Influence of Annealing Temperature on Weak-Cavity Top-Emission Red Quantum Dot Light Emitting Diode

Abstract

:1. Introduction

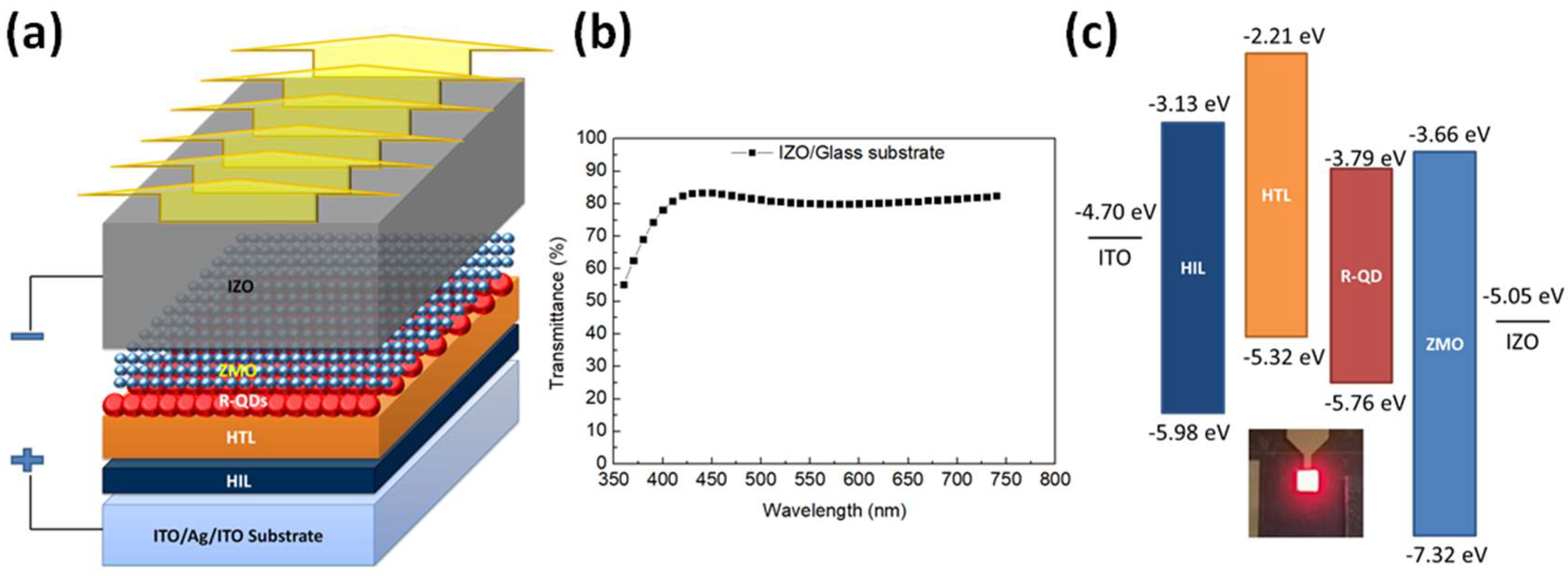

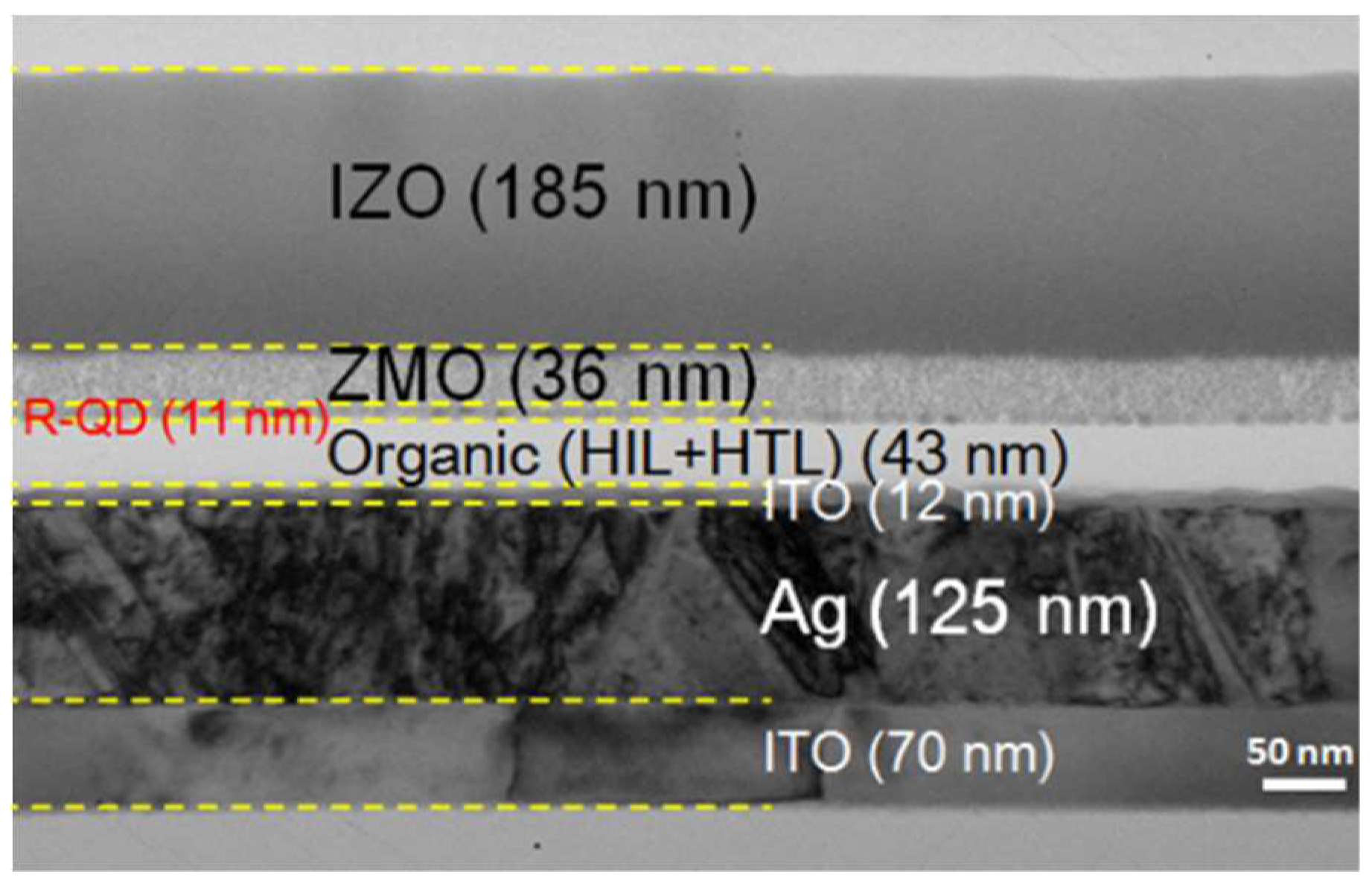

2. Materials and Methods

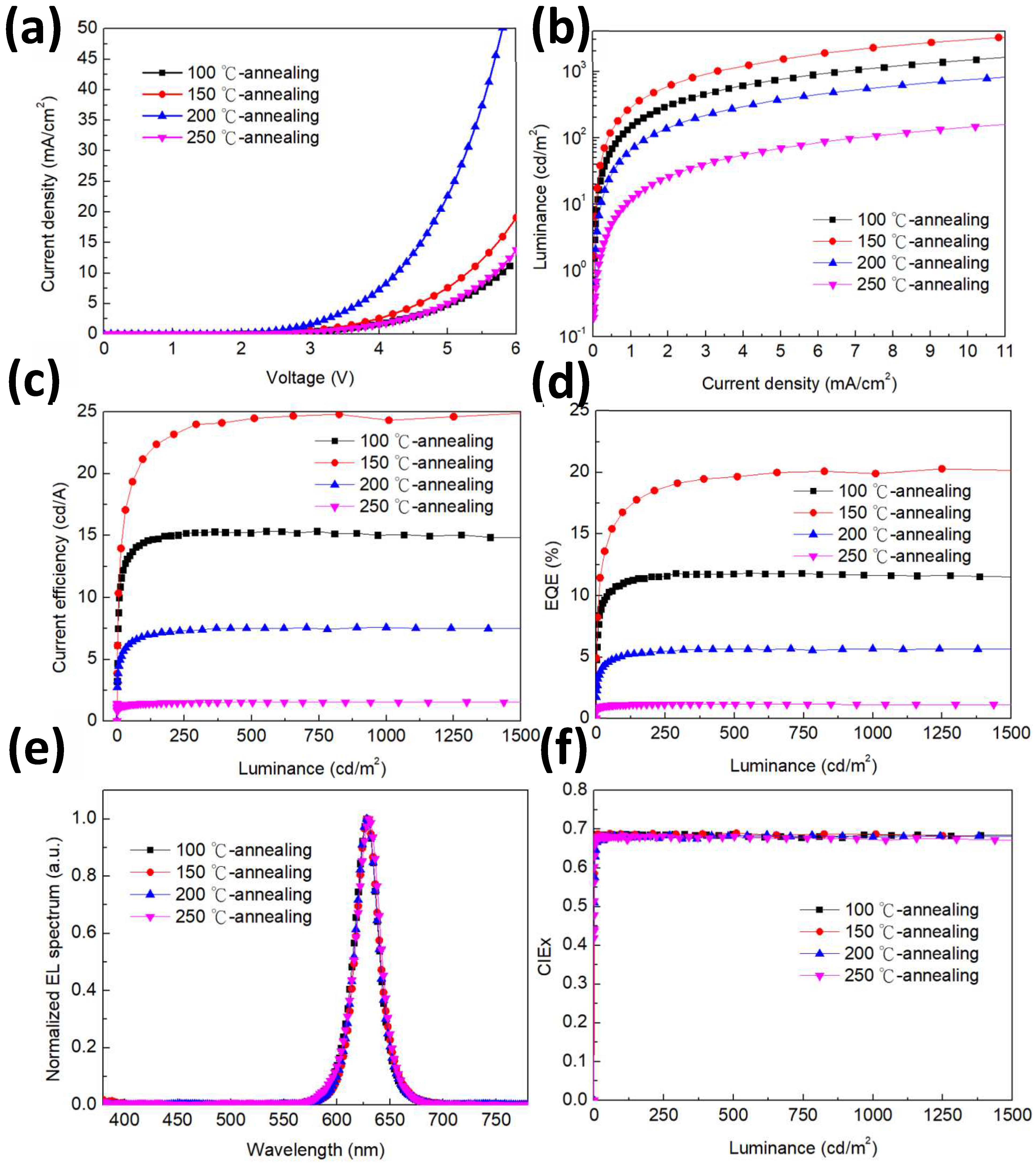

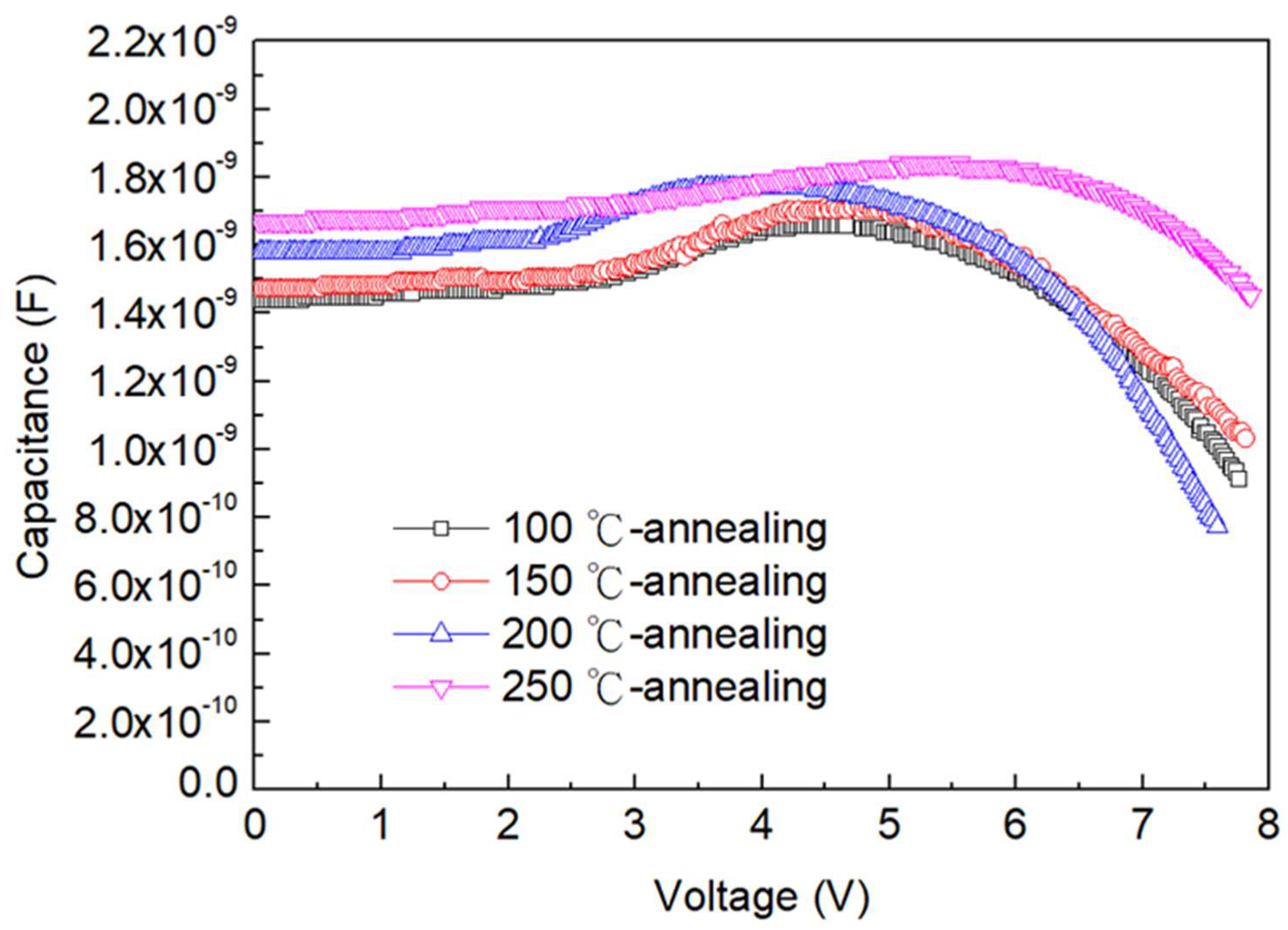

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pan, J.; Wei, C.; Wang, L.; Zhuang, J.; Huang, Q.; Su, W.; Nathan, A.; Lei, W.; Chen, J. Boosting the efficiency of inverted quantum dot light-emitting diodes by balancing charge densities and suppressing exciton quenching through band alignment. Nanoscale 2018, 10, 592–602. [Google Scholar] [CrossRef] [PubMed]

- Mashford, B.S.; Stevenson, M.; Popovic, Z.; Hamilton, C.; Zhou, Z.; Breen, C.; Steckel, J.; Bulovic, V.; Bawendi, M.; Coe-Sullivan, S.; et al. High-efficiency quantum-dot light-emitting devices with enhanced charge injection. Nat. Photonics 2013, 7, 407. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W.; Ji, W.; Yu, J.; Zhang, W.; Zhang, L.; Xie, W. Top-emitting quantum dots light-emitting devices employing microcontact printing with electricfield-independent emission. Sci. Rep. 2016, 6, 22530. [Google Scholar] [CrossRef] [PubMed]

- Liang, H.; Luo, Z.; Zhu, R.; Dong, Y.; Lee, J.H.; Zhou, J.; Wu, S.T. High efficiency quantum dot and organic LEDs with a back-cavity and a high index substrate. J. Phys. D Appl. Phys. 2016, 49, 145103. [Google Scholar] [CrossRef]

- Yang, X.; Dev, K.; Wang, J.; Mutlugun, E.; Dang, C.; Zhao, Y.; Liu, S.; Tang, Y.; Tan, S.T.; Sun, X.W.; et al. Light Extraction Efficiency Enhancement of Colloidal Quantum Dot Light-Emitting Diodes Using Large-Scale Nanopillar Arrays. Adv. Funct. Mater. 2014, 24, 5977–5984. [Google Scholar] [CrossRef]

- Wang, F.; Sun, W.; Liu, P.; Wang, Z.; Zhang, J.; Wei, J.; Li, Y.; Hayat, T.; Alsaedi, A.; Tan, Z. Achieving Balanced Charge Injection of Blue Quantum Dot Light-Emitting Diodes through Transport Layer Doping Strategies. J. Phys. Chem. Lett. 2019, 10, 960–965. [Google Scholar] [CrossRef]

- Small, C.E.; Tsang, S.W.; Kido, J.; So, S.K.; So, F. Origin of enhanced hole injection in inverted organic devices with electron accepting interlayer. Adv. Funct. Mater. 2012, 22, 3261–3266. [Google Scholar] [CrossRef]

- Frecker, T.; Bailey, D.; Arzeta-Ferrer, X.; McBride, J.; Rosenthal, S.J. Quantum dots and their application in lighting, displays, and biology. ECS J. Solid State Sci. Technol. 2016, 5, R3019–R3031. [Google Scholar] [CrossRef]

- Moon, H.; Lee, C.; Lee, W.; Kim, J.; Chae, H. Stability of Quantum Dots, Quantum Dot Films, and Quantum Dot Light-Emitting Diodes for Display Applications. Adv. Mater. 2019, 31, 1804294. [Google Scholar] [CrossRef]

- Bai, J.; Chang, C.; Wei, J.; Dong, C.; Peng, H.; Jin, X.; Zhang, Q.; Li, F.; Li, Q. High efficient light-emitting diodes with improved the balance of electron and hole transfer via optimizing quantum dot structure. Opt. Mater. Express 2019, 9, 3089–3097. [Google Scholar] [CrossRef]

- Su, Q.; Sun, Y.; Zhang, H.; Chen, S. Origin of Positive Aging in Quantum-Dot Light-Emitting Diodes. Adv. Sci. 2018, 5, 1800549. [Google Scholar] [CrossRef] [PubMed]

- Pan, J.; Chen, J.; Huang, Q.; Khan, Q.; Tao, X.L.Z.; Zhang, Z.; Lei, W.; Nathan, A. Size tunable ZnO nanoparticles to enhance electron injection in solution processed QLEDs. ACS Photonics 2016, 3, 215–222. [Google Scholar] [CrossRef]

- Wang, L.; Lv, Y.; Lin, J.; Fan, Y.; Zhao, J.; Wang, Y.; Liu, X. High-efficiency inverted quantum dot light-emitting diodes with enhanced hole injection. Nanoscale 2017, 9, 6748–6754. [Google Scholar] [CrossRef] [PubMed]

- Liang, F.; Liu, Y.; Hu, Y.; Shi, Y.; Liu, Y.; Wang, Z.; Wang, X.; Sun, B.; Liao, L. Polymer as an additive in the emitting layer for high-performance quantum dot light-emitting diodes. ACS Appl. Mater. Interfaces 2017, 9, 20239–20246. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Moon, J.; Cho, H.; Kwon, B.H.; Cho, N.S.; Lee, H. Partially pyridine-functionalized quantum dots for efficient red, green, and blue light-emitting diodes. J. Mater. Chem. C 2019, 7, 3429–3435. [Google Scholar] [CrossRef]

- Ippen, C.; Guo, W.; Zehnder, D.; Kim, D.; Manders, J.; Barrera, D.; Newmeyer, B.; Hamilton, D.; Wang, C.; Hotz, C.; et al. High efficiency heavy metal free QD-LEDs for next generation displays. J. Soc. Inf. Display 2019, 27, 338–346. [Google Scholar] [CrossRef]

- Chrzanowski, M.; Banski, M.; Sitarek, P.; Misiewicz, J.; Podhorodecki, A. Quantum-dot light-emitting diode with ultrathin Au electrode embedded in solution-processed phosphomolybdic acid. RSC Adv. 2019, 9, 10754–10759. [Google Scholar] [CrossRef]

- Chen, S.; Cao, W.; Liu, T.; Tsang, S.W.; Yang, Y.; Yan, X.; Qian, L. On the degradation mechanisms of quantum-dot light-emitting diodes. Nat. Commun. 2019, 10, 765. [Google Scholar] [CrossRef]

- Li, X.; Zhao, Y.B.; Fan, F.; Levina, L.; Liu, M.; Quintero-Bermudez, R.; Gong, X.; Quan, L.N.; Fan, J.; Yang, Z.; et al. Bright colloidal quantum dot light-emitting diodes enabled by efficient chlorination. Nat. Photonics 2018, 12, 159. [Google Scholar] [CrossRef]

- Qian, L.; Zheng, Y.; Xue, J.; Holloway, P.H. Stable and efficient quantum-dot light-emitting diodes based on solution-processed multilayer structures. Nat. Photonics 2011, 5, 543. [Google Scholar] [CrossRef]

- Cao, W.; Xiang, C.; Yang, Y.; Chen, Q.; Chen, L.; Yan, X.; Qian, L. Highly stable QLEDs with improved hole injection via quantum dot structure tailoring. Nat. Commun. 2018, 9, 2608. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Lin, J.; Wang, L.; Lv, Y.; Hu, Y.; Fan, Y.; Guo, X.; Zhao, J.; Wang, Y.; Liu, X. High performance, top-emitting, quantum dot light-emitting diodes with all solution-processed functional layers. J. Mater. Chem. C 2017, 5, 9138–9145. [Google Scholar] [CrossRef]

- Kang, J.; Jeong, W.; Kim, J.; Kim, H.; Kim, D.; Lee, G. High-Performance Flexible Organic Light-Emitting Diodes Using Amorphous Indium Zinc Oxide Anode. Electrochem. Solid State Lett. 2007, 10, J75–J78. [Google Scholar] [CrossRef]

- Kim, H.; Lee, K.; Kwon, J.H. Transparent indium zinc oxide top cathode prepared by plasma damage-free sputtering for top-emitting organic light-emitting diodes. Appl. Phys. Lett. 2006, 88, 012103. [Google Scholar] [CrossRef]

| Weak-Cavity Top-Emission R-QLED | x | y | Peak | FWHM | VT | CE (ηA) | EQE (ηEQE) |

|---|---|---|---|---|---|---|---|

| - | - | nm | nm | V [1 cd/m2] | cd/A | % | |

| 100 °C-annealing | 0.684 | 0.311 | 628 | 26 | 1.9 | 15.1 | 11.6 |

| 150 °C-annealing | 0.687 | 0.307 | 628 | 26 | 1.9 | 24.8 | 20.1 |

| 200 °C-annealing | 0.680 | 0.313 | 628 | 25 | 1.8 | 7.6 | 5.7 |

| 250 °C-annealing | 0.671 | 0.313 | 628 | 27 | 2.6 | 1.5 | 1.2 |

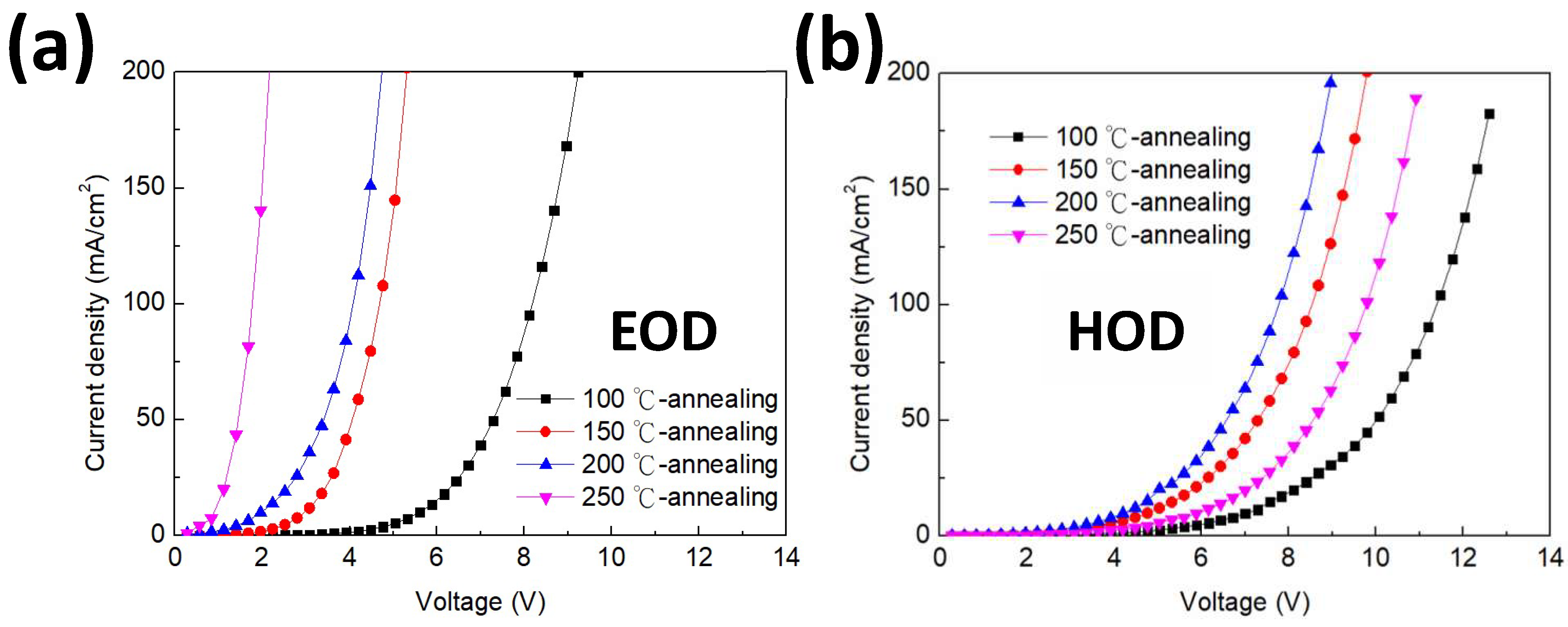

| Unit: cm2 V−1 s−1 | 100 °C-annealing | 150 °C-annealing | 200 °C-annealing | 250 °C-annealing |

|---|---|---|---|---|

| Electron Mobility (μe) | 2.1 × 10−7 | 1.2 × 10−6 | 2.5 × 10−6 | 9.4 × 10−6 |

| Hole Mobility (μh) | 4.2 × 10−9 | 9.8 × 10−8 | 1.2 × 10−7 | 4.2 × 10−9 |

| μe/μh | 50.0 | 12.2 | 20.8 | 2238.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-Y.; Kuo, Y.-P.; Chen, P.-Y.; Lu, H.-H.; Lin, M.Y. Influence of Annealing Temperature on Weak-Cavity Top-Emission Red Quantum Dot Light Emitting Diode. Nanomaterials 2019, 9, 1639. https://doi.org/10.3390/nano9111639

Lee C-Y, Kuo Y-P, Chen P-Y, Lu H-H, Lin MY. Influence of Annealing Temperature on Weak-Cavity Top-Emission Red Quantum Dot Light Emitting Diode. Nanomaterials. 2019; 9(11):1639. https://doi.org/10.3390/nano9111639

Chicago/Turabian StyleLee, Chun-Yu, Ya-Pei Kuo, Peng-Yu Chen, Hsieh-Hsing Lu, and Ming Yi Lin. 2019. "Influence of Annealing Temperature on Weak-Cavity Top-Emission Red Quantum Dot Light Emitting Diode" Nanomaterials 9, no. 11: 1639. https://doi.org/10.3390/nano9111639

APA StyleLee, C.-Y., Kuo, Y.-P., Chen, P.-Y., Lu, H.-H., & Lin, M. Y. (2019). Influence of Annealing Temperature on Weak-Cavity Top-Emission Red Quantum Dot Light Emitting Diode. Nanomaterials, 9(11), 1639. https://doi.org/10.3390/nano9111639