Effects of the Nitrogen Flow Ratio and Substrate Bias on the Mechanical Properties of W–N and W–Si–N Films

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

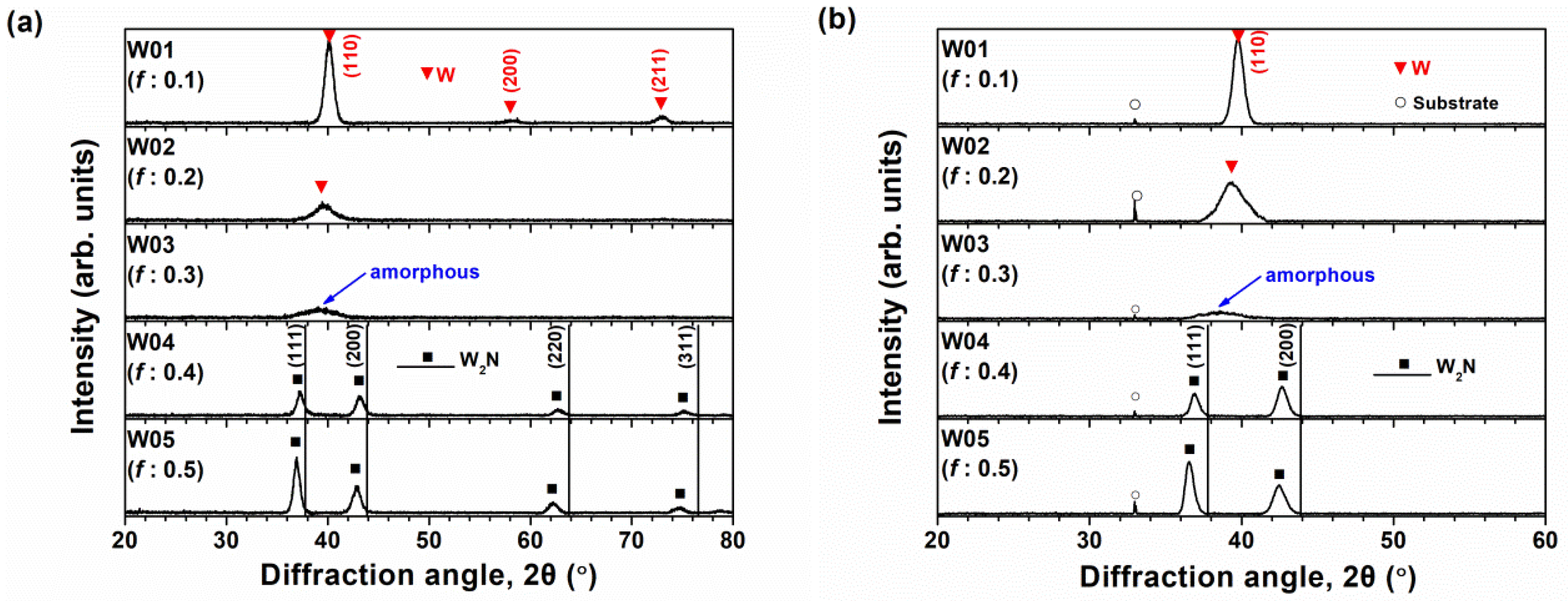

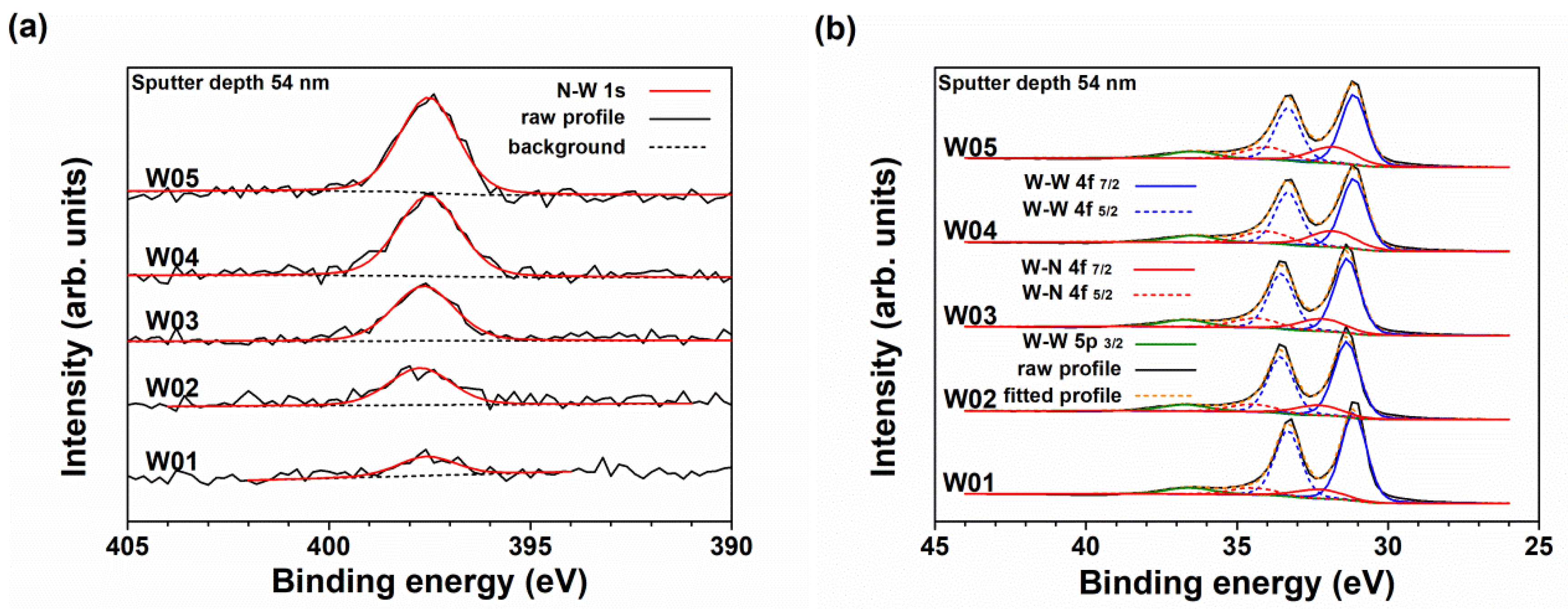

3.1. W–N Films Prepared with Various Nitrogen Flow Ratios

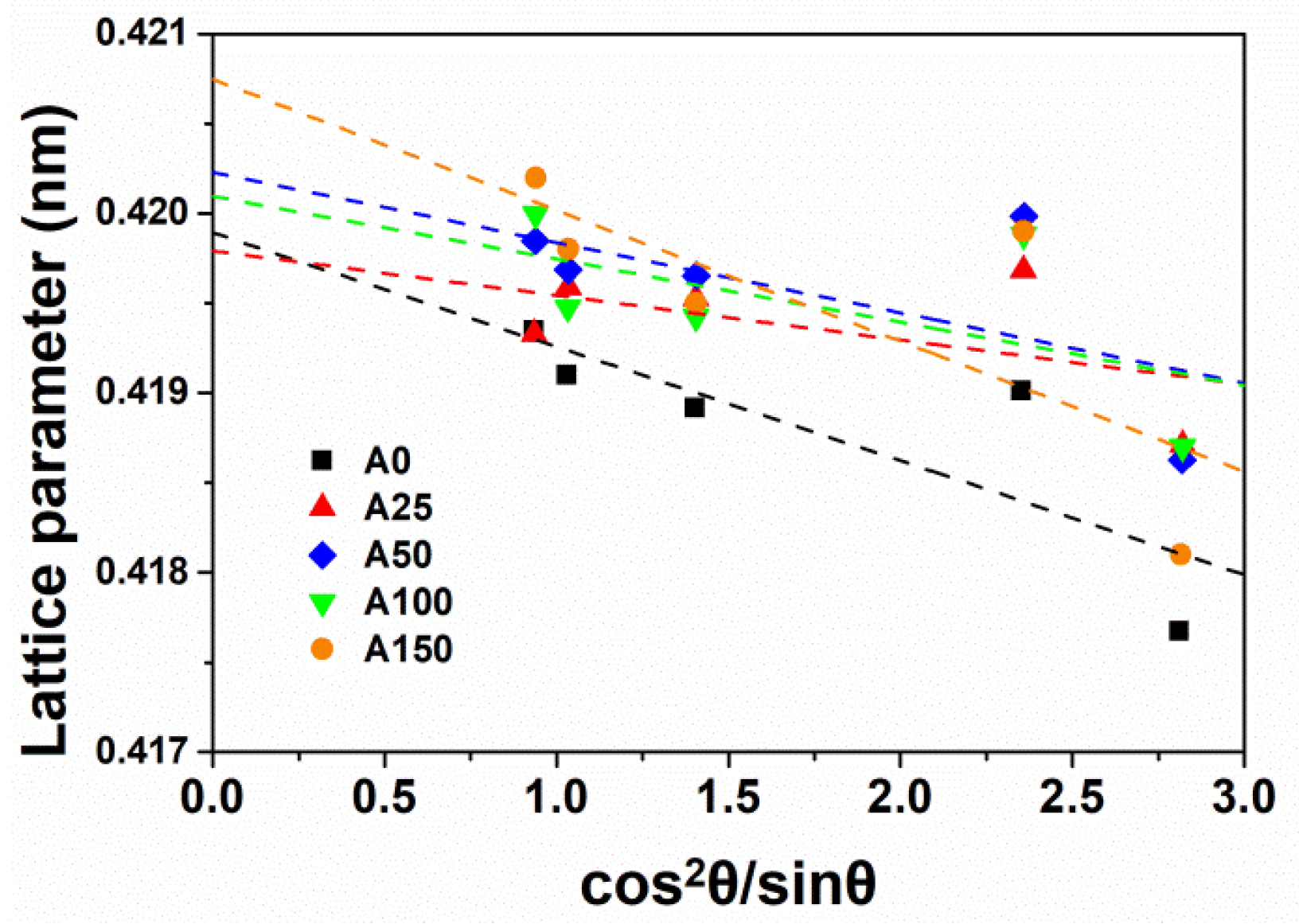

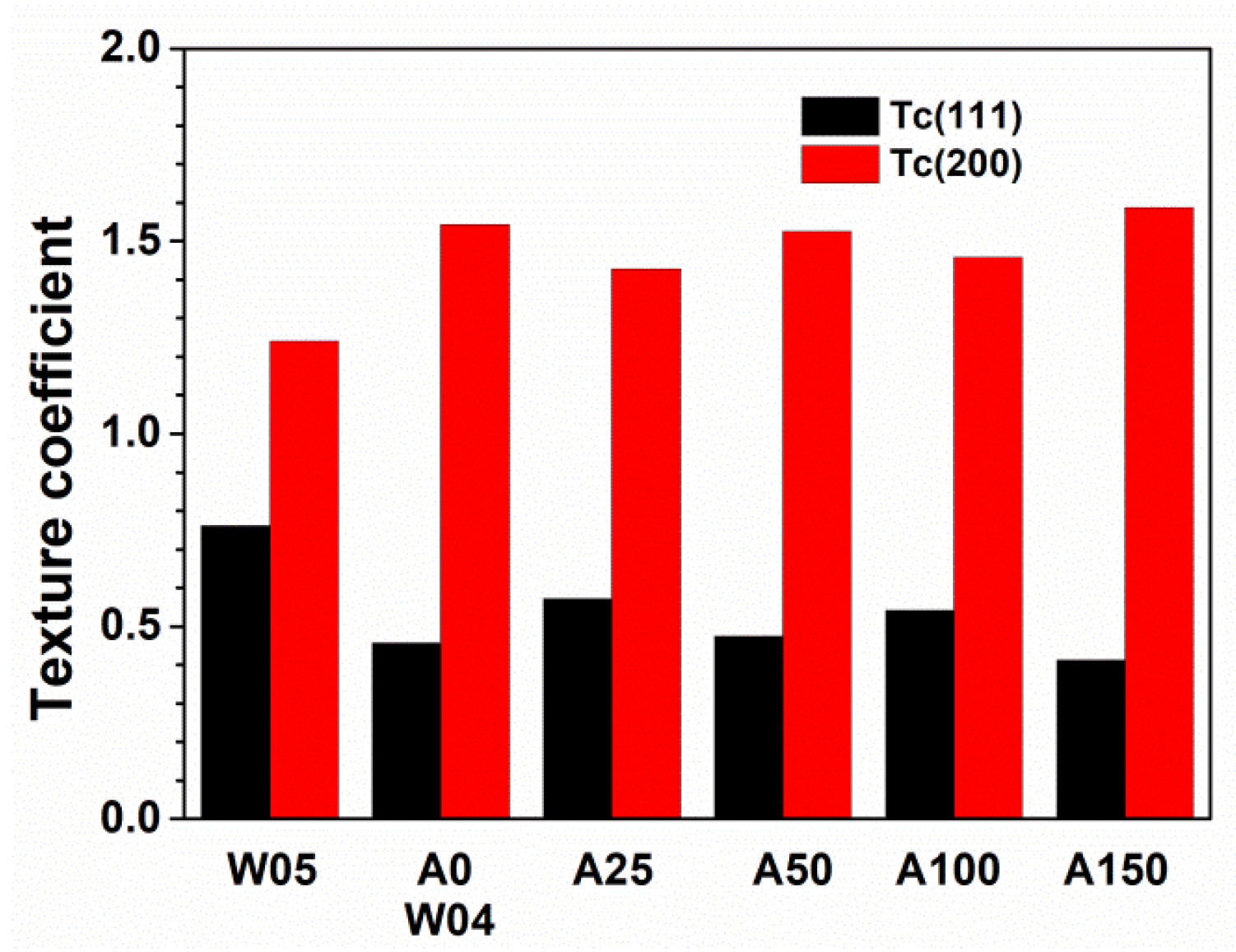

3.2. W–N Films Prepared with Various Bias Voltages

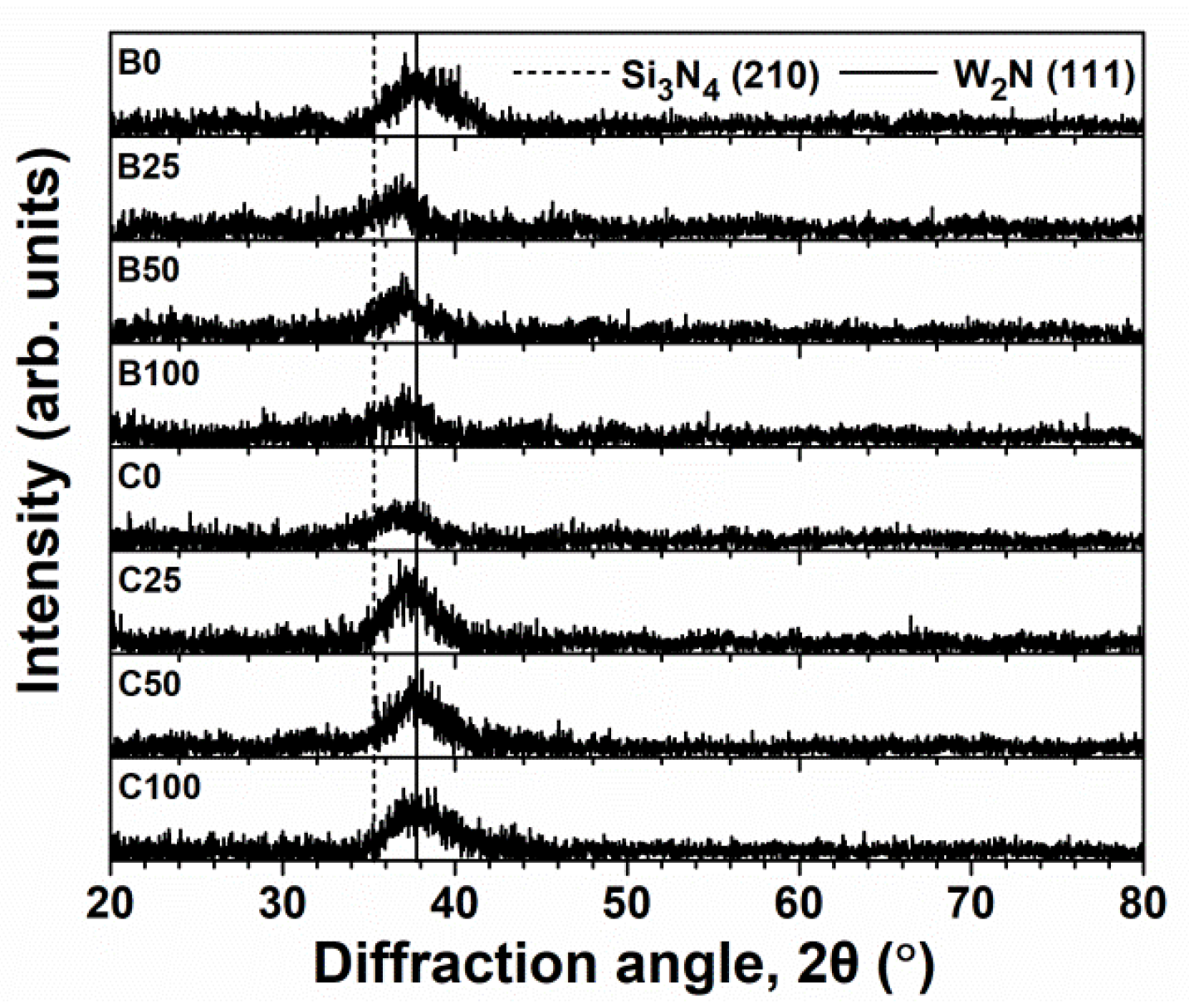

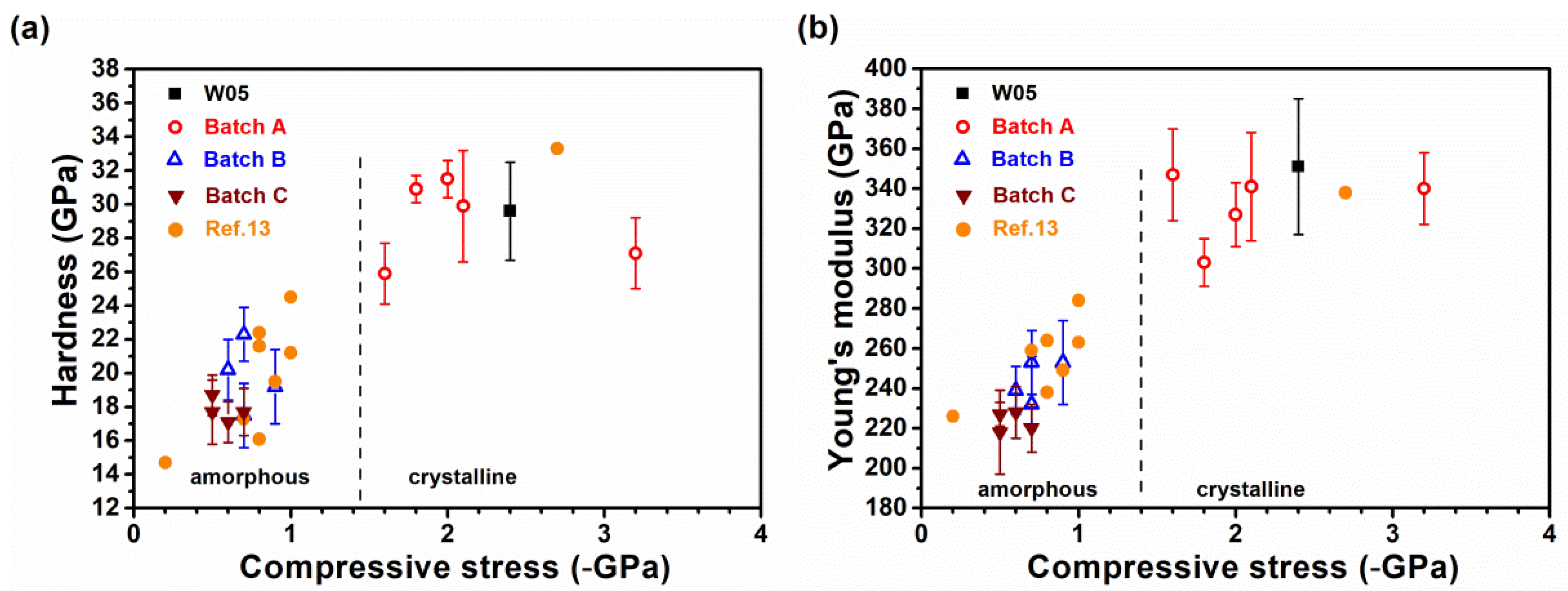

3.3. W–Si–N Films Prepared with Various Bias Voltages

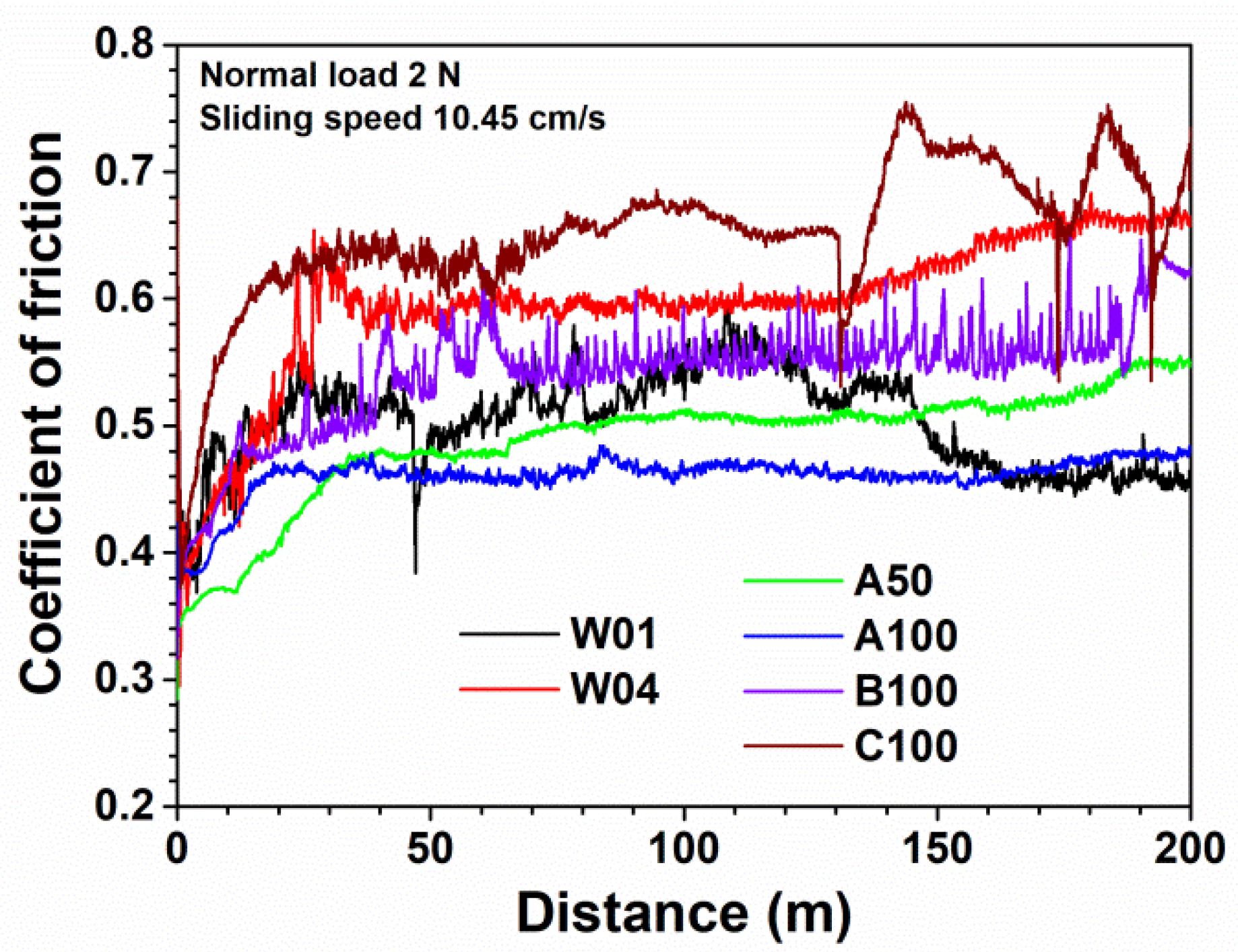

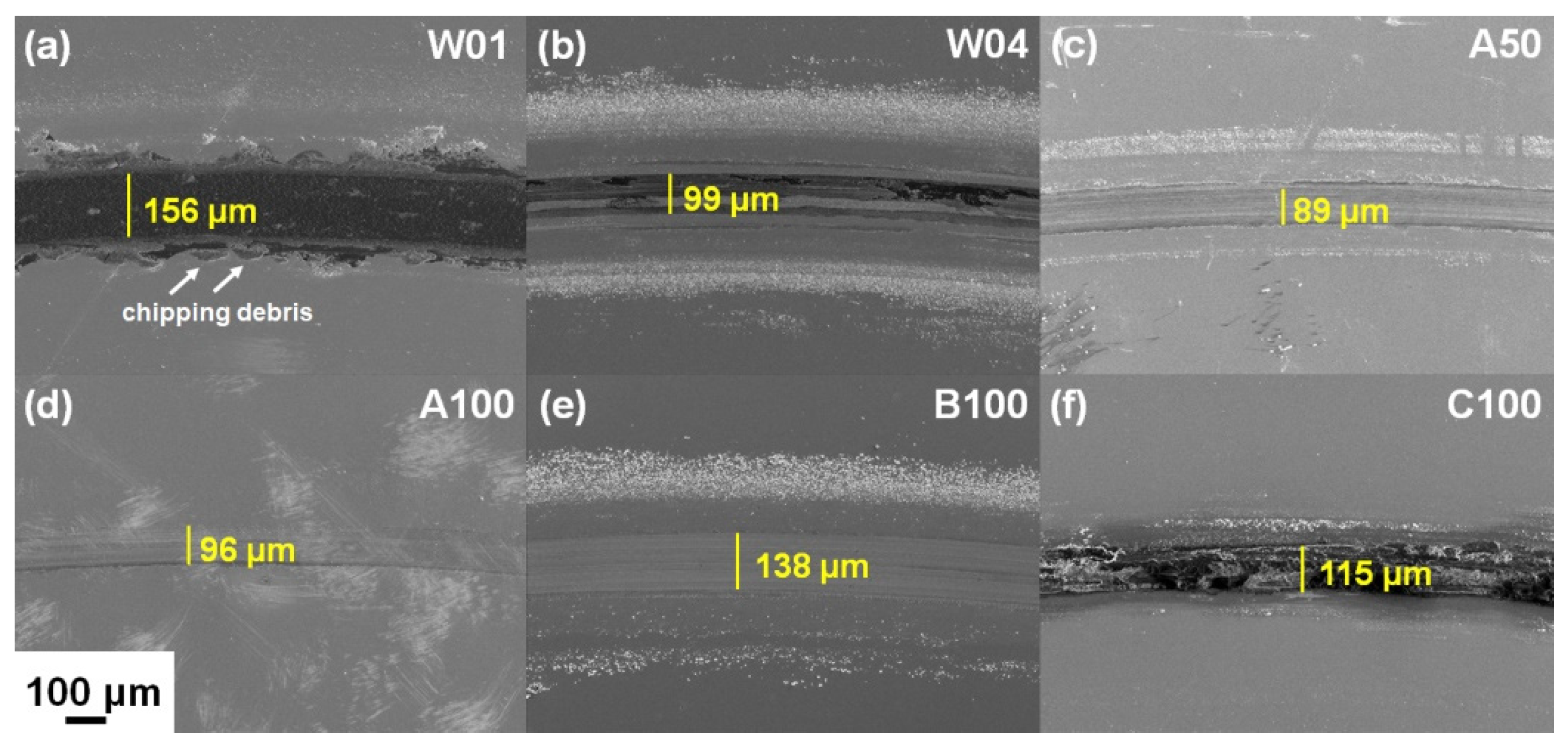

3.4. Wear Test

4. Conclusions

- (1)

- W–N films varied in phase from α-W to amorphous and β-W2N as f increased from 0.1 to 0.5, accompanied by increases in the compressive residual stress, H/E ratio, H3/E2 ratio, and elastic recovery (We).

- (2)

- W–N films fabricated with an f level of 0.4 and a negative substrate bias voltage of 0–150 V exhibited a β-W2N phase with a texture of (200). Films prepared with bias voltages in the range of −25 to −100 V exhibited high H levels of 29.9–31.5 GPa, low E levels of 303–341 GPa, high H/E ratios of 0.088–0.102, high H3/E2 ratios of 0.230–0.321 GPa, and high We values of 66%–67%.

- (3)

- The W–Si–N films with an Si concentration of 13.5–16.5 at.% displayed an amorphous structure. These films, prepared with negative substrate bias voltages of 0–100 V, exhibited limited deviation in residual stress (−0.6 to −0.9 GPa), with low H (17.5–22.3 GPa) and low E (232–253 GPa). Similar results were observed for the amorphous W–Si–N films with a Si concentration of 27.0–30.9 at.%, which behaved similarly to amorphous SiNx films in terms of residual stress (−0.5 to −0.7 GPa), H (17.1–18.7 GPa), and E (218–228 GPa). All of these mechanical properties were the lowest levels in this study.

- (4)

- The wear resistance of the W–N and W–Si–N films was examined using the pin-on-disk test method. The results indicated that the W–N films fabricated with an f level of 0.4 and negative substrate bias voltages of 50–100 V exhibited low wear rates of 7.5–10 × 10−7 mm3/Nm and low COFs of 0.46–0.49, with high H3/E2 ratios of 0.230–0.321 GPa.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Castanho, J.; Cavaleiro, A.; Vieira, M.T. Study of tungsten sputtered films with low nitrogen content. Vacuum 1994, 45, 1051–1053. [Google Scholar] [CrossRef]

- Hones, P.; Martin, N.; Regula, M.; Lévy, F. Structural and mechanical properties of chromium nitride, molybdenum nitride, and tungsten nitride thin films. J. Phys. D Appl. Phys. 2003, 36, 1023–1029. [Google Scholar] [CrossRef]

- Polcar, T.; Parreira, N.M.G.; Cavaleiro, A. Structural and tribological characterization of tungsten nitride coatings at elevated temperature. Wear 2008, 265, 319–326. [Google Scholar] [CrossRef]

- Samano, E.C.; Clemente, A.; Díaz, J.A.; Soto, G. Mechanical properties optimization of tungsten nitride thin films grown by reactive sputtering and laser ablation. Vacuum 2010, 85, 69–77. [Google Scholar] [CrossRef]

- Wen, M.; Meng, Q.N.; Yu, W.X.; Zheng, W.T.; Mao, S.X.; Hua, M.J. Growth, stress and hardness of reactively sputtered tungsten nitride thin films. Surf. Coat. Technol. 2010, 205, 1953–1961. [Google Scholar] [CrossRef]

- Chang, C.L.; Chiou, T.H.; Chen, P.H.; Chen, W.C.; Ho, C.T.; Wu, W.Y. Characteristics of TiN/W2N multilayers prepared using magnetron sputter deposition with dc and pulsed dc powers. Surf. Coat. Technol. 2016, 303, 25–31. [Google Scholar] [CrossRef]

- Lou, B.S.; Moirangthem, I.; Lee, J.W. Fabrication of tungsten nitride thin films by superimposed HiPIMS and MF system: Effects of nitrogen flow rate. Surf. Coat. Technol. 2020, 393, 125743. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. Structure, mechanical properties and tribology of W–N and W–O coatings. Int. J. Refract. Met. Hard Mat. 2010, 28, 15–22. [Google Scholar] [CrossRef]

- Jiang, P.C.; Chen, J.S.; Lin, Y.K. Structural and electrical characteristics of W–N thin films prepared by reactive rf sputtering. J. Vac. Sci. Technol. A 2003, 21, 616–622. [Google Scholar] [CrossRef]

- Baker, C.C.; Shah, S.I. Reactive sputter deposition of tungsten nitride thin films. J. Vac. Sci. Technol. A 2002, 20, 1699–1703. [Google Scholar] [CrossRef]

- Wicher, B.; Chodun, R.; Nowakowska-Langier, K.; Trzcinski, M.; Skowroński, L.; Okrasa, S.; Minikayev, R.; Naparty, M.K.; Zdunek, K. Chemical and structural characterization of tungsten nitride (WNx) thin films synthesized via gas injection magnetron sputtering technique. Vacuum 2019, 165, 266–273. [Google Scholar] [CrossRef]

- Yamamoto, T.; Kawate, M.; Hasegawa, H.; Suzuki, T. Effects of nitrogen concentration on microstructures of WNX films synthesized by cathodic arc method. Surf. Coat. Technol. 2005, 193, 372–374. [Google Scholar] [CrossRef]

- Liu, Y.H.; Chang, L.C.; Liu, B.W.; Chen, Y.I. Mechanical properties and oxidation behavior of W–Si–N coatings. Surf. Coat. Technol. 2019, 375, 727–738. [Google Scholar] [CrossRef]

- Javdošňák, D.; Musil, J.; Soukup, Z.; Haviar, S.; Čerstvý, R.; Houska, J. Tribological properties and oxidation resistance of tungsten and tungsten nitride films at temperatures up to 500 °C. Tribol. Int. 2019, 132, 211–220. [Google Scholar] [CrossRef]

- Bielawski, M. Residual stress control in TiN/Si coatings deposited by unbalanced magnetron sputtering. Surf. Coat. Technol. 2006, 200, 3987–3995. [Google Scholar] [CrossRef]

- Tan, S.; Zhang, X.; Wu, X.; Fang, F.; Jiang, J. Effect of substrate bias and temperature on magnetron sputtered CrSiN films. Appl. Surf. Sci. 2011, 257, 1850–1853. [Google Scholar] [CrossRef]

- Guruvenket, S.; Rao, G.M. Bias induced structural changes in tungsten nitride films deposited by unbalanced magnetron sputtering. Mater. Sci. Eng. B 2004, 106, 172–176. [Google Scholar] [CrossRef]

- Louro, C.; Cavaleiro, A. Mechanical behaviour of amorphous W–Si–N sputtered films after thermal annealing at increasing temperatures. Surf. Coat. Technol. 2000, 123, 192–198. [Google Scholar] [CrossRef]

- Fu, T.; Zhou, Z.F.; Li, K.Y.; Shen, Y.G. Characterization of sputter deposited W–Si–N coatings based on α-W structure. Mater. Lett. 2005, 59, 618–623. [Google Scholar] [CrossRef]

- Musil, J.; Daniel, R.; Soldan, J.; Zeman, P. Properties of reactively sputtered W–Si–N films. Surf. Coat. Technol. 2006, 200, 3886–3895. [Google Scholar] [CrossRef]

- Ju, H.; He, S.; Yu, L.; Asempah, I.; Xu, J. The improvement of oxidation resistance, mechanical and tribological properties of W2N films by doping silicon. Surf. Coat. Technol. 2017, 317, 158–165. [Google Scholar] [CrossRef]

- Anwar, S.; Islam, A.; Anwar, S. Mechanical studies of thermally annealed nc-W2N embedded a-Si3N4 nanocomposite films. Thin Solid Film. 2017, 636, 93–98. [Google Scholar] [CrossRef]

- Zhao, H.; Ye, F. Effect of Si-incorporation on the structure, mechanical, tribological and corrosion properties of WSiN coatings. Appl. Surf. Sci. 2015, 256, 958–966. [Google Scholar] [CrossRef]

- Hong, T.E.; Jung, J.H.; Yeo, S.; Cheon, T.; Bae, S.I.; Kim, S.H.; Yeo, S.J.; Kim, H.S.; Chung, T.M.; Park, B.K.; et al. Highly conformal amorphous W−Si−N thin films by plasma-enhanced atomic layer deposition as a diffusion barrier for Cu metallization. J. Phys. Chem. C 2015, 119, 1548–1556. [Google Scholar] [CrossRef]

- Sandu, C.S.; Sanjinés, R.; Benkahoul, M.; Medjani, F.; Lévy, F. Formation of composite ternary nitride thin films by magnetron sputtering co-deposition. Surf. Coat. Technol. 2006, 201, 4083–4089. [Google Scholar] [CrossRef]

- Sundgren, J.-E.; Johansson, B.-O.; Hentzell, H.T.G.; Karlsson, S.-E. Mechanisms of reactive sputtering of titanium nitride and titanium carbide III: Influence of substrate bias on composition and structure. Thin Solid Film. 1983, 105, 385–393. [Google Scholar] [CrossRef]

- Petrov, I.; Hultman, L.; Helmersson, U.; Sundgren, J.-E.; Greene, J.E. Microstructure modification of TiN by ion bombardment during reactive sputter deposition. Thin Solid Film. 1989, 169, 299–314. [Google Scholar] [CrossRef]

- Lee, H.C.; Lee, J.Y.; Ahn, H.J. Effect of the substrate bias voltage on the crystallographic orientation of reactively sputtered AlN thin films. Thin Solid Film. 1994, 251, 136–140. [Google Scholar] [CrossRef]

- Yang, Z.T.; Yang, B.; Guo, L.P.; Fu, D.J. Effect of bias voltage on the structure and hardness of Ti–Si–N composite coatings synthesized by cathodic arc assisted middle-frequency magnetron sputtering. J. Alloy. Compd. 2009, 473, 437–441. [Google Scholar] [CrossRef]

- Chen, Y.I.; Zheng, Y.Z.; Chang, L.C.; Liu, Y.H. Effect of bias voltage on mechanical properties of HiPIMS/RFMS cosputtered Zr–Si–N films. Materials 2019, 12, 2658. [Google Scholar] [CrossRef] [Green Version]

- Cullity, B.D.; Stock, S.R. Elements of X-ray Diffraction, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Jones, M.I.; McColl, I.R.; Grant, D.M. Effect of substrate preparation and deposition conditions on the preferred orientation of TiN coatings deposited by RF reactive sputtering. Surf. Coat. Technol. 2000, 132, 143–151. [Google Scholar] [CrossRef]

- Saha, R.; Nix, W.D. Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater. 2002, 50, 23–38. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Janssen, G.C.A.M.; Abdalla, M.M.; van Keulen, F.; Pujada, B.R.; van Venrooy, B. Celebrating the 100th anniversary of the Stoney equation for film stress: Developments from polycrystalline steel strips to single crystal silicon wafers. Thin Solid Film. 2009, 517, 1858–1867. [Google Scholar] [CrossRef]

- Chen, Y.I.; Ke, Y.E.; Sung, M.C.; Chang, L.C. Rapid thermal annealing of Cr–Si–N, Ta–Si–N, and Zr–Si–N coatings in glass molding atmospheres. Surf. Coat. Technol. 2020, 389, 125662. [Google Scholar] [CrossRef]

- Shen, Y.G.; Mai, Y.W.; McBride, W.E.; Zhang, Q.C.; McKenzie, D.R. Structural properties and nitrogen-loss characteristics in sputtered tungsten nitride films. Thin Solid Film. 2000, 372, 257–264. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Beresnev, V.M.; Bondar, O.V.; Postolnyi, B.O.; Zaleski, K.; Coy, E.; Jurga, S.; Lisovenko, M.O.; Konarski, P.; Rebouta, L.; et al. Superhard CrN/MoN coatings with multilayer architecture. Mater. Des. 2018, 153, 47–59. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Bhatia, C.S.; White, R.L.; Anders, S.; Anders, A.; Brown, I.G. Nanoindentation and nanoscratching of hard carbon coatings for magnetic disks. Mater. Res. Soc. Symp. Proc. 1995, 383, 447–452. [Google Scholar] [CrossRef] [Green Version]

- Musil, J.; Kunc, F.; Zeman, H.; Poláková, H. Relationships between hardness, Young′s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technol. 2002, 154, 304–313. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behavior. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Qasmi, M.; Delobelle, P. Influence of the average roughness Rms on the precision of the Young’s modulus and hardness determination using nanoindentation technique with a Berkovich indenter. Surf. Coat. Technol. 2007, 201, 1191–1199. [Google Scholar] [CrossRef]

- Walter, C.; Antretter, T.; Daniel, R.; Mitterer, C. Finite element simulation of the effect of surface roughness on nanoindentation of thin films with spherical indenters. Surf. Coat. Technol. 2007, 202, 1103–1107. [Google Scholar] [CrossRef]

- Walter, C.; Mitterer, C. 3D versus 2D finite element simulation of the effect of surface roughness on nanoindentation of hard coatings. Surf. Coat. Technol. 2009, 203, 3286–3290. [Google Scholar] [CrossRef]

- Qi, Z.B.; Sun, P.; Zhu, F.P.; Wang, Z.C.; Peng, D.L.; Wu, C.H. The inverse hall–petch effect in nanocrystalline ZrN coatings. Surf. Coat. Technol. 2011, 205, 3692–3697. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Tischler, G.; Mitterer, C. Microstructure and mechanical/thermal properties of Cr–N coatings deposited by reactive unbalanced magnetron sputtering. Surf. Coat. Technol. 2001, 142–144, 78–84. [Google Scholar] [CrossRef]

- Chen, Y.H.; Guruz, M.; Chung, Y.W.; Keer, L.M. Thermal stability of hard TiN/SiNx multilayer coatings with an equiaxed microstructure. Surf. Coat. Technol. 2002, 154, 162–166. [Google Scholar] [CrossRef]

- Abadias, G.; Uglov, V.V.; Saladukhin, I.A.; Zlotski, S.V.; Tolmachova, G.; Dub, S.N.; Janse van Vuuren, A. Growth, structural and mechanical properties of magnetron-sputtered ZrN/SiNx nanolaminated coatings. Surf. Coat. Technol. 2016, 308, 158–167. [Google Scholar] [CrossRef]

- Liu, K.Y.; Lee, J.W.; Wu, F.B. Fabrication and tribological behavior of sputtering TaN coatings. Surf. Coat. Technol. 2014, 259, 123–128. [Google Scholar] [CrossRef]

| Sample | fa | Bias | Atomic Composition (at.%) | Ratio | Tb | Dc | Stress | |||

|---|---|---|---|---|---|---|---|---|---|---|

| (−V) | W | Si | N | O | N/W | (nm) | (nm/min) | (GPa) | ||

| W01 | 0.1 | 0 | 93.6 ± 0.8 | 0.7 ± 0.1 | 4.7 ± 0.2 | 1.0 ± 0.8 | 0.05 | 675 | 8.4 | 0.0 ± 0.2 |

| W02 | 0.2 | 0 | 85.9 ± 1.4 | 1.9 ± 2.3 | 8.3 ± 2.2 | 3.9 ± 1.5 | 0.10 | 618 | 7.7 | −0.7 ± 0.2 |

| W03 | 0.3 | 0 | 80.5 ± 3.1 | 1.7 ± 2.1 | 12.4 ± 2.8 | 5.4 ± 0.9 | 0.15 | 568 | 7.1 | −1.4 ± 0.2 |

| W04(A0) | 0.4 | 0 | 75.4 ± 0.7 | 0.5 ± 0.0 | 22.5 ± 0.6 | 1.6 ± 0.4 | 0.30 | 582 | 7.3 | −1.6 ± 0.2 |

| W05 | 0.5 | 0 | 72.8 ± 3.8 | 1.7 ± 2.0 | 25.3 ± 4.3 | 0.2 ± 0.4 | 0.35 | 511 | 6.4 | −2.4 ± 0.2 |

| A25 | 0.4 | 25 | 72.8 ± 0.5 | 0.9 ± 0.1 | 25.5 ± 0.8 | 0.8 ± 0.3 | 0.35 | 610 | 7.6 | −2.0 ± 0.2 |

| A50 | 0.4 | 50 | 74.1 ± 0.0 | 0.7 ± 0.0 | 23.6 ± 0.4 | 1.6 ± 0.3 | 0.32 | 562 | 7.0 | −1.8 ± 0.3 |

| A100 | 0.4 | 100 | 70.5 ± 2.4 | 2.0 ± 2.1 | 26.9 ± 0.9 | 0.6 ± 0.1 | 0.38 | 544 | 6.8 | −2.1 ± 0.1 |

| A150 | 0.4 | 150 | 66.3 ± 0.3 | 3.9 ± 0.2 | 29.1 ± 0.6 | 0.7 ± 0.6 | 0.44 | 521 | 6.5 | −3.2 ± 0.8 |

| Sample | W 4f7/2 (eV) | W 4f7/2 (eV) | W 5p3/2 (eV) | N 1s (eV) | Intensity Ratio |

|---|---|---|---|---|---|

| W–W | W–N | N–W | W–W:W–N | ||

| W01 | 31.13 ± 0.01 | 32.25 ± 0.04 | 36.52 ± 0.04 | 397.58 ± 0.16 | 84:16 |

| W02 | 31.37 ± 0.01 | 32.03 ± 0.07 | 36.62 ± 0.03 | 397.70 ± 0.05 | 75:25 |

| W03 | 31.34 ± 0.04 | 32.05 ± 0.09 | 36.64 ± 0.06 | 397.63 ± 0.03 | 74:26 |

| W04(A0) | 31.13 ± 0.01 | 31.91 ± 0.08 | 36.51 ± 0.04 | 397.52 ± 0.02 | 72:28 |

| W05 | 31.20 ± 0.01 | 32.04 ± 0.01 | 36.60 ± 0.02 | 397.56 ± 0.03 | 70:30 |

| A25 | 31.45 ± 0.00 | 32.44 ± 0.01 | 36.90 ± 0.03 | 397.72 ± 0.04 | 80:20 |

| A50 | 31.33 ± 0.01 | 32.62 ± 0.02 | 36.85 ± 0.01 | 397.57 ± 0.02 | 89:11 |

| A100 | 31.12 ± 0.01 | 32.52 ± 0.03 | 36.66 ± 0.01 | 397.39 ± 0.05 | 88:12 |

| A150 | 31.08 ± 0.01 | 32.02 ± 0.03 | 36.54 ± 0.02 | 397.40 ± 0.04 | 76:24 |

| Sample | Stress | Ha | Eb | H/E | H3/E2 | We c | Rad |

|---|---|---|---|---|---|---|---|

| (GPa) | (GPa) | (GPa) | (GPa) | (%) | (nm) | ||

| W01 | 0.0 ± 0.2 | 22.4 ± 3.6 | 335 ± 41 | 0.067 | 0.100 | 53 | 4.25 ± 0.06 |

| W02 | −0.7 ± 0.2 | 26.2 ± 1.8 | 388 ± 32 | 0.068 | 0.119 | 56 | 13.23 ± 0.24 |

| W03 | −1.4 ± 0.2 | 22.1 ± 0.9 | 308 ± 14 | 0.072 | 0.114 | 60 | 3.09 ± 0.04 |

| W04(A0) | −1.6 ± 0.2 | 25.9 ± 1.8 | 347 ± 23 | 0.075 | 0.144 | 60 | 3.42 ± 0.07 |

| W05 | −2.4 ± 0.2 | 29.6 ± 2.9 | 351 ± 34 | 0.084 | 0.211 | 63 | 4.54 ± 0.13 |

| A25 | −2.0 ± 0.2 | 31.5 ± 1.1 | 327 ± 16 | 0.096 | 0.292 | 67 | 3.10 ± 0.11 |

| A50 | −1.8 ± 0.3 | 30.9 ± 0.8 | 303 ± 12 | 0.102 | 0.321 | 66 | 4.93 ± 0.09 |

| A100 | −2.1 ± 0.1 | 29.9 ± 3.3 | 341 ± 27 | 0.088 | 0.230 | 67 | 4.12 ± 0.05 |

| A150 | −3.2 ± 0.8 | 27.1 ± 2.1 | 340 ± 18 | 0.080 | 0.172 | 61 | 3.95 ± 0.07 |

| Sample | Bias | Atomic Composition (at.%) | Ta | Db | Stress | |||

|---|---|---|---|---|---|---|---|---|

| (−V) | W | Si | N | O | (nm) | (nm/min) | (GPa) | |

| PWc = 150 W, PSi d = 150 W | ||||||||

| B0 | 0 | 46.9 ± 0.7 | 16.5 ± 0.1 | 34.0 ± 0.7 | 2.6 ± 0.1 | 646 | 10.8 | −0.9 ± 0.2 |

| B25 | 25 | 46.7 ± 0.9 | 14.9 ± 0.2 | 37.4 ± 1.0 | 1.0 ± 0.2 | 608 | 10.1 | −0.7 ± 0.2 |

| B50 | 50 | 39.9 ± 0.5 | 13.5 ± 0.1 | 46.0 ± 0.5 | 0.6 ± 0.2 | 712 | 11.9 | −0.6 ± 0.2 |

| B100 | 100 | 47.1 ± 0.1 | 15.3 ± 0.2 | 35.8 ± 0.2 | 1.8 ± 0.2 | 634 | 10.6 | −0.7 ± 0.2 |

| PW = 60 W, PSi = 150 W | ||||||||

| C0 | 0 | 25.9 ± 0.4 | 27.0 ± 0.0 | 45.5 ± 0.5 | 1.6 ± 0.6 | 549 | 7.3 | −0.6 ± 0.1 |

| C25 | 25 | 22.0 ± 0.3 | 30.0 ± 0.1 | 47.7 ± 0.2 | 0.3 ± 0.2 | 542 | 7.2 | −0.5 ± 0.2 |

| C50 | 50 | 24.8 ± 0.3 | 28.5 ± 0.2 | 46.3 ± 0.4 | 0.4 ± 0.4 | 545 | 7.3 | −0.7 ± 0.1 |

| C100 | 100 | 20.4 ± 0.5 | 30.9 ± 0.2 | 48.3 ± 0.6 | 0.4 ± 0.1 | 574 | 7.7 | −0.5 ± 0.1 |

| Sample | Stress | Ha | Eb | H/E | H3/E2 | We c | Rad |

|---|---|---|---|---|---|---|---|

| (GPa) | (GPa) | (GPa) | (GPa) | (%) | (nm) | ||

| B0 | −0.9 ± 0.2 | 19.2 ± 2.2 | 253 ± 21 | 0.076 | 0.111 | 66 | 3.65 ± 0.01 |

| B25 | −0.7 ± 0.2 | 17.5 ± 1.9 | 232 ± 24 | 0.076 | 0.100 | 60 | 4.00 ± 0.04 |

| B50 | −0.6 ± 0.2 | 20.2 ± 1.8 | 239 ± 12 | 0.084 | 0.144 | 60 | 2.10 ± 0.05 |

| B100 | −0.7 ± 0.2 | 22.3 ± 1.6 | 253 ± 16 | 0.088 | 0.173 | 60 | 2.35 ± 0.07 |

| C0 | −0.6 ± 0.1 | 17.1 ± 1.2 | 228 ± 13 | 0.075 | 0.096 | 64 | 2.37 ± 0.06 |

| C25 | −0.5 ± 0.2 | 18.7 ± 1.2 | 227 ± 6 | 0.083 | 0.127 | 57 | 2.85 ± 0.05 |

| C50 | −0.7 ± 0.1 | 17.7 ± 1.4 | 220 ± 12 | 0.080 | 0.115 | 58 | 2.65 ± 0.02 |

| C100 | −0.5 ± 0.1 | 17.7 ± 1.9 | 218 ± 21 | 0.081 | 0.117 | 59 | 3.06 ± 0.09 |

| Sample | Thickness | Wear Depth a | Width a | μ b | Wear Rate | H3/E2 | Rac |

|---|---|---|---|---|---|---|---|

| (nm) | (nm) | (μm) | (mm3/Nm) | (GPa) | (nm) | ||

| W01 | 675 | 1334 | 156 | 0.52 | 2.4 × 10−5 | 0.100 | 4.25 |

| W04(A0) | 582 | 341 | 99 | 0.60 | 1.8 × 10−6 | 0.144 | 3.42 |

| A50 | 636 | 218 | 89 | 0.49 | 1.0 × 10−6 | 0.321 | 4.93 |

| A100 | 574 | 208 | 96 | 0.46 | 7.5 × 10−7 | 0.230 | 4.12 |

| B100 | 634 | 319 | 138 | 0.55 | 4.9 × 10−6 | 0.173 | 2.35 |

| C100 | 574 | 1404 | 115 | 0.65 | 5.6 × 10−6 | 0.117 | 3.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, L.-C.; Sung, M.-C.; Chu, L.-H.; Chen, Y.-I. Effects of the Nitrogen Flow Ratio and Substrate Bias on the Mechanical Properties of W–N and W–Si–N Films. Coatings 2020, 10, 1252. https://doi.org/10.3390/coatings10121252

Chang L-C, Sung M-C, Chu L-H, Chen Y-I. Effects of the Nitrogen Flow Ratio and Substrate Bias on the Mechanical Properties of W–N and W–Si–N Films. Coatings. 2020; 10(12):1252. https://doi.org/10.3390/coatings10121252

Chicago/Turabian StyleChang, Li-Chun, Ming-Ching Sung, Li-Heng Chu, and Yung-I Chen. 2020. "Effects of the Nitrogen Flow Ratio and Substrate Bias on the Mechanical Properties of W–N and W–Si–N Films" Coatings 10, no. 12: 1252. https://doi.org/10.3390/coatings10121252

APA StyleChang, L.-C., Sung, M.-C., Chu, L.-H., & Chen, Y.-I. (2020). Effects of the Nitrogen Flow Ratio and Substrate Bias on the Mechanical Properties of W–N and W–Si–N Films. Coatings, 10(12), 1252. https://doi.org/10.3390/coatings10121252