Effect of Thickness of Molybdenum Nano-Interlayer on Cohesion between Molybdenum/Titanium Multilayer Film and Silicon Substrate

Abstract

1. Introduction

2. Experimental Details

2.1. Film Growth and Sample Preparation

2.2. Sample Characterizations

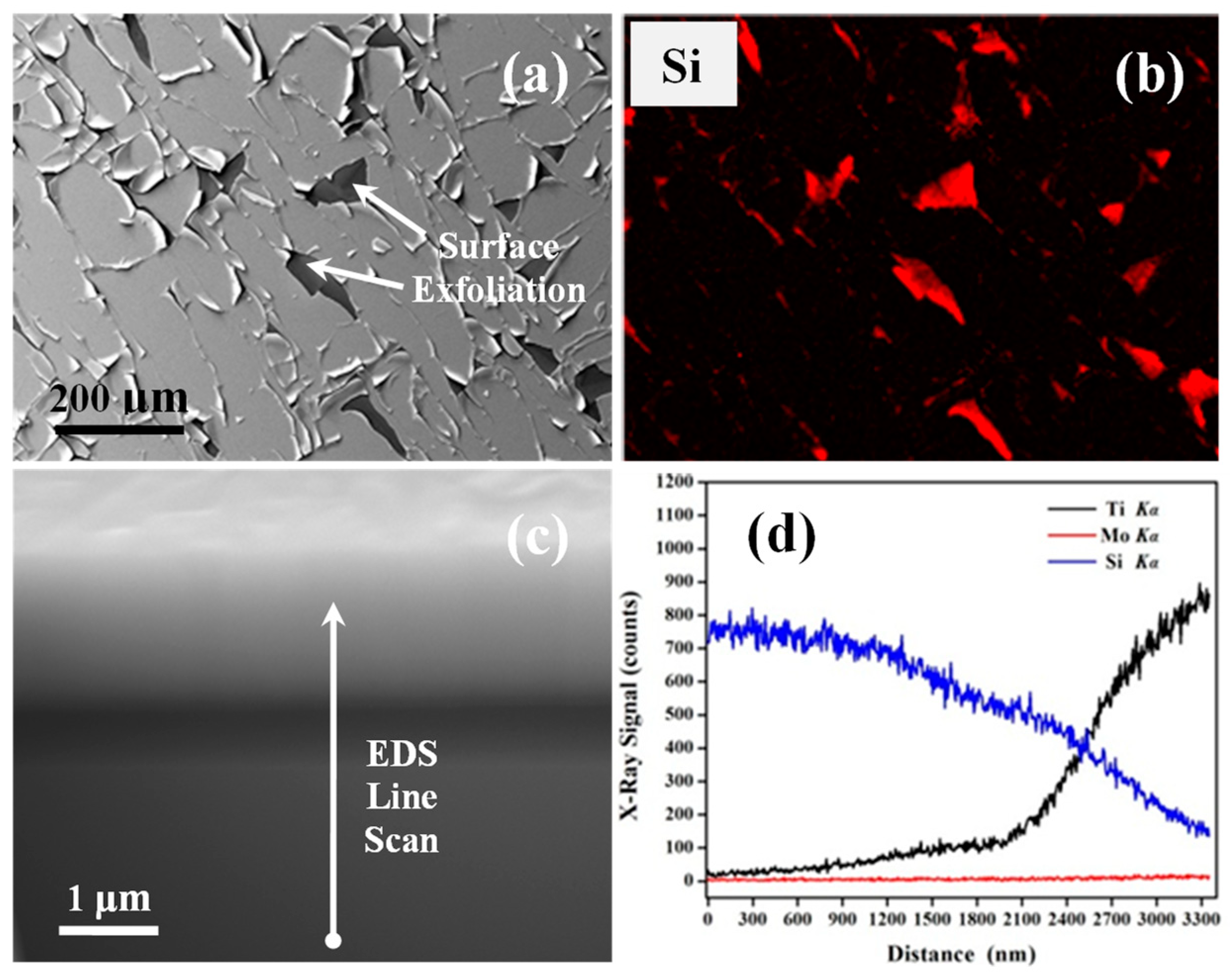

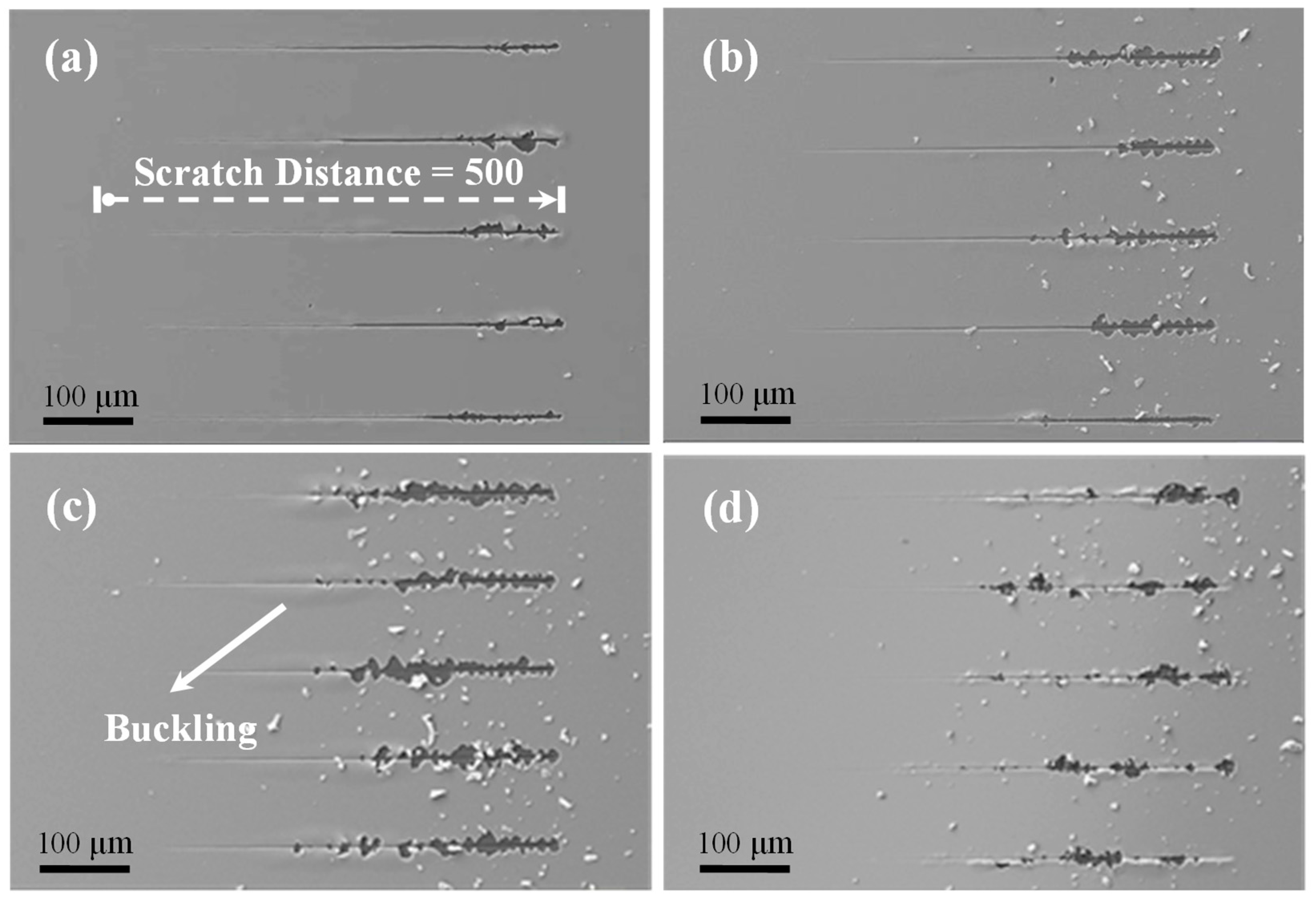

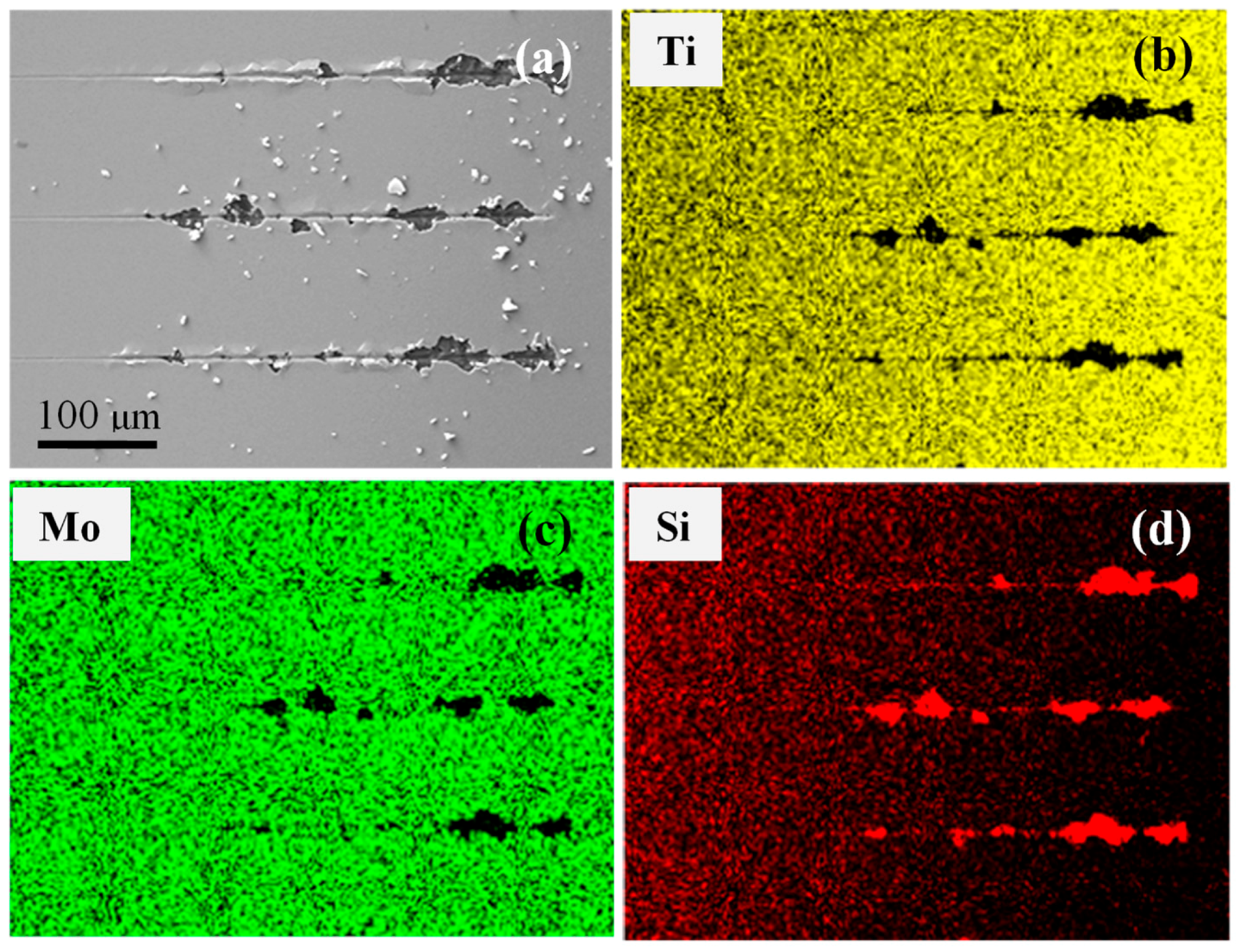

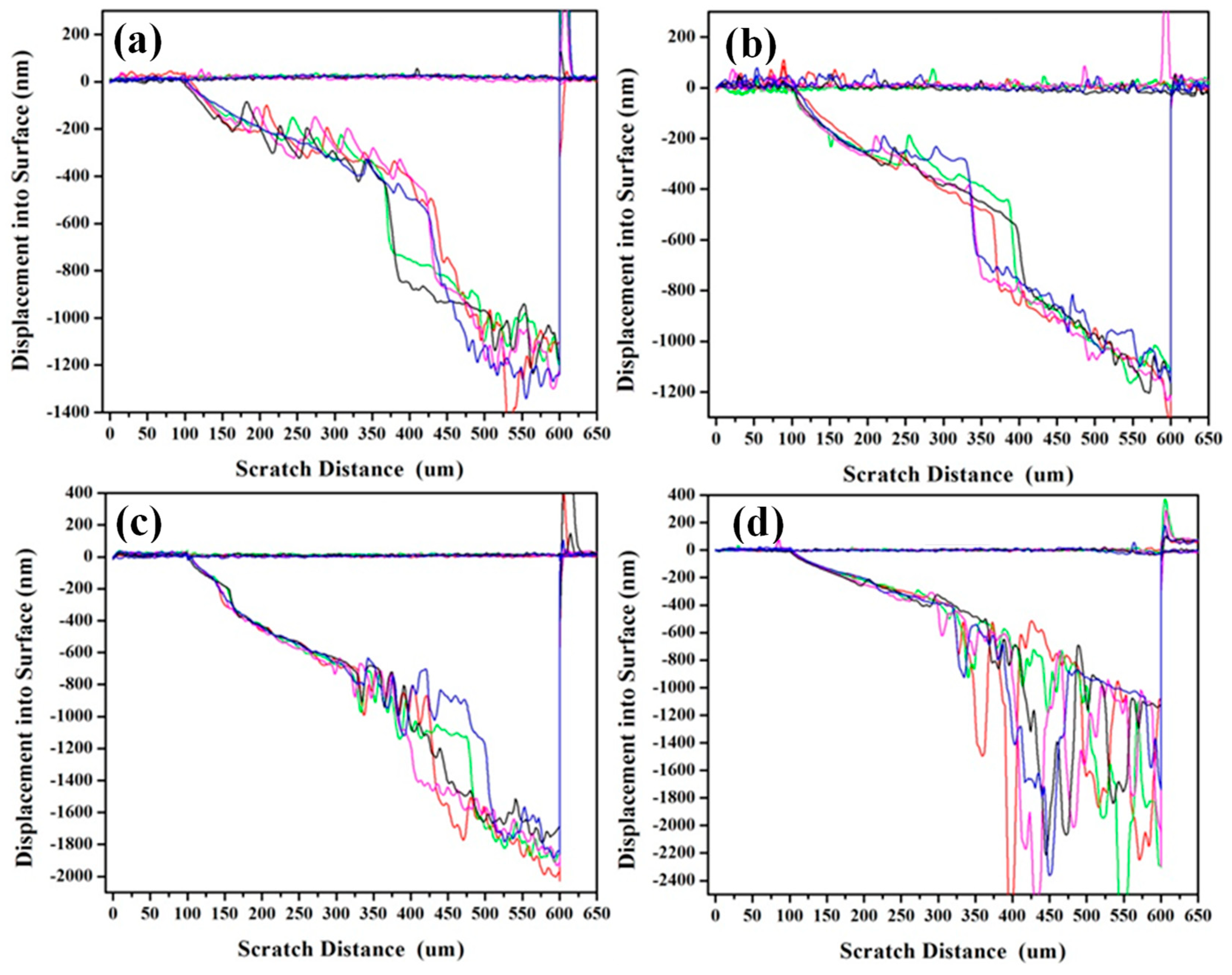

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kalisvaart, W.P.; Niessen, R.A.H.; Notten, P.H.L. Electrochemical hydrogen storage in MgSc alloys: A comparative study between thin films and bulk materials. J. Alloys Compd. 2006, 417, 280–291. [Google Scholar] [CrossRef]

- Pugh, R.D.; Sabochick, M.J.; Luke, T.E. A comparison of ferroelectric aging in bulk and thin-film materials. J. Appl. Phys. 1992, 72, 1049–1055. [Google Scholar] [CrossRef]

- Yoder, K.B.; Stone, D.S.; Lin, J.C.; Hoffmann, R.A. Indentation Creep of Molybdenum: Comparison Between Thin Film and Bulk Material. MRS Proc. 2011, 356, 651. [Google Scholar] [CrossRef]

- Zhou, X.S.; Chen, G.J.; Peng, S.M.; Long, X.G.; Liang, J.H.; Fu, Y.Q. Thermal desorption of tritium and helium in aged titanium tritide films. Int. J. Hydrogen Energy 2014, 39, 11006–11015. [Google Scholar] [CrossRef]

- Parish, C.M.; Snow, C.S.; Kammler, D.R.; Brewer, L.N. Processing effects on microstructure in Er and ErD2 thin-films. J. Nucl. Mater. 2010, 403, 191–197. [Google Scholar] [CrossRef]

- Detor, A.J.; Hodge, A.M.; Chason, E.; Wang, Y.; Xu, H.; Conyers, M.; Nikroo, A.; Hamza, A. Stress and microstructure evolution in thick sputtered films. Acta Mater. 2009, 57, 2055–2065. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Sharshir, S.W.; Ahmed Ali, M.K.; Shaibo, J.; Edreis, E.M.A.; Abdelhamid, T.; Du, C.; Haiou, Z. Thin film technology for solar steam generation: A new dawn. Sol. Energy 2019, 177, 561–575. [Google Scholar] [CrossRef]

- Tian, K.; Baskaran, K.; Tiwari, A. Growth of two-dimensional WS2 thin films by pulsed laser deposition technique. Thin Solid Films 2018, 668, 69–73. [Google Scholar] [CrossRef]

- Venkata Subbaiah, Y.P.; Saji, K.J.; Tiwari, A. Atomically Thin MoS2: A Versatile Nongraphene 2D Material. Adv. Funct. Mater. 2016, 26, 2046–2069. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Mishchenko, A.; Carvalho, A.; Castro Neto, A.H. 2D materials and van der Waals heterostructures. Science 2016, 353, 9439. [Google Scholar] [CrossRef]

- Parish, C.M.; Snow, C.S.; Brewer, L.N. The manifestation of oxygen contamination in ErD2 thin films. J. Mater. Res. 2009, 24, 1868–1879. [Google Scholar] [CrossRef]

- Rodriguez, M.A.; Browning, J.F.; Frazer, C.S.; Snow, C.S.; Tissot, R.G.; Boespflug, E.P. Unit cell expansion in ErT2 films. Powder Diffr. 2007, 22, 118–121. [Google Scholar] [CrossRef][Green Version]

- Shen, H.H.; Peng, S.M.; Long, X.G.; Zhou, X.S.; Liu, J.H.; Sun, K.; Yang, L.; Sun, Q.Q.; Zu, X.T. Influence of growth parameters on the microstructures of erbium films deposited on Si(111) substrates. Vacuum 2012, 86, 2075–2081. [Google Scholar] [CrossRef]

- Zhu, H.; Dong, Z.; Niu, X.; Li, J.; Shen, K.; Mai, Y.; Wan, M. DC and RF sputtered molybdenum electrodes for Cu(In,Ga)Se2 thin film solar cells. Appl. Surf. Sci. 2019, 465, 48–55. [Google Scholar] [CrossRef]

- Liang, G.-X.; Luo, Y.-D.; Hu, J.-G.; Chen, X.-Y.; Zeng, Y.; Su, Z.-H.; Luo, J.-T.; Fan, P. Influence of annealed ITO on PLD CZTS thin film solar cell. Surf. Coat. Technol. 2019, 358, 762–764. [Google Scholar] [CrossRef]

- Beltiukov, A.N.; Stashkova, E.V.; Boytsova, O.V. Anodic oxidation of Al/Ge/Al multilayer films. Appl. Surf. Sci. 2018, 459, 583–587. [Google Scholar] [CrossRef]

- Çölmekçi, S.; Karpuz, A.; Köçkar, H. Total film thickness controlled structural and related magnetic properties of sputtered Ni/Cu multilayer thin films. J. Magn. Magn. Mater. 2019, 478, 48–54. [Google Scholar] [CrossRef]

- Li, N.; Fu, E.G.; Wang, H.; Carter, J.J.; Shao, L.; Maloy, S.A.; Misra, A.; Zhang, X. He ion irradiation damage in Fe/W nanolayer films. J. Nucl. Mater. 2009, 389, 233–238. [Google Scholar] [CrossRef]

- Singh, J.P.; Lim, W.C.; Gautam, S.; Asokan, K.; Chae, K.H. Swift heavy ion irradiation induced effects in Fe/MgO/Fe/Co multilayer. Mater. Des. 2016, 101, 72–79. [Google Scholar] [CrossRef]

- Callisti, M.; Karlik, M.; Polcar, T. Competing mechanisms on the strength of ion-irradiated Zr/Nb nanoscale multilayers: Interface strength versus radiation hardening. Scr. Mater. 2018, 152, 31–35. [Google Scholar] [CrossRef]

- Du, S.; Zhang, K.; Wen, M.; Ren, P.; Meng, Q.; Hu, C.; Zheng, W. Tribochemistry dependent tribological behavior of superhard TaC/SiC multilayer films. Surf. Coat. Technol. 2018, 337, 492–500. [Google Scholar] [CrossRef]

- Zhou, Q.; Ren, Y.; Du, Y.; Hua, D.P.; Han, W.C.; Xia, Q.S. Adhesion energy and related plastic deformation mechanism of Cu/Ru nanostructured multilayer film. J. Alloys Compd. 2019, 772, 823–827. [Google Scholar] [CrossRef]

- Postolnyi, B.O.; Beresnev, V.M.; Abadias, G.; Bondar, O.V.; Rebouta, L.; Araujo, J.P.; Pogrebnjak, A.D. Multilayer design of CrN/MoN protective coatings for enhanced hardness and toughness. J. Alloys Compd. 2017, 725, 1188–1198. [Google Scholar] [CrossRef]

- Pshyk, A.; Coy, E.; Kempiński, M.; Iatsunskyi, I.; Załęski, K.; Pogrebnjak, A.; Jurga, S. Microstructure, phase composition and mechanical properties of novel nanocomposite (TiAlSiY)N and nano-scale (TiAlSiY)N/MoN multifunctional heterostructures. Surf. Coat. Technol. 2018, 350, 376–390. [Google Scholar] [CrossRef]

- Mellali, M.; Fauchais, P.; Grimaud, A. Influence of substrate roughness and temperature on the adhesion/cohesion of alumina coatings. Surf. Coat. Technol. 1996, 81, 275–286. [Google Scholar] [CrossRef]

- Pershin, V.; Lufitha, M.; Chandra, S.; Mostaghimi, J. Effect of substrate temperature on adhesion strength of plasma-sprayed nickel coatings. J. Therm. Spray Technol. 2003, 12, 370–376. [Google Scholar] [CrossRef]

- Takimoto, K.; Fukuta, A.; Yamamoto, Y.; Yoshida, N.; Itoh, T.; Nonomura, S. Linear thermal expansion coefficients of amorphous and microcrystalline silicon films. J. Non-Cryst. Solids 2002, 299-302, 314–317. [Google Scholar] [CrossRef]

- Dehm, G.; Weiss, D.; Arzt, E. In situ transmission electron microscopy study of thermal-stress-induced dislocations in a thin Cu film constrained by a Si substrate. Mater. Sci. Eng. A 2001, 309-310, 468–472. [Google Scholar] [CrossRef]

- Leterrier, Y.; Andersons, J.; Pitton, Y.; Månson, J.-A.E. Adhesion of silicon oxide layers on poly(ethylene terephthalate). II: Effect of coating thickness on adhesive and cohesive strengths. J. Polym. Sci. Pol. Phys. 1997, 35, 1463–1472. [Google Scholar] [CrossRef]

- Kumar, D.D.; Kumar, N.; Kalaiselvam, S.; Thangappan, R.; Jayavel, R. Film thickness effect and substrate dependent tribo-mechanical characteristics of titanium nitride films. Surf. Interfaces 2018, 12, 78–85. [Google Scholar] [CrossRef]

- Roshangias, A.; Pelzer, R.; Khatibi, G.; Steinbrenner, J. Thickness dependency of adhesion properties of TiW thin films. In Proceedings of the 2014 IEEE 16th Electronics Packaging Technology Conference (EPTC), Singapore, 3–5 December 2014; pp. 192–195. [Google Scholar]

- Coy, E.; Yate, L.; Kabacińska, Z.; Jancelewicz, M.; Jurga, S.; Iatsunskyi, I. Topographic reconstruction and mechanical analysis of atomic layer deposited Al2O3/TiO2 nanolaminates by nanoindentation. Mater. Des. 2016, 111, 584–591. [Google Scholar] [CrossRef]

- Goyenola, C.; Gueorguiev, G.K.; Stafström, S.; Hultman, L. Fullerene-like CSx: A first-principles study of synthetic growth. Chem. Phys. Lett. 2011, 506, 86–91. [Google Scholar] [CrossRef]

- Ren, Y.; Liu, X. Strain and Cohesive Energy of TiN Deposit on Al(001) Surface: Density Functional Calculation. Int. J. Nanosci. 2016, 15, 1650017. [Google Scholar] [CrossRef]

- Jiménez, C.; Garcia-Moreno, F.; Pfretzschner, B.; Klaus, M.; Wollgarten, M.; Zizak, I.; Schumacher, G.; Tovar, M.; Banhart, J. Decomposition of TiH2 studied in situ by synchrotron X-ray and neutron diffraction. Acta Mater. 2011, 59, 6318–6330. [Google Scholar] [CrossRef]

- Corgnale, C.; Hardy, B.; Motyka, T.; Zidan, R.; Teprovich, J.; Peters, B. Screening analysis of metal hydride based thermal energy storage systems for concentrating solar power plants. Renew. Sustain. Energy Rev. 2014, 38, 821–833. [Google Scholar] [CrossRef]

- Xiaosong, Z.; Xinggui, L.; Lin, Z.; Shuming, P.; Shunzhong, L. X-ray diffraction analysis of titanium tritide film during 1600 days. J. Nucl. Mater. 2010, 396, 223–227. [Google Scholar] [CrossRef]

- Wang, H.; Peng, S.; Zhou, X.; Long, X.; Shen, H. Evolution of 3He bubble microstructure in TiT2 films during aging. J. Nucl. Mater. 2018, 509, 700–706. [Google Scholar] [CrossRef]

- Shen, H.H.; Peng, S.M.; Zhou, X.S.; Sun, K.; Wang, L.M.; Zu, X.T. Microstructure evolution of zircaloy-4 during Ne ion irradiation and annealing: An in-situ TEM investigation. Chin. Phys. B 2014, 23, 036102. [Google Scholar] [CrossRef]

- Zhou, X.S.; Liu, Q.; Zhang, L.; Peng, S.M.; Long, X.G.; Ding, W.; Cheng, G.J.; Wang, W.D.; Liang, J.H.; Fu, Y.Q. Effects of tritium content on lattice parameter, 3He retention, and structural evolution during aging of titanium tritide. Int. J. Hydrogen Energy 2014, 39, 20062–20071. [Google Scholar] [CrossRef]

- Snow, C.S.; Browning, J.F.; Bond, G.M.; Rodriguez, M.A.; Knapp, J.A. 3He bubble evolution in ErT2: A survey of experimental results. J. Nucl. Mater. 2014, 453, 296–306. [Google Scholar] [CrossRef]

- Juang, M.H.; Cheng, H.C. Novel annealing scheme for fabricating high-quality Ti-silicided shallow n+p junction by P+ implantation into thin Ti films on Si substrate. Appl. Phys. Lett. 1992, 60, 1579–1581. [Google Scholar] [CrossRef]

- Bensch, W.; Pamler, W. The formation of titanium silicides by rapid thermal processing: An XRD and AES study. React. Solids 1989, 7, 249–262. [Google Scholar] [CrossRef]

- Chason, E.; Sheldon, B.W.; Freund, L.B.; Floro, J.A.; Hearne, S.J. Origin of compressive residual stress in polycrystalline thin films. Phys. Rev. Lett. 2002, 88, 156103. [Google Scholar] [CrossRef] [PubMed]

- Floro, J.A.; Chason, E.; Cammarata, R.C.; Srolovitz, D.J. Physical Origins of Intrinsic Stresses in Volmer–Weber Thin Films. MRS Bull. 2011, 27, 19–25. [Google Scholar] [CrossRef]

- Shen, H.H.; Peng, S.M.; Long, X.G.; Zhou, X.S.; Yang, L.; Zu, X.T. The effect of substrate temperature on the oxidation behavior of erbium thick films. Vacuum 2012, 86, 1097–1101. [Google Scholar] [CrossRef]

- Shen, H.H.; Peng, S.M.; Xiang, X.; Naab, F.N.; Sun, K.; Zu, X.T. Proton irradiation effects on the precipitate in a Zr–1.6Sn–0.6Nb–0.2Fe–0.1Cr alloy. J. Nucl. Mater. 2014, 452, 335–342. [Google Scholar] [CrossRef]

- Yang, X.; Qiu, Z.; Li, X. Investigation of scratching sequence influence on material removal mechanism of glass-ceramics by the multiple scratch tests. Ceram. Int. 2019, 45, 861–873. [Google Scholar] [CrossRef]

- Kleinbichler, A.; Pfeifenberger, M.J.; Zechner, J.; Wöhlert, S.; Cordill, M.J. Scratch induced thin film buckling for quantitative adhesion measurements. Mater. Des. 2018, 155, 203–211. [Google Scholar] [CrossRef]

- Meneses-Amador, A.; Jiménez-Tinoco, L.F.; Reséndiz-Calderon, C.D.; Mouftiez, A.; Rodríguez-Castro, G.A.; Campos-Silva, I. Numerical evaluation of scratch tests on boride layers. Surf. Coat. Technol. 2015, 284, 182–191. [Google Scholar] [CrossRef]

- Lee, A.; Clemens, B.M.; Nix, W.D. Stress induced delamination methods for the study of adhesion of Pt thin films to Si. Acta Mater. 2004, 52, 2081–2093. [Google Scholar] [CrossRef]

- Gale, W.F.; Totemeier, T.C. Elastic properties, damping capacity and shape memory alloys. In Smithells Metals Reference Book, Eighth Edition; Gale, W.F., Totemeier, T.C., Eds.; Butterworth-Heinemann: Oxford, UK, 2004; pp. 1–45. [Google Scholar]

- Hsueh, C.H. Thermal stresses in elastic multilayer systems. Thin Solid Films 2002, 418, 182–188. [Google Scholar] [CrossRef]

- Speight, J.G. Inorganic Chemistry. In Lange’s Handbook of Chemistry, 16th ed.; McGraw-Hill: New York, NY, USA, 2005; pp. 1.128–1.131. [Google Scholar]

- Dauskardt, R.H.; Lane, M.; Ma, Q.; Krishna, N. Adhesion and debonding of multi-layer thin film structures. Eng. Fract. Mech. 1998, 61, 141–162. [Google Scholar] [CrossRef]

- Xi, Y.; Gao, K.; Pang, X.; Yang, H.; Xiong, X.; Li, H.; Volinsky, A.A. Film thickness effect on texture and residual stress sign transition in sputtered TiN thin films. Ceram. Int. 2017, 43, 11992–11997. [Google Scholar] [CrossRef]

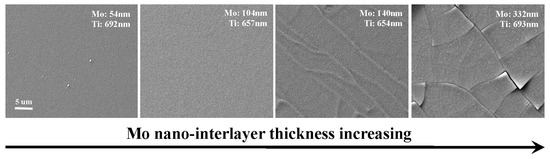

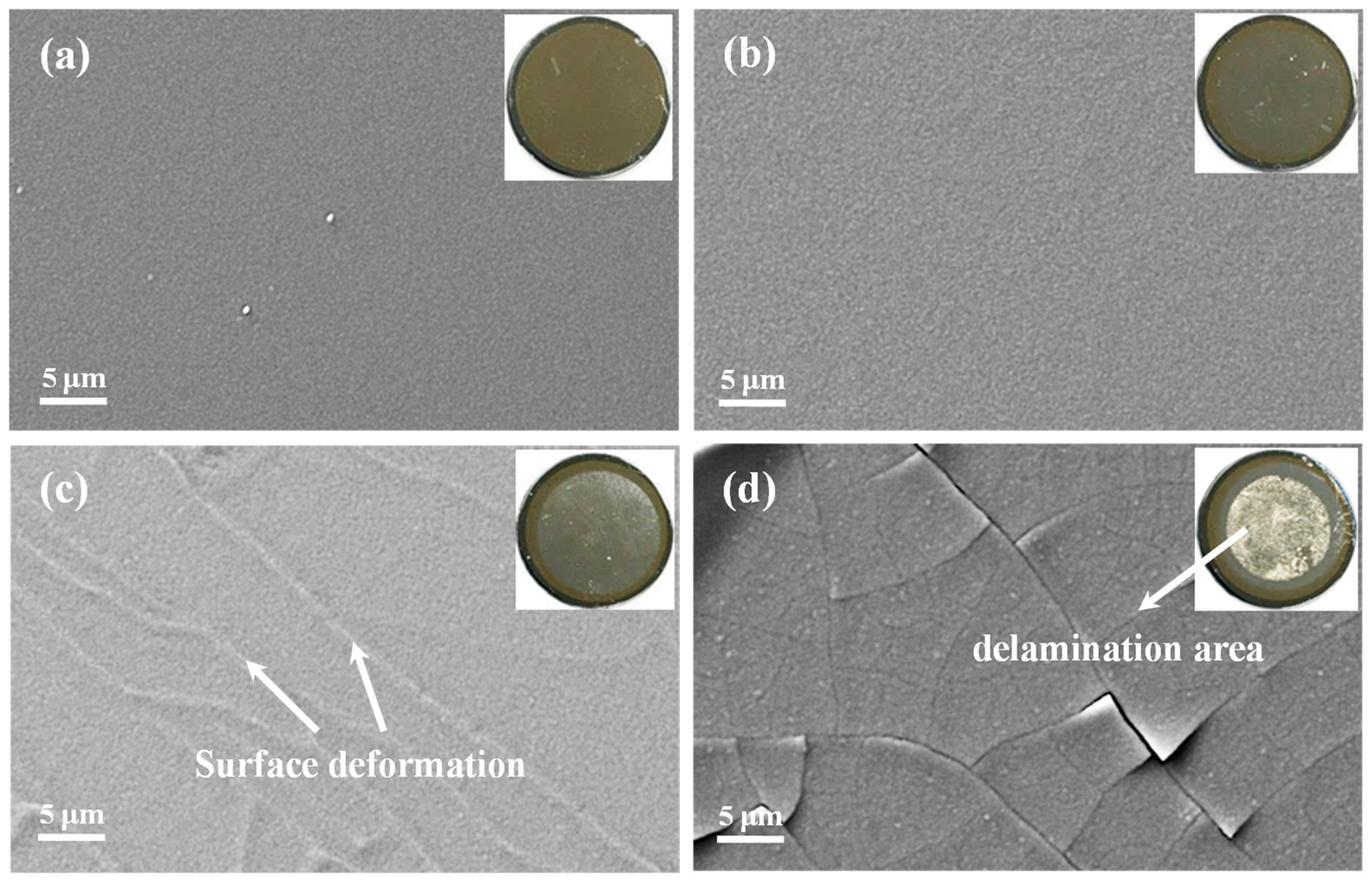

| Sample Designation | Mo-1 | Mo-2 | Mo-4 | Mo-8 |

|---|---|---|---|---|

| Deposition time of Mo films (min) | 1 | 2 | 4 | 8 |

| Thickness of Mo films (nm) | 54.3 | 103.7 | 139.8 | 331.5 |

| Thickness of Ti films (nm) | 692.0 | 657.0 | 654.3 | 693.2 |

| Sample Number | Mo-1 | Mo-2 | Mo-4 | Mo-8 |

|---|---|---|---|---|

| Scratch distance (nm) | 301.1 ± 29.6 | 262.1 ± 26.7 | 227.4 ± 8.7 | 224.5 ± 22.7 |

| Displacement into surface (nm) | 469.4 ± 51.0 | 433.8 ± 92.1 | 689.3 ± 27.6 | 419.6 ± 63.0 |

| Sample Number | Mo-1 | Mo-2 | Mo-4 | Mo-8 |

|---|---|---|---|---|

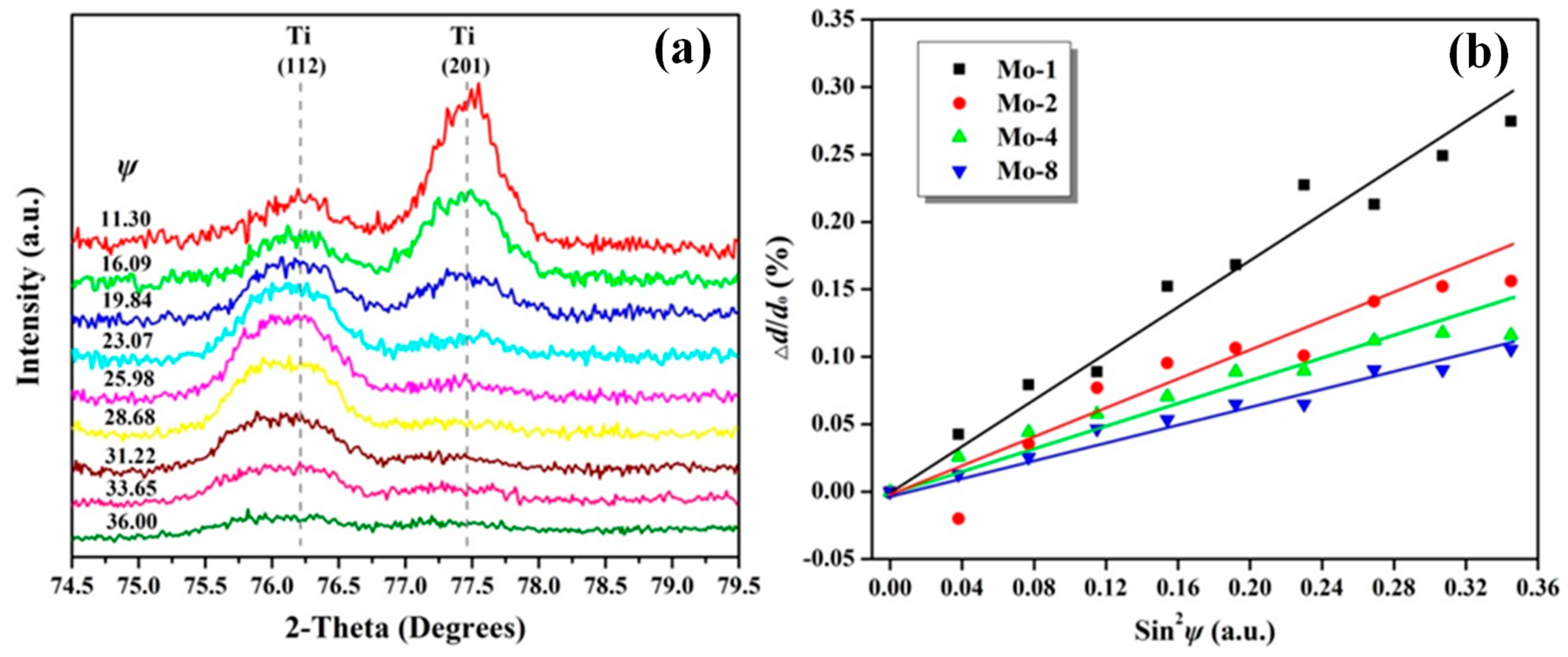

| Residual stress (MPa) | 686.4 ± 40.6 | 395.1 ± 34.6 | 294.0 ± 22.2 | 257.6 ± 14.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, H.; Yao, B.; Zhang, J.; Zhu, X.; Xiang, X.; Zhou, X.; Zu, X. Effect of Thickness of Molybdenum Nano-Interlayer on Cohesion between Molybdenum/Titanium Multilayer Film and Silicon Substrate. Nanomaterials 2019, 9, 616. https://doi.org/10.3390/nano9040616

Shen H, Yao B, Zhang J, Zhu X, Xiang X, Zhou X, Zu X. Effect of Thickness of Molybdenum Nano-Interlayer on Cohesion between Molybdenum/Titanium Multilayer Film and Silicon Substrate. Nanomaterials. 2019; 9(4):616. https://doi.org/10.3390/nano9040616

Chicago/Turabian StyleShen, Huahai, Bing Yao, Jianwei Zhang, Xinqiao Zhu, Xia Xiang, Xiaosong Zhou, and Xiaotao Zu. 2019. "Effect of Thickness of Molybdenum Nano-Interlayer on Cohesion between Molybdenum/Titanium Multilayer Film and Silicon Substrate" Nanomaterials 9, no. 4: 616. https://doi.org/10.3390/nano9040616

APA StyleShen, H., Yao, B., Zhang, J., Zhu, X., Xiang, X., Zhou, X., & Zu, X. (2019). Effect of Thickness of Molybdenum Nano-Interlayer on Cohesion between Molybdenum/Titanium Multilayer Film and Silicon Substrate. Nanomaterials, 9(4), 616. https://doi.org/10.3390/nano9040616