3D Printing of UV-Curable Polyurethane Incorporated with Surface-Grafted Nanocellulose

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Isolation and Defibrillation of Cellulose

2.3. Surface Modification of Cellulose Nanofibrils

2.4. Resin Composition for Stereolithography

2.5. Characterization

3. Results and Discussion

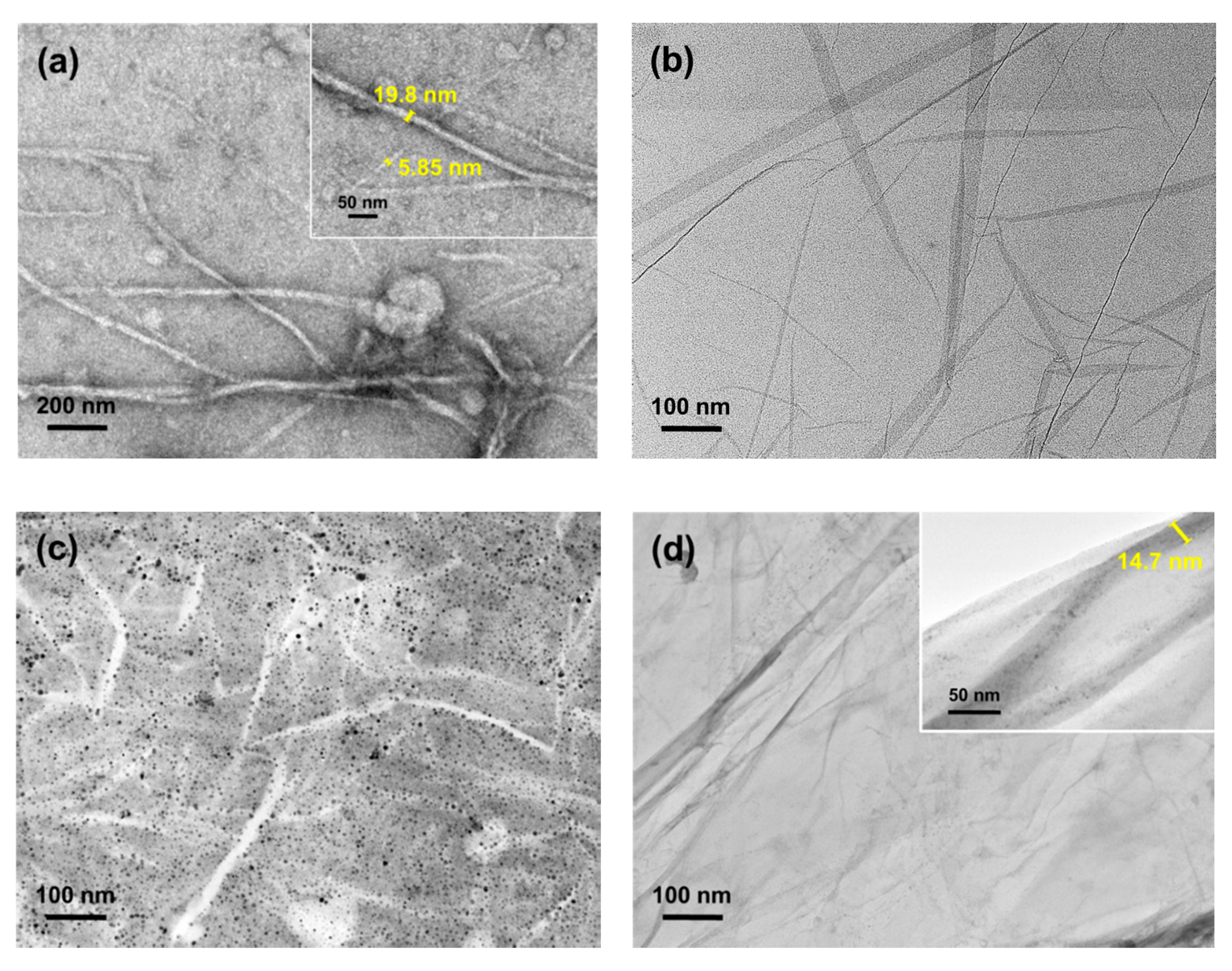

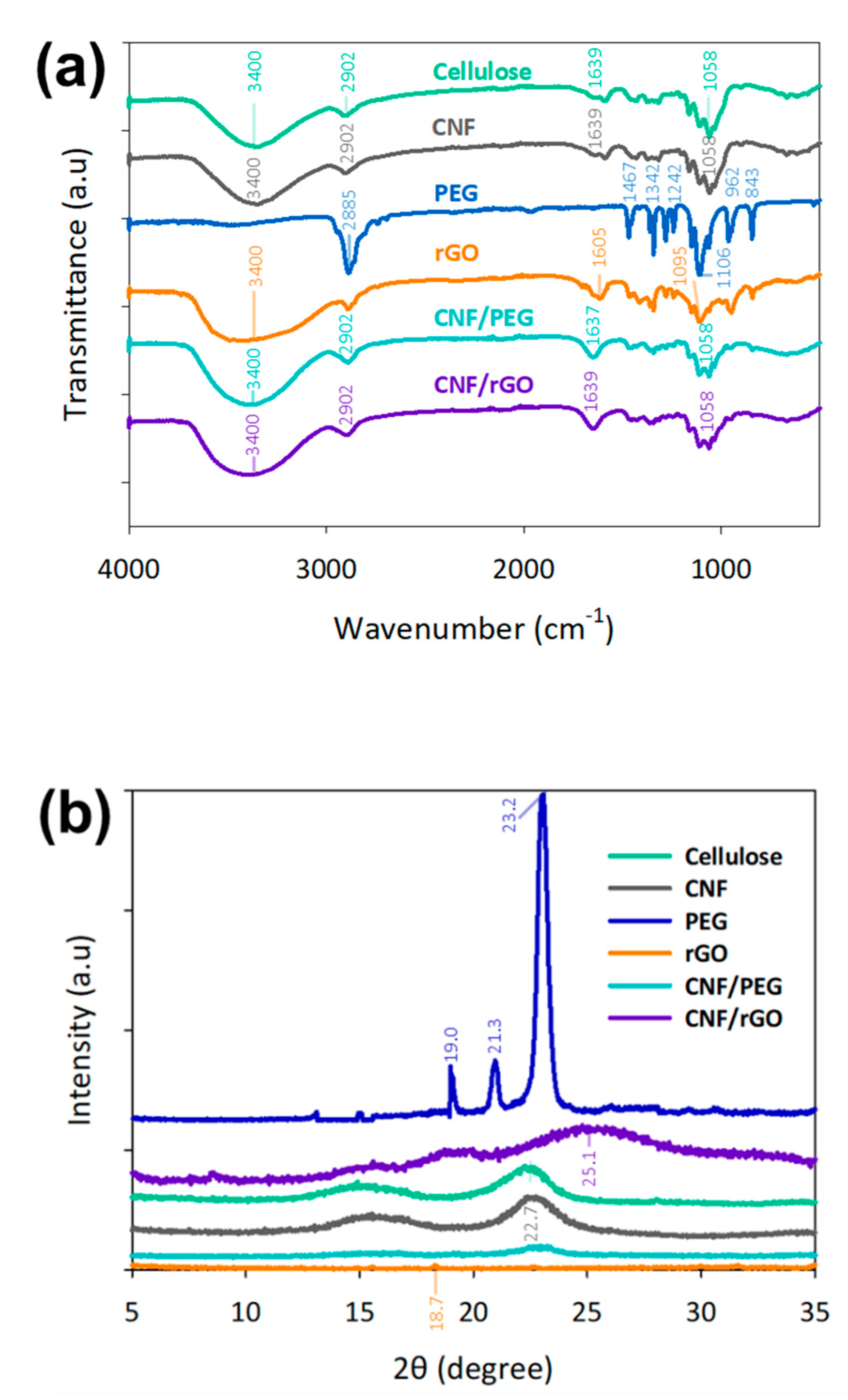

3.1. Characterization of Surface-Grafted CNF

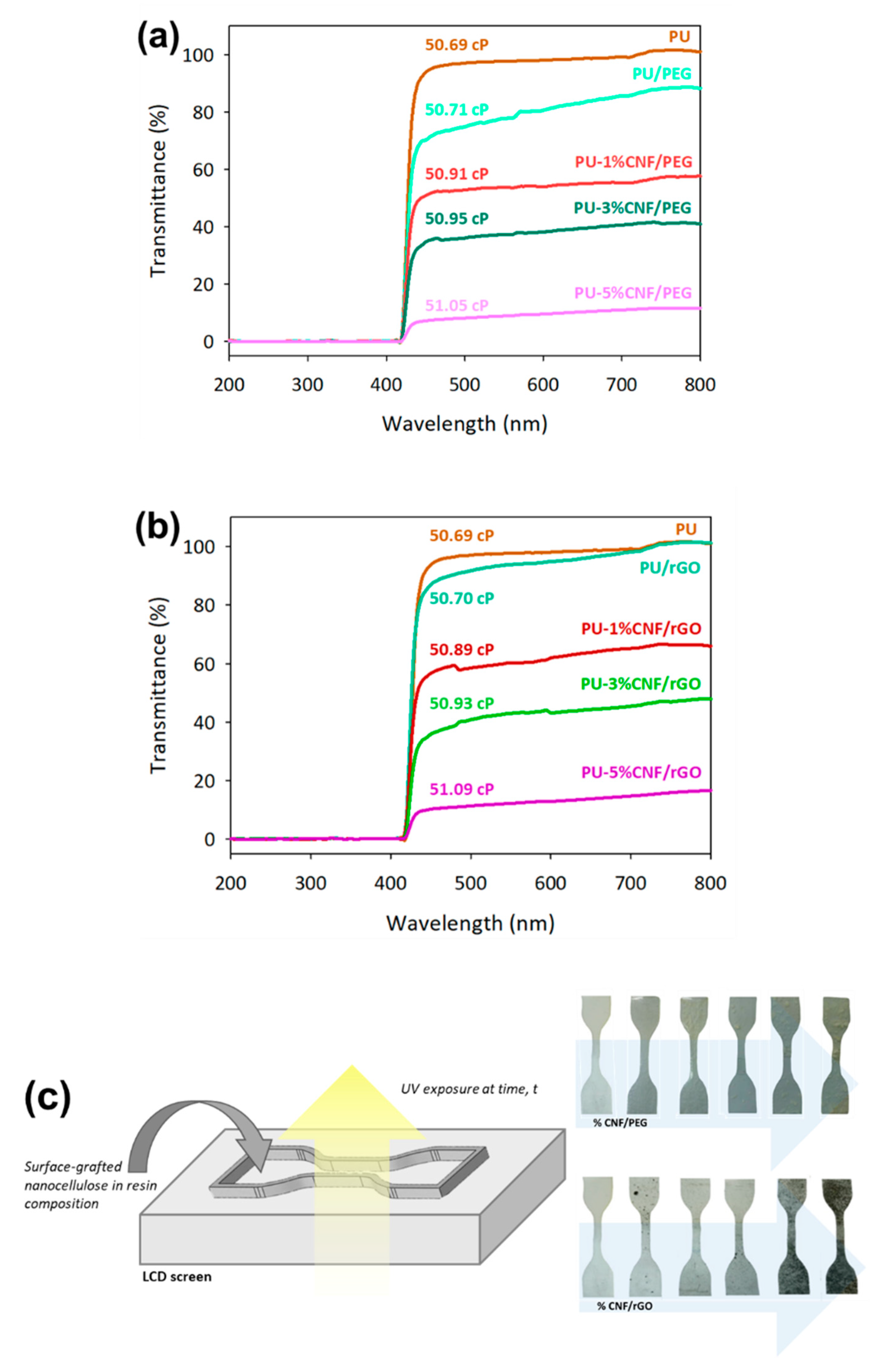

3.2. Transmittance and Curing Efficiency of Resin Composition

3.3. Characterization of UV-Cured Composites

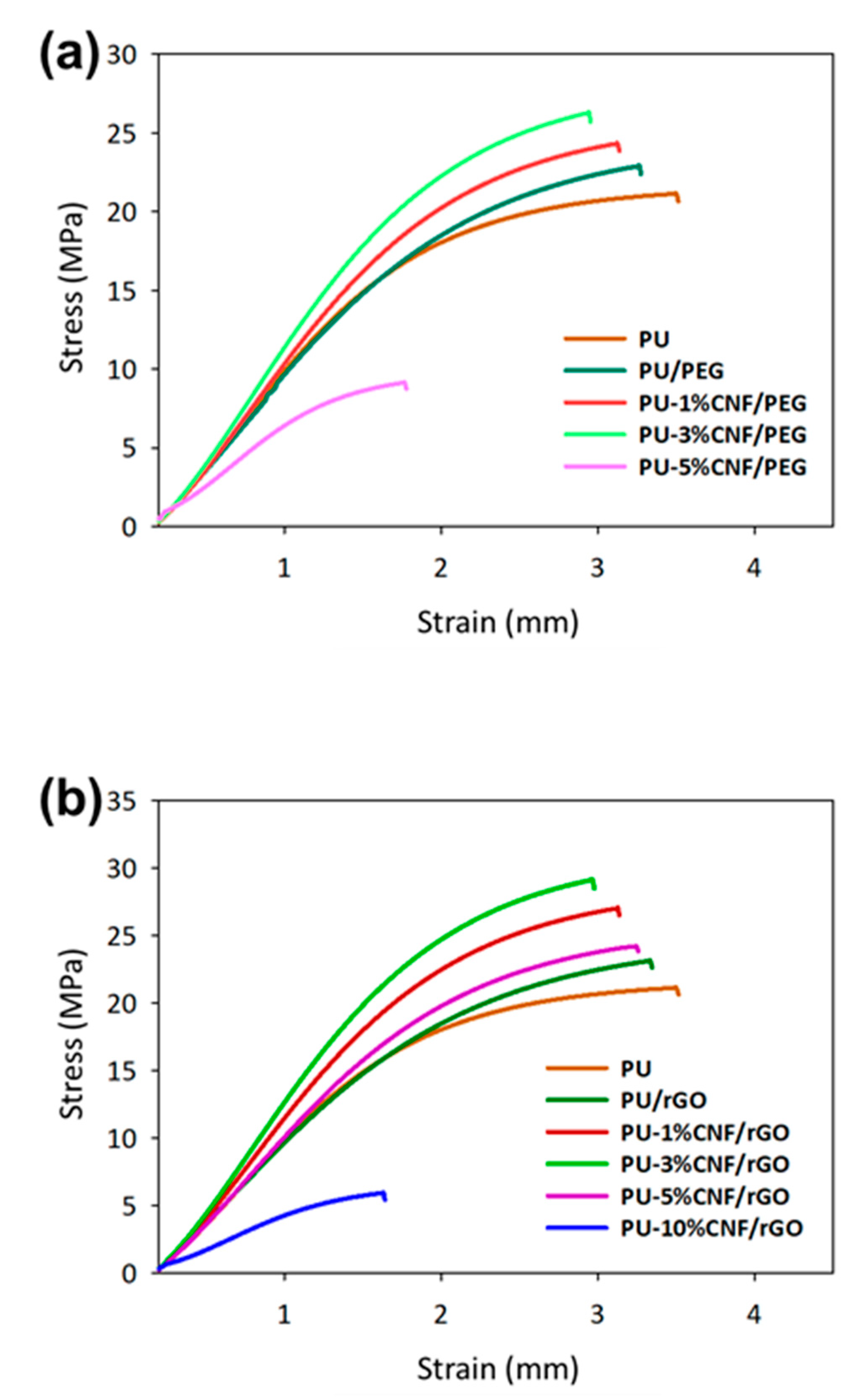

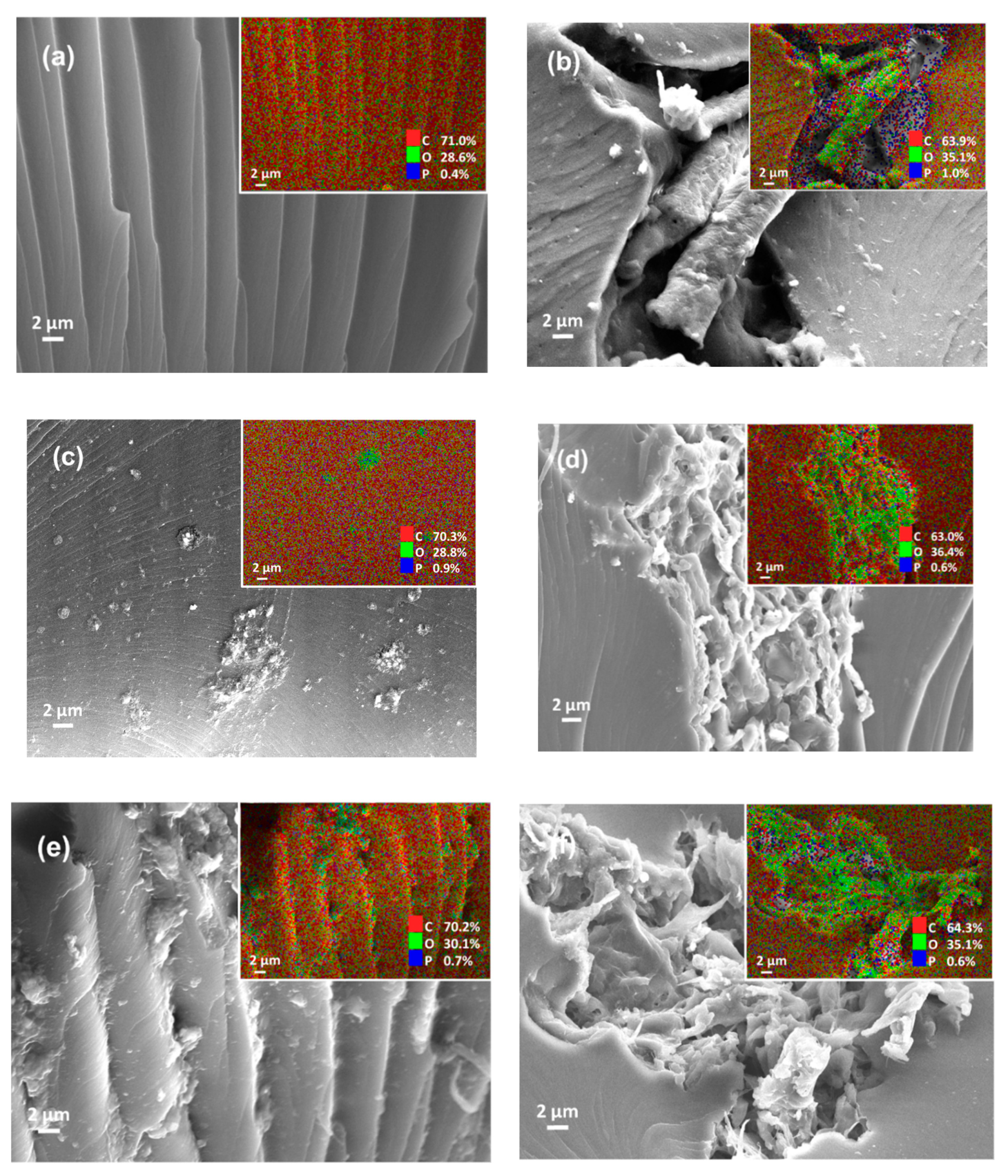

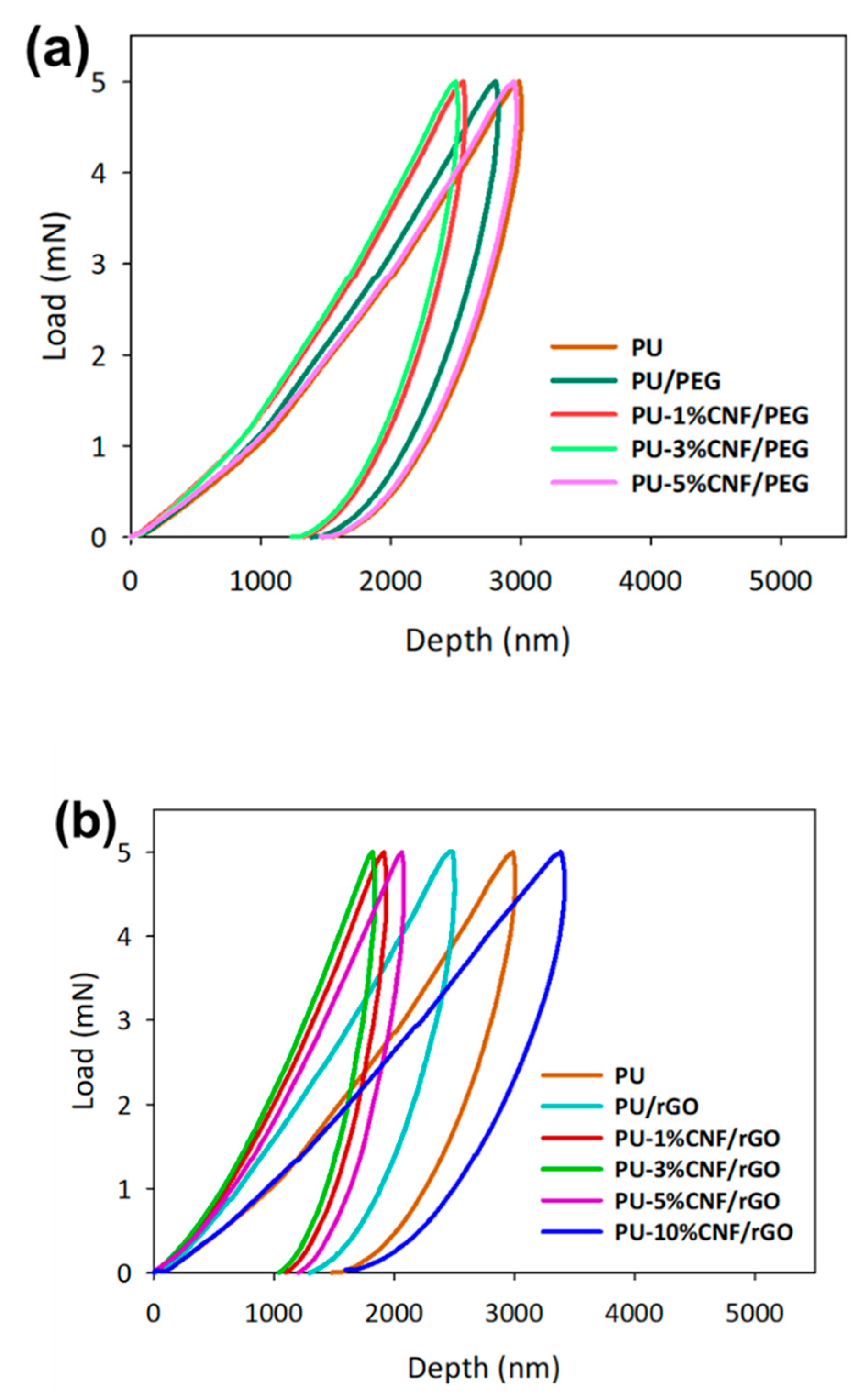

3.4. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- MPOB. Malaysian Oil Palm Statistics 2017; MPOB: Selangor, Malaysia, 2018; pp. 1–6.

- Awalludin, M.F.; Sulaiman, O.; Hashim, R.; Nadhari, W.N.A.W. An overview of the oil palm industry in Malaysia and its waste utilization through thermochemical conversion, specifically via liquefaction. Renew. Sustain. Energy Rev. 2015, 50, 1469–1484. [Google Scholar] [CrossRef]

- Palamae, S.; Dechatiwongse, P.; Choorit, W.; Chisti, Y.; Prasertsan, P. Cellulose and hemicellulose recovery from oil palm empty fruit bunch (EFB) fibers and production of sugars from the fibers. Carbohydr. Polym. 2017, 155, 491–497. [Google Scholar] [CrossRef] [PubMed]

- Derman, E.; Abdulla, R.; Marbawi, H.; Sabullah, M.K. Oil palm empty fruit bunches as a promising feedstock for bioethanol production in Malaysia. Renew. Energy 2018, 129, 285–298. [Google Scholar] [CrossRef]

- Lamaming, J.; Hashim, R.; Sulaiman, O.; Leh, C.P.; Sugimoto, T.; Nordin, N.A. Cellulose nanocrystals isolated from oil palm trunk. Carbohydr. Polym. 2015, 127, 202–208. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Sun, S.; Cao, X.; Sun, R. The role of pretreatment in improving the enzymatic hydrolysis of lignocellulosic materials. Bioresour. Technol. 2016, 199, 49–58. [Google Scholar] [CrossRef] [PubMed]

- Misra, M.; Pandey, J.K.; Mohanty, A.K. Biocomposites: Design and Mechanical Performance; Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; Amaral Da Silva, I.L.; Da Costa, L.L. Natural lignocellulosic fibers as engineering materials-An overview. Metall. Mater. Trans. A 2011, 42, 2963–2974. [Google Scholar] [CrossRef]

- Bourmaud, A.; Morvan, C.; Bouali, A.; Placet, V.; Perré, P.; Baley, C. Relationships between micro-fibrillar angle, mechanical properties and biochemical composition of flax fibers. Ind. Crops Prod. 2013, 44, 343–351. [Google Scholar] [CrossRef]

- Kaco, H.; Zakaria, S.; Chia, C.H.; Sajab, M.S.; Saidi, A.S.M. Characterization of aldehyde crosslinked kenaf regenerated cellulose film. BioResources 2015, 10, 6705–6719. [Google Scholar] [CrossRef]

- Kim, H.; Park, E.; Kim, S.; Park, B.; Kim, N.; Lee, S. Experimental study on mechanical properties of single- and dual-material 3D printed products. Procedia Manuf. 2017, 10, 887–897. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Catarino, S.; Lima, R.; Minas, G. Smart Devices: Lab-on-a-Chip; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; ISBN 9780081007464. [Google Scholar]

- Ligon-Auer, S.C.; Schwentenwein, M.; Gorsche, C.; Stampfl, J.; Liska, R. Toughening of photo-curable polymer networks: A review. Polym. Chem. 2016, 7, 257–286. [Google Scholar] [CrossRef]

- Mondschein, R.J.; Kanitkar, A.; Williams, C.B.; Verbridge, S.S.; Long, T.E. Polymer structure-property requirements for stereolithographic 3D printing of soft tissue engineering scaffolds. Biomaterials 2017, 140, 170–188. [Google Scholar] [CrossRef] [PubMed]

- Salehudin, M.H.; Salleh, E.; Muhamad, I.I.; Mamat, S.N.H. Starch-based biofilm reinforced with empty fruit bunch cellulose nanofibre. Mater. Res. Innov. 2014, 18, S6-322–S6-325. [Google Scholar] [CrossRef]

- Abdellaoui, H.; Raji, M.; Essabir, H.; Bouhfid, R.; Qaiss, A. Mechanical behavior of carbon/natural fiber-based hybrid composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Cambridge, UK, 2019; pp. 103–122. [Google Scholar]

- Kumar, A.K.; Sharma, S. Recent updates on different methods of pretreatment of lignocellulosic feedstocks: A review. Bioresour. Bioprocess. 2017, 4, 7. [Google Scholar] [CrossRef]

- Taib, M.N.A.M.; Yehye, W.A.; Julkapli, N.M.; Hamid, S.B.O.A.A. Influence of hydrophobicity of acetylated nanocellulose on the mechanical performance of nitrile butadiene rubber (NBR) composites. Fibers Polym. 2018, 19, 383–392. [Google Scholar] [CrossRef]

- Qu, P.; Gao, Y.; Wu, G.; Zhang, L. Nanocomposites of poly(lactic acid) reinforced with cellulose nanofibrils. BioResources 2010, 5, 1811–1823. [Google Scholar]

- Yang, W.; Zhao, Z.; Wu, K.; Huang, R.; Liu, T.; Jiang, H.; Chen, F.; Fu, Q. Ultrathin flexible reduced graphene oxide/cellulose nanofiber composite films with strongly anisotropic thermal conductivity and efficient electromagnetic interference shielding. J. Mater. Chem. C 2017, 5, 3748–3756. [Google Scholar] [CrossRef]

- Santanaraj, J.; Sajab, M.S.; Mohammad, A.W.; Harun, S.; Chia, C.H.; Zakari, S.; Kaco, H. Enhanced delignification of oil palm empty fruit bunch fibers with in situ fenton-oxidation. BioResources 2017, 12, 5223–5235. [Google Scholar] [CrossRef]

- Sajab, M.S.; Mohan, D.; Santanaraj, J.; Chia, C.H.; Kaco, H.; Harun, S.; Kamarudin, N.H.N. Telescopic synthesis of cellulose nanofibrils with a stable dispersion of Fe(0) nanoparticles for synergistic removal of 5-fluorouracil. Sci. Rep. 2019, 9, 11703. [Google Scholar] [CrossRef]

- Ibrahim, F.; Mohan, D.; Sajab, M.S.; Bakarudin, S.B.; Kaco, H. Evaluation of the compatibility of organosolv lignin-graphene nanoplatelets with photo-curable polyurethane in stereolithography 3d printing. Polymers 2019, 11, 1544. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Liu, C.; Feng, F.; Wang, D.; Mo, H.; Si, L.; Wei, G.; Shen, J. Polyurethane/polyurethane nanoparticle-modified expanded poly(tetrafluoroethylene) vascular patches promote endothelialization. J. Biomed. Mater. Res. Part A 2018, 106, 2131–2140. [Google Scholar] [CrossRef]

- Chan, C.H.; Chia, C.H.; Zakaria, S.; Sajab, M.S.; Chin, S.X. Cellulose nanofibrils: A rapid adsorbent for the removal of methylene blue. RSC Adv. 2015, 5, 18204–18212. [Google Scholar] [CrossRef]

- Sajab, M.S.; Chia, C.H.; Chan, C.H.; Zakaria, S.; Kaco, H.; Chook, S.W.; Chin, S.X.; Noor, A.M. Bifunctional graphene oxide-cellulose nanofibril aerogel loaded with Fe(iii) for the removal of cationic dye via simultaneous adsorption and Fenton oxidation. RSC Adv. 2016, 6, 19819–19825. [Google Scholar] [CrossRef]

- Hou, M.; Xu, M.; Li, B. Enhanced electrical conductivity of cellulose nanofiber/graphene composite paper with a sandwich structure. ACS Sustain. Chem. Eng. 2018, 6, 2983–2990. [Google Scholar] [CrossRef]

- Abouloula, C.N.; Rizwan, M.; Selvanathan, V.; Abdullah, C.I.; Hassan, A.; Yahya, R.; Oueriagli, A. A novel application for oil palm empty fruit bunch: Extraction and modification of cellulose for solid polymer electrolyte. Ionics 2018, 24, 3827–3836. [Google Scholar] [CrossRef]

- Fu, X.; Kong, W.; Zhang, Y.; Jiang, L.; Wang, J.; Lei, J. Novel solid—Solid phase change materials with biodegradable trihydroxy surfactants for thermal energy storage. RSC Adv. 2015, 5, 68881–68889. [Google Scholar] [CrossRef]

- Zhang, C.; Dabbs, D.M.; Liu, L.-M.; Aksay, I.A.; Car, R.; Selloni, A. Combined effects of functional groups, lattice defects and edges in the infrared spectra of graphene oxide. J. Phys. Chem. C 2015, 119, 18167–18176. [Google Scholar] [CrossRef]

- Rahimi, M.K.S.; Brown, R.J.; Tsuzuki, T.; Rainey, T.J. A comparison of cellulose nanocrystals and cellulose nanofibers extracted from bagasse using acid and ball milling methods. Adv. Nat. Nanosci. Nanotechnol. 2016, 7. [Google Scholar] [CrossRef]

- Saleem, H.; Haneef, M.; Abbasi, H.Y. Synthesis route of reduced graphene oxide via thermal reduction of chemically exfoliated graphene oxide. Mater. Chem. Phys. 2018, 204, 1–7. [Google Scholar] [CrossRef]

- Vinodhkumar, G.; Ramya, R.; Potheher, I.; Cyrac Peter, A. Reduced graphene oxide based on simultaneous detection of neurotransmitters. Prog. Chem. Biochem. Res. 2018, 1, 40–49. [Google Scholar] [CrossRef]

- Kuzmenko, V.; Wang, N.; Haque, M.; Naboka, O.; Flygare, M.; Svensson, K.; Gatenholm, P.; Liu, J.; Enoksson, P. Cellulose-derived carbon nanofibers/graphene composite electrodes for powerful compact supercapacitors. RSC Adv. 2017, 7, 45968–45977. [Google Scholar] [CrossRef]

- Wang, L.; Okada, K.; Hikima, Y.; Ohshima, M.; Sekiguchi, T.; Yano, H. Effect of cellulose nanofiber (CNF) surface treatment on cellular structures and mechanical properties of polypropylene/CNF nanocomposite foams via core-back foam injection molding. Polymers 2019, 11, 249. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Wu, K.; Hu, Y.; Zhuo, H.; Chen, Z.; Jing, S.; Liu, Q.; Liu, C.; Zhong, L. A mechanically strong and sensitive CNT/rGO-CNF carbon aerogel for piezoresistive sensors. J. Mater. Chem. A 2018, 6, 23550–23559. [Google Scholar] [CrossRef]

- Xu, Z.; Li, J.; Zhou, H.; Jiang, X.; Yang, C.; Wang, F.; Pan, Y.; Li, N.; Li, X.; Shi, L.; et al. Morphological and swelling behavior of cellulose nanofiber (CNF)/poly(vinyl alcohol) (PVA) hydrogels: Poly(ethylene glycol) (PEG) as porogen. RSC Adv. 2016, 6, 43626–43633. [Google Scholar] [CrossRef]

- Becker, H.; Locascio, L.E. Polymer microfluidic devices. Talanta 2002, 56, 267–287. [Google Scholar] [CrossRef]

- Yang, Z.; Li, X.; Si, J.; Cui, Z.; Peng, K. Morphological, mechanical and thermal properties of poly (lactic acid) (PLA)/cellulose nanofibrils (CNF) composites nanofiber for tissue engineering. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2019, 34, 207–215. [Google Scholar] [CrossRef]

- Rahmani, H.; Najafi, S.H.M.; Saffarzadeh-Matin, S.; Ashori, A. Mechanical properties of carbon fiber/epoxy composites: Effects of number of plies, fiber contents, and angle-ply layers. Polym. Eng. Sci. 2013, 54, 2676–2682. [Google Scholar] [CrossRef]

- Parizi, M.T.; Ebrahimi, G.R.; Ezatpour, H.R. Effect of graphene nanoplatelets content on the microstructural and mechanical properties of AZ80 magnesium alloy. Mater. Sci. Eng. A 2019, 742, 373–389. [Google Scholar] [CrossRef]

- Park, Y.T.; Qian, Y.; Chan, C.; Suh, T.; Nejhad, M.G.; Macosko, C.W.; Stein, A. Epoxy toughening with low graphene loading. Adv. Funct. Mater. 2015, 25, 575–585. [Google Scholar] [CrossRef]

- Chen, T.; Soroush, A.; Rahaman, M.S. Highly Hydrophobic electrospun reduced graphene oxide/poly (vinylidene fluoride-co-hexafluoropropylene) membranes for use in membrane distillation. Ind. Eng. Chem. Res. 2018, 57, 14535–14543. [Google Scholar] [CrossRef]

- Zainuddin, M.F.; Raikhan, N.N.; Othman, N.H.; Abdullah, W.F.H. Synthesis of Reduced Graphene Oxide (rGO) Using Different Treatments of Graphene Oxide (GO); IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Zhou, Y.; Pervin, F.; Jeelani, S.; Mallick, P.K. Improvement in mechanical properties of carbon fabric-epoxy composite using carbon nanofibers. J. Mater. Process. Technol. 2008, 198, 445–453. [Google Scholar] [CrossRef]

- Venkatesh, A.; Thunberg, J.; Moberg, T.; Klingberg, M.; Hammar, L.; Peterson, A.; Müller, C.; Boldizar, A. Cellulose nanofibril-reinforced composites using aqueous dispersed ethylene-acrylic acid copolymer. Cellulose 2018, 25, 4577–4589. [Google Scholar] [CrossRef]

- Bal, S.; Saha, S. Fabrication and Characterization of Carbon Nanofiber (CNF) Based Epoxy Composites; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2015. [Google Scholar]

- Cai, D.; Jin, J.; Yusoh, K.; Rafiq, R.; Song, M. High performance polyurethane/functionalized graphene nanocomposites with improved mechanical and thermal properties. Compos. Sci. Technol. 2012, 72, 702–707. [Google Scholar] [CrossRef]

- Yang, R.; Zhang, Q.; Xiao, P.; Jun, W.; Bai, Y. Two opposite size effects of hardness at real nano-scale and their distinct origins. Sci. Rep. 2017, 7, 6053. [Google Scholar] [CrossRef] [PubMed]

- Gupta, T.K.; Singh, B.P.; Tripathi, R.K.; Dhakate, S.R.; Singh, V.N.; Panwar, O.S.; Mathur, R.B. Superior nano-mechanical properties of reduced graphene oxide reinforced polyurethane composites. RSC Adv. 2015, 5, 16921–16930. [Google Scholar] [CrossRef]

| Time, t (min) | Weight of Sample After Curing at a Time, t (g) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| PU | PU/PEG | PU/rGO | |||||||

| 0% CNF | 1% CNF | 3% CNF | 5% CNF | 0% CNF | 1% CNF | 3% CNF | 5% CNF | ||

| 1 | 1.08 | 1.08 | 1.09 | 1.14 | 1.06 | 1.11 | 1.14 | 1.21 | 1.10 |

| 2 | 1.85 | 1.86 | 1.89 | 1.94 | 1.77 | 1.91 | 1.99 | 2.08 | 1.82 |

| 3 | 2.06 | 2.07 | 2.16 | 2.21 | 1.96 | 2.12 | 2.27 | 2.36 | 2.01 |

| 4 | 2.21 | 2.22 | 2.30 | 2.35 | 2.14 | 2.28 | 2.42 | 2.51 | 2.20 |

| 5 | 2.36 | 2.37 | 2.41 | 2.46 | 2.30 | 2.43 | 2.53 | 2.63 | 2.37 |

| 6 | 2.46 | 2.47 | 2.50 | 2.55 | 2.40 | 2.53 | 2.63 | 2.73 | 2.47 |

| 7 | 2.52 | 2.53 | 2.56 | 2.61 | 2.46 | 2.60 | 2.69 | 2.79 | 2.53 |

| 8 | 2.52 | 2.53 | 2.56 | 2.61 | 2.46 | 2.60 | 2.69 | 2.79 | 2.53 |

| 9 | 2.52 | 2.53 | 2.56 | 2.61 | 2.46 | 2.60 | 2.69 | 2.79 | 2.53 |

| Sample | Tensile Strength (MPa) | Elongation (mm) | Young’s Modulus (MPa) | Max Depth (nm) | Hardness (MPa) |

|---|---|---|---|---|---|

| PU | 21.24 ± 0.21 | 3.50 ± 0.21 | 9.79 ± 0.15 | 3008 ± 15 | 32.7 ± 0.2 |

| PU-PEG | 22.93 ± 0.20 | 3.26 ± 0.14 | 9.74 ± 0.12 | 2538 ± 3 | 40.2 ± 0.2 |

| PU-1%CNF/PEG | 24.34 ± 0.19 | 3.14 ± 0.15 | 10.15 ± 0.12 | 2229 ± 11 | 52.8 ± 0.1 |

| PU-3%CNF/PEG | 26.30 ± 0.23 | 2.94 ± 0.19 | 10.78 ± 0.14 | 2185 ± 7 | 59.6 ± 0.3 |

| PU-5%CNF/PEG | 9.14 ± 0.16 | 1.76 ± 0.23 | 6.18 ± 0.09 | 2707 ± 5 | 32.5 ± 0.1 |

| PU-rGO | 23.15 ± 0.19 | 3.35 ± 0.23 | 10.43 ± 0.13 | 2502 ± 8 | 46.9 ± 0.2 |

| PU-1%CNF/rGO | 27.07 ± 0.30 | 3.14 ± 0.15 | 10.88 ± 0.16 | 2000 ± 12 | 74.4 ± 0.3 |

| PU-3%CNF/rGO | 29.16 ± 0.26 | 2.97 ± 0.21 | 12.41 ± 0.18 | 1934 ± 8 | 75.0 ± 0.2 |

| PU-5%CNF/rGO | 24.21 ± 0.21 | 3.25 ± 0.24 | 9.93 ± 0.12 | 2018 ± 6 | 68.2 ± 0.3 |

| PU-10%CNF/rGO | 5.94 ± 0.12 | 1.64 ± 0.32 | 3.44 ± 0.09 | 3419 ± 7 | 26.4 ± 0.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohan, D.; Sajab, M.S.; Kaco, H.; Bakarudin, S.B.; Mohamed Noor, A. 3D Printing of UV-Curable Polyurethane Incorporated with Surface-Grafted Nanocellulose. Nanomaterials 2019, 9, 1726. https://doi.org/10.3390/nano9121726

Mohan D, Sajab MS, Kaco H, Bakarudin SB, Mohamed Noor A. 3D Printing of UV-Curable Polyurethane Incorporated with Surface-Grafted Nanocellulose. Nanomaterials. 2019; 9(12):1726. https://doi.org/10.3390/nano9121726

Chicago/Turabian StyleMohan, Denesh, Mohd Shaiful Sajab, Hatika Kaco, Saiful Bahari Bakarudin, and An’amt Mohamed Noor. 2019. "3D Printing of UV-Curable Polyurethane Incorporated with Surface-Grafted Nanocellulose" Nanomaterials 9, no. 12: 1726. https://doi.org/10.3390/nano9121726

APA StyleMohan, D., Sajab, M. S., Kaco, H., Bakarudin, S. B., & Mohamed Noor, A. (2019). 3D Printing of UV-Curable Polyurethane Incorporated with Surface-Grafted Nanocellulose. Nanomaterials, 9(12), 1726. https://doi.org/10.3390/nano9121726