Damage Assessment and Fracture Resistance of Functionally Graded Advanced Thermal Barrier Coating Systems: Experimental and Analytical Modeling Approach

Abstract

1. Introduction

- (a)

- Physics-based damage analysis and modeling of failure mechanism(s) involved through experimental research. Both kinetics of oxide growth and crack formation are considered as the primary and secondary damages, respectively.

- (b)

- Fracture mechanics-based analytical approach to propose a design parameter for apply FGTBC for enhancement of fracture resistance. Development of a simplistic model to characterize fracture resistance of the interfacial region and compare various conventional and advanced TBC systems. The attempt made here should be treated as the initial step towards more refined modeling for realistic situations.

2. Experimental Study

- (a)

- Assessment of TGO oxidation kinetics under thermal cycling effects and quantitative relations with damage induced crack length;

- (b)

- Modeling of the physical damage accumulation and cracking mechanisms in presence of changing TGO geometric profiles;

- (c)

- The following sections discuss the experimental procedures followed, physical damages assessed, results obtained, empirical relations established, and phenomenological model developed.

2.1. Experimentation

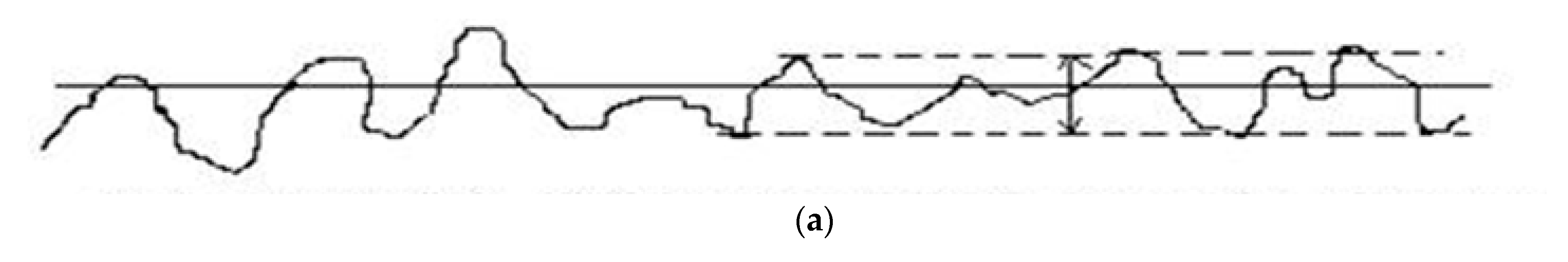

2.2. TGO Damage Assessment

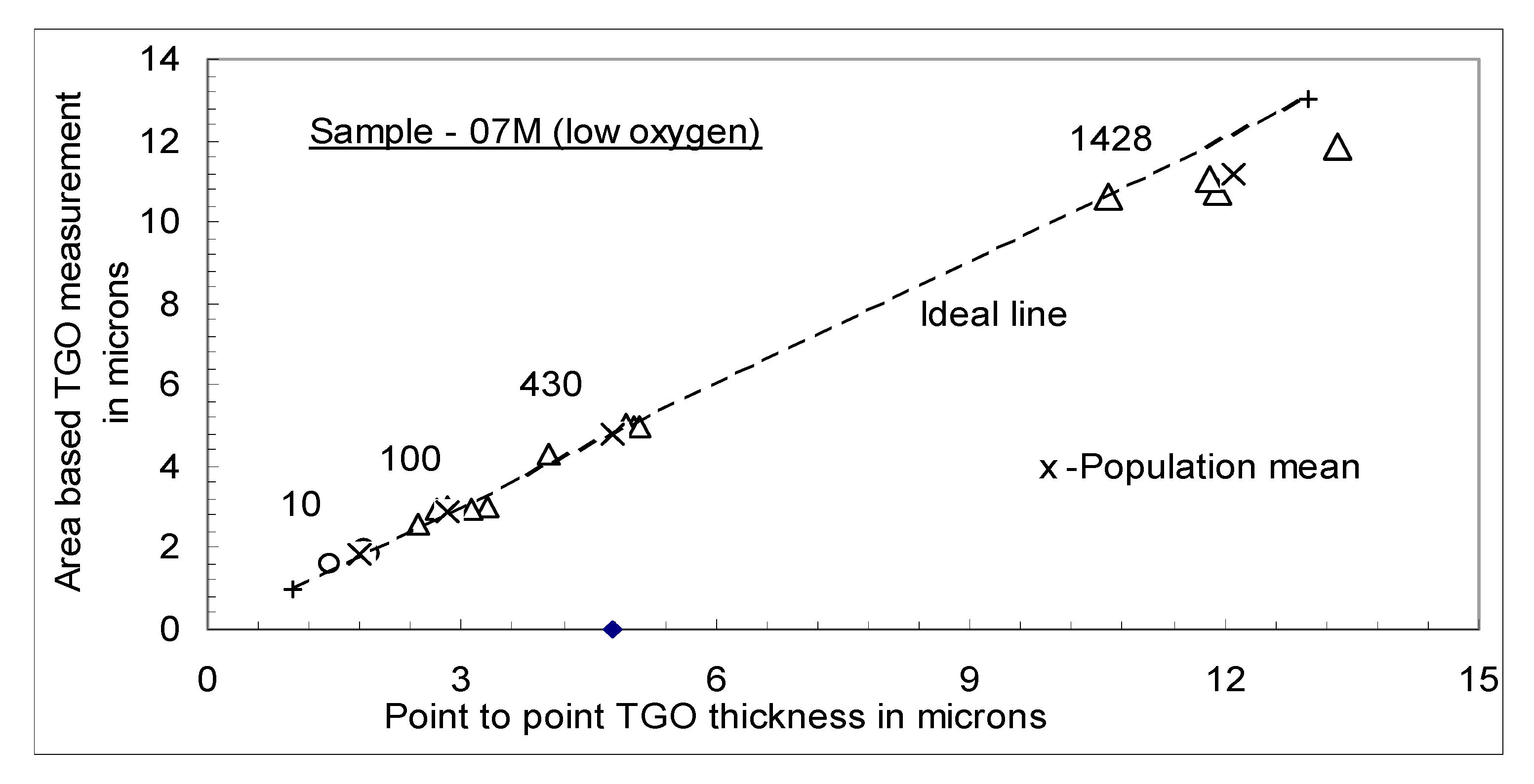

2.2.1. Area Based

2.2.2. Point to Point Measurement

2.3. Crack Length

3. Results and Discussion

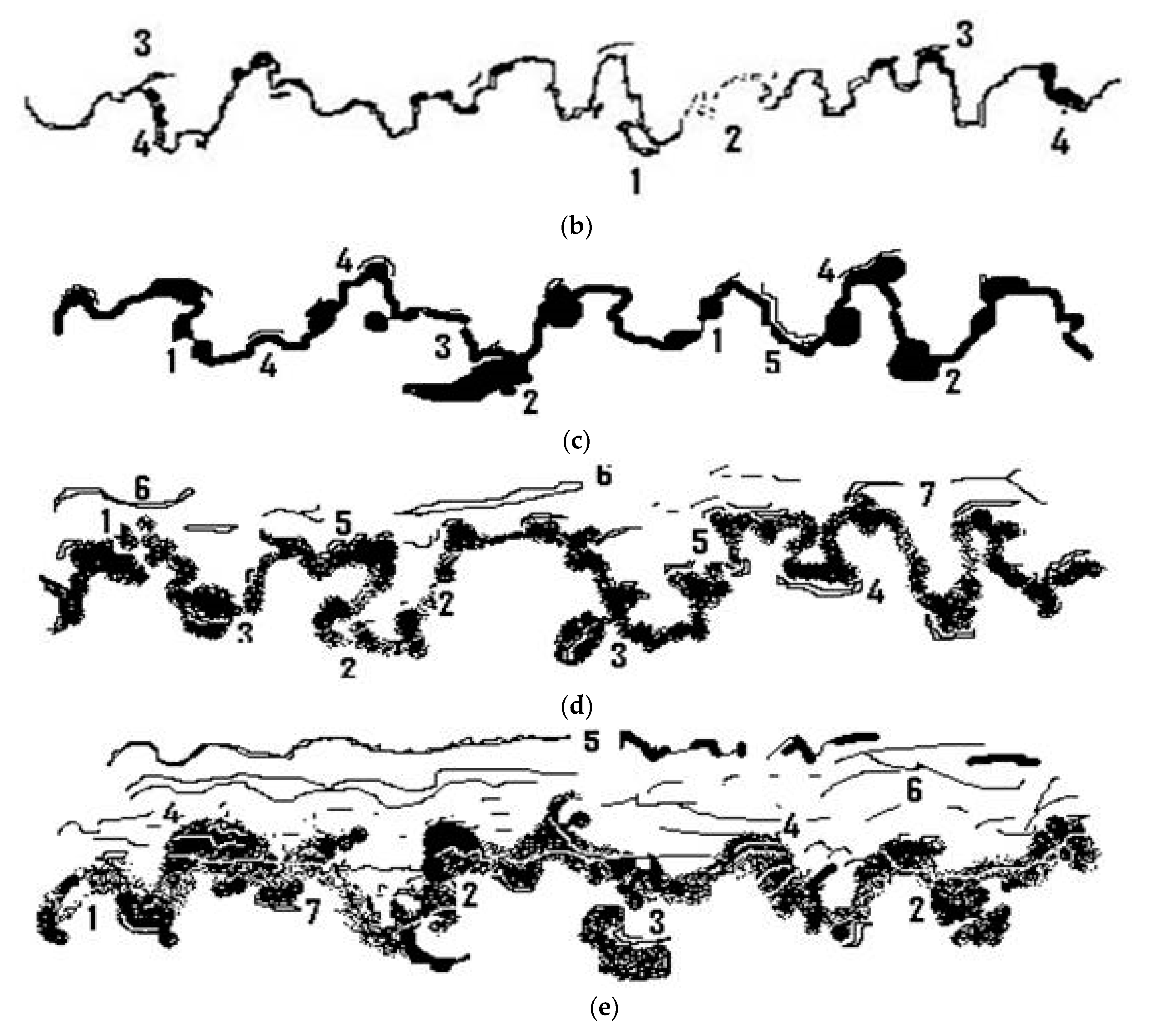

3.1. Microstructural Analysis

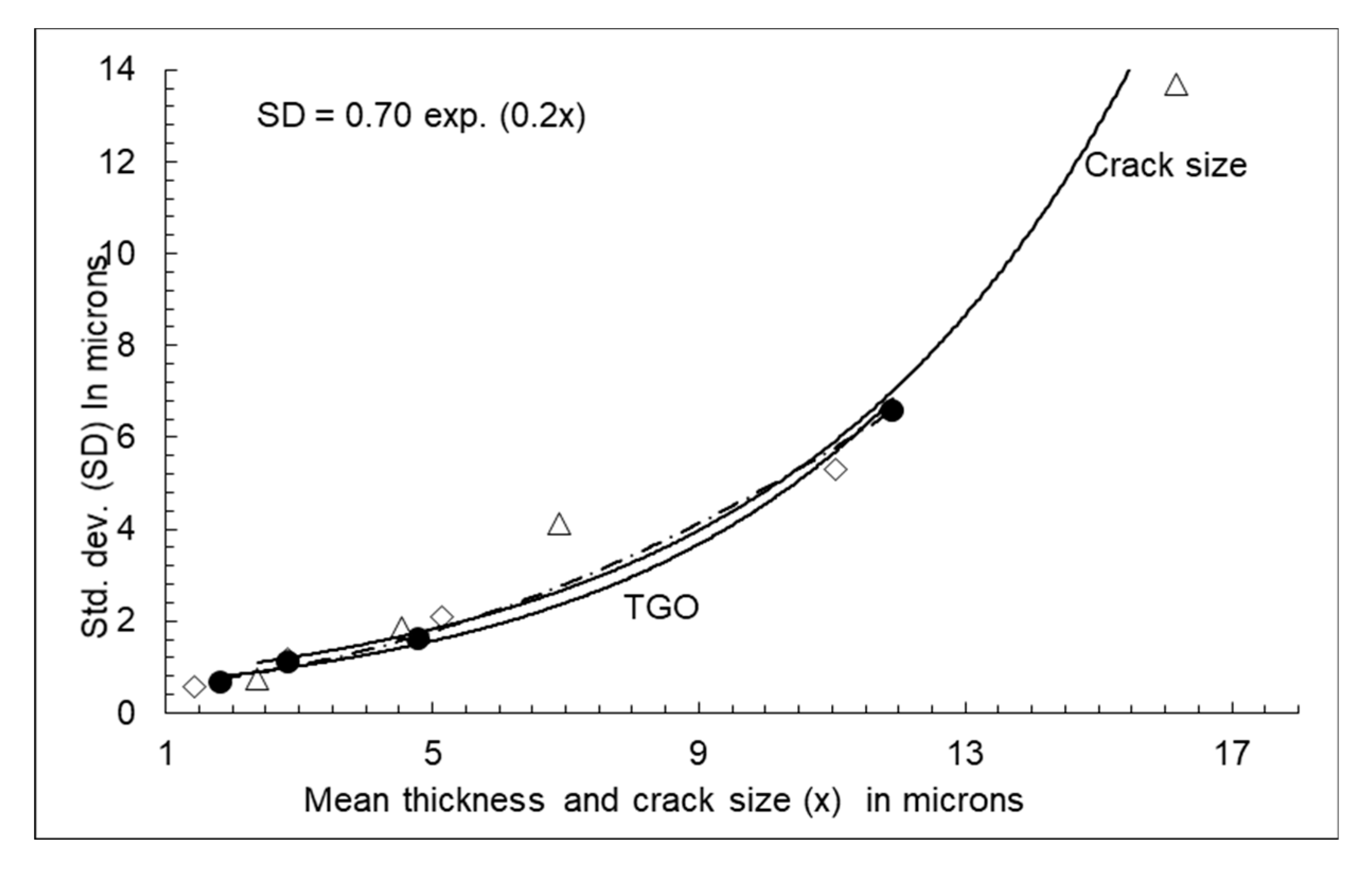

3.2. TGO Thickness and Crack Length

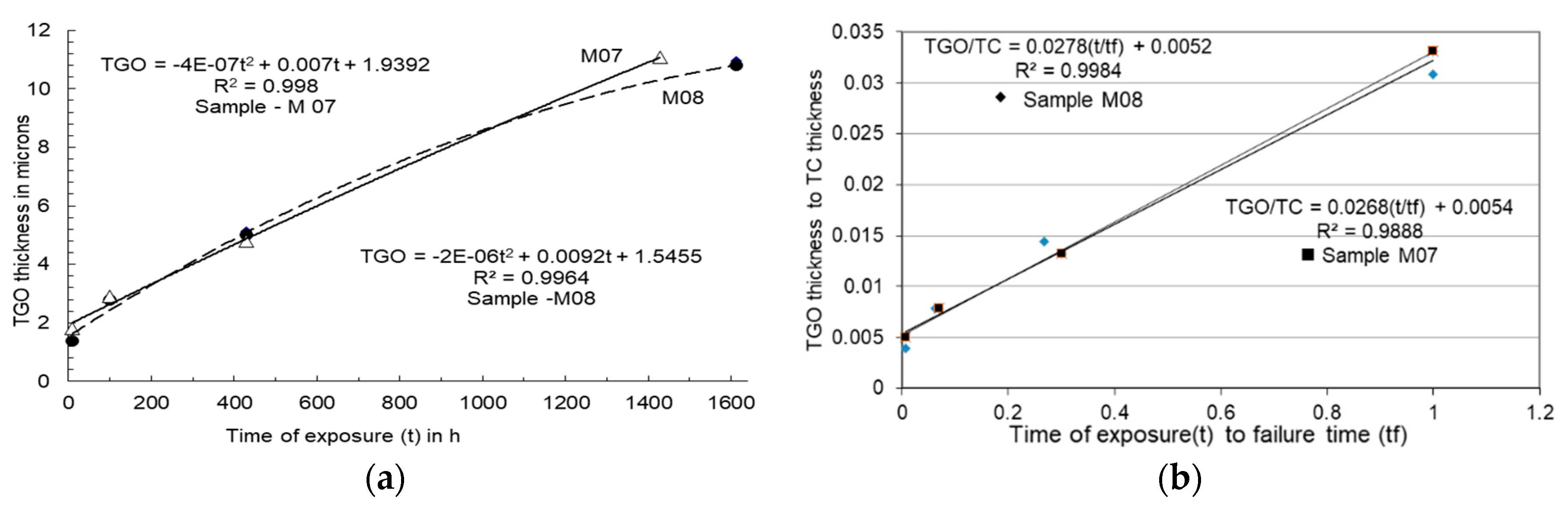

3.3. Thermal Cycling vs. TGO Growth

Linearity vs. Nonlinearity Trend

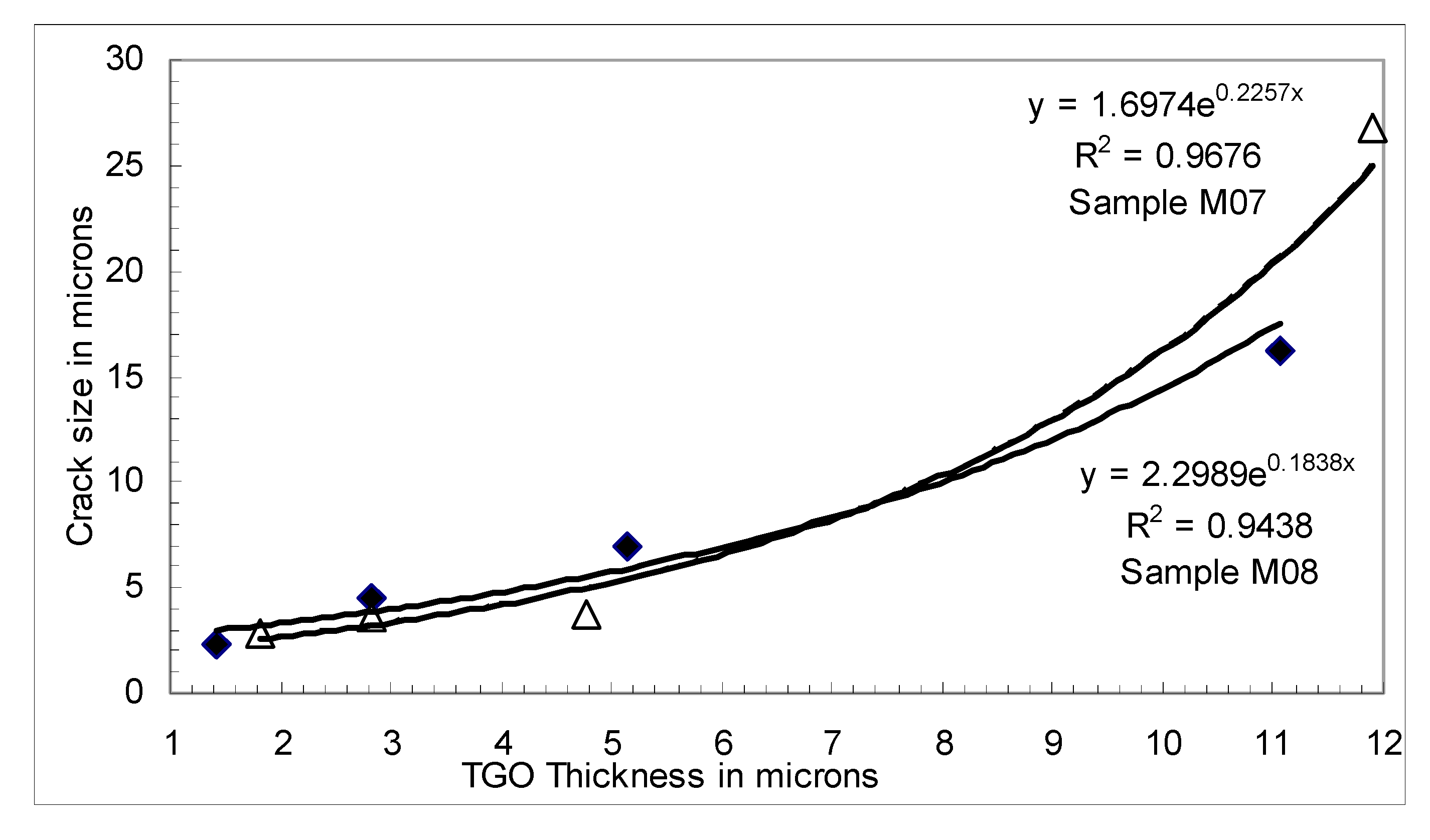

3.4. Crack Length vs. TGO Thickness

4. Phenomenological Modeling

5. Analytical Modeling for TBC Instability

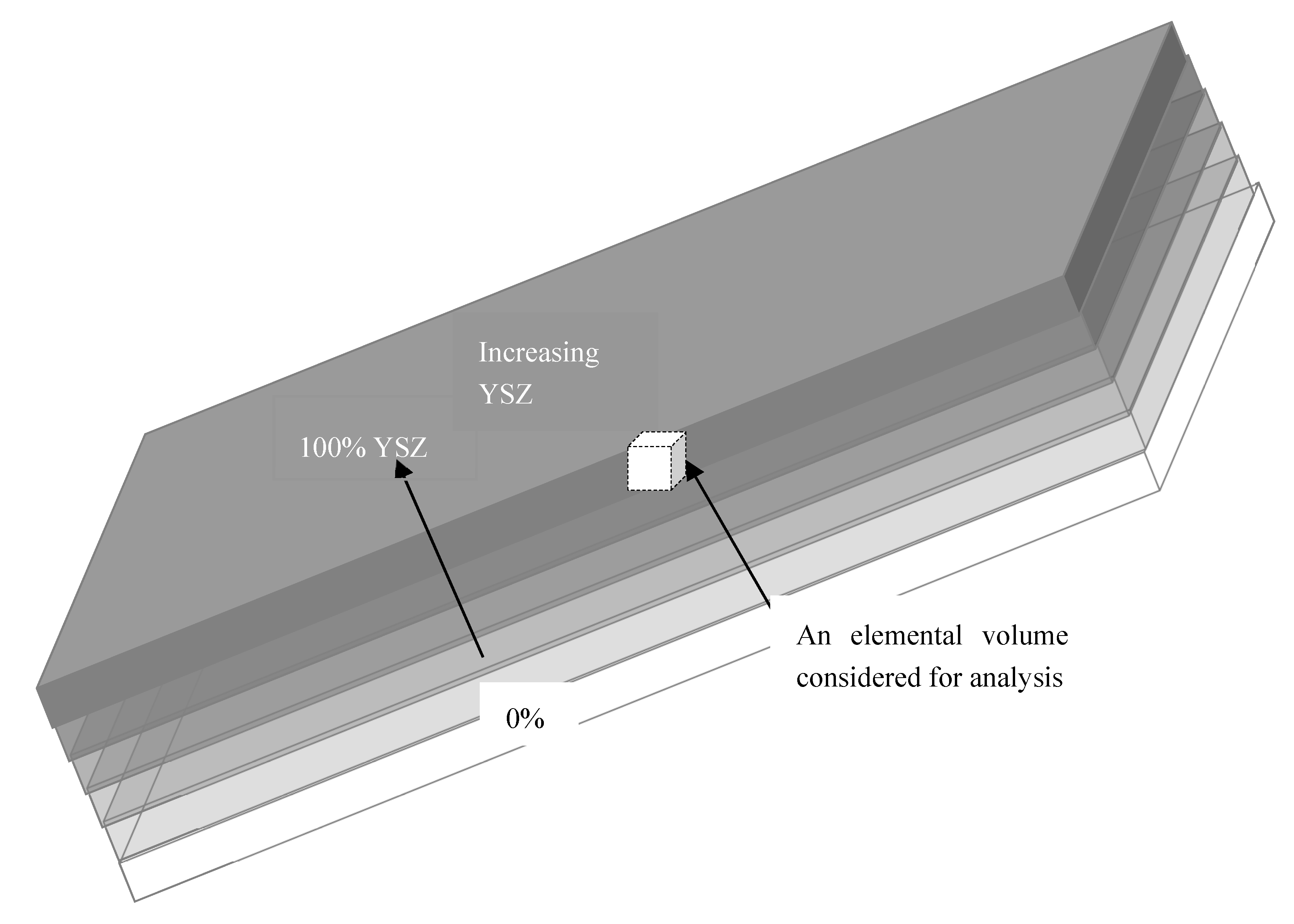

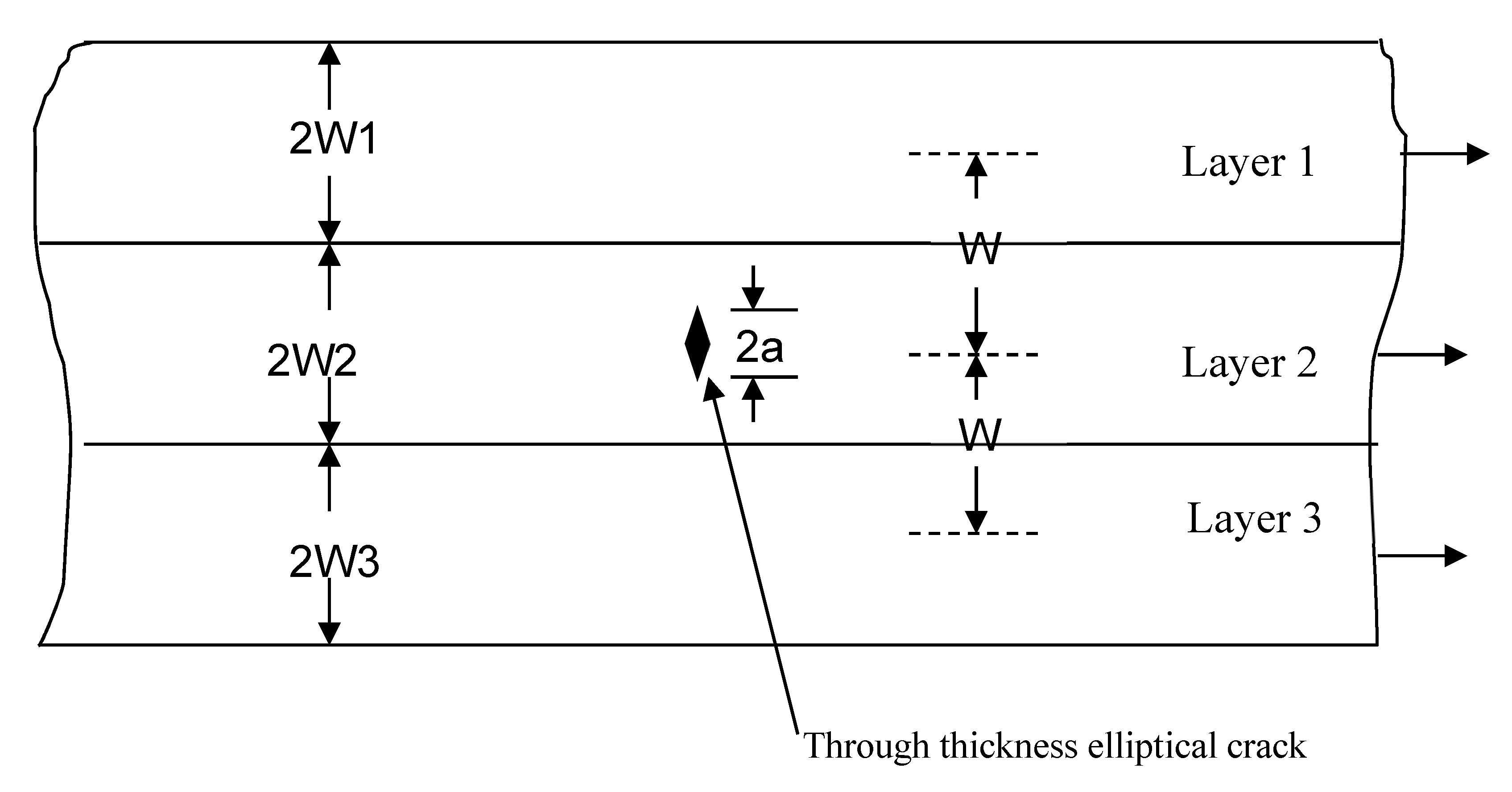

5.1. Model of Layered TBC

5.2. Assumptions

- Firstly, the different layers in TBC FGM are subjected to isostrain condition under external applied force prior to the onset of crack initiation.

- Secondly, the energy balance criterion is maintained during the stage of loading and straining. The work done by the external force is used up in the process of crack initiation and this may be estimated from the local stress distribution in the vicinity of crack tip.

- Thirdly, linear elastic fracture mechanic (LEFM) situation is maintained during mode I loading around the crack tip so that stress intensity factor criterion is the appropriate solution to deal with cracking of FGM.

- Furthermore, only externally applied mechanical forces are present and no stress effect due to temperature fluctuations is considered. TBC FGM is considered as an asymmetrical composite system where only layers of identical dimensions but different characteristics are considered for fracture mechanical analysis.

- In all the analysis presented here, the preexisting crack length as assumed in the model is considered to be a deep crack with crack length to width ratio as 0.5.

- No thermal and TGO stress effect is considered in the analysis, and the multilayer TBC system is assumed to operate at room temperature only. Room temperature material properties are considered in the simulations. Among other material properties affecting the thermal protection performance and lifetime, thermal conductivity (TC) play a significant role. This is truer for graded TBC systems with different compositions and materials. However, for a simple approach considered in the modeling, TC is not considered, as thermal effects due to fluctuations is beyond the scope of the present research. Also, the influence of TC in altering the RT modulus is not taken into consideration, as sufficient data is not available.

5.3. Fracture Mechanics Model

6. Functionally Graded TBC

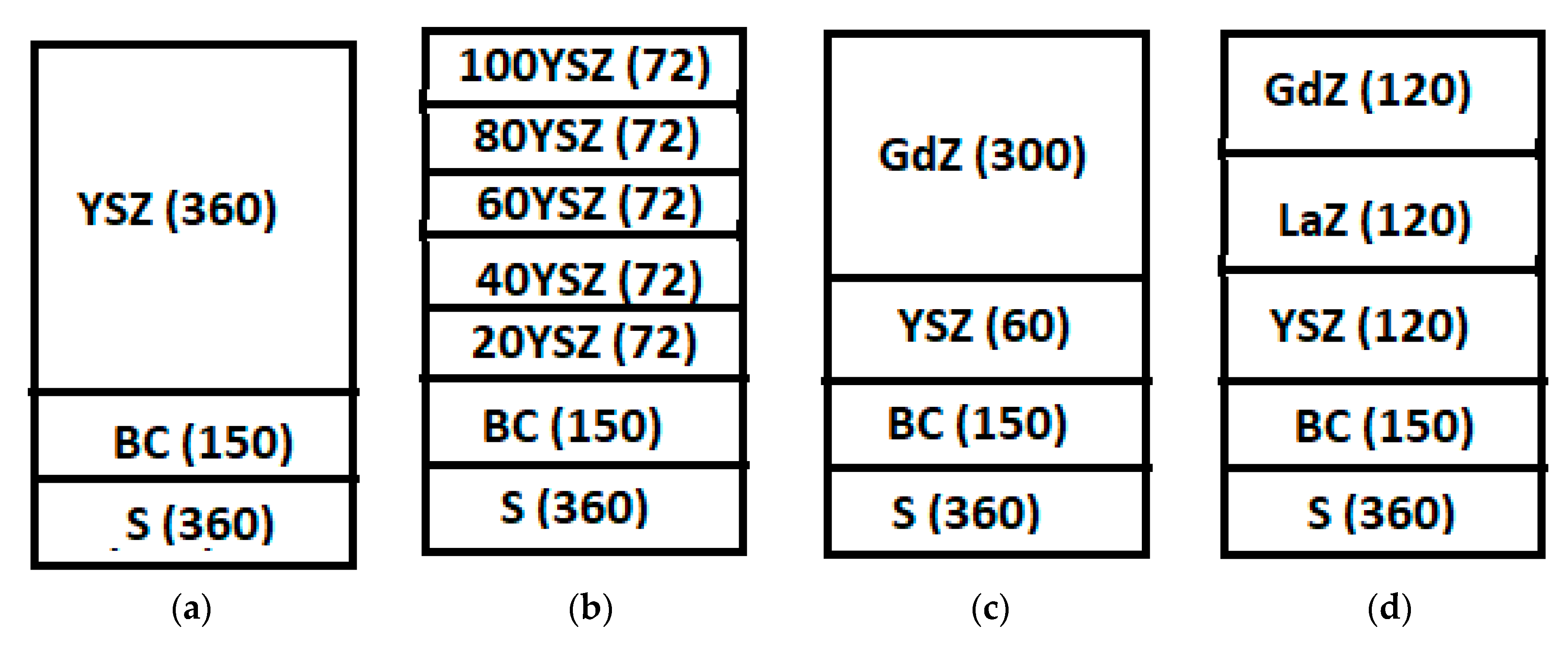

6.1. TBC Architecture

Interfaces

6.2. Top Coat (TC)

6.2.1. YSZ TC

6.2.2. Gadolinium Zirconate TC

6.2.3. Lanthanum Zirconate TC

7. Simulations, Results and Discussion

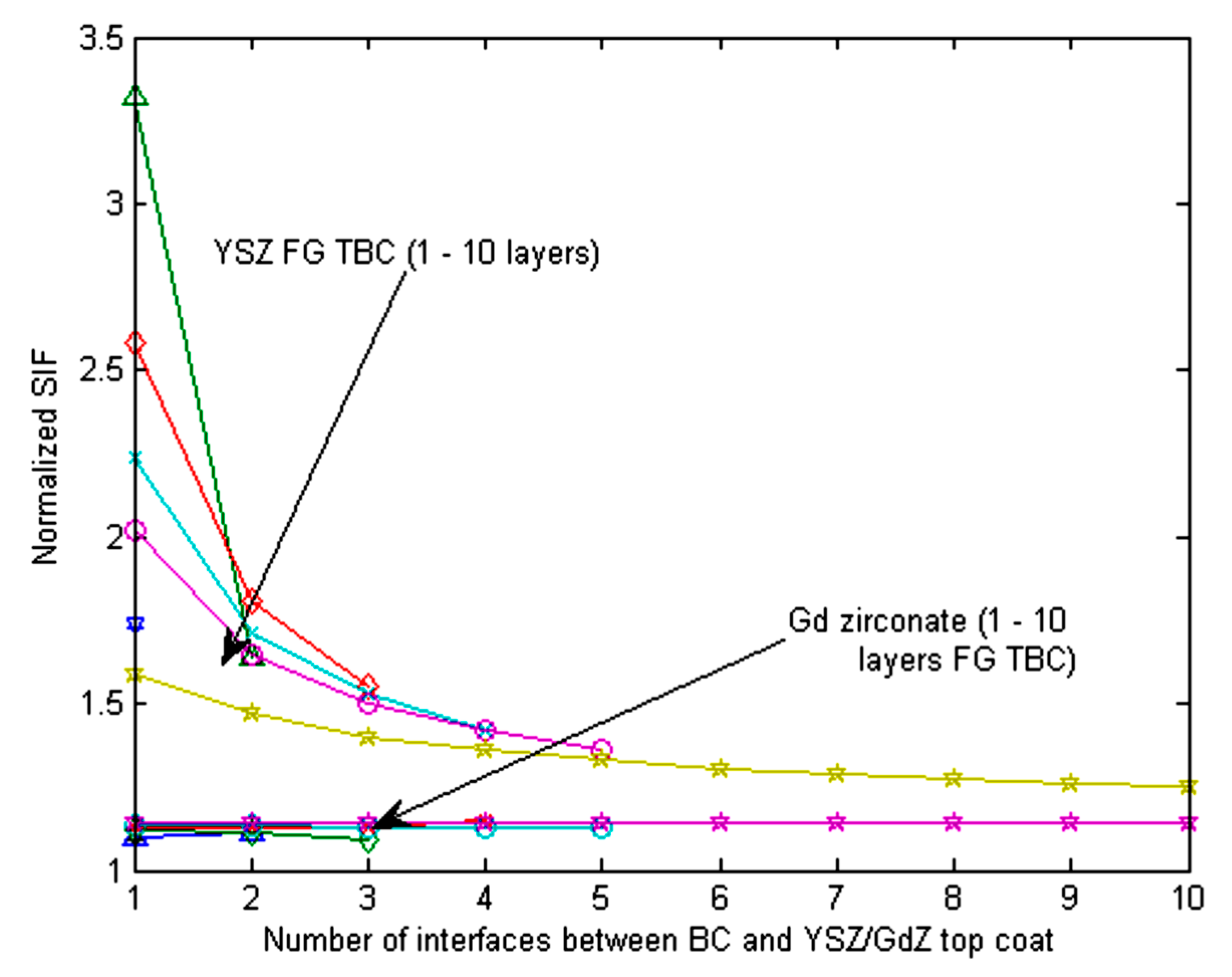

7.1. YSZ System

- Number of FG layers,

- Compositions of layers,

- Thickness of layers.

7.1.1. Number of Layers

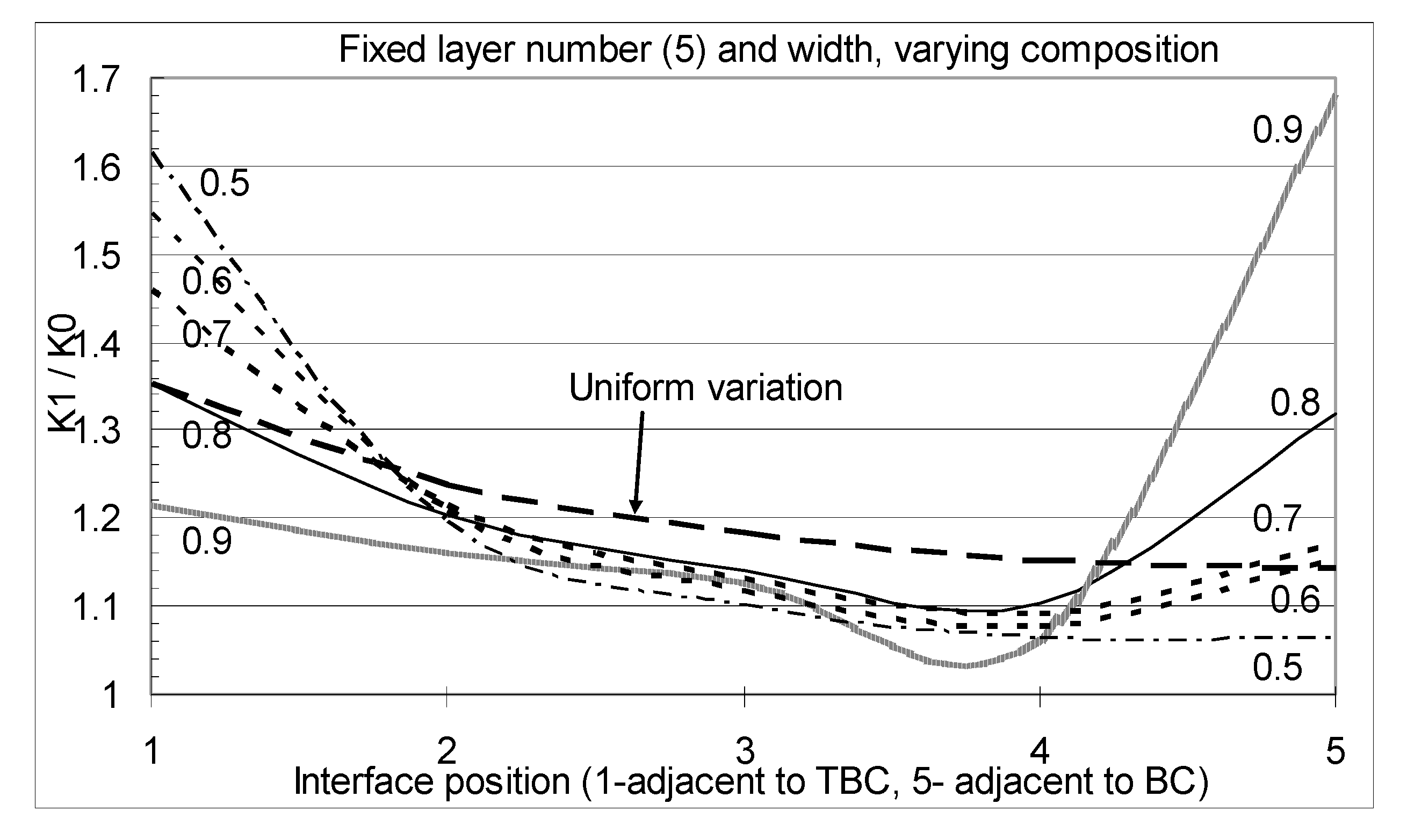

7.1.2. Compositional Effects

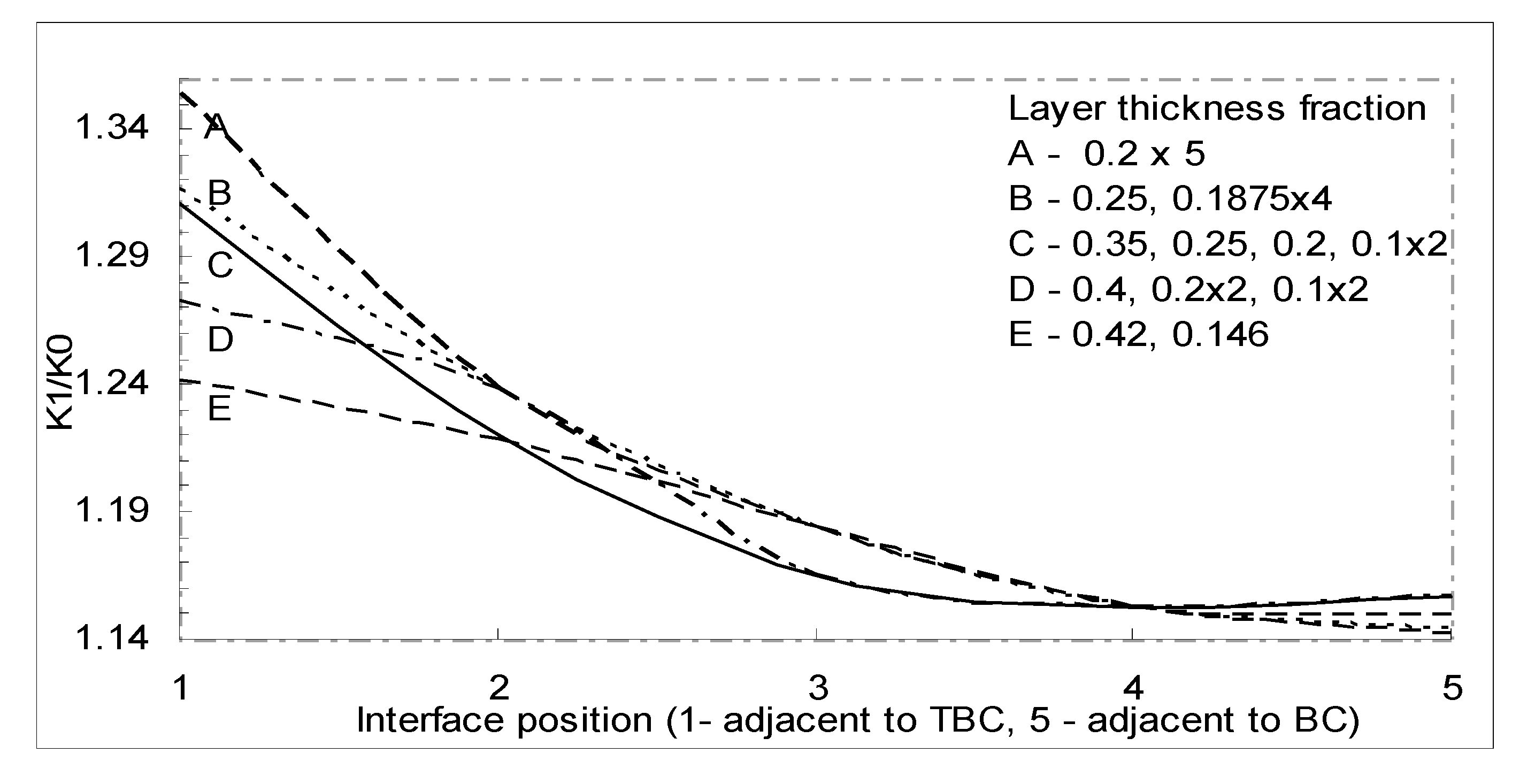

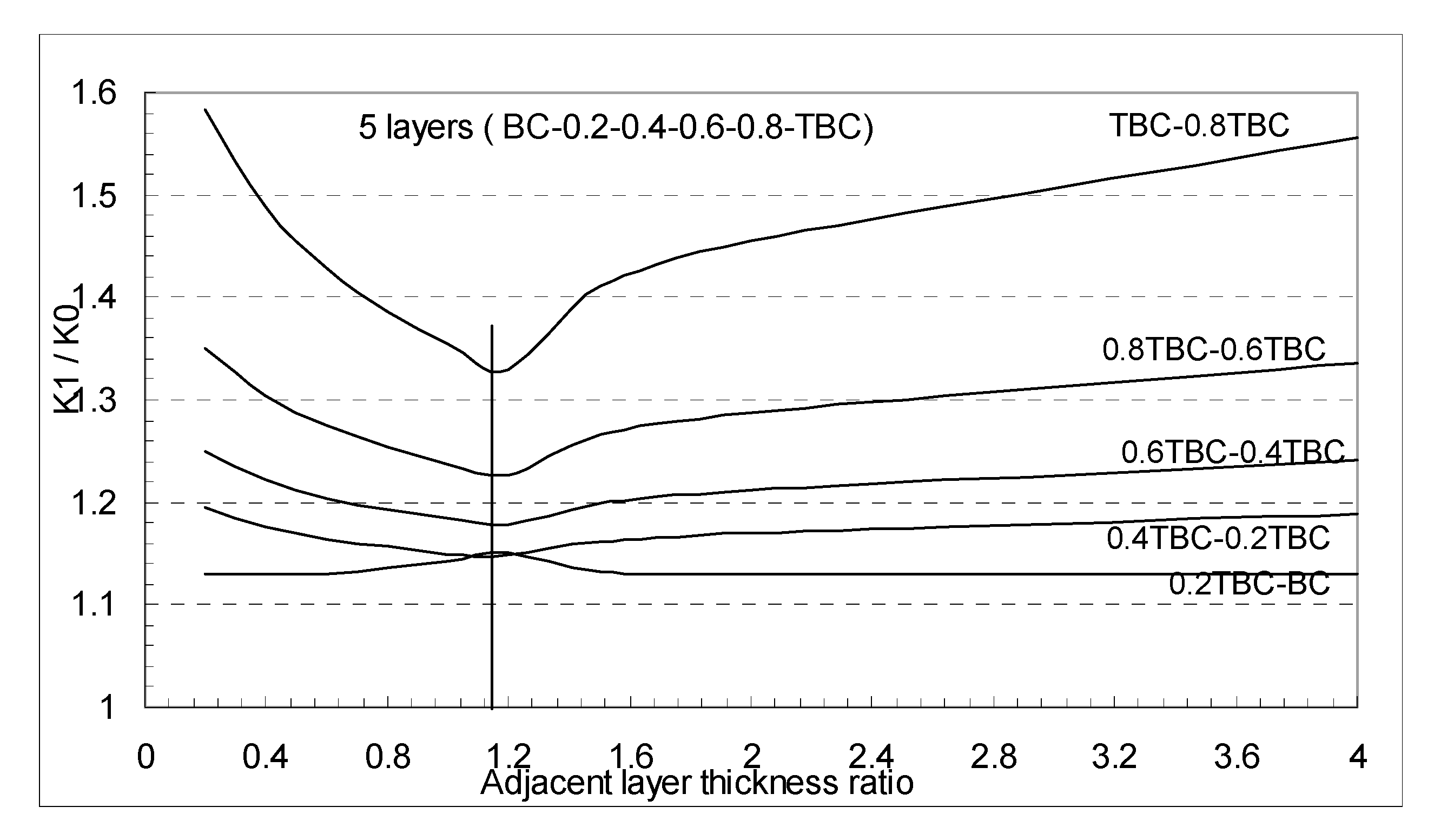

7.1.3. Layer Thickness

7.2. Advanced TBC

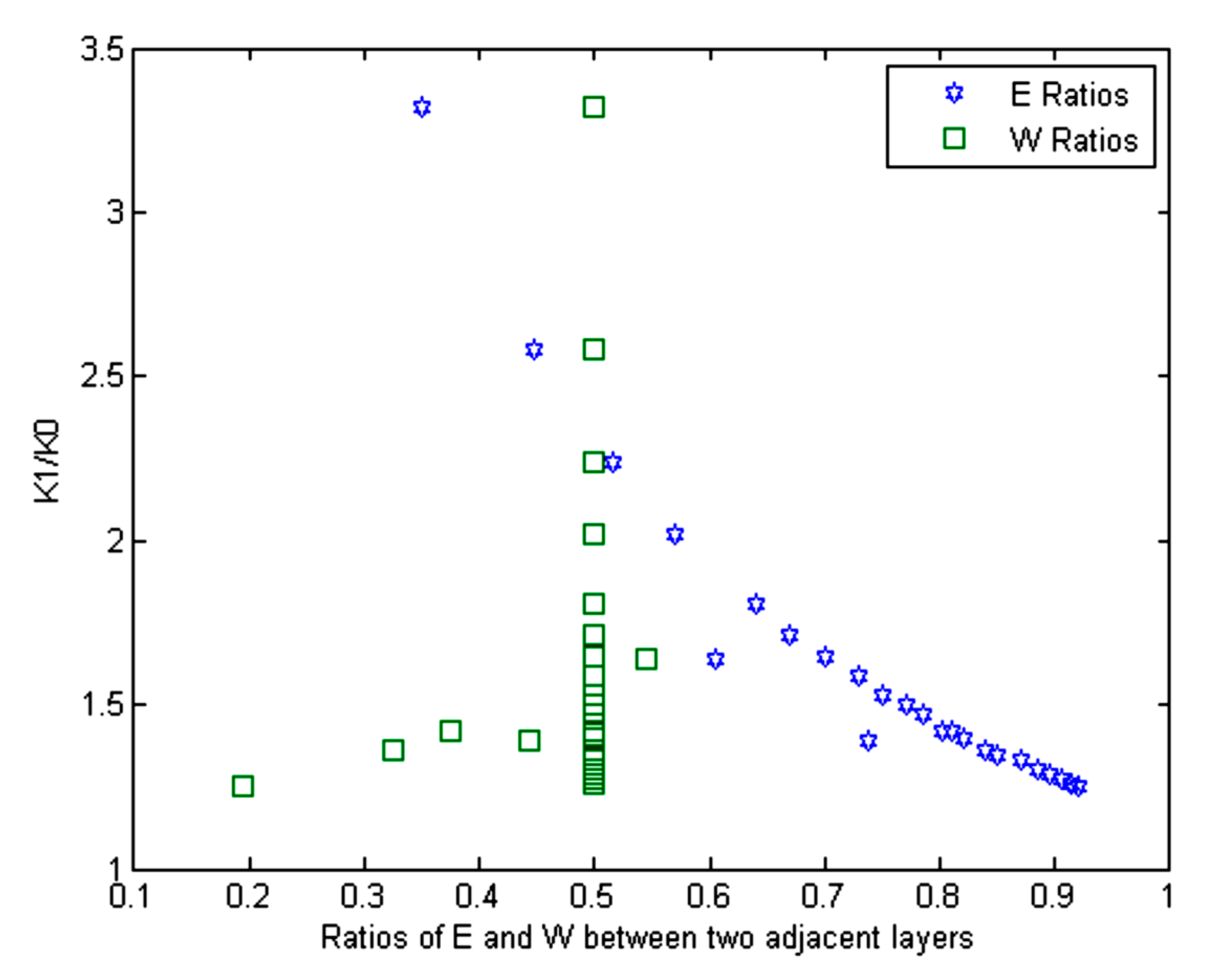

7.2.1. FG GdZ System

7.2.2. GdZ-YSZ DL System

7.2.3. Hybrid System

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Karlsson, A.M.; Xu, T.; Evans, A.G. The Effect of Thermal Barrier Coating on the Displacement Instability in Thermal Barrier System. Acta Mater. 2002, 50, 1211–1218. [Google Scholar] [CrossRef]

- Clarke, D.R.; Levi, C.G. Materials Design for the Next Generation Thermal Barrier Coatings. Rev. Mater. Res. 2003, 33, 383–417. [Google Scholar] [CrossRef]

- He, M.Y.; Hutchinson, J.W.; Evans, A.G. Simulation of Stresses and Delamination in a Plasma-Sprayed Thermal Barrier System upon Thermal Cycling. Mater. Sci. Eng. 2003, A345, 172–178. [Google Scholar] [CrossRef]

- Shillington, E.A.G.; Clarke, D.R. Spalling Failure of a Thermal Barrier Coating Associated with Aluminium in the Bondcoat. Acta Mater. 1999, 47, 1297–1305. [Google Scholar] [CrossRef]

- Stiger, M.J.; Yanar, N.M.; Topping, M.G.; Pettit, F.S.; Meier, G.H. Thermal Barrier Coatings for the 21st Century. Zeitschrift für Metallkunde 1999, 90, 1069–1078. [Google Scholar]

- Casu, A.; Marqués, J.L.; Vassen, R.; Stöver, D. Modeling of Crack Growth Near the Metallic-Ceramic Interface during Thermal Cycling of Air Plasma Sprayed Thermal Barrier Coatings. Key Eng. Mater. 2007, 333, 263–268. [Google Scholar] [CrossRef]

- Chen, W.R.; Wu, X.; Marple, B.R.; Patnaik, P.C. The Growth and Influence of Thermally Grown Oxide in a Thermal Barrier Coating. Surf. Coat. Technol. 2006, 201, 1074–1079. [Google Scholar] [CrossRef]

- Sudarshan, R.; Kokini, K. Estimating the Fracture Resistance of Functionally Graded Thermal Barrier Coatings from Thermal Shock Tests. Surf. Coat. Technol. 2003, 173, 201–212. [Google Scholar]

- Rangaraj, S.V. Time-Dependent Behavior and Thermal Fracture in Functionally Graded Thermal Barrier Coatings. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2003. [Google Scholar]

- Sahin, A. An Interface Crack between a Graded Coating and a Homogeneous Substrate. Turkish J. Eng. Environ. Sci. 2004, 28, 135–148. [Google Scholar]

- Gasik, M.M.; Kawasaki, A.; Kang, Y.S. Optimization of FGM TBC and Their Thermal Cycling Stability. In Materials Science Forum Functionally Graded Materials VIII, 492–493; van der Biest, O., Gasik, M., Vleugels, J., Eds.; Trans Tech Publications Ltd.: Kapellweg, Switzerland, 2005; pp. 9–14. [Google Scholar]

- Kim, J.H.; Kim, M.C.; Park, C.G. Evaluation of Functionally Graded Thermal Barrier Coatings Fabricated by Detonation Gun Spray Technique. Surf. Coat. Technol. 2003, 168, 275–280. [Google Scholar] [CrossRef]

- Ho, S.Y.; Kotousov, A.; Nguyen, P.; Harding, S.; Codrington, J.; Tsukamoto, H. FGM (Functionally Graded Material) Thermal Barrier Coatings for Hypersonic Structures—Design and Thermal Structural Analysis. Available online: https://www.researchgate.net/publication/235054135_FGM_Functionally_Graded_Material_Thermal_Barrier_Coatings_for_Hypersonic_Structures_-_Design_and_Thermal_Structural_Analysis (accessed on 12 May 2020).

- Lee, W.Y.; Stinton, D.P.; Berndt, C.C.; Erdogan, F.; Lee, Y.D.; Mutasim, Z. Concept of Functionally Graded Materials for Advanced Thermal Barrier Coating Applications. J. Am. Ceram. Soc. 2005, 79, 3003–3012. [Google Scholar] [CrossRef]

- Sniezewski, J.; Vidal, V.; Lours, P.; Le Maoult, Y. Thermal Barrier Coatings Adherence and Spallation: Interfacial Indentation Resistance and Cyclic Oxidation Behaviour under Thermal Gradient. Surf. Coat. Technol. 2009, 204, 807–811. [Google Scholar] [CrossRef]

- Zhang, X.C.; Xu, B.S.; Wang, H.D.; Jiang, Y.; Wu, Y.X. Application of Functionally Graded Interlayer on Reducing the Residual Stress Discontinuities at Interfaces within a Plasma-Sprayed Thermal Barrier Coating. Surf. Coat. Technol. 2007, 201, 5716–5719. [Google Scholar] [CrossRef]

- Vassen, R.; Kassner, H.; Stuke, A.; Mack, D.E.; Ophelia, M.; Jarligo, D.; Stöver, D. Functionally Graded Thermal Barrier Coatings with Improved Reflectivity and High-Temperature Capability. In Materials Science Forum, Multiscale, Multifunctional and Functionally Graded Materials; Kawasaki, A., Kumakawa, A., Niino, M., Eds.; Trans Tech Publications Ltd.: Kapellweg, Switzerland, 2009; Volume 631–632, pp. 73–78. [Google Scholar]

- Available online: http://techtransfer.universityofcalifornia.edu/NCD/11370.html (accessed on 12 May 2020).

- Image Tool Software, Open-Source. Available online: https://sourceforge.net/projects/imagetoolsnet/ (accessed on 12 May 2020).

- Kumar, A. Physics Based Modeling of Thermally Grown Oxide Layer and Failure Mechanisms in Thermal Barrier Coating System; Technical Report No.TR-TC-44; Tecsis Corporation: Ottawa, ON, USA, 2008. [Google Scholar]

- Carlsson, K. A Study of Failure Development in Thick Thermal Barrier Coating. Master’s Thesis, Linkopings University, Linköping, Sweden, 2007. [Google Scholar]

- Evans, A.G.; Munn, D.R.; Hutchinson, J.W.; Meier, G.H.; Pettit, F.S. Mechanisms Controlling the Durability of Thermal Barrier Coatings. Prog. Mater. Sci. 2001, 46, 505–553. [Google Scholar] [CrossRef]

- Chen, W.R.; Wu, X.; Marple, B.R.; Patnaik, P.C. Oxidation and Crack Nucleation/Growth in an Air Plasma Sprayed Thermal Barrier Coating with NiCrAlY Bond Coat. Surf. Coat. Technol. 2005, 197, 109–115. [Google Scholar] [CrossRef]

- Chan, K.S.; Cheruvu, N.S. Degradation Mechanism. Characterization and Remaining Life Prediction for NiCoCrAlY Coatings. In ASME Turbo Expo 2004: Power for Land, Sea, and Air; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2004. [Google Scholar]

- Freborg, A.M.; Ferguson, B.L.; Brindley, W.J.; Petrus, G.J. Modeling Oxidation Induced Stresses in Thermal Barrier Coatings. Mater. Sci. Eng. A 1998, 245, 182–190. [Google Scholar] [CrossRef]

- Evans, H.E.; Taylor, M.P. Delamination Processes in Thermal Barrier Coating Systems. J. Corros. Sci. Eng. 2003, 6, H011. [Google Scholar]

- Adesanya, O.A.; Bouhanek, K.; Stott, F.H.; Skeldon, P.; Lees, D.G.; Wood, G.C. Cyclic Oxidation of Two Bond Coats in Thermal Barrier Coating Systems on CMSX-4 Substrates. Mater. Sci. Forum 2001, 369–372, 639–646. [Google Scholar] [CrossRef]

- Kumar, A.N.; Nayak, A.; Patnaik, A.R.; Wu, X.; Patnaik, P.C. Instability Analysis for Thermal Barrier Coating by Fracture Mechanical Modeling. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007. [Google Scholar]

- Tzimas, E.; Mullejans, H.; Peteves SD Bressers, J.; Stamm, W. Failure of TBC Systems Under Cyclic Thermomechanical Loading. Acta Mater. 2000, 48, 4699–4707. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Bakan, E.; Mack, D.E.; Mauer, G.; Vassen, R. Gadolinium Zirconate/YSZ Thermal Barrier Coatings: Plasma Spraying Microstructure, and Thermal Cycling Behavior. J. Am. Ceram. Soc. 2014, 97, 4045–4051. [Google Scholar] [CrossRef]

- Jiang, C.; Jordan, E.H.; Harris, A.B.; Gell, M.; Roth, J. Double-Layer Gadolinium Zirconate/Yttria-Stabilized Zirconia Thermal Barrier Coatings Deposited by the Solution Precursor Plasma Spray Process. J. Therm. Spray Technol. 2015, 6, 895–906. [Google Scholar] [CrossRef]

- Mahade, S. Functional Performance of Gadolinium Zirconate/Yttria Stabilized Zirconia Multi-Layered Thermal Barrier Coatings Licentiate. Ph.D. Thesis, University West, Trollhättan, Sweden, 2016. [Google Scholar]

- Gok, M.G.; Goller, G. State of the Art of Gadolinium Zirconate Based Thermal Barrier Coatings: Design, Processing and Characterization. In Coatings Technology; IntechOpen: London, UK, 2019. [Google Scholar]

- Naveen, A.; Krishnamurthy, L.; Shridhar, T.N. A review on thermal barrier coatings and its deposition techniques. Int. J. Eng. Sci. Manag. Res. 2016, 3, 1–9. [Google Scholar]

- Cao, X. Development of New Thermal Barrier Coating Materials for Gas Turbines. Berichte des Forschungszentrums Julich 2004, 4127, 1–118. [Google Scholar]

- Zhang, J.; Xingye, G.; Yeon, J. Lanthanum zirconate based thermal barrier coatings: A review. Surf. Coat. Technol. 2017, 323, 18–29. [Google Scholar] [CrossRef]

| Sample Description | Number of TGO Measurements | TGO Thickness (μm) | Number of Crack Length Measurements | Crack Size (μm) | ||

|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | |||

| Air-10 cycles | 385 | 1.4 | 0.6 | 18 | 2.4 | 0.8 |

| Air-100 cycles | 496 | 2.8 | 1.2 | 29 | 4.5 | 1.8 |

| Air-430 cycles | 690 | 5.2 | 2.1 | 79 | 6.9 | 4.1 |

| Air-1612 cycles | 345 | 11.1 | 5.3 | 24 | 16.2 | 13.7 |

| low O2-10 cycles | 488 | 1.8 | 0.7 | 22 | 2.9 | 1.6 |

| low O2-100 cycles | 463 | 2.8 | 1.1 | 59 | 3.6 | 2.2 |

| low O2-430 cycles | 469 | 4.8 | 1.6 | 34 | 3.8 | 2.4 |

| low O2-1428 cycles | 240 | 11.9 | 6.6 | 13 | 26.8 | 13.2 |

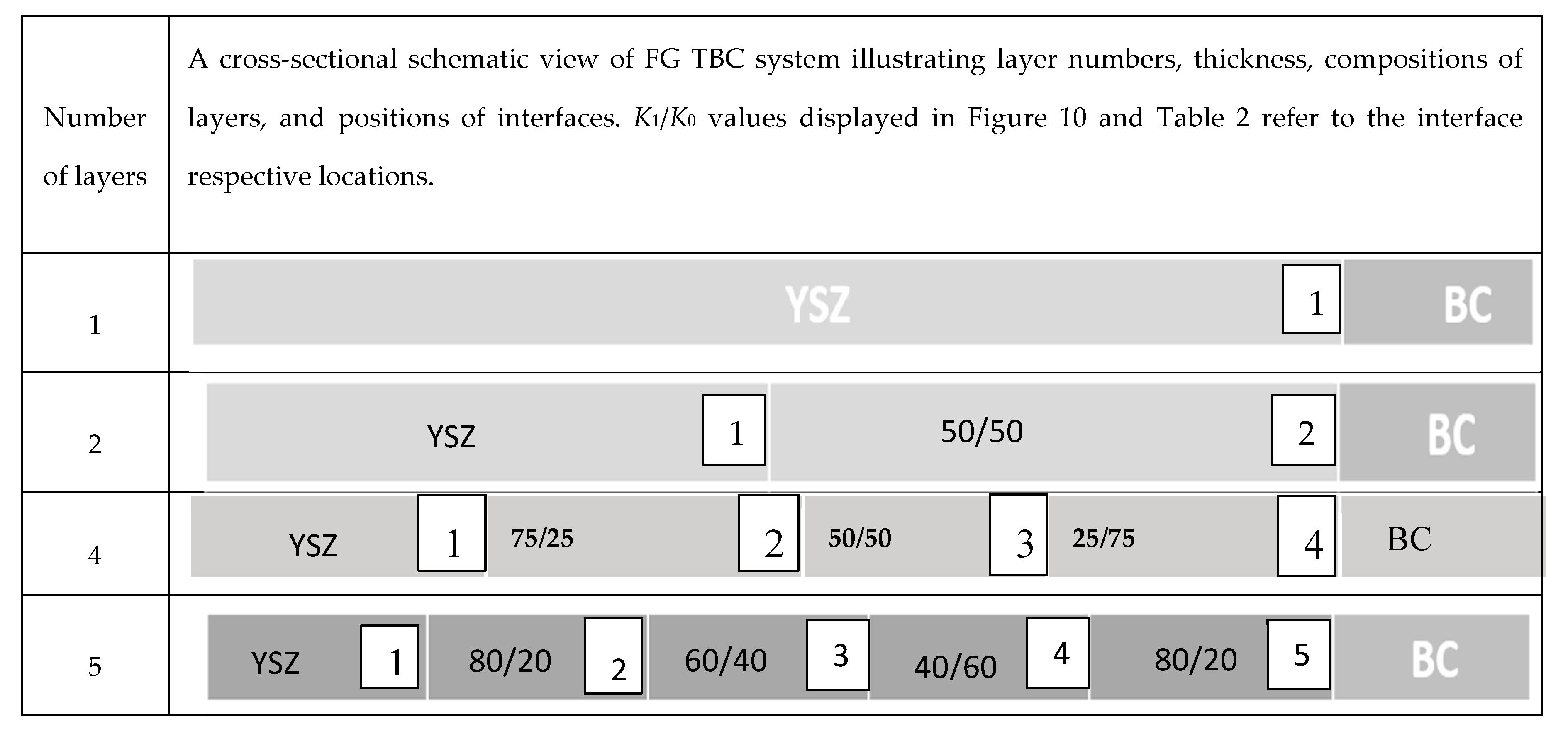

| Number of Layers and Interfaces | Layer Thickness in μ | Composition of Each Composite FG Layer over the BC Layer | K1/K0 at BC-TC Interface |

|---|---|---|---|

| 1 | 360 | 100% YSZ | 1.74 |

| 2 | 180 | 0.5YSZ-0.5BC, 100% YSZ | 1.62 |

| 3 | 120 | 0.67YSZ-0.33BC and 0.33YSZ-0.67BC, 100% YSZ | 1.49 |

| 4 | 90 | 0.75YSZ-0.25BC, 0.50YSZ-0.50BC and 0.25YSZ-0.75BC, 100% YSZ | 1.41 |

| 5 | 72 | 0.8YSZ-0.2BC, 0.6YSZ-0.4BC, 0.4YSZ-0.6BC and 0.2YSZ-0.8BC, 100% YSZ | 1.35 |

| 10 | 36 | 0.9YSZ-0.1BC, 0.8YSZ-0.2BC, 0.7YSZ-0.3BC, 0.6YSZ-0.4BC; 0.5YSZ-0.5BC, 0.4YSZ-0.6BC, 0.3YSZ-0.7BC, 0.2YSZ-0.8BC and 0.1YSZ-0.9BC, 100% YSZ | 1.22 |

| FG System (DL) | Width | K1/K0 (1) | K1/K0 (2) | K1/K0 (3) |

| GdZ–YSZ-BC | 300-60-150 | 0.58 | 1.32 | – |

| GdZ–YSZ-BC | 200-160-150 | 0.284 | 3.53 | – |

| GdZ-YSZ-BC | 180-180-150 | 0.22 | 2.82 | – |

| YSZ-GdZ-BC | 180-180-150 | 6.07 | 1.07 | – |

| FG System (Hybrid) | Width | K1/K0 (1) | K1/K0 (2) | K1/K0 (3) |

| GdZ-LaZ-YSZ-BC | 120-120-120-150 | 0.96 | 0.264 | 2.71 |

| YSZ-GdZ-YSZ-BC | 120-120-120-150 | 6.06 | 0.22 | 2.70 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, A.; Patnaik, P.C.; Chen, K. Damage Assessment and Fracture Resistance of Functionally Graded Advanced Thermal Barrier Coating Systems: Experimental and Analytical Modeling Approach. Coatings 2020, 10, 474. https://doi.org/10.3390/coatings10050474

Kumar A, Patnaik PC, Chen K. Damage Assessment and Fracture Resistance of Functionally Graded Advanced Thermal Barrier Coating Systems: Experimental and Analytical Modeling Approach. Coatings. 2020; 10(5):474. https://doi.org/10.3390/coatings10050474

Chicago/Turabian StyleKumar, Amarnath, Prakash C. Patnaik, and Kuiying Chen. 2020. "Damage Assessment and Fracture Resistance of Functionally Graded Advanced Thermal Barrier Coating Systems: Experimental and Analytical Modeling Approach" Coatings 10, no. 5: 474. https://doi.org/10.3390/coatings10050474

APA StyleKumar, A., Patnaik, P. C., & Chen, K. (2020). Damage Assessment and Fracture Resistance of Functionally Graded Advanced Thermal Barrier Coating Systems: Experimental and Analytical Modeling Approach. Coatings, 10(5), 474. https://doi.org/10.3390/coatings10050474