Modeling Analysis of Silk Fibroin/Poly(ε-caprolactone) Nanofibrous Membrane under Uniaxial Tension

Abstract

1. Introduction

2. Modeling Analysis

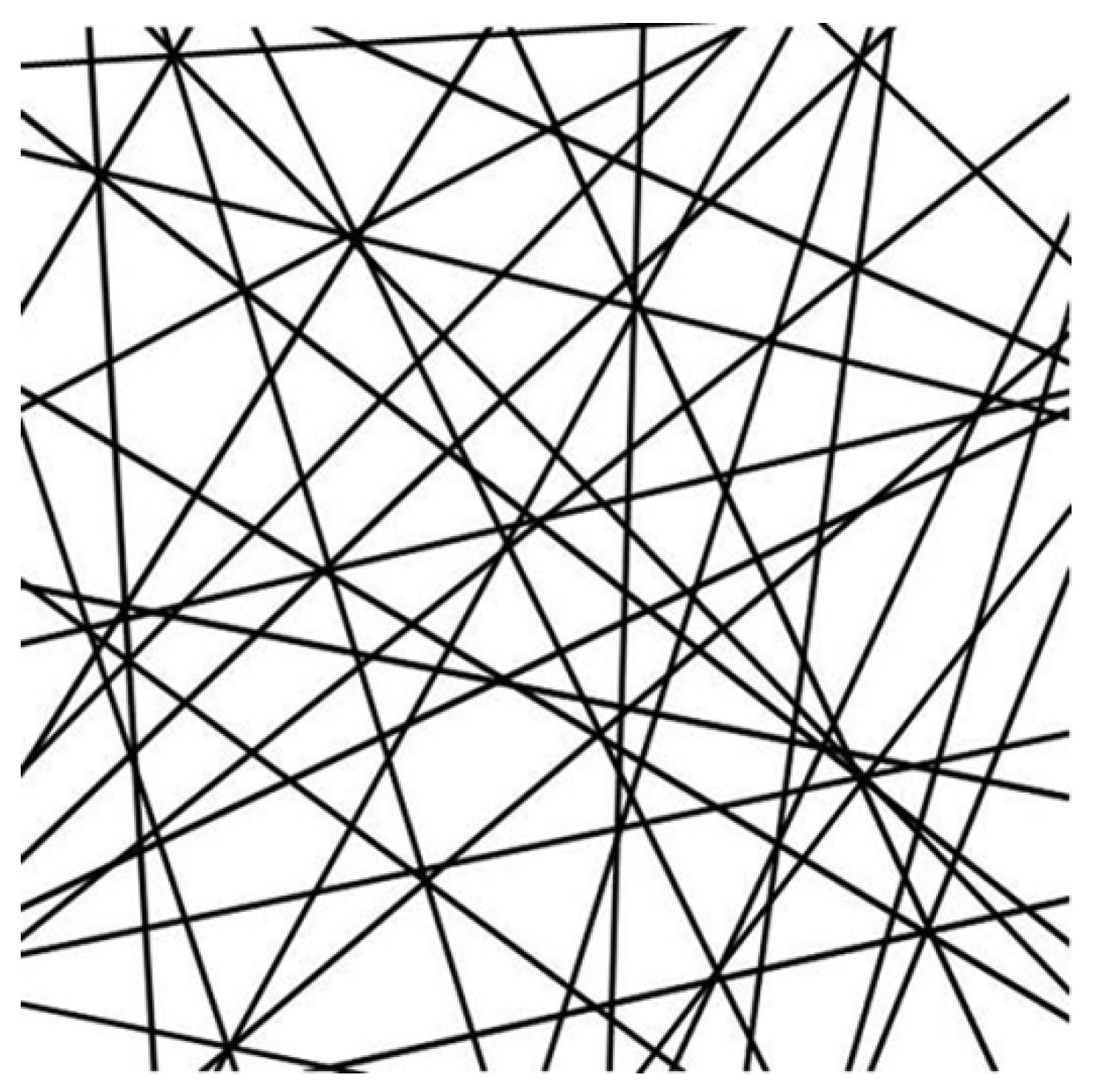

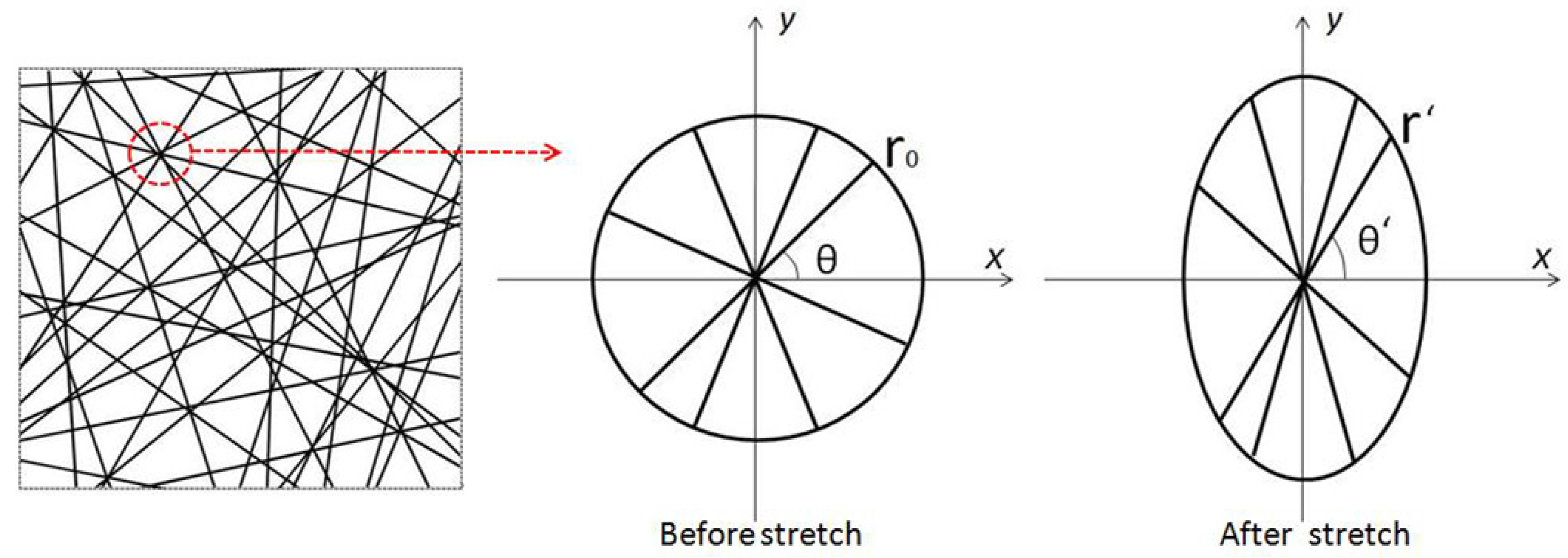

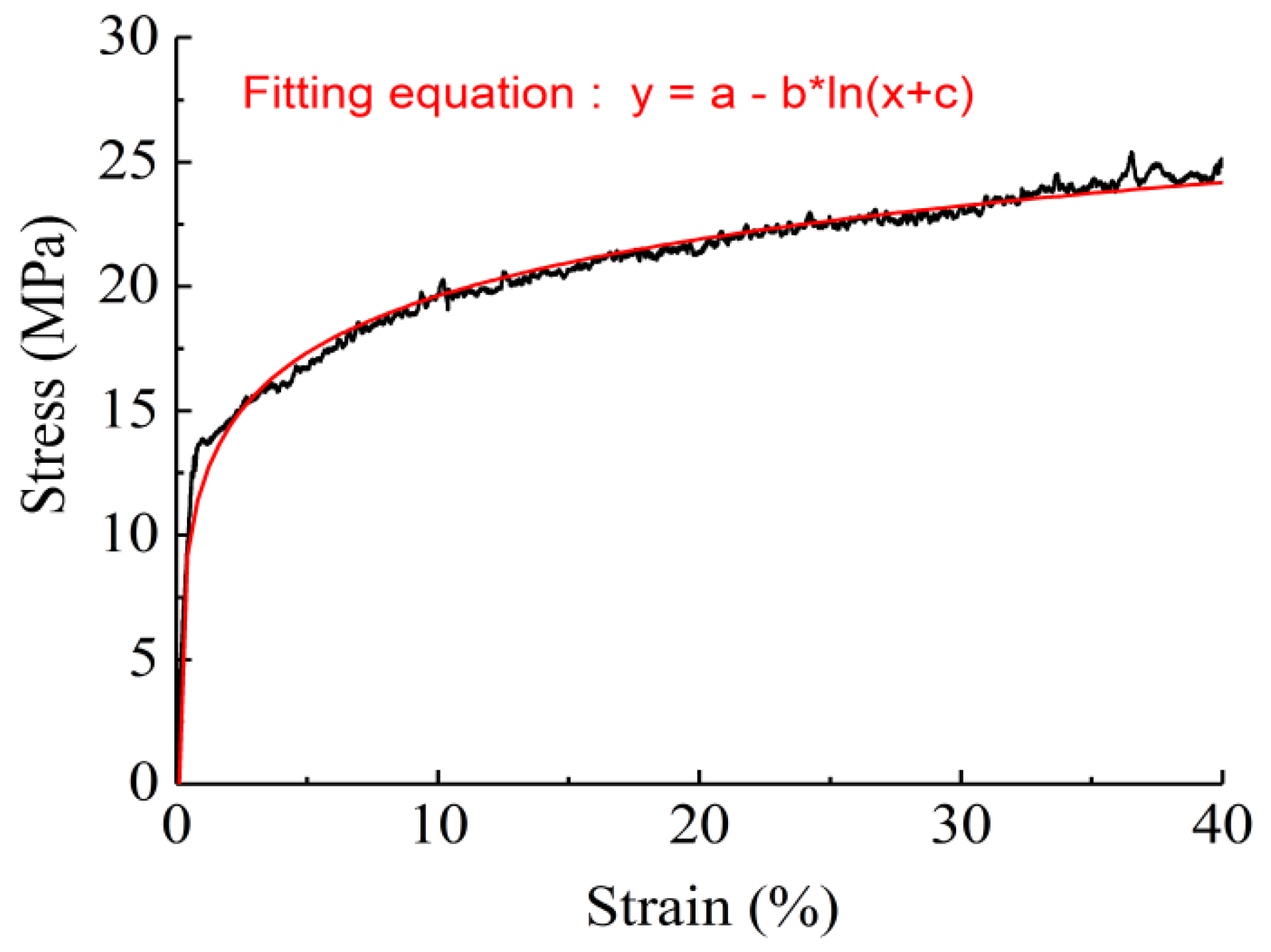

2.1. Assumptions

2.2. Derivation

3. Materials and Methods

3.1. Materials

3.2. Preparation of Stock SF Sponge

3.3. Preparation of SF/PCL Solutions

3.4. Preparation of SF/PCL Nanofibrous Membranes

3.5. Morphology of the Prepared Nanofibrous Membranes

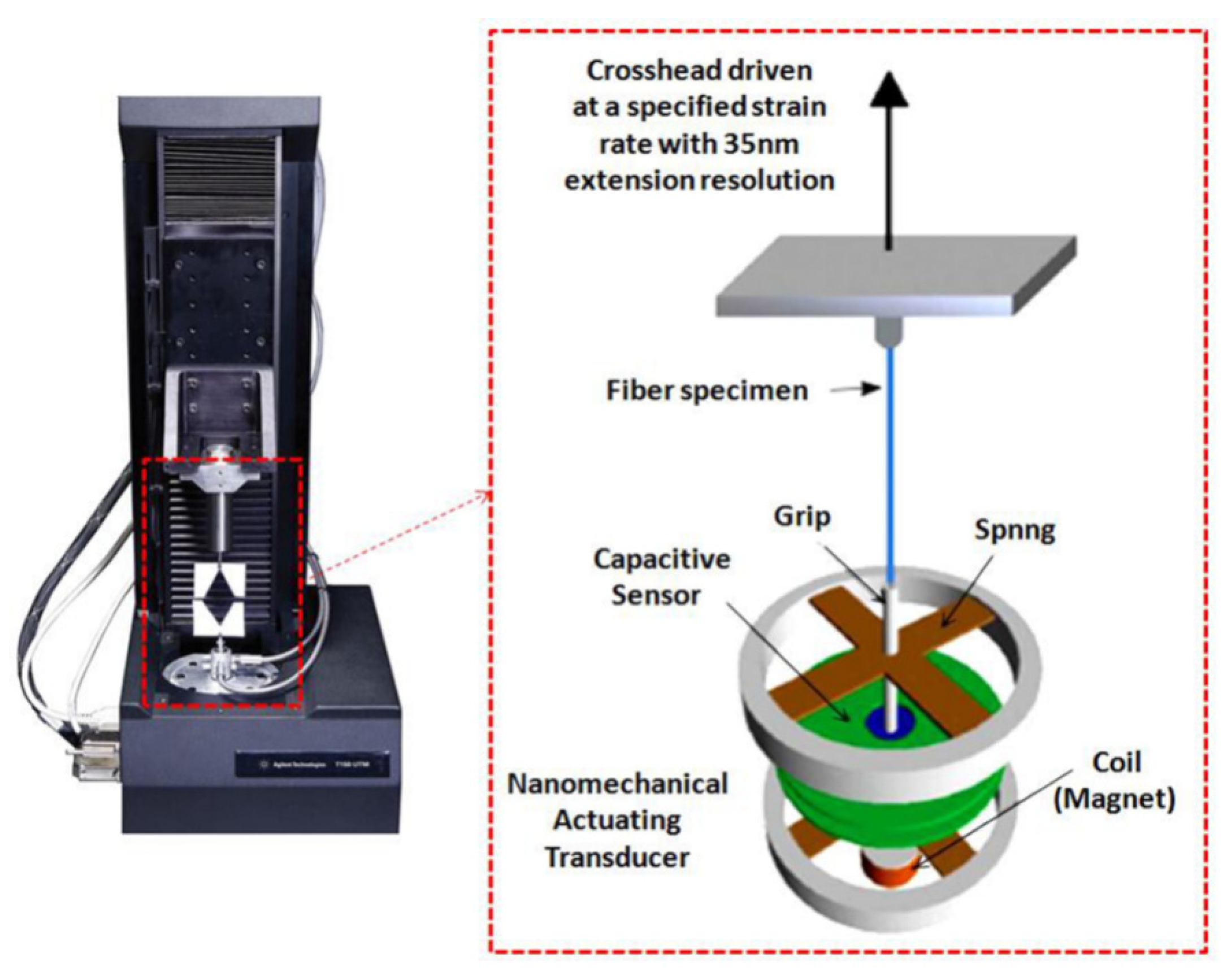

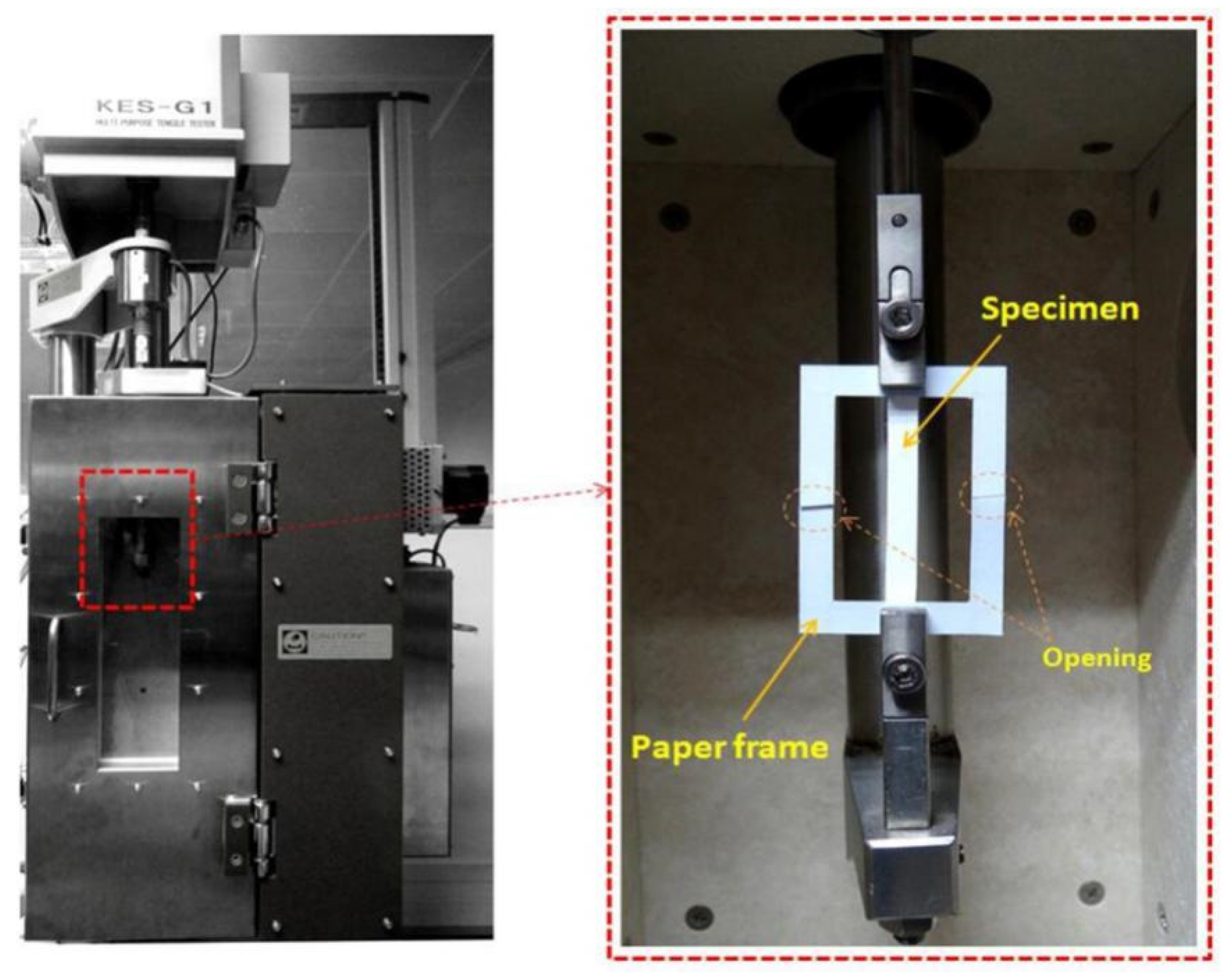

3.6. Tensile Test for Single Nanofiber and Nanofibrous Membranes

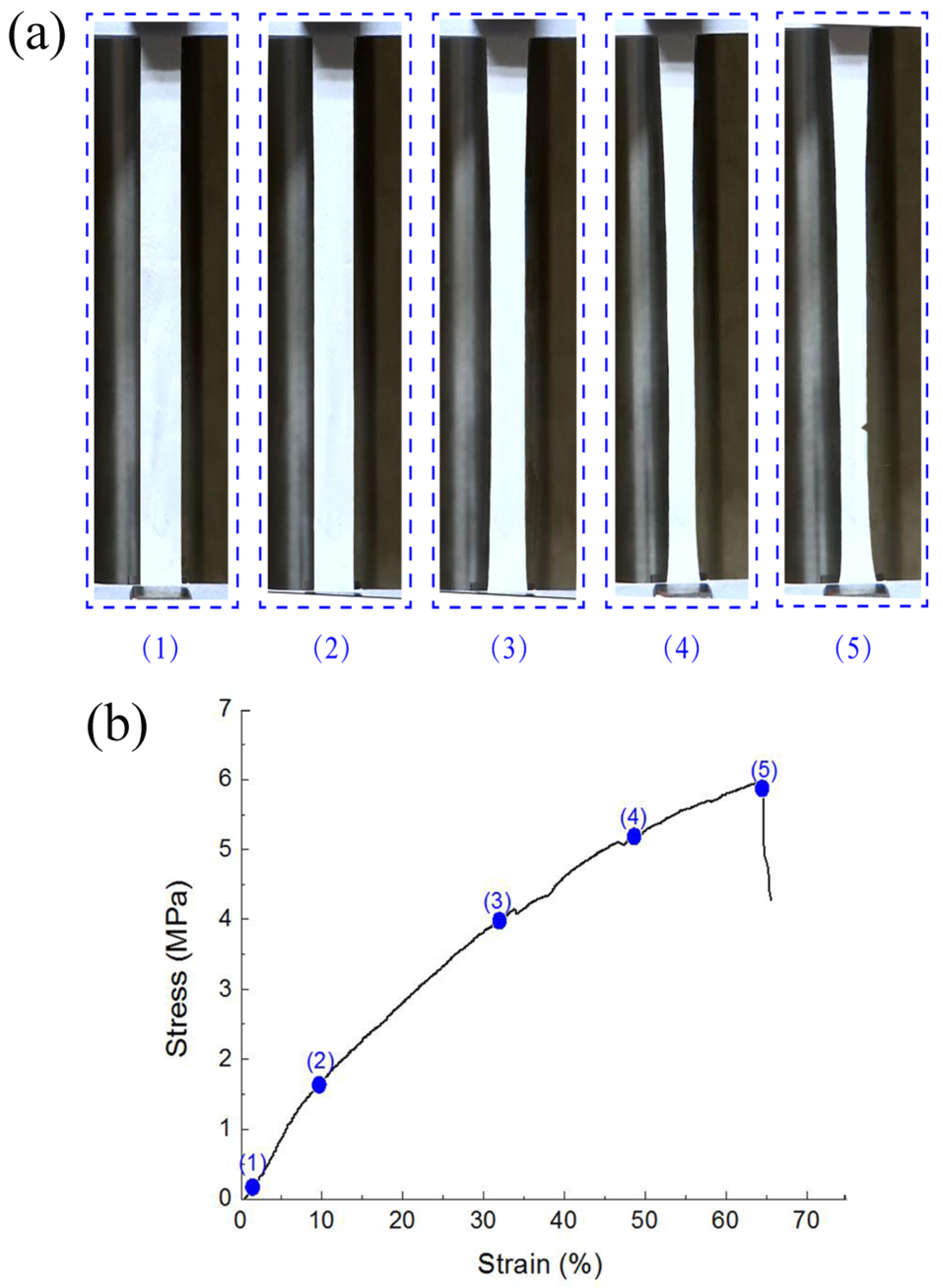

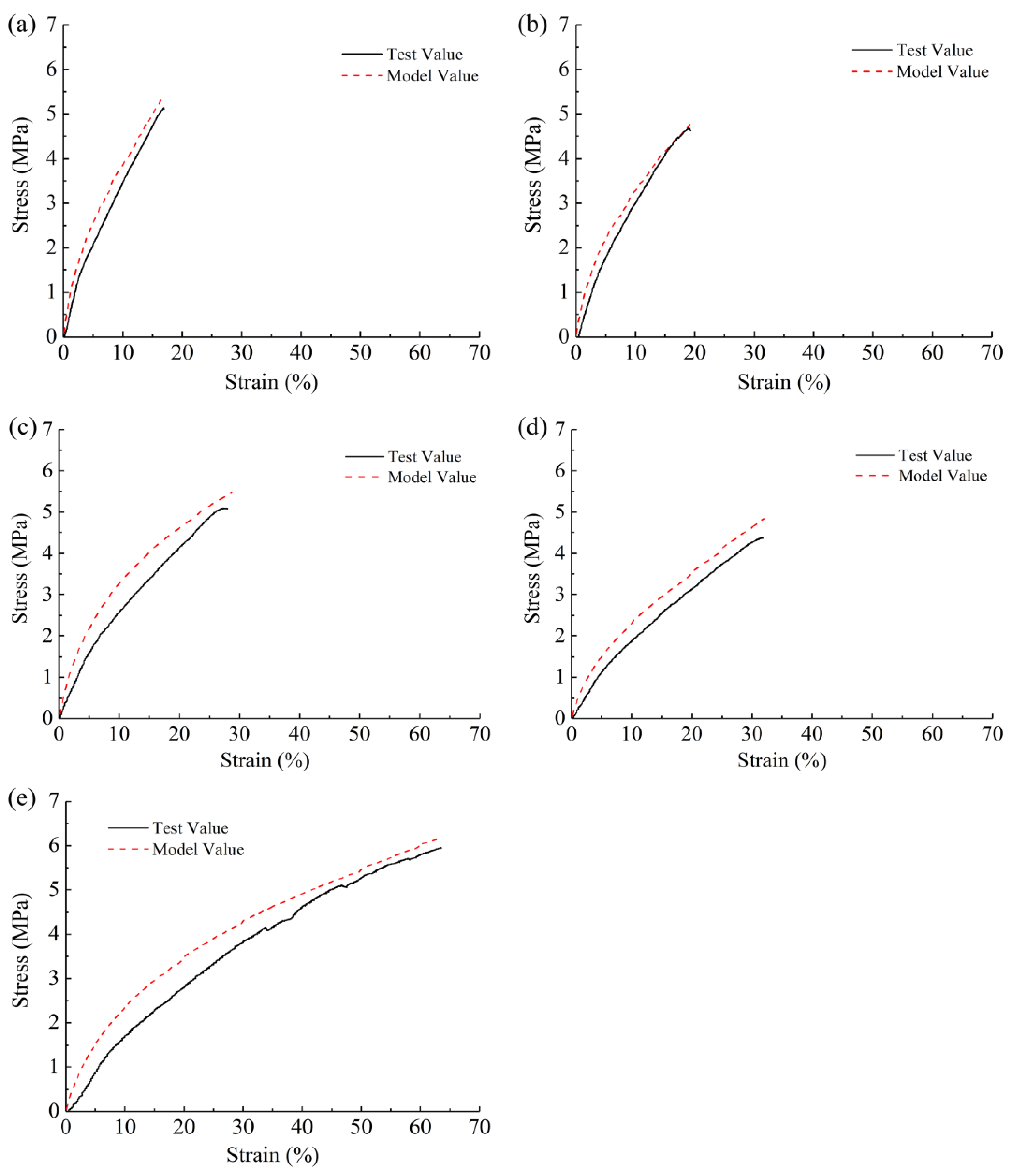

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, M.; Duan, X.P.; Li, Y.M.; Yang, D.P.; Long, Y.Z. Electrospun nanofibers for wound healing. Mater. Sci. Eng. C 2017, 76, 1413–1423. [Google Scholar] [CrossRef] [PubMed]

- Nosratollah, Z.; Roghayeh, S.; Amir, F.; Abbas, M.; Mehdi, D.; Younes, P.-S. An Overview on Application of Natural Substances Incorporated with Electrospun Nanofibrous Scaffolds to Development of Innovative Wound Dressings. Mini-Rev. Med. Chem. 2017, 17, 1–14. [Google Scholar]

- Dong, C.; Lv, Y. Application of collagen scaffold in tissue engineering: Recent advances and new perspectives. Polymers 2016, 8, 42. [Google Scholar] [CrossRef] [PubMed]

- Salifu, A.A.; Lekakou, C.; Labeed, F.H. Electrospun oriented gelatin-hydroxyapatite fiber scaffolds for bone tissue engineering. J. Biomed. Mater. Res. Part A 2017, 105, 1911–1926. [Google Scholar] [CrossRef] [PubMed]

- Weng, L.; Xie, J. Smart electrospun nanofibers for controlled drug release: Recent advances and new perspectives. Curr. Pharm. Des. 2015, 21, 1944–1959. [Google Scholar] [CrossRef] [PubMed]

- Gnavi, S.; Fornasari, B.E.; Tonda-Turo, C.; Laurano, R.; Zanetti, M.; Ciardelli, G.; Geuna, S. The Effect of Electrospun Gelatin Fibers Alignment on Schwann Cell and Axon Behavior and Organization in the Perspective of Artificial Nerve Design. Int. J. Mol. Sci. 2015, 16, 12925–12942. [Google Scholar] [CrossRef] [PubMed]

- Zou, B.; Guo, Y.; Shen, N.; Xiao, A.; Li, M.; Zhu, L.; Wan, P.; Sun, X. Sulfophenyl-Functionalized Reduced Graphene Oxide Networks on Electrospun 3D Scaffold for Ultrasensitive NO2 Gas Sensor. Sensors 2017, 17, 2954. [Google Scholar] [CrossRef]

- Huan, S.; Liu, G.; Cheng, W.; Han, G.; Bai, L. Electrospun Poly(lactic acid)-Based Fibrous Nanocomposite Reinforced by Cellulose Nanocrystals: Impact of Fiber Uniaxial Alignment on Microstructure and Mechanical Properties. Biomacromolecules 2018, 19, 1037–1046. [Google Scholar] [CrossRef]

- Cho, H.J.; Ki, C.S.; Oh, H.; Lee, K.H.; Um, I.C. Molecular weight distribution and solution properties of silk fibroins with different dissolution conditions. Int. J. Biol. Macromol. 2012, 51, 336–341. [Google Scholar] [CrossRef]

- Park, S.Y.; Ki, C.-S.; Park, Y.H.; Jung, H.M. Electrospun Silk Fibroin Scaffolds with Macropores for Bone Regeneration: An In Vitro and In Vivo Study. Tissue Eng. Part A 2010, 16, 1271–1279. [Google Scholar] [CrossRef]

- Chutipakdeevong, J.; Ruktanonchai, U.; Supaphol, P. Hybrid biomimetic electrospun fibrous mats derived from poly(ε-caprolactone) and silk fibroin protein for wound dressing application. J. Appl. Polym. Sci. 2014, 132, 41653. [Google Scholar] [CrossRef]

- Chen, W.; Li, D.; EI-Shanshory, A.; EI-Newehy, M.; EI-Hamshary, H.A.; AI-Deyab, S.S.; He, C.L.; Mo, X. Dexamethasone loaded core-shell SF/PEO nanofibers via green electrospinning reduced endothelial cells inflammatory damage. Colloids Surf. B Biointerfaces 2015, 126, 561–568. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Qiao, X.; Sun, K.; Chen, X. Mechanical and viscoelastic properties of novel silk fibroin fiber/poly(ε-caprolactone) biocomposites. J. Appl. Polym. Sci. 2008, 110, 134–139. [Google Scholar] [CrossRef]

- Buasri, A.; Chaiyut, N.; Loryuenyong, V.; Jaritkaun, N. Mechanical and thermal properties of silk fiber reinforced poly(lactic acid) biocomposites. Optoelectron. Adv. Mater.-Rapid Commun. 2013, 7, 938–942. [Google Scholar]

- Zhang, J.; Mo, X. Current research on electrospinning of silk fibroin and its blends with natural and synthetic biodegradable polymers. Front. Mater. Sci. 2013, 7, 129–142. [Google Scholar] [CrossRef]

- Zhang, K.; Qing, Y.; Yan, Z. Degradation of electrospun SF/P (LLA-CL) blended nanofibrous scaffolds in vitro. Polym. Degrad. Stab. 2011, 96, 2266–2275. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, H.; Huang, C.; Su, Y. Fabrication of silk fibroin blended P (LLA-CL) nanofibrous scaffolds for tissue engineering. J. Biomed. Mater. Res. Part A 2010, 93, 984–993. [Google Scholar] [CrossRef]

- Gunn, J.; Zhang, M. Polyblend nanofibers for biomedical applications: Perspectives and challenges. Trends Biotechnol. 2010, 28, 189–197. [Google Scholar] [CrossRef]

- Yin, Y.; Xiong, J. Effect of the Distribution of Fiber Orientation on the Mechanical Properties of Silk Fibroin/Polycaprolactone Nanofiber Mats. J. Eng. Fibers Fabr. 2016, 12, 17–28. [Google Scholar] [CrossRef]

- Yuan, H.; Shi, H.; Qiu, X.; Chen, Y. Mechanical property and biological performance of electrospun silk fibroin-polycaprolactone scaffolds with aligned fibers. J. Biomater. Sci. Polym. Ed. 2016, 27, 1–24. [Google Scholar] [CrossRef]

- Lv, J.; Chen, L.; Zhu, Y.; Hou, L.; Liu, Y. Promoting epithelium regeneration for esophageal tissue engineering through basement membrane reconstitution. ACS Appl. Mater. Interfaces 2014, 6, 4954–4964. [Google Scholar] [CrossRef]

- Sridhar, S.; Venugopal, J.R.; Sridhar, R.; Ramakrishna, S. Cardiogenic differentiation of mesenchymal stem cells with gold nanoparticle loaded functionalized nanofibers. Colloids Surf. B-Biointerfaces 2015, 134, 346–354. [Google Scholar] [CrossRef]

- Kim, B.S.; Park, K.E.; Kim, M.H.; You, H.K.; Lee, J.; Park, W.H. Effect of nanofiber content on bone regeneration of silk fibroin/poly(ε-caprolactone) nano/microfibrous composite scaffolds. Int. J. Nanomed. 2015, 10, 485–502. [Google Scholar]

- Wolfe, P.S.; Madurantakam, P.; Garg, K.; Sell, S.A.; Beckman, M.J.; Bowlin, G.L. Evaluation of thrombogenic potential of electrospun bioresorbable vascular graft materials: Acute monocyte tissue factor expression. J. Biomed. Mater. Res. Part A 2010, 92, 1321–1328. [Google Scholar] [CrossRef]

- Ko, F.; Gogotsi, Y.; Ali, A.A.; Naguib, N. Electrospinning of Continuous Carbon Nanotube-Filled Nanofiber Yarns. Adv. Mater. 2003, 15, 1161–1165. [Google Scholar] [CrossRef]

- Tan, E.P.S.; Goh, C.N.; Sow, C.H.; Lim, C.T. Tensile test of a single nanofiber using an atomic force microscope tip. Appl. Phys. Lett. 2005, 86, 073115. [Google Scholar] [CrossRef]

- Tan, E.P.S.; Ng, S.Y.; Lim, C.T. Tensile testing of a single ultrafine polymeric fiber. Biomaterials 2005, 26, 1453–1456. [Google Scholar] [CrossRef]

- Lin, Y.; Clark, D.M.; Reneker, D.H. Mechanical properties of polymer nanofibers revealed by interaction with streams of air. Polymer 2012, 53, 782–790. [Google Scholar] [CrossRef]

- Lee, K.H.; Kim, H.Y.; Khil, M.S.; Ra, Y.M.; Lee, D.R. Characterization of nano-structured poly(ε-caprolactone) nonwoven mats via electrospinning. Polymer 2003, 44, 1287–1294. [Google Scholar] [CrossRef]

- Huang, Z.M.; Zhang, Y.Z.; Ramakrishna, S.; Lim, C.T. Electrospinning and mechanical characterization of gelatin nanofibers. Polymer 2004, 45, 5361–5368. [Google Scholar] [CrossRef]

- Ayutsede, J.; Gandhi, M.; Sukigara, S.; Micklus, M.; Chen, H.E.; Ko, F. Regeneration of Bombyx mori silk by electrospinning. Part 3: Characterization of electrospun nonwoven mat. Polymer 2005, 46, 1625–1634. [Google Scholar] [CrossRef]

- Qiang, J.; Wan, Y.; Yang, L.; Cao, Q. Effect of Ultrasonic Vibration on Structure and Performance of Electrospun PAN Fibrous Membrane. J. Nano Res. 2013, 23, 96–103. [Google Scholar] [CrossRef]

- Cao, Q.; Wan, Y.; Qiang, J.; Yang, R.; Fu, J.; Wang, H.; Gao, W.; Ko, F. Effect of sonication treatment on electrospinnability of high-viscosity PAN solution and mechanical performance of microfiber mat. Iran. Polym. J. 2014, 23, 1–7. [Google Scholar] [CrossRef]

- Petterson, D.R. Mechanics of Nonwoven Fabrics. Ind. Eng. Chem. 1959, 51, 902–903. [Google Scholar] [CrossRef][Green Version]

- Hearle, J.W.S.; Stevenson, P.J. Studies in Nonwoven Fabrics Part IV: Prediction of Tensile Properties1. Text. Res. J. 1964, 34, 181–191. [Google Scholar] [CrossRef]

- Yin, Y.; Pu, D.; Xiong, J. Analysis of the Comprehensive Tensile Relationship in Electrospun Silk Fibroin/Polycaprolactone Nanofiber Membranes. Membranes 2017, 7, 67. [Google Scholar] [CrossRef]

- Wan, L.Y.; Wang, H.; Gao, W.; Ko, F. An analysis of the tensile properties of nanofiber mats. Polymer 2015, 73, 62–67. [Google Scholar] [CrossRef]

- Pai, C.L.; Boyce, M.C.; Rutledge, G.C. On the importance of fiber curvature to the elastic moduli of electrospun nonwoven fiber meshes. Polymer 2011, 52, 6126–6133. [Google Scholar] [CrossRef]

- Rizvi, M.S.; Pal, A. Statistical model for the mechanical behavior of the tissue engineering non-woven fibrous matrices under large deformation. J. Mech. Behav. Biomed. Mater. 2014, 37, 235–250. [Google Scholar] [CrossRef]

- Ban, E.; Barocas, V.H.; Shephard, M.S.; Picu, C.R. Effect of fiber crimp on the elasticity of random fiber networks with and without embedding matrices. J. Appl. Mech. 2016, 83, 0410081–0410087. [Google Scholar] [CrossRef]

- Silberstein, M.N.; Pai, C.L.; Rutledge, G.C.; Boyce, M.C. Elastic-plastic behavior of non-woven fibrous mats. J. Mech. Phys. Solids 2012, 60, 295–318. [Google Scholar] [CrossRef]

- Broedersz, C.P.; Mao, X.; Lubensky, T.C.; MacKintosh, F.C. Criticality and isostaticity in fibre networks. Nat. Phys. 2011, 7, 983–988. [Google Scholar] [CrossRef]

- Petterson, D.R. On the Mechanics of Non-Woven Fabrics; Massachusetts Institute of Technology: Cambridge, MA, USA, 1959. [Google Scholar]

| Type | aa | ba | ca | R2 b |

|---|---|---|---|---|

| SF/PCL = 100/0 | 27.207 | −3.297 | 1.006 × 10−4 | 0.984 |

| SF/PCL = 75/25 | 22.669 | −2.810 | 2.663 × 10−4 | 0.976 |

| SF/PCL = 50/50 | 26.576 | −4.313 | 1.290 × 10−3 | 0.975 |

| SF/PCL = 25/75 | 12.569 | −1.802 | 5.822 × 10−4 | 0.949 |

| SF/PCL = 0/100 | 17.130 | −3.219 | 8.120 × 10−3 | 0.975 |

| Type | Arithmetic Average Diameter (nm) | Root-Mean-Square Diameter (nm) | Harmonic Average of Diameter (nm) |

|---|---|---|---|

| SF/PCL = 100/0 | 85.87 | 91.29 | 79.49 |

| SF/PCL = 75/25 | 70.52 | 76.12 | 62.96 |

| SF/PCL = 50/50 | 63.76 | 71.91 | 57.11 |

| SF/PCL = 25/75 | 76.56 | 80.41 | 70.54 |

| SF/PCL = 0/100 | 99.37 | 110.18 | 88.62 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Y.; Zhao, X.; Xiong, J. Modeling Analysis of Silk Fibroin/Poly(ε-caprolactone) Nanofibrous Membrane under Uniaxial Tension. Nanomaterials 2019, 9, 1149. https://doi.org/10.3390/nano9081149

Yin Y, Zhao X, Xiong J. Modeling Analysis of Silk Fibroin/Poly(ε-caprolactone) Nanofibrous Membrane under Uniaxial Tension. Nanomaterials. 2019; 9(8):1149. https://doi.org/10.3390/nano9081149

Chicago/Turabian StyleYin, Yunlei, Xinfei Zhao, and Jie Xiong. 2019. "Modeling Analysis of Silk Fibroin/Poly(ε-caprolactone) Nanofibrous Membrane under Uniaxial Tension" Nanomaterials 9, no. 8: 1149. https://doi.org/10.3390/nano9081149

APA StyleYin, Y., Zhao, X., & Xiong, J. (2019). Modeling Analysis of Silk Fibroin/Poly(ε-caprolactone) Nanofibrous Membrane under Uniaxial Tension. Nanomaterials, 9(8), 1149. https://doi.org/10.3390/nano9081149