Abstract

Molybdenum (Mo) is considered a plasma facing material alternative to tungsten (W) for manufacturing the divertor armours of International Thermonuclear Experimental Reactor (ITER). Transient thermal loads of high energy occurring in a tokamak during the service life have been simulated through a single laser pulse delivered by a Nd:YAG/Glass laser, and the effects have then been examined through scanning electron microscopy (SEM) observations. An erosion crater forms in correspondence with the laser spot due to the vaporization and melting of the metal, while all around a network of cracks induced by thermal stresses is observed. The findings have been compared to results of similar experiments on W and literature data. The morphology of the crater and the surrounding area is different from that of W: the crater is larger and shallower in the case of Mo, while its walls are characterized by long filaments, not observed in W, because the lower viscosity and surface tension of Mo allow an easier flow of the liquid metal. Most importantly, the volume of Mo ablated from the surface by the single laser pulse is about ten times that of W. This critical aspect is of particular relevance and leads us to conclude that W remains the best solution for manufacturing the armours of the ITER divertor.

1. Introduction

Plasma facing materials (PFM) of future nuclear fusion reactors will be exposed, in addition to a steady state heat flux, to transient events of high energy such as disruption, edge localized modes (ELM), and vertical displacement events (VDE). The large heat fluxes occurring during transient events induced by plasma instabilities may lead to the melting and vaporization of PFMs with the consequent contamination of plasma and the damage of PFM components.

At present, tungsten (W) and W-1%La2O3 alloy are the most promising materials for manufacturing the divertor armours of ITER [1,2,3,4,5]. W has the highest melting point of all metals and exhibits excellent thermo-mechanical characteristics, a low sputtering rate, and a tritium inventory; therefore, thin W coatings on graphite and carbon fibre composites have already been adopted in reactors like JET [5] and ASDEX-U [6]. The drawbacks of W are the poor machinability at an ambient temperature and the high ductile-to-brittle transition temperature. Moreover, the resistance to thermal shocks during ELMs is also a matter of concern [7] because a fibrous nanostructure forms on the W surface due to low-energy He ion irradiation with detrimental effects on the thermo-mechanical properties [8].

The dispersion of La2O3 particles in the W matrix improves the toughness [9], enhances the resistance to thermal shocks and creep, increases the recrystallization temperature, and hinders grain growth at a high temperature (up to ~1750 °C).

Some studies were also carried out to assess the effects of the dispersion in W of other oxides (Y2O3, TiO, etc.) or other elements (Ta, Ti), with controversial results [10,11]. In fact, some properties resulted in being improved; however, the added components often involve the generation of W dust into plasma; thus, as of now, all the required conditions to develop a reliable divertor armour have not been satisfied.

Recently, molybdenum (Mo) has attracted increasing interest as a possible PFM alternative to W [12,13,14,15,16]. As shown in Table 1, Mo is a high-Z refractory metal with very good physical properties (density, melting point, boiling point, and thermal conductivity), even if it is a little inferior to W. On the contrary, the ductile to brittle transition temperature (DBTT) of Mo is much lower, and it exhibits a better resistance to thermal shocks [15,16,17].

Table 1.

A comparison of some physical properties of W and Mo: atomic number Z, density ρA, melting point TM, boiling point TB, thermal conductivity ξ, ductile to brittle transition temperature DBTT, latent heat of fusion EM, and latent heat of vaporization EV.

Another relevant advantage of Mo to W is its behavior under prolonged irradiation by 14 MeV neutrons of a fusion power plant. W transmutes to osmium (Os) via rhenium (Re) and forms the W–Os–Re alloy. Cottrell [18] calculated that five years in a fusion power plant will have transmuted pure W into an alloy of about 75 (at.%) W, 13 (at.%) Os, and 12 (at.%) Re, a composition close to that of the brittle σ phase. In the same irradiation conditions, Mo would produce 1.1% Tc and 0.65% Ru after 5 years, well inside the primary Mo phase field at 1500 °C.

The erosion/redeposition characteristics of pure Mo and W are similar [19], but the fractional hydrogen isotope retention is lower in Mo than in W [20].

In this work the specific conditions of transient events have been simulated by irradiating Mo samples through a Nd:YAG/Glass high power laser source, suitable to release a high thermal load in a very short time (~15 ns) on a small area (~200 μm) and to reach a surface power density on the focal plane of about 1.7 × 1012 W·cm−2.

The effects of the laser pulse on the sample surface have been then investigated through 3D surface analysis and scanning electron microscopy (SEM) observations. The same experimental procedure was adopted in previous works of present authors to study the behavior of W (bulk and plasma sprayed) [21,22] and W-1%La2O3 alloy [23]. The results are discussed in comparison to those previously obtained by us on W, the principal candidate material for building the armours of ITER, and in general to literature data. A recent critical overview about material erosion of candidate materials like W and Mo is reported in [24].

2. Material and Experimental Section

2.1. Sample Characteristics

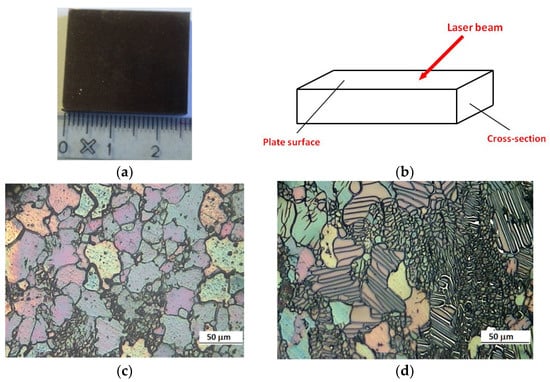

The material (purity of 99.9 wt.%) examined in the present work was supplied by PLANSEE (Metallwerk Plansee, Reutte, Austria) in the form of plates with a thickness of 25 mm, which were cut to obtain samples with dimensions of 25 mm × 20 mm (Figure 1a).

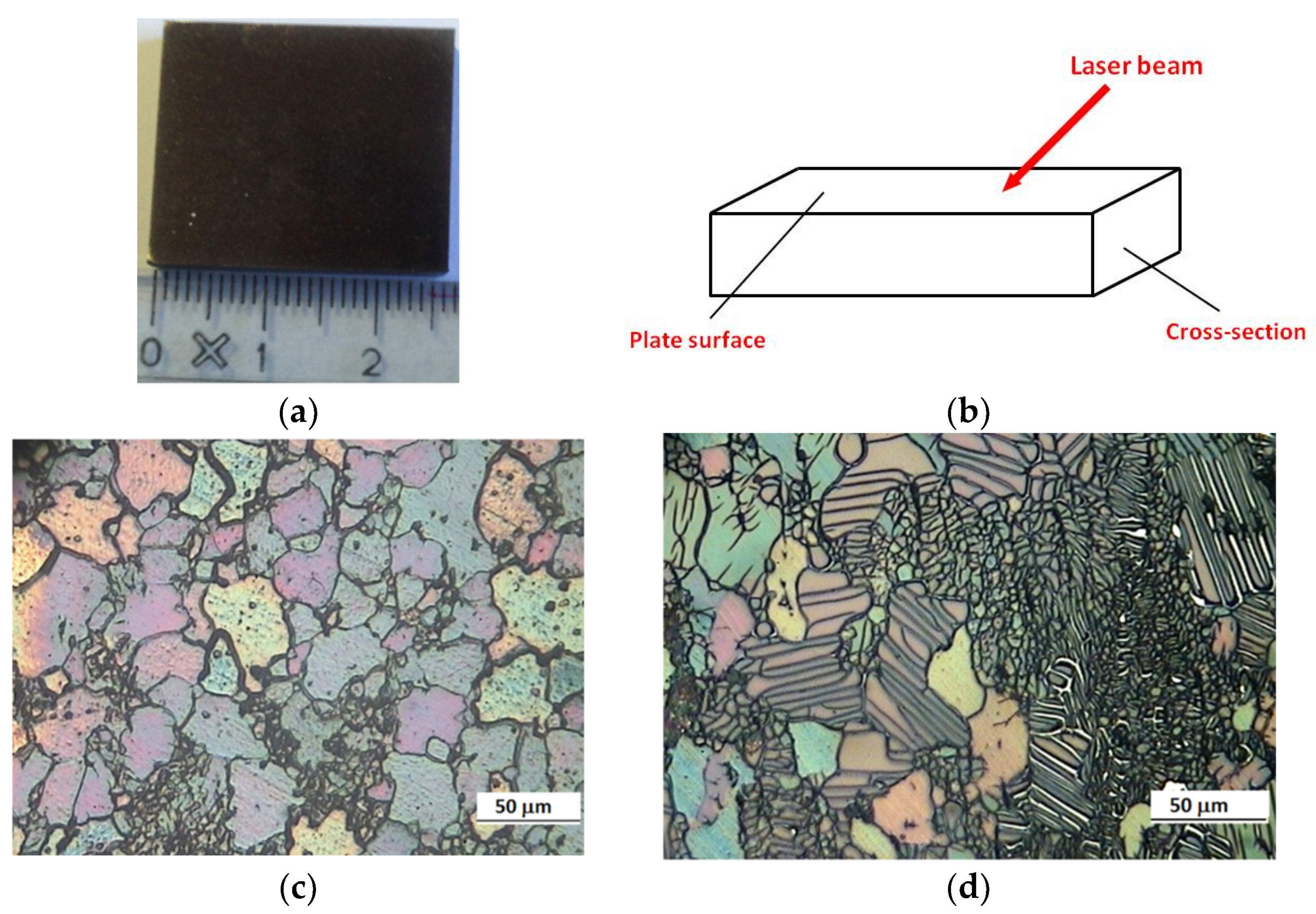

Figure 1.

Picture(a) and (b) sketch of the sample. The structure of the examined Mo samples: plate surface (c), cross-section (d).

The structure of Mo grains on the plate surface and in the cross-section (Figure 1b) has been examined through light microscopy. After conventional metallographic surface preparation, the sample has been etched by immersion for 60 s in a boiling solution of H2O 100 mL with H2O2 (30%) 1 mL, and observed by using an optical microscope (Union Optical Co., Ltd., Tokyo, Japan).

Figure 1c,d shows how the grain structure is different on the plate surface (c) and in the cross-section (d). A large part of the plate surface is covered by grains with a mean size D of about 40 µm, while some zones exhibit smaller grains of about 5 µm (Figure 1b). In the cross-section, small grains (~5 µm) are the dominant feature, and only few grains of larger size are present and show elongated substructures.

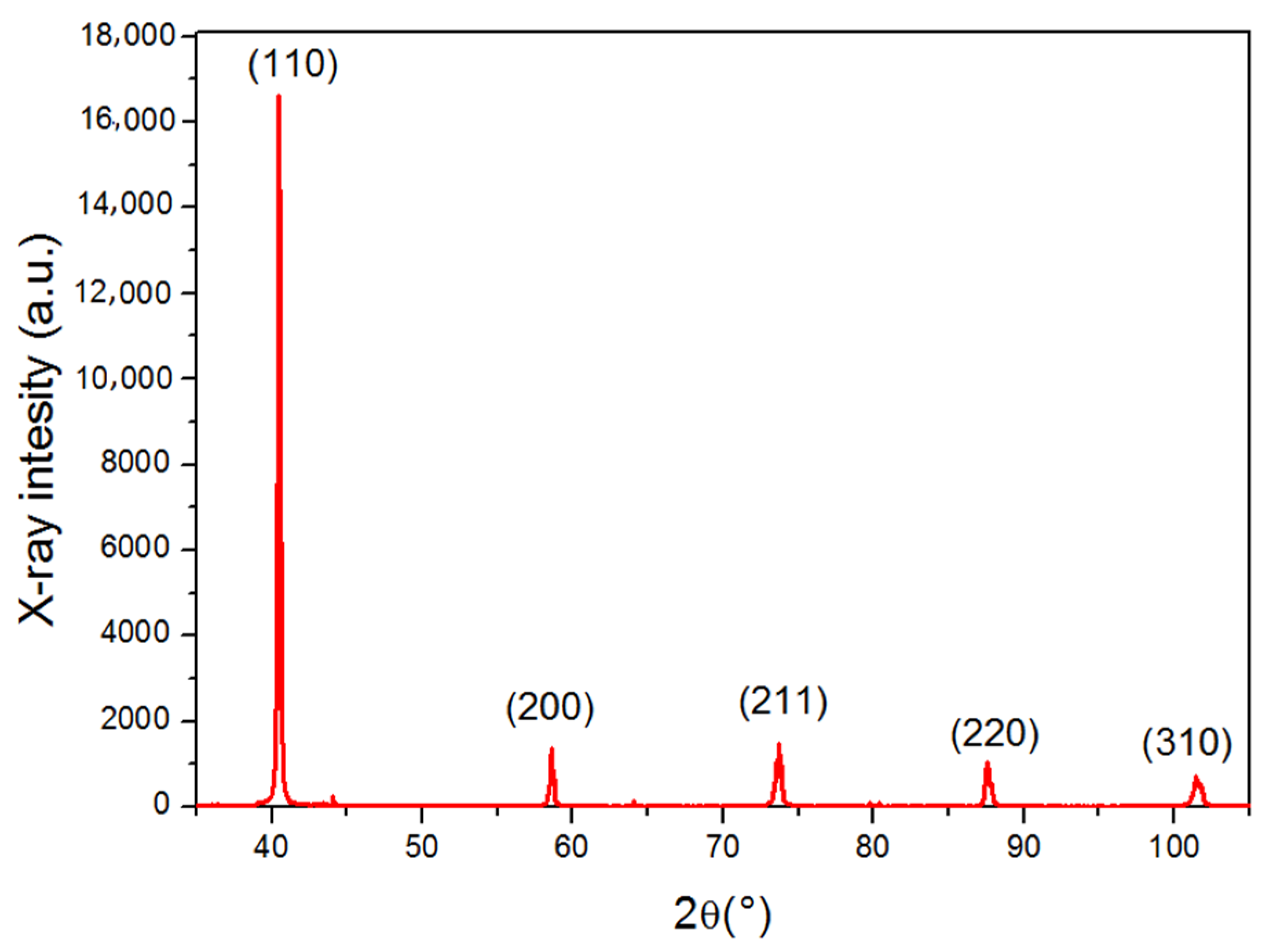

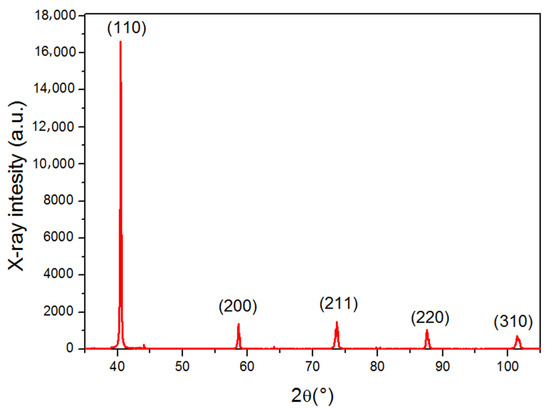

The Mo samples were then characterized through X-ray diffraction (XRD, diffractometer Philips, Eindhoven, The Netherlands). Figure 2 displays the XRD pattern obtained by focusing the beam on the plate surface.

Figure 2.

The XRD pattern of the examined Mo.

The XRD pattern displayed in Figure 2 was collected by operating in a step-scanning mode with Cu-Kα radiation (wavelength λ = 0.1508 nm), 2θ steps of 0.05°, and a counting time of 5 s per step. To assess the possible presence of preferred grain orientations, the relative intensities of the main reflections have been compared to those reported in the JCPDS-ICDD database [25], file 42-1120, and corresponding to a material with random oriented grains. The results displayed in Table 2 show that Mo used in the present experiments exhibits a strong {110} texture.

Table 2.

A comparison of the intensities of main reflections to those reported in the JCPDS-ICDD database.

To determine the cell parameter and the dislocation density, high precision peak profiles were recorded with 2θ steps of 0.005° and a counting time of 5 s per step. The cell parameter a resulted in 0.3150 nm, very close to the value of 0.3147 nm given by the JCPDS-ICDD database.

The dislocation density ρ has been determined from the line broadening of XRD peak profiles. The total line broadening βT of a peak is the sum of two contributions due to the size D of coherently diffracting domains (βD), namely the grains, and to the micro-strains ε (βε):

θ being the Bragg angle and K = 0.89. Since the mean D value is ~10 µm, βD is negligible and βT ≅ βε. The dislocation density ρ has then been calculated using the Williamson-Smallman relationship [26]:

where Ξ = 16.1 and k0 ≅ 1 are constants, and b = 0.18186 nm is the modulus of Burgers vector. The dislocation density ρ resulted in 2.0 × 1010 cm−2.

The samples were also submitted to Vickers micro-hardness tests (Shimadzu corporation, Kyoto, Japan). The mean value obtained from 20 tests (300 g, 10 s) was 211 ± 5 HV. The yield stress σY = 540 MPa was determined from the FIMEC test [27].

2.2. Laser Source

The plate surface of the Mo samples have been irradiated (see Figure 1) by a single laser pulse delivered by the laser system—Tor Vergata Laser-Plasma Source (TVLPS) [28], a no-commercial device which consists of a Nd:YAG oscillator, based on the Q-switched technique, followed by four amplification stages. The first two are also Nd:YAG, while the last ones are Nd:Glass. The pulse parameters of the present experiments are: wavelength λ = 1064 nm, pulse duration Δτ ≈ 15 ns, pulse energy Ep ≈ 8 J, Transverse Electromagnetical Mode is TEM00, P-polarized, focal spot size Φ = 200 μm, and surface power density on the focal plane I = 1.7 × 1012 W·cm−2. The plasma electronic temperature at the critical surface (Te ≈ 1.218 × 106 K) simulates the conditions of transient events occurring in a tokamak due to plasma instability.

The experiments were carried out in a vacuum chamber (P ≈ 10−5 bar), and the laser beam hits the samples with an incidence angle of 45° to minimize debris projection near the target. More details about the experimental set-up are reported in previous works [21,22,23] on W (bulk and plasma sprayed) and W-1%La2O3 alloy, which were irradiated in the same conditions.

A spectrometer USB 2000 model (Ocean Optics, 4301 Metric Drive, Winter Park, FL, USA) was used to collect the spectrum from plasma induced by a laser pulse.

After laser irradiation, the surface morphological changes of the Mo samples were studied through SEM observations (Hitachi SU70, Hitachi, Tokyo, Japan). A 3D surface analyzer (TalySurf CLI 2000, Taylor Hobson, Leicester, UK) was used to get level profiles in the zone hit by the laser spot.

3. Results and Discussion

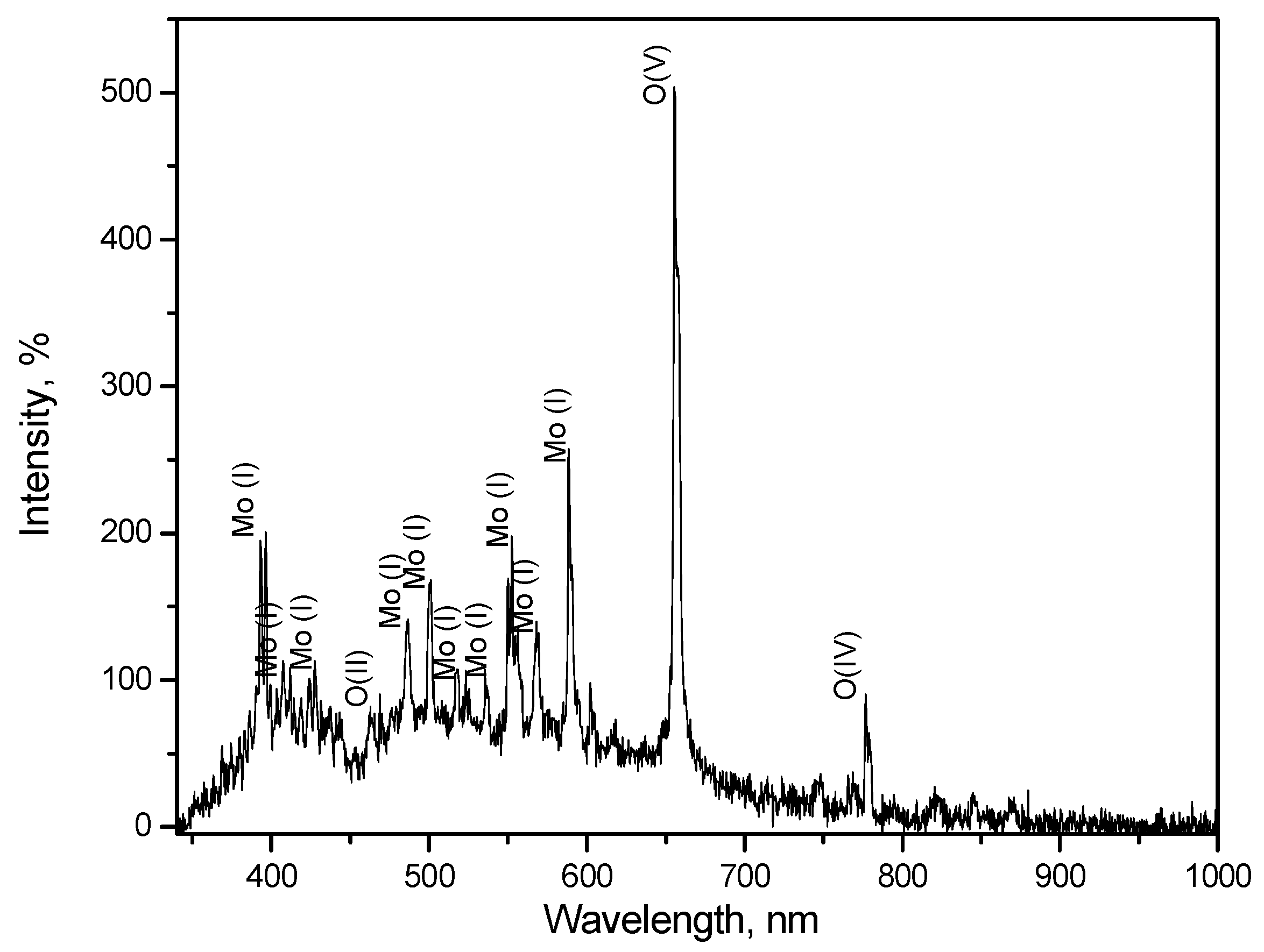

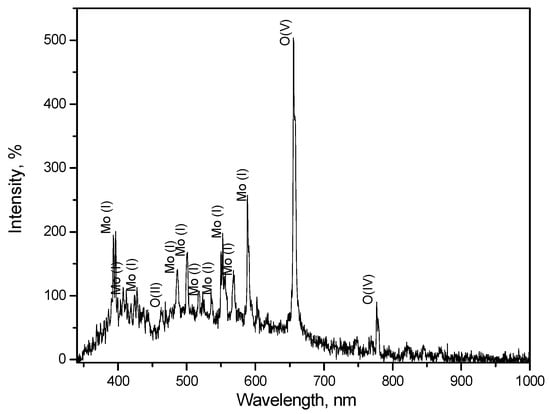

Figure 3 displays the spectrum recorded from plasma induced by a laser pulse through the spectrometer USB 2000. It only exhibits the lines of Mo, whereas those of other metals are not present. Some lines of low intensity corresponding to O are also detected and can be attributed to native oxide on the sample surface.

Figure 3.

Spectrum recorded from plasma induced by a laser pulse (wavelengths from 250 to 1000 nm).

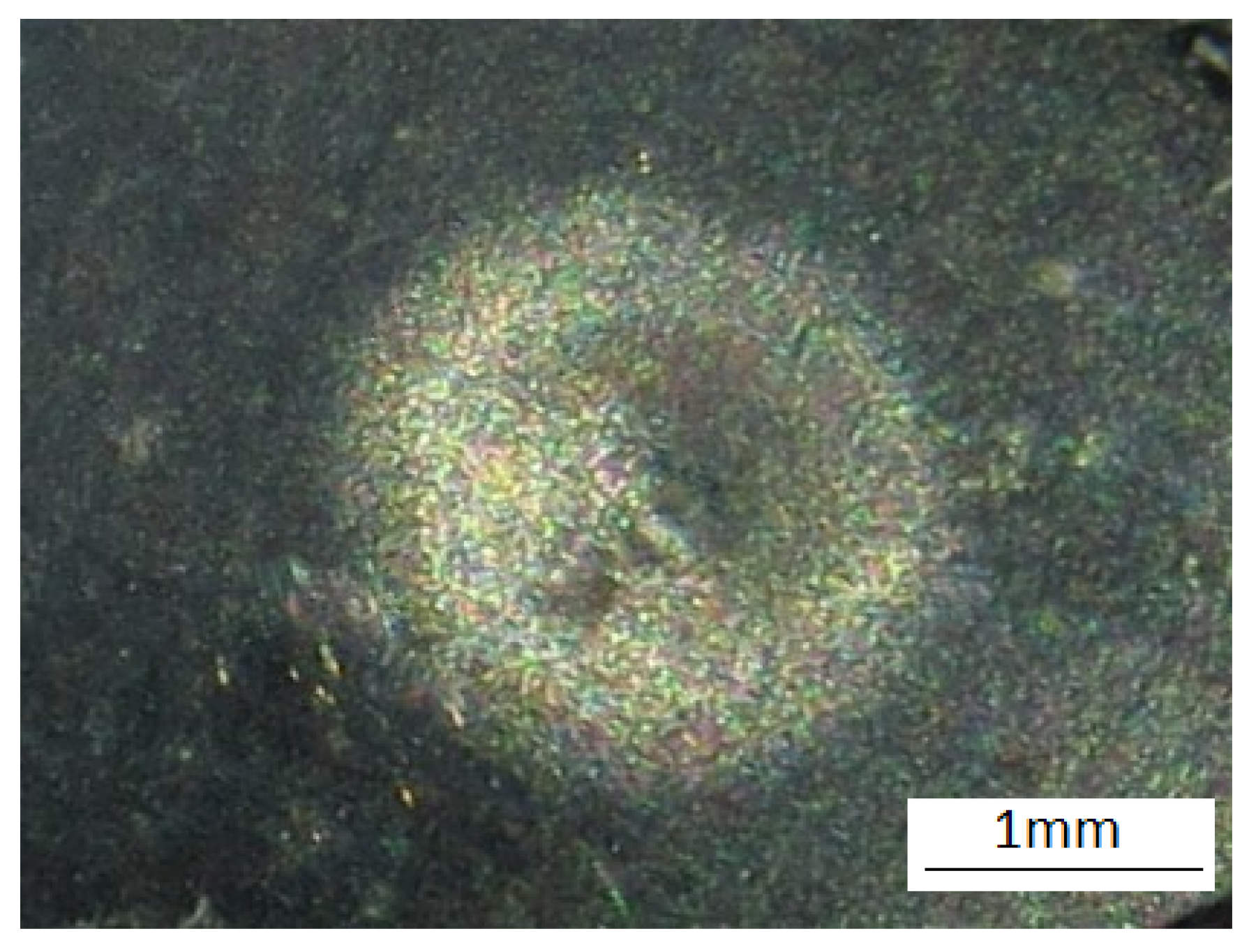

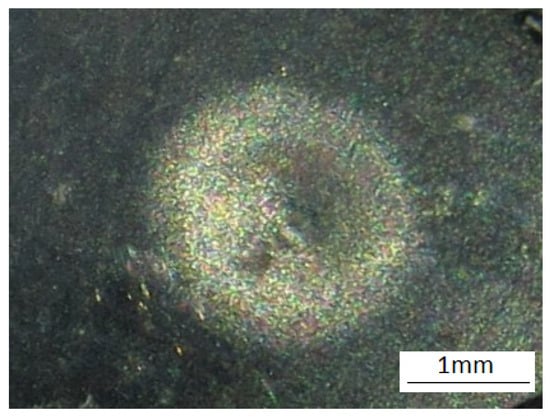

The zone on the sample surface affected by laser pulse irradiation is almost circular with a diameter of ~2.2 mm (Figure 4), i.e., much larger than that of the laser spot (Φ = 200 μm).

Figure 4.

The surface zone affected by the laser pulse.

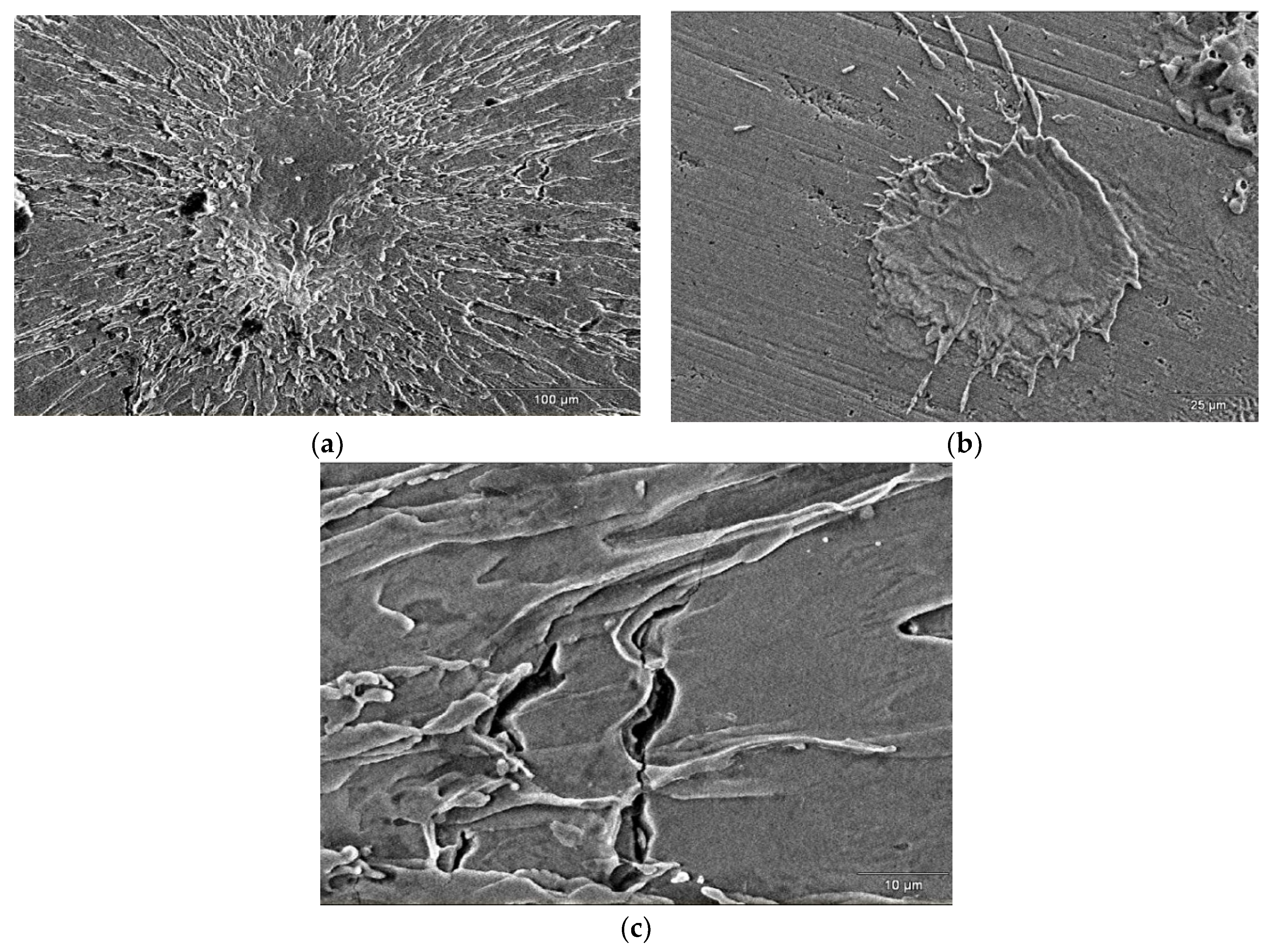

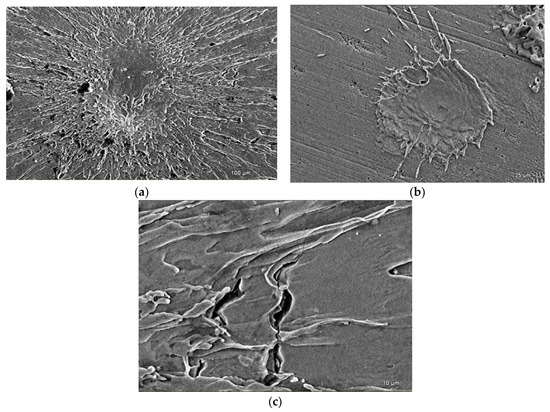

As shown in the SEM micrographs of Figure 5, an erosion crater with a diameter of ~300 μm (a) forms in the central area of the laser spot where the beam has the highest intensity. The laser intensity has a Gaussian shape; thus, its maximum is at the centre, and it radially decreases toward the periphery. The larger fraction of the energy is released in the central part of the spot, causing the melting and vaporization of the metal; the crater formation is due to the ejection of part of the molten metal. Figure 5b displays a drop of the ejected metal fallen and re-solidified in a zone near the crater. Sinclair et al. [16] demonstrated that the surface melting of Mo begins when the energy density reaches a value of ~1.0 MJ·m−2 and that the droplet formation and boiling starts from ~1.4 MJ·m−2, namely values much lower than those involved in the present experiments.

Figure 5.

SEM micrographs displaying the zone irradiated by the laser pulse: (a) the crater; (b) the splash of molten metal ejected from the crater; and (c) a detail of the crater at a higher magnification showing some cracks.

Another effect resulting from the Gaussian intensity profile of the spot is the occurrence of a temperature gradient in molten metal leading to a liquid movement along the radial direction, giving rise to the typical morphology of crater walls shown in the detail of Figure 5c and to the formation of a ridge around the crater. The crater walls are decorated by radially oriented filaments that are produced by the movement and successive solidification of the liquid metal.

The thermal stresses arising from the rapid heating and successive cooling of the external zone of the crater lead to the nucleation and growth of cracks like those shown in Figure 5c.

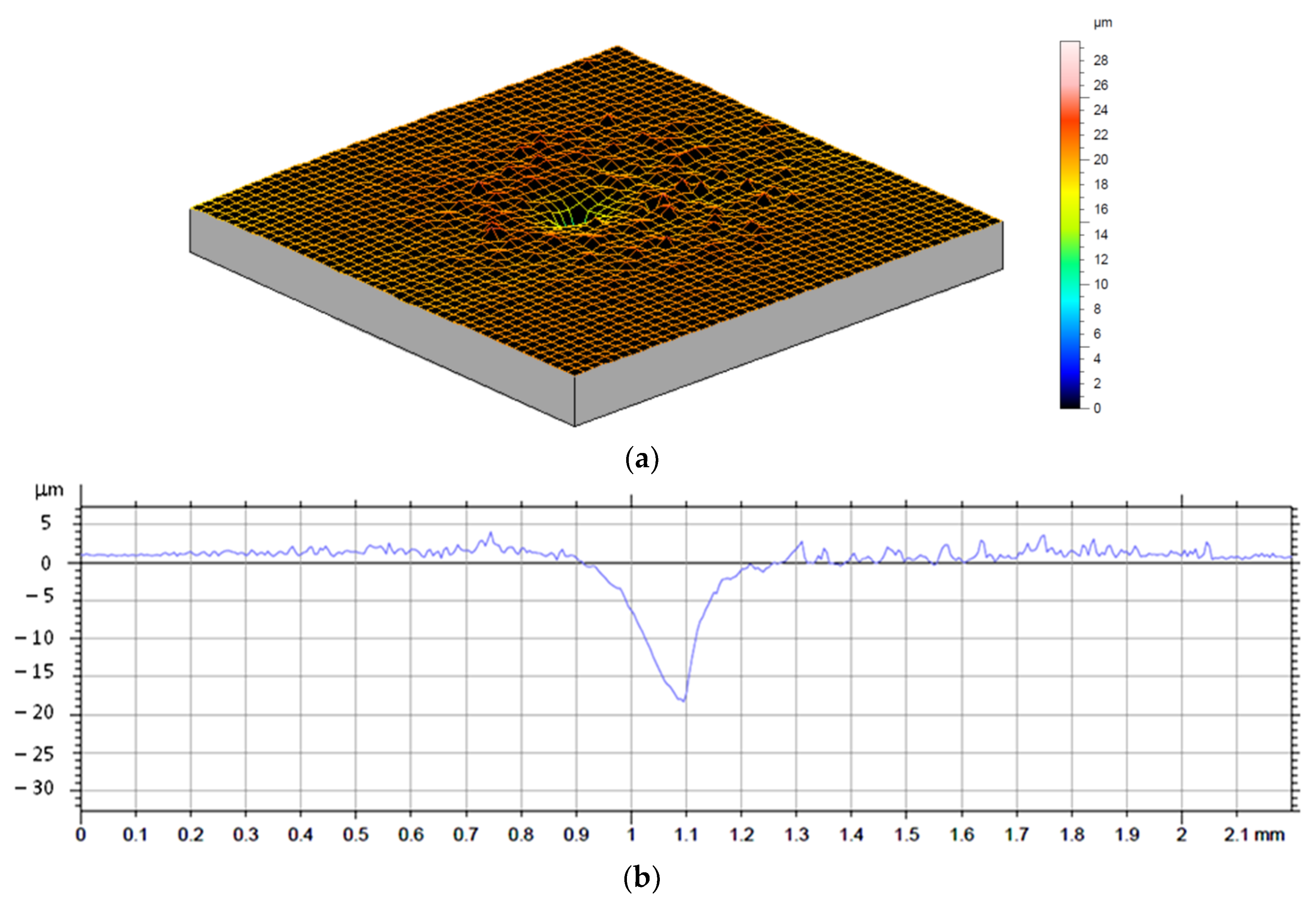

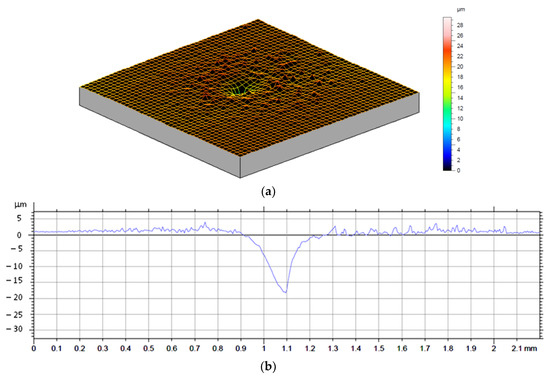

The morphology of the area affected by the laser pulse has been recorded through a 3D surface analyzer (see Figure 6a), and 10 level profiles of the crater, such as that displayed in Figure 6b, have been measured along different directions. The mean diameter and depth was 300 ± 9 and 17 ± 2 μm, respectively; thus, the aspect ratio of the crater (depth/diameter) is ~0.05666. The shape of the crater is quite different from that produced in W under the same experimental conditions (crater diameter = 75 μm, depth = 25 μm, and aspect ratio ~0.333 [21]), namely in the case of Mo it is larger and shallower. Such difference can be explained by considering the specific microstructure of the examined Mo and W samples and its relation with the thermal conductivity affecting the heat flow through the materials. Since the correlation between incoming and outgoing phonons is destroyed by the scattering occurring at an interface like a grain boundary [29,30], the thermal conductivity C decreases with the decreasing grain size d and can be written as:

where C0 is the grain interior thermal conductivity and RK is the Kapitza resistance that measures the interface resistance to the thermal flow [31,32].

Figure 6.

(a) The morphology of the laser irradiated zone measured through a 3D surface analyzer. A level profile of the crater determined from the image in (a) is displayed in (b).

W has equiaxed grains; thus, there is not a preferred direction for the heat flow, as a result of which the crater diameter and depth are comparable. On the contrary, in the case of Mo, heat moves easier along the surface than in the perpendicular direction because it encounters a lower number of interfaces (see Figure 1b,c), giving rise to a larger and shallower crater.

However, the most important difference between the behaviour of the two refractory metals regards the volume of material ablated from the surface by the single laser pulse. A rough estimation of such a volume has been made by considering the crater like a cone. From this calculation, the ablated volume in the case of Mo is about ten times that of W. This strictly depends on the latent heat of fusion EM and latent heat of vaporization EV of W, which are remarkably higher than those of Mo (see Table 1).

After melting, the liquid metal is flushed to the periphery, and its viscosity and surface tension determine the morphological features of the crater and surrounding zones, which are different from those of W because in that case [21,22] solidified drops decorating the crater walls have been observed but the long filaments displayed by Mo have not (see Figure 5).

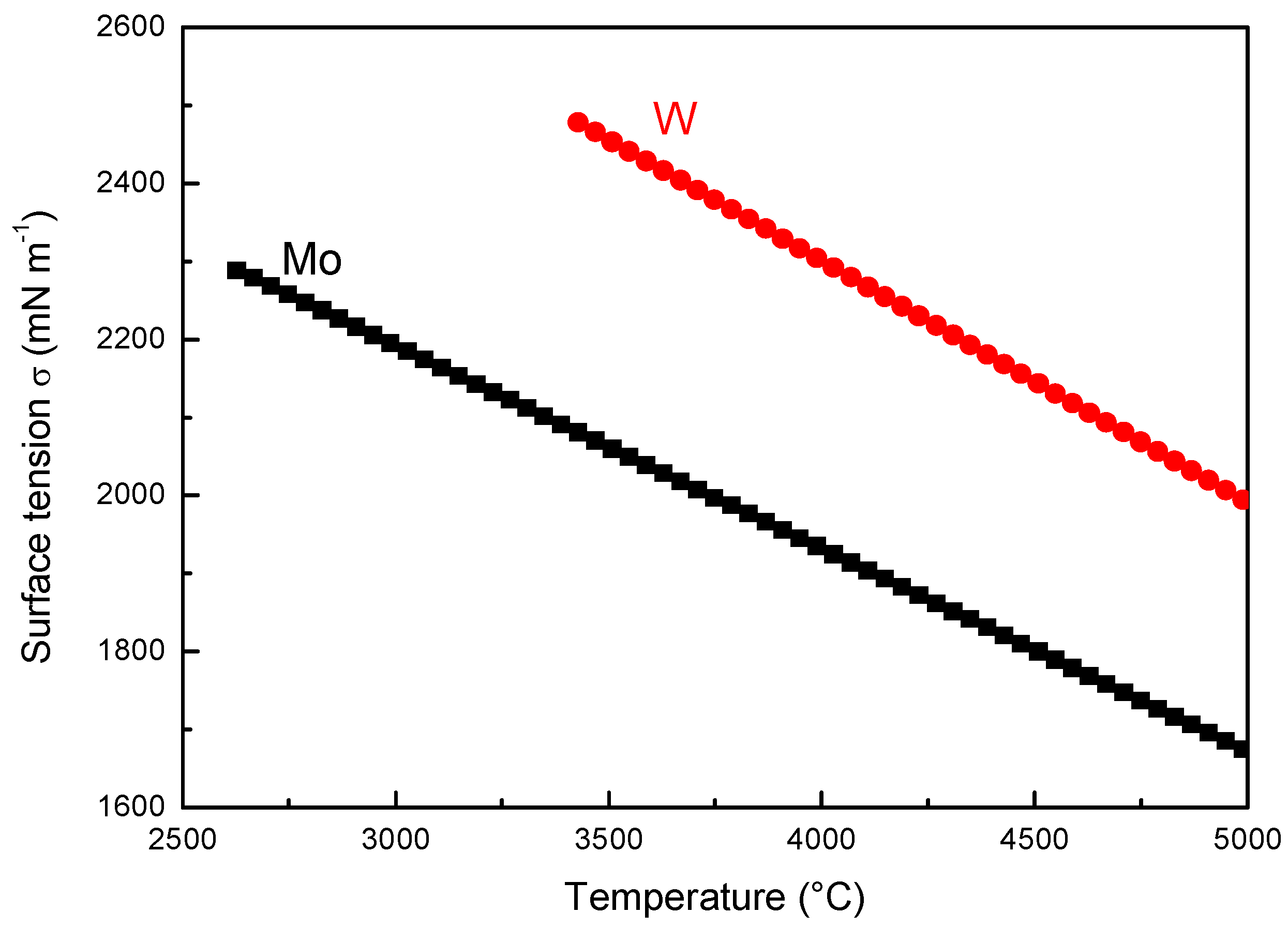

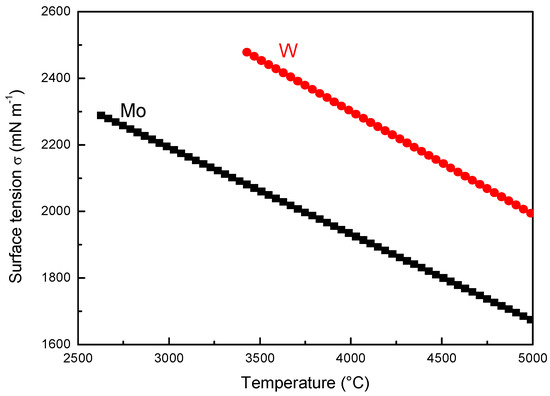

The surface tension of Mo, determined by Paradis et al. [33] through the oscillation drop technique in conjunction with a vacuum electrostatic levitation furnace, can be expressed as:

while that of W is [34]:

σ(T) = 2.29 × 103 − 0.26(T − Tm) (mN·m−1)

σ(T) = 2.48 × 103 − 0.31(T − Tm) (mN·m−1)

The surface tension values of molten Mo and W vs. temperature, calculated according to Equations (4) and (5), are plotted in Figure 7.

Figure 7.

Surface tension of W and Mo vs. temperature, calculated according to the relationships of Paradis et al. [33,34].

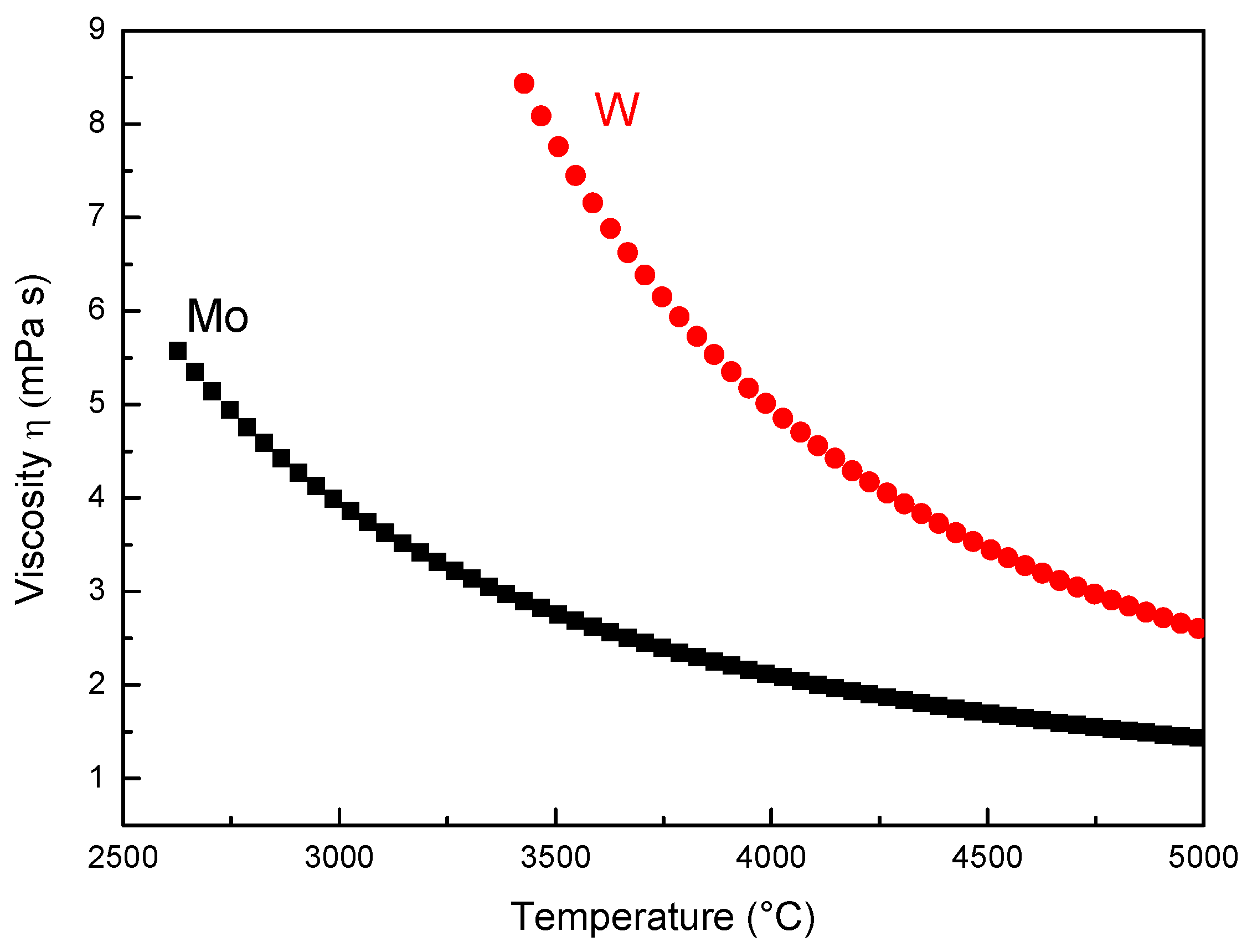

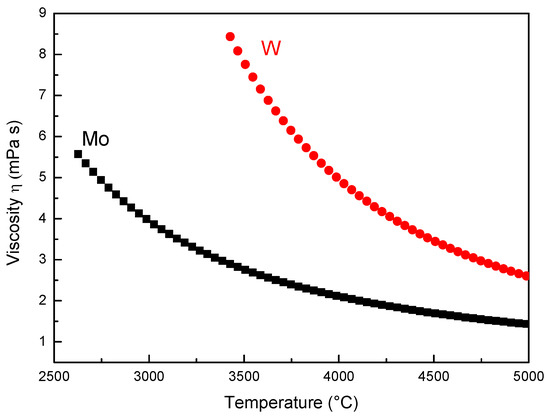

The viscosity trends of liquid Mo [33,34,35] and W [36] vs. temperature are given by the Equations (6) and (7), respectively, and are plotted in Figure 8.

η(T) = 0.27exp[73 × 103/RT] (mPa·s)

η(T) = 0.16exp[3.9713TM/T] (mPa·s)

Figure 8.

Viscosity of W and Mo vs. temperature, calculated according to Equations (5) and (6).

On these grounds, it is clear that the lower viscosity of Mo allows an easier flow of the liquid metal, leading to the formation of long filaments (see Figure 5) that are not observed in the case of W.

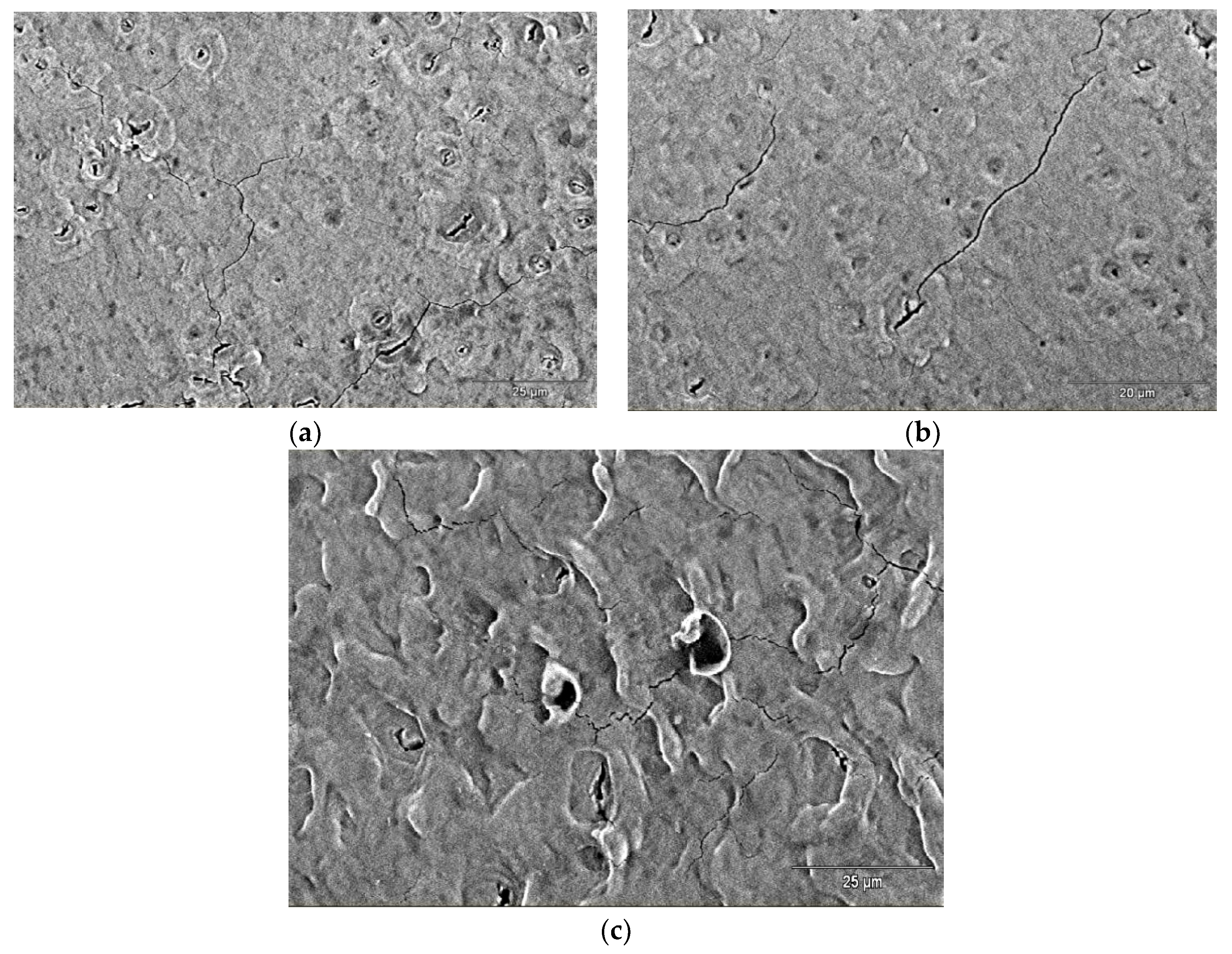

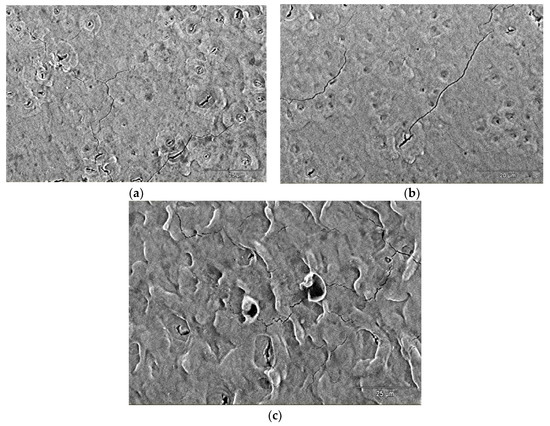

In a more external region outside the crater, from 300 μm to ~1 mm, the material exhibits bubbles like those shown in Figure 9a,b and long cracks. Such cracks are due to thermal stresses occurring in the metal after fast heating and successive cooling; as shown in Figure 9c, they depart from the bubbles to then propagate through the material. Similar results have been recently published by Straus et al. [37], who studied the damage of W and Mo surfaces induced by an ultraviolet laser radiation (λ ∼ 47 nm).

Figure 9.

(a–c) The zone around the crater exhibits bubbles and long cracks often departing from the bubbles.

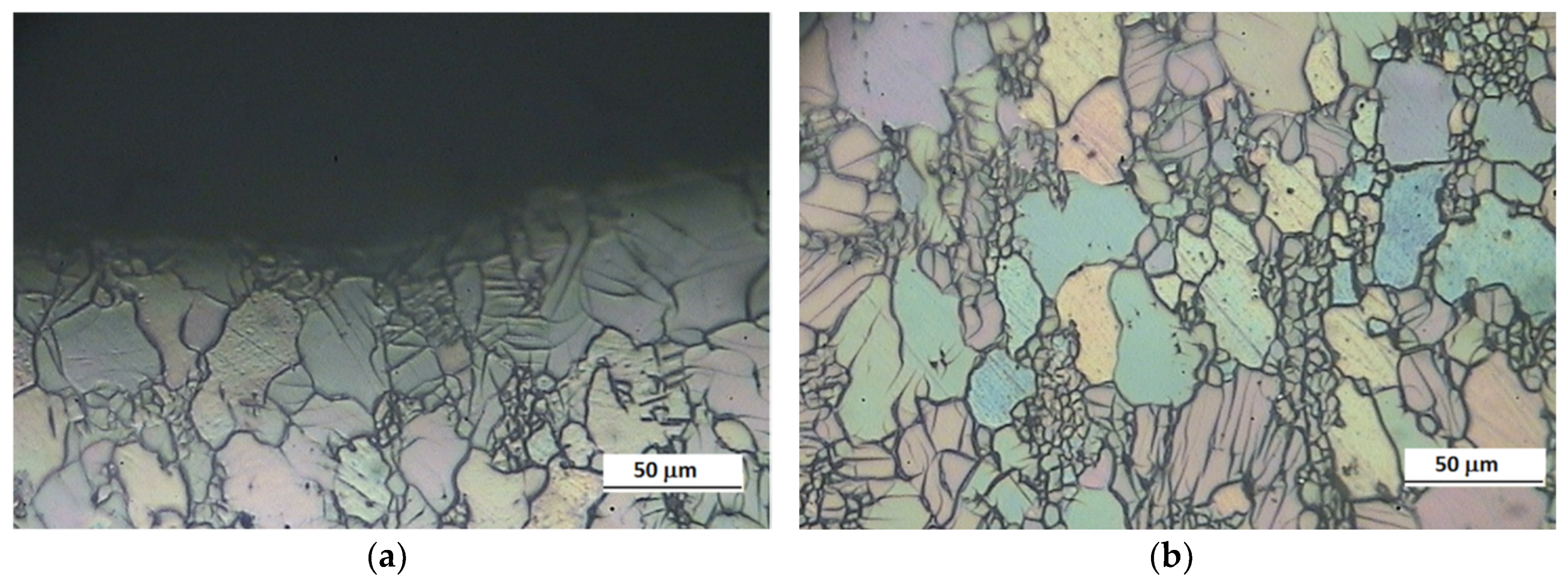

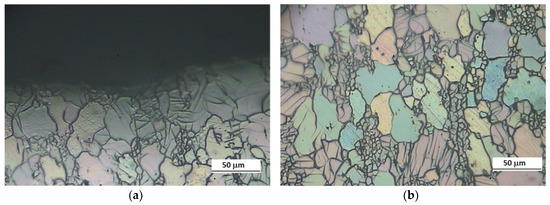

Figure 10a shows a cross-section of the crater: the morphology and size of the grains differs remarkably from that of the unaffected material (Figure 1c), since elongated substructures substantially disappeared, and grains with a size of a few microns cover only a small part of the observed area. The change can be explained by the grain growth induced by the strong heating in the zone close to where the melting occurs. The same phenomenon is also observed in Figure 10b, taken from a zone below the crater at a distance of about 500 μm from the sample surface, even if in this case the effect is limited because the larger distance involves a lower temperature increase.

Figure 10.

(a) Cross-section of the crater and (b) of the zone just below.

Finally, no microstructural change has been detected at a distance of about 1 mm.

In future work, research will be focused on the regimes of high-energy exposure in order to explore the effects of different thermal loads. Treatments suitable for improving the structure and mechanical properties of Mo will also be investigated in order to get better behaviour under laser irradiation and to eliminate surface cracking. Another aspect that deserves to be deeply examined is the role of the original sample roughness, which can affect the erosion as well as tritium retention (e.g., see the paper of Eksaeva et al. [38]). However, the most critical aspect evidenced by the present experiments, namely the large volume ablated from the surface by the single laser pulse (~ten times that of W), seems difficult to resolve because the latent heat of fusion and latent heat of vaporization are intrinsic properties of the material and are not easily modifiable. On these grounds, W remains the first choice for manufacturing the armours of the ITER divertor, even if the decrease of DBTT and the increase of ductility and fracture toughness are mandatory requirements for a successful application of the material. Aiming for this goal, three approaches are currently being studied to ductilize W [17,39,40]: (i) the preparation of W solid solutions (Re, Ir, Ta, and V are the most promising alloying elements), (ii) the synthesis of ultra-fine-grained W, and (iii) the synthesis of W composites. The last one consists in reinforcing a W matrix through W fibres coated by an engineered interface and seems to guarantee the best results.

4. Conclusions

The effects on Mo of transient high energy thermal loads occurring in a Tokamak during operative conditions have been simulated through a single laser pulse delivered by a Nd:YAG/Glass laser.

The examination of the irradiated zone evidenced that an erosion crater forms in the spot’s central area due to metal vaporization and the ejection of molten metal. The thermal gradient leads to radial flushing of liquid metal, giving rise to a ridge around the crater and long filaments along the crater walls. Moreover, in a more external area (up to a distance of about 1 mm from the laser spot center), the surface shows bubbles and long cracks.

The results have been compared to those of previous experiments carried out in the same conditions on W, the material considered to be the principal candidate for building the armours of ITER.

Although some morphological features, namely the presence of an erosion crater at the centre of a more extended zone with surface modifications, are similar in Mo and W, these metals exhibit relevant differences:

- the crater is larger and shallower in the case of Mo;

- the volume of Mo ablated from the surface by a single laser pulse is about ten times that of W owing to the remarkably higher latent heat of fusion and latent heat of vaporization of W;

- the morphological features of the Mo crater walls are characterized by long filaments, not observed in the case of W, because the lower viscosity and surface tension of Mo allow an easier flow of the liquid metal;

- grain growth has been observed in a material layer of about 1 mm under the crater, with the effects decreasing as the distance from the surface increases.

In conclusion, the higher erosion of Mo indicates that W remains the best solution for manufacturing the armours of the ITER divertor.

Author Contributions

Conceptualization, R.M., E.P., R.R., M.R. and A.V.; Data curation, R.M., E.P., R.R., M.R. and A.V.; Investigation, E.P., R.R., M.R. and A.V.; Supervision, R.M.; Writing—original draft, R.M., E.P. and M.R. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been carried out within the framework of the EUROfusion Consortium and has received funding from the Euratom research and training programme 2014–2018 and 2019–2020 under Grant Agreement No. 633053. The views and opinions expressed herein do not necessarily reflect those of the European Commission.

Acknowledgments

The authors are grateful to Piero Plini and Benedetto Iacovone of Department of Industrial Engineering for the assistance in sample preparation.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Riccardi, B.; Pizzuto, A.; Orsini, A.; Libera, S.; Visca, E.; Bertamini, L.; Casadei, F.; Severini, E.; Montanari, R.; Vesprini, R.; et al. Tungsten thick coatings for plasma facing components. Fusion Technol. 1998, 31, 223–226. [Google Scholar]

- Roedig, M.; Kuehnlein, W.; Linke, J.; Merola, M.; Rigal, E.; Schedler, B.; Visca, E. Investigation of tungsten alloys as plasma facing materials for the ITER divertor. Fusion Eng. Des. 2002, 61, 135–140. [Google Scholar] [CrossRef]

- Bolt, H.; Barabash, V.; Krauss, W.; Linke, J.; Neu, R.; Suzuki, S.; Nyoshida, N. Materials for the plasma facing components of fusion reactors. J. Nucl. Mater. 2004, 329, 66–73. [Google Scholar] [CrossRef]

- Uytdenhouwen, I.; Decreton, M.; Hirai, T.; Linke, J.; Pintsuk, G.; Van Oost, G. Influence of recrystallization on thermal shock resistance of various tungsten grades. J. Nucl. Mater. 2007, 363, 1099–1103. [Google Scholar] [CrossRef]

- Maier, H.; Hirai, T.; Rubel, M.; Neu, R.; Mertens, P.; Greuner, H.; Hopf, C.; Matthews, G.F.; Neubauer, O.; Piazza, G.; et al. Tungsten and beryllium armour development for the JET ITER-like wall project. Nucl. Fusion 2007, 47, 222. [Google Scholar] [CrossRef]

- Herrmann, A.; Greuner, H.; Fuchs, J.C.; de Marné, P.; Neu, R.; ASDEX Upgrade Team. Experiences with tungsten coatings in high heat flux tests and under plasma load in ASDEX Upgrade. Phys. Scr. 2009, T138, 014059. [Google Scholar] [CrossRef]

- Cui, S.; Simmonds, M.; Qin, W.; Ren, F.; Tynan, G.R.; Doerner, R.P.; Chen, R. Thermal conductivity reduction of tungsten plasma facing material due to helium plasma irradiation in PISCES using the improved 3-omega method. J. Nucl. Mater. 2017, 486, 267–273. [Google Scholar] [CrossRef]

- Kajita, S.; De Temmerman, G.; Morgan, T.; Van Eden, S.; de Kruif, T.; Ohno, N. Thermal response of nanostructured tungsten. Nucl. Fusion 2014, 54, 033005. [Google Scholar] [CrossRef]

- Uytdenhouwen, I.; Massaut, V.; Linke, J.; Van Oost, G. Plasma wall interaction phenomena on tungsten armour materials for fusion applications. In Proceedings of the International Youth Nuclear Congress 2008, Interlaken, Switzerland, 20–26 September 2008. [Google Scholar]

- Lemahieu, N.; Linke, J.; Pintsuk, G.; Van Oost, G.; Wirtz, M.; Zhou, Z. Performance of yttrium doped tungsten under “edge localized mode”-like loading conditions. Phys. Scr. 2014, T159, 014035. [Google Scholar] [CrossRef]

- Shirokova, V.; Laas, T.; Ainsaar, A.; Priimets, J.; Ugaste, U.; Väli, B.; Gribkov, V.A.; Maslyaev, S.A.; Demina, E.V.; Dubrovsky, A.D.; et al. Armor materials’ behavior under repetitive dense plasma shots. Phys. Scr. 2014, T161, 014045. [Google Scholar] [CrossRef]

- De Temmerman, G.C.; Bystrov, K.E.; Zielinski, J.J.; Balden, M.; Matern, G.; Arnas, C.; Marot, L. Nanostructuring of molybdenum and tungsten surfaces by low-energy helium ions. J. Vac. Sci. Technol. A Vac. Surf. Film. 2012, 30, 41306. [Google Scholar] [CrossRef]

- Tripathi, J.K.; Novakowski, T.J.; Hassanein, A. Tailoring molybdenum nanostructure evolution by low energy He+ ion irradiation. Appl. Surf. Sci. 2015, 353, 1070–1081. [Google Scholar] [CrossRef]

- Sinclair, G.; Tripathi, J.K.; Diwakar, P.K.; Hassanein, A. Structural response of transient heat loading on molybdenum surface exposed to low-energy helium ion irradiation. Nucl. Fusion 2016, 56, 36005. [Google Scholar] [CrossRef]

- Brooks, J.N.; El-Guebaly, L.; Hassanein, A.; Sizyuk, T. Plasma-facing material alternatives to tungsten. Nucl. Fusion 2015, 55, 43002. [Google Scholar] [CrossRef]

- Sinclair, G.; Tripathi, J.K.; Diwakar, P.K.; Hassanein, A. Melt layer erosion during ELM-like heat loading on molybdenum as an alternative plasma-facing material. Sci. Rep. 2017, 7, 12273. [Google Scholar] [CrossRef]

- Rieth, M.; Dudarev, S.L.; De Vicente, S.M.G.; Aktaa, J.; Ahlgren, T.; Antusch, S.; Armstrong, D.E.J.; Balden, M.; Baluc, N.; Barthe, M.-F.; et al. Recent progress in research on tungsten materials for nuclear fusion applications in Europe. J. Nucl. Mater. 2013, 432, 482–500. [Google Scholar] [CrossRef]

- Cottrell, G.A. Sigma phase formation in irradiated tungsten, tantalum and molybdenum in a fusion power plant. J. Nucl. Mater. 2004, 334, 166–168. [Google Scholar] [CrossRef]

- Sizyuk, T.; Hassanein, A. Dynamic analysis and evolution of mixed materials bombarded with multiple ions beams. J. Nucl. Mater. 2010, 404, 60. [Google Scholar] [CrossRef]

- Sharpe, J.P.; Kolasinski, R.D.; Shimada, M.; Calderoni, P.; Causey, R.A. Retention behavior in tungsten and molybdenum exposed to high fluences of deuterium ions in TPE. J. Nucl. Mater. 2009, 390, 709–712. [Google Scholar] [CrossRef]

- Richetta, M.; Gaudio, P.; Montanari, R.; Pakhomova, E.; Antonelli, L. Laser pulse simulation of high energy transient thermal loads on bulk and plasma sprayed W for NFR. Mater. Sci. Forum 2017, 879, 1576–1581. [Google Scholar] [CrossRef]

- Montanari, R.; Pakhomova, E.; Pizzoferrato, R.; Richetta, M.; Varone, A. Laser pulse effects on plasma sprayed and bulk tungsten. Metals 2017, 7, 454. [Google Scholar] [CrossRef]

- Gaudio, P.; Montanari, R.; Pakhomova, E.; Richetta, M.; Varone, A. W-1%La2O3 submitted to a single laser pulse: Effect of particles on heat transfer and surface morphology. Metals 2018, 8, 389. [Google Scholar] [CrossRef]

- Rubel, M.; Brezinsek, S.; Coenen, J.W.; Huber, A.; Kirschner, A.; Kreter, A.; Petersson, P.; Philipps, V.; Pospieszczyk, A.; Schweer, B.; et al. Overview of wall probes for erosion and deposition studies in the TEXTOR tokamak. Matter Radiat. Extrem. 2017, 2, 87–104. [Google Scholar] [CrossRef]

- International Centre for Diffraction Data; JCPDS: Newtown Square, PA, USA, 1907.

- Williamson, G.K.; Smallman, R.A. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye-Scherrer spectrum. Philos. Mag. 1956, 1, 34–45. [Google Scholar] [CrossRef]

- Gondi, P.; Donato, A.; Montanari, R.; Sili, A. Miniaturized test method for the mechanical characterization of structural materials for fusion reactors. J. Nucl. Mater. 1996, 233, 1557–1560. [Google Scholar] [CrossRef]

- Francucci, M.; Gaudio, P.; Martellucci, S.; Richetta, M. Spectroscopy methods and applications of the Tor Vergata laser-plasma facility driven by GW-level laser system. Int. J. Spectrosc. 2011, 2011. [Google Scholar] [CrossRef]

- Dong, H.; Wen, B.; Melnik, R. Relative importance of grain boundaries and size effects in thermal conductivity of nanocrystalline materials. Nat. Sci. Rep. 2014, 4, 7037. [Google Scholar] [CrossRef]

- Swartz, E.T.; Pohl, R.O. Thermal boundary resistance. Rev. Mod. Phys. 1989, 61, 605. [Google Scholar] [CrossRef]

- Nan, C.-W.; Birringer, R.; Clarke, D.R.; Gleiter, H. Effective thermal conductivity of particulate composites with interfacial thermal resistance. J. Appl. Phys. 1997, 81, 6692–6699. [Google Scholar] [CrossRef]

- Yang, H.-S.; Bai, G.-R.; Thompson, L.; Eastman, J. Interfacial thermal resistance in nanocrystalline yttria-stabilized zirconia. Acta Mater. 2002, 50, 2309–2317. [Google Scholar] [CrossRef]

- Paradis, P.F.; Ishikawa, T.; Koike, N. Non-contact measurements of the surface tension and viscosity of molybdenum using an electrostatic levitation furnace. Int. J. Refract. Met. Hard Mater. 2007, 25, 95–100. [Google Scholar] [CrossRef]

- Paradis, P.F.; Ishikawa, T.; Fujii, R.; Yoda, S. Physical properties of liquid and undercooled tungsten by levitation techniques. Appl. Phys. Lett. 2005, 86, 041901. [Google Scholar] [CrossRef]

- Cagran, C.; Wilthan, B.; Pottlacher, G. Normal spectral emissivity at a wavelength of 684.5 nm and thermophysical properties of solid and liquid molybdenum. In Proceedings of the 5th Symposium on Thermophysical Properties, Boulder, CO, USA, 23–28 June 2003. [Google Scholar]

- Ishikawa, T.; Paradis, P.-F.; Okada, J.T.; Kumar, M.V.; Watanabe, Y. Viscosity of molten Mo, Ta, Os, Re, and W measured by electrostatic levitation. J. Chem. Thermodyn. 2013, 65, 1–6. [Google Scholar] [CrossRef]

- Straus, J.; Kolacek, K.; Schmidt, J.; Frolov, O.; Vilemova, M.; Matejicek, J.; Jager, A.; Juha, L.; Toufarova, M.; Choukourov, A.; et al. Response of fusion plasma-facing materials to nanosecond pulses of extreme ultraviolet radiation. Laser Part. Beam 2018, 36, 293–307. [Google Scholar] [CrossRef]

- Eksaeva, A.; Borodin, D.; Romazanov, J.; Kirschner, A.; Kreter, A.; Eichler, M.; Rasinski, M.; Pospieszczyk, A.; Unterberg, B.; Brezinsek, S.; et al. Surface roughness effect on Mo physical sputtering and re-deposition in the linear plasma device PSI-2 predicted by ERO2.0. Nucl. Mater. Energy 2019, 19, 13–18. [Google Scholar] [CrossRef]

- Wurster, S.; Baluc, N.; Battabyal, M.; Crosby, T.; Du, J.; Garca-Rosales, C.; Hasegawa, A.; Hoffmann, A.; Kimura, A.; Kurishita, H.; et al. Recent progress in R&D on tungsten alloys for divertor structural and plasma facing materials. J. Nucl. Mater. 2013, 442, S181–S189. [Google Scholar]

- Linsmeier, C.; Rieth, M.; Aktaa, J.; Chikada, T.; Hoffmann, A.; Hoffmann, J.; Houben, A.; Kurishita, H.; Jin, X.; Li, M.; et al. Development of advanced high heat flux and plasma-facing materials. Nucl. Fusion 2017, 57, 092007. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).