Application of a Molybdenum and Tungsten Disulfide Coating to Improve Tribological Properties of Orthodontic Archwires

Abstract

:1. Introduction

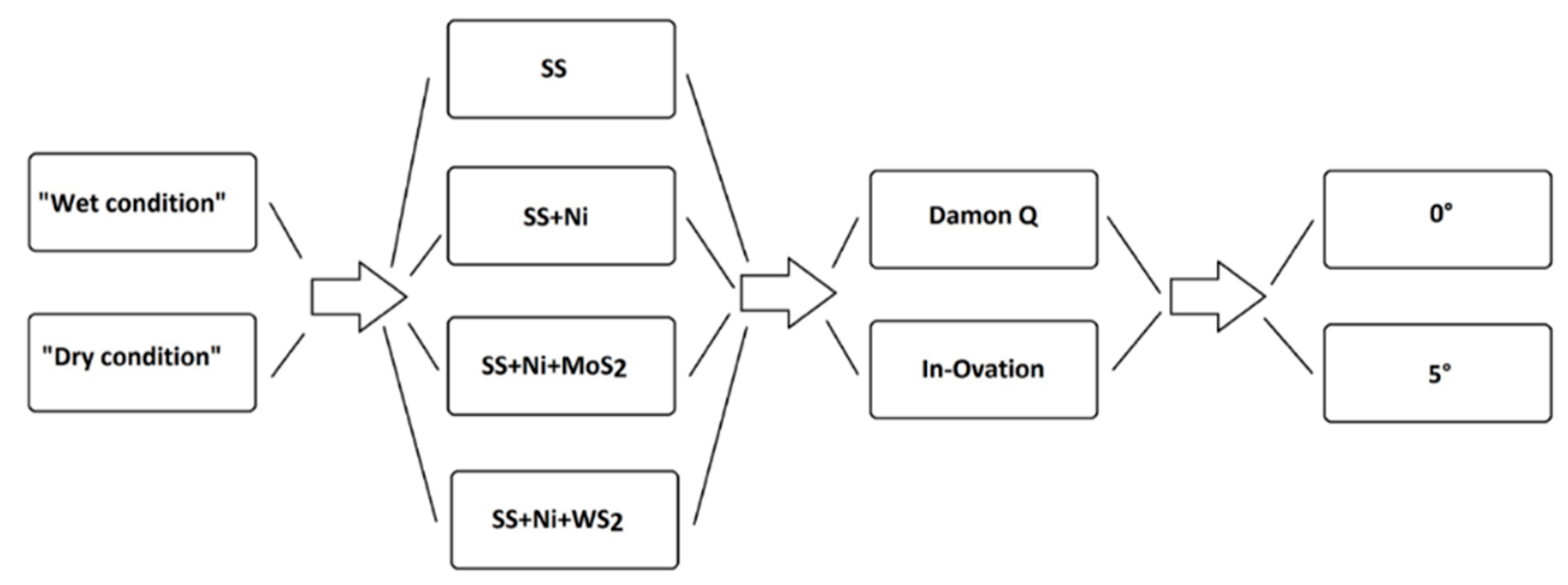

2. Materials and Methods

2.1. Nanoparticles

2.2. Bracket

- 40 In-Ovation (Dentsply Sirona, New York, US) upper right central incisors bracket (tq 12°, tip 5°).

- 40 Damon Q (Ormco, 200 S. Kraemer Blvd., Building E Brea, California 92821) upper right central incisors bracket (tq 15°, tip 5°).

2.3. Artificial Saliva

2.4. Coatings’ Deposition on Orthodontic Wires

- Mechanical abrasion with abrasive paper of silicon carbide (500 grains/unit area), to clean orthodontic wires.

- Solvent degreasing with acetone in an ultrasonic cleaner for 2 min, to remove organic residues and dust of abrasive paper.

- Rinsing with deionized water and drying.

- Positioning of orthodontic wires on a special frame, with the aim of being able to handle more easily without leaving traces on the substrates to be coated.

- Immersion of the frame with the wires in sulfuric acid at 0.5 M with cathodic polarization to −1 V.

- Rinsing with deionized water.

- GROUP 1: control group; wires of this group were not applied any coating.

- GROUP 2: wires of this group were coated with a Ni film by electrochemical co-deposition.

- GROUP 3: wires of this group were coated with a Ni + MoS2 film by electrochemical co-deposition.

- GROUP 4: wires of this group were coated with a Ni + WS2 film by electrochemical co-deposition.

- GROUP 2: wires were inserted in a Watts bath, with a direct current of 0.04 A and starting the process of electrochemical co-deposition for 25 min.

- GROUP 3: wires were inserted in a Watts bath in which 2 g/L of MoS2 NP was dispersed; since MoS2 NP are hardly wettable, a cationic surfactant (CTAB cetyl trimethyl aminobromide) was added to the bath (0.4 gr/L of CTAB). To minimize agglomeration of MoS2 NP, the bath was maintained in constant agitation with the use of a mechanical stirrer (activated 12 h before the deposition and during the entire deposition step) and ultrasound treatment. Electrochemical co-deposition was processed for 25 min with a direct current of 0.04 A.

- GROUP 4: wires were inserted in a Watts bath in which 2 g/L of WS2 NP was dispersed; since WS2 NP are hardly wettable, a cationic surfactant (CTAB cetyl trimethyl aminobromide) was added to the bath (0.2 gr of CTAB). To minimize agglomeration of WS2 NP, the bath was maintained in constant agitation with the use of a mechanical stirrer (activated 12 h before the deposition and during the entire deposition step) and ultrasound treatment. Electrochemical co-deposition was processed for 25 min with a direct current of 0.04 A.

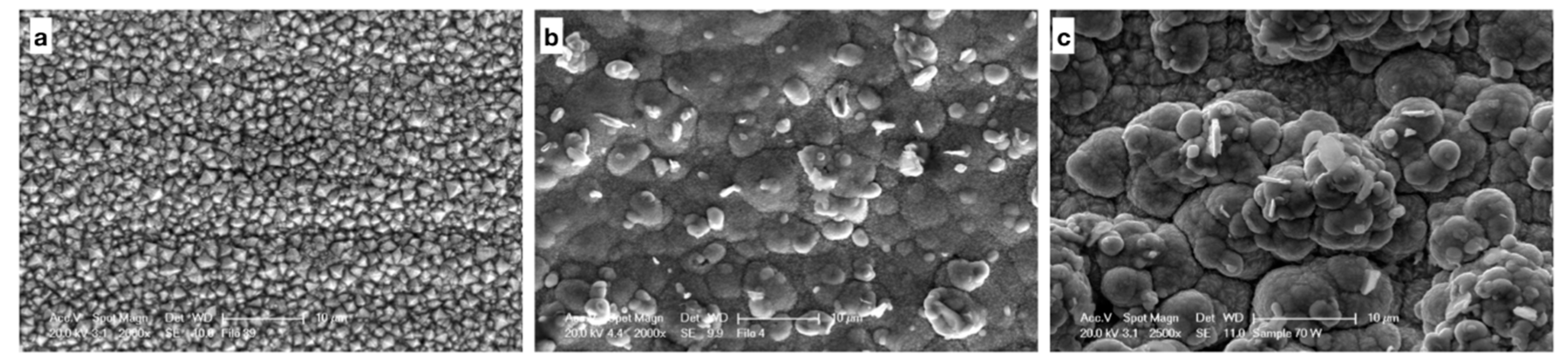

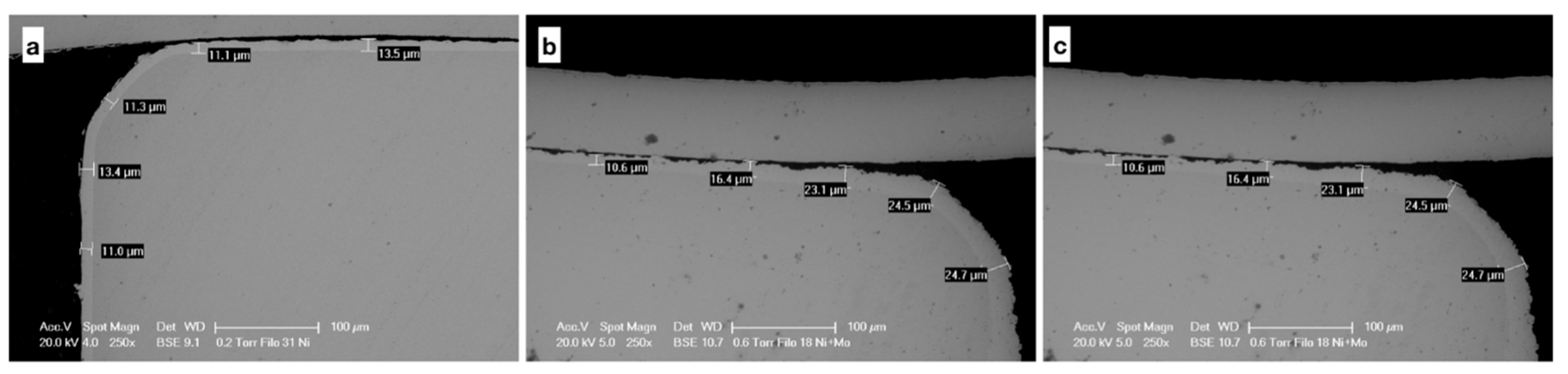

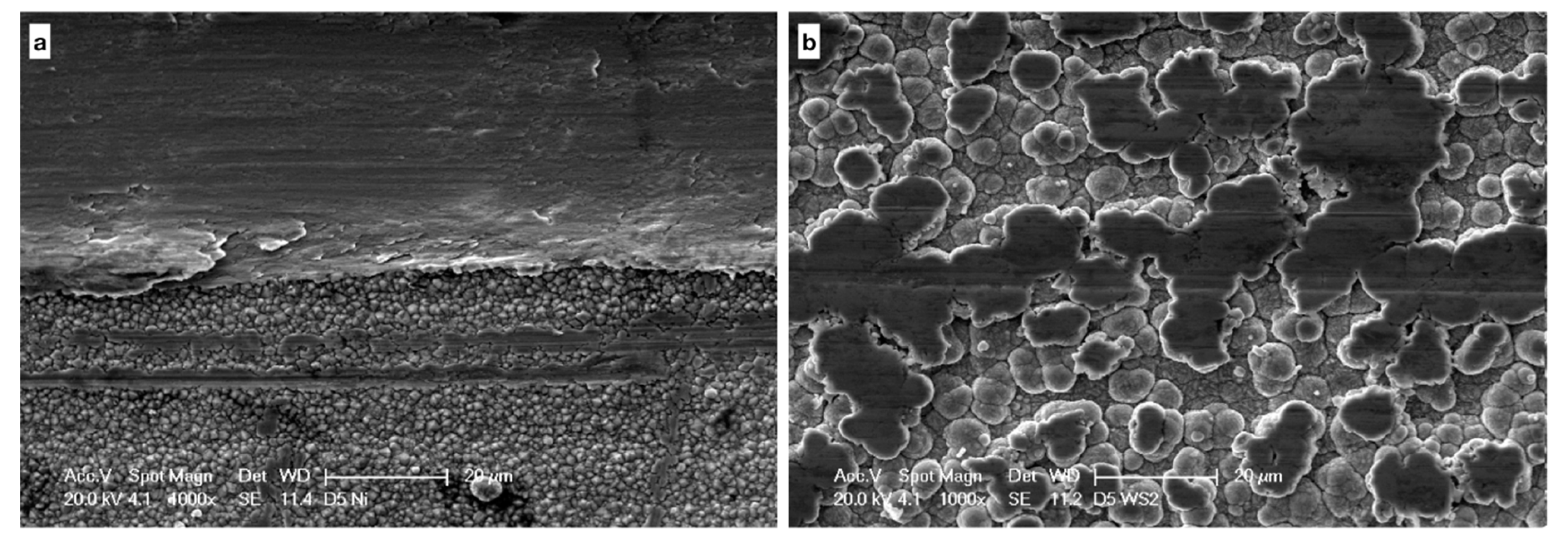

2.5. Analysis of Coated Orthodontic Wires

2.6. Friction Measurements of the Wires

2.7. Data Analysis

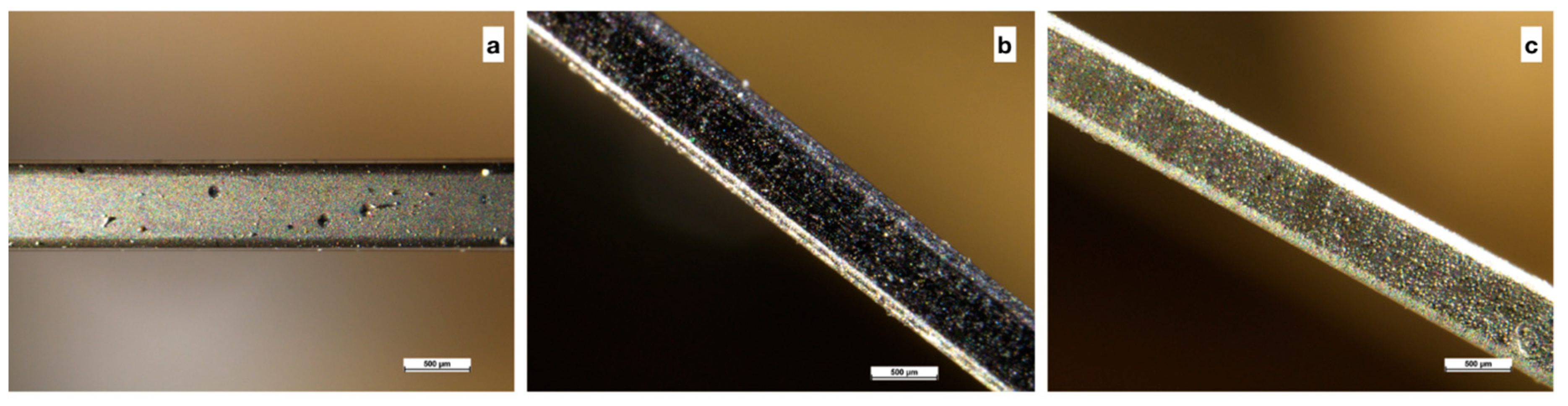

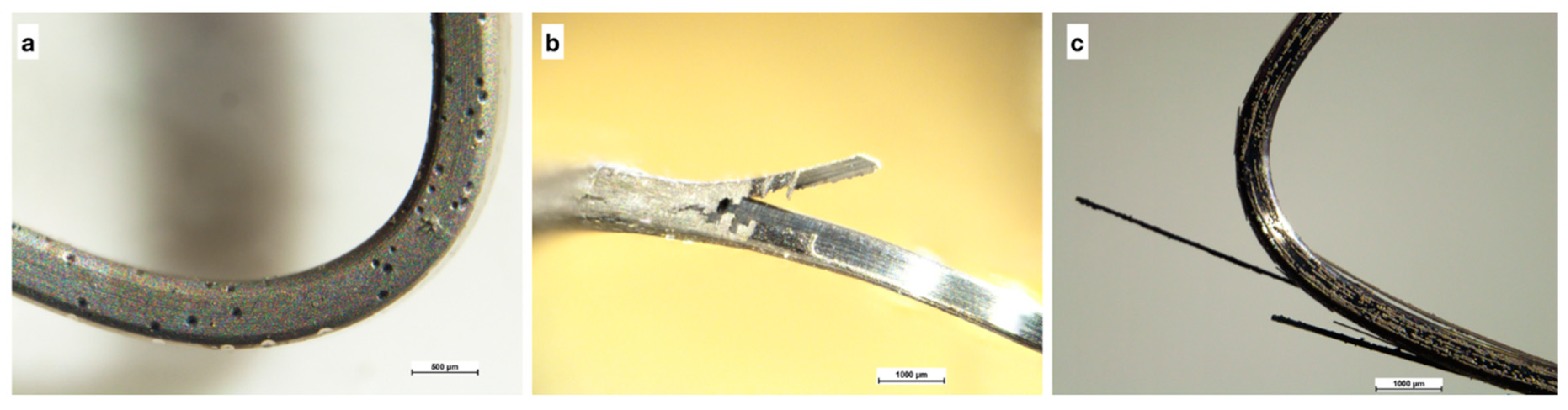

2.8. Analysis of Coated and Uncoated Orthodontic Wires after Friction Test

3. Results

3.1. Analysis of Coated Orthodontic Wires

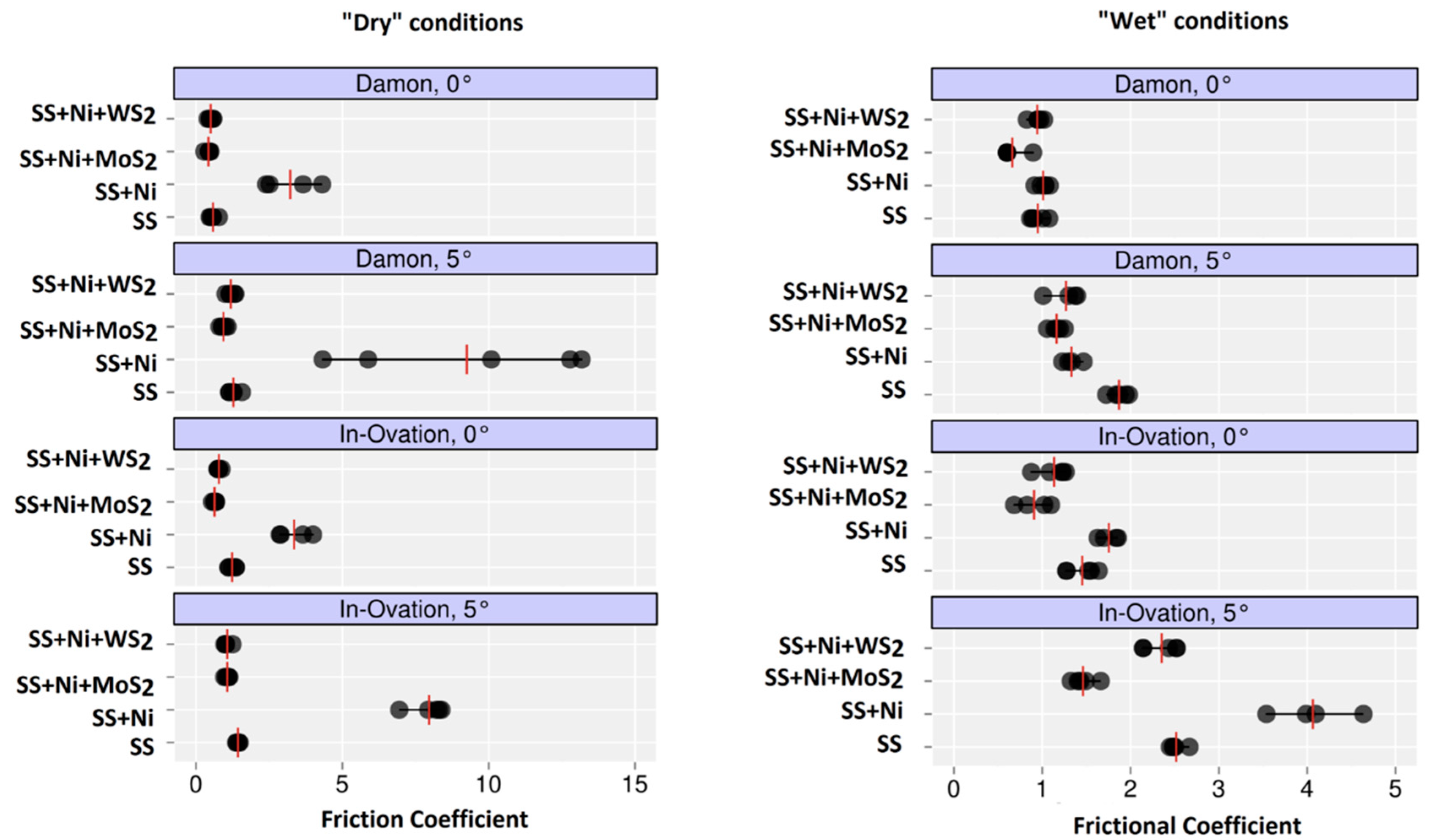

3.2. Friction Measurements of the Wires

3.2.1. “Dry” Conditions

- No significant differences were found between Ni + MoS2 and Ni + WS2 films even if, from a descriptive point of view, wires coated with Ni + MoS2 show lower friction values;

- Wires coated with Ni + MoS2 and Ni + WS2 films have friction values significantly lower than wires coated with Ni;

- If paired to the In-Ovation bracket, SS uncoated wires differ from all others, both from wires coated with Ni (whose friction coefficient is greater) and wires coated with Ni + MoS2 and Ni + WS2 (whose friction coefficients are lower);

- If paired to the Damon Q bracket, SS uncoated wires have lower friction coefficient only for wires coated with Ni, while they do not significantly differ from wires coated with Ni + MoS2 and Ni + WS2.

3.2.2. “Wet” Conditions

- Comparing Ni + MoS2 and Ni + WS2, from a descriptive point of view, wires coated with Ni + MoS2 always show lower friction values. Tukey’s test results state that Ni + MoS2 presents a lower friction coefficient for both Damon 0° and In-Ovation 5°.

- Wires coated with Ni + MoS2 and Ni + WS2 films have friction values significantly lower than wires coated with Ni except for Damon 5°.

- If paired to the In-Ovation bracket, SS uncoated wires differ from wires coated with Ni + MoS2 (whose friction coefficient is lower).

- If paired to the Damon Q bracket, SS uncoated significantly differ from wires coated with Ni + MoS2 and Ni + WS2 (whose friction coefficients are lower) only for angulation of 5°.

3.3. Analysis of Coated and Uncoated Orthodontic Wires after Friction Test

4. Discussion

- Films’ adhesion was homogeneous, with few uncoated areas.

- The coatings’ thickness was contained within values that would allow the insertion of the wires into the slot and the sliding along the bracket.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kusy, R.P.; Whitley, J.Q. Friction between different wire-bracket configurations and materials. Semin. Orthod. 1997, 3, 166–177. [Google Scholar] [CrossRef]

- Reznikov, N.; Har-Zion, G.; Barkana, I.; Abed, Y.; Redlich, M. Influence of friction resistance on expression of superelastic properties of initial NiTi wires in “reduced friction” and conventional bracket systems. J. Dent. Biomech. 2010, 2010, 613142. [Google Scholar] [CrossRef] [PubMed]

- Taniguchi, N. On the basic concept of nanotechnology. In Proceedings of the International Conference Production Engineering; Japan Society of Precision Engineering: Tokyo, Japan, 1974; pp. 18–23, Part II. [Google Scholar]

- Kroto, H. C60 and carbon: A postbuckminsterfullerene perspective. Int. J. Mass Spectrom. 2000, 200, 253–260. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Tenne, R.; Margulis, L.; Genut, M.; Hodes, G. Polyhedral and cylindrical structures of tungsten disulphide. Nature 1992, 360, 444–446. [Google Scholar] [CrossRef]

- Rapoport, L.; Bilik, Y.; Feldman, Y.; Homyonfer, M. Hollow nanoparticles of WS2 as potential solid-state lubricants. Nature 1997, 387, 791–793. [Google Scholar] [CrossRef]

- Feldman, Y.; Wasserman, E.; Srolovitz, D.J.; Tenne, R. High-rate, gas-phase growth of MoS2 nested inorganic fullerenes and nanotubes. Science 1995, 267, 222–225. [Google Scholar] [CrossRef]

- Katz, A.; Redlich, M.; Rapoport, L.; Wagner, H.D.; Tenne, R. Self-lubricating coatings containing fullerene-like WS2 nanoparticles for orthodontic wires and other possible medical applications. Tribol. Lett. 2006, 21, 135–139. [Google Scholar] [CrossRef]

- Redlich, M.; Gorodnev, A.; Feldman, Y.; Kaplan-Ashiri, I.; Tenne, R.; Fleischer, N.; Feuerstein, N. Friction reduction and wear resistance of electro-co-deposited inorganic fullerene-like WS2 coating for improved stainless steel orthodontic wires. J. Mater. Res. 2008, 23, 2909–2915. [Google Scholar] [CrossRef]

- Redlich, M.; Katz, A.; Rapoport, L.; Wagner, H.D.; Feldman, Y.; Tenne, R. Improved orthodontic stainless steel wires coated with inorganic fullerene-like nanoparticles of WS2 impregnated in electroless nickel-phosphorous film. Dent. Mater. 2008, 24, 1640–1646. [Google Scholar] [CrossRef] [PubMed]

- Samorodnitzky, G.R.; Redlich, M.; Rapoport, L.; Feldman, Y.; Tenne, R. Inorganic fullerene-like tungsten disulfide nanocoating for friction reduction of nickel—Titanium alloys. Nanomedicine 2009, 4, 943–950. [Google Scholar] [CrossRef] [PubMed]

| MoS2 | WS2 | |

|---|---|---|

| Purity | 99.90% | 99.90% |

| Color | Black | Black |

| Morphology | Spherical | Spherical |

| APS | 80–100 nm | 40–80 nm |

| Density | 5.06 g/cm3 | ND |

| Melting Point | 1185 °C | ND |

| Synthesis | MOCVD | MOCVD |

| SS | SS + Ni | SS + Ni + MoS2 | SS + Ni + WS2 | |

|---|---|---|---|---|

| Damon Q/0° | 0.58(0.12) | 3.22(0.92) | 0.42(0.08) | 0.50(0.08) |

| Damon Q/5° | 1.27(0.18) | 9.25(4.01) | 0.94(0.11) | 1.19(0.14) |

| In-Ovation/0° | 1.24(0.12) | 3.35(0.57) | 0.64(0.06) | 0.79(0.06) |

| In-Ovation/5° | 1.43(0.06) | 7.96(0.59) | 1.06(0.07) | 1.06(0.13) |

| SS | SS + Ni | SS + Ni + MoS2 | SS + Ni + WS2 | |

|---|---|---|---|---|

| Damon Q/0° | 0.95(0.09) | 1.01(0.07) | 0.66(0.13) | 0.94(0.07) |

| Damon Q/5° | 1.87(0.10) | 1.33(0.10) | 1.16(0.07) | 1.27(0.18) |

| In-Ovation/0° | 1.45(0.17) | 1.75(0.11) | 0.91(0.19) | 1.13(0.16) |

| In-Ovation/5° | 2.52(0.09) | 4.06(0.45) | 1.46(0.13) | 2.35(0.19) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gracco, A.; Dandrea, M.; Deflorian, F.; Zanella, C.; De Stefani, A.; Bruno, G.; Stellini, E. Application of a Molybdenum and Tungsten Disulfide Coating to Improve Tribological Properties of Orthodontic Archwires. Nanomaterials 2019, 9, 753. https://doi.org/10.3390/nano9050753

Gracco A, Dandrea M, Deflorian F, Zanella C, De Stefani A, Bruno G, Stellini E. Application of a Molybdenum and Tungsten Disulfide Coating to Improve Tribological Properties of Orthodontic Archwires. Nanomaterials. 2019; 9(5):753. https://doi.org/10.3390/nano9050753

Chicago/Turabian StyleGracco, Antonio, Martina Dandrea, Flavio Deflorian, Caterina Zanella, Alberto De Stefani, Giovanni Bruno, and Edoardo Stellini. 2019. "Application of a Molybdenum and Tungsten Disulfide Coating to Improve Tribological Properties of Orthodontic Archwires" Nanomaterials 9, no. 5: 753. https://doi.org/10.3390/nano9050753

APA StyleGracco, A., Dandrea, M., Deflorian, F., Zanella, C., De Stefani, A., Bruno, G., & Stellini, E. (2019). Application of a Molybdenum and Tungsten Disulfide Coating to Improve Tribological Properties of Orthodontic Archwires. Nanomaterials, 9(5), 753. https://doi.org/10.3390/nano9050753