Enhanced Light Extraction of Flip-Chip Mini-LEDs with Prism-Structured Sidewall

Abstract

:1. Introduction

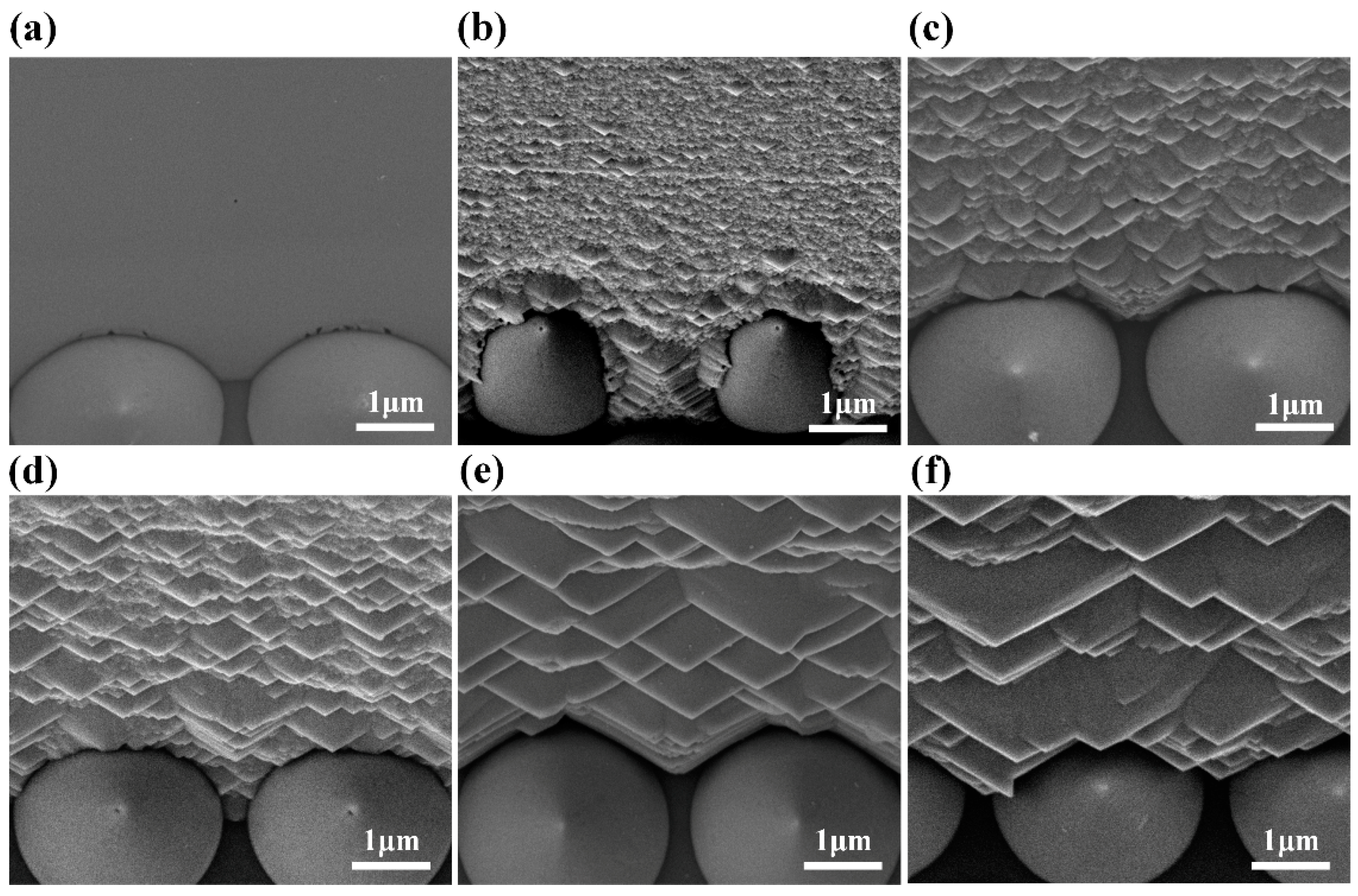

2. Materials and Methods

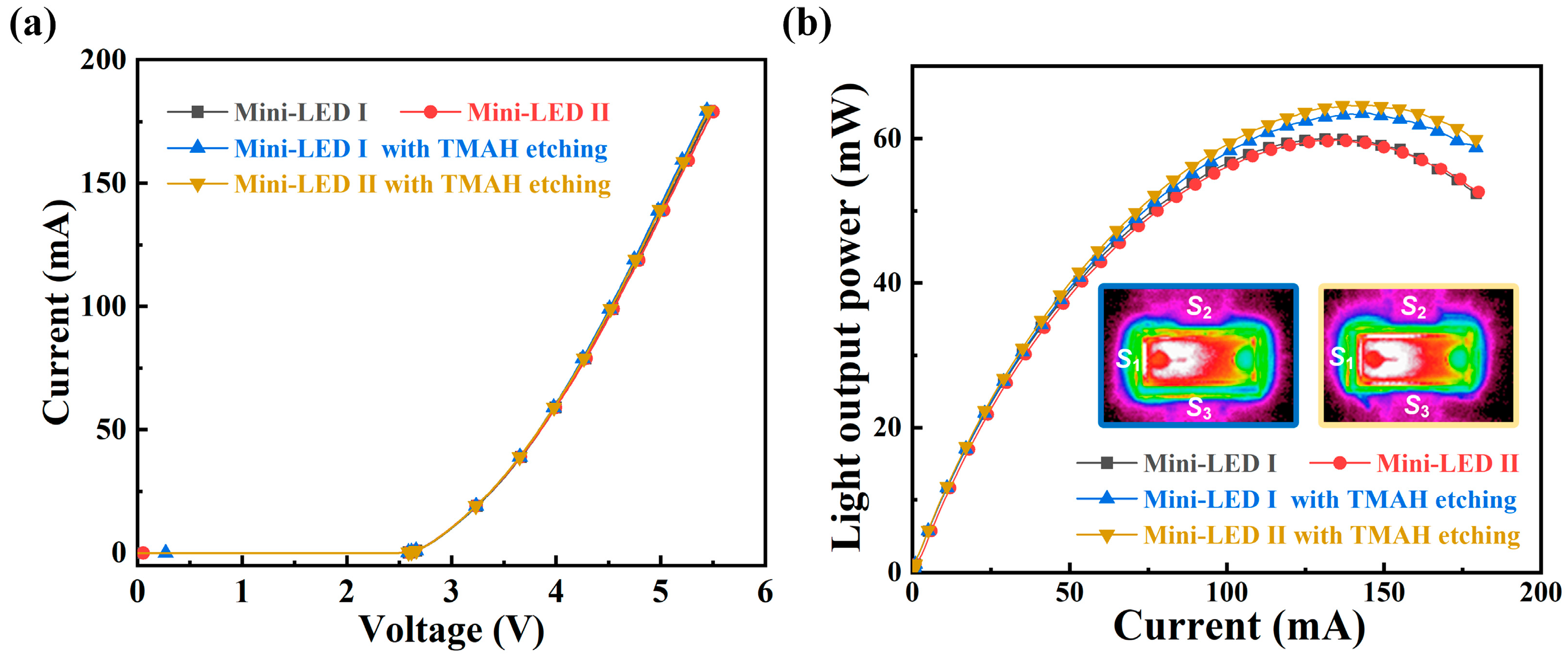

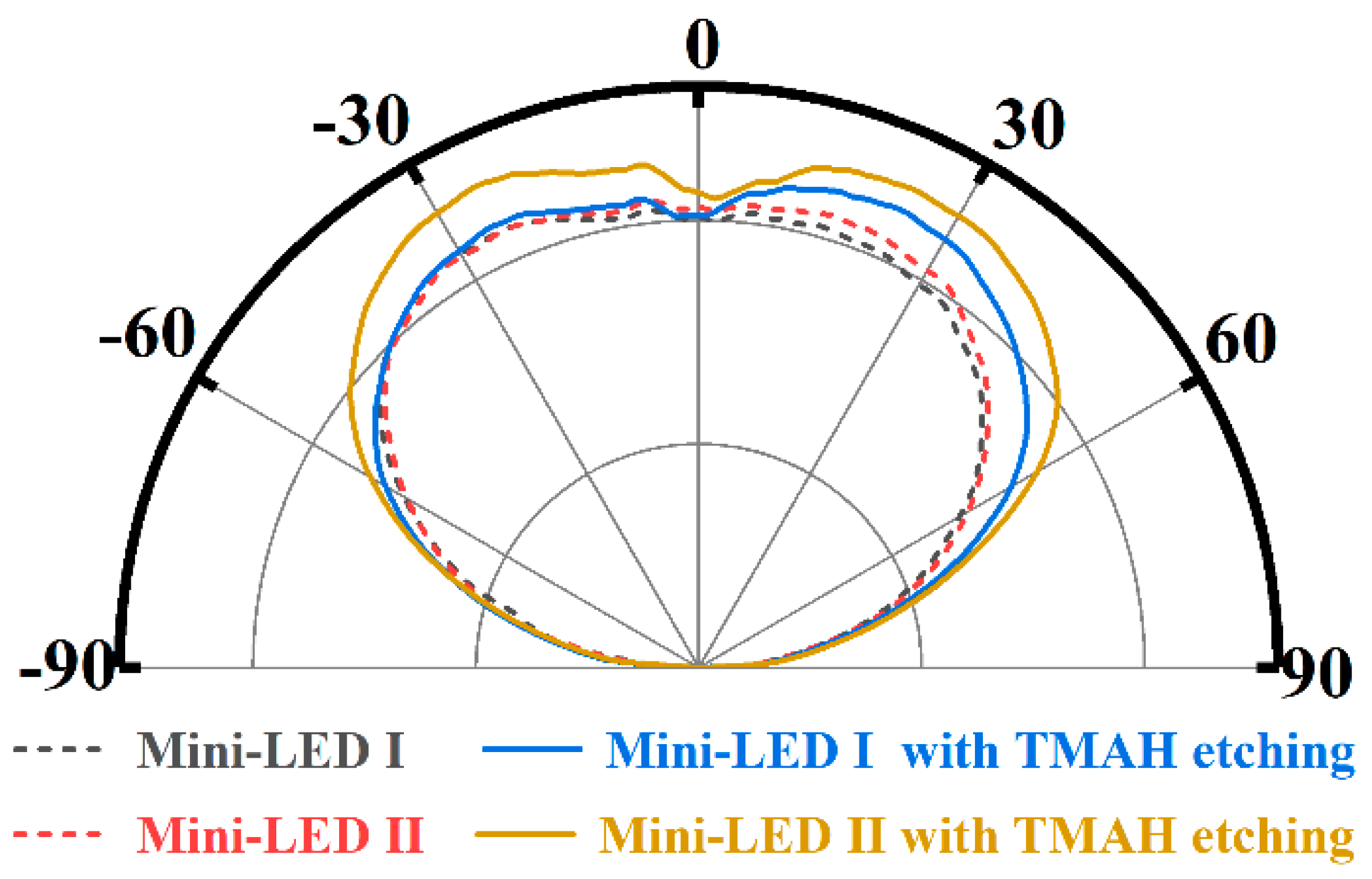

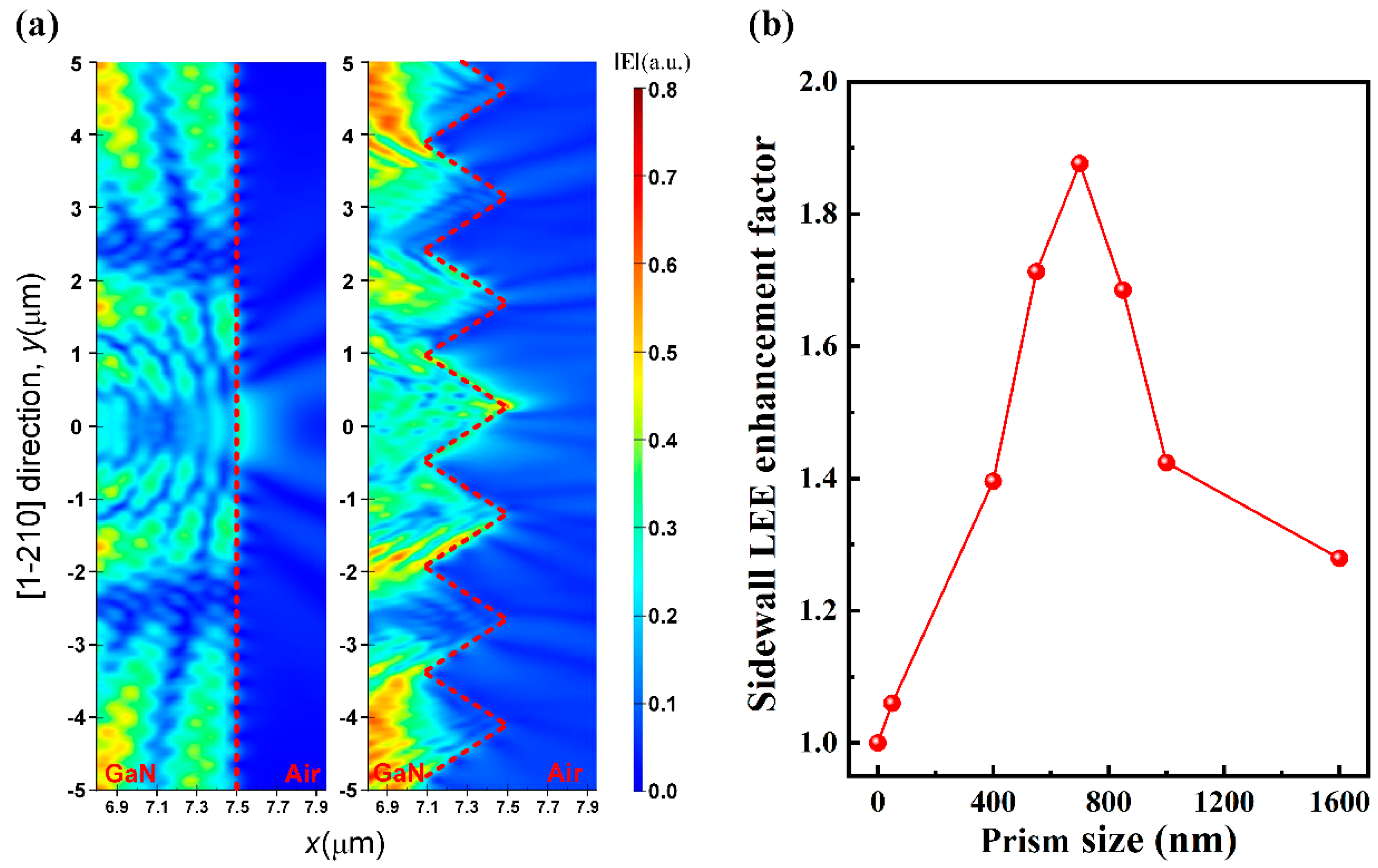

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tan, G.; Huang, Y.; Li, M.-C.; Lee, S.-L.; Wu, S.-T. High dynamic range liquid crystal displays with a mini-LED backlight. Opt. Express 2018, 26, 16572–16584. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Zou, X.; Liu, C.; Lau, K.M. Voltage-Controlled GaN HEMT-LED Devices as Fast-Switching and Dimmable Light Emitters. IEEE Electron Device Lett. 2018, 39, 224–227. [Google Scholar] [CrossRef]

- Wu, T.; Sher, C.-W.; Lin, Y.; Lee, C.-F.; Liang, S.; Lu, Y.; Huang Chen, S.-W.; Guo, W.; Kuo, H.-C.; Chen, Z. Mini-LED and Micro-LED: Promising Candidates for the Next Generation Display Technology. Appl. Sci. 2018, 8, 1557. [Google Scholar] [CrossRef]

- Son, K.R.; Lee, T.H.; Lee, B.R.; Im, H.S.; Kim, T.G. Nitride-Based Microlight-Emitting Diodes Using AlN Thin-Film Electrodes with Nanoscale Indium/Tin Conducting Filaments. Small 2018, 14, 1801032. [Google Scholar] [CrossRef] [PubMed]

- Daly, S.; Kunkel, T.; Sun, X.; Farrell, S.; Crum, P. 41.1: Distinguished Paper: Viewer Preferences for Shadow, Diffuse, Specular, and Emissive Luminance Limits of High Dynamic Range Displays. In SID Symposium Digest of Technical Papers; Blackwell Publishing Ltd.: Oxford, UK, 2013; Volume 44, pp. 563–566. [Google Scholar]

- Hu, H.; Zhou, S.; Liu, X.; Gao, Y.; Gui, C.; Liu, S. Effects of GaN/AlGaN/Sputtered AlN nucleation layers on performance of GaN-based ultraviolet light-emitting diodes. Sci. Rep. 2017, 7, 44627. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alhassan, A.I.; Young, N.G.; Farrell, R.M.; Pynn, C.; Wu, F.; Alyamani, A.Y.; Nakamura, S.; DenBaars, S.P.; Speck, J.S. Development of high performance green c-plane III-nitride light-emitting diodes. Opt. Express 2018, 26, 5591–5601. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Yuan, S.; Liu, Y.; Guo, L.J.; Liu, S.; Ding, H. Highly efficient and reliable high power LEDs with patterned sapphire substrate and strip-shaped distributed current blocking layer. Appl. Surf. Sci. 2015, 355, 1013–1019. [Google Scholar] [CrossRef]

- Muhammed, M.M.; Alwadai, N.; Lopatin, S.; Kuramata, A.; Roqan, I.S. High-Efficiency InGaN/GaN Quantum Well-Based Vertical Light-Emitting Diodes Fabricated on β-Ga2O3 Substrate. ACS Appl. Mater. Interfaces 2017, 9, 34057–34063. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Xu, H.; Hu, H.; Gui, C.; Liu, S. High quality GaN buffer layer by isoelectronic doping and its application to 365 nm InGaN/AlGaN ultraviolet light-emitting diodes. Appl. Surf. Sci. 2019, 471, 231–238. [Google Scholar] [CrossRef]

- Zhao, J.; Ding, X.; Miao, J.; Hu, J.; Wan, H.; Zhou, S. Improvement in Light Output of Ultraviolet Light-Emitting Diodes with Patterned Double-Layer ITO by Laser Direct Writing. Nanomaterials 2019, 9, 203. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Zhang, W.; Peng, M.; Dai, J.; Chen, C. Light-extraction enhancement of GaN-based 395 nm flip-chip light-emitting diodes by an Al-doped ITO transparent conductive electrode. Opt. Lett. 2018, 43, 2684–2687. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Liu, X.; Gao, Y.; Liu, Y.; Liu, M.; Liu, Z.; Gui, C.; Liu, S. Numerical and experimental investigation of GaN-based flip-chip light-emitting diodes with highly reflective Ag/TiW and ITO/DBR Ohmic contacts. Opt. Express 2017, 25, 26615–26627. [Google Scholar] [CrossRef] [PubMed]

- Wei, T.B.; Ji, X.L.; Wu, K.; Zheng, H.Y.; Du, C.X.; Chen, Y.; Yan, Q.F.; Zhao, L.X.; Zhou, Z.; Wang, J.X.; et al. Efficiency improvement and droop behavior in nanospherical-lens lithographically patterned bottom and top photonic crystal InGaN/GaN light-emitting diodes. Opt. Lett. 2014, 39, 379–382. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.H.; Kim, H.G.; Chandramohan, S.; Kim, H.K.; Kim, H.Y.; Ryu, J.H.; Park, Y.J.; Beak, Y.S.; Lee, J.-S.; Park, J.S.; et al. Improving the optical performance of InGaN light-emitting diodes by altering light reflection and refraction with triangular air prism arrays. Opt. Lett. 2012, 37, 88–90. [Google Scholar] [CrossRef] [PubMed]

- Shen, C.F.; Chang, S.J.; Chen, W.S.; Ko, T.K.; Kuo, C.T.; Shei, S.C. Nitride-Based High-Power Flip-Chip LED with Double-Side Patterned Sapphire Substrate. IEEE Photonics Technol. Lett. 2007, 19, 780–782. [Google Scholar] [CrossRef]

- Huang, K.-C.; Huang, Y.-R.; Tseng, C.-M.; Tseng, S.H.; Huang, J.-E. Increased viewing angle and light extraction efficiency of flip-chip light-emitting diode using double-side patterned sapphire substrate. Scr. Mater. 2015, 108, 40–43. [Google Scholar] [CrossRef]

- Lee, C.; Lee, Y.; Kuo, H.; Tsai, M.; Cheng, B.S.; Lu, T.; Wang, S.; Kuo, C. Enhancement of Flip-Chip Light-Emitting Diodes with Omni-Directional Reflector and Textured Micropillar Arrays. IEEE Photonics Technol. Lett. 2007, 19, 1200–1202. [Google Scholar] [CrossRef]

- Lee, C.E.; Kuo, H.C.; Lee, Y.C.; Tsai, M.R.; Lu, T.C.; Wang, S.C.; Kuo, C.T. Luminance Enhancement of Flip-Chip Light-Emitting Diodes by Geometric Sapphire Shaping Structure. IEEE Photonics Technol. Lett. 2008, 20, 184–186. [Google Scholar] [CrossRef]

- Huang, S.; Horng, R.; Wen, K.; Lin, Y.; Yen, K.; Wuu, D. Improved Light Extraction of Nitride-Based Flip-Chip Light-Emitting Diodes Via Sapphire Shaping and Texturing. IEEE Photonics Technol. Lett. 2006, 18, 2623–2625. [Google Scholar] [CrossRef]

- Nami, M.; Feezell, D.F. Optical properties of plasmonic light-emitting diodes based on flip-chip III-nitride core-shell nanowires. Opt. Express 2014, 22, 29445–29455. [Google Scholar] [CrossRef] [PubMed]

- Baek, S.; Kang, G.; Shin, D.; Bae, K.; Kim, Y.H.; Kim, K. Improvement of Light Extraction Efficiency in Flip-Chip Light Emitting Diodes on SiC Substrate via Transparent Haze Films with Morphology-Controlled Collapsed Alumina Nanorods. ACS Appl. Mater. Interfaces 2016, 8, 135–141. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.; Lin, N.; Shei, S. GaN-Based Power Flip-Chip LEDs with SILAR and Hydrothermal ZnO Nanorods. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 431–435. [Google Scholar] [CrossRef]

- Su, Y.K.; Chen, J.J.; Lin, C.L.; Kao, C.C. Structural analysis of nitride-based LEDs grown on micro- and nano-scale patterned sapphire substrates. Phys. Status Solidi C 2010, 7, 1784–1786. [Google Scholar] [CrossRef]

- Lin, Z.; Yang, H.; Zhou, S.; Wang, H.; Hong, X.; Li, G. Pattern Design of and Epitaxial Growth on Patterned Sapphire Substrates for Highly Efficient GaN-Based LEDs. Cryst. Growth Des. 2012, 12, 2836–2841. [Google Scholar] [CrossRef]

- Su, Y.K.; Chen, J.J.; Lin, C.L.; Chen, S.M.; Li, W.L.; Kao, C.C. Pattern-size dependence of characteristics of nitride-based LEDs grown on patterned sapphire substrates. J. Cryst. Growth 2009, 311, 2973–2976. [Google Scholar] [CrossRef]

- Zhou, S.; Hu, H.; Liu, X.; Liu, M.; Ding, X.; Gui, C.; Liu, S.; Guo, L.J. Comparative study of GaN-based ultraviolet LEDs grown on different-sized patterned sapphire substrates with sputtered AlN nucleation layer. Jpn. J. Appl. Phys. 2017, 56, 111001. [Google Scholar] [CrossRef]

- Zhuang, D.; Edgar, J.H. Wet etching of GaN, AlN, and SiC: A review. Mat. Sci. Eng. R 2005, 48, 1–46. [Google Scholar] [CrossRef]

- Li, D.; Sumiya, M.; Fuke, S.; Yang, D.; Que, D.; Suzuki, Y.; Fukuda, Y. Selective etching of GaN polar surface in potassium hydroxide solution studied by x-ray photoelectron spectroscopy. J. Appl. Phys. 2001, 90, 4219–4223. [Google Scholar] [CrossRef]

- Lai, Y.-Y.; Hsu, S.-C.; Chang, H.-S.; Wu, Y.S.; Chen, C.-H.; Chen, L.-Y.; Cheng, Y.-J. The study of wet etching on GaN surface by potassium hydroxide solution. Res. Chem. Intermed. 2017, 43, 3563–3572. [Google Scholar] [CrossRef]

- Choi, H.W.; Dawson, M.D.; Edwards, P.R.; Martin, R.W. High extraction efficiency InGaN micro-ring light-emitting diodes. Appl. Phys. Lett. 2003, 83, 4483–4485. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Cao, X.A. Removing plasma-induced sidewall damage in GaN-based light-emitting diodes by annealing and wet chemical treatments. J. Vac. Sci. Technol. B 2009, 27, 2337–2341. [Google Scholar] [CrossRef]

- Shakya, J.; Knabe, K.; Kim, K.H.; Li, J.; Lin, J.Y.; Jiang, H.X. Polarization of III-nitride blue and ultraviolet light-emitting diodes. Appl. Phys. Lett. 2005, 86, 091107. [Google Scholar] [CrossRef]

- Campbell, P.; Green, M.A. Light trapping properties of pyramidally textured surfaces. J. Appl. Phys. 1987, 62, 243–249. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, B.; Miao, J.; Liu, Y.; Wan, H.; Li, N.; Zhou, S.; Gui, C. Enhanced Light Extraction of Flip-Chip Mini-LEDs with Prism-Structured Sidewall. Nanomaterials 2019, 9, 319. https://doi.org/10.3390/nano9030319

Tang B, Miao J, Liu Y, Wan H, Li N, Zhou S, Gui C. Enhanced Light Extraction of Flip-Chip Mini-LEDs with Prism-Structured Sidewall. Nanomaterials. 2019; 9(3):319. https://doi.org/10.3390/nano9030319

Chicago/Turabian StyleTang, Bin, Jia Miao, Yingce Liu, Hui Wan, Ning Li, Shengjun Zhou, and Chengqun Gui. 2019. "Enhanced Light Extraction of Flip-Chip Mini-LEDs with Prism-Structured Sidewall" Nanomaterials 9, no. 3: 319. https://doi.org/10.3390/nano9030319