Analytical Solution of the Time-Dependent Microfluidic Poiseuille Flow in Rectangular Channel Cross-Sections and Its Numerical Implementation in Microsoft Excel

Abstract

1. Introduction

2. Numerical Scheme

2.1. Navier–Stokes Equation for Time-Dependent Flow

2.2. Numerical Scheme for the Second-Order Partial Differential Equations

2.3. Numerical Scheme for the First-Order Partial Differential with Respect to Time

2.4. Correcting Units

3. Implementation in Microsoft Excel

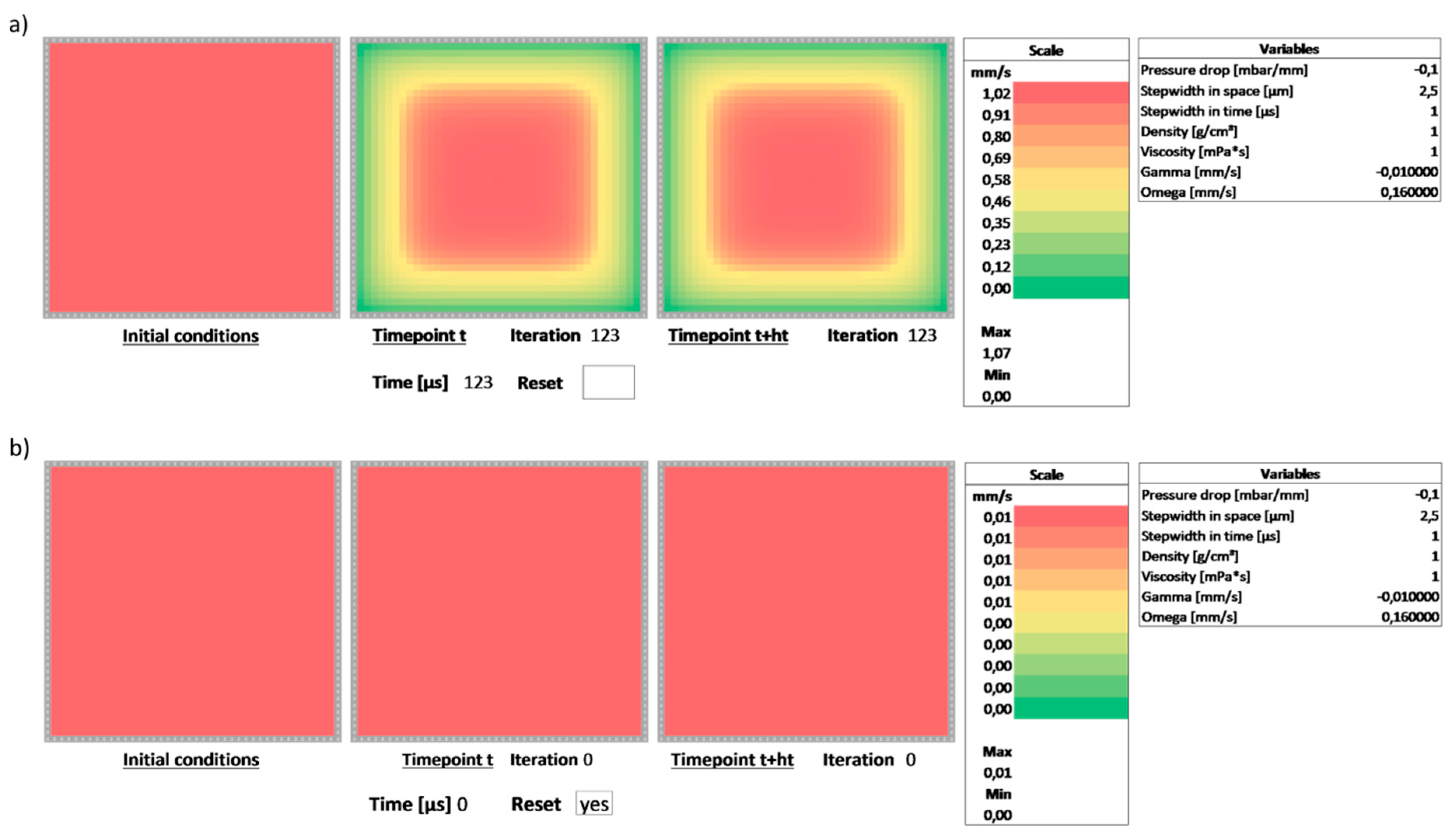

3.1. Layout of the Spreadsheet

- left panel—initial conditions: these are the values of the flow in the channel at the beginning of the calculation; for a first demonstration, we assume the flow to be non-moving, i.e., all values are 0

- center panel—velocity profile at time point : this is the velocity profile in the channel at the current timepoint, i.e., ; the scheme is assumed to step from this point to

- right panel—velocity profile at time point : this is the velocity profile calculated by stepping from timepoint t via the numerical scheme of Equation (9)

- independent variables and : μm

- pressure drop : mbar/mm

- step width in space : μm

- step width in time : μs

- density of the fluid: g/cm3

- viscosity of the fluid: mPa·s

3.2. Iteration

3.3. Implementation of the Numerical Scheme

3.4. Resetting the Calculation and Implementing the Boundary Conditions

4. Analytical Solution for Initiating Two-Dimensional Flow in Rectangular Channel Cross-Sections

4.1. Derivation

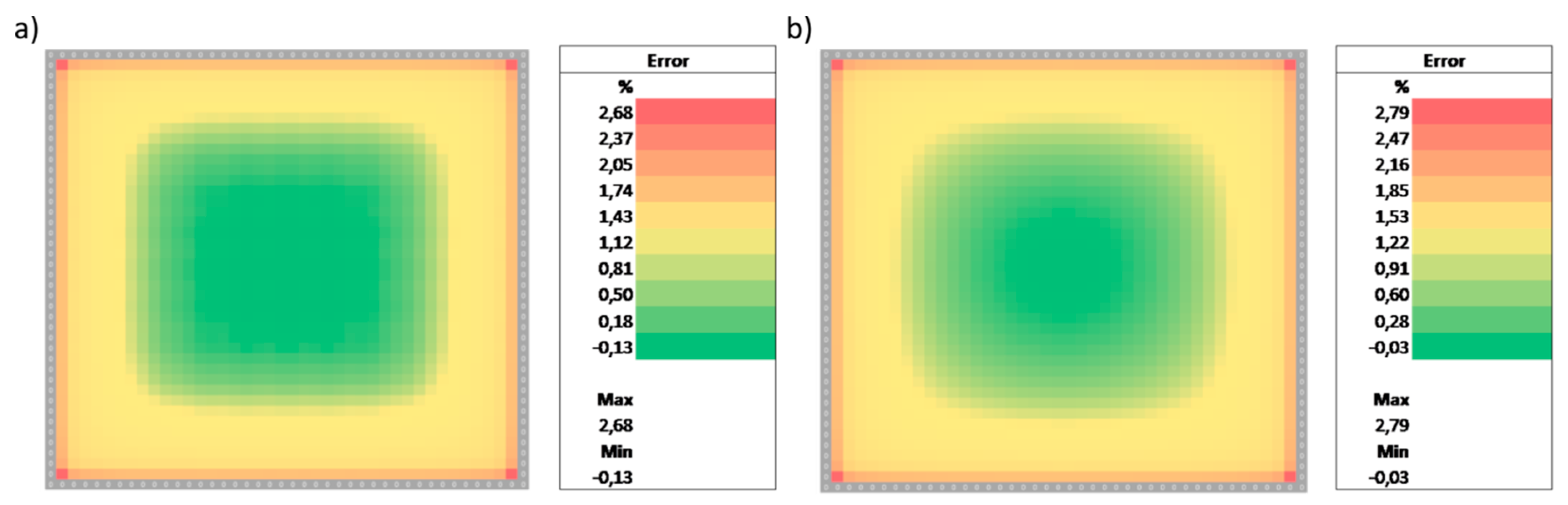

Visualization

4.2. Application of the Derived Spreadsheet

4.2.1. Initiating Two-Dimensional Flow in Rectangular Channel Cross-Sections

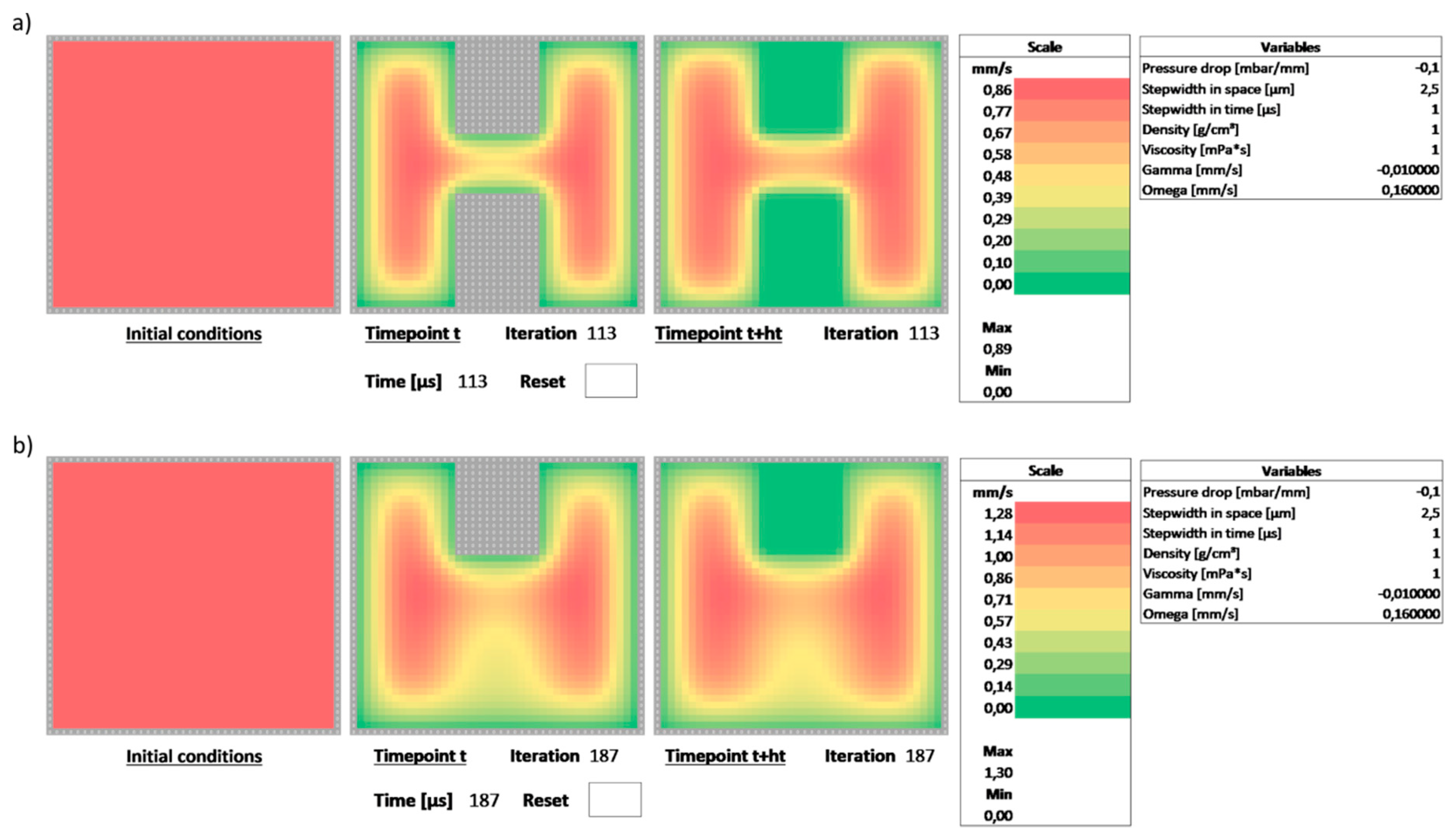

4.2.2. Complex Flow Cases: Different Channel Cross-Sections

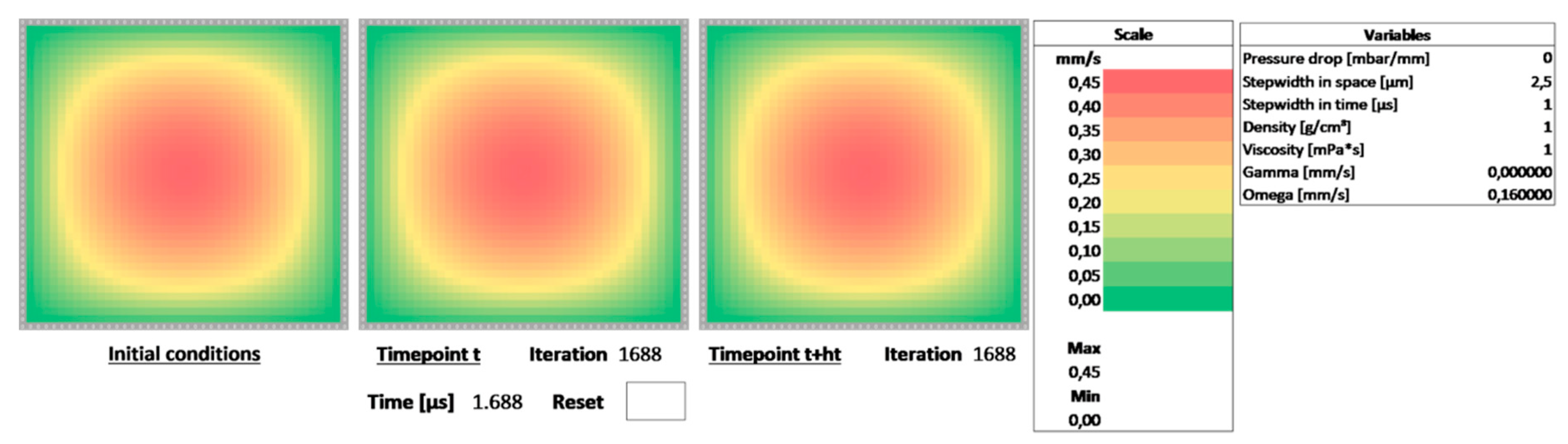

4.2.3. Boundary Conditions and Initial Conditions

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Vijayendran, R.A.; Motsegood, K.M.; Beebe, D.J.; Leckband, D.E. Evaluation of a three-dimensional micromixer in a surface-based biosensor. Langmuir 2003, 19, 1824–1828. [Google Scholar] [CrossRef]

- Baronas, R.; Ivanauskas, F.; Kulys, J. The effect of diffusion limitations on the response of amperometric biosensors with substrate cyclic conversion. J. Math. Chem. 2004, 35, 199–213. [Google Scholar] [CrossRef]

- Li, Y.; Van Roy, W.; Lagae, L.; Vereecken, P.M. Analysis of fully on-chip microfluidic electrochemical systems under laminar flow. Electrochim. Acta 2017, 231, 200–208. [Google Scholar] [CrossRef]

- Squires, T.M.; Quake, S.R. Microfluidics: Fluid physics at the nanoliter scale. Rev. Mod. Phys. 2005, 77, 977–1026. [Google Scholar] [CrossRef]

- Koo, J.M.; Kleinstreuer, C. Liquid flow in microchannels: Experimental observations and computational analyses of microfluidics effects. J. Micromech. Microeng. 2003, 13, 568–579. [Google Scholar] [CrossRef]

- Richter, C.; Kotz, F.; Giselbrecht, S.; Helmer, D.; Rapp, B.E. Numerics made easy: Solving the navier–stokes equation for arbitrary channel cross-sections using microsoft excel. Biomed. Microdevices 2016, 18, 52. [Google Scholar] [CrossRef] [PubMed]

- Richter, C.; Kotz, F.; Keller, N.; Nargang, T.M.; Sachsenheimer, K.; Helmer, D.; Rapp, B.E. An analytical solution to neumann-type mixed boundary poiseuille microfluidic flow in rectangular channel cross-sections (slip/no-slip) including a numerical technique to derive it. J. Biomed. Sci. Eng. 2017, 10, 205–219. [Google Scholar] [CrossRef][Green Version]

- Rapp, B.E. Microfluidics: Modeling, Mechanics and Mathematics; William Andrew: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Elvira, K.S.; Solvas, X.C.I.; Wootton, R.C.R.; de Mello, A.J. The past, present and potential for microfluidic reactor technology in chemical synthesis. Nat. Chem. 2013, 5, 905–915. [Google Scholar] [CrossRef] [PubMed]

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef] [PubMed]

- Ohno, K.; Tachikawa, K.; Manz, A. Microfluidics: Applications for analytical purposes in chemistry and biochemistry. Electrophoresis 2008, 29, 4443–4453. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Risch, P.; Helmer, D.; Kotz, F.; Rapp, B.E. Analytical Solution of the Time-Dependent Microfluidic Poiseuille Flow in Rectangular Channel Cross-Sections and Its Numerical Implementation in Microsoft Excel. Biosensors 2019, 9, 67. https://doi.org/10.3390/bios9020067

Risch P, Helmer D, Kotz F, Rapp BE. Analytical Solution of the Time-Dependent Microfluidic Poiseuille Flow in Rectangular Channel Cross-Sections and Its Numerical Implementation in Microsoft Excel. Biosensors. 2019; 9(2):67. https://doi.org/10.3390/bios9020067

Chicago/Turabian StyleRisch, Patrick, Dorothea Helmer, Frederik Kotz, and Bastian E. Rapp. 2019. "Analytical Solution of the Time-Dependent Microfluidic Poiseuille Flow in Rectangular Channel Cross-Sections and Its Numerical Implementation in Microsoft Excel" Biosensors 9, no. 2: 67. https://doi.org/10.3390/bios9020067

APA StyleRisch, P., Helmer, D., Kotz, F., & Rapp, B. E. (2019). Analytical Solution of the Time-Dependent Microfluidic Poiseuille Flow in Rectangular Channel Cross-Sections and Its Numerical Implementation in Microsoft Excel. Biosensors, 9(2), 67. https://doi.org/10.3390/bios9020067