Microstructure and Sliding Wear Resistance of Plasma Sprayed Al2O3-Cr2O3-TiO2 Ternary Coatings from Blends of Single Oxides

Abstract

1. Introduction

2. Materials and Methods

3. Results

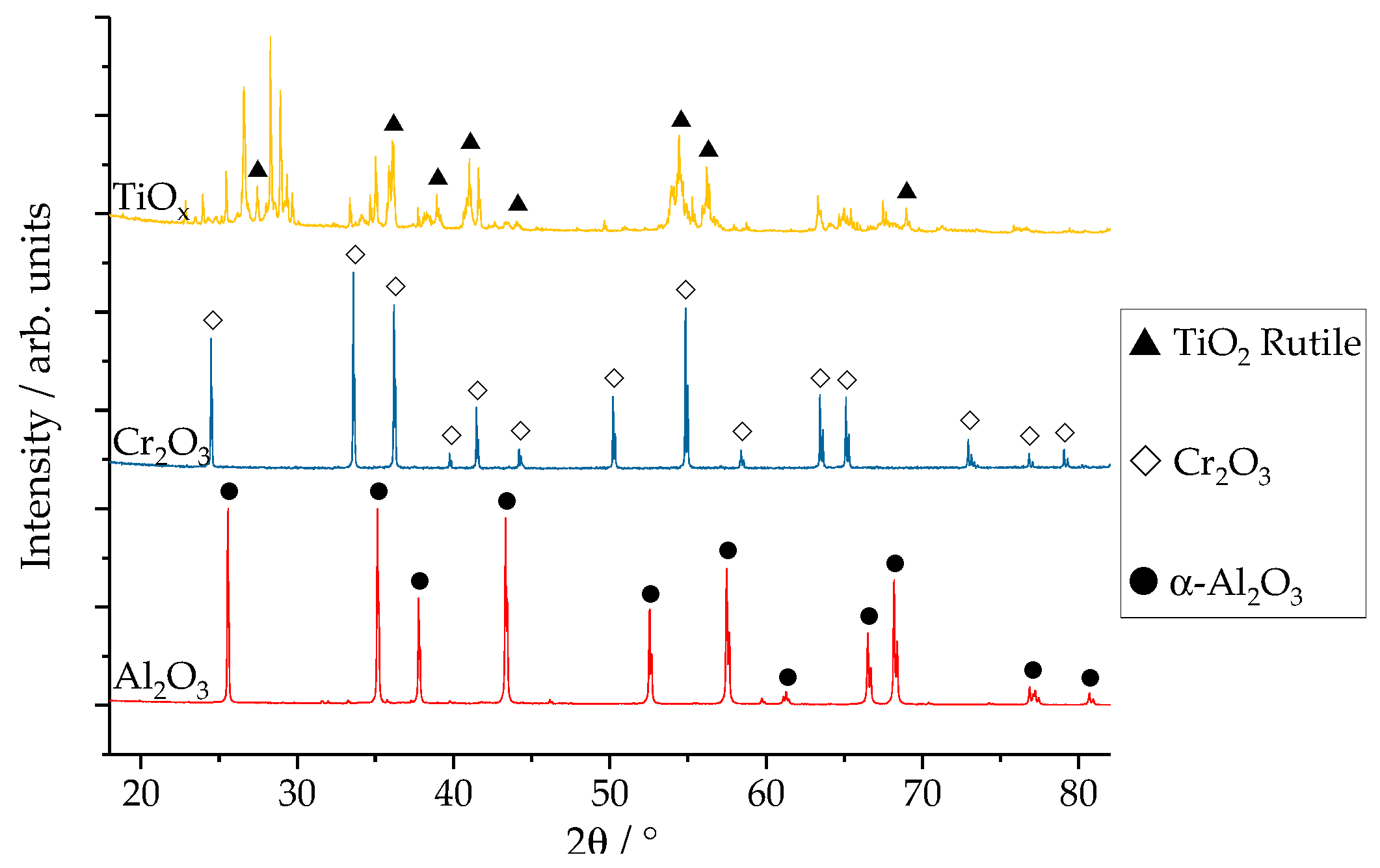

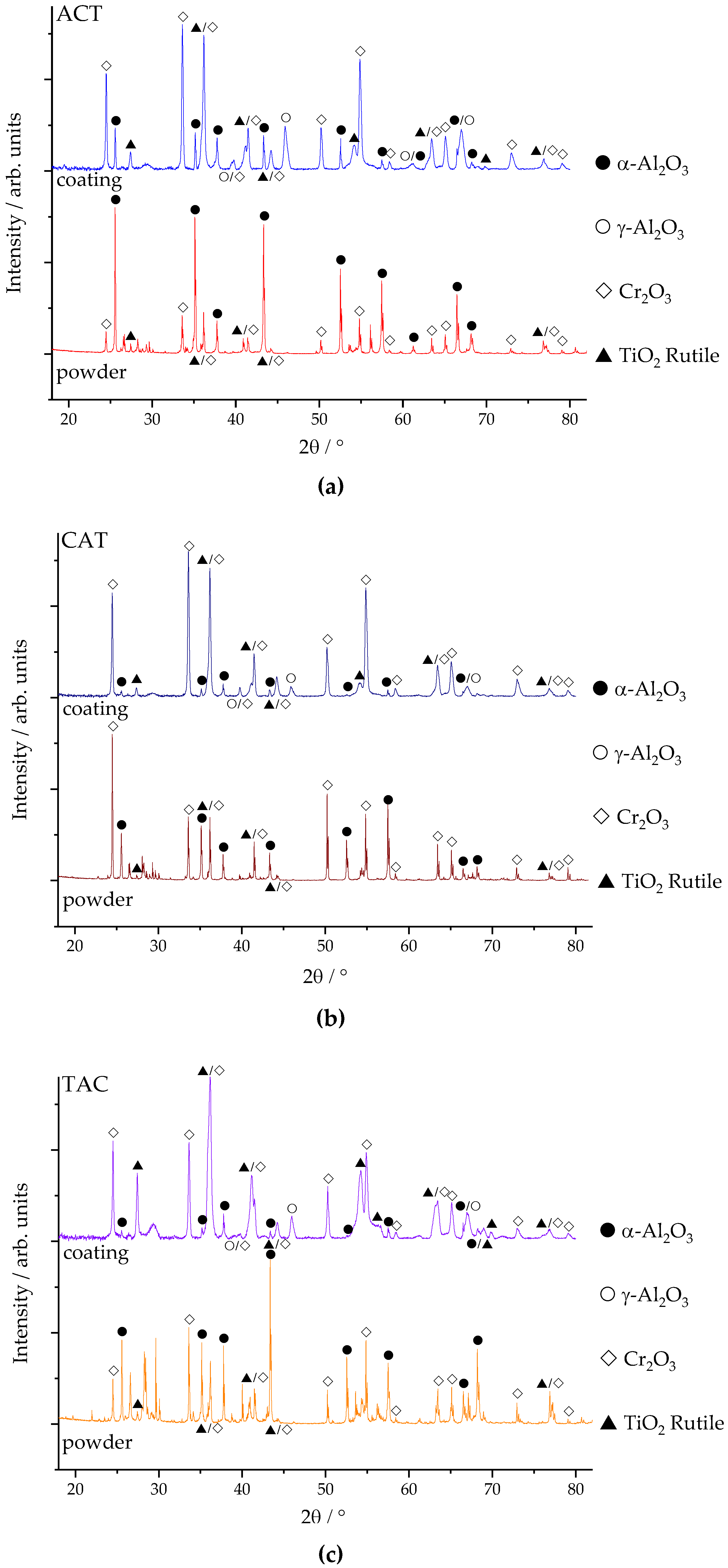

3.1. Feedstock Powder Characterisation

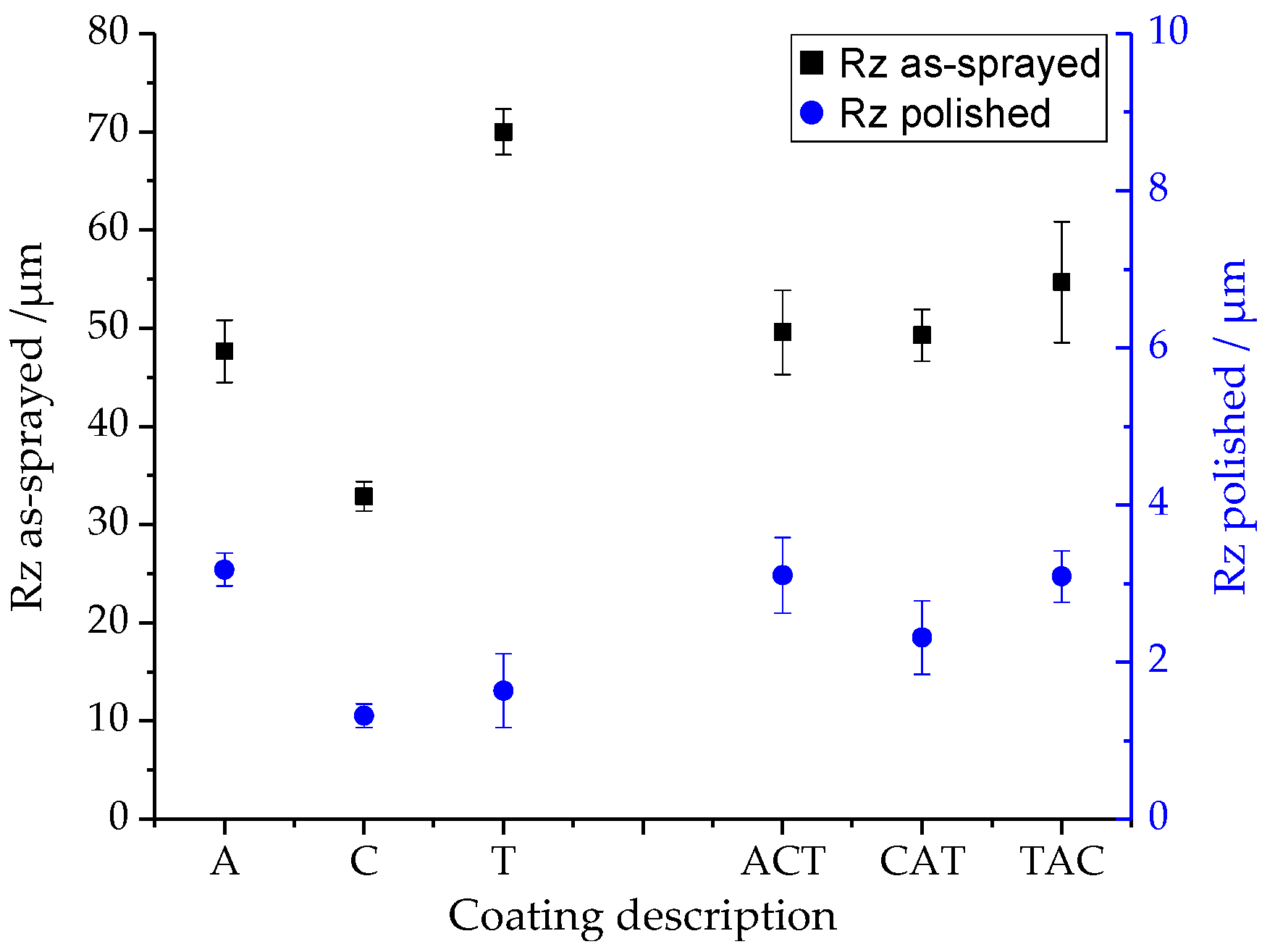

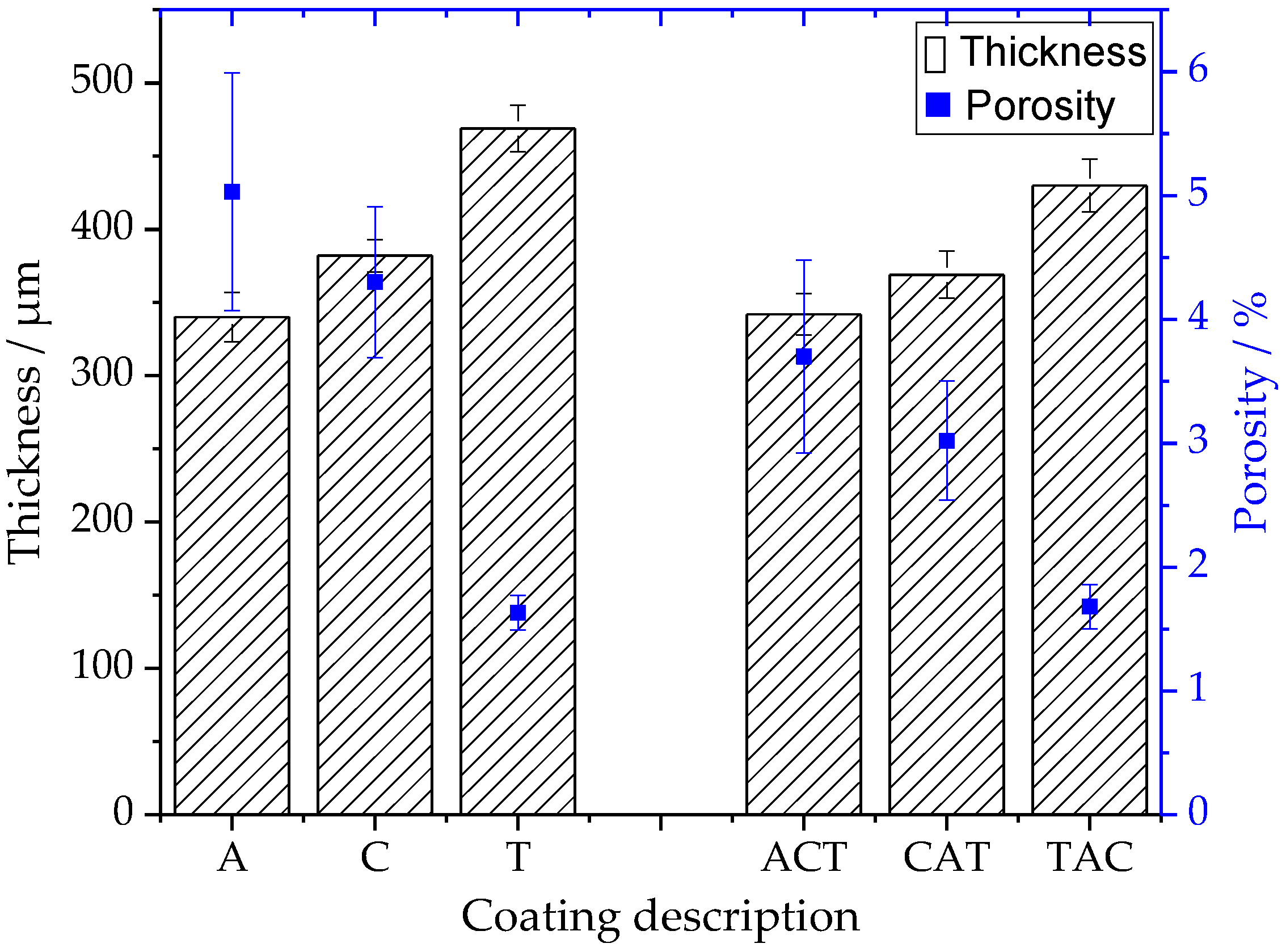

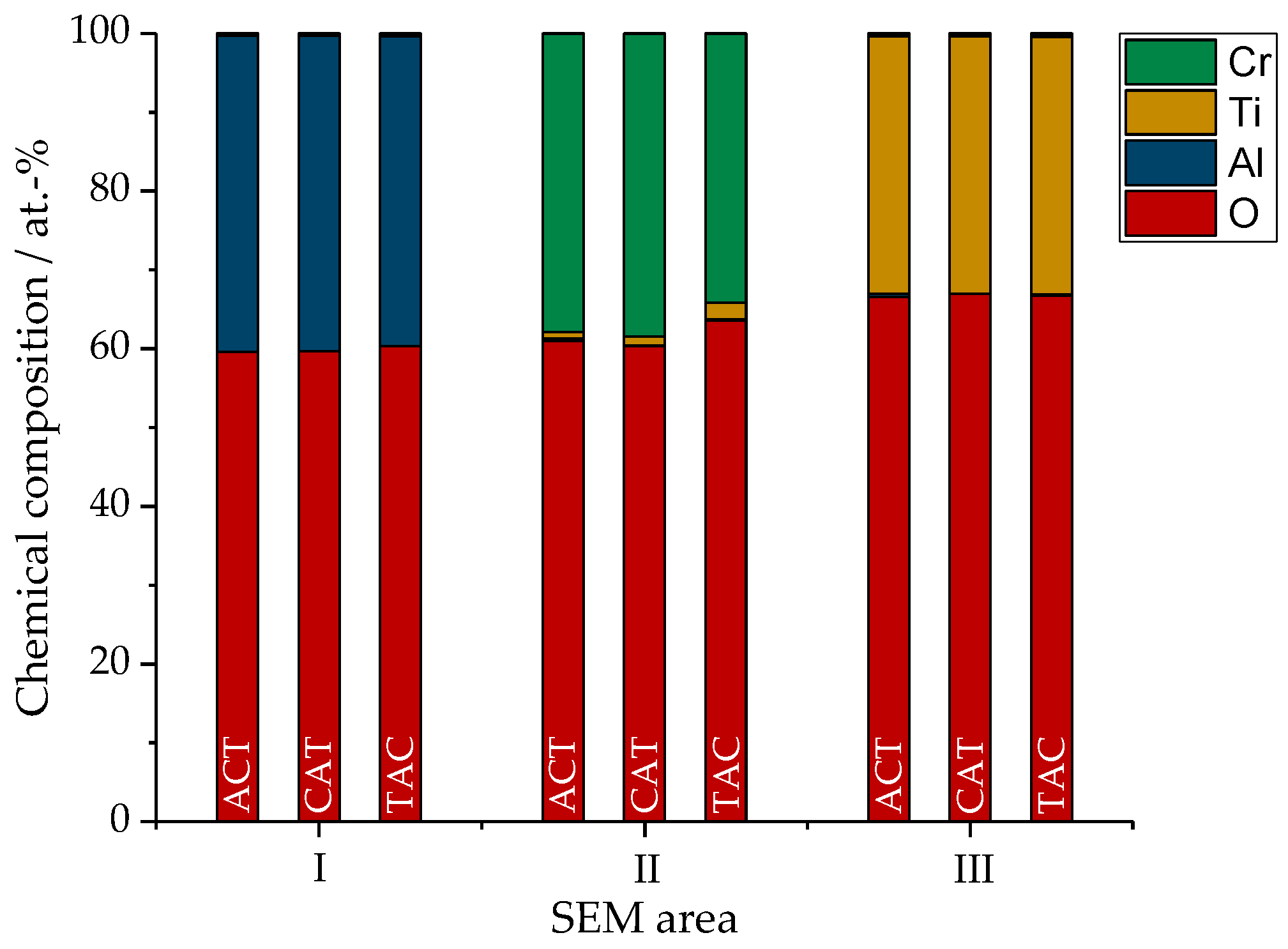

3.2. Coating Characterisation

4. Discussion

5. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Berger, L.-M.; Toma, F.-L.; Scheitz, S.; Trache, R.; Börner, T. Thermisch gespritzte Schichten im System Al2O3-Cr2O3-TiO2—ein Update. Mater. Werkst. 2014, 45, 465–475. [Google Scholar] [CrossRef]

- Berger, L.-M. Tribology of Thermally Sprayed Coatings in the Al2O3-Cr2O3-TiO2 System. In Thermal Sprayed Coatings and Their Tribological Performances; Roy, M., Davim, J.P., Eds.; Engineering Science Reference: Hershey, PA, USA, 2015; pp. 227–267. [Google Scholar] [CrossRef]

- Fauchais, P.L.; Heberlein, J.V.R.; Boulos, M.I. Thermal Spray Fundamentals: From Powder to Part; Springer: New York, NY, USA; Heidelberg, Germany; Dordrecht, The Netherlands; London, UK, 2014. [Google Scholar] [CrossRef]

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings, 2nd ed.; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar]

- Toma, F.-L.; Potthoff, A.; Berger, L.-M.; Leyens, C. Demands, Potentials, and Economic Aspects of Thermal Spraying with Suspensions: A Critical Review. J. Therm. Spray Technol. 2015, 24, 1143–1152. [Google Scholar] [CrossRef]

- Potthoff, A.; Kratzsch, R.; Barbosa, M.; Kulissa, N.; Kunze, O.; Toma, F.-L. Development and Application of Binary Suspensions in the Ternary System Cr2O3-TiO2-Al2O3 for S-HVOF Spraying. J. Therm. Spray Technol. 2018, 27, 710–717. [Google Scholar] [CrossRef]

- McPherson, R. On the formation of thermally sprayed alumina coatings. J. Mater. Sci. 1980, 15, 3141–3149. [Google Scholar] [CrossRef]

- Chráska, P.; Dubsky, J.; Neufuss, K.; Pisacka, J. Alumina-base plasma-sprayed materials part I: Phase stability of alumina and alumina-chromia. J. Therm. Spray Technol. 1997, 6, 320–326. [Google Scholar] [CrossRef]

- Dubsky, J.; Chraska, P.; Kolman, B.; Stahr, C.C.; Berger, L.-M. Phase formation control in plasma sprayed alumina-chromia coatings. Ceram. Silik. 2011, 55, 294–300. [Google Scholar]

- Stahr, C.C.; Saaro, S.; Berger, L.-M.; Dubský, J.; Neufuss, K.; Herrmann, M. Dependence of the stabilization of α-Alumina on the spray process. J. Therm. Spray Technol. 2007, 16, 822–830. [Google Scholar] [CrossRef]

- Heintze, G.N.; Uematsu, S. Preparation and structures of plasma-sprayed γ- and α-Al2O3 coatings. Surf. Coat. Technol. 1992, 50, 213–222. [Google Scholar] [CrossRef]

- Marple, B.R.; Voyer, J.; Béchard, P. Sol infiltration and heat treatment of alumina-chromia plasma-sprayed coatings. J. Eur. Ceram. Soc. 2001, 21, 861–868. [Google Scholar] [CrossRef]

- Lampke, T.; Meyer, D.; Alisch, G.; Nickel, D.; Scharf, I.; Wagner, L.; Raab, U. Alumina coatings obtained by thermal spraying and plasma anodising—A comparison. Surf. Coat. Technol. 2011, 206, 2012–2016. [Google Scholar] [CrossRef]

- Toma, F.-L.; Potthoff, A.; Barbosa, M. Microstructural Characteristics and Performances of Cr2O3 and Cr2O3-15%TiO2 S-HVOF Coatings Obtained from Water-Based Suspensions. J. Therm. Spray Technol. 2018, 27, 344–357. [Google Scholar] [CrossRef]

- Yu, S.H.; Wallar, H. Chromia Spray Powders and a Process for Making the Same. U.S. Patent 6,774,076, 10 August 2004. [Google Scholar]

- Richter, A.; Berger, L.-M.; Conze, S.; Sohn, Y.J.; Vaßen, R. Emergence and impact of Al2TiO5 in Al2O3-TiO2 APS coatings. In Proceedings of the IOP Conference Series: Materials Science and Engineering 21th Chemnitz Seminar on Materials Engineering, Chemnitz, Germany, 6–7 March 2019; Volume 480, p. 012007. [Google Scholar] [CrossRef]

- Sert, Y.; Toplan, N. Tribological behavior of a plasma-sprayed Al2O3-TiO2-Cr2O3 coating. Mater. Tehnol. 2013, 47, 181–184. [Google Scholar]

- Vernhes, L.; Bekins, C.; Lourdel, N.; Poirier, D.; Lima, R.S.; Li, D.; Klemberg-Sapieha, J.E. Nanostructured and Conventional Cr2O3, TiO2, and TiO2-Cr2O3 Thermal-Sprayed Coatings for Metal-Seated Ball Valve Applications in Hydrometallurgy. J. Therm. Spray Technol. 2016, 25, 1068–1078. [Google Scholar] [CrossRef]

- Richter, A.; Berger, L.-M.; Sohn, Y.J.; Conze, S.; Sempf, K.; Vaßen, R. Impact of Al2O3-40 wt.% TiO2 feedstock powder characteristics on the sprayability, microstructure and mechanical properties of plasma sprayed coatings. J. Eur. Ceram. Soc. 2019, 39, 5391–5402. [Google Scholar] [CrossRef]

- Ctibor, P.; Píš, I.; Kotlan, J.; Pala, Z.; Khalakhan, I.; Štengl, V.; Homola, P. Microstructure and properties of plasma-sprayed mixture of Cr2O3 and TiO2. J. Therm. Spray Technol. 2013, 22, 1163–1169. [Google Scholar] [CrossRef]

- Fervel, V.; Normand, B.; Coddet, C. Tribological behavior of plasma sprayed Al2O3-based cermet coatings. Wear 1999, 230, 70–77. [Google Scholar] [CrossRef]

| Material | Supplier | Particle Size | Granulometric Data | ||

|---|---|---|---|---|---|

| d10 | d50 | d90 | |||

| Al2O3 | Saint Gobain Coating Solutions, Avignon, France | −45 + 15 µm | 21 | 34 | 56 |

| Cr2O3 | GTV, Luckenbach, Germany | −45 + 15 µm | 19 | 34 | 54 |

| TiOx | Ceram, Albbruck-Birndorf, Germany | −45 +20 µm | 22 | 39 | 61 |

| Designation of the Blend/Coating | Components (at %) | Components (wt %) | ||||

|---|---|---|---|---|---|---|

| Al2O3 | Cr2O3 | TiO2 | Al2O3 | Cr2O3 | TiO2 | |

| ACT | 50 | 25 | 25 | 47 | 35 | 18 |

| CAT | 25 | 50 | 25 | 21 | 63 | 16 |

| TAC | 25 | 25 | 50 | 25 | 36 | 39 |

| Argon | Hydrogen | Current | Spraying Distance | Traverse Speed | No. of Passes | Powder Feed Rate |

|---|---|---|---|---|---|---|

| 41 L/min | 11 L/min | 600 A | 110 mm | 0.4 m/s | 10 | 30 g/min |

| Force | Radius | Speed | Cycles | Wear Distance | Counter Body | |

|---|---|---|---|---|---|---|

| Material | Diameter | |||||

| 10 N | 5 mm | 0.05 m/s | 15916 | 500 m | Al2O3 | 6 mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grimm, M.; Conze, S.; Berger, L.-M.; Paczkowski, G.; Lindner, T.; Lampke, T. Microstructure and Sliding Wear Resistance of Plasma Sprayed Al2O3-Cr2O3-TiO2 Ternary Coatings from Blends of Single Oxides. Coatings 2020, 10, 42. https://doi.org/10.3390/coatings10010042

Grimm M, Conze S, Berger L-M, Paczkowski G, Lindner T, Lampke T. Microstructure and Sliding Wear Resistance of Plasma Sprayed Al2O3-Cr2O3-TiO2 Ternary Coatings from Blends of Single Oxides. Coatings. 2020; 10(1):42. https://doi.org/10.3390/coatings10010042

Chicago/Turabian StyleGrimm, Maximilian, Susan Conze, Lutz-Michael Berger, Gerd Paczkowski, Thomas Lindner, and Thomas Lampke. 2020. "Microstructure and Sliding Wear Resistance of Plasma Sprayed Al2O3-Cr2O3-TiO2 Ternary Coatings from Blends of Single Oxides" Coatings 10, no. 1: 42. https://doi.org/10.3390/coatings10010042

APA StyleGrimm, M., Conze, S., Berger, L.-M., Paczkowski, G., Lindner, T., & Lampke, T. (2020). Microstructure and Sliding Wear Resistance of Plasma Sprayed Al2O3-Cr2O3-TiO2 Ternary Coatings from Blends of Single Oxides. Coatings, 10(1), 42. https://doi.org/10.3390/coatings10010042