Mechanical and Structural Properties of Nanocomposite CrAlSiN–AlSiN Coating with Periodically Modulated Composition

Abstract

1. Introduction

2. Experimental Details

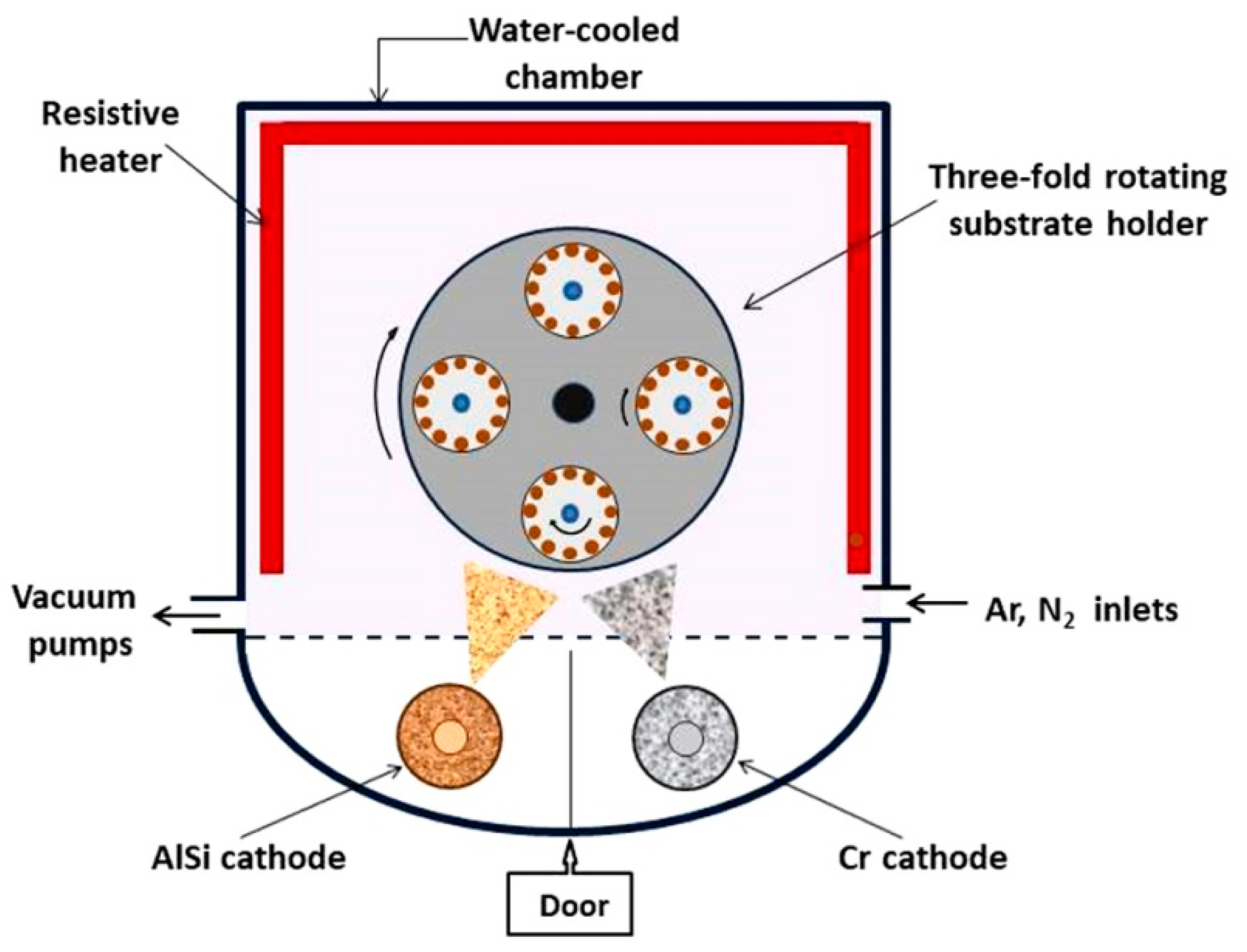

2.1. Coating Preparation

2.2. Characterization Methods

3. Results and Discussion

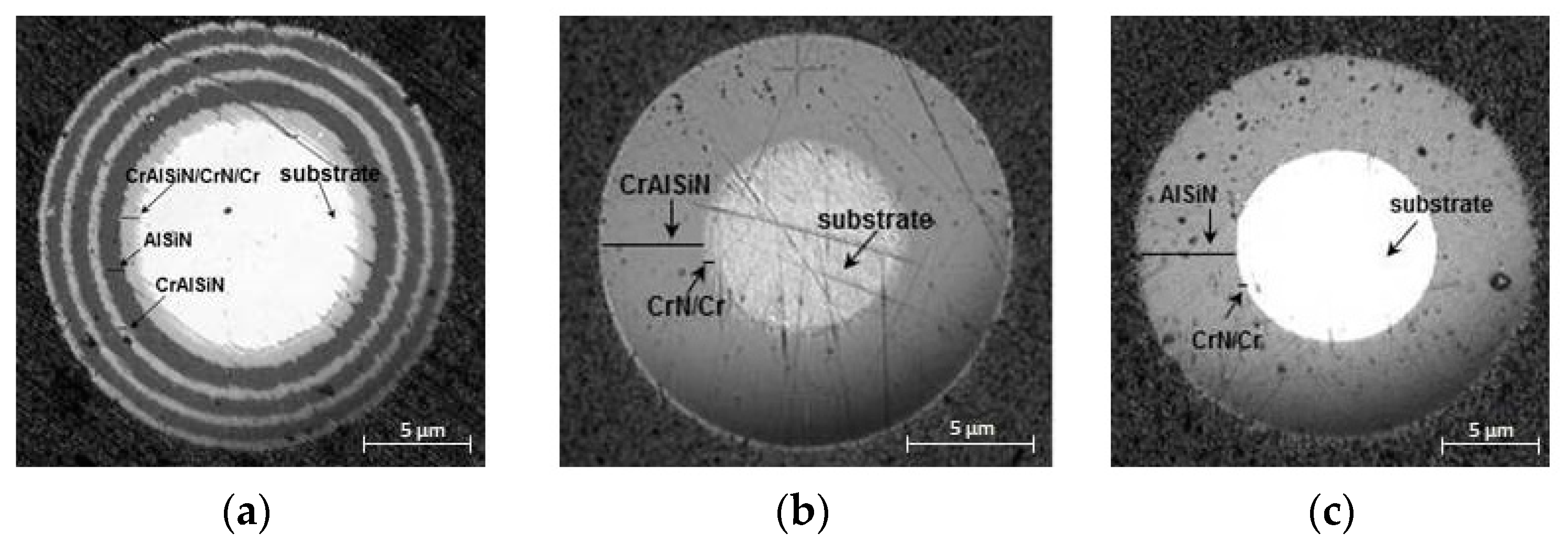

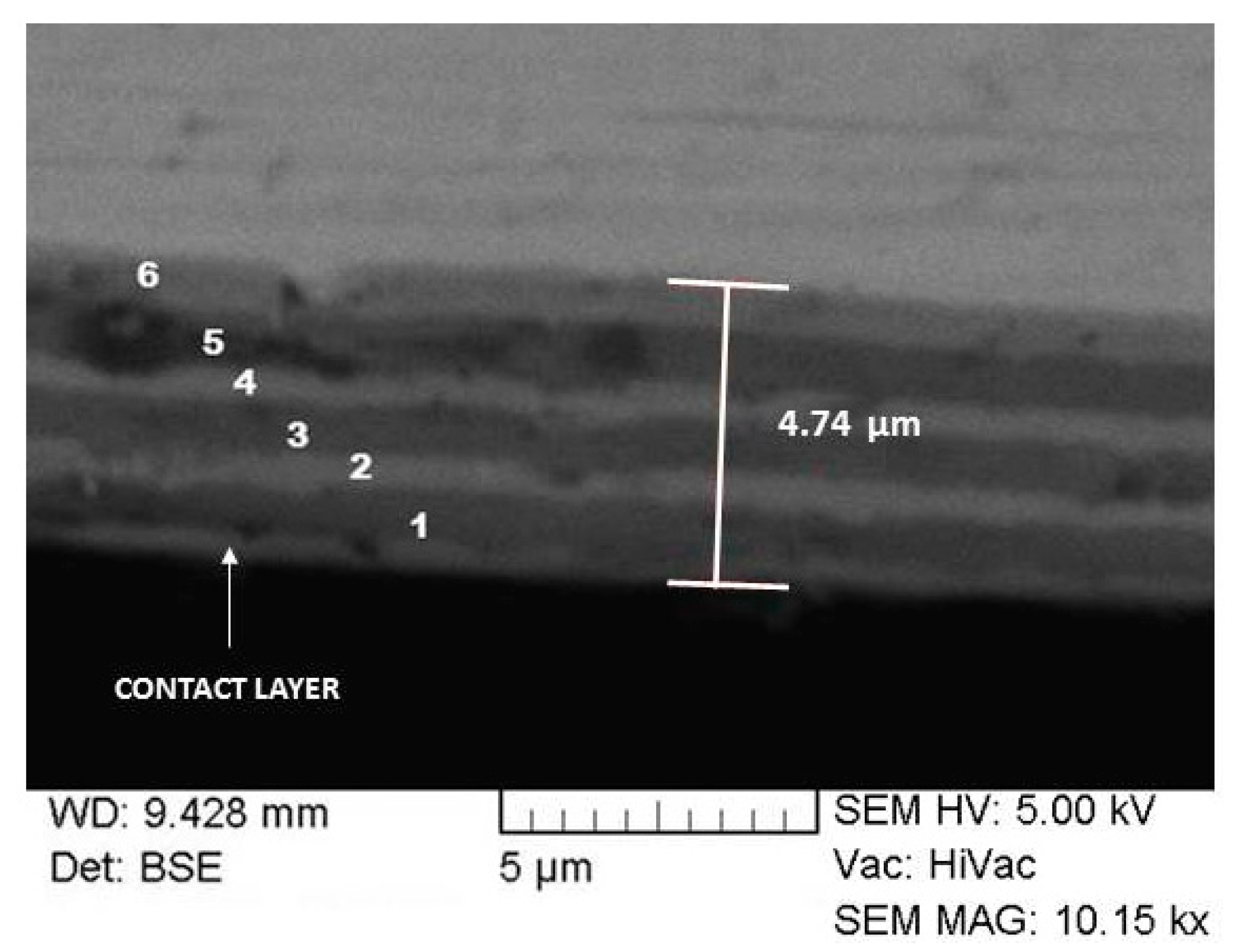

3.1. Thickness

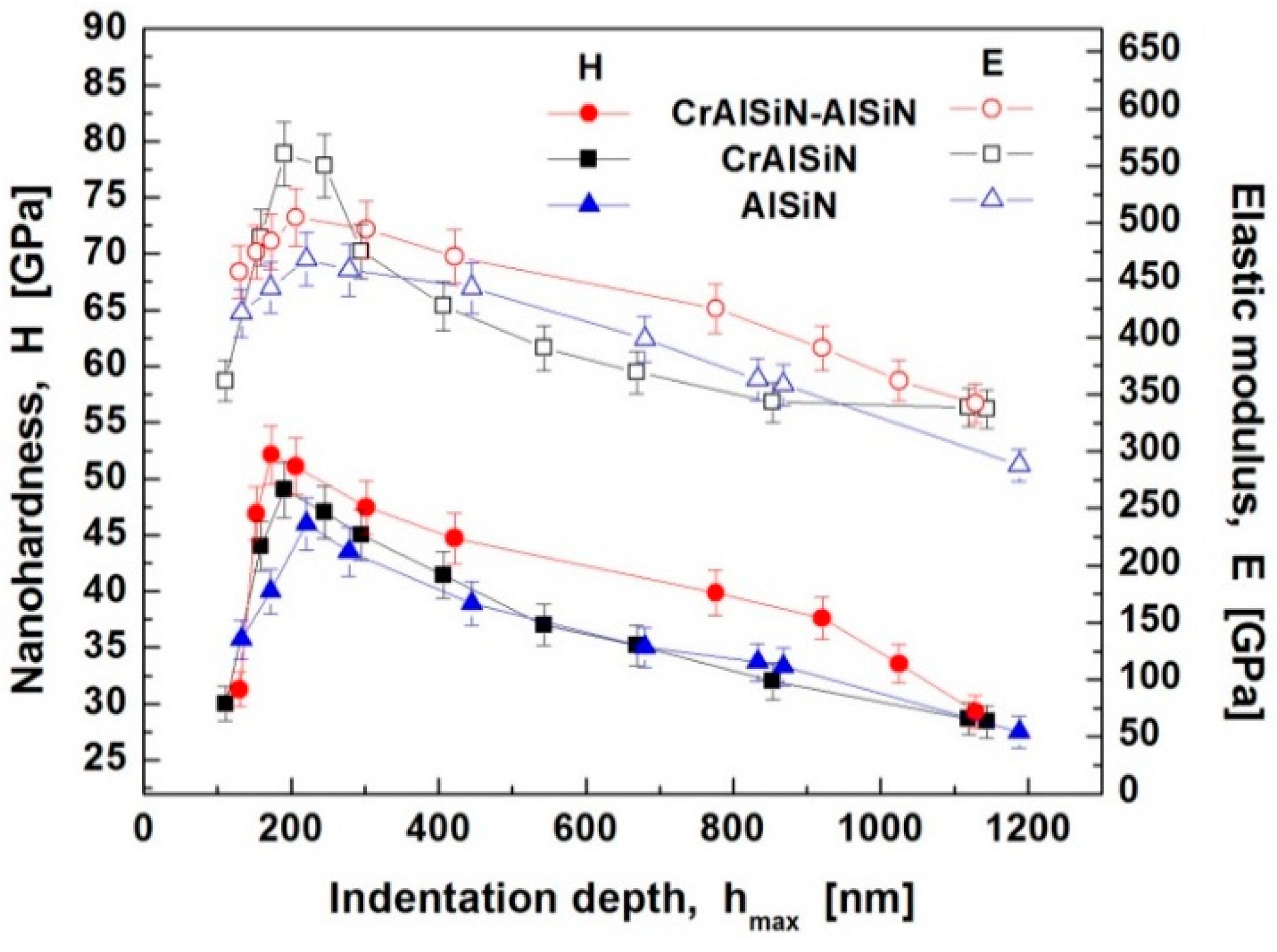

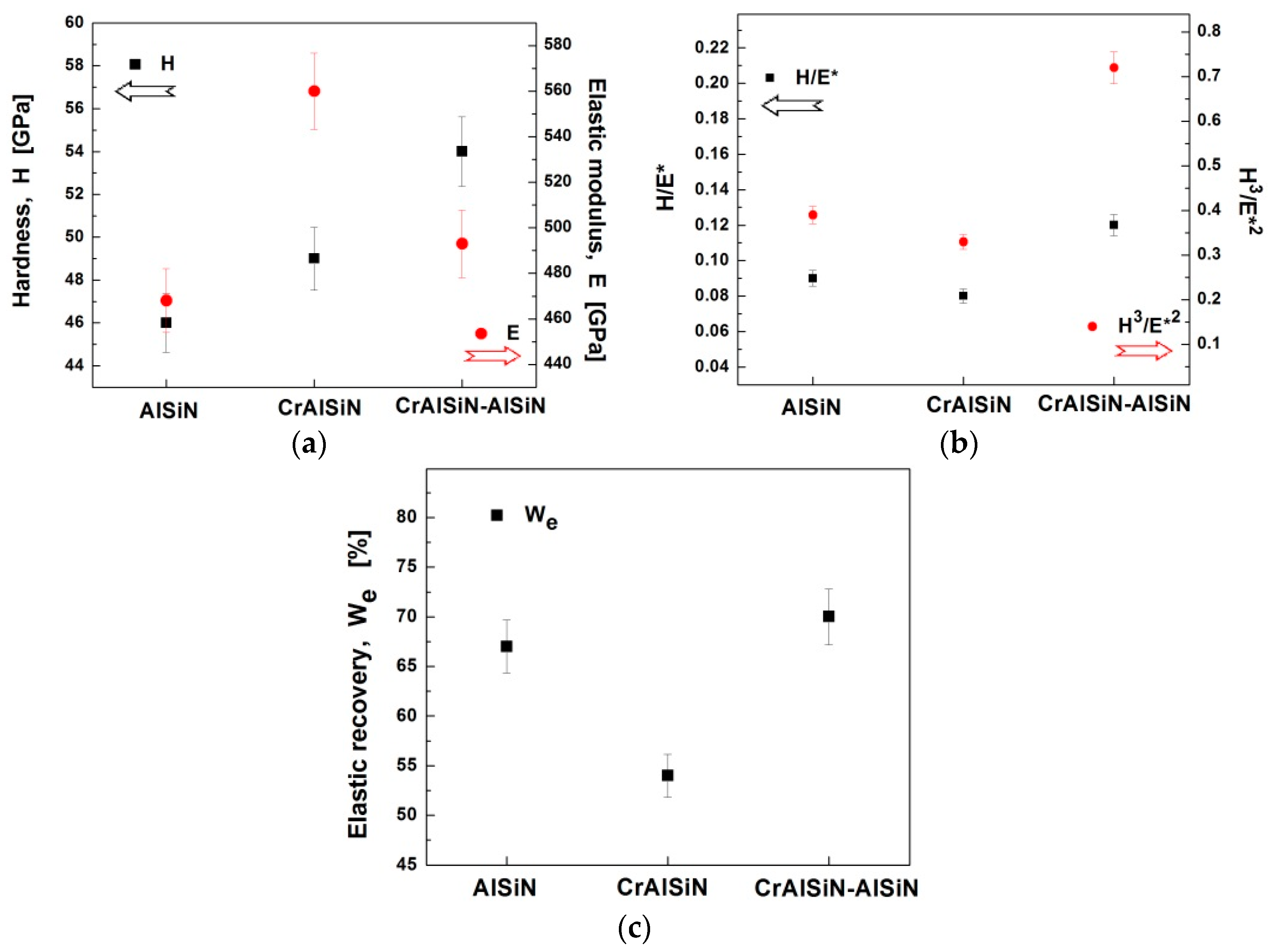

3.2. Mechanical Properties

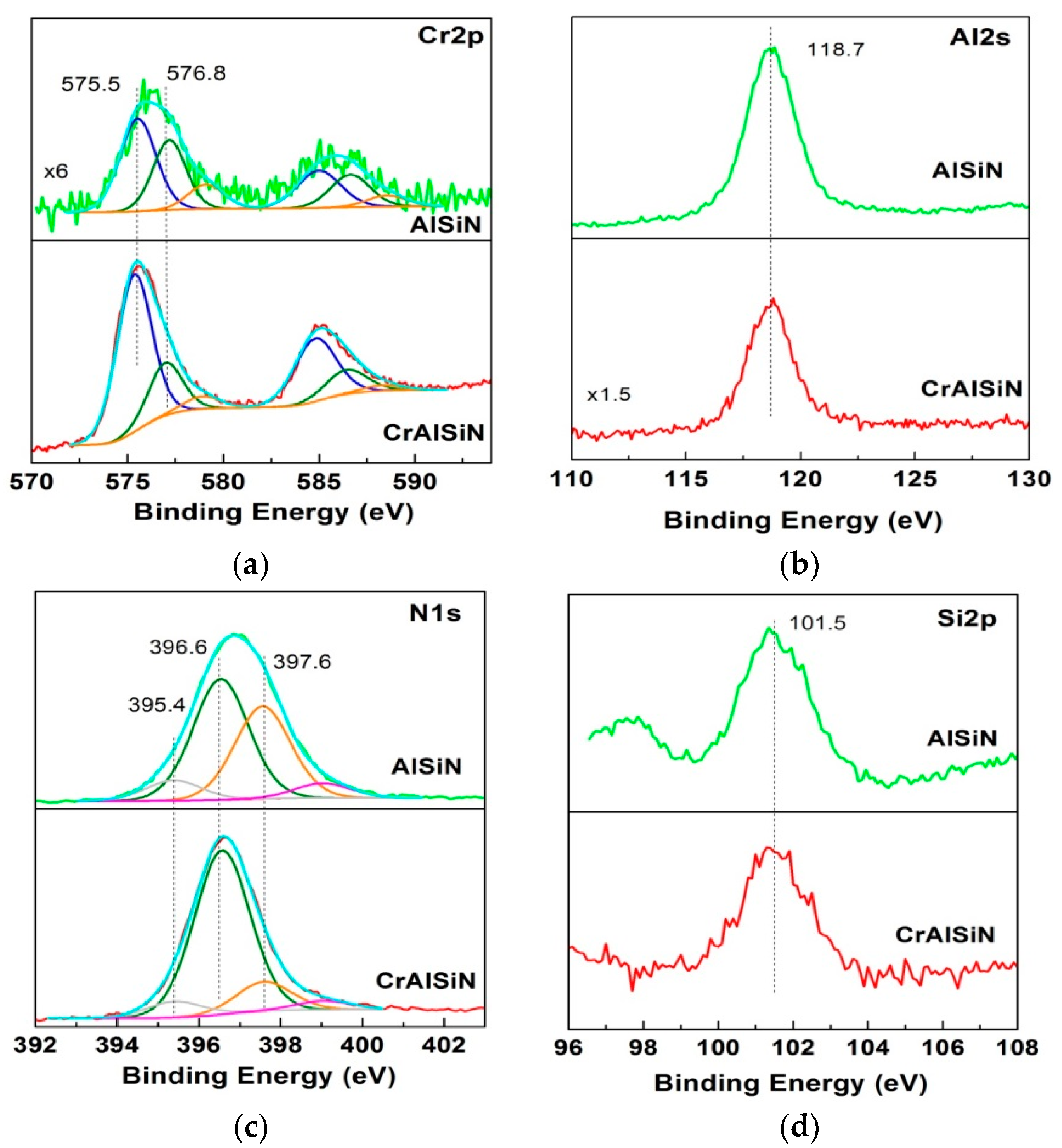

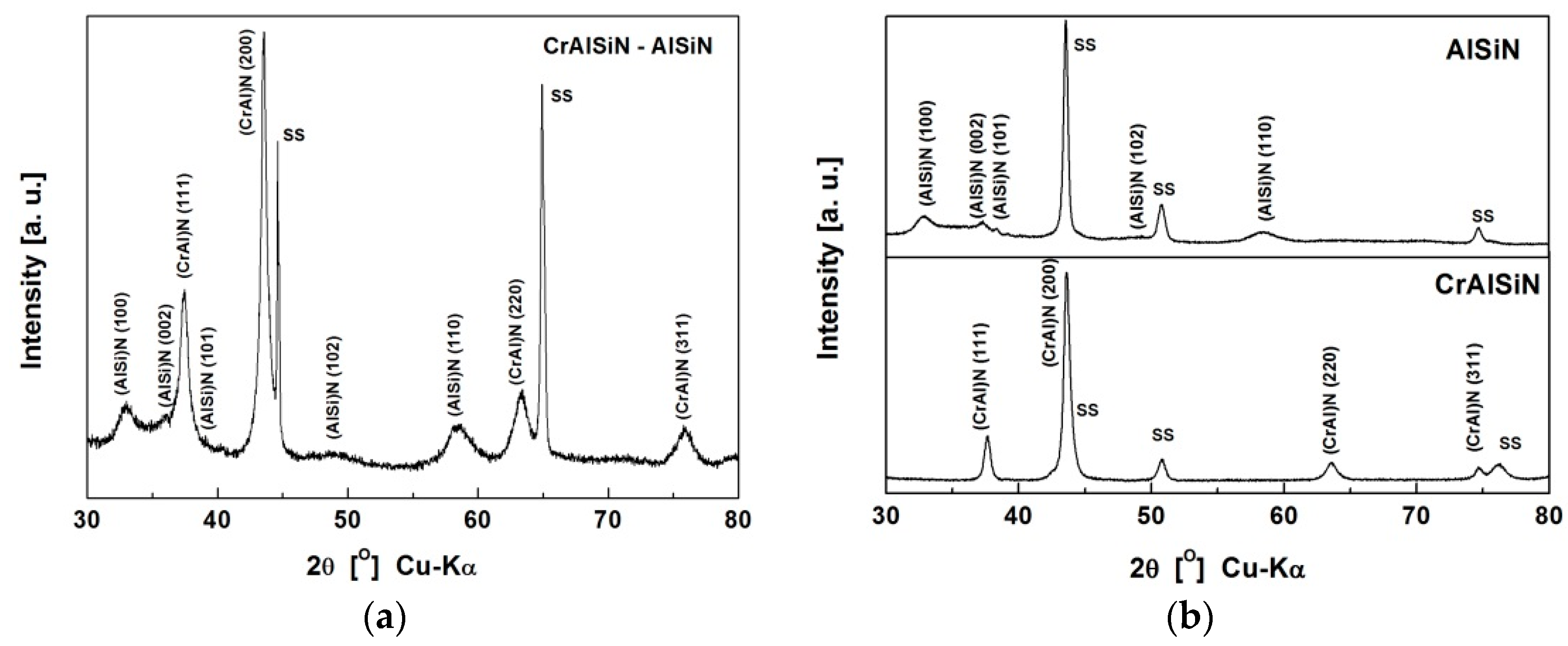

3.3. Composition and Structure

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, J.; Zhang, S.; Li, M. Influence of the C2H2 flow rate on gradient TiCN films deposited by multi-arc ion plating. Appl. Surf. Sci. 2013, 283, 134–144. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Yang, S.J.; Wu, W.; Kuo, Y.C.; Lee, J.W.; Wang, C.J. Mechanical properties of gradient and multi-layered TiAlSiN hard coatings. Thin Solid Films 2009, 9517, 4934–4937. [Google Scholar] [CrossRef]

- Faga, M.G.; Gautier, G.; Calzavarini, R.; Perucca, M.; Aimo Boot, E.; Cartasegna, F.; Settineri, L. AlSiTiN nanocomposite coatings developed via Arc Cathodic PVD: Evaluation of wear resistance via tribological analysis and high speed machining operations. Wear 2007, 263, 1306–1314. [Google Scholar] [CrossRef]

- Chen, L.; Wang, S.Q.; Du, Y.; Zhou, S.Z.; Gang, T.; Fen, J.C.; Chang, K.K.; Li, Y.W.; Xiong, X. Machining performance of Ti–Al–Si–N coated inserts. Surf. Coat. Technol. 2010, 205, 582–586. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Browne, T.; Heckerman, B.; Meletis, E.I. Mechanical and tribological properties of nanocomposite TiSiN coatings. Surf. Coat. Technol. 2010, 204, 2123–2129. [Google Scholar] [CrossRef]

- Lukaszkowicz, K.; Sondor, J.; Kriz, A.; Pancielejko, M. Structure, mechanical properties and corrosion resistance of nanocomposite coatings deposited by PVD technology onto the X6CrNiMoTi17-12-2 and X40CrMoV5-1 steel substrates. J. Mater. Sci. 2010, 45, 1629–1637. [Google Scholar] [CrossRef]

- Lukaszkowicz, K.; Dobrzanski, L.A.; Kwasny, W.; Labisz, K.; Pancielejko, M. Microstructure and mechanical properties of nanocomposite coatings deposited by cathodic arc evaporation. J. Achiev. Mater. Manuf. Eng. 2010, 42, 156–163. [Google Scholar]

- Ding, X.Z.; Zeng, X.T.; Liu, Y.C. Structure and properties of CrAlSiN Nanocomposite coatings deposited by lateral rotating cathode arc. Thin Solid Films 2011, 519, 1894–1900. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.; Wang, Q.; Li, M. A superhard CrAlSiN superlattice coating deposited by a multi-arc ion plating: I. Microstructure and mechanical properties. Surf. Coat. Technol. 2013, 214, 160–167. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.; Wang, Q.; Li, M. A superhard CrAlSiN superlattice coating deposited by a multi-arc ion plating: II. Thermal stability and oxidation resistance. Surf. Coat. Technol. 2013, 214, 153–159. [Google Scholar] [CrossRef]

- Veprek, S.; Zhang, R.; Veprek-Heijman, M.G.J.; Sheng, S.; Argon, A. Search for ultrahard materials and recent progress in the understanding of hardness enhancement and properties of nanocomposites. Solid State Phenom. 2010, 159, 1–11. [Google Scholar] [CrossRef]

- Ritchie, R. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef] [PubMed]

- Leynad, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behavior. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Musil, J. Hard and superhard nanocomposite coatings. Surf. Coat. Technol. 2000, 125, 322–330. [Google Scholar] [CrossRef]

- Su, Y.L.; Yao, S.H. On the performance and application of CrN coating. Wear 1997, 205, 112–119. [Google Scholar] [CrossRef]

- Chim, Y.C.; Ding, X.Z.; Zeng, X.T.; Zhang, S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Solid Films 2009, 517, 4845–4849. [Google Scholar] [CrossRef]

- Park, I.; King, D.; Moore, J.; Kwon, S.; Rha, J.; Kim, K. Microstructures, mechanical properties, and tribological behaviors of Cr–Al–N, Cr–Si–N, and Cr–Al–Si–N coatings. Surf. Coat. Technol. 2007, 201, 5223–5227. [Google Scholar] [CrossRef]

- Schlögl, M.; Paulitsch, J.; Keckes, J.; Mayrhofer, P.H. Influence of AlN layers on mechanical properties and thermal stability of Cr-based nitride coatings. Thin Solid Films 2013, 531, 113–118. [Google Scholar] [CrossRef]

- Dopita, M.; Rafaja, D.; Wüstefeld, C.; Ruzicka, M.; Klemm, V.; Heger, D.; Schreiber, G.; Sima, M. Interplay of microstructural features in Cr1−xAlxN and Cr1−x−yAlxSiyN nanocomposite coatings deposited by cathodic arc evaporation. Surf. Coat. Technol. 2008, 202, 3199–3207. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhang, S.; Lee, J.W.; Lew, W.S.; Sun, D.; Li, B. Toward hard yet tough CrAlSiN coatings via compositional grading. Surf. Coat. Technol. 2013, 231, 346–352. [Google Scholar] [CrossRef]

- Ding, J.; Zhang, T.; Kang, M.; Wang, Q.; Kim, K.H. Microstructure, mechanical, oxidation and corrosion properties of the Cr-Al-Si-N coatings deposited by a hybrid sputtering system. Coatings 2017, 7, 119. [Google Scholar] [CrossRef]

- Fan, Q.; Liang, Y.; Wu, Z.; Liu, Y.; Wang, T. Microstructure and properties of CrAlSiN coatings deposited by HiPIMS and direct-current magnetron sputtering. Coatings 2019, 9, 512. [Google Scholar] [CrossRef]

- Schecker, A.P.; Hug, H.J.; Patscheider, J. Morphology, microstructure evolution and optical properties of Al–Si–N nanocomposite coatings. Surf. Coat. Technol. 2014, 257, 114–120. [Google Scholar] [CrossRef]

- Musil, J.; Remnev, G.; Legostaev, V.; Uglov, V.; Lebedynskiy, A.; Lauk, A.; Procházka, J.; Haviar, S.; Smolyanskiy, E. Flexible hard Al–Si–N films for high temperature operation. Surf. Coat. Technol. 2016, 307, 1112–1118. [Google Scholar] [CrossRef]

- Jiang, X.; Yang, F.C.; Chen, W.C.; Lee, J.W.; Chang, C.L. Effect of nitrogen-argon flow ratio on the microstructural and mechanical properties of AlSiN thin films prepared by high power impulse magnetron sputtering. Surf. Coat. Technol. 2017, 320, 138–145. [Google Scholar] [CrossRef]

- Illana, A.; Almandoz, E.; Fuentes, G.G.; Perez, F.J.; Mato, S. Comparative study of CrAlSiN monolayer and CrN/AlSiN superlattice multilayer coatings: Behavior at high temperature in steam atmosphere. J. Alloys Compd. 2019, 778, 652–661. [Google Scholar] [CrossRef]

- Tsai, S.H.; Duh, J.G. Microstructure and mechanical properties of CrAlN/SiNx nanostructure multilayered coatings. Thin Solid Films 2009, 518, 1480–1483. [Google Scholar] [CrossRef]

- Wu, W.; Chen, W.; Yang, S.; Lin, Y.; Zhang, S.; Cho, T.Y.; Lee, G.H.; Kwon, S.C. Design of AlCrSiN multilayers and nanocomposite coating for HSS cutting tools. Appl. Surf. Sci. 2015, 351, 803–810. [Google Scholar] [CrossRef]

- Hong, Y.S.; Kwon, S.H.; Wang, T.; Kim, D.I.; Choi, J.; Kim, K.H. Effects of Cr interlayer on mechanical and tribological properties of Cr–Al–Si–N nanocomposite coating. Trans. Nonferrous Met. Soc. China 2011, 21, 62–67. [Google Scholar] [CrossRef]

- Lin, C.K.; Hsu, C.H.; Kung, S.C. Effect of electroless nickel interlayer on wear behavior of CrN/ZrN multilayer films on Cu-alloyed ductile iron. Appl. Surf. Sci. 2013, 284, 59–65. [Google Scholar] [CrossRef]

- Chaliampalias, D.; Pliatsikas, N.; Pavlidou, E.; Kolaklieva, L.; Kakanakov, R.; Vouroutzis, N.; Patsalas, P.; Vourlias, G.; Polychroniadis, E.K. Structural examination of multilayer CrAlSiN/AlSiN coatings deposited by CAD. J. Nano Res. 2017, 48, 62–70. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Mikičić, D.; Kunosić, A.; Zlatanović, M. Contact Force determination in abrasive wear test. Tribol. Ind. 2005, 27, 34–37. [Google Scholar]

- Chang, Y.; Chang, C.; Wang, D.; Yang, S.; Wu, W. High temperature oxidation resistance of CrAlSiN coatings synthesized by a cathodic arc deposition process. J. Alloys Compd. 2008, 461, 336–341. [Google Scholar] [CrossRef]

- Veprek, S.; Veprek-Heijman, M.G.J. The formation and role of interfaces in superhard nc-MenN/a-Si3N4 nanocomposites. Surf. Coat. Technol. 2007, 201, 6064–6070. [Google Scholar] [CrossRef]

- Veprek, S.; Veprek-Heijman, M.G.J.; Karvankova, P.; Prochazka, J. Different approaches to superhard coatings and nanocomposites. Thin Solid Films 2005, 476, 1–29. [Google Scholar] [CrossRef]

- Schmitt, T.; Steyer, P.; Fontaine, J.; Mary, N.; Esnouf, C.; O’Sullivan, M.; Sanchette, F. Cathodic arc deposited (Cr,Six)N coatings: From solid solution to nanocomposite structure. Surf. Coat. Technol. 2012, 213, 117–125. [Google Scholar] [CrossRef]

- Flink, A.; Larsson, T.; Sjolen, J.; Karlsson, L.; Hultman, L. Influence of Si on the microstructure of arc evaporated (Ti,Si)N thin films; evidence for cubic solid solutions and their thermal stability. Surf. Coat. Technol. 2005, 200, 1535–1542. [Google Scholar] [CrossRef]

- Chen, W.; Lin, Y.; Zheng, J.; Zhang, S.; Liu, S.; Kwon, S.C. Preparation and characterization of CrAlN/TiAlSiN nano-multilayers by cathodic vacuum arc. Surf. Coat. Technol. 2015, 265, 205–211. [Google Scholar] [CrossRef]

- Conde, A.; Cristóbal, A.B.; Fuentes, G.; Tate, T.; de Damborene, J. Surface analysis of electrochemically stripped CrN coatings. Surf. Coat. Technol. 2006, 201, 3588–3595. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Grundmeier, G.; Arcos, T.; Wiesing, M.; Kruppe, N. (Cr,Al)N/(Cr,Al)ON oxy-nitride coatings deposited by hybrid dcMS/HPPMS for plastics processing applications. Surf. Coat. Technol. 2016, 308, 394–403. [Google Scholar] [CrossRef]

- Rosenberger, L.; Baird, R.; McCullen, E.; Aunern, G.; Shreve, G. XPS analysis of aluminum nitride films deposited by plasma source molecular beam epitaxy. Surf. Interface Anal. 2008, 40, 1254–1261. [Google Scholar] [CrossRef]

- Tan, S.; Zhang, X.; Wu, X.; Fang, F.; Jiang, J. Effect of substrate bias and temperature on magnetron sputtered CrSiN films. Appl. Surf. Sci. 2011, 257, 1850–1853. [Google Scholar] [CrossRef]

- Lewin, E.; Loch, D.; Montagne, A.; Ehiasarian, A.P.; Patscheider, J. Comparison of Al–Si–N nanocomposite coatings deposited by HIPIMS and DC magnetron sputtering. Surf. Coat. Technol. 2013, 232, 680–689. [Google Scholar] [CrossRef]

- Pelisson, A.; Parlinska-Wojtan, M.; Hug, H.J.; Patscheider, J. Microstructure and mechanical properties of Al–Si–N transparent hard coatings deposited by magnetron sputtering. Surf. Coat. Technol. 2007, 202, 884–889. [Google Scholar] [CrossRef]

- Padmavathi, D.A. Potential Energy Curves & Material Properties. Mater. Sci. Appl. 2011, 2, 97–104. [Google Scholar] [CrossRef]

- Lide, D.R. CRC Handbook of Chemistry and Physics, 79th ed.; CRC Press LLC, N.W.: Boca Raton, FL, USA, 1998; pp. 51–53. [Google Scholar]

| Coating | Period/Sublayer | Element Concentration, at.% | Elemental Composition | |||

|---|---|---|---|---|---|---|

| N | Al | Cr | Si | |||

| CrAlSiN–AlSiN | CrAlSiN | 49 | 21 | 26 | 4 | Cr051Al0.41Si0.08N |

| AlSiN | 50 | 41 | 4 | 7 | Al0.82Cr0.04Si0.14N | |

| CrAlSiN | 50 | 19 | 27 | 4 | Cr0.54Al0.38Si0.08N | |

| AlSiN | 50 | 41 | 2 | 7 | Al0.82Cr0.04Si0.14N | |

| CrAlSiN | 51 | 20 | 25 | 4 | Cr0.51Al0.41Si0.08N | |

| AlSiN | 50 | 40 | 3 | 7 | Al0.80Cr0.06Si0.14N | |

| CrAlSIN | CrAlSiN | 50 | 19 | 27 | 4 | Cr0.54Al0.38Si0.08N |

| AlSiN | AlSiN | 50 | 41 | 1 | 8 | Al0.82Cr0.02Si0.16N |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolaklieva, L.; Kakanakov, R.; Stefanov, P.; Kovacheva, D.; Atanasova, G.; Russev, S.; Chitanov, V.; Cholakova, T.; Bahchedjiev, C. Mechanical and Structural Properties of Nanocomposite CrAlSiN–AlSiN Coating with Periodically Modulated Composition. Coatings 2020, 10, 41. https://doi.org/10.3390/coatings10010041

Kolaklieva L, Kakanakov R, Stefanov P, Kovacheva D, Atanasova G, Russev S, Chitanov V, Cholakova T, Bahchedjiev C. Mechanical and Structural Properties of Nanocomposite CrAlSiN–AlSiN Coating with Periodically Modulated Composition. Coatings. 2020; 10(1):41. https://doi.org/10.3390/coatings10010041

Chicago/Turabian StyleKolaklieva, Lilyana, Roumen Kakanakov, Plamen Stefanov, Daniela Kovacheva, Genoveva Atanasova, Stoyan Russev, Vasiliy Chitanov, Tetyana Cholakova, and Christo Bahchedjiev. 2020. "Mechanical and Structural Properties of Nanocomposite CrAlSiN–AlSiN Coating with Periodically Modulated Composition" Coatings 10, no. 1: 41. https://doi.org/10.3390/coatings10010041

APA StyleKolaklieva, L., Kakanakov, R., Stefanov, P., Kovacheva, D., Atanasova, G., Russev, S., Chitanov, V., Cholakova, T., & Bahchedjiev, C. (2020). Mechanical and Structural Properties of Nanocomposite CrAlSiN–AlSiN Coating with Periodically Modulated Composition. Coatings, 10(1), 41. https://doi.org/10.3390/coatings10010041