Abstract

The ferroelectric barium–strontium titanate (BST) multi-layer structure has been formed directly on silicon carbide by serial deposition and “in situ” annealing of layers. This approach allowed us to achieve the high-quality perovskite lattice of ferroelectric that provides the best combination of high tunability and low losses for BST/SiC structures at microwaves. Electric characteristics of BST/SiC planar capacitor structures were studied under the high level of microwave power for the first time. The BST/SiC structure consisted of highly oriented ferroelectric film on highly heat-conducting substrate have demonstrated the absence of the overheating of the active area of the capacitor under dissipated power density up to 125 W/mm.

1. Introduction

Today there is a stable interest in ferroelectric (FE) materials for tunable microwave (MW) applications caused by the dependence of dielectric permittivity of ferroelectrics on the strength of applied electric field [1,2,3,4]. The perspective properties of ferroelectrics at microwaves are high dielectric nonlinearity, low losses, fast switching time, low power consumption, and possibility to work under the high level of operating power [5,6,7,8]. Phase shifters for phased array antennas, tunable capacitors and filters for telecommunication systems is the area of the possible application of ferroelectrics. Being compared with semiconductor elements, ferroelectric devices can be characterized by more simple fabrication technology, lower losses at microwaves and higher levels of working signal [9,10]. The most promising ferroelectric materials for MW applications are solid solutions of barium and strontium titanates BaSrTiO (BST) in thin-film form, which exhibit a dielectric permittivity from 150 to 6000 when the x parameter changes from 0 to 0.6, while the material remains in the paraelectric state at room temperature [3,6,8,11,12,13,14]. Previous researches demonstrated that BST ferroelectric films maintain the high tunability and low dielectric loss in the wide frequency range ( increases from 0.01 to 0.06 at frequencies from 1 to 60 GHz [9,15,16]). Voltage-controlled tunable capacitors, phase shifters, and delay lines for frequencies up to 60 GHz have been realized based on BST films [2,6,11,17,18,19].

Operational requirements for microwave transmitting systems support the effort to developing ferroelectric capacitive elements with high power handling capability (PHC), i.e., the ability of element to operate under the high power MW signal without the degradation of the device’s parameters [2,20,21,22,23]. The variation of capacitance of FE elements under the operating signal is generally defined by two mechanisms: the electrical nonlinearity of the dielectric permittivity under the MW electric field, which can be suppressed by the number of methods [24,25], and the heating process caused by dissipation of MW power.

It is well known that the low thermal conductivity of dielectric substrates commonly used at microwaves, such as alumina, sapphire, magnesium oxide, is one of the reason for the overheating of the active area of thin-film element [26,27]. So, the usage of high heat-conducting substrate can significantly improve the heat sink, as was demonstrated for BST capacitor on diamond substrate in [28,29]. However, diamond is a rather expensive material and highly difficult to process. In this case, semi-insulating silicon carbide (SiC) can be considered as a prospective alternative to diamond. Silicon carbide reveals the thermal conductivity of = 500 W·mK, outstanding mechanical hardness, low dielectric losses and stable permittivity of about 6 [30,31].

Recent researches on ferroelectric films on an SiC substrate are described in [32,33,34]. However, first of them are dedicated to structure properties investigations only [32], second ones study PZT films, which are not suitable for microwave applications [34], other works estimate dielectric properties at low frequencies [33], but there are no articles devoted to characterization of BST/SiC structures under high power microwave signal.

BST planar capacitors on semi-insulating SiC characterized at microwave frequencies were demonstrated in [35] and the oriented growth of BST film directly on SiC for the first time was described in [36]. All these works have analyzed the small-signal characteristics of BST films on silicon carbide but PHC studies have not been performed on BST/SiC structures.

Therefore, the aim of this article is to investigate the effect of microwave signal of high magnitude on the electric properties of BST/SiC thin film capacitors. However, prior to investigating the large-signal characteristics, the growth mechanisms and structure properties of BST films on silicon carbide substrate were estimated, and the capacitance and Q-factor of planar BST/SiC elements were measured at 2 GHz at a small signal, since these properties are related to the nonlinear performance.

Although there are analytical models [26], which allow us to estimate the capacitor overheating under high microwave power, they cannot consider all possible ways of a heat generation and removal in the real capacitor. Moreover, they are limited by the fact that there is no reliable information about the thermal conductivity of thin ferroelectric film, except for a few indirect experiments [23], that does not allow to accurately simulate the overheating by finite element simulation software also. Therefore, as in [28], in this work the effect of electric nonlinearity on the capacitance variation was calculated and it was assumed that all changes beyond calculated ones are related to the effect of overheating.

2. Materials and Methods

Thin BST films were deposited on SiC substrates fabricated by Svetlana–Electronpribor (St. Petersburg, Russia) [36,37] by RF magnetron sputtering of a BaSrTiO ceramic target. Oxygen was used as a working gas at a pressure of 2 Pa providing optimal conditions for thin film deposition, oxidation of sputtered atoms, and crystallization of perovskite phase.

The following reasons were taken into consideration for a choosing of BST film deposition technique:

- (i)

- According to the recent investigations of initial stages of BST films growth on SiC substrate [38], the mechanism of film growth is determined by a substrate temperature. As it was shown, the heating of the SiC substrate until C leads to the “growth in height”, i.e., formation of high islands without spread of thicknesses, that is due to the mechanism of diffusion of adatoms through the gaseous phase is predominant. The decrease in from 880 to 800 C leads to an increase in the SiC substrate area covered by islands with simultaneous decrease in the island height, which indicate the change in the mechanisms of the mass transfer from the diffusion via a gaseous phase to the surface diffusion, and, hence, the change from the “growth in height” to the “lateral growth”.

- (ii)

- The change of mass transfer from the diffusion via a gaseous phase to the surface diffusion at certain conditions can lead to the oriented growth of thin films on non-matched substrates [39,40].

- (iii)

- The growth of continuous 300-nm-thick BST films on SiC substrate both at C and 880 C leads to a polycrystalline film formation [36].

- (iv)

- The structure and microwave properties of BST films on the monocrystal substrate can be significantly improved by the multi-step deposition method using the intermediate annealing during the film growth [41], which allows us to correct the lattice defects during the layer deposition.

According to the above-mentioned reasons, the following deposition technique was applied for the preparation of heterostructure “ferroelectric film/silicon carbide”.

The initial BST layer of 50 nm thickness was deposited during 20 min onto the SiC substrate. The substrate temperature was kept at C for the first 5 min of deposition and after that, it was decreased to C. After 20 min of film growth the discharge was turned off, the temperature was increased to C and the “in situ” intermediate annealing (IA) was performed for 10 min. Then, the second BST layer was deposited onto the first one with the simultaneous decrease of temperature from 880 to C for the first 5 min. The deposition and annealing procedures were repeated six times providing the 300 nm total thickness of films. The single layer films of the 300 nm thickness were prepared at C for comparison reasons. The phase composition of obtained BST films was studied by X-ray diffraction (XRD, DRON-6, Cu K source).

For electrophysical investigations planar capacitors with a gap width of 2 and 5 m and a length of 400 m were fabricated. Measurements of the microwave properties of capacitors investigated were performed by the resonance technique. The half-wavelength resonator based on the symmetrical stripline with short-circuited ends and resonant frequency of about 2 GHz was used. A capacitor under test was placed into the gap at the center of the stripline. The bias voltage was applied to the capacitor through the ends of the stripline, short-circuited for the microwaves by the large blocking capacitors, but isolated for the direct current.

The resonance frequency and Q-factor of the resonator with a capacitor included can be calculated in capacitance and the Q-factor of the capacitor itself. The method of calculation was described in the details in [26]. In the low-signal mode the resonator provides the accuracy of capacitance and quality factor measurements of 1% and 5% respectively. Capacitance and the quality factor Q = 1/, were measured at room temperature. Bias voltage U applied to a capacitor was varied within 0–300 V, which corresponded to a field strength of 0–60 V/m in the FE film.

The capacitor behavior under the elevated power can be estimated by the distortion of the resonance curve (non-symmetrical shift of the peak), which is caused by the variation of the capacitance under the microwave voltage [26,27]. The distortion is caused by two factors: electrical non-linearity and overheating under the influence of dissipated microwave power. While the first factor is determined only by the tunability of the capacitor, the second is strongly influenced by the thermal conductivity of the substrate. The composition of BST film used in the capacitor under test provides the phase transition at the temperature much lower than the room temperature, so both electrical and thermal factors should shift the capacitance down (and the resonant frequency up consequently).

The resonance parameters at high microwave power can be calculated to the capacitance and the Q-factor of the capacitor as well. Moreover, the microwave voltage amplitude () can be found by methods presented in [26,27]. CV-curve of the capacitor measured in small-signal mode can be approximated with fitting parameters K and [27] (which are interpreted as the tunability at infinite voltage and voltage of half-tunability, respectively). The relative capacitance variance with account of the electrical non-linearity is estimated as [27]

3. Results

3.1. Structure Characterization of BST Films on SiC

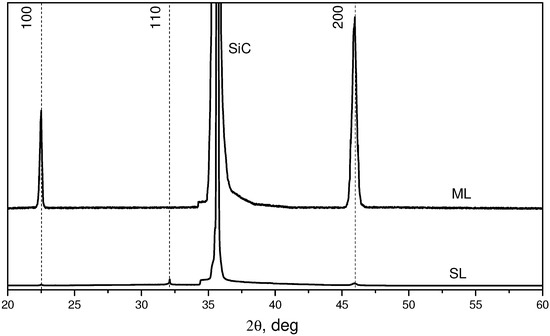

Figure 1 shows comparative XRD patterns of the 300 nm BST films deposited on SiC substrates. The multi-layer BST thin film prepared by using the intermediate annealing (C, C, indicated in Figure 1 as “ML”) and the single-layer BST thin film (C, indicated as “SL”) show different growth behaviors. A scan indicates that multi-layer film shows highly (h00) oriented perovskite structure while the single-layer film is polycrystalline. The value of the calculated cubic lattice parameter of both grown films is 0.3947 nm, giving the composition BaSrTiO, which corresponds to the BST target stoichiometry. This fact is confirmed by the dielectric permittivity behavior vs. temperature with maximum at 200 K (not presented here), which is equal to the phase transition temperature of bulk ceramic.

Figure 1.

XRD patterns for the multi-layer and single-layer BST films on silicon carbide.

3.2. Small Signal Microwave Characterization of BST Film Capacitors

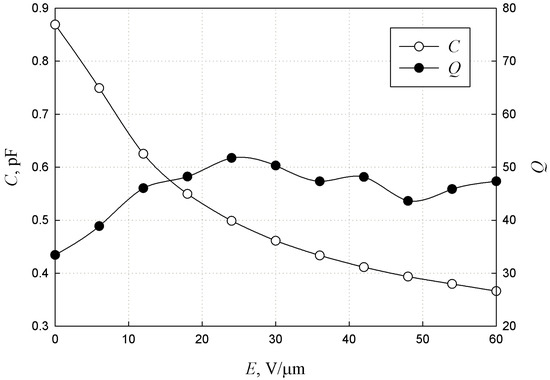

Figure 2 presents the experimental dependence of small-signal capacitance and Q-factor on field strength E (gap width m) tested at 2 GHz. The results of the small-signal measurements carried out at K showed that the application of dc bias voltage 300 V ( 60 V/m) led to a capacitance decrease by a factor of 2.4. For all BST capacitors tested, was in the range from 0.02 to 0.03. BST/SiC structures obtained in this work demonstrate combination of high tunability and low losses that distinguishes favorably from the values reported in the literature for BST films on silicon carbide [32,33,35,36].

Figure 2.

Small signal capacitance and Q-factor of BST film capacitor measured at GHz versus dc field strength.

3.3. High Power Microwave Characterization of BST/SiC Capacitors

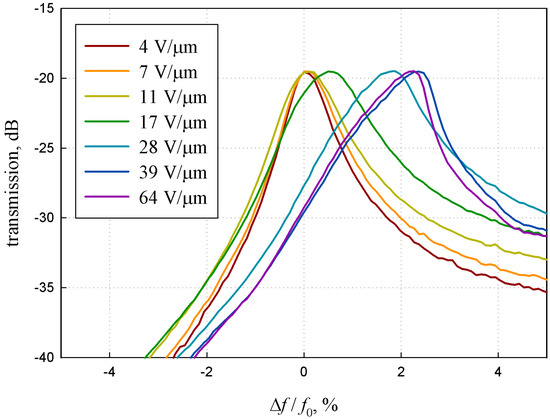

The measurements of BST capacitor response on high power MW signal were performed for the planar capacitor with a gap width of m to reach the high power density in the gap of the capacitor and, consequently, to enhance the influence of non-linear effects. The voltage-capacitance characteristic of the capacitor under test was approximated with the parameters and V and accuracy of 0.5%. The resonance characteristics of the resonator with the capacitor included under the different microwave magnitudes of the electric field strength are presented in Figure 3. For the better visual understanding the transmission coefficient was brought to one level, and the frequency shift was normalized to the resonant frequency at the small-signal microwave amplitude ( GHz at = 4 V/m). Resonance frequency variance is connected with the capacitance variance as [26], where is inclusion coefficient estimated as for the resonator used.

Figure 3.

Shift of the resonance characteristics under the microwave power (at the different magnitude of electric field strength).

4. Discussion

The oriented growth of the multi-layer BST film can be explained in terms of theory of heterogeneous nucleation of multicomponent systems. At the first 5 min of deposition when the substrate is heated to C and the diffusion of adatoms through the gaseous phase is predominant, the columnar structure of the first layer of BST film is formed [38]. Then, the decrease in C determines the change of the growth mechanism and the lateral growth on “columnar basis” begins, leading to the oriented layer formation. This layer is similar to a pile-supported bridge and is almost unstressed.

When the discharge is turned off during the intermediate annealing, the film has enough time to absorb all the incoming atoms, which increases the probability to form the highly oriented lattice.

When the discharge is turned on after the intermediate annealing, the annealed layer begins to play the role of a new substrate heated to a temperature that higher than the deposition one (C) at the absence of an interphase energy barrier, since the new layer is formed on its own material. The stages of columnar structure formation and further lateral growth are repeated leading to the next oriented layer formation.

So, the intermediate annealing of the as-deposited layer at a temperature higher than that of growth creates conditions for the oriented nucleation of each next layer. This approach makes the film more ordered and less defective, hence promising better electrical characteristics.

The experimental results of capacitance shift () under the high microwave power in comparison with calculated capacitance shift by the electrical non-linearity (Equation (1)) versus are presented in Figure 4. One can see that the experimental and calculated results are in good agreement with an accuracy of about 2% (the experimental point at Vm can be explained by the breakdown approach). Thus, the capacitance shift can be explained by the electrical non-linearity only, not by the overheating for microwave voltage amplitude up to about V.

Figure 4.

Capacitance shift versus microwave signal field strength.

The value of the microwave power dissipated in the capacitor at V can be estimated as mW. The working area of the planar capacitor under test is m that in turn corresponds to the dissipated power density of 0.125 mW/m, however, no overheating of the active area was observed. Earlier in [28,29] the performance of the BST capacitors on diamond and sapphire substrates at high MW power was investigated. The BST capacitor on the sapphire substrate was overheated by 20 K at the dissipated power density of 200 mW m = 0.01 mW/m, whereas the BST/diamond structure was overheated on 2 K at the same power density [29]. Despite the excellent heat-conductivity of the diamond substrate, the overheating was observed due to the low Q-factor of the capacitor fabricated. Thus, the BST/SiC structure presented in this article compares favorably to the BST/diamond one in terms of high-power microwave performance due to high-oriented crystal lattice and, hence, higher Q-factor.

In the Table 1 the comparative estimations of the overheating along with the microwave parameters for BST capacitors prepared on different substrates are presented.

Table 1.

Comparative data for the power handling capability of barium–strontium titanate (BST) capacitors on different substrates.

5. Conclusions

In this work, electric characteristics of BST/SiC planar capacitor structures were studied under a high level of microwave power for the first time. It was shown that the intermediate annealing technique allows us to improve substantially the crystal quality of multi-layered BST films that, in turn, determines the enhanced electrical quality of capacitors on their base. The capacitor based on the these BST films demonstrated a tunability at an electric field strength of 60 V/m, and of not higher than 0.03 at a frequency of 2 GHz, giving the best combination of tunability and losses for BST/SiC structures at microwaves. The experimental results confirmed that the electric field effect is the dominating mechanism in average capacitance variation, and the overheating is negligible for the FE capacitor on the SiC substrate. BST/SiC structure investigated has demonstrated the absence of the overheating of an active area of the capacitor under dissipated power density up to 125 W/mm. The BST/SiC elements look favorably from the PHC point of view in comparison with the analogs on other substrates. The usage of silicon carbide as a high thermal conductive substrate effectively solves the problem of the overheating of ferroelectric tunable elements at high microwave power that is very important for telecommunication and radar transmitting systems.

Author Contributions

Conceptualization, A.T.; methodology, A.T. and A.G.; formal analysis, A.G. (microwave) and A.T. (structure); investigation, A.T. and M.Z. (sample fabrication and XRD), A.G. and A.A. (microwave); writing—original draft preparation, A.T. and A.G.; writing—review and editing, A.T. and A.G.; visualization, E.S. and M.Z.; supervision, A.A.; funding acquisition, A.A. All authors have read and agreed to the published version of the manuscript.

Funding

Ferroelectric samples fabrication and structure investigations carried out by M. Zlygostov and E. Sapego were supported by the Russian Foundation for Basic Research (projects 18-37-00348 and 19-37-90055 respectively). The investigations of ferroelectric capacitor response on high power MW signal carried out by A. Tumarkin and A. Altynnikov were supported by the Russian Scientific Foundation (project 18-79-10156).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Martínez-Viviente, F.L.; Hinojosa, J. 12—Tunable ferroelectrics for frequency agile microwave and THz devices. In Magnetic, Ferroelectric, and Multiferroic Metal Oxides; Stojanovic, B.D., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 251–264. [Google Scholar] [CrossRef]

- Romanofsky, R.R.; Toonen, R.C. Past, present and future of ferroelectric and multiferroic thin films for array antennas. Multidimens. Syst. Signal Process. 2018, 29, 475–487. [Google Scholar] [CrossRef]

- Nadaud, K.; Borderon, C.; Renoud, R.; Ghalem, A.; Crunteanu, A.; Huitema, L.; Dumas-Bouchiat, F.; Marchet, P.; Champeaux, C.; Gundel, H.W. Diffuse phase transition of BST thin films in the microwave domain. Appl. Phys. Lett. 2018, 112, 262901. [Google Scholar] [CrossRef]

- Dragoman, M.; Aldrigo, M.; Modreanu, M.; Dragoman, D. Extraordinary tunability of high-frequency devices using Hf0.3Zr0.7O2 ferroelectric at very low applied voltages. Appl. Phys. Lett. 2017, 110, 103104. [Google Scholar] [CrossRef]

- Ahmed, A.; Goldthorpe, I.A.; Khandani, A.K. Electrically tunable materials for microwave applications. Appl. Phys. Rev. 2015, 2, 011302. [Google Scholar] [CrossRef]

- Meyers, C.J.G.; Freeze, C.R.; Stemmer, S.; York, R.A. (Ba,Sr)TiO3 tunable capacitors with RF commutation quality factors exceeding 6000. Appl. Phys. Lett. 2016, 109, 112902. [Google Scholar] [CrossRef]

- Meyers, C.J.G.; Freeze, C.R.; Stemmer, S.; York, R.A. Effect of BST film thickness on the performance of tunable interdigital capacitors grown by MBE. Appl. Phys. Lett. 2017, 111, 262903. [Google Scholar] [CrossRef]

- Lai, L.; Xu, Y.; Ren, Y.; Gao, H.; Wang, X.; Zhu, J.; He, Y.; Zhu, X. Low loss and highly tunable (Ba,Sr)(Ti,Mn)O3/(Ba,Sr)TiO3 bilayered films for electrically tunable microwave device applications. J. Mater. Sci. Mater. Electron. 2017, 28, 5718–5724. [Google Scholar] [CrossRef]

- Altynnikov, A.; Gagarin, A.; Tumarkin, A.; Kotel’nikov, I. Characterization of the properties of barium–strontium titanate films and controlled elements based on them in the frequency range of 1–60 GHz. Tech. Phys. Lett. 2019, 45, 540–543. [Google Scholar] [CrossRef]

- Vendik, O.G. Ferroelectrics find their “niche” among microwave control devices. Phys. Solid State 2009, 51, 1529–1534. [Google Scholar] [CrossRef]

- Wang, X.; Bao, P.; Jackson, T.; Lancaster, M. Tunable microwave filters based on discrete ferroelectric and semiconductor varactors. IET Microw. Antennas Propag. 2011, 5, 776–782. [Google Scholar] [CrossRef]

- Ioachim, A.; Toacsan, M.; Banciu, M.; Nedelcu, L.; Vasiliu, F.; Alexandru, H.; Berbecaru, C.; Stoica, G. Barium strontium titanate-based perovskite materials for microwave applications. Prog. Solid State Chem. 2007, 35, 513–520. [Google Scholar] [CrossRef]

- Alexandru, H.; Berbecaru, C.; Ioachim, A.; Toacsen, M.; Banciu, M.; Nedelcu, L.; Ghetu, D. Oxides ferroelectric (Ba, Sr)TiO3 for microwave devices. Mater. Sci. Eng. B 2004, 109, 152–159. [Google Scholar] [CrossRef]

- Ranasingha, O.; Haghzadeh, M.; Armiento, C.; Akyurtlu, A. Formulation and characterization of sinterless Barium Strontium Titanate (BST) nanocomposite dielectric inks for flexible RF and Microwave electronics applications. In APS Meeting Abstracts; APS: Boston, MA, USA, 2019. [Google Scholar]

- Vélu, G.; Houzet, G.; Burgnies, L.; Carru, J.C.; Marteau, A.; Blary, K.; Lippens, D.; Mounaix, P.; Tondusson, M.; Nguéma, E. Electrical characterizations of paraelectric BST thin films up to 1 THz: Realization of microwave phaseshifters. Ferroelectrics 2007, 353, 29–37. [Google Scholar] [CrossRef]

- Banciu, M.G.; Geambasu, D.C.; Nedelcu, L.; Iuga, A.; Chirila, C.; Hrib, L.; Trupina, L.; Furuya, T.; Tani, M.; Pantelica, D.; et al. Millimeter Wave and Terahertz Investigations on Some Dielectric Materials. In Proceedings of the 2018 International Semiconductor Conference (CAS), Sinaia, Romania, 10–12 October 2018; pp. 287–290. [Google Scholar] [CrossRef]

- Karnati, K.K.; Shen, Y.; Trampler, M.E.; Ebadi, S.; Wahid, P.F.; Gong, X. A BST-integrated capacitively loaded patch for Ka- and X-band beamsteerable reflectarray antennas in satellite communications. IEEE Trans. Antennas Propag. 2015, 63, 1324–1333. [Google Scholar] [CrossRef]

- De Paolis, R.; Payan, S.; Maglione, M.; Guegan, G.; Coccetti, F. High-tunability and high-Q-factor integrated ferroelectric circuits up to millimeter waves. IEEE Trans. Microw. Theory Tech. 2015, 63, 2570–2578. [Google Scholar] [CrossRef]

- Velu, G.; Blary, K.; Burgnies, L.; Marteau, A.; Houzet, G.; Lippens, D.; Carru, J. A 360∘ BST phase shifter with moderate bias voltage at 30 GHz. IEEE Trans. Microw. Theory Tech. 2007, 55, 438–444. [Google Scholar] [CrossRef]

- Yu, M. Power-handling capability for RF filters. IEEE Microw. Mag. 2007, 8, 88–97. [Google Scholar] [CrossRef]

- Dussopt, L.; Rebeiz, G.M. Intermodulation distortion and power handling in RF MEMS switches, varactors, and tunable filters. IEEE Trans. Microw. Theory Tech. 2003, 51, 1247–1256. [Google Scholar] [CrossRef]

- Kienemund, D.; Kohler, C.; Fink, T.; Abrecht, M.; Wiens, A.; Bigler, W.; Binder, J.R.; Maune, H.; Jakoby, R. A fully-printed MIM varactor for high power application. In Proceedings of the 2016 46th European Microwave Conference (EuMC), London, UK, 4–6 October 2016; pp. 623–626. [Google Scholar] [CrossRef]

- Maune, H.; Kienemund, D.; Wiens, A.; Preis, S.; Schuster, C.; Walk, D.; Bengtsson, O.; Jakoby, R. Ferroelectrics for Tunable High-Power Applications. In Proceedings of the 2018 IEEE MTT-S International Microwave Workshop Series on Advanced Materials and Processes for RF and THz Applications (IMWS-AMP), Ann Arbor, MI, USA, 16–18 July 2018; pp. 1–3. [Google Scholar] [CrossRef]

- York, R.A. Circuit Configuration for DC-Biased Capacitors. U.S. Patent 6,674,321, 6 January 2004. [Google Scholar]

- Fu, J.S.; Zhu, X.A.; Chen, D.Y.; Phillips, J.D.; Mortazawi, A. A linearity improvement technique for thin-film barium strontium titanate capacitors. In Proceedings of the 2006 IEEE MTT-S International Microwave Symposium Digest, San Francisco, CA, USA, 11–16 June 2006; pp. 560–563. [Google Scholar]

- Kozyrev, A.; Ivanov, A.; Samoilova, T.; Soldatenkov, O.; Astafiev, K.; Sengupta, L.C. Nonlinear response and power handling capability of ferroelectric BaxSr1−xTiO3 film capacitors and tunable microwave devices. J. Appl. Phys. 2000, 88, 5334–5342. [Google Scholar] [CrossRef]

- Soldatenkov, O.; Samoilova, T.; Ivanov, A.; Kozyrev, A.; Ginley, D.; Kaydanova, T. Nonlinear properties of thin ferroelectric film-based capacitors at elevated microwave power. Appl. Phys. Lett. 2006, 89, 232901. [Google Scholar] [CrossRef]

- Tumarkin, A.; Razumov, S.; Gagarin, A.; Altynnikov, A.; Mikhailov, A.; Platonov, R.; Kotelnikov, I.; Kozyrev, A.; Butler, J.E. Ferroelectric varactor on diamond for elevated power microwave applications. IEEE Electron Device Lett. 2016, 37, 762–765. [Google Scholar] [CrossRef]

- Tumarkin, A.; Razumov, S.; Gagarin, A.; Altynnikov, A.; Mikhailov, A.; Platonov, R.; Kotelnikov, I.; Kozyrev, A.; Butler, J. Thin film ferroelectric structures on diamond for high power microwave applications. Diam. Relat. Mater. 2017, 75, 176–180. [Google Scholar] [CrossRef]

- Levinshtein, M.E.; Rumyantsev, S.L.; Shur, M.S. Properties of Advanced Semiconductor Materials: GaN, AIN, InN, BN, SiC, SiGe; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Clarke, R.C.; Palmour, J.W. SiC microwave power technologies. Proc. IEEE 2002, 90, 987–992. [Google Scholar] [CrossRef]

- Lee, J.S.; Jo, Y.D.; Koh, J.H.; Ha, J.G.; Koo, S.M. Crystalline and electrical properties of BST/4H-SiC capacitors. J. Korean Phys. Soc. 2010, 57, 1889–1892. [Google Scholar] [CrossRef]

- Song, L.; Chen, Y.; Wang, G.; Yang, L.; Ge, J.; Dong, X.; Xiang, P.; Zhang, Y.; Tang, X. Fabrication and dielectric properties of Ba0.63Sr0.37TiO3 thin films on SiC substrates. J. Am. Ceram. Soc. 2014, 97, 3048–3051. [Google Scholar] [CrossRef]

- Östling, M.; Koo, S.M.; Zetterling, C.M.; Khartsev, S.; Grishin, A. Ferroelectric thin films on silicon carbide for next-generation nonvolatile memory and sensor devices. Thin Solid Films 2004, 469–470, 444–449. [Google Scholar] [CrossRef]

- Tumarkin, A.V.; Razumov, S.V.; Gagarin, A.G.; Odinets, A.A.; Mikhailov, A.K.; Pronin, I.P.; Stozharov, V.M.; Senkevich, S.V.; Travin, N.K. Ferroelectric films of barium strontium titanate on semi-insulating silicon carbide substrates. Tech. Phys. Lett. 2016, 42, 423–426. [Google Scholar] [CrossRef]

- Tumarkin, A.; Gagarin, A.; Odinets, A.; Zlygostov, M.; Sapego, E.; Kotelnikov, I. Structural and microwave characterization of BaSrTiO3 thin films deposited on semi-insulating silicon carbide. Jpn. J. Appl. Phys. 2018, 57, 11UE02. [Google Scholar] [CrossRef]

- Parshin, V.; Serov, E.; Denisov, G.; Garin, B.; Denisyuk, R.; V’yuginov, V.; Klevtsov, V.; Travin, N. Silicon carbide for high-power applications at MM and THz ranges. Diam. Relat. Mater. 2017, 80, 1–4. [Google Scholar] [CrossRef]

- Tumarkin, A.V.; Serenkov, I.T.; Sakharov, V.I.; Razumov, S.V.; Odinets, A.A.; Zlygostov, M.V.; Sapego, E.N.; Afrosimov, V.V. Initial stages of the growth of barium strontium titanate films on a semi-isolating silicon carbide substrate. Phys. Solid State 2017, 59, 2374–2380. [Google Scholar] [CrossRef]

- Kukushkin, S.; Sakalo, T. Diffusional coalescence of island films on the real crystal surface in the case of layer-by-layer growth of islands—II. An open system. Undamped sources of deposited atoms. Acta Metall. Mater. 1993, 41, 1243–1244. [Google Scholar] [CrossRef]

- Kukushkin, S.; Osipov, A.; Bessolov, V.; Konenkova, E.; Panteleev, V. Misfit dislocation locking and rotation during gallium nitride growth on SiC/Si substrates. Phys. Solid State 2017, 59, 674–681. [Google Scholar] [CrossRef]

- Tumarkin, A.; Razumov, S.; Odinets, A.; Gagarin, A.; Altynnikov, A.; Kozyrev, A. Ferroelectric BaSrTiO3 films structured by an intermediate annealing during the deposition. Integr. Ferroelectr. 2016, 173, 38–45. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).