The Problem of Copper Softening During Cold Gas Dynamic Spraying

Abstract

1. Introduction

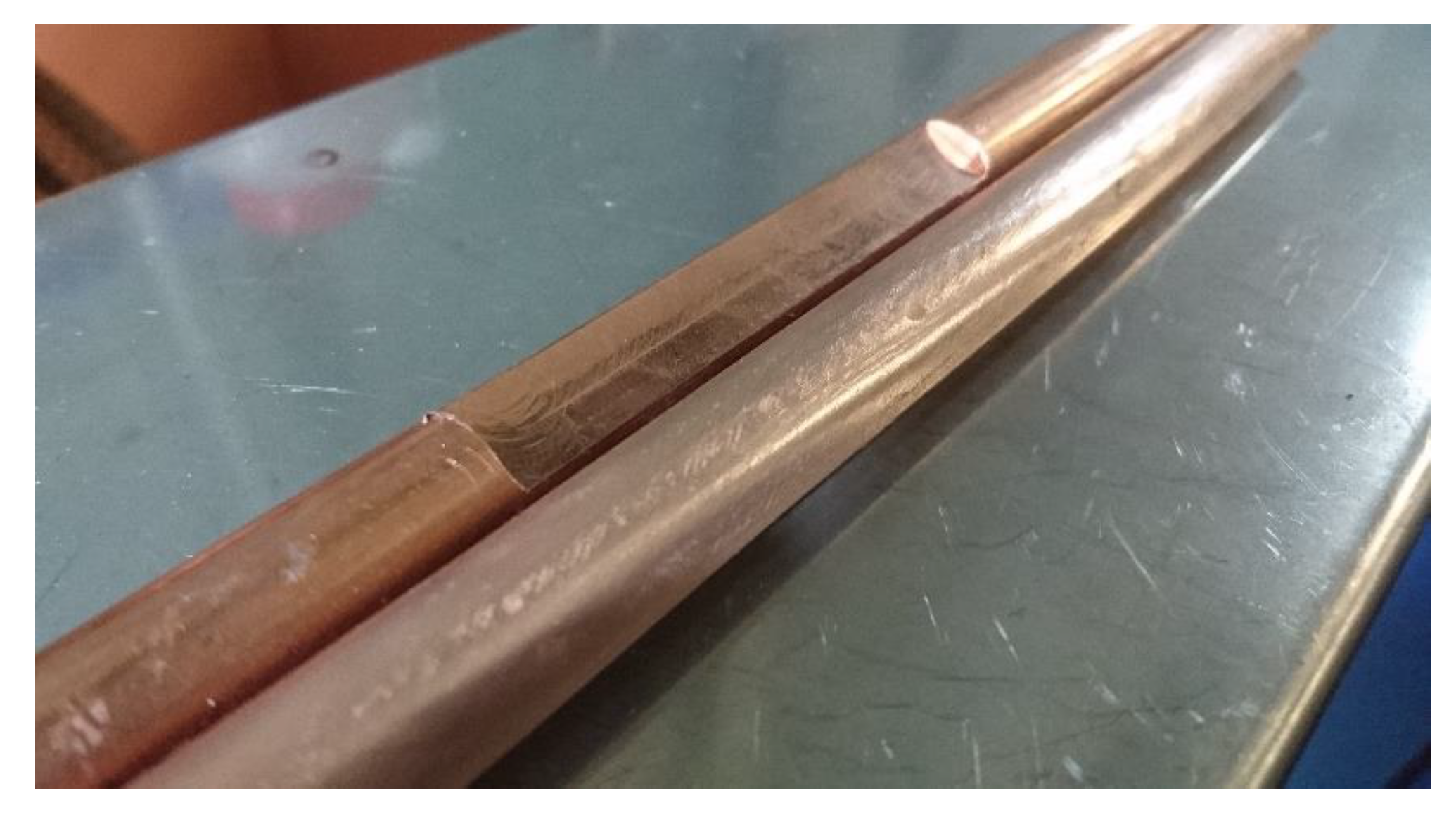

2. Materials and Methods

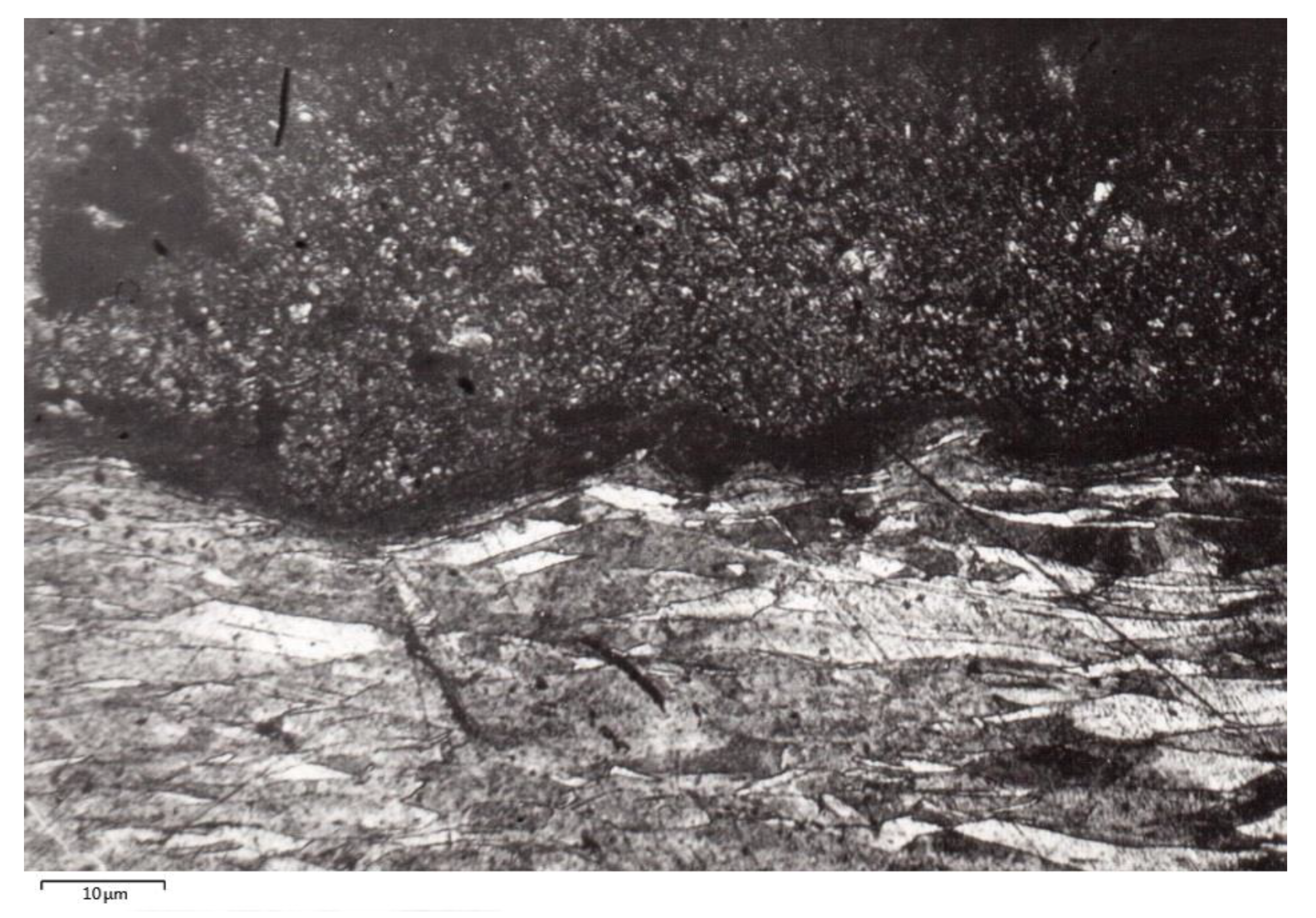

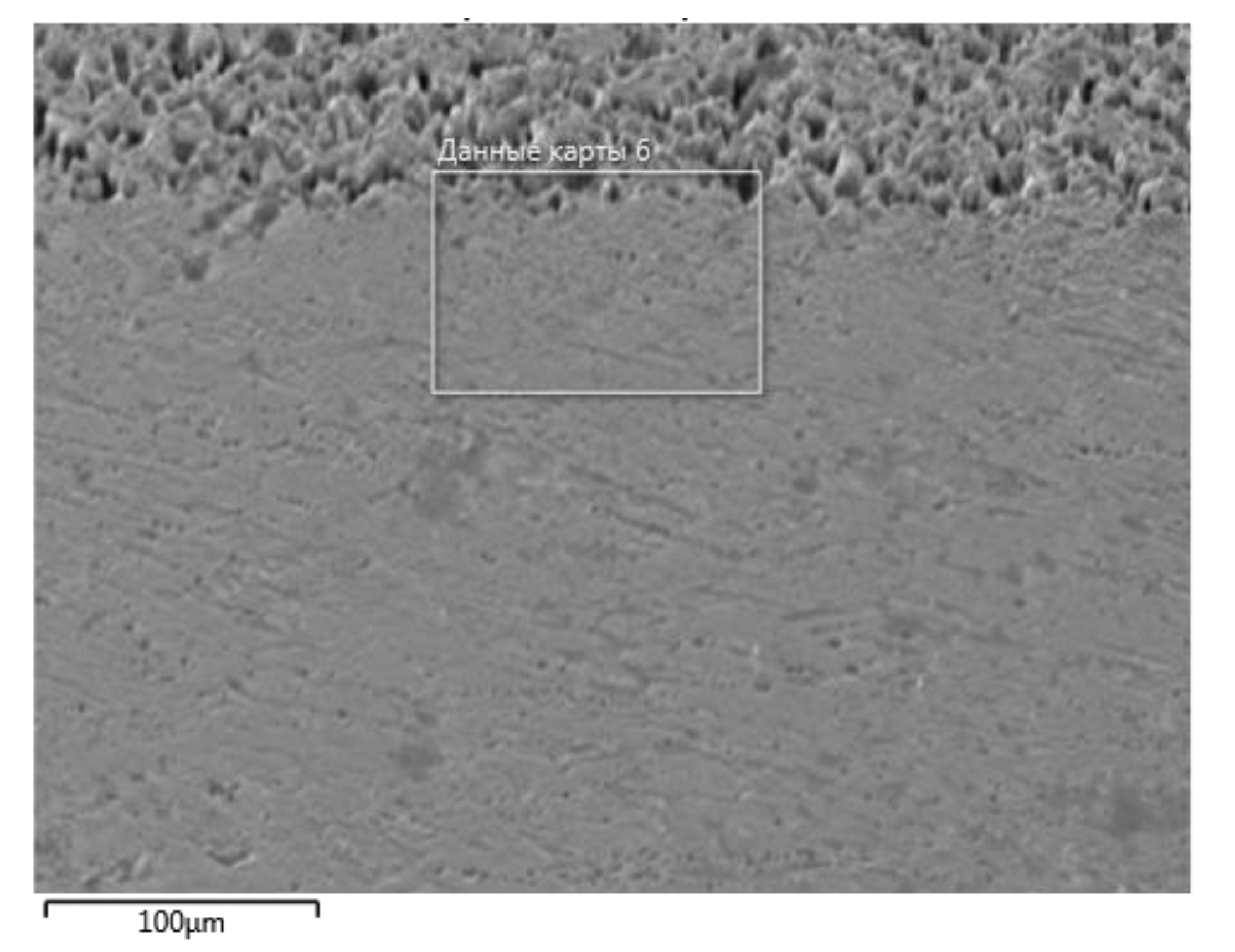

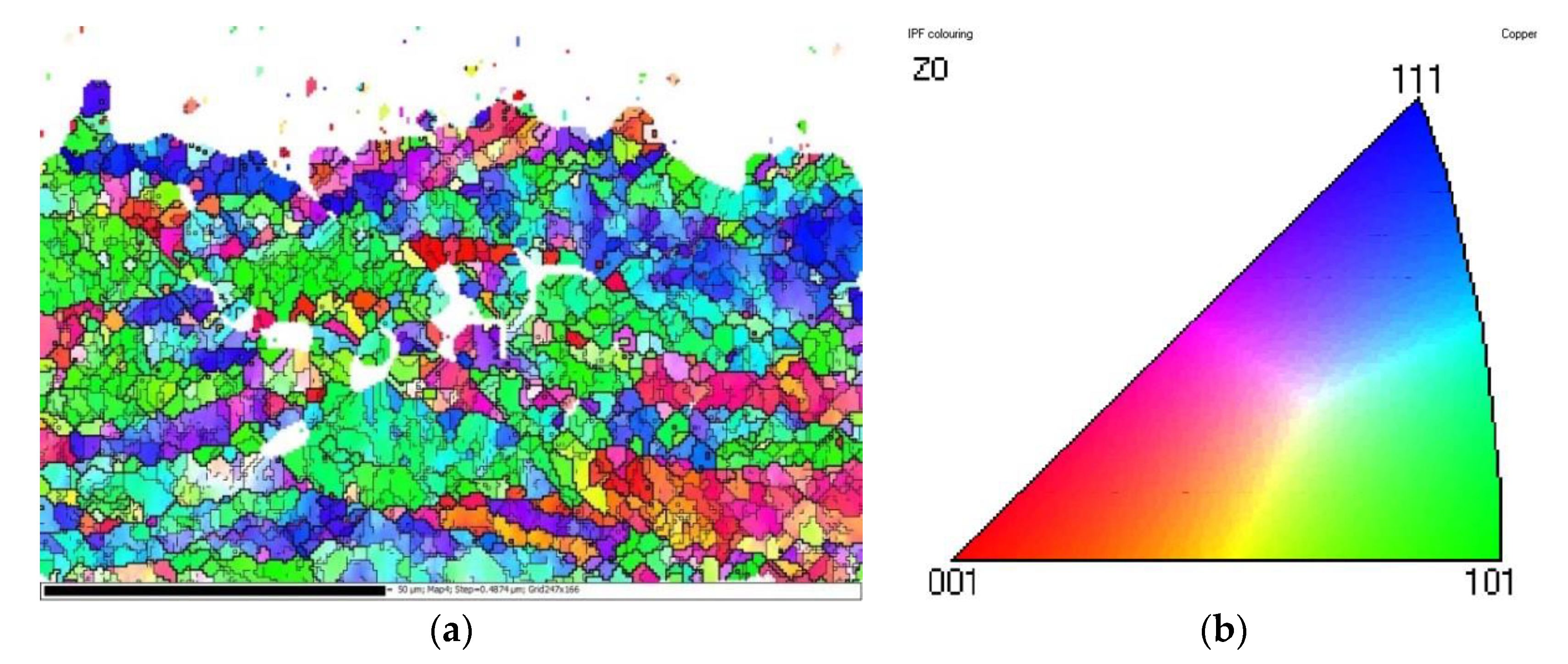

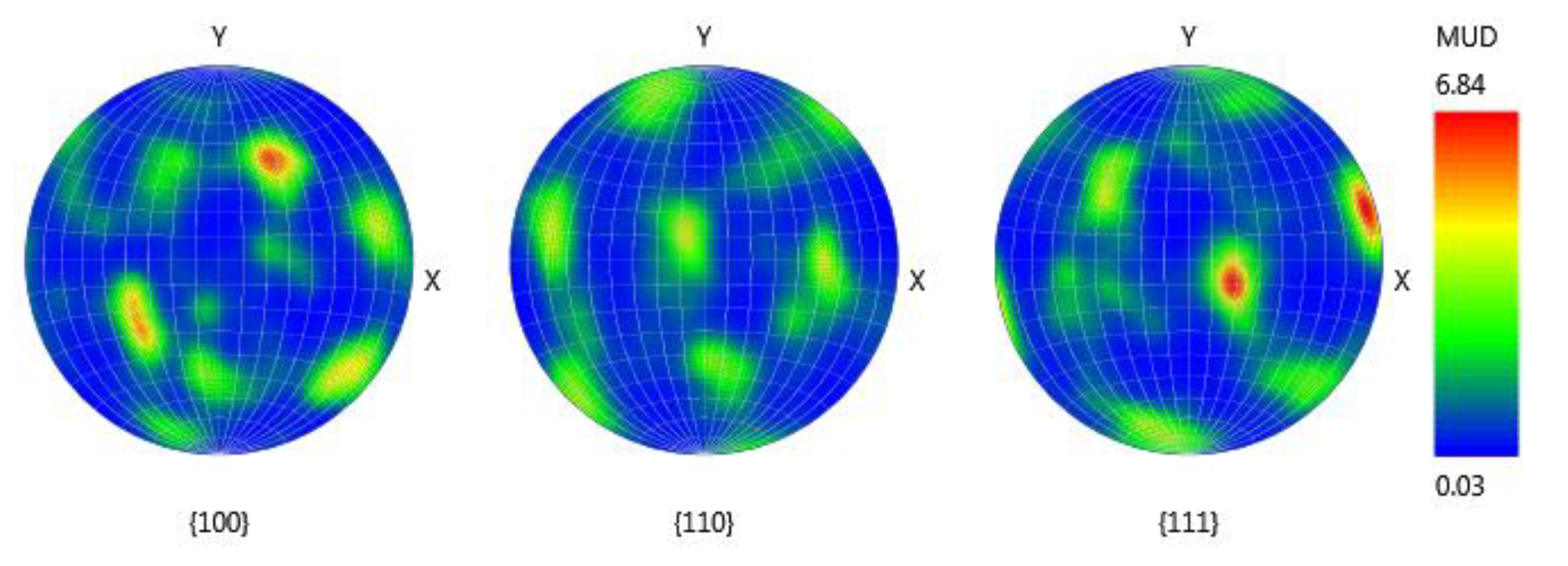

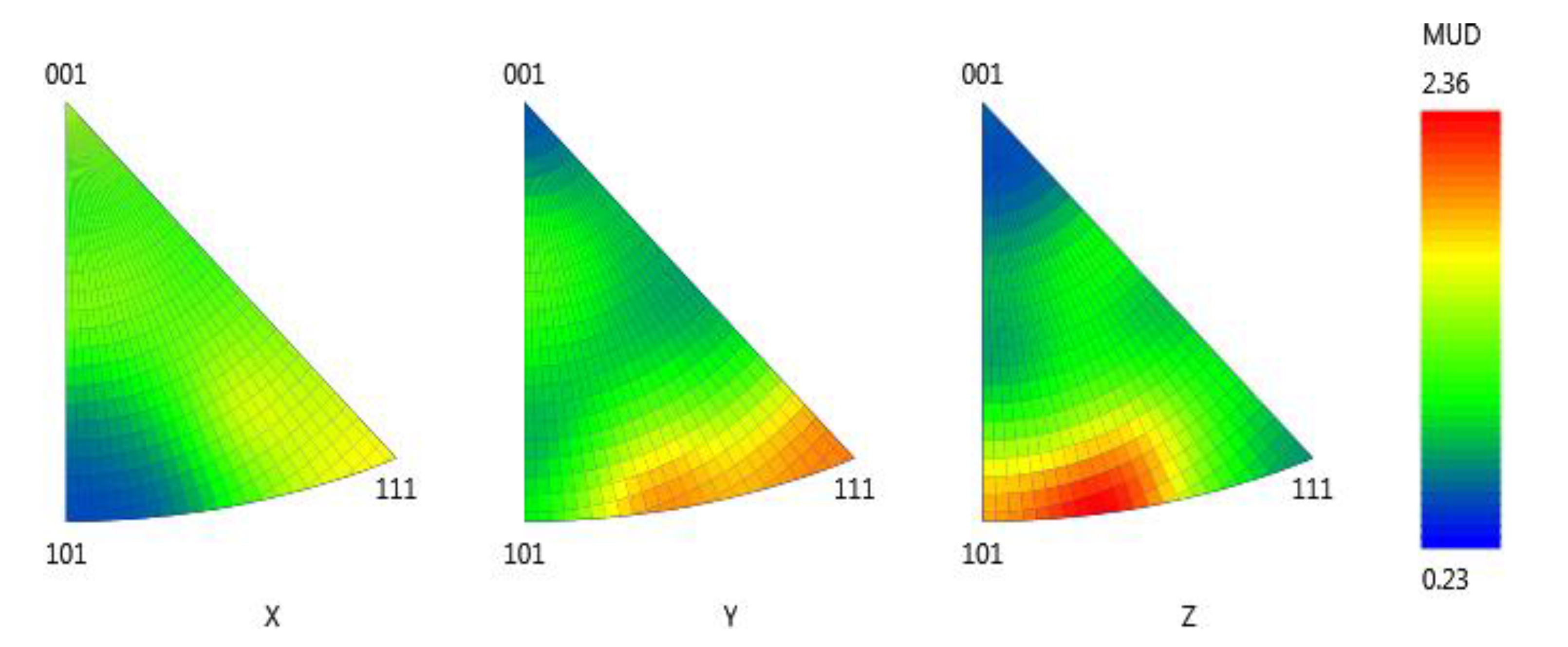

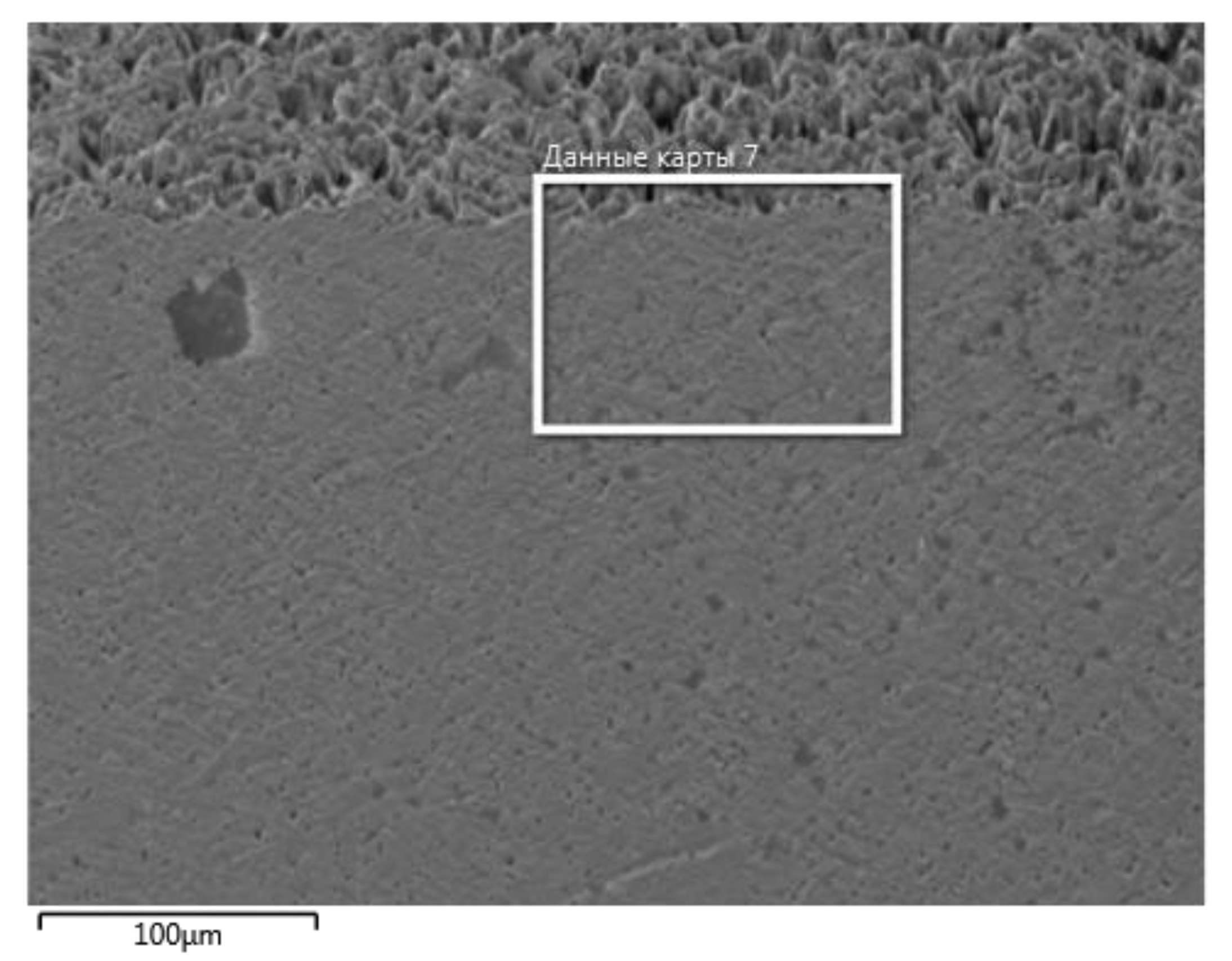

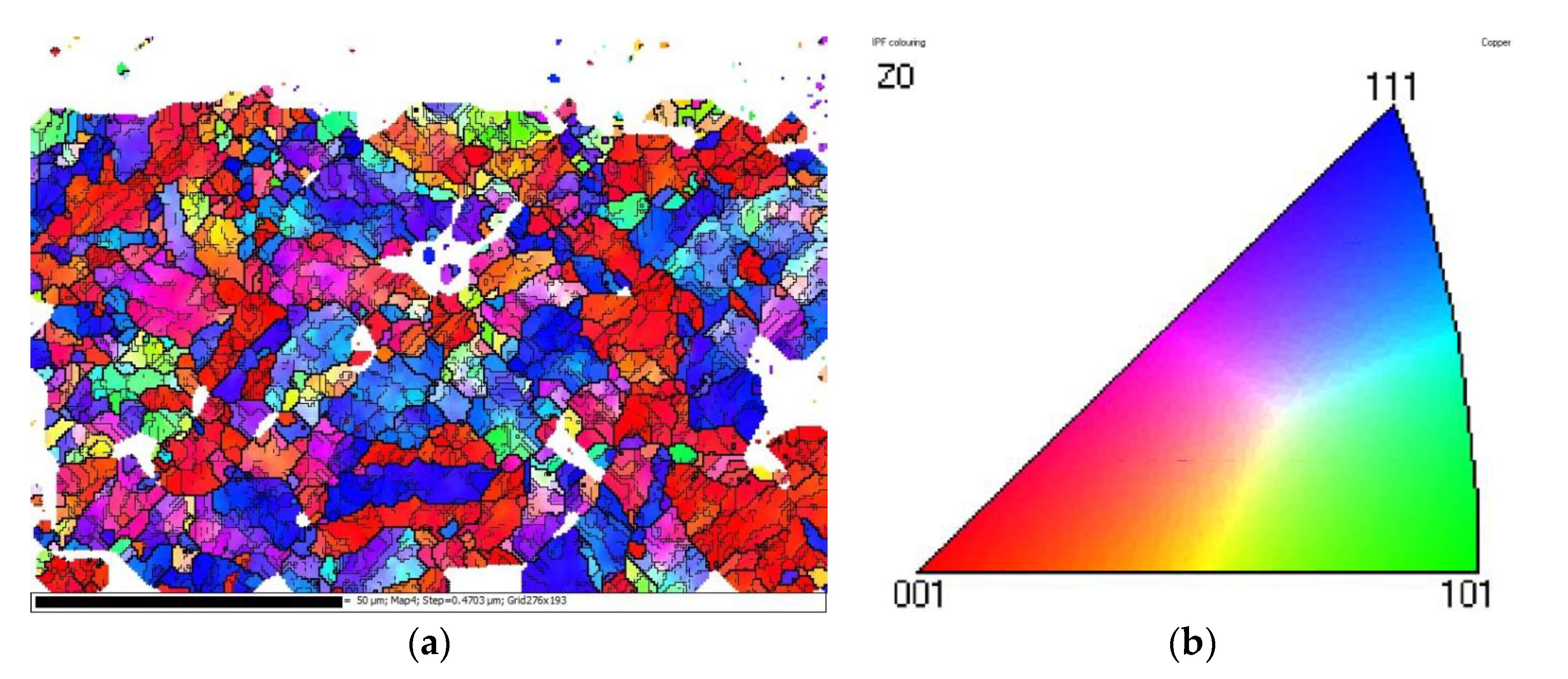

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kuraoka, T.; Ideno, I. Research on Reduction of Wear of Contact Wires in Overlap Sections. 2012. Available online: https://www.semanticscholar.org/paper/Research-on-Reduction-of-Wear-of-Contact-Wires-in-Kuraoka-Ideno/de5b2d5c52f59fbbec279a7ecc1043262bd9975e (accessed on 16 December 2019).

- Shimizu, M. A Measure to Reduce Contact Wire Wear in Shinkansen Overlap Sections. 2004. Available online: https://www.rtri.or.jp/eng/publish/newsletter/pdf/06/RTA-06-38.pdf (accessed on 16 December 2019).

- Ikeda, K. Development of Method for Improving Overhead Line Equipment for Implementation of Stable Current Collection at High Speed. 2010. Available online: https://trid.trb.org/view/793419 (accessed on 16 December 2019).

- Nagasaka, S.; Aboshi, M. Measurment and estimation of contact wire unevenness. QR RTRI 2004, 45, 86–91. [Google Scholar] [CrossRef][Green Version]

- Amari, S.; Tsunemoto, M.; Kusumi, S.; Kuraoka, T.; Hamada, T.; Minamoto, M. Evaluation of resistance at supporting pulley of messenger wire and its inluance on current collection characteristics. QR RTRI 2009, 50, 137–143. [Google Scholar] [CrossRef][Green Version]

- Sugahara, A. Reduction of contact wire strain near dead sections by considering sliding level differences. QR RTRI 2004, 45, 75–79. [Google Scholar] [CrossRef]

- Biesenack, H.; Biesenack, H.; Pintscher, F. Kontakt Zwischen Fahrdraht und Schleifleiste-Ausgangspunkte zur Bestimmung des Elektrischen Verschleißes Elektrische Bahnen; Oldenbourg Industrieverlag GmbH: München, Germany, 2005; pp. 138–146. [Google Scholar]

- Iosif, S.; Gershman, E.; Fox-Rabinovich, G.; Veldhuis, S. Description of seizure process for gas dynamic spray of metal powders from non-equilibrium thermodynamics standpoint. Entropy 2016, 18, 315. [Google Scholar]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold spray coating: Review of material systems and future perspectives. Surf. Eng. 2014, 36, 369–395. [Google Scholar] [CrossRef]

- Champagne, V.; Helfritch, D. Fundamentals of Cold-Gas Dynamics Spray; Woodhead Publishing: Cambridge, UK, 2007; p. 427. [Google Scholar]

- Irissou, E.; Legoux, J.G.; Arsenault, B.; Moreau, C. Investigation of Al-Al2O3 cold spray coating formation and properties. In Proceedings of the International Thermal Spray Conference, Beijing, China, 14–16 May 2007; ASM International: Cleveland, OH, USA, 2007; pp. 210–216. [Google Scholar]

- Wu, J.; Fang, H.; Yoon, S.; Kim, H.J.; Lee, C. Measurement of particle velocity and characterization of deposition in aluminum alloy kinetic spraying process. Appl. Surf. Sci. 2005, 252, 1368–1377. [Google Scholar] [CrossRef]

- Jen, T.C.; Li, L.; Cui, W.; Chen, Q.; Zhang, X. Numerical investigations on cold gas dynamic spray process with nano- and microsize particles. Int. J. Heat Mass Transf. 2005, 48, 4384–4396. [Google Scholar] [CrossRef]

- Jodoin, B.; Raletz, F.; Vardelle, M. Cold spray modeling and validation using an optical diagnostic method. Surf. Coat. Technol. 2006, 200, 4424–4432. [Google Scholar] [CrossRef]

- Vinnicki, M.; Piwowarczyk, T.; Malachowska, A. General description of cold sprayed coatings formation and of their properties. Bulletin of the pjlish academy of sciences. Tech. Sci. 2018, 66, 301–310. [Google Scholar]

- Gopinath, M.; John Sujin Mon, T.S.; Glarance, J.; John Britto, X.; Dhakshnamoorthy, M. Ohtimization of copper particles deposition using cold spray process. Int. J. Innov. Res. Sci. Eng. Technol. 2015, 4, 4189–4200. [Google Scholar]

- Vinnicki, M.; Piwowarczyk, T.; Malachowska, A.; Ambroziak, A. Effect of gas pressure and temperature on stereometric properties of Al + Al2O3 composite coatings deposited by LPCS method. Arch. Metall. Mater. 2014, 59, 879–886. [Google Scholar] [CrossRef]

- Huang, G.; Wang, H.; Li, X.; Xing, L. Study on the growth of holes in cold spraying via numerical simulation and experimental methods. Coatings 2017, 7, 2. [Google Scholar] [CrossRef]

- Kim, D.-Y.; Park, J.-J.; Lee, J.-G.; Kim, D.; Tark, S.J.; Ahn, S.; Yun, J.H.; Gwak, J.; Yoon, K.H.; Chandra, S.; et al. Cold spray deposition of copper electrodes on silicon and glass substrates. J. Therm. Spray Technol. 2013, 22, 1092–1102. [Google Scholar] [CrossRef]

- Vo, P.; Poirier, D.; Legoux, J.-G.; Keech, P.G.; Doyle, D.; Jakupi, P.; Irissou, E. Development of Cold Spray Technology for Copper Coating of Carbon Steel Used Fuel Container Prototipes for CANDU Fuel; NWMO: Toronto, ON, Canada, 2015. [Google Scholar]

- Zahiri, S.H.; Fraser, D.; Gulizia, S.; Jahedi, M. Effect of processing conditions on porosity formation in cold gas dynamic spraying of copper. J. Therm. Spray Technol. 2006, 15, 422–430. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Verdy, C.; Liao, H. Cold gas dynamic spray additive manufacturing today: Deposit possibilities, technological solutions and viable applications. Mater. Des. 2017, 133, 266–287. [Google Scholar] [CrossRef]

- Stoltenhoff, T.; Borchers, C.; Gärtner, F.; Kreye, H. Microstructures and key properties of cold-sprayed and thermally sprayed copper coatings. Surf. Coat. Technol. 2006, 200, 4947–4960. [Google Scholar] [CrossRef]

- Schmidt, T.; Assadi, H.; Gärtner, F.; Richter, H.; Stoltenhoff, T.; Kreye, H.; Klassen, T. From particle acceleration to impact and bonding in cold spraying. J. Therm. Spray Technol. 2009, 18, 794–808. [Google Scholar] [CrossRef]

- Borchers, C.; Gärtner, F.; Stoltenhoff, T.; Assadi, H.; Kreye, H. Microstructural and macroscopic properties of cold sprayed copper coatings. J. Appl. Phys. 2003, 93, 10064–10070. [Google Scholar] [CrossRef]

- McCune, R.C.; Donlon, W.T.; Popoola, O.O.; Cartwright, E.L. Characterization of copper layers produced by cold gas-dynamic spraying. J. Therm. Spray Technol. 2000, 9, 73–82. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Pergamon: Oxford, UK, 2004. [Google Scholar]

- Rokni, M.R.; Widener, C.A.; Crawford, G.A.; West, M.K. An investigation into microstructer and mechanical properties of cold sprayed 7075 Al deposition. Mater. Sci. Eng. A 2015, 625, 19–27. [Google Scholar] [CrossRef]

- Zou, Y.; Qin, W.; Irissou, E.; Legoux, J.-G.; Yue, S.; Szpunar, J.A. Dynamic recrystallization in the particle/particle interfacial region of cold sprayed nickel coating: Electron backscatter diffraction characterization. Scr. Mater. 2009, 61, 899–902. [Google Scholar] [CrossRef]

- Rafaja, D.; Schucknecht, T.; Klemm, V.; Paul, A.; Berek, H. Microstructural characterization of titanium coatings deposited using cold gas spraying on Al2O3 substrates. Surf. Coat. Technol. 2009, 203, 3206–3213. [Google Scholar] [CrossRef]

- Cho, J.; Jin, Y.; Park, D.; Kim, H.; Oh, I.; Lee, K. Manufacture and properties of cold spray deposited large thickness Cu coating material for sputtering target. Met. Mater. Int. 2011, 17, 157–166. [Google Scholar] [CrossRef]

- Kang, K.; Park, H.; Bae, G.; Lee, C. Microstructure and texture of Al coating during kinetic spraying and heat treatment. J. Mater. Sci. 2012, 47, 4053–4061. [Google Scholar] [CrossRef]

- Zhang, Y.; Brodusch, N.; Descartes, S.; Chromik, R.R.; Gauvin, R. Microstructure refinement of cold-sprayed copper investigated by electron channeling contrast imaging. Microsc. Microanal. 2014, 20, 1499–1506. [Google Scholar] [CrossRef]

| Composition of Powder Mixtures to be Sprayed | Ultimate Tensile Strength, MPa | Relative Elongation, % |

|---|---|---|

| Unrepaired | 362.5 | 4.6 |

| Cu-50% Al2O3 | 360.9 | 4.5 |

| Cu-60% Al2O3 | 362.7 | 4.3 |

| Cu-50% Al2O3-5% Zn | 364.1 | 4.6 |

| Cu-50% Al2O3-10% Zn | 362.2 | 4.1 |

| Composition of Powder Mixtures to be Sprayed | Elongation, mm |

|---|---|

| Unrepaired | 2.4 |

| Cu-50% Al2O3 | 2.1 |

| Cu-60% Al2O3 | 2.5 |

| Cu-50% Al2O3-5% Zn | 2.1 |

| Cu-50% Al2O3-10% Zn | 2.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gershman, E.; Gershman, I.; Mironov, A.; Peretyagin, P. The Problem of Copper Softening During Cold Gas Dynamic Spraying. Coatings 2020, 10, 7. https://doi.org/10.3390/coatings10010007

Gershman E, Gershman I, Mironov A, Peretyagin P. The Problem of Copper Softening During Cold Gas Dynamic Spraying. Coatings. 2020; 10(1):7. https://doi.org/10.3390/coatings10010007

Chicago/Turabian StyleGershman, Eugeniy, Iosif Gershman, Alexander Mironov, and Pavel Peretyagin. 2020. "The Problem of Copper Softening During Cold Gas Dynamic Spraying" Coatings 10, no. 1: 7. https://doi.org/10.3390/coatings10010007

APA StyleGershman, E., Gershman, I., Mironov, A., & Peretyagin, P. (2020). The Problem of Copper Softening During Cold Gas Dynamic Spraying. Coatings, 10(1), 7. https://doi.org/10.3390/coatings10010007