Influence of the Long-Term Oven Aging on the Performance of the Reinforced Asphalt Mixtures

Abstract

1. Introduction

2. Materials and Methods

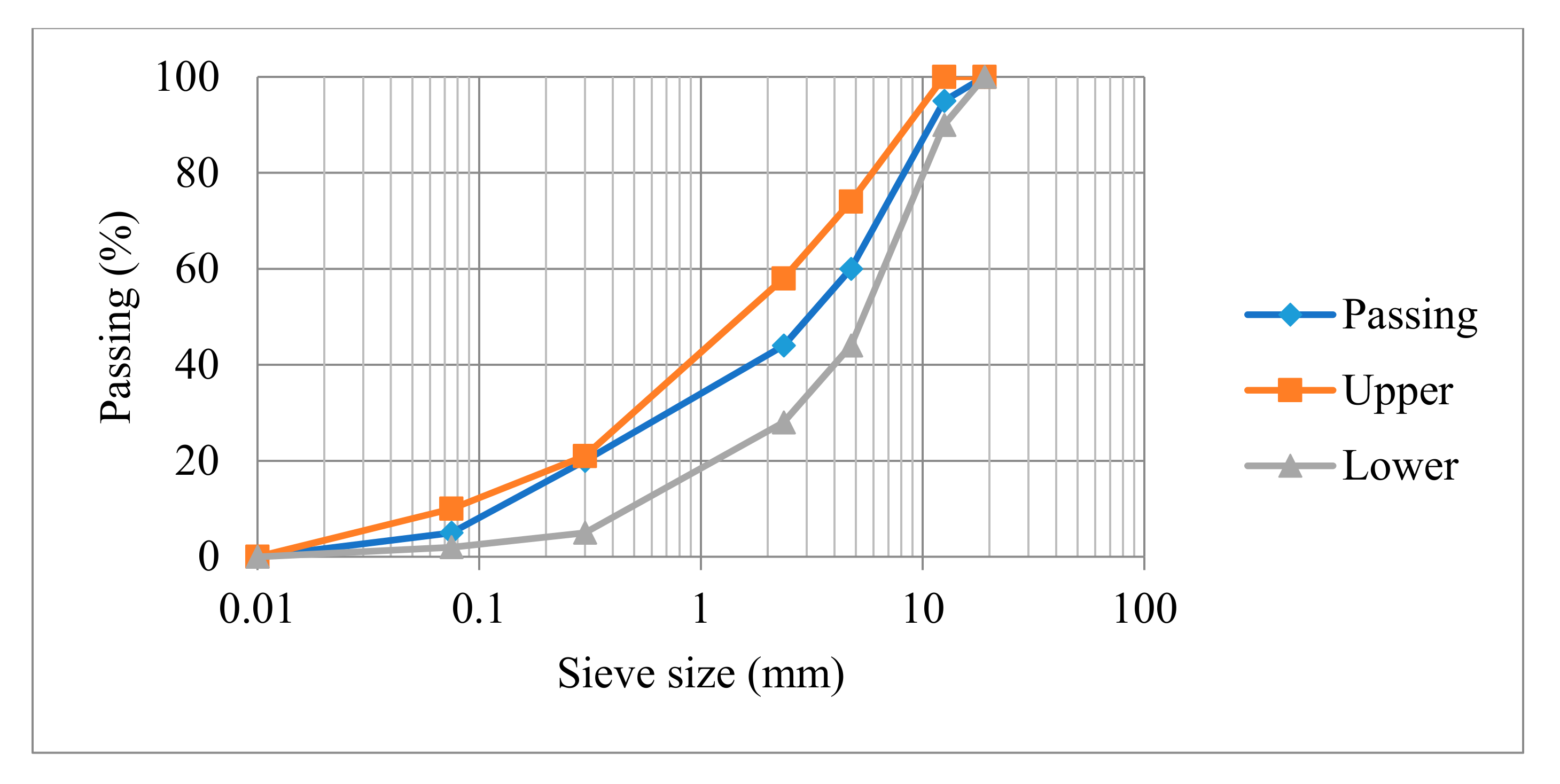

2.1. Materials

2.2. Preparation of the Samples

2.3. Resilinet Modulus Test

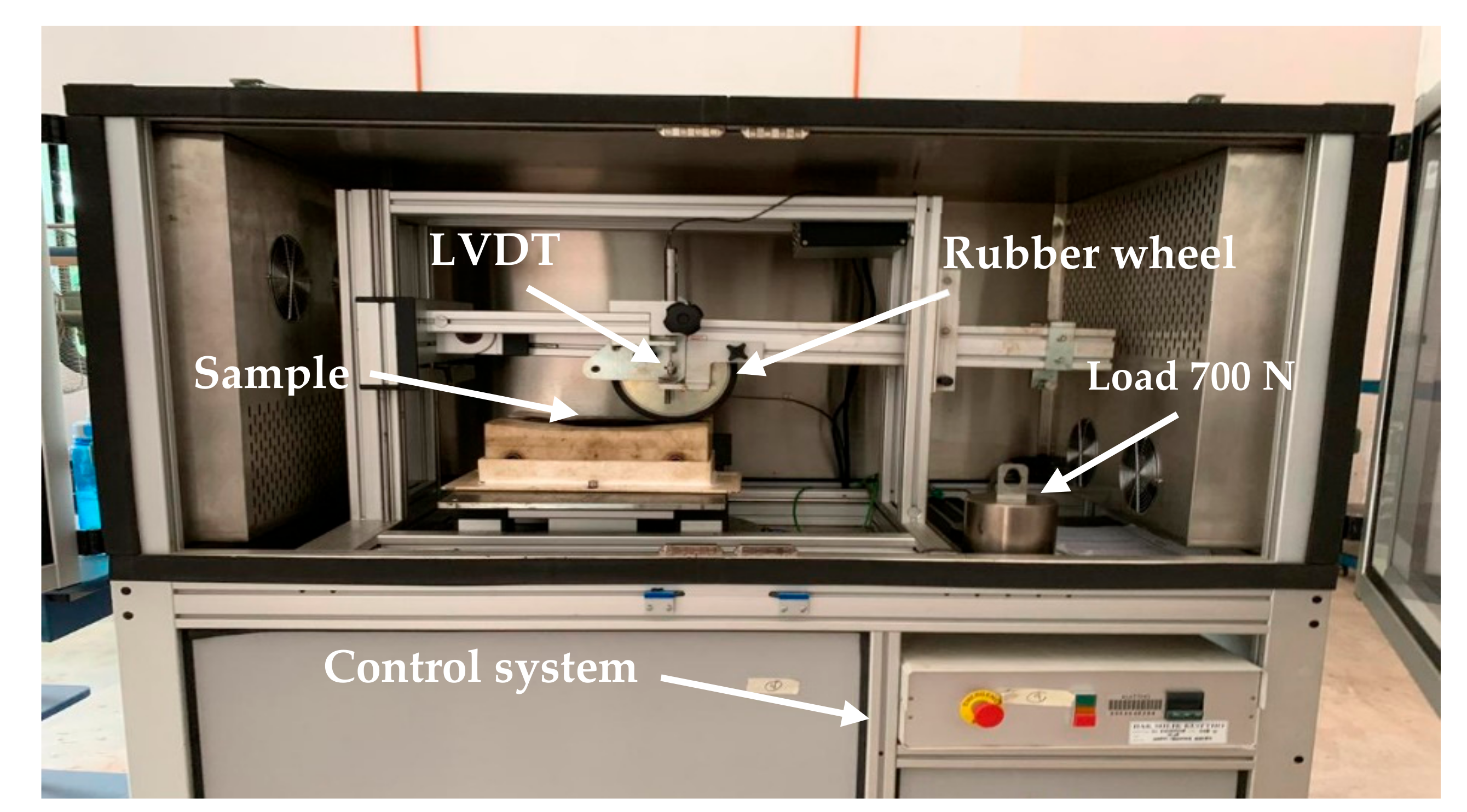

2.4. Wheel Tracking Test

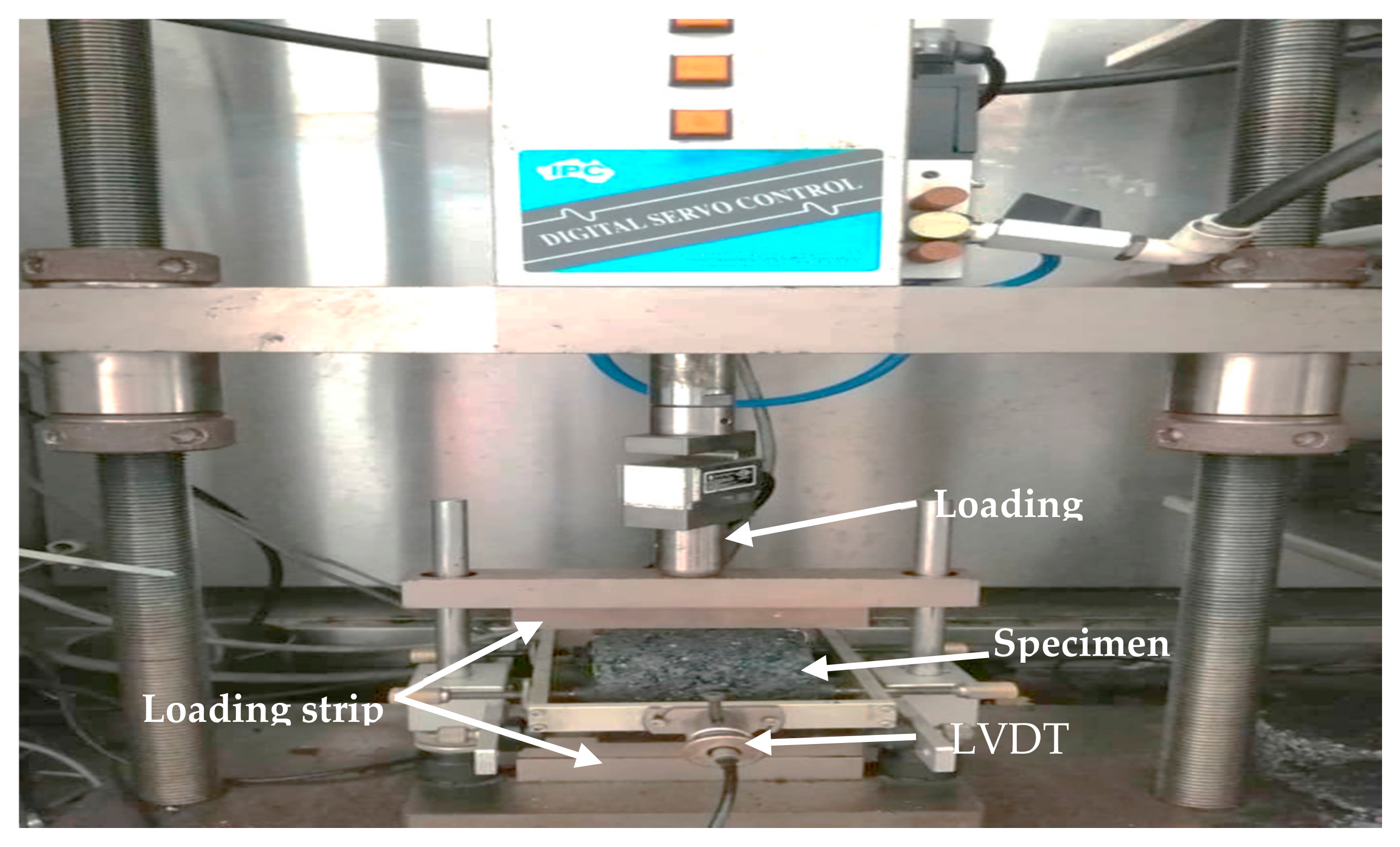

2.5. Cracking Test

3. Results and Discussion

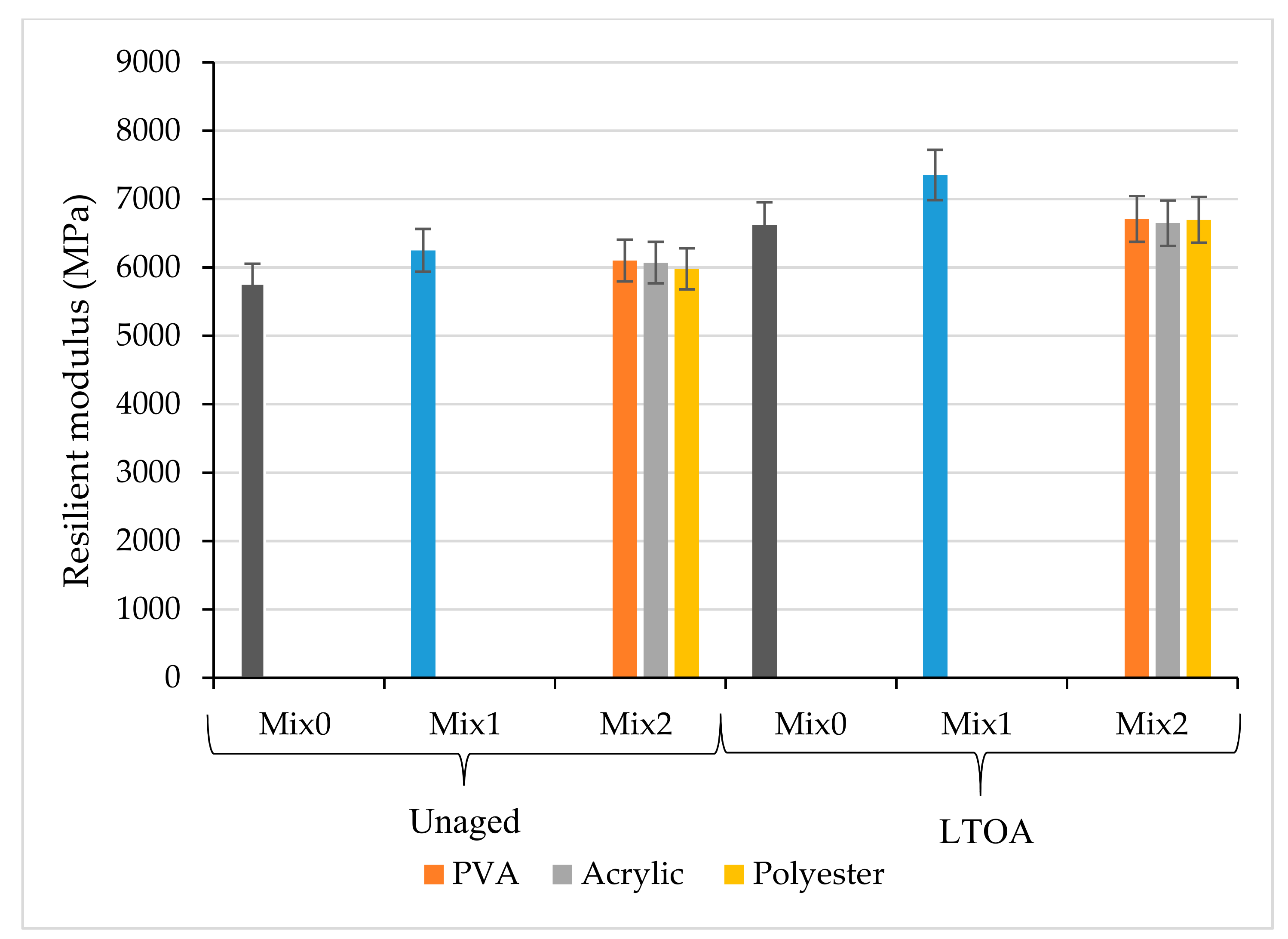

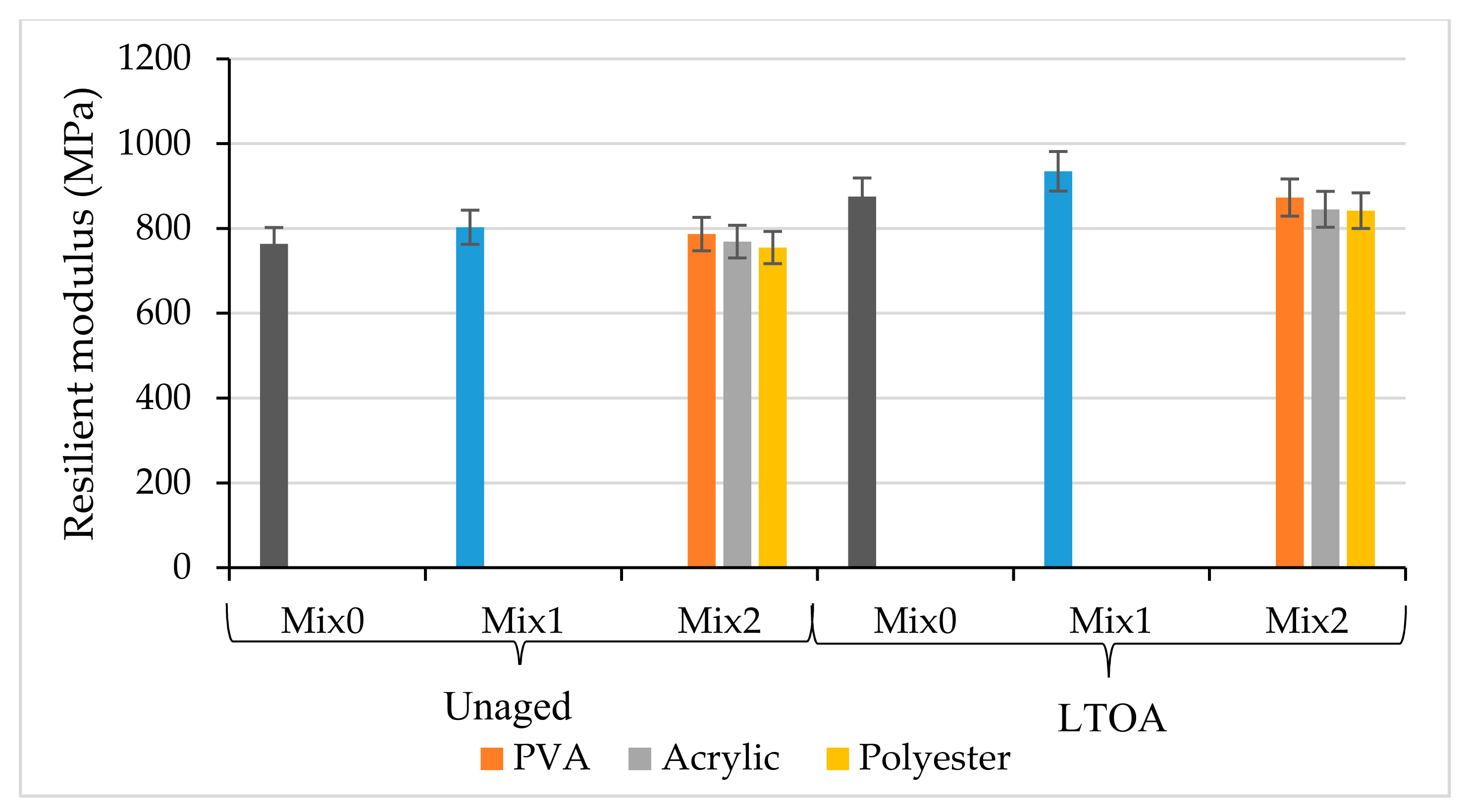

3.1. Resilient Modulus of the Asphalt Mixtures

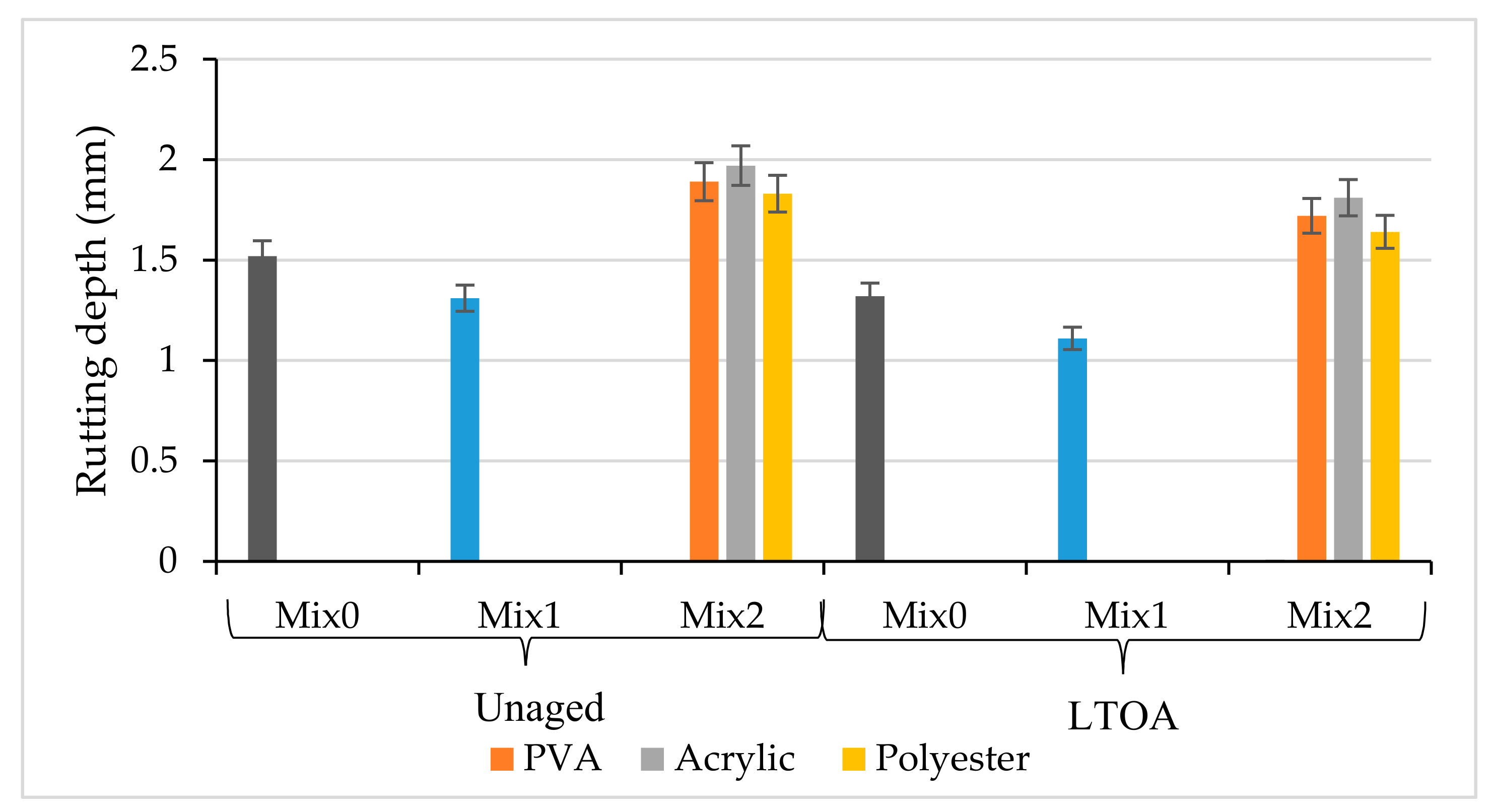

3.2. The Resistance of the Asphalt Mixtures to Permanent Deformation

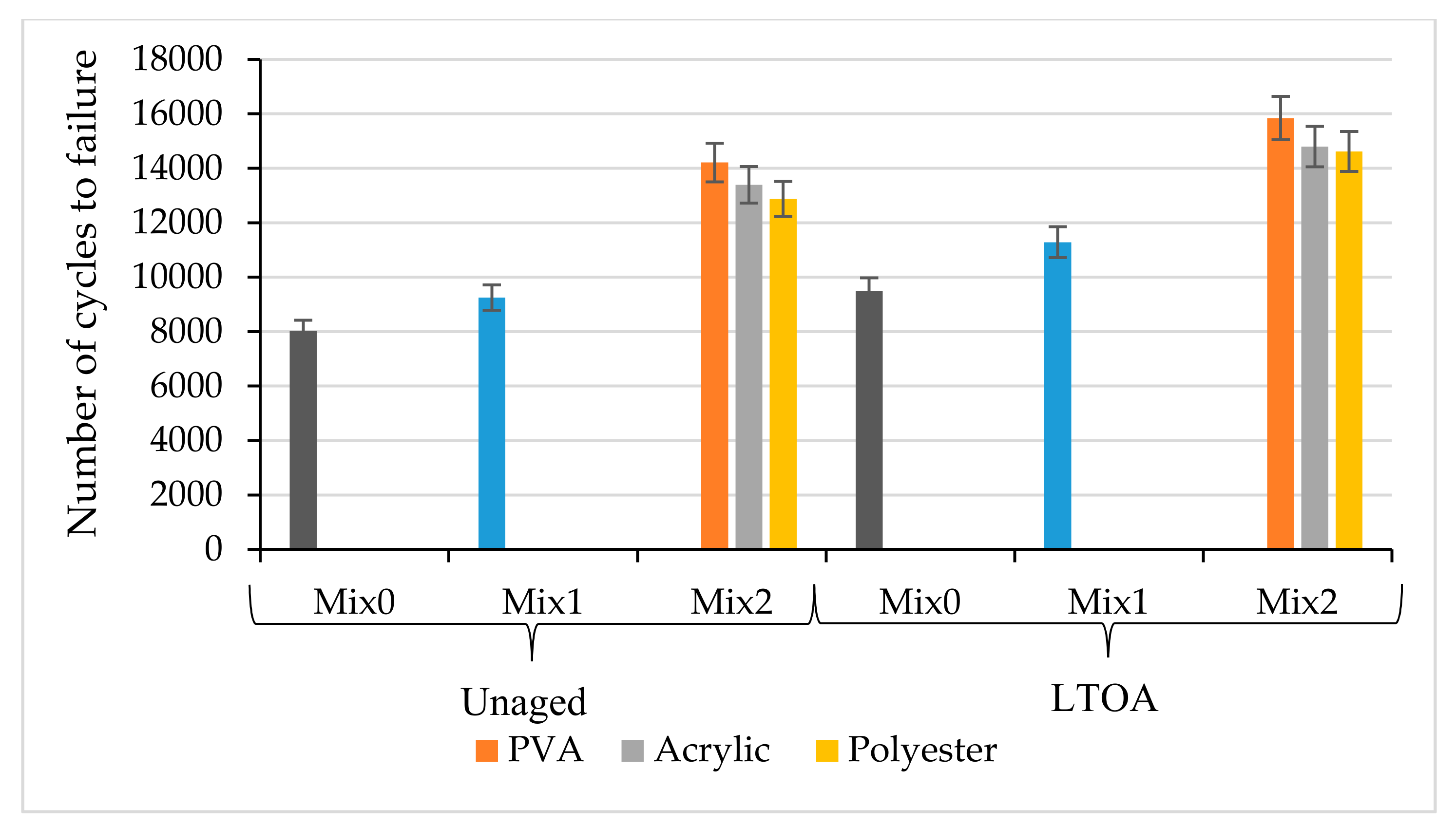

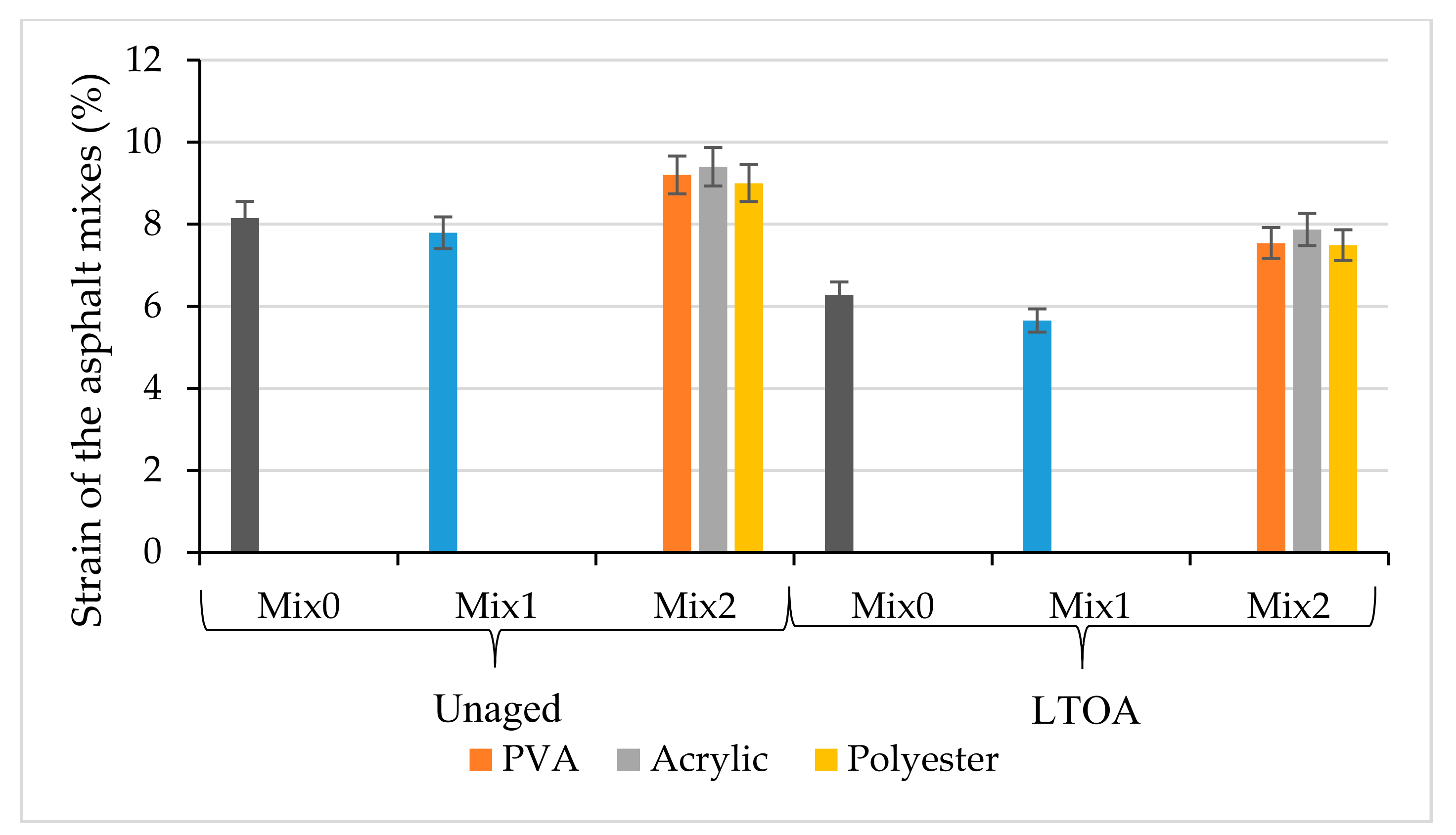

3.3. The Resistance of the Asphalt Mixtures to Cracking

3.4. Aging Index

3.5. Effect of the Voids in the Mineral Aggregate (VMA) of the Asphalt Mixtures on the Aging Index

3.6. The Benefit of Reinforcing the Asphalt Layer with Synthetic Fibers in Terms of Extending the Initial Service Life

4. Conclusions

- The asphalt mixture incorporating coarse steel slag aggregate has shown better performance than the mixture containing granite aggregate, and it also exhibited a higher potential to aging than the mixture containing granite aggregate;

- Reinforcing the asphalt mixtures with synthetic fiber has slightly increased the content of the bitumen in comparison with the unreinforced mixtures. Furthermore, the reinforced asphalt mixtures exhibited lower density and higher VMA than the unreinforced mixtures;

- Regarding the performance of the unaged reinforced asphalt mixtures, adding synthetic fiber to the asphalt mixtures has slightly decreased the resilient modulus at the temperatures of 25 and 40 °C. Additionally, the outputs of the wheel-tracking test showed that the reinforced asphalt mixtures exhibited a higher rut depth than the unreinforced mixtures. On the other hand, the modified asphalt mixtures with fibers exhibited the highest resistance to cracking than the other mixtures;

- The outcomes of the performance tests of the aged asphalt mixtures demonstrated that introducing synthetic fibers to the asphalt mixtures containing coarse steel slag aggregate has decreased the effect of the long-term oven aging (LTOA) on the performance of the asphalt mixtures. The lower susceptibility to aging is highly attributed to the elasticity of the reinforced asphalt mixtures.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Petersen, J.C. A Review of the Fundamentals of Asphalt Oxidation: Chemical, Physicochemical, Physical Property and Durability Relationships, E-C140; Transportation Research Board: Washington, DC, USA, 2009. [Google Scholar]

- Traxler, R.N. Relation between asphalt composition and hardening by volatilization and oxidation. In Proceedings of the Association of Asphalt Paving Technologists-Proceedings of the Technical Sessions, Washington, DC, USA, 1 January 1961. [Google Scholar]

- Petersen, J.C. Chemical Composition of asphalt as related to asphalt durability. In Developments in Petroleum Science; Teh, F.Y., George, V.C., Eds.; Elsevier: Amsterdam, The Netherlands, 2000; Volume 2, pp. 363–399. [Google Scholar]

- Sirin, O.; Paul, D.K.; Kassem, E. State of the art study on aging of asphalt mixtures and use of antioxidant additives. Adv. Civ. Eng. 2018, 2018, 3428961. [Google Scholar] [CrossRef]

- Liu, W.; Li, H.; Zhu, H.; Xu, P. Properties of a steel slag–permeable asphalt mixture and the reaction of the steel slag–asphalt interface. Materials 2019, 12, 3603. [Google Scholar] [CrossRef]

- Liu, Q.; Li, B.; Schlangen, E.; Sun, Y.; Wu, S. Research on the mechanical, thermal, induction heating and healing properties of steel slag/steel fibers composite asphalt mixture. Appl. Sci. 2017, 7, 1088. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (EAF) steel slag. Constr. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

- Skaf, M.; Manso, J.M.; Aragón, Á.; Fuente-Alonso, J.A.; Ortega-López, V. EAF slag in asphalt mixes: A brief review of its possible re-use. Resour. Conserv. Recycl. 2017, 120, 176–185. [Google Scholar] [CrossRef]

- Alnadish, A.; Aman, Y. A study on the economic using of steel slag aggregate in asphalt mixtures reinforced by aramid fiber. ARPN J. Eng. Appl. Sci. 2018, 1, 276. [Google Scholar]

- Masoudi, S.; Abtahi, S.M.; Goli, A. Evaluation of electric arc furnace steel slag coarse aggregate in warm mix asphalt subjected to long-term aging. Constr. Build. Mater. 2017, 135, 260–266. [Google Scholar] [CrossRef]

- Kumar, A. Effect of Film Thickness, Voids, and Permeability on Asphalt Hardening in Asphalt Mixtures; Purdue University: West Lafayette, IN, USA, 1976. [Google Scholar]

- Kandhal, P.S.; Foo, K.Y.; Mallick, R.B. Critical review of voids in mineral aggregate requirements in superpave. Transp. Res. Rec. 1998, 1609, 21–27. [Google Scholar] [CrossRef]

- Superpave Mix Design, 2nd ed.; Asphalt Institute: Lexington, KY, USA, 1996.

- Recasens, R.; Martínez, A.; Jiménez, F.; Bianchetto, H. Effect of filler on the aging potential of asphalt mixtures. Transp. Res. Board 2005, 1901, 10–17. [Google Scholar] [CrossRef]

- Mahrez, A.; Karim, M.R.; bt Katman, H.Y. Fatigue and deformation properties of glass fiber reinforced bituminous mixes. J. East. Asia Soc. Transp. Stud. 2005, 6, 997–1007. [Google Scholar]

- Chen, H.; Xu, Q.; Chen, S.; Zhang, Z. Evaluation and design of fiber-reinforced asphalt mixtures. Mater. Des. 2009, 30, 2595–2603. [Google Scholar] [CrossRef]

- Xu, Q.; Chen, H.; Prozzi, J.A. Performance of fiber reinforced asphalt concrete under environmental temperature and water effects. Constr. Build. Mater. 2010, 24, 2003–2010. [Google Scholar] [CrossRef]

- Kim, M.J.; Yoo, D.Y.; Shin, H.O. Enhancing mechanical properties of asphalt concrete using synthetic fibers. Constr. Build. Mater. 2018, 178, 233–243. [Google Scholar] [CrossRef]

- Wu, S.; Ye, Q.; Li, N. Investigation of rheological and fatigue properties of asphalt mixtures containing polyester fibers. Constr. Build. Mater. 2008, 22, 2111–2115. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Tomás-Fortún, E.; Rubio-Gámez, M.C. High-modulus asphalt mixtures modified with acrylic fibers for their use in pavements under severe climate conditions. J. Cold Reg. Eng. 2016, 30, 04016003. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Z.; Zhan, S.; Ding, L.; Jin, K. Fatigue performance and model of polyacrylonitrile fiber reinforced asphalt mixture. Appl. Sci. 2018, 8, 1818. [Google Scholar] [CrossRef]

- Alnadish, A.; Aman, Y. Mechanistic approach for reducing the thickness of asphalt layer incorporating steel slag aggregate. Civ. Eng. J. 2018, 4, 334–345. [Google Scholar] [CrossRef]

- ASTM D5 Standard Test Method for Penetration of Bituminous Materials; ASTM: West Conshohocken, PA, USA, 2013.

- ASTM D36 Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus); ASTM: West Conshohocken, PA, USA, 2014.

- ASTM D113 Standard Test Methods for Ductility of Bituminous Materials; ASTM: West Conshohocken, PA, USA, 2007.

- ASTM D4402 Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer; ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D2493 Viscosity-Temperature Chart for Asphalts; ASTM: West Conshohocken, PA, USA, 2009.

- ASTM C.131 Resistance to Abrasion of Small-Size Coarse Aggregate by Use of the Los Angeles Machine; ASTM: West Conshohocken, PA, USA, 1989.

- IS: 2386 (Part IV). Tests on Aggregate; Bureau of Indian Standards: Manak Bhavan, India, 1963.

- ASTM C127 Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate; ASTM: West Conshohocken, PA, USA, 2012.

- ASTM S. D. Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate; ASTM: West Conshohocken, PA, USA, 2010.

- ASTM D5821 Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate; ASTM: West Conshohocken, PA, USA, 1995.

- Cominsky, R.J.; Huber, G.A.; Kennedy, T.W.; Anderson, M. The Superpave Mix Design Manual for New Construction and Overlays; No. SHRP-A-407; National Research Council: Washington, DC, USA, 1994.

- Coree, B.; Hislop, W.P. A Laboratory Investigation into the Effects of Aggregate-Related Factors of Critical VMA in Asphalt Paving Mixtures; No. IDOT TR-415; Center for Transportation Research and Education, Iowa State University: Washington, DC, USA, 2000. [Google Scholar]

- AASHTO Standard Practice for Mixture Conditioning of Hot-Mix Asphalt (HMA); American Association of State Highway and Transportation Organization: Washington, DC, USA, 2002.

- Papagiannakis, A.T.; Masad, E.A. Pavement Design and Materials; John Wiley & Sons: Washington, DC, USA, 2017. [Google Scholar]

- ASTM D3769 Standard Test Method for Determining the Resilient Modulus of Bituminous Mixtures by Indirect Tension Test; ASTM: West Conshohocken, PA, USA, 2011.

- He, G.; Wong, W. Laboratory study on permanent deformation of foamed asphalt mix incorporating reclaimed asphalt pavement materials. Constr. Build. Mater. 2007, 21, 1809–1819. [Google Scholar] [CrossRef]

- British Standards Institution. Sampling and Examination of Bituminous Mixtures for Roads and Other Paved Areas—Part 110: Methods of Test for the Determination of Wheel-Tracking Rate and Depth; British Standards Institute: London, UK, 1998; pp. 110–598. [Google Scholar]

- Suo, Z.; Wong, W.G. Analysis of fatigue crack growth behavior in asphalt concrete material in wearing course. Constr. Build. Mater. 2009, 23, 462–468. [Google Scholar] [CrossRef]

- Walubita, L.F.; Faruk, A.N.; Koohi, Y.; Luo, R.; Scullion, T.; Lytton, R.L. The Overlay Tester (OT): Comparison with Other Crack Test Methods and Recommendations for Surrogate Crack Tests, No. FHWA/TX-13/0-6607-2; Texas Department of Transportation, Research and Technology Implementation Office: Austin, TX, USA, October 2012.

- Standard, BS-EN. Bituminous Mixtures, Test Methods for Hot Mix Asphalt, Part 26: Stiffness; British Standards Institution: London, UK, 2012; pp. 12697–127026. [Google Scholar]

- Aman, M.Y.; Alnadish, A.M.; Rohani, M.M.; Danial, D.B.; Tahir, M.M. Effect of the densification of the reinforced asphalt mixtures on the permanent deformation. IOP Conf. Ser. Earth Environ. Sci. 2020, 498, 012027. [Google Scholar] [CrossRef]

- Miao, Y.; Wang, T.; Wang, L. Influences of interface properties on the performance of fiber-reinforced asphalt binder. Polymers 2019, 11, 542. [Google Scholar] [CrossRef]

- Ma, T.; Cui, K.; Zhao, Y.; Huang, X. Fatigue evaluation of recycled asphalt mixture based on energy-controlled mode. Adv. Mater. Sci. Eng. 2017, 2017, 362365. [Google Scholar]

- Hamedi, G.H.; Saedi, D.; Ghahremani, H. Effect of short-term aging on low-temperature cracking in asphalt mixtures using mechanical and thermodynamic methods. J. Mater. Civil Eng. 2020, 32, 04020288. [Google Scholar] [CrossRef]

- Huang, B.S.; Shu, X.; Vukosavljevic, D. Laboratory investigation of cracking resistance of hot-mix asphalt field mixtures containing screened reclaimed asphalt pavement. J. Mater. Civil Eng. 2011, 23, 1535–1543. [Google Scholar] [CrossRef]

- Roesler, J.; Harders, H.; Baeker, M. Mechanical Behaviour of Engineering Materials: Metals, Ceramics, Polymers, and Composites; Springer: Berlin, Germany, 2010; pp. 333–349. [Google Scholar]

- Stroup-Gardiner, M.; Newcomb, D.E.; Olson, R.; Teig, J. Traffic densification of asphalt concrete pavements. Transportation research record. J. Transp. Res. Board 1997, 1575, 1–9. [Google Scholar] [CrossRef]

| Properties | Result | Standard |

|---|---|---|

| Bitumen Grade | 80/100 | – |

| Penetration @ 25 °C (0.1 mm) | 93 | ASTM D5 [24] |

| Softening Point (°C) | 45 | ASTM D36 [25] |

| Ductility @ 25 °C (cm) | 141 | ASTM D113 [26] |

| Penetration Index (PI) | −1 | – |

| Viscosity @ 135 °C (cP) | 487 | – |

| Viscosity @ 165 °C (cP) | 144 | ASTM D4402 [27] |

| Mixing Temperature | 160 °C | – |

| Compaction Temperature | 150 °C | ASTM D2493 [28] |

| Properties | Result | Specification | Standard | |

|---|---|---|---|---|

| Granite | Steel Slag | |||

| Loss Angeles Abrasion | 22 | 17.80 | ≤25% | ASTM C131 [29] |

| Aggregate Crushing Value (%) | 25 | 22.60 | ≤25% | IS: 2386 (Part IV) [30] |

| Bulk S.G. (g/cm3) | 2.63 | 3.22 | N/A | ASTM C127 [31] |

| Water absorption (%) | 0.84 | 2.75 | ≤3% | ASTM C127 |

| Flat and Elongated (%) | 8.40 | 3.90 | ≤10% | ASTM D4791 [32] |

| Angularity (%) | 84 | 95 | ≥80% | ASTM D5821 [33] |

| Free CaO content (%) | – | 1.17 | ≤4% | – |

| Physical Properties | Polyvinyl Alcohol (PVA) | Acrylic | Polyester |

|---|---|---|---|

| Density (g/cm3) | 1.29 | 1.17 | 1.38 |

| Tensile Strength (MPa) | >1200 | >700 | >500 |

| Young’s Modulus (GPa) | >20 | >28 | >7 |

| Melting Point (°C) | >200 | >230 | >240 |

| Color | Light Yellow | Yellow | White |

| Length (mm) | 6 | 6 | 6 |

| Diameter (μm) | 10–20 | 10–25 | 10–25 |

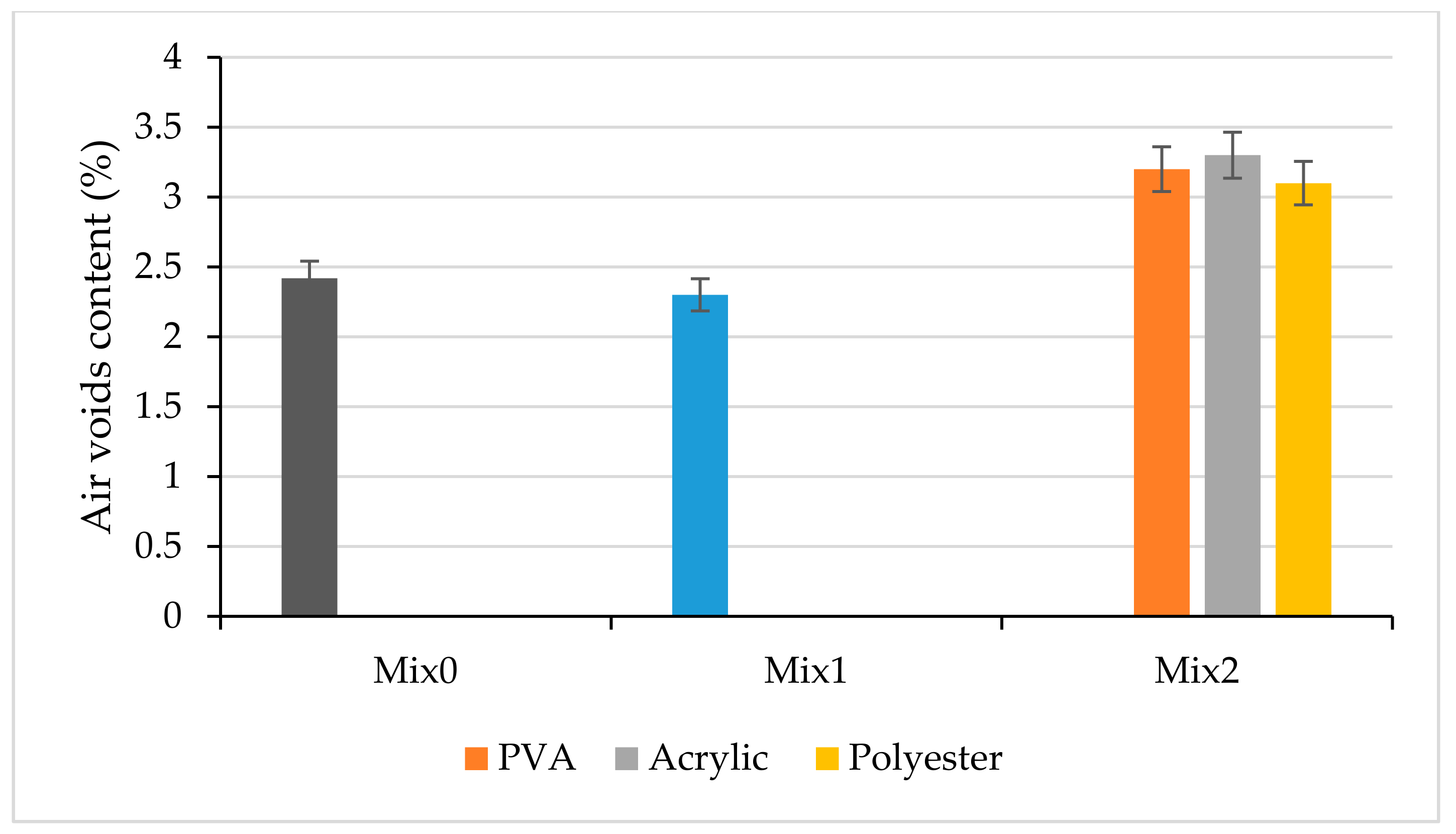

| Volumetric Properties | Mix0 | Mix1 | Mix2 | Specifications | ||

|---|---|---|---|---|---|---|

| PVA | Acrylic | Polyester | ||||

| OBC (%) | 4.78 | 4.90 | 5.10 | 5.20 | 5.20 | – |

| Air voids (%) | 4 | 4 | 4 | 4 | ≥4 | 4% |

| VMA (%) | 15.9 | 16 | 16.20 | 16.53 | 16.13 | 14% |

| VFA (%) | 74.84 | 75 | 75.30 | 75.80 | 75.20 | 65–75% |

| Density (g/cm3) | 2.343 | 2.560 | 2.539 | 2.536 | 2.541 | – |

| Performance Tests | Aging Index | ||||

|---|---|---|---|---|---|

| Mix0 | Mix1 | Mix2 | |||

| PVA | Acrylic | Polyester | |||

| Resilient Modulus at 25 °C | 1.15 | 1.18 | 1.10 | 1.09 | 1.12 |

| Resilient Modulus at 40 °C | 1.14 | 1.16 | 1.11 | 1.09 | 1.11 |

| Permanent Deformation | 0.87 | 0.85 | 0.90 | 0.92 | 0.89 |

| Cracking | 1.18 | 1.22 | 1.12 | 1.10 | 1.14 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnadish, A.M.; Aman, M.Y.; Katman, H.Y.B.; Ibrahim, M.R. Influence of the Long-Term Oven Aging on the Performance of the Reinforced Asphalt Mixtures. Coatings 2020, 10, 953. https://doi.org/10.3390/coatings10100953

Alnadish AM, Aman MY, Katman HYB, Ibrahim MR. Influence of the Long-Term Oven Aging on the Performance of the Reinforced Asphalt Mixtures. Coatings. 2020; 10(10):953. https://doi.org/10.3390/coatings10100953

Chicago/Turabian StyleAlnadish, Adham Mohammed, Mohamad Yusri Aman, Herda Yati Binti Katman, and Mohd Rasdan Ibrahim. 2020. "Influence of the Long-Term Oven Aging on the Performance of the Reinforced Asphalt Mixtures" Coatings 10, no. 10: 953. https://doi.org/10.3390/coatings10100953

APA StyleAlnadish, A. M., Aman, M. Y., Katman, H. Y. B., & Ibrahim, M. R. (2020). Influence of the Long-Term Oven Aging on the Performance of the Reinforced Asphalt Mixtures. Coatings, 10(10), 953. https://doi.org/10.3390/coatings10100953