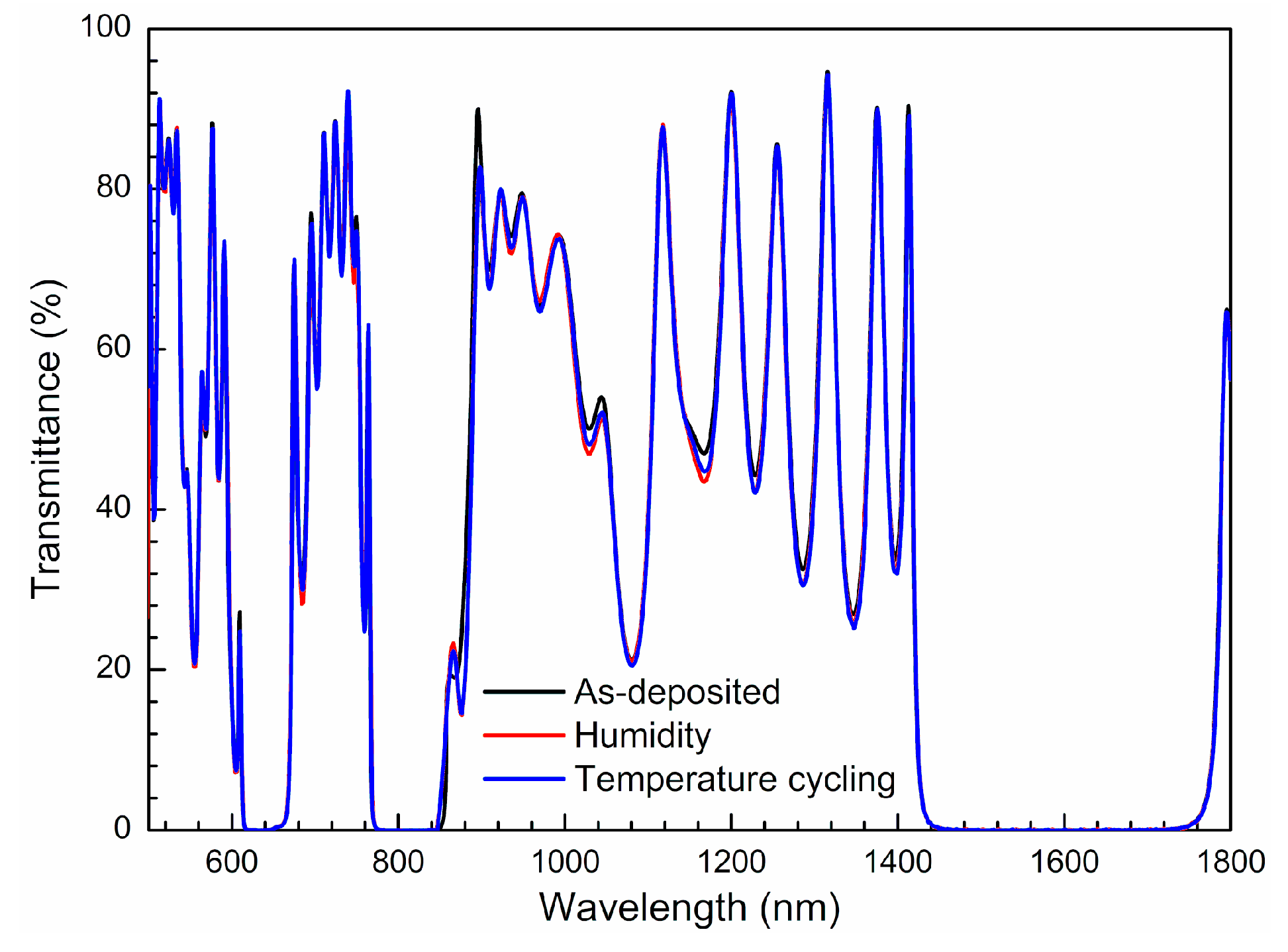

3.2. Multilayer Coatings

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Negres, R.A.; Stolz, C.J.; Thomas, M.D.; Caputo, M. 1064 nm, nanosecond laser mirror thin film damage competition. SPIE 2018, 10805, 108050Y. [Google Scholar] [CrossRef]

- Stolz, C.J.; Negres, R.A.; Feigenbaum, E. Trends observed in 10 years of thin film coating laser damage competitions. In Proceedings of the Optical Interference Coatings Conference (OIC) 2019, Santa Ana Pueblo, NM, USA, 2–7 June 2019. [Google Scholar]

- Oliver, J.B.; Bromage, J.; Smith, C.; Sadowski, D.; Dorrer, C.; Rigatti, A.L. Plasma-ion-assisted coatings for 15 femtosecond laser systems. Appl. Opt. 2014, 53, A221–A228. [Google Scholar] [CrossRef] [PubMed]

- Amotchkina, T.; Trubetskov, M.K.; Pervak, Y.; Veisz, L.; Pervak, V. Stress compensation with antireflection coatings for ultrafast laser applications: From theory to practice. Opt. Express 2014, 22, 30387–30393. [Google Scholar] [CrossRef]

- Pinard, L.; Sassolas, B.; Flaminio, R.; Forest, D.; Lacoudre, A.; Michel, C.; Montorio, J.L.; Morgado, N. Toward a new generation of low-loss mirrors for the advanced gravitational waves interferometers. Opt. Let. 2011, 36, 1407–1409. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Degallaix, J.; CMichel, C.; Sassolas, B.; Allocca, A.; Cagnoli, G.; Balzarini, L.; Dolique, V.; Flaminio, R.; Forest, D.; Granata, M.; et al. Large and extremely low loss: The unique challenges of gravitational wave mirrors. J. Opt. Soc. Am. A 2019, 36, C85–C94. [Google Scholar] [CrossRef] [PubMed]

- Oliver, J.B.; Kupinski, P.; Rigatti, A.L.; Schmid, A.W.; Lambropoulos, J.C.; Papernov, S.; Kozlov, A.; Smith, C.; Hand, R.D. Stress compensation in hafnia/silica optical coatings by inclusion of alumina layers. Opt. Express 2012, 20, 16596–16610. [Google Scholar] [CrossRef]

- Oliver, J.B.; Smith, C.; Spaulding, J.; Rigatti, A.L.; Charles, B.; Papernov, S.; Taylor, B.; Foster, J.; Carr, C.W.; Luthi, R.; et al. Glancing-angle-deposited magnesium oxide films for high-fluence applications. Opt. Mater. Express 2016, 6, 2291–2303. [Google Scholar] [CrossRef]

- Steinecke, M.; Kiedrowski, K.; Jupé, M.; Ristau, D. Very thick mixture oxide ion beam sputtering films for investigation of onolinear meterial properties. Eur. Phys. J. Appl. Phys. 2017, 80, 30301–30305. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Long, G.Y.; Zhou, H.; Fan, J.Q.; Cui, H.; Cheng, L. Finite-element-method study of the effect of thin-film residual stresses on high-order aberrations of deformable mirrors. Surf. Coat. Technol. 2019, 366, 35–40. [Google Scholar] [CrossRef]

- Kičas, S.; Gimževskis, U.; Melnikas, S. Post deposition annealing of IBS mixture coatings for compensation of film induced stress. Opt. Mater. Express 2016, 6, 2236–2243. [Google Scholar] [CrossRef]

- Tian, X.X.; Xiong, S.M.; Zhang, Y.H.; Zhang, K.P. Simulation of thermal stress in ion beam sputtered Ta2O5/SiO2 multilayer coatings on different substrates by finite element analysis. Surf Coat. Technol. 2019, 362, 225–233. [Google Scholar] [CrossRef]

- Brossmann, J.; Lappschies, M.; Jakobs, S. Precisely stress compensated dielectric laser mirrors deposited by PARMS on thin deformable substrates. In Proceedings of the Optical Interference Coatings Conference (OIC) 2019, Santa Ana Pueblo, NM, USA, 2–7 June 2019. [Google Scholar]

- Biscwas, D.; Sinha, A.K.; Chakraborty, S. Effects of oxygen partial pressure and annealing temperature on the residual stress of hafnium oxide thin-films on silicon using synchrotron-based grazing incidence X-ray diffraction. Appl. Surf. Sci. 2016, 384, 376–379. [Google Scholar] [CrossRef]

- Oliver, J.B.; Spaulding, J.; Charles, B. Stress compensation by deposition of a nonuniform corrective coating. App. Opt. 2020, 59, A54–A57. [Google Scholar] [CrossRef] [PubMed]

- Gensemer, S.; Gross, M. Figuring large optics at the sub-nanometer level: Compensation for coatings and gravity distortions. Opt. Express 2015, 23, 31171–31180. [Google Scholar] [CrossRef]

- Begou, T.; Lumeau, J. Accurate analysis of mechanical stress in dielectric multilayers. Opt. Let. 2017, 42, 3217–3220. [Google Scholar] [CrossRef]

- Bischoff, M.; Nowitzki, T.; Voß, O.; Wilbrandt, S.; Stenzel, O. Postdeposition treatment of IBS coatings for UV applications with optimized thin-film stress properties. Appl. Opt. 2014, 53, A212–A220. [Google Scholar] [CrossRef]

- Lemarquis, F. Athermal compensation of the stress-induced surface deflection of optical coatings using iso-admittance layers. Appl. Opt. 2014, 53, A229–A236. [Google Scholar] [CrossRef]

- Denus-Baillargeon, M.; Schmitt, T.; Larouche, S.; Martinu, L. Design and fabrication of stress-compensated optical coatings: Fabry-Perot filters for astronomical applications. Appl. Opt. 2014, 53, 2616–2624. [Google Scholar] [CrossRef]

- Yao, Y.W.; Chalifoux, B.D.; Heilmann, R.K.; Schattenburg, M.L. Thermal oxide pattering method for compensating coating stress in silicon substrates. Opt. Express 2019, 27, 1010–1025. [Google Scholar] [CrossRef] [Green Version]

- Chalifoux, B.D.; Yao, Y.W.; Woller, K.B.; Heilmann, R.K.; Schattenburg, M.L. Compensating film stress in thin silicon substrates using ion implantation. Opt. Express 2019, 27, 11182–11195. [Google Scholar] [CrossRef] [Green Version]

- Tajima, N.; Murotani, H.; Matumoto, S.; Honda, H. Stress control of an optical thin film by sputtering and vacuum deposition. In Proceedings of the Optical Interference Coatings 2016, Tucson, AZ, USA, 19–24 June 2016. [Google Scholar]

- Woo, S.H.; Hwangbo, C.K. Influence of plasma ion-beam assistance on TiO2 and MgF2 thin films deposited by plasma ion-assisted deposition. Surf. Coat. Technol. 2007, 201, 8250–8257. [Google Scholar] [CrossRef]

- Liu, H.; Jensen, L.; Ma, P.; Ristau, D. Stress compensated anti-reflection coating for high power laser deposited with IBS SiO2 and ALD Al2O3. Appl. Sur. Sci. 2019, 476, 521–527. [Google Scholar] [CrossRef]

- Jellison, G.E., Jr.; Modine, F.A. Parameterization of the optical functions of amorphous materials in the interband region. Appl. Phys. Lett. 1996, 69, 371–373. [Google Scholar] [CrossRef]

- Fakhouri, H.N.; Hudaib, A.; Sleit, A. Multivector particle swarm optimization algorithm. Soft Comput. 2019, 24, 11695–11713. [Google Scholar] [CrossRef]

- Tikhonravov, A.; Trubetskov, M.; Amotchkina, T.; DeBell, G.; Pervak, V.; Sytchkova, A.K.; Grilli, M.L.; Ristau, D. Optical parameters of oxide films typically used in optical coating production. Appl. Opt. 2011, 50, C75–C85. [Google Scholar] [CrossRef]

- Amotchkina, T.; Trubetskov, M.; Tikhonov, A.; Angelov, I.B.; Pervak, V. Reliable optical characterization of e-beam evaporated TiO2 films deposited at different substrate temperatures. Appl. Opt. 2014, 53, A8–A15. [Google Scholar] [CrossRef]

- Nezar, S.; Saoula, N.; Sali, S.; Faiz, M.; Mekki, M.; Laoufi, N.A.; Tabet, N. Properties of TiO2 thin films deposited by rf reactive magnetron sputtering on biased substrates. Appl. Surf. Sci. 2017, 395, 172–179. [Google Scholar] [CrossRef]

- Optilayer. Available online: www.optilayer.com (accessed on 16 April 2020).

- Kong, M.D.; Guo, C.; Li, B.C.; He, W.Y.; Wei, M. Fabrication of multi-wavelength visible and infrared filter for solar atomsphere tomographic imaging. Chin. Opt. Lett. 2017, 15, 123101. [Google Scholar] [CrossRef]

- Hilfiker, J.N.; Pribil, G.K.; Synowicki, R.; Martin, A.C.; Hale, J.S. Spectroscopic ellipsometry characterization of multilayer optical coatings. Surf. Coat. Technol. 2019, 357, 114–121. [Google Scholar] [CrossRef]

- Lv, Q.P.; Huang, M.L.; Deng, S.W.; Zhang, S.Q.; Li, G. Effects of oxygen flows on optical properties, micro-structure and residual stress of Ta2O5 films deposited by DIBS. Optik 2018, 166, 278–284. [Google Scholar] [CrossRef]

- Jena, S.; Tokas, R.B.; Thakur, S.; Udupa, D.V. Study of aging effects on optical properties and residual stress of HfO2 thin film. Optik 2019, 185, 71–81. [Google Scholar] [CrossRef]

| Material | Substrate Temperature (°C) | Deposition Rate (nm/s) | Bias Voltage (V) | Discharge Current (A) | Gas Flow Rate (sccm) | |

|---|---|---|---|---|---|---|

| Ar | O2 | |||||

| TiO2 | 180 | 0.2 | 120 | 50 | 12 | 25 |

| SiO2 | 0.4 | 140 | 12 | 5 | ||

| Material | Thickness (nm) | Refractive Index | Energy Band Gap (eV) | RMS Roughness (nm) | Phase Composition | Stress (MPa) |

|---|---|---|---|---|---|---|

| TiO2 | 372.9 | 2.436 | 3.34–3.38 | 0.52 | amorphous | +164.8 |

| SiO2 | 936.7 | 1.477 | – | 1.39 | −395.8 |

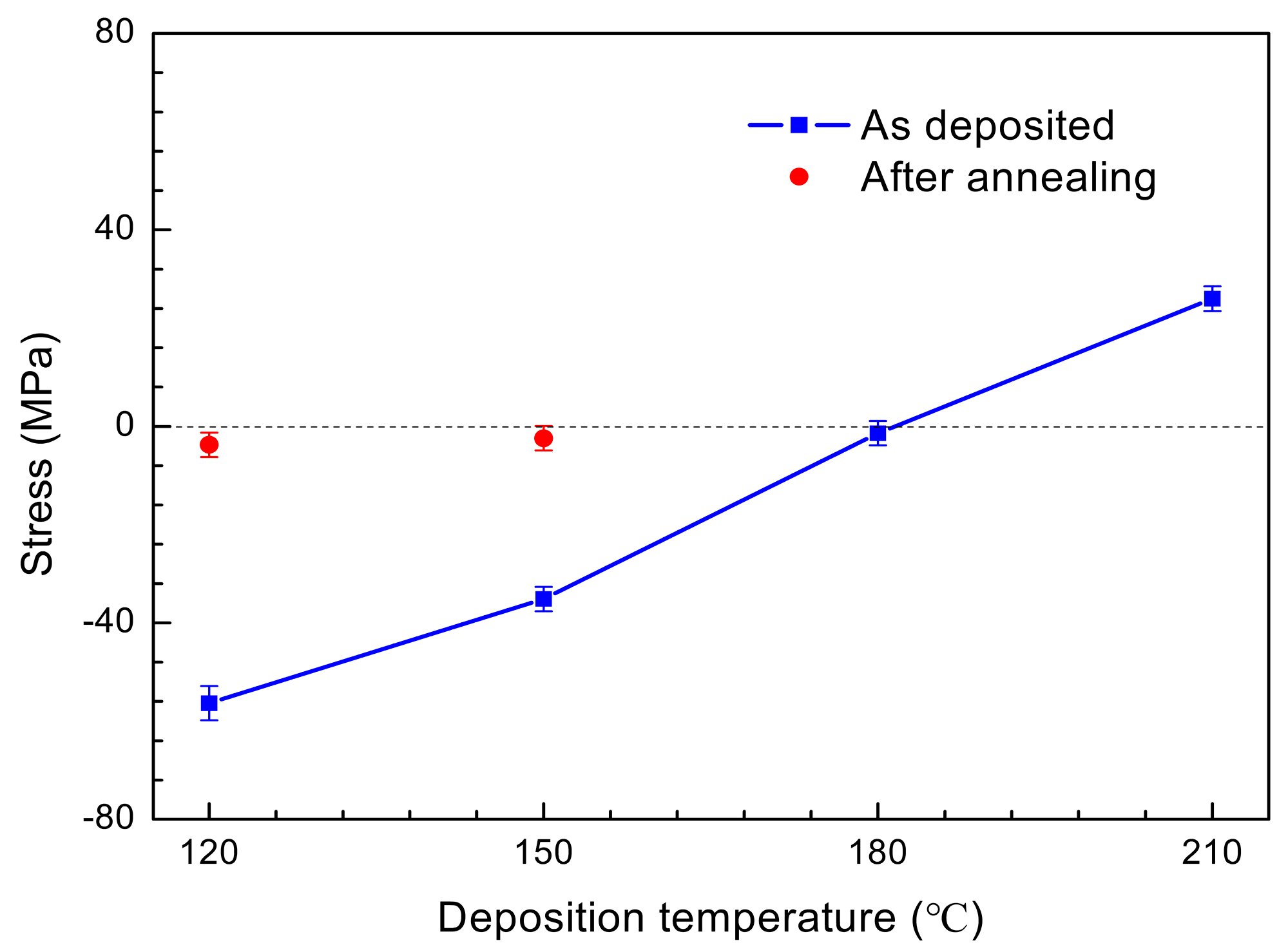

| Deposition Temperature (°C) | Stress (MPa) | |

|---|---|---|

| As-Deposited | Annealing Treatment | |

| 120 | −56.4 | −3.8 |

| 150 | −35.2 | −2.4 |

| 180 | −1.4 | – |

| 210 | +25.9 | – |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, C.; Kong, M. Fabrication of Ultralow Stress TiO2/SiO2 Optical Coatings by Plasma Ion-Assisted Deposition. Coatings 2020, 10, 720. https://doi.org/10.3390/coatings10080720

Guo C, Kong M. Fabrication of Ultralow Stress TiO2/SiO2 Optical Coatings by Plasma Ion-Assisted Deposition. Coatings. 2020; 10(8):720. https://doi.org/10.3390/coatings10080720

Chicago/Turabian StyleGuo, Chun, and Mingdong Kong. 2020. "Fabrication of Ultralow Stress TiO2/SiO2 Optical Coatings by Plasma Ion-Assisted Deposition" Coatings 10, no. 8: 720. https://doi.org/10.3390/coatings10080720

APA StyleGuo, C., & Kong, M. (2020). Fabrication of Ultralow Stress TiO2/SiO2 Optical Coatings by Plasma Ion-Assisted Deposition. Coatings, 10(8), 720. https://doi.org/10.3390/coatings10080720