Biocompatibility Evaluation and Enhancement of Elastomeric Coatings Made Using Table-Top Optical 3D Printer

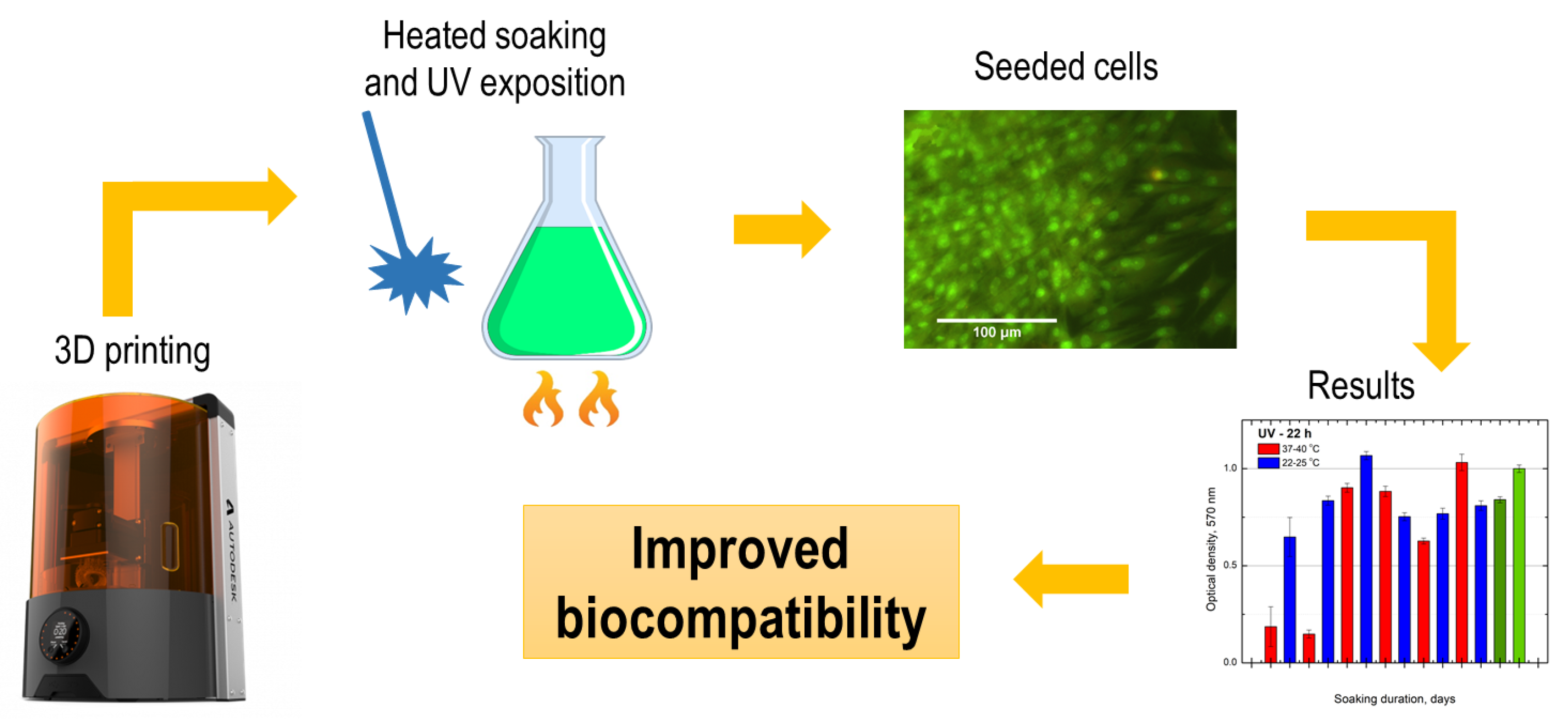

Abstract

1. Introduction

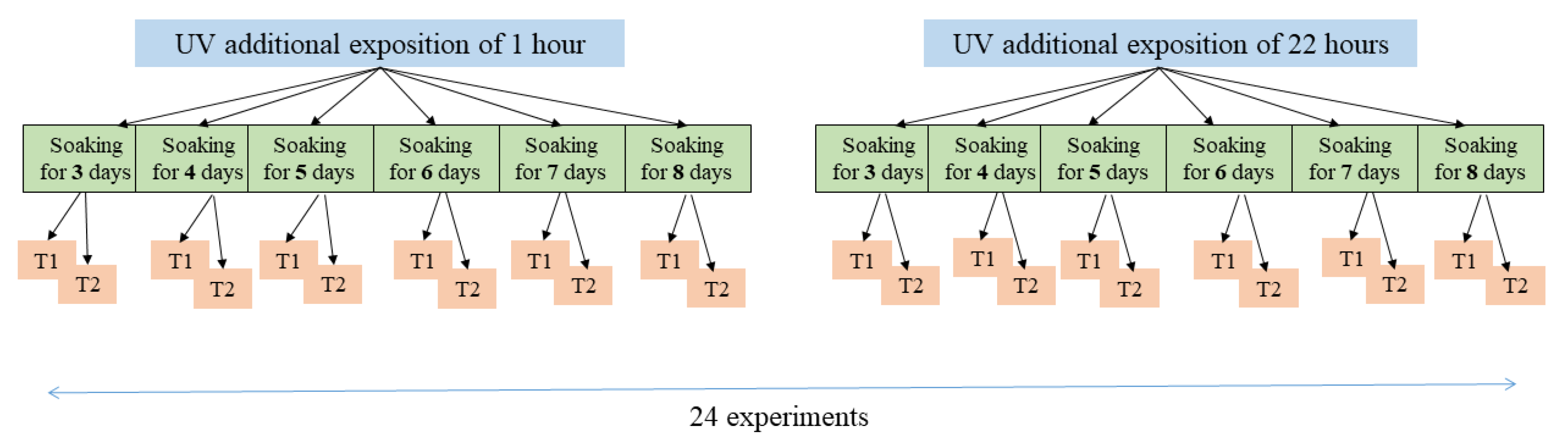

2. Materials and Methods

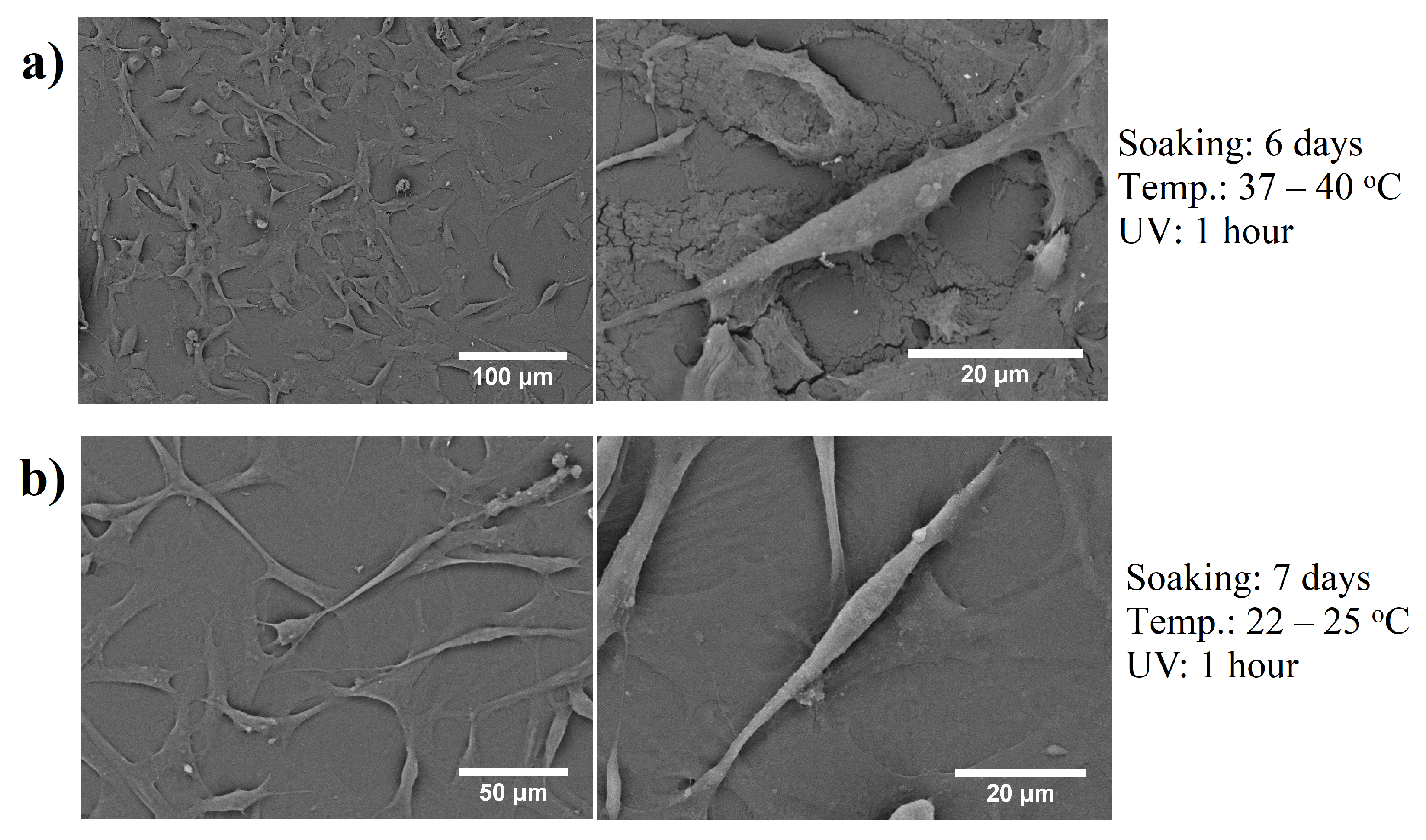

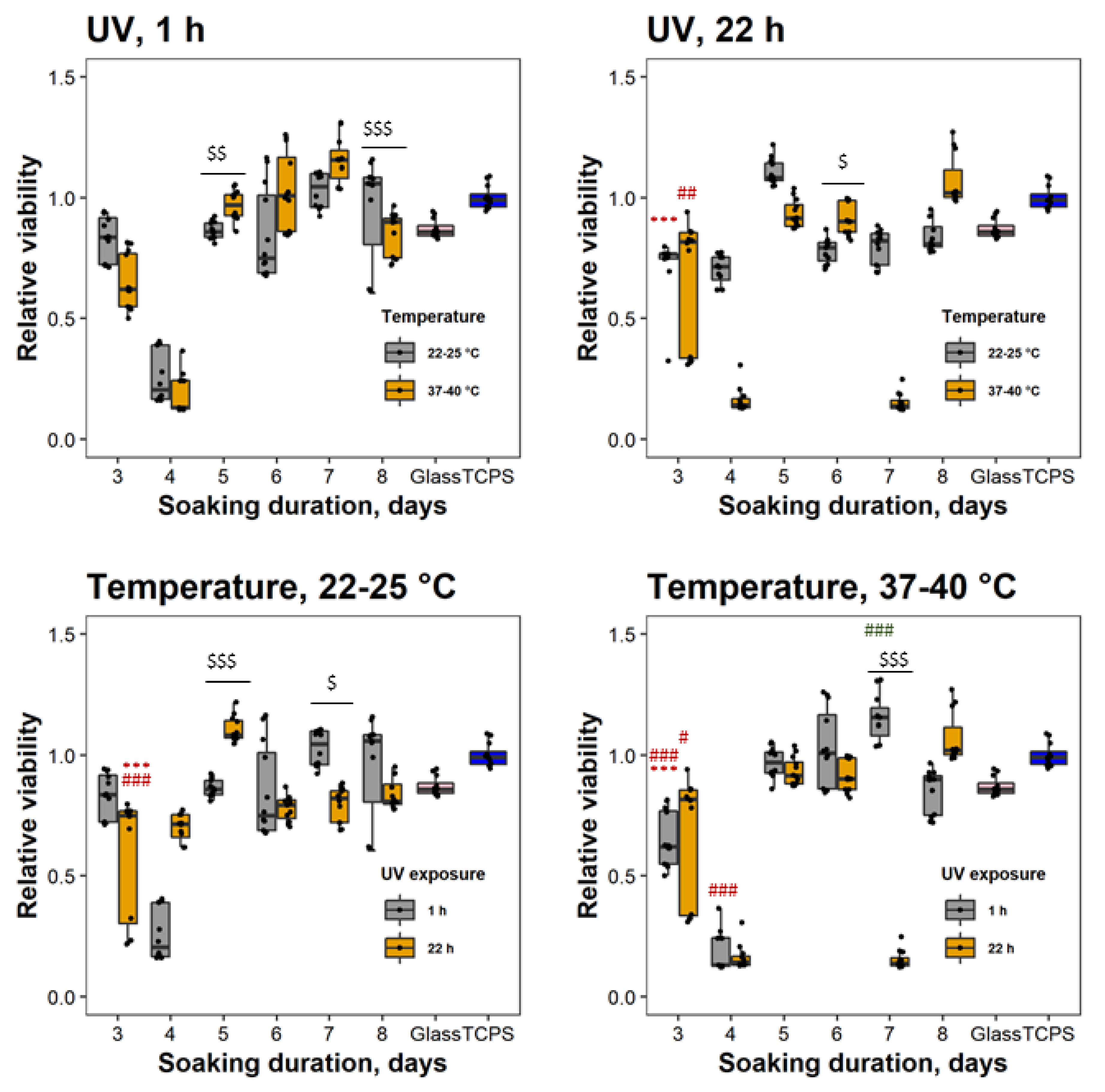

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jonušauskas, L.; Juodkazis, S.; Malinauskas, M. Optical 3D printing: Bridging the gaps in the mesoscale. J. Opt. 2018, 20, 053001. [Google Scholar] [CrossRef]

- Schubert, C.; Langeveld, M.C.; Donoso, L.A. Innovations in 3D printing: A 3D overview from optics to organs. Br. J. Ophthalmol. 2014, 98, 159–161. [Google Scholar] [CrossRef] [PubMed]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Auricchio, F.; Marconi, S. 3D printing: Clinical applications in orthopaedics and traumatology. EFORT Open Rev. 2017, 1, 121–127. [Google Scholar] [CrossRef]

- Naftulin, J.S.; Kimchi, E.; Cash, S.S. Stramlined, Inexpensive 3D Printing of the Brain and Skull. PLoS ONE 2015, 10, e0136198. [Google Scholar] [CrossRef]

- Dawood, A.; Marti, B.M.; Saurent-Jackson, V.; Darwood, A. 3D printing in dentistry. BDJ 2015, 219, 521–529. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef]

- Mačiulaitis, J.; Deveikytė, M.; Rekštytė, S.; Bratchikov, M.; Darinskas, A.; Šimbelytė, A.; Daunoras, G.; Laurinavičienė, A.; Laurinavičius, A.; Gudas, R.; et al. Preclinical study of SZ2080 material 3D microstructured scaffolds for cartilage tissue engineering made by femtosecond direct laser writing lithography. Biofabrication 2015, 7, 015015. [Google Scholar] [CrossRef]

- Ovsianikov, A.; Gruene, M.; Pflaum, M.; Koch, L.; Maiorana, F.; Wilhelmi, M.; Haverich, A.; Chichkov, B. Laser printing of cells into 3D scaffolds. Biofabrication 2010, 2, 014104. [Google Scholar] [CrossRef]

- Richter, B.; Hahn, V.; Bertels, S.; Claus, T.K.; Wegener, M.; Delaittre, G.; Barner-Kowollik, C.; Bastmeyer, M. Guiding Cell Attachment in 3D Microscaffolds Selectively Functionalized with Two Distinct Adhesion Proteins. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef]

- Cao, Y.; Vacanti, J.P.; Paige, K.T.; Upton, J.; Vacanti, C.A. Transplantation of chondrocytes utilizing a polymer-cell construct to produce tissue-engineered cartilage in the shape of a human ear. Plast. Reconstr. Surg. 1997, 100, 297–302. [Google Scholar] [CrossRef] [PubMed]

- Tappa, K.; Jammalamadaka, U. Novel Biomaterials Used in Medical 3D Printing Techniques. J. Funct. Biomater. 2018, 9, 17. [Google Scholar] [CrossRef] [PubMed]

- Jammalamadaka, U.; Tappa, K. Recent Advances in Biomaterials for 3D Printing and Tissue Engineering. J. Funct. Biomater. 2018, 9, 22. [Google Scholar] [CrossRef] [PubMed]

- Pashneh-Tala, S.; Owen, R.; Bahmaee, H.; Rekštytė, S.; Malinauskas, M.; Claeyssens, F. Synthesis, Characterization and 3D Micro-Structuring via 2-Photon Polymerization of Poly(glycerol sebacate)-Methacrylate–An Elastomeric Degradable Polymer. Front. Phys. 2018, 6, 41. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, B.; Li, H.; Fu, F.; Shi, X.; Dong, X.; Dai, M. A novel 3D-printed head phantom with 189 anatomically realistic geometry and continuously varying skull resistivity distribution for electrical impedance tomography. Sci. Rep. 2017, 7, 4608. [Google Scholar] [CrossRef]

- Carve, M.; Wlodkowoc, D. 3D-printed chips: Compatibility of additive manufacturing photopolymeric substrata with biological apllications. Micromachines 2018, 9, 91. [Google Scholar] [CrossRef]

- Lin, N.J.; Bailey, L.O.; Becker, M.L.; Washburn, N.R.; Handerson, L.A. Macrophage response to methacrylate conversion using a gradient approach. Acta Biomater. 2007, 3, 163–173. [Google Scholar] [CrossRef]

- Schmal, G.; Arenholt-Bindslev, D. Biocompatibility of Denatal Materials; Spinger: Berlin/Heidelberg, Germany, 2009; Volume 1, pp. 1–379. [Google Scholar]

- Ortega, I.; Deshpande, P.; Gill, A.A.; MacNeil, S.; Claeyssens, F. Development of a microfabricated artificial limbus with micropockets for cell delivery to the cornea. Biofabrication 2013, 5, 025008. [Google Scholar] [CrossRef]

- Popov, V.K.; Evseev, A.V. Laser stereolitography and supercritical fluid processing for custum-designed implant fabrication. J. Mater. Sci. Mater. Med. 2004, 15, 123–128. [Google Scholar] [CrossRef]

- Macdonald, N.P.; Zhu, F.; Hal, C.J.; Reboud, J.; Crosier, P.S.; Patton, E.E.; Wlodkowic, D.; Cooper, J.M. Lab on a chip assessment of biocompatibility of 3D printed photopolymers using zebrafish embryo toxicity. Lab Chip 2016, 16, 291–297. [Google Scholar] [CrossRef]

- van den Driesche, S.; Lucklum, F.; Bunge, F.; Vellekoop, M. 3D printing solution for microfluidic chip-to-world connections. Micromachines 2018, 9, 71. [Google Scholar] [CrossRef] [PubMed]

- Formlabs. Using Flexible Resin. Available online: www.formlabs.com (accessed on 3 January 2020).

- Zukauskas, A.; Matulaitiene, I.; Paipulas, D.; Niaura, G.; Malinauskas, M.; Gadonas, R. Tuning the refractive index in 3D direct laser writing lithography: Towards GRIN microoptics. Laser Photon. Rev. 2015, 9, 706–712. [Google Scholar] [CrossRef]

- Mercille, S.; Massie, B. Induction of apoptosis in oxygen-deprived cultures of hybridoma cells. Cytotechnology 1994, 15, 117–128. [Google Scholar] [CrossRef] [PubMed]

- Qu-Petersen, Z.; Deasy, B.; Jankowski, R.; Ikezawa, M.; Cummins, J.; Pruchnic, R.; Mytinger, J.; Cao, B.; Gates, C.; Wernig, A.; et al. Identification of a novel population of muscle stem cells in mice: potential for muscle regeneration. J. Cell Biol. 2002, 157, 851–864. [Google Scholar] [CrossRef]

- Ūsas, A.; Mačulaitis, J.; Mačiulaitis, R.; Jakubonienė, N.; Milašius, A.; Hardy, J. Skeletal muscle-derived stem cells: Implications for cell-mediated therapies. Medicina 2011, 47, 469. [Google Scholar] [CrossRef]

- Pavyde, E.; Maciulaitis, R.; Mauricas, M.; Sudzius, G.; Didziokiene, E.I.; Laurinavicius, A.; Sutkeviciene, N.; Stankevicius, E.; Maciulaitis, J.; Usas, A. Skeletal muscle-derived stem/progenitor cells: A potential strategy for the treatment of acute kidney injury. Stem Cells Int. 2016, 2016, 9618480. [Google Scholar] [CrossRef]

- Zou, J.; Yuan, C.; Wu, C.; Cao, C.; Shi, Q.; Yang, H. Isolation and osteogenic differentiation of skeletal muscle-derived stem cells for bone tissue engineering. Mol. Med. Rep. 2014, 9, 185–191. [Google Scholar] [CrossRef]

- Hart, M.L.; Lauer, J.C.; Selig, M.; Hanak, M.; Walters, B.; Rolauffs, B. Shaping the Cell and the Future: Recent Advancements in Biophysical Aspects Relevant to Regenerative Medicine. J. Funct. Morphol. Kinesiol. 2018, 3, 2. [Google Scholar] [CrossRef]

- Jonušauskas, L.; Skliutas, E.; Butkus, S.; Malinauskas, M. Custom on demand 3D printing of functional microstructures. Lith. J. Phys. 2015, 55, 227–236. [Google Scholar] [CrossRef]

- Amato, L.; Gu, Y.; Bellini, N.; Eaton, S.M.; Cerullo, G.; Osellame, R. Integrated three-dimensional filter separates nanoscale from microscale elements in a microfluidic chip. Lab Chip 2012, 12, 1135–1142. [Google Scholar] [CrossRef]

- Jonušauskas, L.; Rekštytė, S.; Buividas, R.; Butkus, S.; Gadonas, R.; Juodkazis, S.; Malinauskas, M. Hybrid Subtractive-Additive-Welding Microfabrication for Lab-on-Chip (LOC) Applications via Single Amplified Femtosecond Laser Source. Opt. Eng. 2017, 56, 094108. [Google Scholar] [CrossRef]

- Baseman, R.J.; Gupta, A.; Sausa, R.C.; Progler, C. Laser induced forward transfer. Mater. Res. Soc. Symp. Proc. 1987, 101, 237. [Google Scholar] [CrossRef]

- Maximova, K.; Wang, X.; Balčytis, A.; Fan, L.; Li, J.; Juodkazis, S. Silk patterns made by direct femtosecond laser writing. Biomicrofluidics 2016, 10, 054101. [Google Scholar] [CrossRef] [PubMed]

- Jonušauskas, L.; Gailevičius, D.; Mikoliūnaitė, L.; Sakalauskas, D.; Šakirzanovas, S.; Juodkazis, S.; Malinauskas, M. Optically Clear and Resilient Free-Form μ-Optics 3D-Printed via Ultrafast Laser Lithography. Materials 2017, 10, 12. [Google Scholar] [CrossRef] [PubMed]

- Jonušauskas, L.; Lau, M.; Gruber, P.; Gokce, B.; Barcikowski, S.; Malinauskas, M.; Ovsianikov, A. Plasmon assisted 3D microstructuring of gold nanoparticle-doped polymers. Nanotechnology 2016, 27, 154001. [Google Scholar] [CrossRef]

- Buividas, R.; Rekštytė, S.; Malinauskas, M.; Juodkazis, S. Nano-groove and 3D fabrication by controlled avalanche using femtosecond laser pulses. Opt. Mater. Express 2013, 3, 1674–1686. [Google Scholar] [CrossRef]

- O’Brien, F.J. Biomaterials & scaffolds for tissue engineering. Mater. Today 2011, 14, 88–95. [Google Scholar]

- Geurtsen, W. Biocompatibiliy of resin-modified filling materials. Crit. Rev. Oral Biol. Med. 2000, 11, 333–355. [Google Scholar] [CrossRef]

- John, A.A.; Subramanian, A.P.; Vellayappan, M.V.; Balaji, A.; Jaganathan, S.K.; Mohandas, H.; Paramalinggam, T.; Supriyantoa, E.; Yusofa, M. Review: Physico-chemical modification as a versatile strategy for the biocompatibility enhancement of biomaterials. RSC Adv. 2015, 5. [Google Scholar] [CrossRef]

| Formlabs Flexible | ||

|---|---|---|

| Mechanical Property | Resin | Cured Object |

| Tensile strength | 3.3–3.4 MPa | 7.7–8.5 MPa |

| Elongation | 60% | 75–85% |

| Tear force | 9.5–9.6 kN/m | 13.3–14.1 kN/m |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigaleviciute, G.; Baltriukiene, D.; Bukelskiene, V.; Malinauskas, M. Biocompatibility Evaluation and Enhancement of Elastomeric Coatings Made Using Table-Top Optical 3D Printer. Coatings 2020, 10, 254. https://doi.org/10.3390/coatings10030254

Grigaleviciute G, Baltriukiene D, Bukelskiene V, Malinauskas M. Biocompatibility Evaluation and Enhancement of Elastomeric Coatings Made Using Table-Top Optical 3D Printer. Coatings. 2020; 10(3):254. https://doi.org/10.3390/coatings10030254

Chicago/Turabian StyleGrigaleviciute, Giedre, Daiva Baltriukiene, Virginija Bukelskiene, and Mangirdas Malinauskas. 2020. "Biocompatibility Evaluation and Enhancement of Elastomeric Coatings Made Using Table-Top Optical 3D Printer" Coatings 10, no. 3: 254. https://doi.org/10.3390/coatings10030254

APA StyleGrigaleviciute, G., Baltriukiene, D., Bukelskiene, V., & Malinauskas, M. (2020). Biocompatibility Evaluation and Enhancement of Elastomeric Coatings Made Using Table-Top Optical 3D Printer. Coatings, 10(3), 254. https://doi.org/10.3390/coatings10030254