Effect of Thickness on Tribological Behavior of Hydrogen Free Diamond-like Carbon Coating

Abstract

1. Introduction

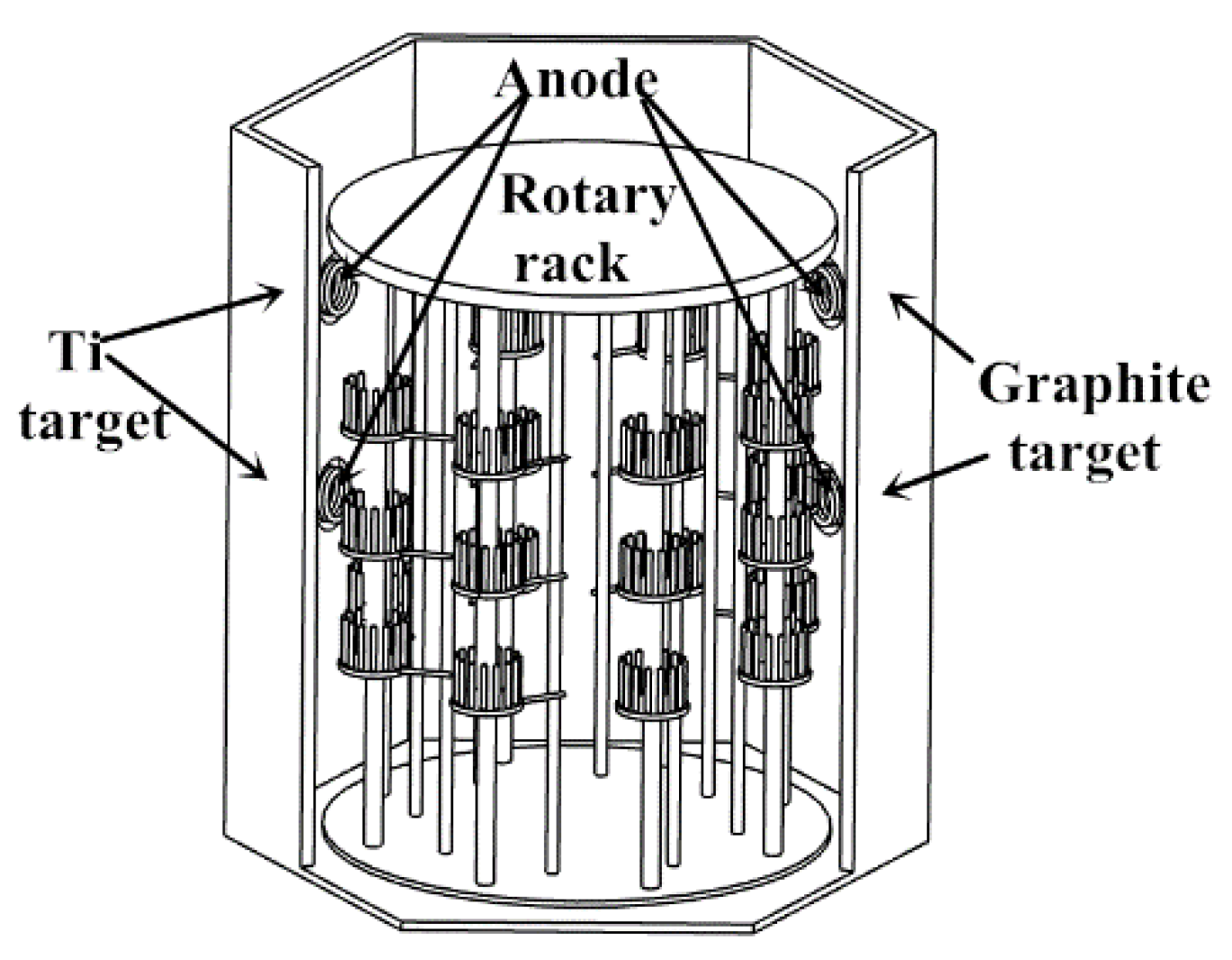

2. Film Deposition

3. Results and Discussions

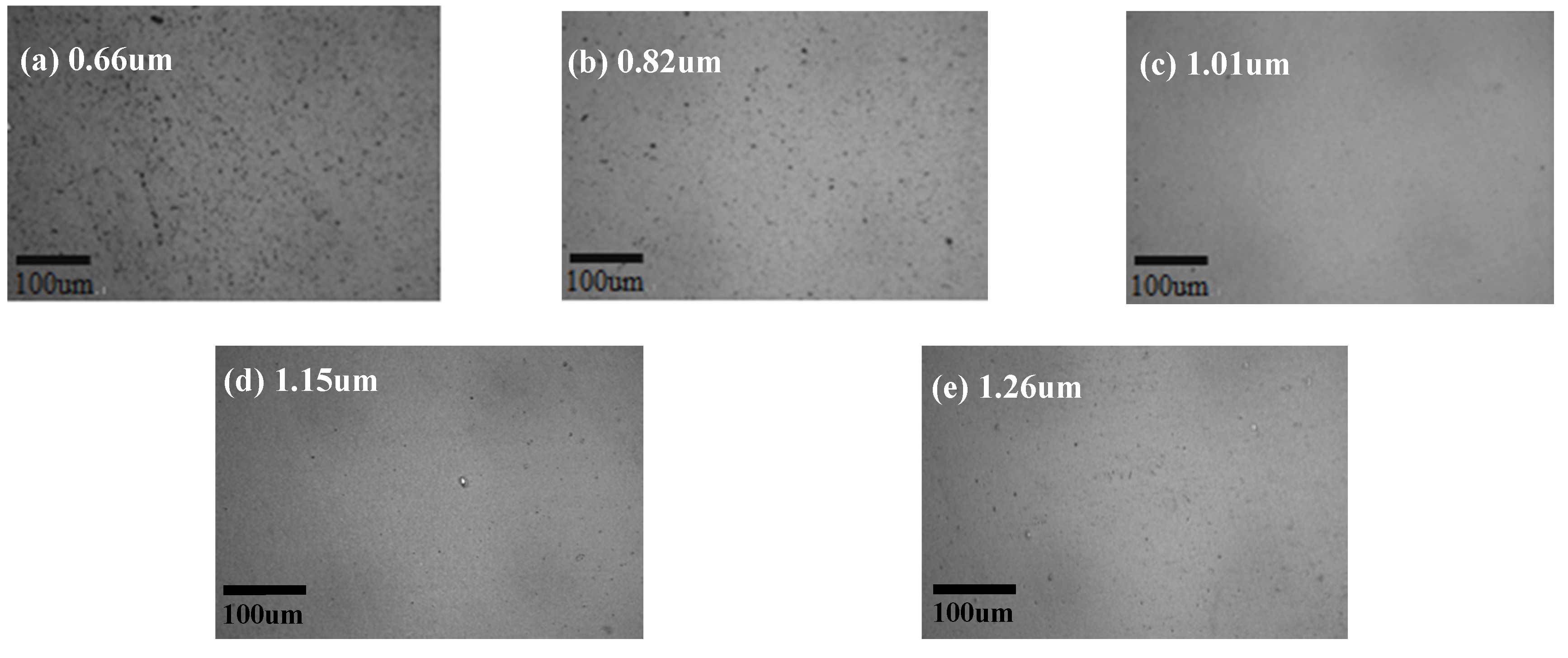

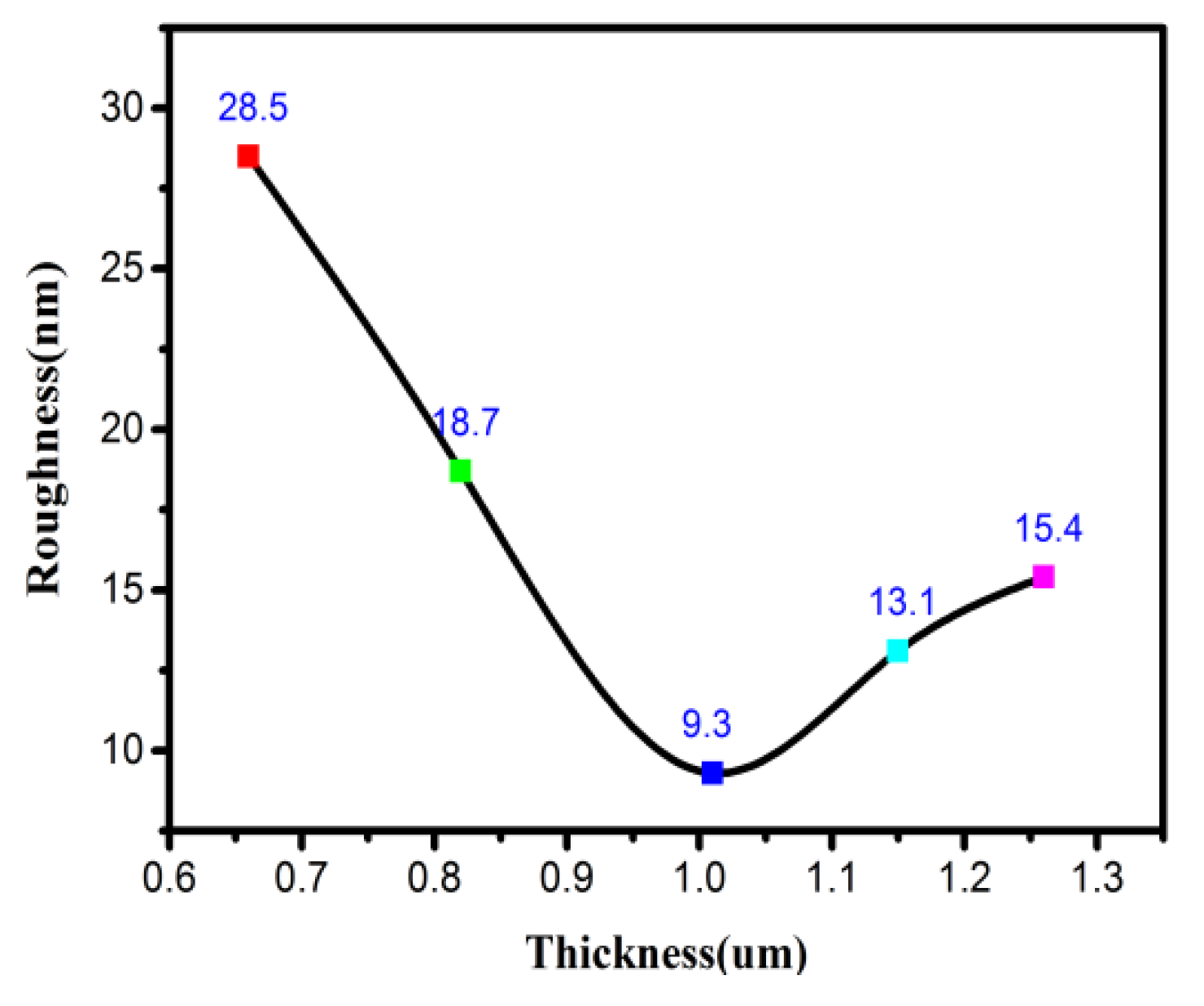

3.1. Surface Morphology

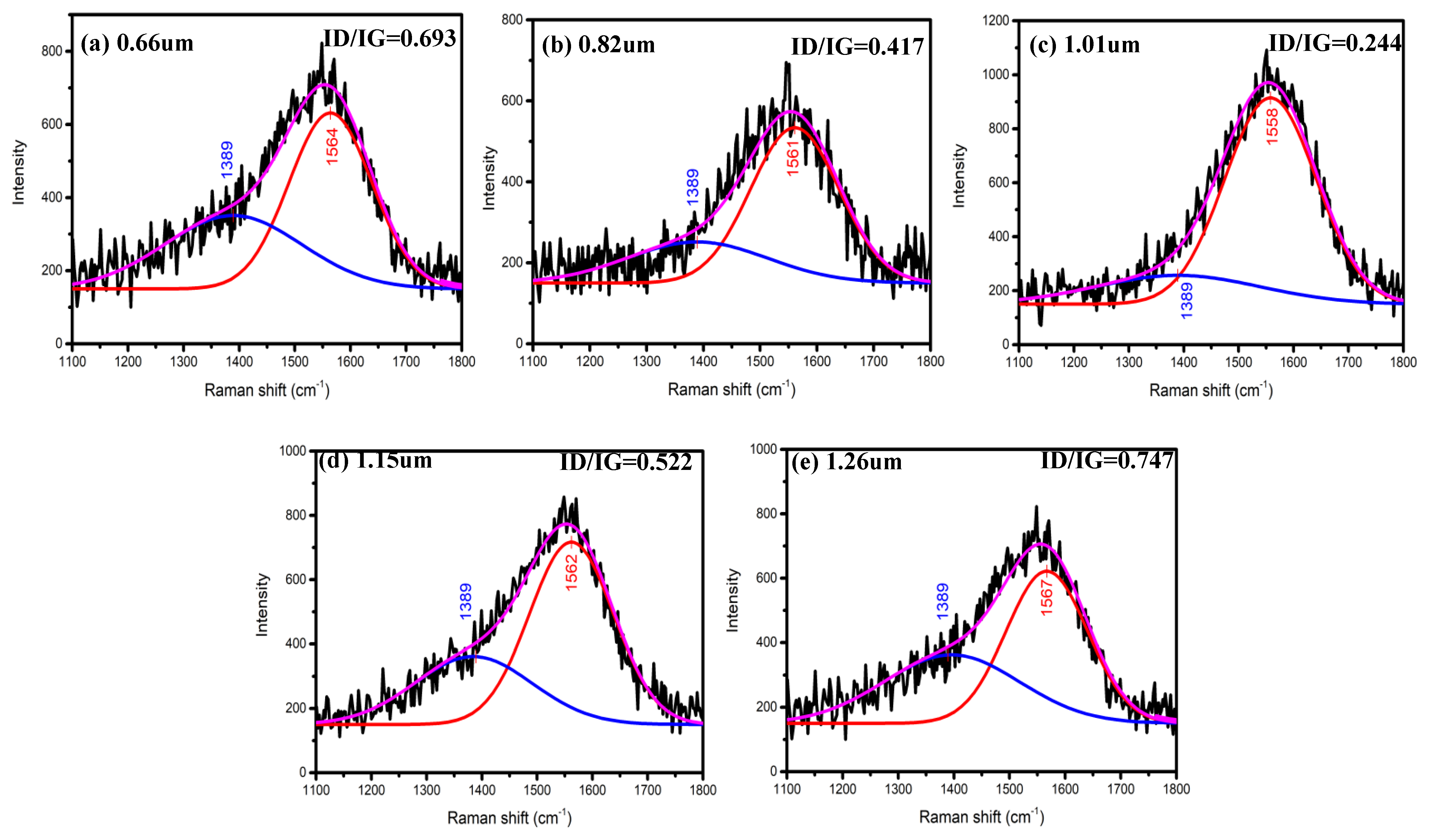

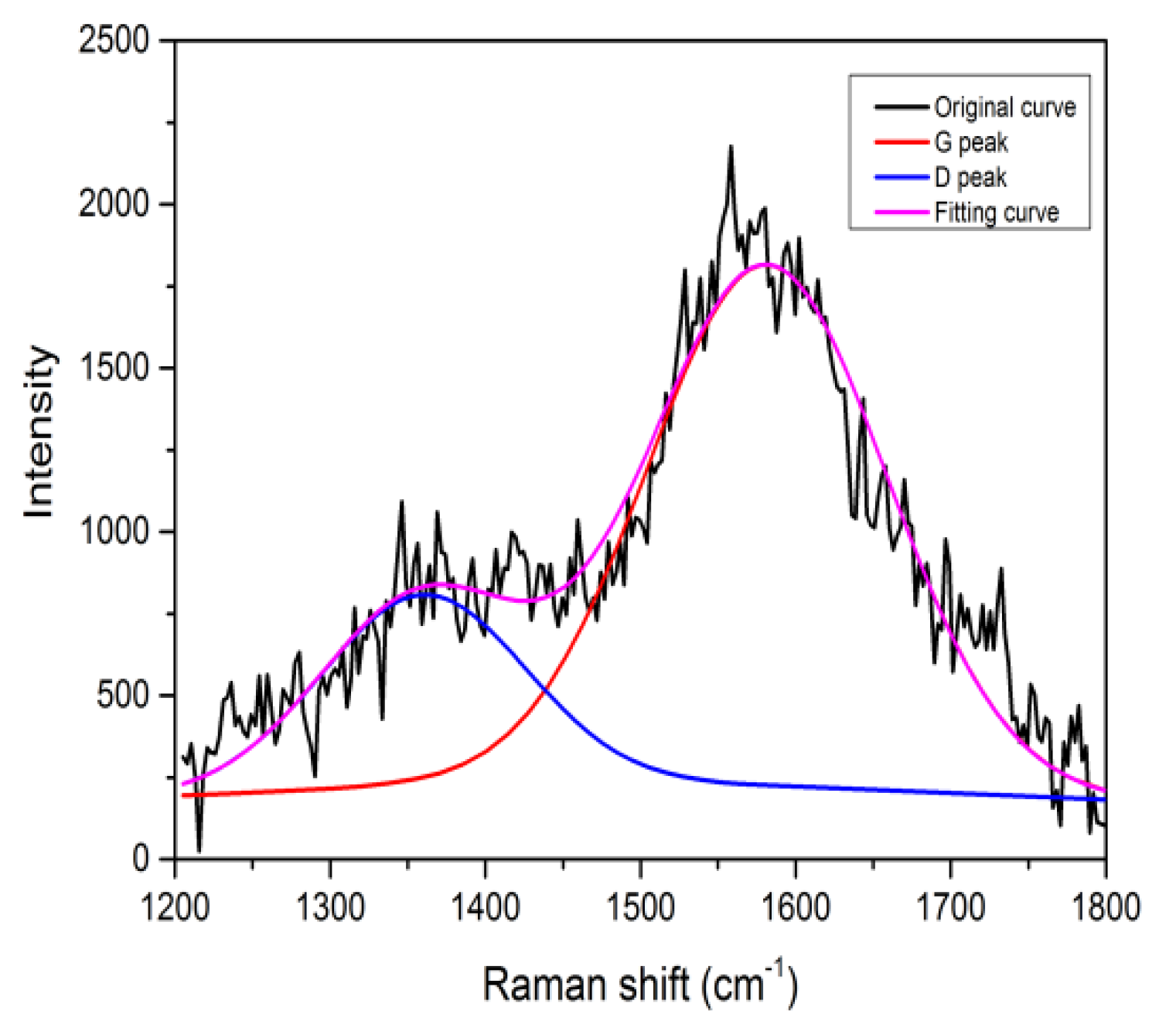

3.2. Microstructures of the Films

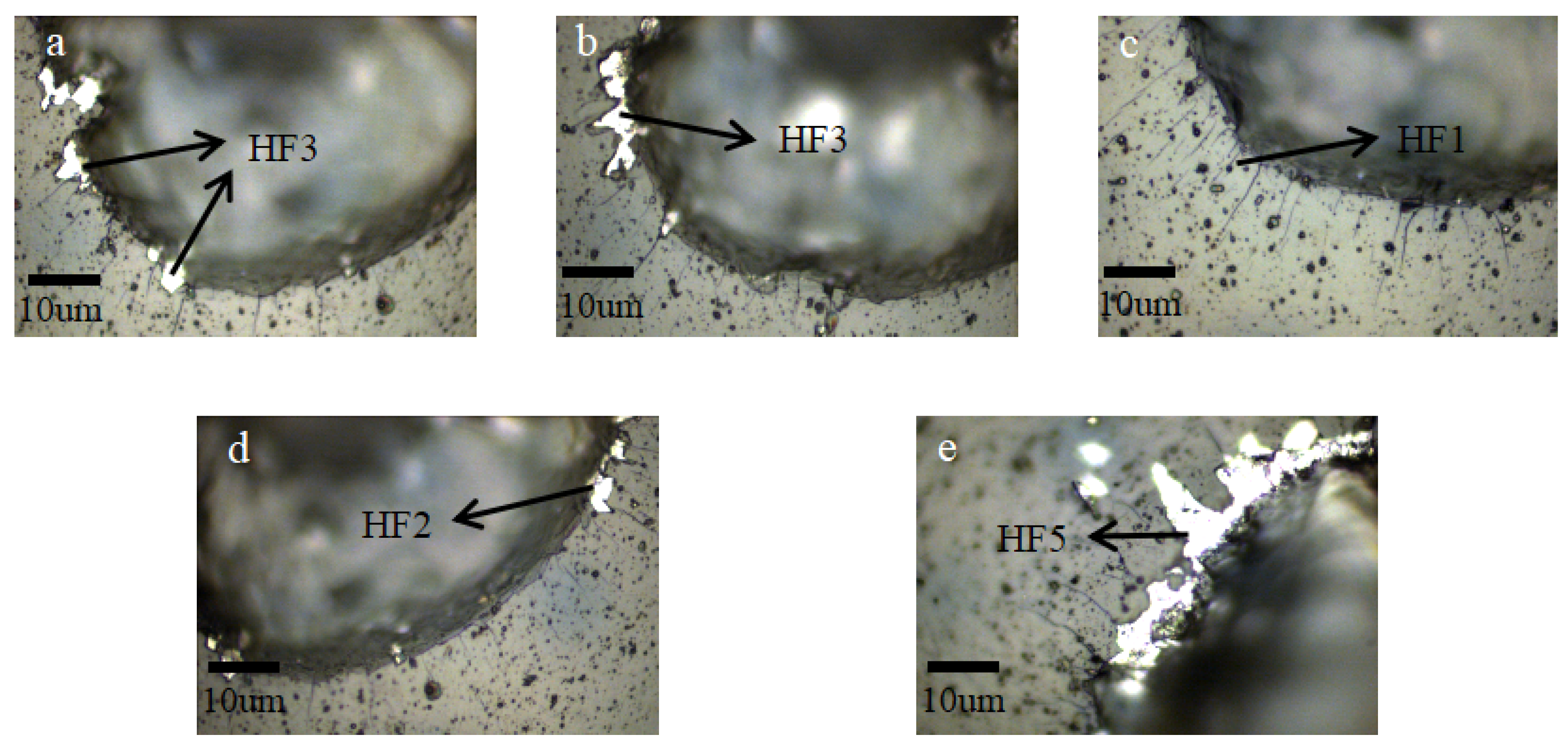

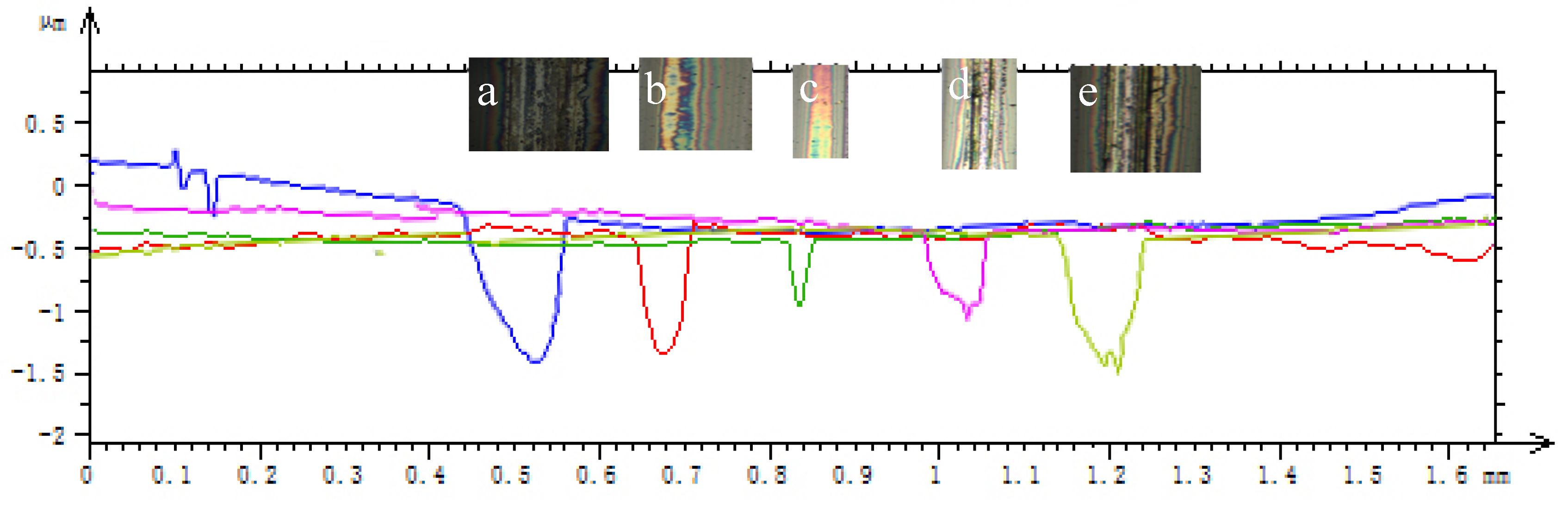

3.3. Adhesion Strength

3.4. Tribological Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, X.; Zhang, H.; Wu, X.; Zhang, T.; Zhang, X.; Sang, J. Structure and wear resistance of tetrahedral amorphous carbon films. Nucl. Instrum. Methods Phys. Res. Sect. B: Beam Interact. Mater. 2003, 206, 215–218. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R: Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Donnet, C.; Erdemir, A. Historical developments and new trends in tribological and solid lubricant coatings. Surf. Coat. Technol. 2004, 180, 76–84. [Google Scholar] [CrossRef]

- Ucun, I.; Aslantas, K.; Bedir, F. The performance of dlc-coated and uncoated ultra-fine carbide tools in micromilling of inconel 718. Precis. Eng. 2015, 41, 135–144. [Google Scholar] [CrossRef]

- Khadem, M.; Penkov, O.V.; Pukha, V.E.; Maleyev, M.V.; Kim, D.-E. Ultra-thin nano-patterned wear-protective diamond-like carbon coatings deposited on glass using a c60 ion beam. Carbon 2014, 80, 534–543. [Google Scholar] [CrossRef]

- Yeo, R.J.; Dwivedi, N.; Tripathy, S.; Bhatia, C.S. Excellent wear life of silicon nitride/tetrahedral amorphous carbon bilayer overcoat on functional tape heads. Appl. Phys. Lett. 2015, 106, 091604. [Google Scholar] [CrossRef]

- Xie, J. Synthesis and Characterization of Amorphous Carbon Films for Magnetic Storage Technology. Ph.D. Dissertation, University of California, Berkeley, San Francisco, CA, USA, 2015. [Google Scholar]

- Bewilogua, K.; Hofmann, D. History of diamond-like carbon films—from first experiments to worldwide applications. Surf. Coat. Technol. 2014, 242, 214–225. [Google Scholar] [CrossRef]

- Erdemir, A.; Donnet, C. Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. D: Appl. Phys. 2006, 39, R311. [Google Scholar] [CrossRef]

- Robertson, J. Hard amorphous (diamond-like) carbons. Prog. Solid State Chem. 1991, 21, 199–333. [Google Scholar] [CrossRef]

- Majdič, F.; Velkavrh, I.; Kalin, M. Improving the performance of a proportional 4/3 water–hydraulic valve by using a diamond-like-carbon coating. Wear 2013, 297, 1016–1024. [Google Scholar] [CrossRef]

- Capote, G.; Ramírez, M.; da Silva, P.; Lugo, D.; Trava-Airoldi, V. Improvement of the properties and the adherence of dlc coatings deposited using a modified pulsed-dc pecvd technique and an additional cathode. Surf. Coat. Technol. 2016, 308, 70–79. [Google Scholar] [CrossRef]

- Neuville, S.; Matthews, A. A perspective on the optimisation of hard carbon and related coatings for engineering applications. Thin Solid Film. 2007, 515, 6619–6653. [Google Scholar] [CrossRef]

- Dorner-Reisel, A.; Lieberwirth, R.; Svoboda, S.; Günther, K.; Röder, C.; Himcinschi, C.; Irmer, G.; Weißmantel, S. Wear behaviour of hydrogen free diamond-like carbon thin films in diesel fuel at different temperatures. Diam. Relat. Mater. 2014, 44, 78–87. [Google Scholar] [CrossRef]

- Kao, W.; Su, Y.; Horng, J.; Yu, C. Effects of pulse power and argon flux flow rate on mechanical and tribological properties of diamond-like carbon coatings prepared using high power impulse magnetron sputtering technology. Thin Solid Film. 2020, 693, 137712. [Google Scholar] [CrossRef]

- Liu, J.; Li, L.; Wei, B.; Wen, F.; Cao, H.; Pei, Y. Effect of sputtering pressure on the surface topography, structure, wettability and tribological performance of dlc films coated on rubber by magnetron sputtering. Surf. Coat. Technol. 2019, 365, 33–40. [Google Scholar] [CrossRef]

- Erdemir, A.; Eryilmaz, O.L.; Fenske, G. Synthesis of diamondlike carbon films with superlow friction and wear properties. Vac. Sci. Technol. 2000, 18, 1987–2010. [Google Scholar] [CrossRef]

- Ruiqiang, H.; Shengli, M.; Paul, C.K. Effects of diamond-like carbon coatings with different thickness on mechanical properties and corrosion behavior of biomedical niti alloy. Rare Met. Mater. Eng. 2012, 41, 1505–1510. [Google Scholar] [CrossRef]

- Bolelli, G.; Lusvarghi, L.; Barletta, M. Hvof-sprayed wc–cocr coatings on al alloy: Effect of the coating thickness on the tribological properties. Wear 2009, 267, 944–953. [Google Scholar] [CrossRef]

- Shen, W.; Jiang, B.; Gasworth, S.M.; Mukamal, H. Study of tribological properties of coating/substrate system in micrometer and nanometer scales with a scanning probe microscope. Tribol. Int. 2001, 34, 135–142. [Google Scholar] [CrossRef]

- Carlsson, P.; Bexell, U.; Olsson, M. Tribological performance of thin organic permanent coatings deposited on 55% al–zn coated steel—influence of coating composition and thickness on friction and wear. Wear 2001, 251, 1075–1084. [Google Scholar] [CrossRef]

- Kataria, S.; Dhara, S.; Barshilia, H.C.; Dash, S.; Tyagi, A. Evolution of coefficient of friction with deposition temperature in diamond like carbon thin films. J. Appl. Phys. 2012, 112, 023525. [Google Scholar] [CrossRef]

- Lifshitz, Y.; Lempert, G.; Grossman, E.; Avigal, I.; Uzan-Saguy, C.; Kalish, R.; Kulik, J.; Marton, D.; Rabalais, J. Growth mechanisms of dlc films from c+ ions: Experimental studies. Diam. Relat. Mater. 1995, 4, 318–323. [Google Scholar] [CrossRef]

- Lifshitz, Y.; Lempert, G.; Grossman, E. Substantiation of subplantation model for diamondlike film growth by atomic force microscopy. Phys. Rev. Lett. 1994, 72, 2753. [Google Scholar] [CrossRef]

- Casiraghi, C.; Ferrari, A.; Robertson, J. Raman spectroscopy of hydrogenated amorphous carbons. Phys. Rev. B 2005, 72, 085401. [Google Scholar] [CrossRef]

- Ferrari, A.; Robertson, J. Resonant raman spectroscopy of disordered, amorphous, and diamondlike carbon. Phys. Rev. B 2001, 64, 075414. [Google Scholar] [CrossRef]

- Li, C. Investigationn of Thermal Stability, Microstructure as well as Mechanical Property and Cutting Performance. Ph.D. Dissertation, Central South University, Changsha, China, 2009. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, B.; Zhou, Q.; Zhang, E.-g. Effect of Thickness on Tribological Behavior of Hydrogen Free Diamond-like Carbon Coating. Coatings 2020, 10, 243. https://doi.org/10.3390/coatings10030243

Huang B, Zhou Q, Zhang E-g. Effect of Thickness on Tribological Behavior of Hydrogen Free Diamond-like Carbon Coating. Coatings. 2020; 10(3):243. https://doi.org/10.3390/coatings10030243

Chicago/Turabian StyleHuang, Biao, Qiong Zhou, and Er-geng Zhang. 2020. "Effect of Thickness on Tribological Behavior of Hydrogen Free Diamond-like Carbon Coating" Coatings 10, no. 3: 243. https://doi.org/10.3390/coatings10030243

APA StyleHuang, B., Zhou, Q., & Zhang, E.-g. (2020). Effect of Thickness on Tribological Behavior of Hydrogen Free Diamond-like Carbon Coating. Coatings, 10(3), 243. https://doi.org/10.3390/coatings10030243