Numerical Analysis of Carbon Nanotube-Based Nanofluid Unsteady Flow Amid Two Rotating Disks with Hall Current Coatings and Homogeneous–Heterogeneous Reactions

Abstract

1. Introduction

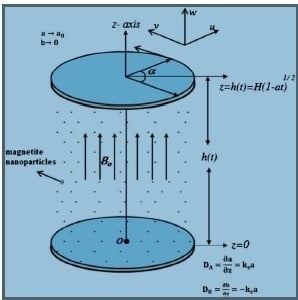

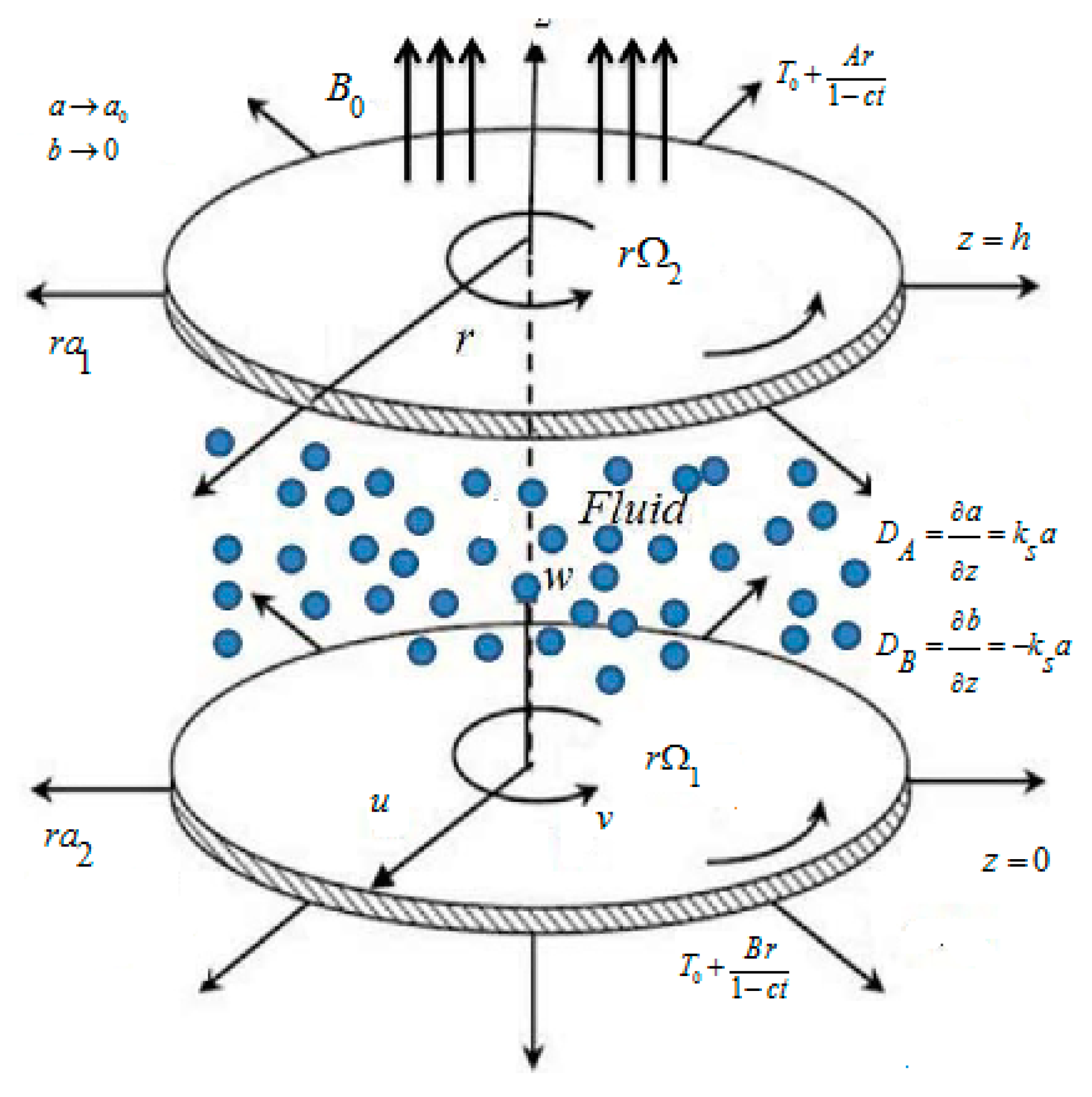

2. Problem Formulation

3. Skin Friction and Local Nusselt Number

4. Numerical Method

5. Outcomes with Discussion

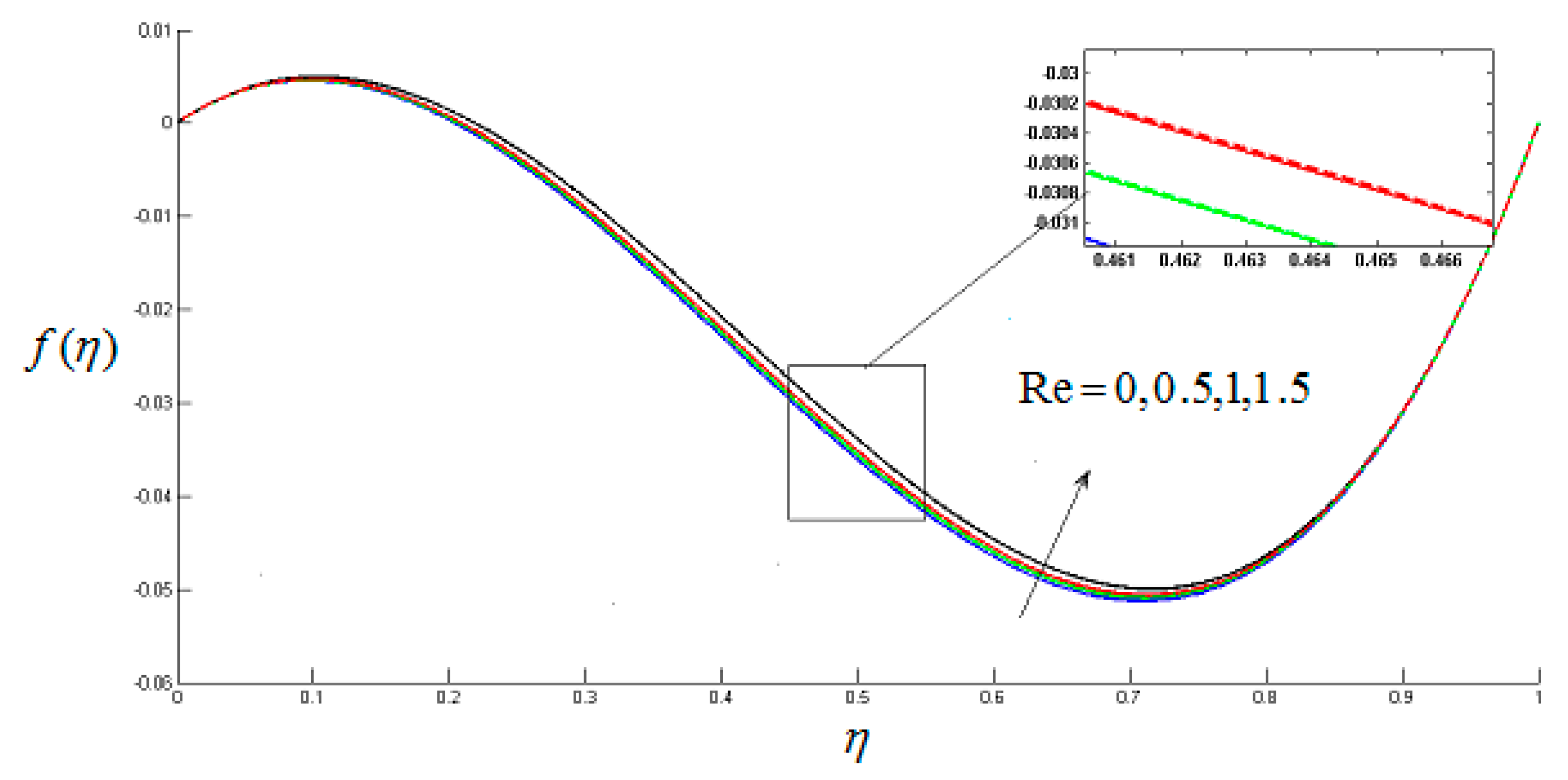

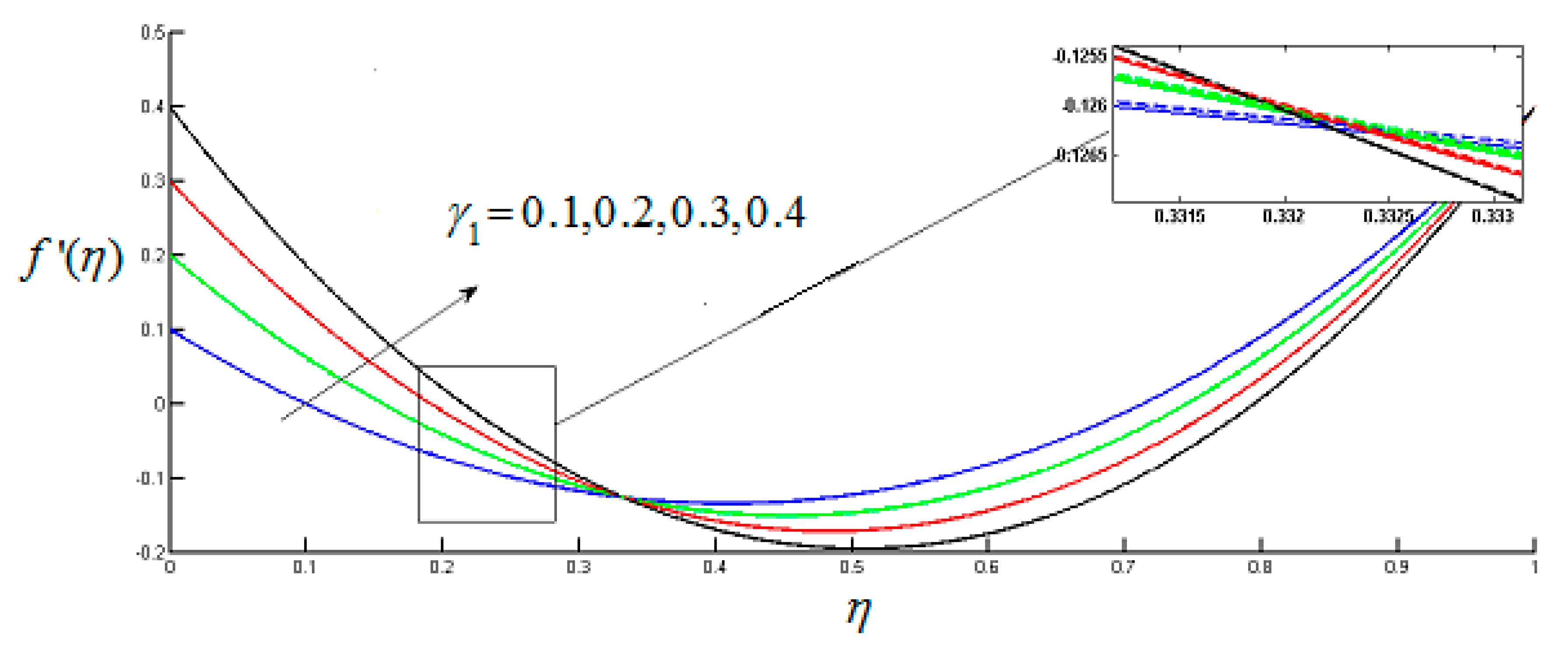

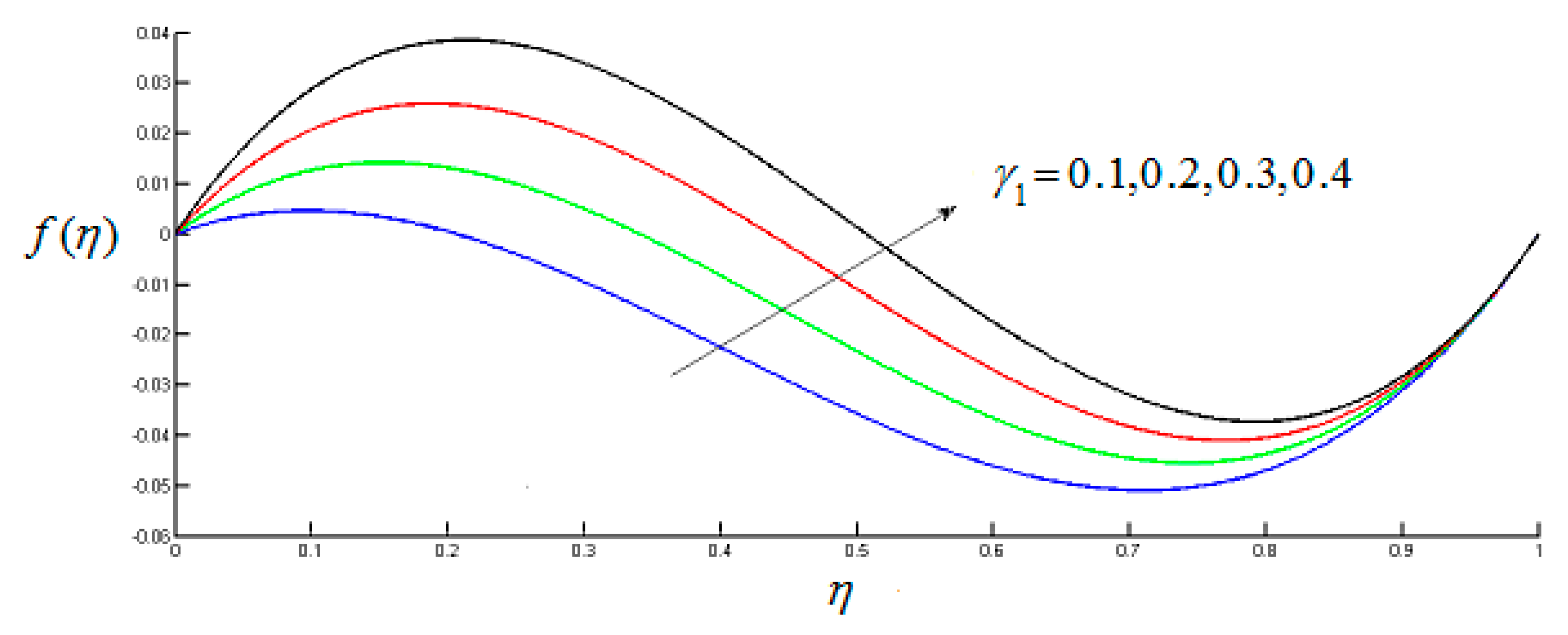

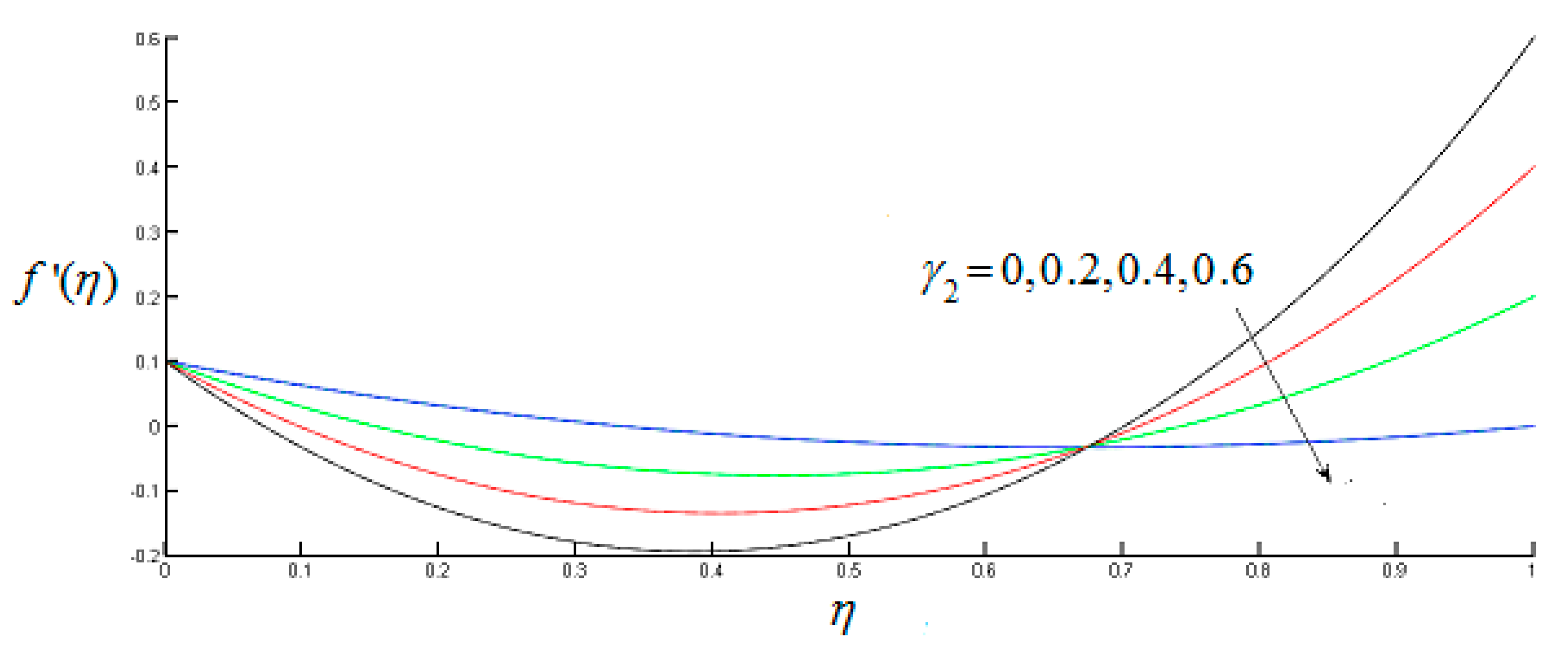

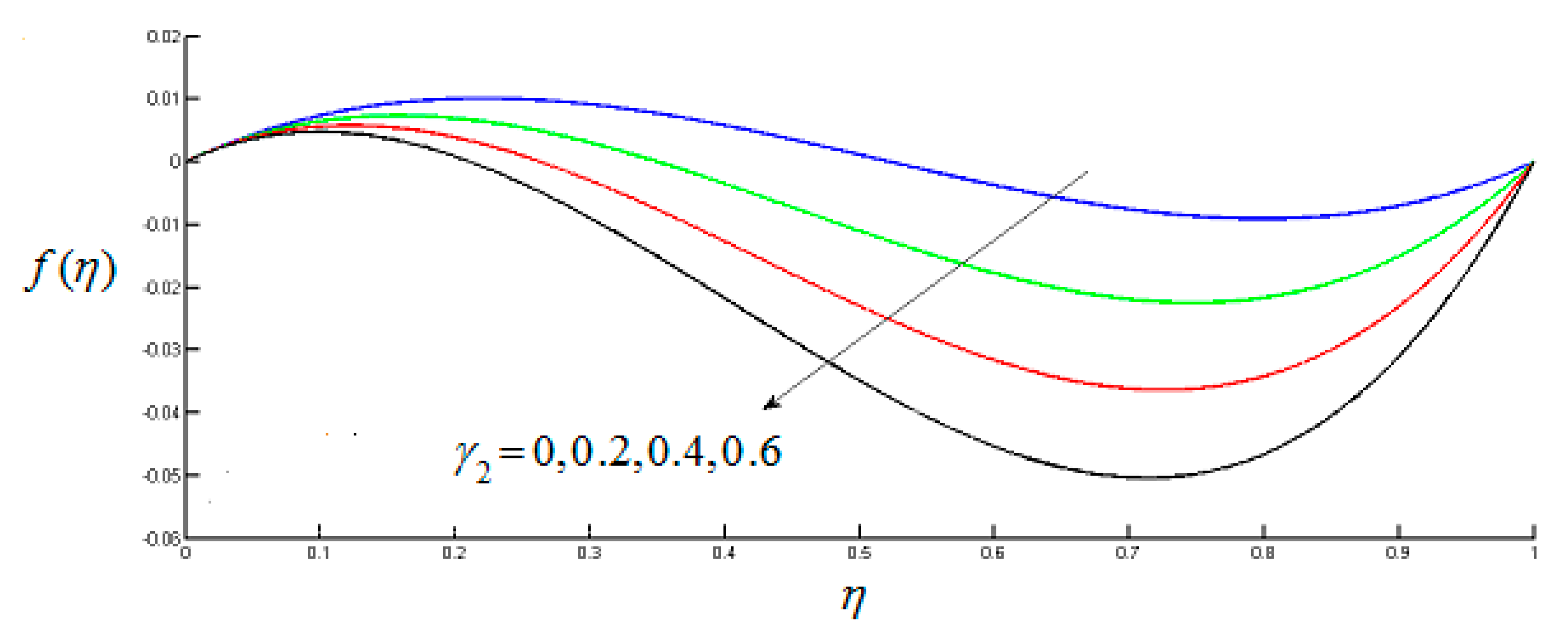

5.1. Radial and Axial Velocity Profile

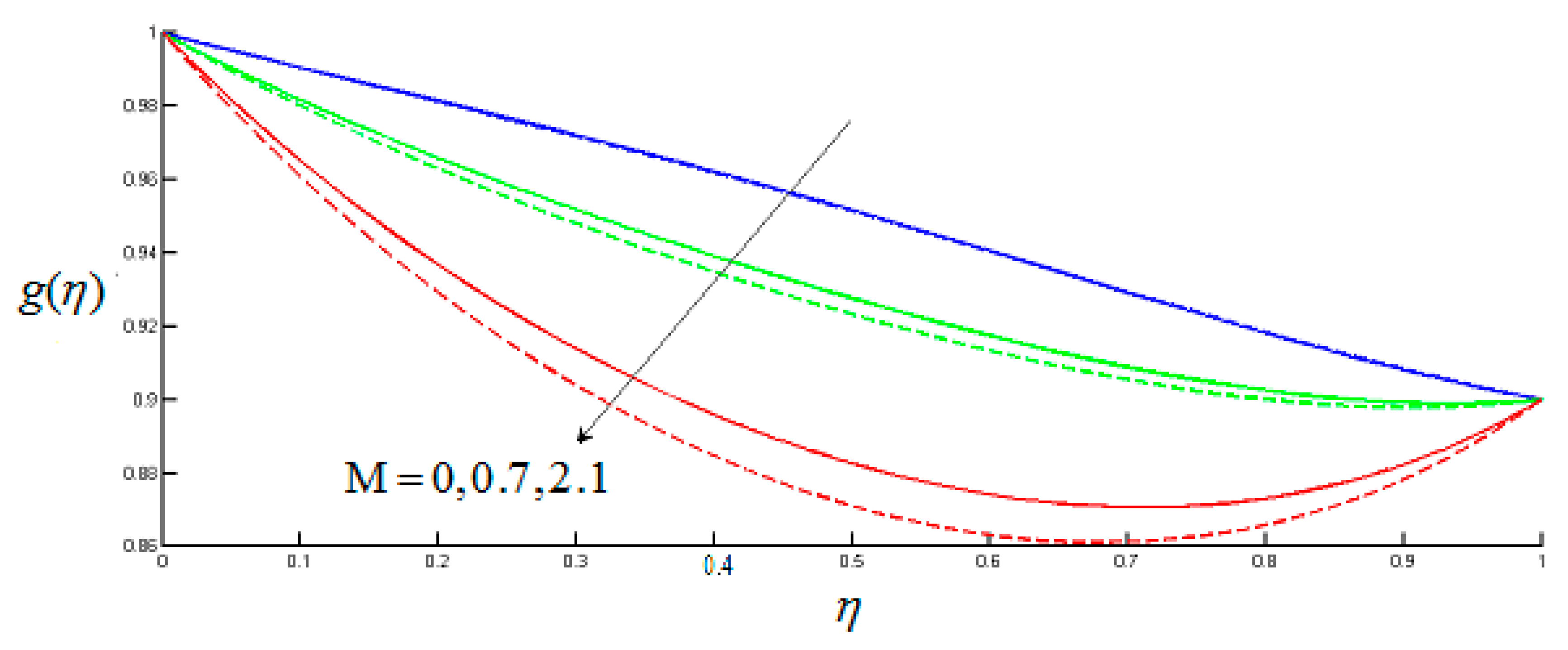

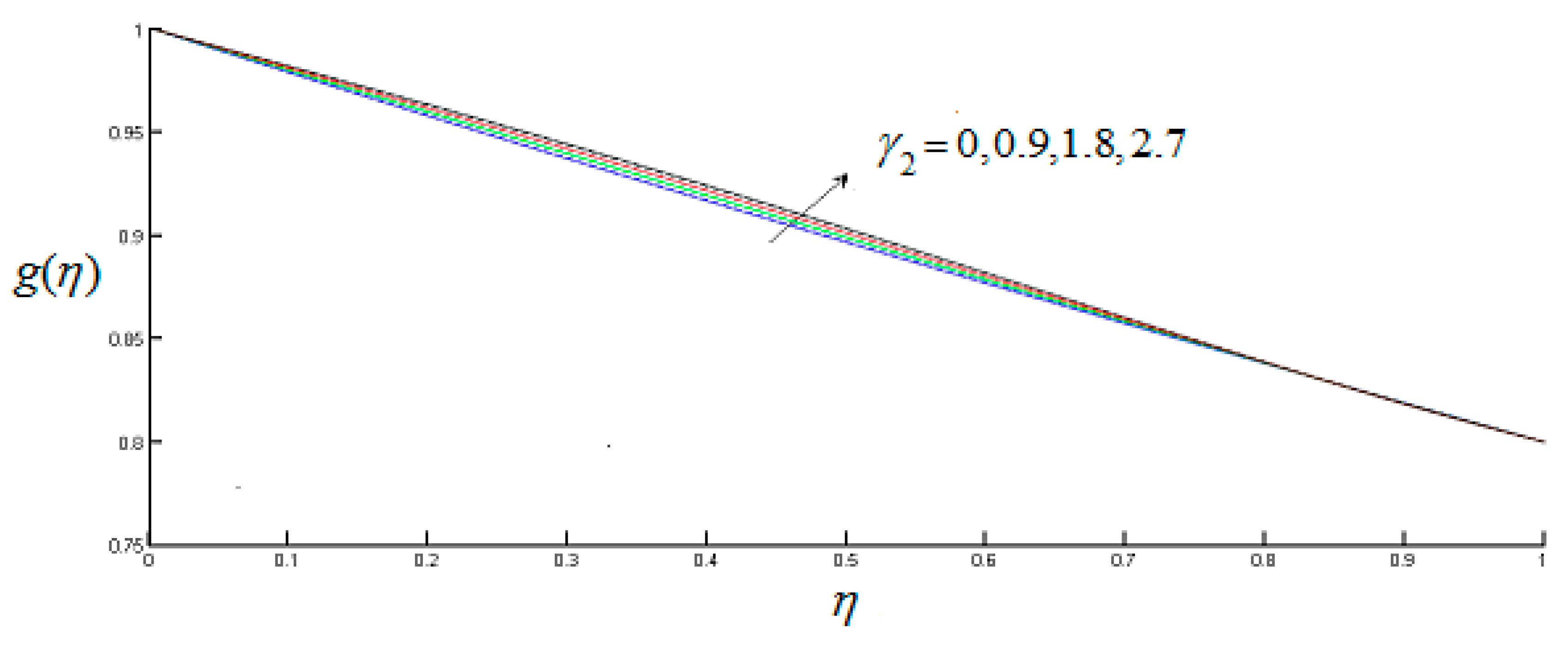

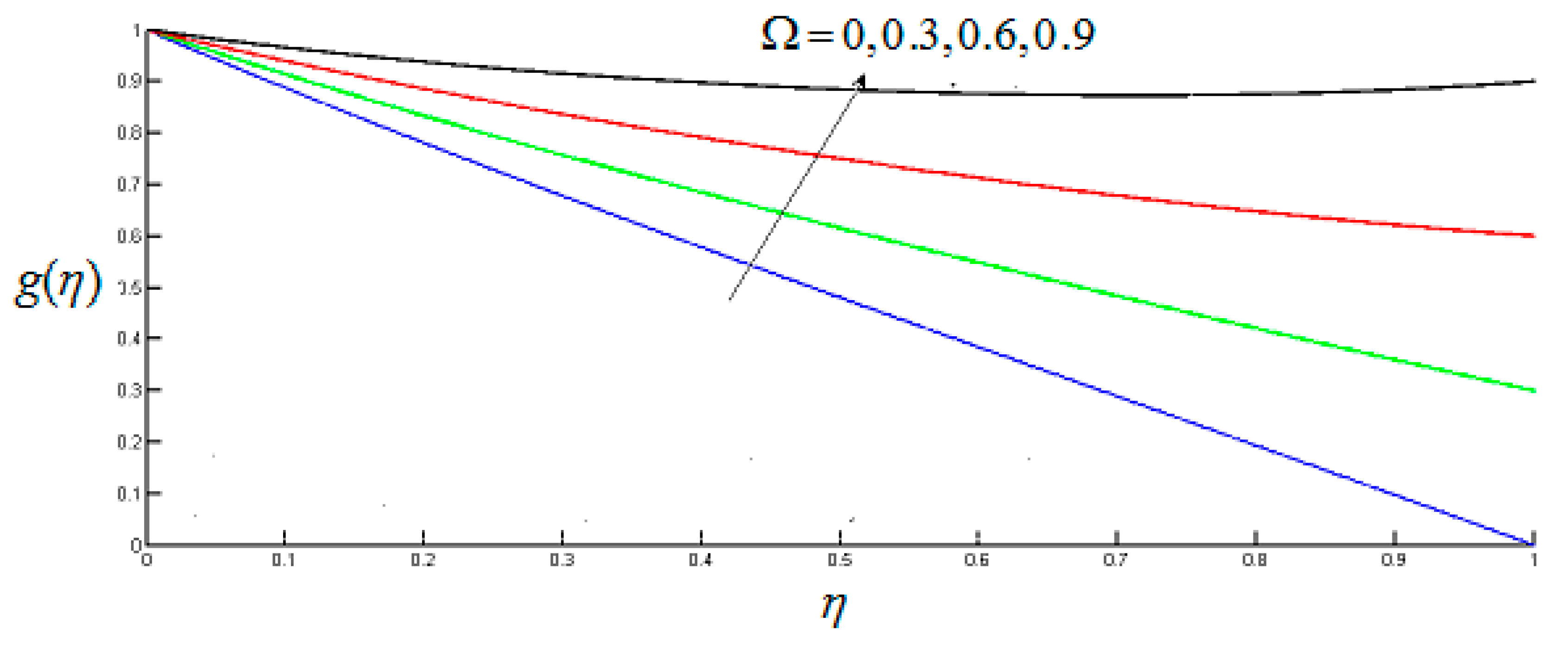

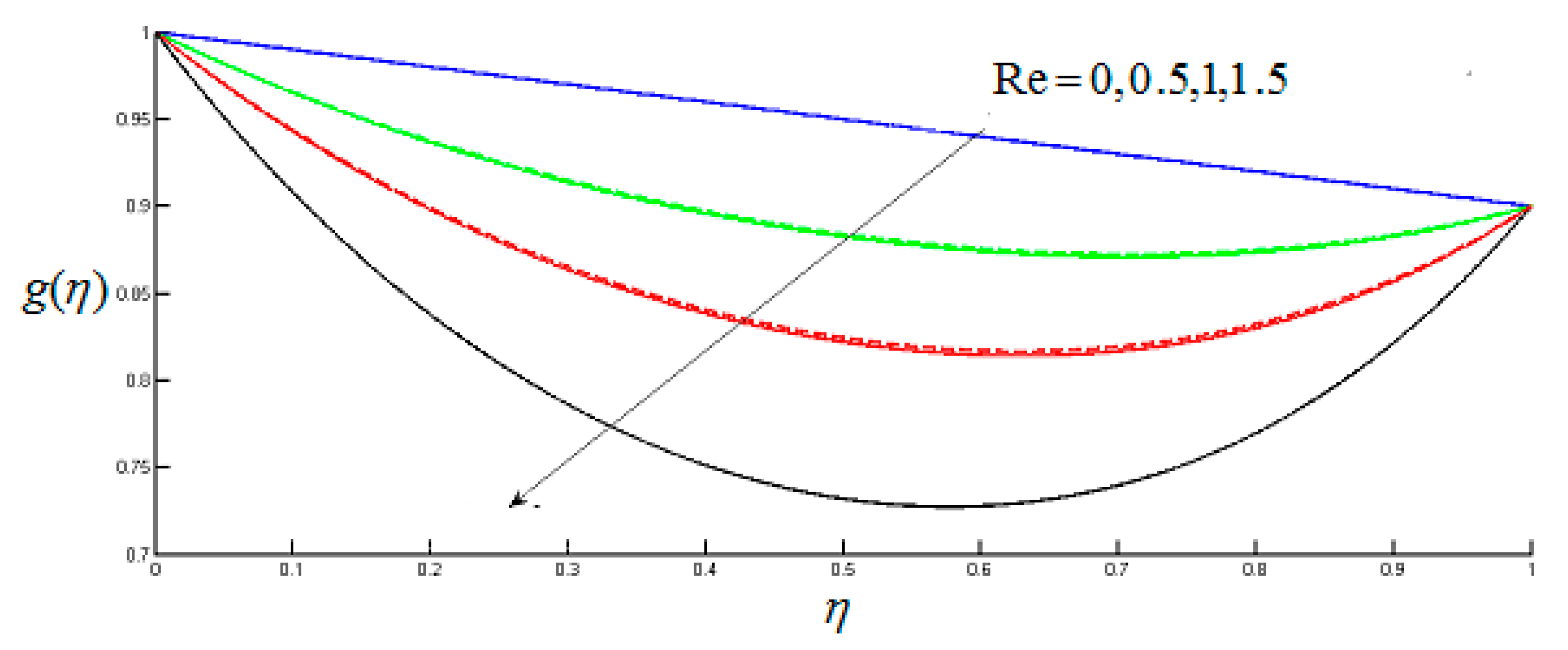

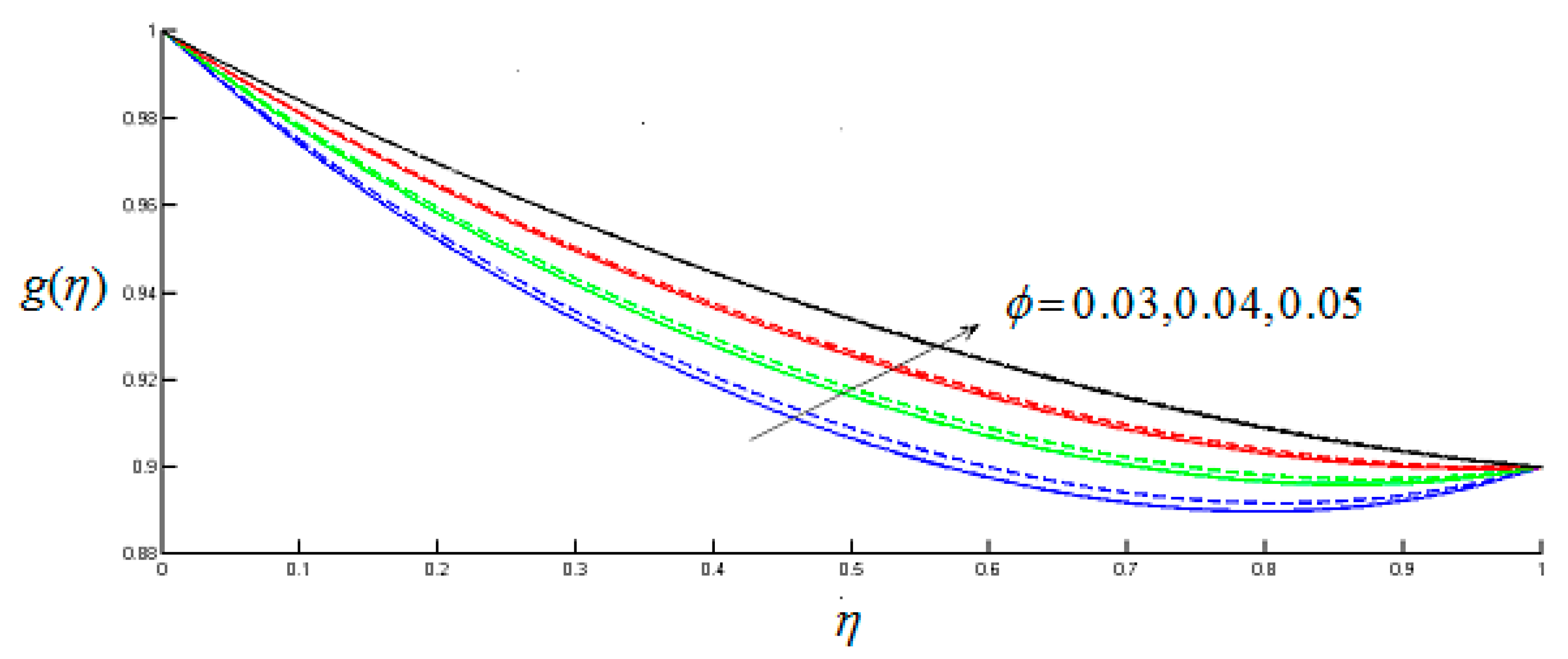

5.2. Tangential Velocity Profile

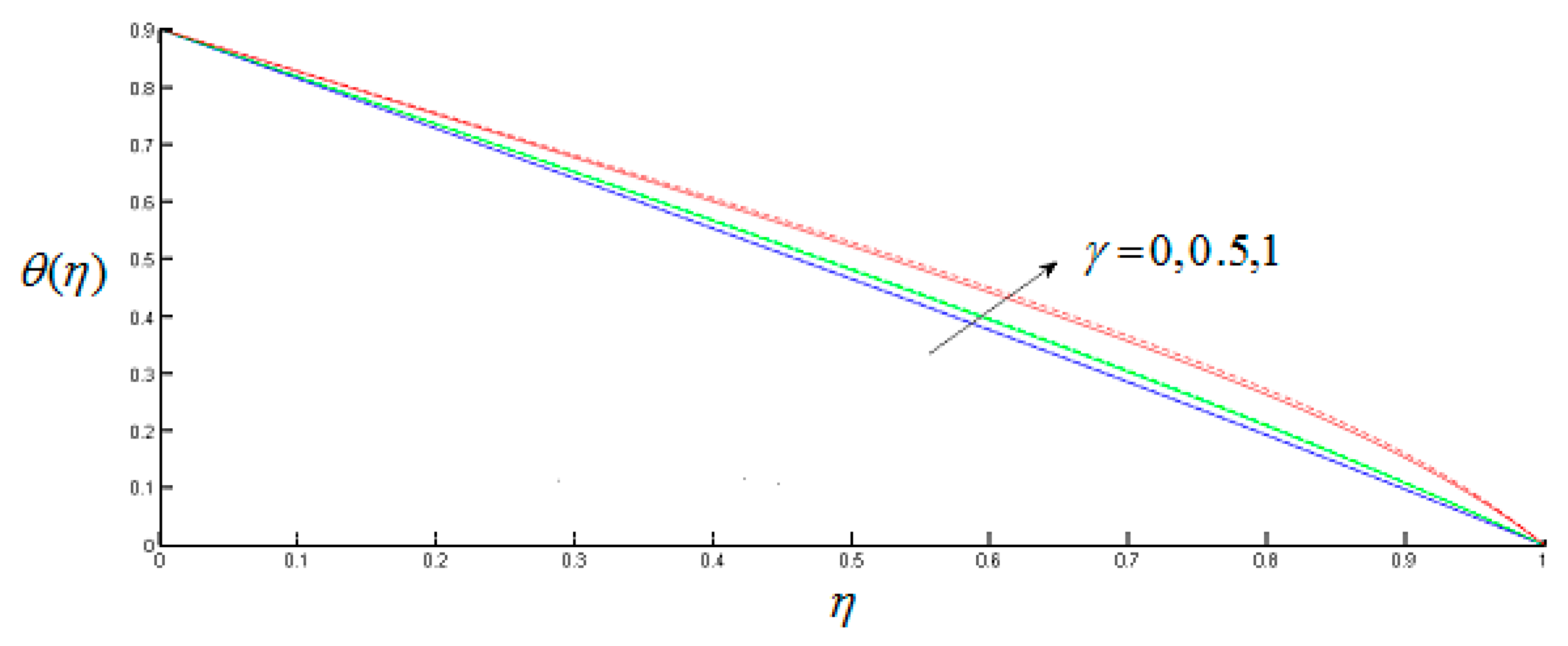

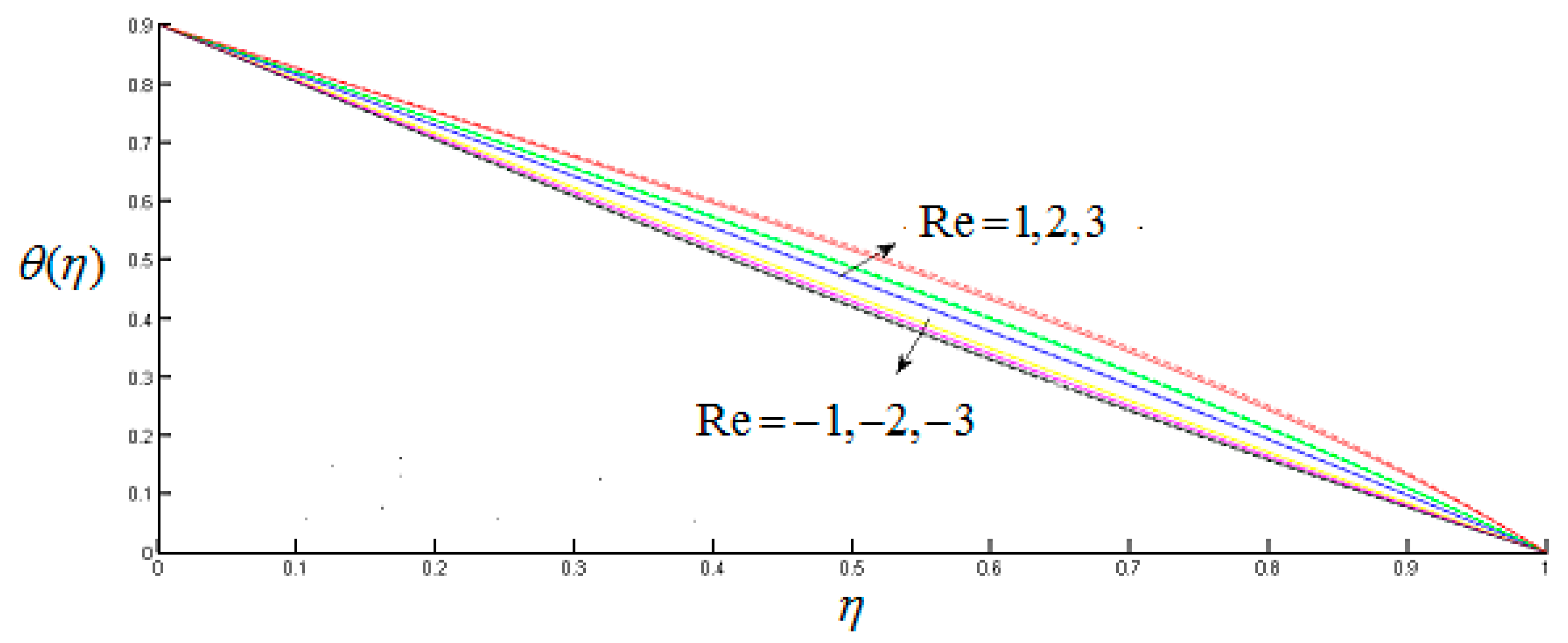

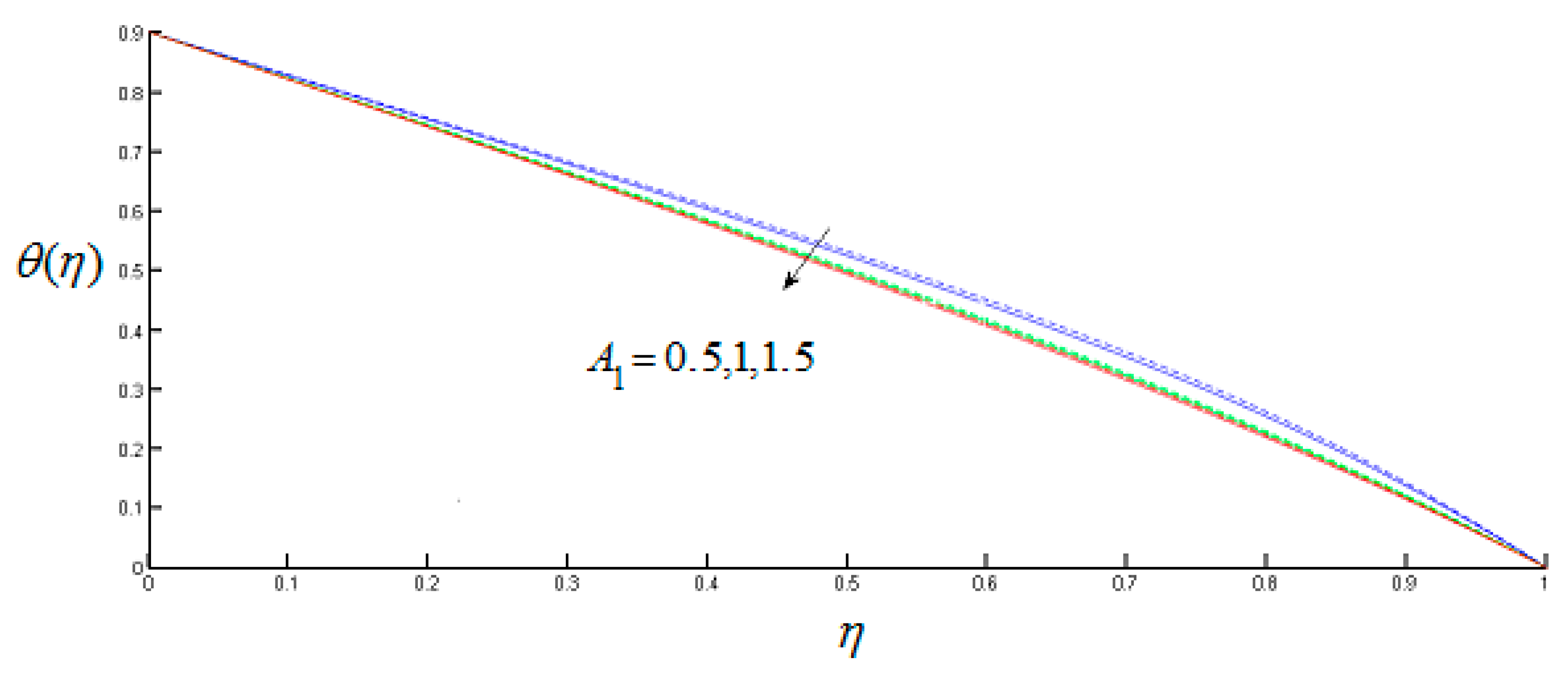

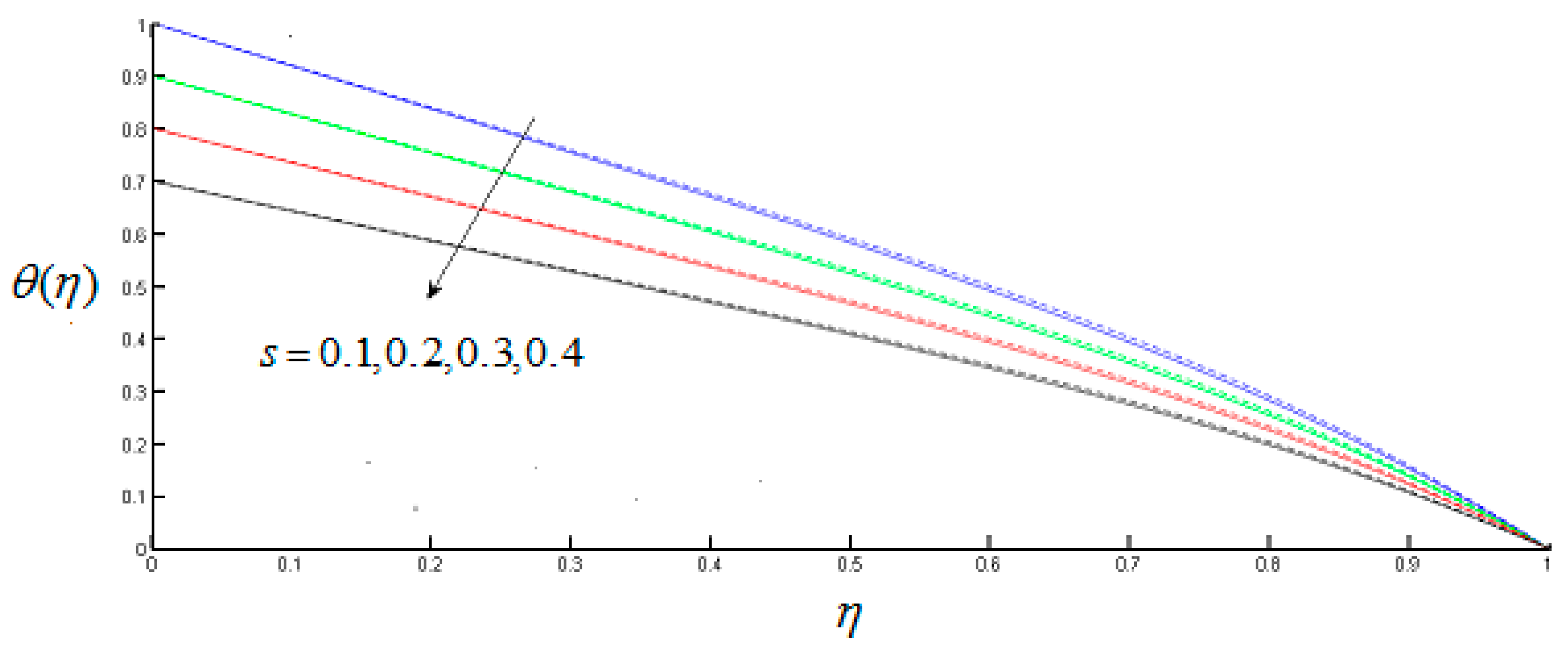

5.3. Dimensionless Temperature Distribution

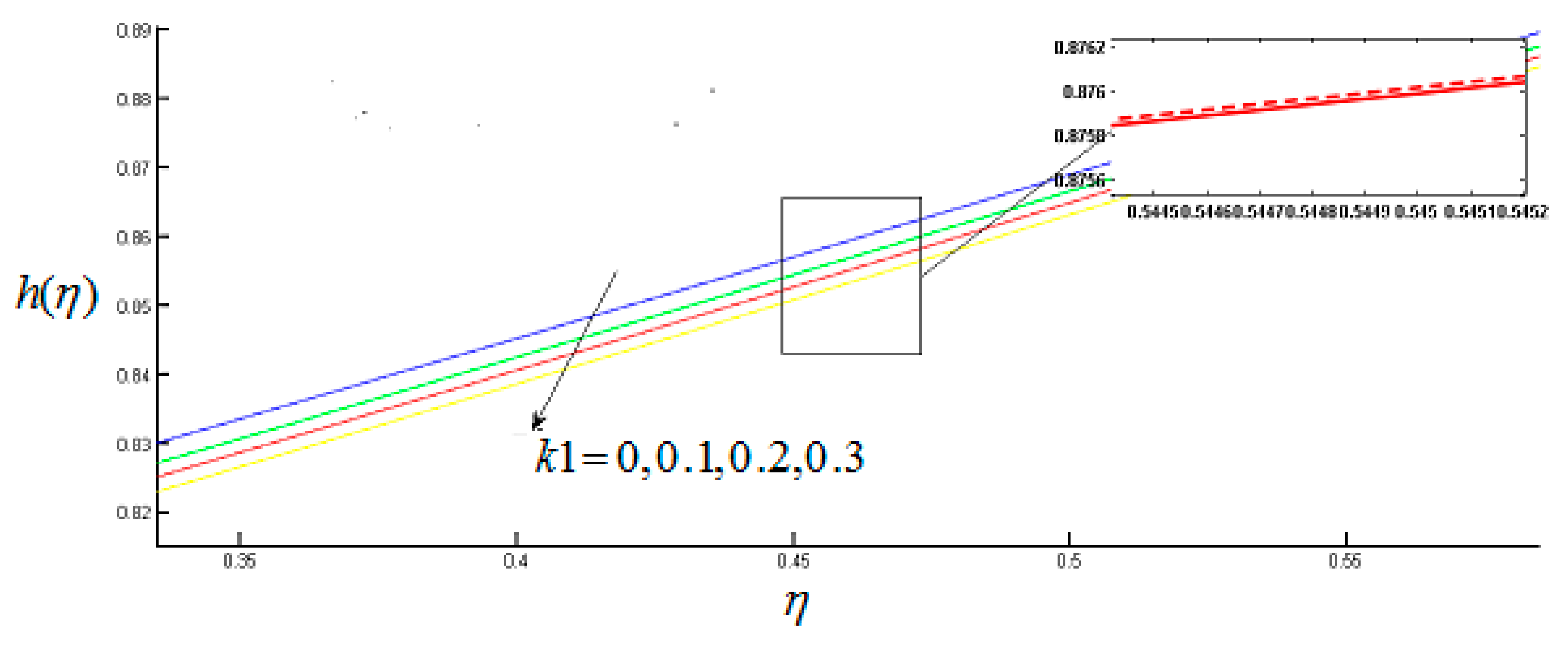

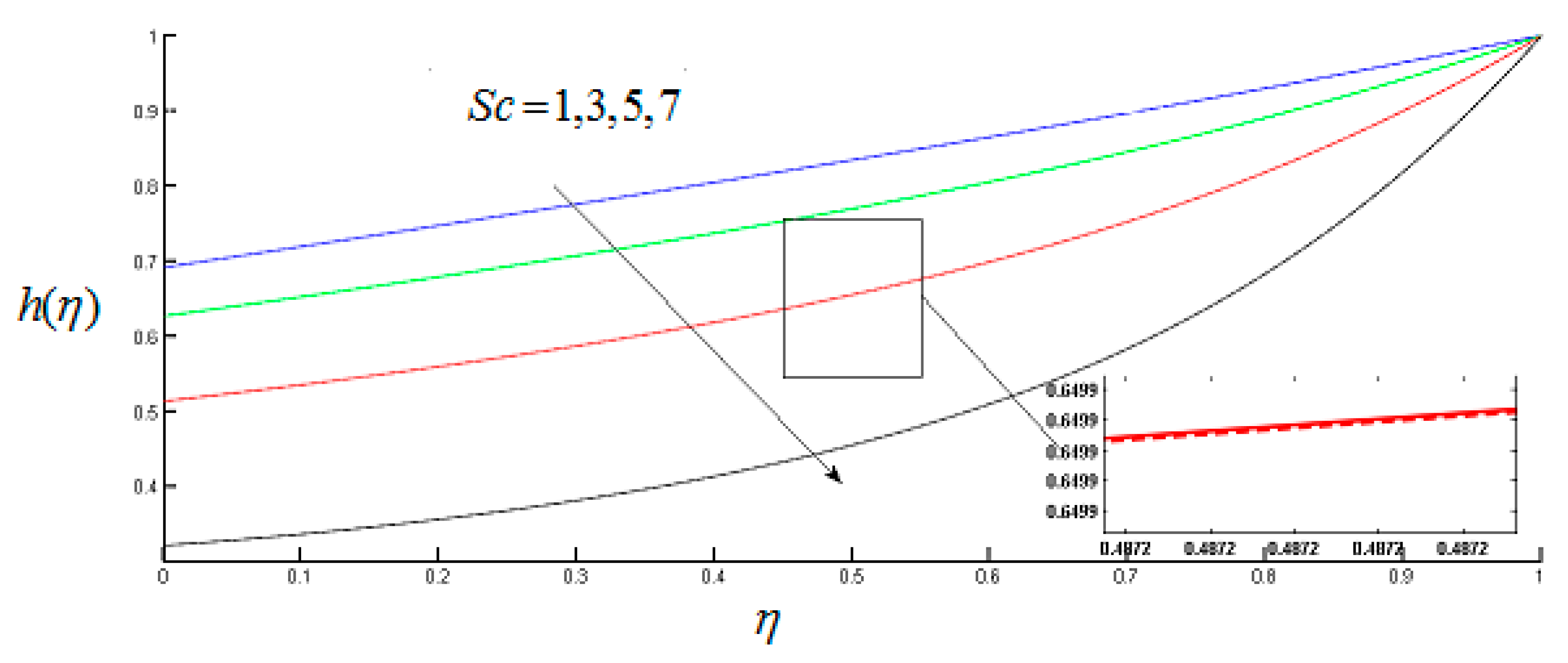

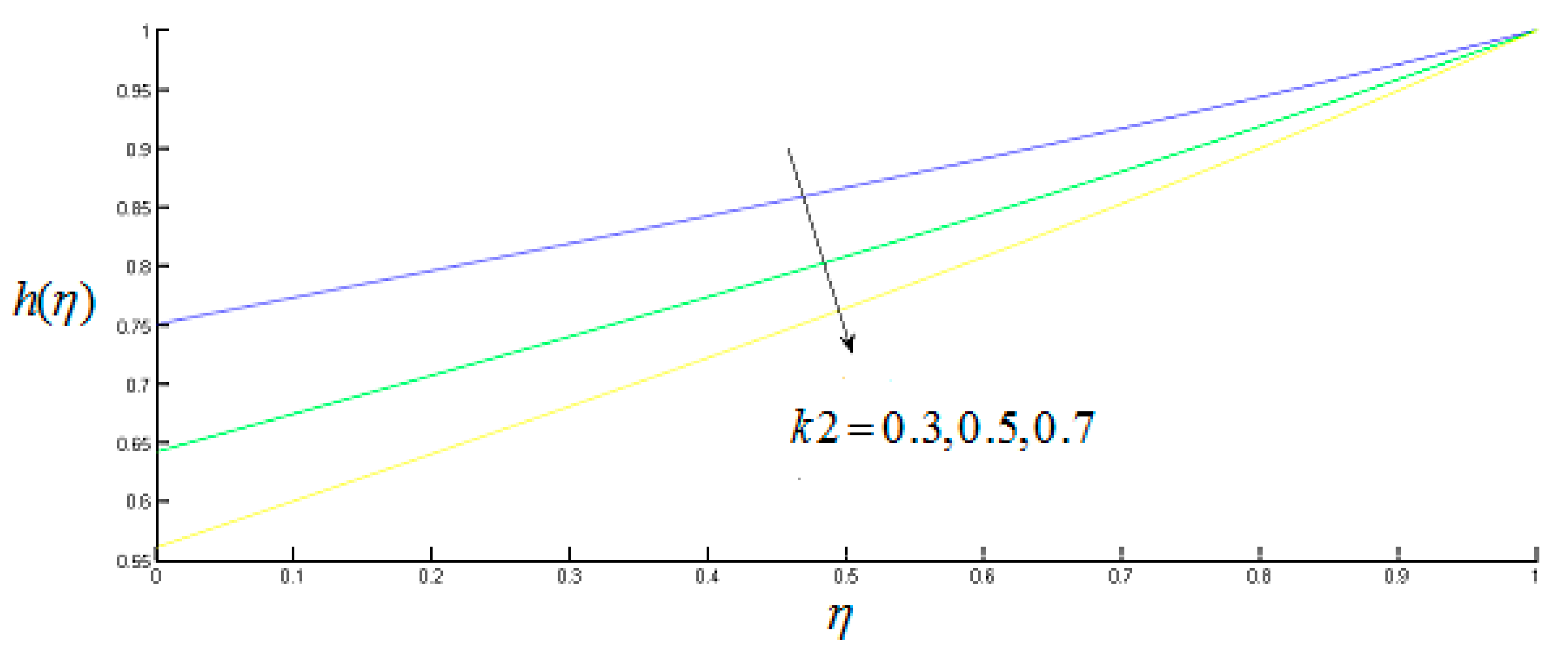

5.4. Concentration Profile

5.5. Drag Force Coefficient and Heat Transfer Rate

6. Conclusions

- Radial velocity increases and declines in the vicinity of the lower and the upper disks respectively.

- Radial and axial velocity profile is increasing for stretching parameter and decreasing behavior near the lower disks for both types of walls.

- Tangential velocity increases with increasing Hall current parameter and decreases with increasing Hartmann number in case of SWCNTs and MWCNTs.

- Temperature increases for thermal relaxation parameter, and decreases for nanoparticle volume fraction.

- In H-H reactions the concentration profile decreases for both types of CNTs.

- For incremental value of thermal stratification parameters temperature profile decreases.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbols | Description |

| Velocity of the fluid | |

| Hartmann number | |

| Temperature | |

| Reference temperature | |

| The dimensional constant | |

| Scale stretching parameters at lower disk | |

| Scale stretching parameters at upper disk | |

| Angular velocity of the lower disk | |

| Angular velocity of the upper disk | |

| Specific heat | |

| Unsteadiness parameter | |

| Thermal relaxation time | |

| Applied magnetic field | |

| Thermal conductivity of nanofluid | |

| Thermal conductivity of the fluid | |

| Measure of strength of homogeneous reaction | |

| Rotation parameter | |

| Schmidt number | |

| Diffusion coefficient of chemical species | |

| Thermal stratification parameter | |

| Measure of strength of heterogeneous reaction | |

| Reynolds number | |

| Dynamic viscosity of fluid | |

| Dynamic viscosity of nanofluid | |

| Density of the fluid | |

| Thermal conductivity of the nanofluid | |

| Density of the nanofluid | |

| Thermal conductivity of carbon nanotubes | |

| Thermal conductivity of the fluid | |

| Ratio of diffusion coefficients | |

| Diffusion coefficient of chemical species | |

| Prandtl number | |

| Pressure parameter |

References

- Suleman, M.; Ramzan, M.; Ahmad, S.; Lu, D.; Muhammad, T.; Chung, J.D. A Numerical Simulation of Silver–Water Nanofluid Flow with Impacts of Newtonian Heating and Homogeneous–Heterogeneous Reactions Past a Nonlinear Stretched Cylinder. Symmetry 2019, 11, 295. [Google Scholar] [CrossRef]

- Wang, X.Q.; Mujumdar, A.S. Heat transfer characteristics of nanofluids: A review. Int. J. Therm. Sci. 2007, 46, 1–19. [Google Scholar] [CrossRef]

- Alawi, O.A.; Sidik, N.A.C.; Xian, H.W.; Kean, T.H.; Kazi, S.N. Thermal conductivity and viscosity models of metallic oxides nanofluids. Int. J. Heat Mass Transf. 2018, 116, 1314–1325. [Google Scholar] [CrossRef]

- Choi, S.U.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles; (No. ANL/MSD/CP-84938; CONF-951135-29); Argonne National Lab.: Lemont, IL, USA, 1995. [Google Scholar]

- Ali, N.; Teixeira, J.A.; Addali, A. A review on nanofluids: Fabrication, stability, and thermophysical properties. J. Nanomater. 2018. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Ellahi, R.; Vafai, K. Study of Fe3O4-water nanofluid with convective heat transfer in the presence of magnetic source. Alex. Eng. J. 2018, 57, 565–575. [Google Scholar] [CrossRef]

- Haq, R.U.; Noor, N.F.M.; Khan, Z.H. Numerical simulation of water based magnetite nanoparticles between two parallel disks. Adv. Powder Technol. 2016, 27, 1568–1575. [Google Scholar] [CrossRef]

- Khan, Z.H.; Hussain, S.T.; Hammouch, Z. Flow and heat transfer analysis of water and ethylene glycol based Cu nanoparticles between two parallel disks with suction/injection effects. J. Mol. Liq. 2016, 221, 298–304. [Google Scholar]

- Saidi, M.H.; Tamim, H. Heat transfer and pressure drop characteristics of nanofluid in unsteady squeezing flow between rotating porous disks considering the effects of thermophoresis and Brownian motion. Adv. Powder Technol. 2016, 27, 564–574. [Google Scholar] [CrossRef]

- Hayat, T.; Javed, M.; Imtiaz, M.; Alsaedi, A. Convective flow of Jeffrey nanofluid due to two stretchable rotating disks. J. Mol. Liq. 2017, 240, 291–302. [Google Scholar] [CrossRef]

- Pourmehran, O.; Sarafraz, M.M.; Rahimi-Gorji, M.; Ganji, D.D. Rheological behaviour of various metal-based nano-fluids between rotating discs: A new insight. J. Taiwan Inst. Chem. Eng. 2018, 88, 37–48. [Google Scholar] [CrossRef]

- Herlem, G.; Picaud, F.; Girardet, C.; Micheau, O. Carbon Nanotubes: Synthesis, Characterization, and Applications in Drug-Delivery Systems. In Nanocarriers for Drug Delivery; Elsevier: Amsterdam, The Netherlands, 2019; pp. 469–529. [Google Scholar]

- Ong, Y.T.; Ahmad, A.L.; Zein, S.H.S.; Tan, S.H. A review on carbon nanotubes in an environmental protection and green engineering perspective. Braz. J. Chem. Eng. 2010, 27, 227–242. [Google Scholar] [CrossRef]

- Simon, J.; Flahaut, E.; Golzio, M. Overview of Carbon Nanotubes for Biomedical Applications. Materials 2019, 12, 624. [Google Scholar] [CrossRef]

- Imtiaz, M.; Hayat, T.; Alsaedi, A.; Ahmad, B. Convective flow of carbon nanotubes between rotating stretchable disks with thermal radiation effects. Int. J. Heat Mass Transf. 2016, 101, 948–957. [Google Scholar] [CrossRef]

- Haq, R.U.; Hammouch, Z.; Khan, W.A. Water-based squeezing flow in the presence of carbon nanotubes between two parallel disks. Therm. Sci. 2016, 20. [Google Scholar] [CrossRef]

- Mosayebidorcheh, S.; Hatami, M. Heat transfer analysis in carbon nanotube-water between rotating disks under thermal radiation conditions. J. Mol. Liq. 2017, 240, 258–267. [Google Scholar] [CrossRef]

- Jyothi, K.; Reddy, P.S.; Reddy, M.S. Influence of magnetic field and thermal radiation on convective flow of SWCNTs-water and MWCNTs-water nanofluid between rotating stretchable disks with convective boundary conditions. Powder Technol. 2018, 331, 326–337. [Google Scholar] [CrossRef]

- Kaempgen, M.; Duesberg, G.S.; Roth, S. Transparent carbon nanotube coatings. Appl. Surf. Sci. 2005, 252, 425–429. [Google Scholar] [CrossRef]

- Keefer, E.W.; Botterman, B.R.; Romero, M.I.; Rossi, A.F.; Gross, G.W. Carbon nanotube coating improves neuronal recordings. Nat. Nanotechnol. 2008, 3, 434. [Google Scholar] [CrossRef]

- Besteman, K.; Lee, J.O.; Wiertz, F.G.; Heering, H.A.; Dekker, C. Enzyme-coated carbon nanotubes as single-molecule biosensors. Nano Lett. 2003, 3, 727–730. [Google Scholar] [CrossRef]

- Lu, D.; Ramzan, M.; Mohammad, M.; Howari, F.; Chung, J.D. A Thin Film Flow of Nanofluid Comprising Carbon Nanotubes Influenced by Cattaneo-Christov Heat Flux and Entropy Generation. Coatings 2019, 9, 296. [Google Scholar] [CrossRef]

- Ramzan, M.; Gul, H.; Kadry, S. Onset of Cattaneo-Christov Heat Flux and Thermal Stratification in Ethylene-Glycol Based Nanofluid Flow Containing Carbon Nanotubes in a Rotating Frame. IEEE Access 2019, 7, 146190–146197. [Google Scholar] [CrossRef]

- Khan, U.; Ahmad, S.; Ramzan, M.; Suleman, M.; Lu, D.; Inam, S. Numerical Simulation of Darcy–Forchheimer 3D Unsteady Nanofluid Flow Comprising Carbon Nanotubes with Cattaneo–Christov Heat Flux and Velocity and Thermal Slip Conditions. Processes 2019, 7, 687. [Google Scholar] [CrossRef]

- Ramzan, M.; Mohammad, M.; Howari, F. Magnetized suspended carbon Nanotubes based nanofluid flow with bio-convection and entropy generation past a vertical cone. Sci. Rep. 2019, 9, 1–15. [Google Scholar] [CrossRef]

- Bilal, M.; Ramzan, M. Hall current effect on unsteady rotational flow of carbon nanotubes with dust particles and nonlinear thermal radiation in Darcy–Forchheimer porous media. J. Therm. Anal. Calorim. 2019, 138, 3127–3137. [Google Scholar] [CrossRef]

- Ramzan, M.; Shaheen, N. Thermally stratified Darcy–Forchheimer nanofluid flow comprising carbon nanotubes with effects of Cattaneo–Christov heat flux and homogeneous–heterogeneous reactions. Phy. Scr. 2019, 95, 015701. [Google Scholar] [CrossRef]

- Ramzan, M.; Mohammad, M.; Howari, F.; Chung, J.D. Entropy analysis of carbon nanotubes based nanofluid flow past a vertical cone with thermal radiation. Entropy 2019, 21, 642. [Google Scholar] [CrossRef]

- Hayat, T.; Haider, F.; Muhammad, T.; Ahmad, B. Darcy–Forchheimer flow of carbon nanotubes due to a convectively heated rotating disk with homogeneous–heterogeneous reactions. J. Therm. Anal. Calorimetry 2019, 137, 1939–1949. [Google Scholar] [CrossRef]

- Ramzan, M.; Sheikholeslami, M.; Chung, J.D.; Shafee, A. Melting heat transfer and entropy optimization owing to carbon nanotubes suspended Casson nanoliquid flow past a swirling cylinder-A numerical treatment. AIP Adv. 2018, 8, 115130. [Google Scholar] [CrossRef]

- Mahian, O.; Kianifar, A.; Kalogirou, S.A.; Pop, I.; Wongwises, S. A review of the applications of nanofluids in solar energy. Int. J. Heat Mass Transf. 2013, 57, 582–594. [Google Scholar] [CrossRef]

- Cattaneo, C. Sulla Conduzione del Calore; Atti Sem. Mat. Fis. Univ: Modena, Italy, 1948; Volume 3, pp. 83–101. [Google Scholar]

- Christov, C.I. On frame indifferent formulation of the Maxwell–Cattaneo model of finite-speed heat conduction. Mech. Res. Commun. 2009, 36, 481–486. [Google Scholar] [CrossRef]

- Hayat, T.; Qayyum, S.; Imtiaz, M.; Alsaedi, A. Flow between two stretchable rotating disks with Cattaneo-Christov heat flux model. Results Phys. 2017, 7, 126–133. [Google Scholar] [CrossRef]

- Dogonchi, A.S.; Chamkha, A.J.; Seyyedi, S.M.; Ganji, D.D. Radiative nanofluid flow and heat transfer between parallel disks with penetrable and stretchable walls considering Cattaneo–Christov heat flux model. Heat Transf. Asian Res. 2018, 47, 735–753. [Google Scholar] [CrossRef]

- Lu, D.; Li, Z.; Ramzan, M.; Shafee, A.; Chung, J.D. Unsteady squeezing carbon nanotubes based nano-liquid flow with Cattaneo–Christov heat flux and homogeneous–heterogeneous reactions. Appl. Nanosci. 2019, 9, 169–178. [Google Scholar] [CrossRef]

- Ramzan, M.; Liaquet, A.; Kadry, S.; Yu, S.; Nam, Y.; Lu, D. Impact of Second-Order Slip and Double Stratification Coatings on 3D MHD Williamson Nanofluid Flow with Cattaneo–Christov Heat Flux. Coatings 2019, 9, 849. [Google Scholar] [CrossRef]

- Ramzan, M.; Gul, H.; Sheikholeslami, M. Effect of second order slip condition on the flow of tangent hyperbolic fluid—A novel perception of Cattaneo–Christov heat flux. Phys. Scr. 2019, 94, 115707. [Google Scholar] [CrossRef]

- Alebraheem, J.; Ramzan, M. Flow of nanofluid with Cattaneo–Christov heat flux model. Appl. Nanosci. 2019, 1–11. [Google Scholar] [CrossRef]

- Lu, D.; Ramzan, M.; Ahmad, S.; Chung, J.D.; Farooq, U. Upshot of binary chemical reaction and activation energy on carbon nanotubes with Cattaneo-Christov heat flux and buoyancy effects. Phys. Fluids 2017, 29, 123103. [Google Scholar] [CrossRef]

- Chaudhary, M.A.; Merkin, J.H. A simple isothermal model for homogeneous-heterogeneous reactions in boundary-layer flow. II Different diffusivities for reactant and autocatalyst. Fluid Dyn. Res. 1995, 16, 335. [Google Scholar] [CrossRef]

- Stewartson, K. On the flow between two rotating coaxial disks. In Mathematical Proceedings of the Cambridge Philosophical Society; Cambridge University Press: Cambridge, UK, 1953; Volume 49, pp. 333–341. [Google Scholar]

| Author | CC Heat Flux | HH Reactions | Nanofluid with CNTs | Hall Effect | Thermal Stratification | Rotating Parallel Disks |

|---|---|---|---|---|---|---|

| Hayat et al. [10] | × | × | × | × | × | √ |

| Imtiaz et al. [15] | × | × | √ | × | × | √ |

| Hayat et al. [34] | √ | × | √ | × | × | √ |

| Lu et al. [36] | √ | √ | √ | × | × | √ |

| Present | √ | √ | √ | √ | √ | √ |

| Physical Properties | Base Fluid (H2O) | MWCNTs | SWCNTs |

|---|---|---|---|

| 4179 | 796 | 425 | |

| 997.1 | 1600 | 2600 | |

| 0.613 | 3000 | 6600 |

| Ω | Present | Present | ||

|---|---|---|---|---|

| SWCNTs | MWCNTs | SWCNTs | MWCNTs | |||||

|---|---|---|---|---|---|---|---|---|

| 0 | 0 | – | – | – | 5.03411 | 5.03457 | 6.04242 | 6.04063 |

| – | 0.5 | – | – | – | 5.02568 | 5.02466 | 6.04163 | 6.0397 |

| – | 1 | – | – | – | 5.01732 | 5.01486 | 6.04091 | 6.03888 |

| 0.5 | 0 | – | – | – | 5.03411 | 5.03457 | 6.04242 | 6.04063 |

| – | 0.5 | – | – | – | 5.02896 | 5.02852 | 6.04023 | 6.03805 |

| – | 1 | – | – | – | 5.02385 | 5.02253 | 6.03808 | 6.03553 |

| 0.5 | 0.5 | 0.5 | – | – | 4.13561 | 4.14261 | 5.58341 | 5.59479 |

| – | – | 1 | – | – | 4.2427 | 4.48904 | 5.984181 | 6.19988 |

| – | – | 1.5 | – | – | 5.15702 | 6.33493 | 7.14381 | 8.20049 |

| – | – | 0.1 | 0.1 | – | 2.94098 | 2.94399 | 4.87809 | 4.86666 |

| – | – | – | 0.2 | – | 3.60549 | 3.60836 | 5.22787 | 5.21623 |

| – | – | – | 0.1 | 0.6 | 2.94098 | 2.94399 | 4.87809 | 4.86666 |

| – | – | – | – | 0.8 | 3.553583 | 3.56223 | 6.32921 | 6.31152 |

| SWCNTs | MWCNTs | SWCNTs | MWCNTs | ||||

|---|---|---|---|---|---|---|---|

| 0.2 | – | – | – | 4.14135 | 3.83131 | 4.49696 | 4.16193 |

| 0.4 | – | – | – | 3.10577 | 2.87324 | 3.37182 | 3.12053 |

| 0.6 | – | – | – | 2.01701 | 1.91516 | 2.24668 | 2.07914 |

| 0.7 | – | – | – | 1.5524 | 1.43613 | 1.68411 | 1.55844 |

| 0.2 | 3.9 | – | – | 4.12824 | 3.81806 | 4.51945 | 4.18466 |

| – | 5.2 | – | – | 4.12164 | 3.81139 | 4.530861 | 4.19621 |

| – | 1.3 | 0.2 | – | 4.13503 | 3.82486 | 4.50794 | 4.17309 |

| – | – | 0.5 | – | 4.11594 | 3.81839 | 4.54154 | 4.18437 |

| – | – | 0.1 | 0.6 | 4.10289 | 3.79571 | 4.593021 | 4.25082 |

| – | – | – | 0.7 | 4.05746 | 3.75367 | 4.705941 | 4.35533 |

| – | – | – | 0.8 | 4.00509 | 3.7052 | 4.83659 | 4.47624 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramzan, M.; Riasat, S.; Kadry, S.; Kuntha, P.; Nam, Y.; Howari, F. Numerical Analysis of Carbon Nanotube-Based Nanofluid Unsteady Flow Amid Two Rotating Disks with Hall Current Coatings and Homogeneous–Heterogeneous Reactions. Coatings 2020, 10, 48. https://doi.org/10.3390/coatings10010048

Ramzan M, Riasat S, Kadry S, Kuntha P, Nam Y, Howari F. Numerical Analysis of Carbon Nanotube-Based Nanofluid Unsteady Flow Amid Two Rotating Disks with Hall Current Coatings and Homogeneous–Heterogeneous Reactions. Coatings. 2020; 10(1):48. https://doi.org/10.3390/coatings10010048

Chicago/Turabian StyleRamzan, Muhammad, Saima Riasat, Seifedine Kadry, Pin Kuntha, Yunyoung Nam, and Fares Howari. 2020. "Numerical Analysis of Carbon Nanotube-Based Nanofluid Unsteady Flow Amid Two Rotating Disks with Hall Current Coatings and Homogeneous–Heterogeneous Reactions" Coatings 10, no. 1: 48. https://doi.org/10.3390/coatings10010048

APA StyleRamzan, M., Riasat, S., Kadry, S., Kuntha, P., Nam, Y., & Howari, F. (2020). Numerical Analysis of Carbon Nanotube-Based Nanofluid Unsteady Flow Amid Two Rotating Disks with Hall Current Coatings and Homogeneous–Heterogeneous Reactions. Coatings, 10(1), 48. https://doi.org/10.3390/coatings10010048