Effect of Functionalized Graphene Nanoplatelets on the Delamination-Buckling and Delamination Propagation Resistance of 3D Fiber-Metal Laminates Under Different Loading Rates

Abstract

1. Introduction

2. Materials and Methods

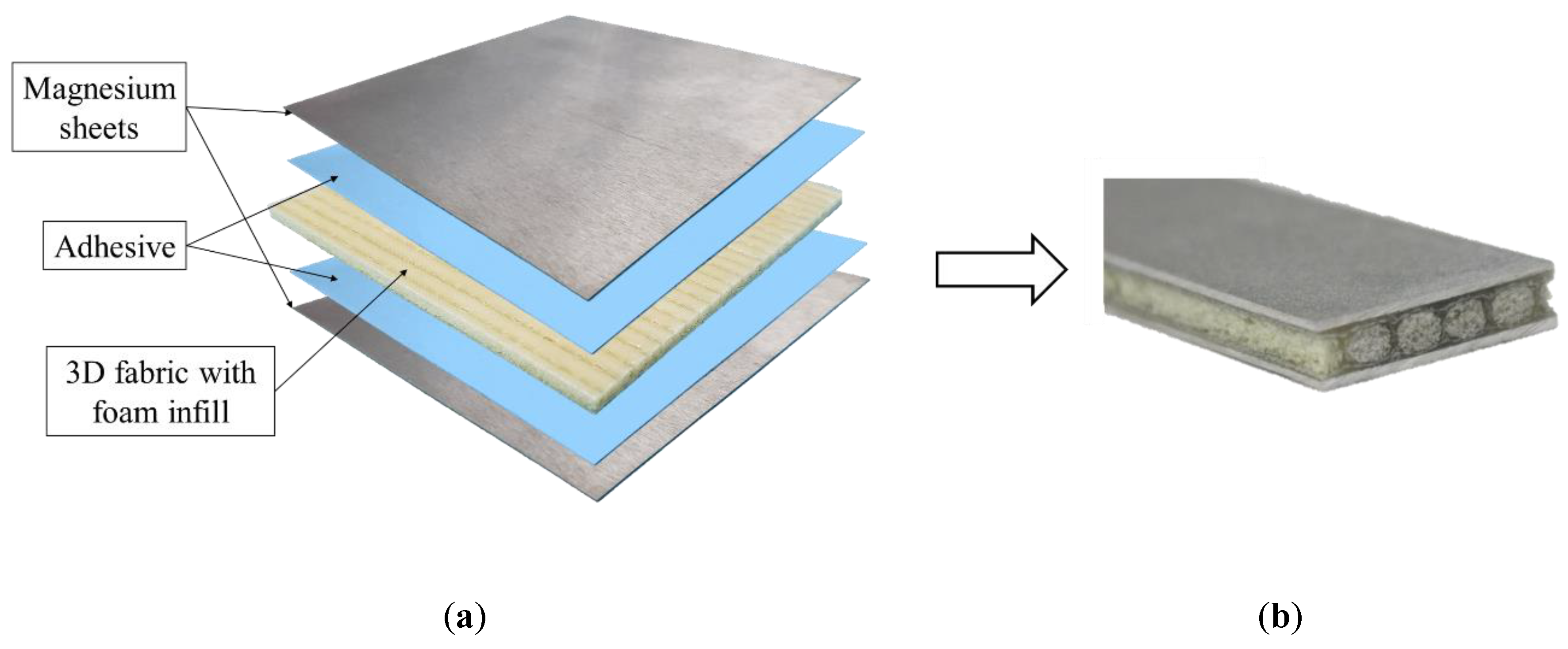

2.1. Materials

2.2. Specimen’s Fabrication

- (i)

- in the first method (referred to as SB, hereafter), the hot-cure resin was directly applied onto the substrates (skins and core), and then the resulting sandwich was vacuum bagged and cured for two hours at 60 °C and eight hours at 120 °C.

- (ii)

- in the second method (referred to as SBC, hereafter), the magnesium bonding surfaces were pre-coated with a thin layer of cold-cure resin, cured for 24 h under vacuum. In a second step, another layer of cold-cure resin was applied to both adherends and they were sealed under vacuum and let cure at room temperature for 24 h. This second method was developed by the authors and the resulting gain in the interface bond strength under different loading conditions, including axial impact loading, was reported in [67].

2.3. Testing Apparatus, Procedures and Data Acquisition

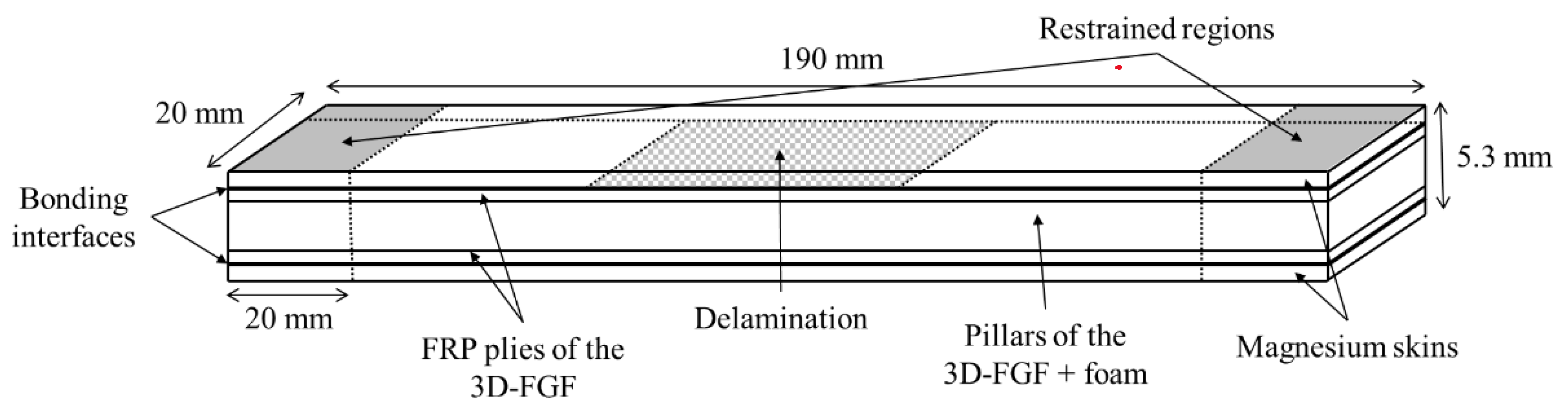

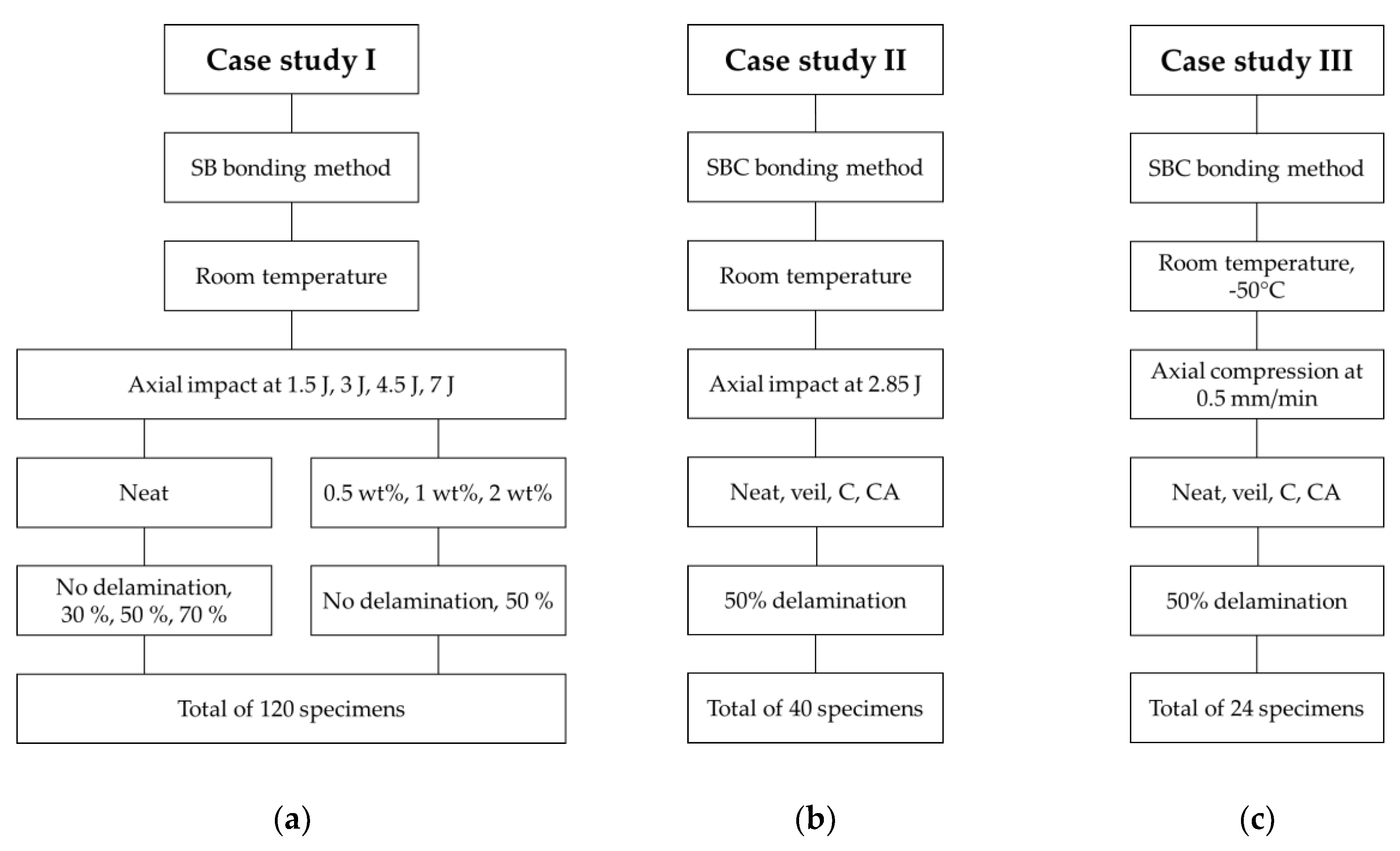

2.3.1. Case Studies I

2.3.2. Case Study II

- (i)

- included only in the resin used to coat the magnesium skins was reinforced with the GNPs (these specimens are identified as “C” specimens);

- (ii)

- included in the resin used to coat the skins and in the resin used for bonding the skins to FRP were both reinforced with the GNPs (specimens of this category are identified by “CA”).

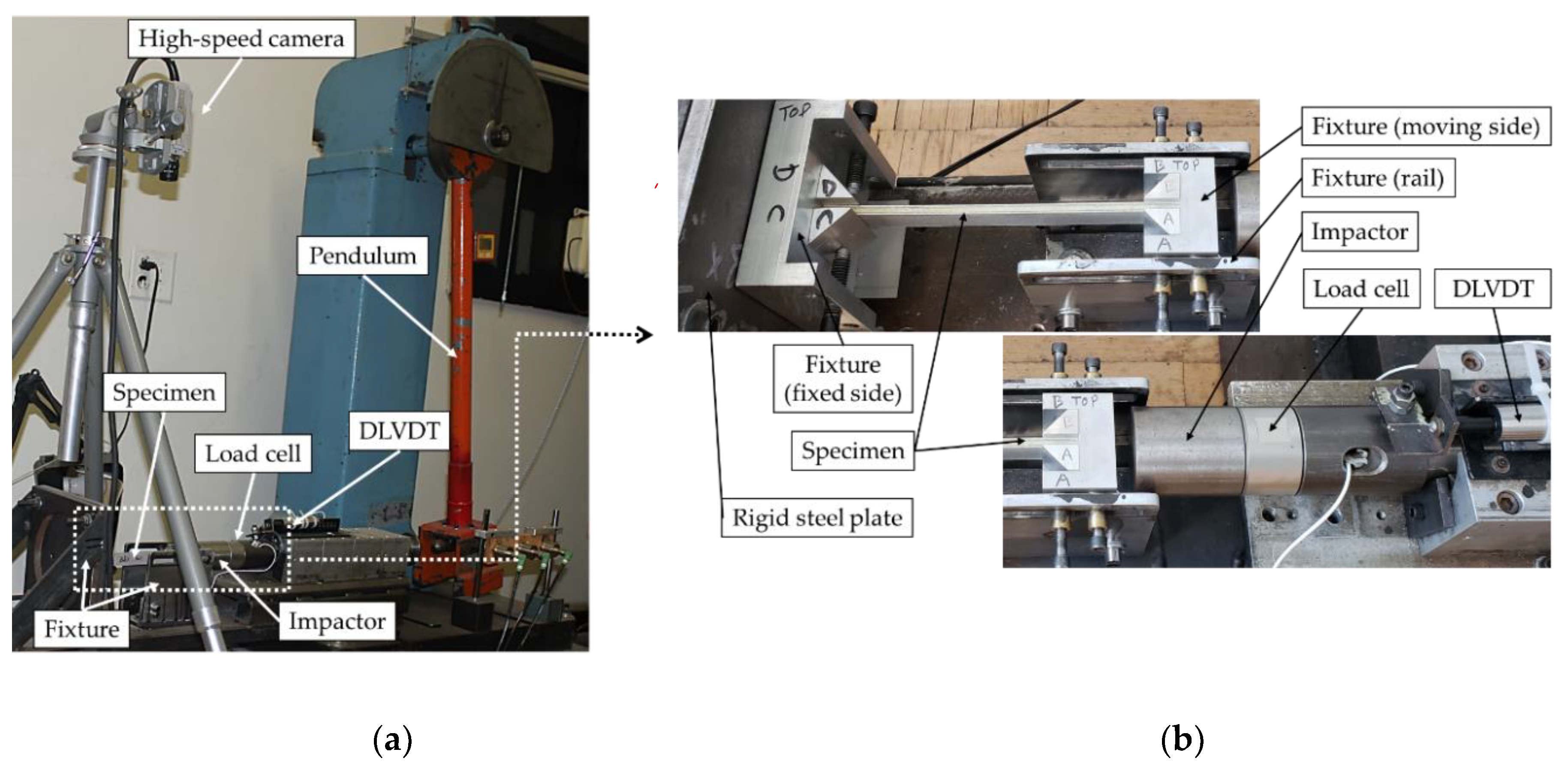

2.3.3. Impact Testing Apparatus

2.3.4. Case Study III

2.4. Data Processing

3. Results and Discussion

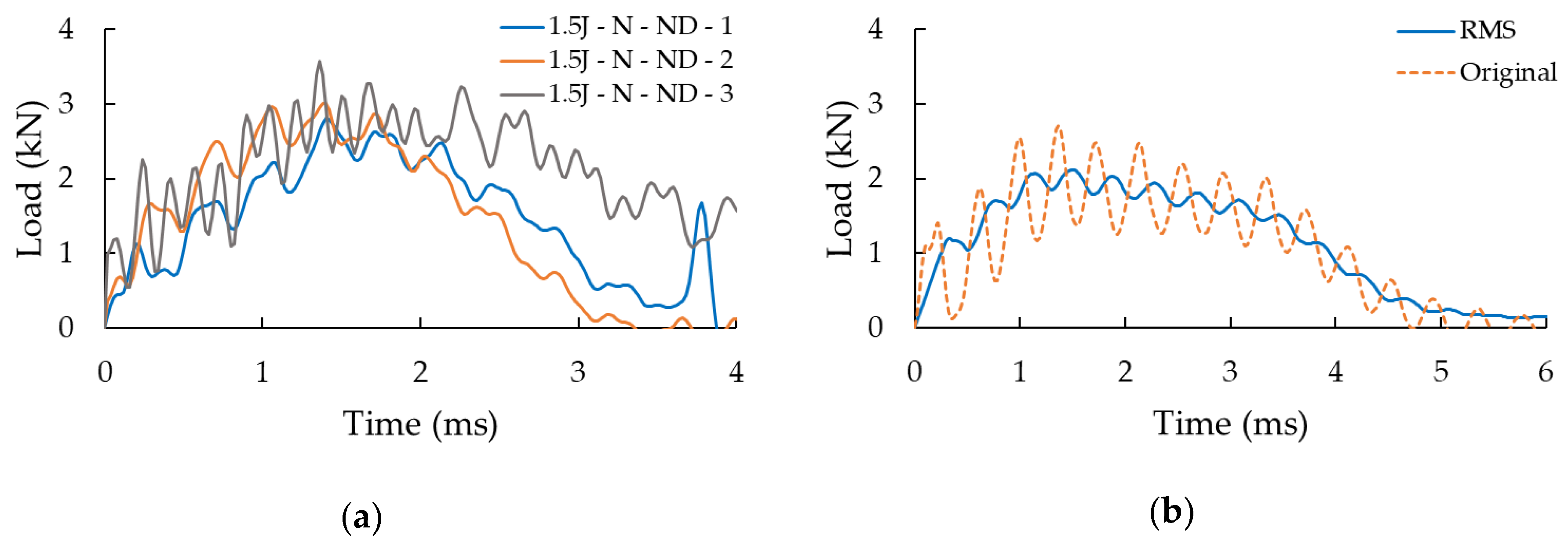

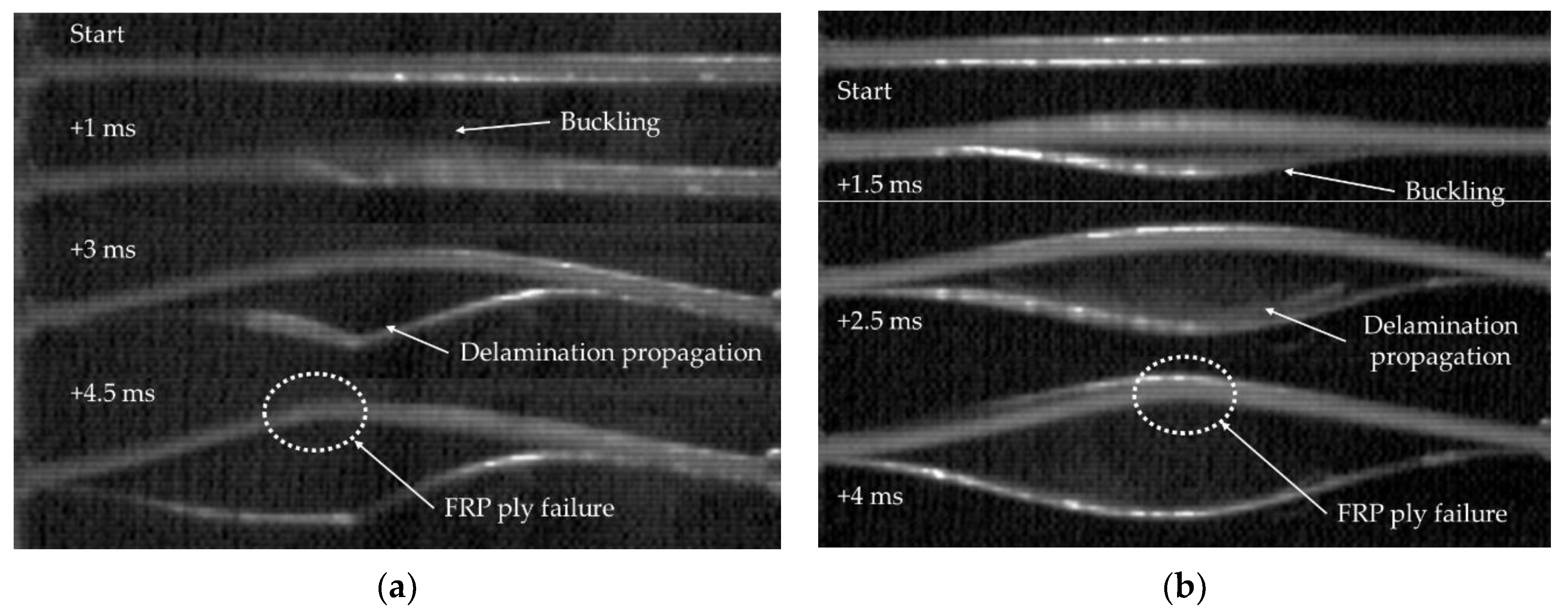

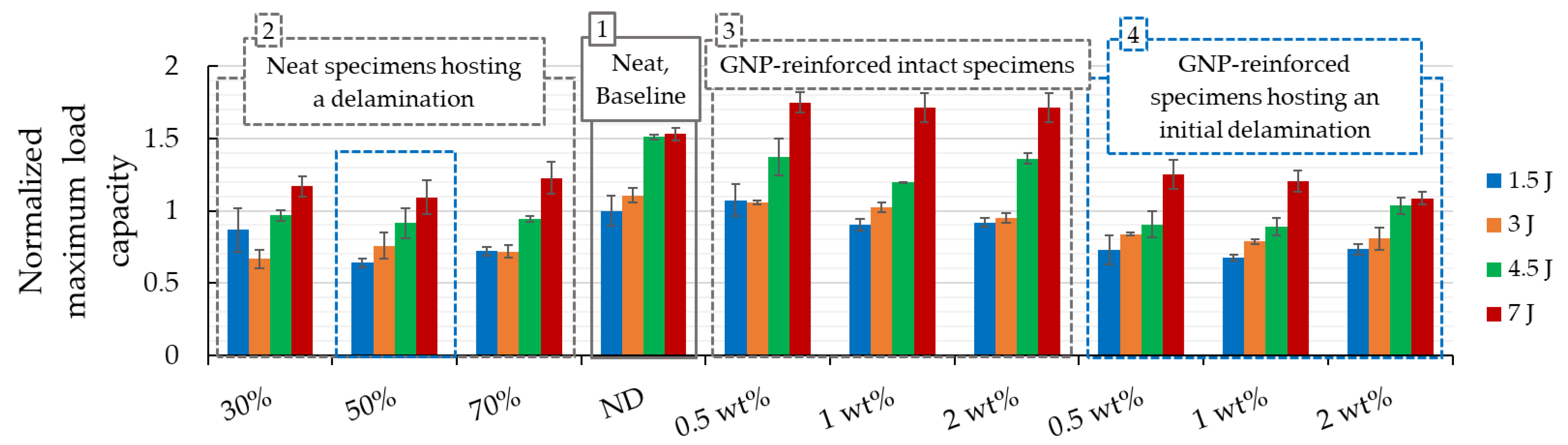

3.1. Case Study I

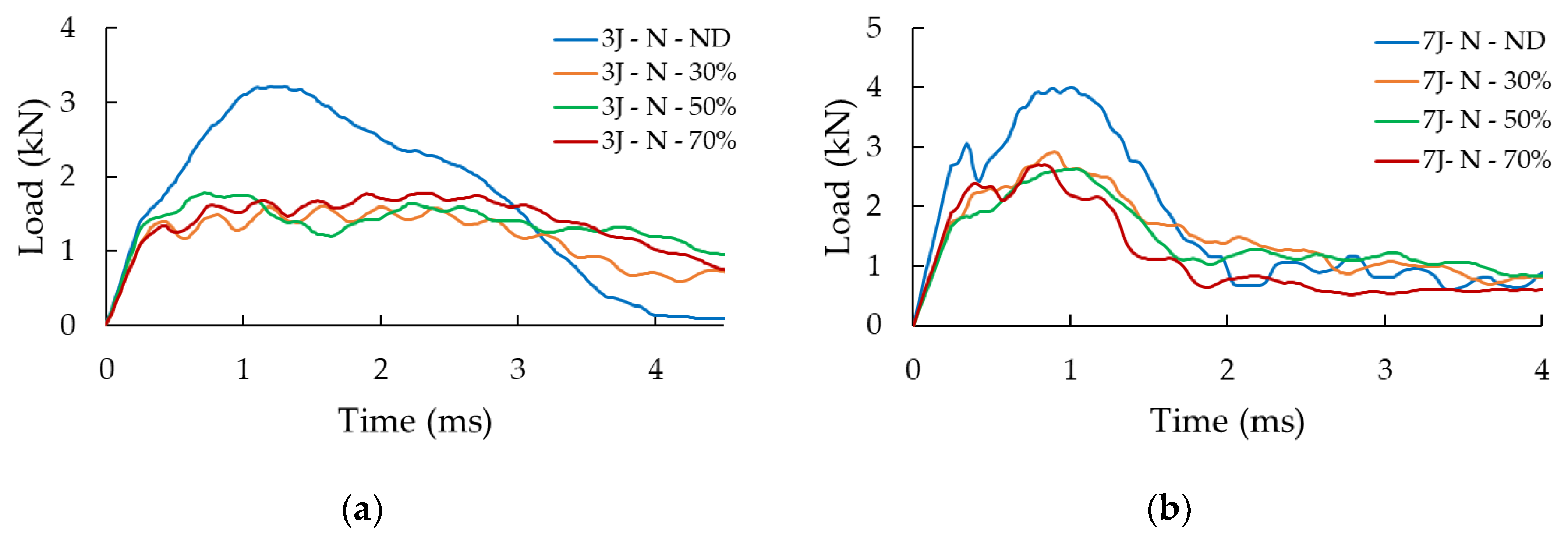

3.2. Case Study II

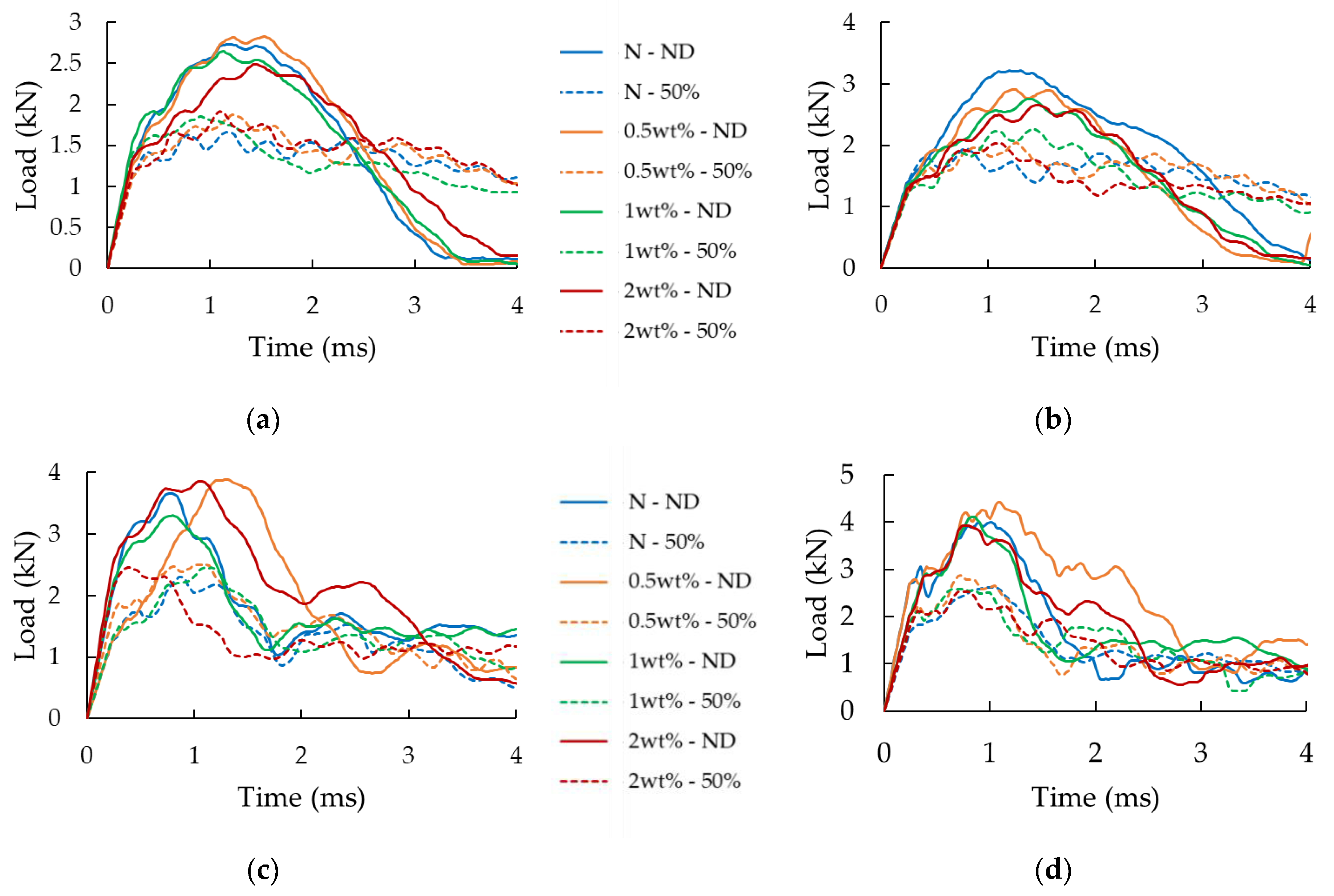

3.3. Case Study III

4. Summary and Conclusions

- The presence of initial delamination greatly affected the load-bearing capacity of the specimens, but its length had a negligible effect.

- For the intact specimens (i.e., with no initial delamination), the incorporation of GNPs showed its maximum enhancing effect when the specimens were subjected to the highest impact energy (7 J). The observed enhancements were 12.5%, 10.9%, and 10.7% corresponding to GNP contents of 0.5 wt%, 1 wt%, and 2 wt%, respectively. Ironically, a degradation of the strength was noted in specimens that were subjected to 4.5 J impact energy.

- Among the specimens that hosted a delamination, the specimens that were reinforced with 0.5 wt% of GNP content exhibited the most gain in strength under three out of the four impact energies tried. The exceptions were the specimens that were subjected to 4.5 J impact energy, for which 2 wt% GNP content produced the best results.

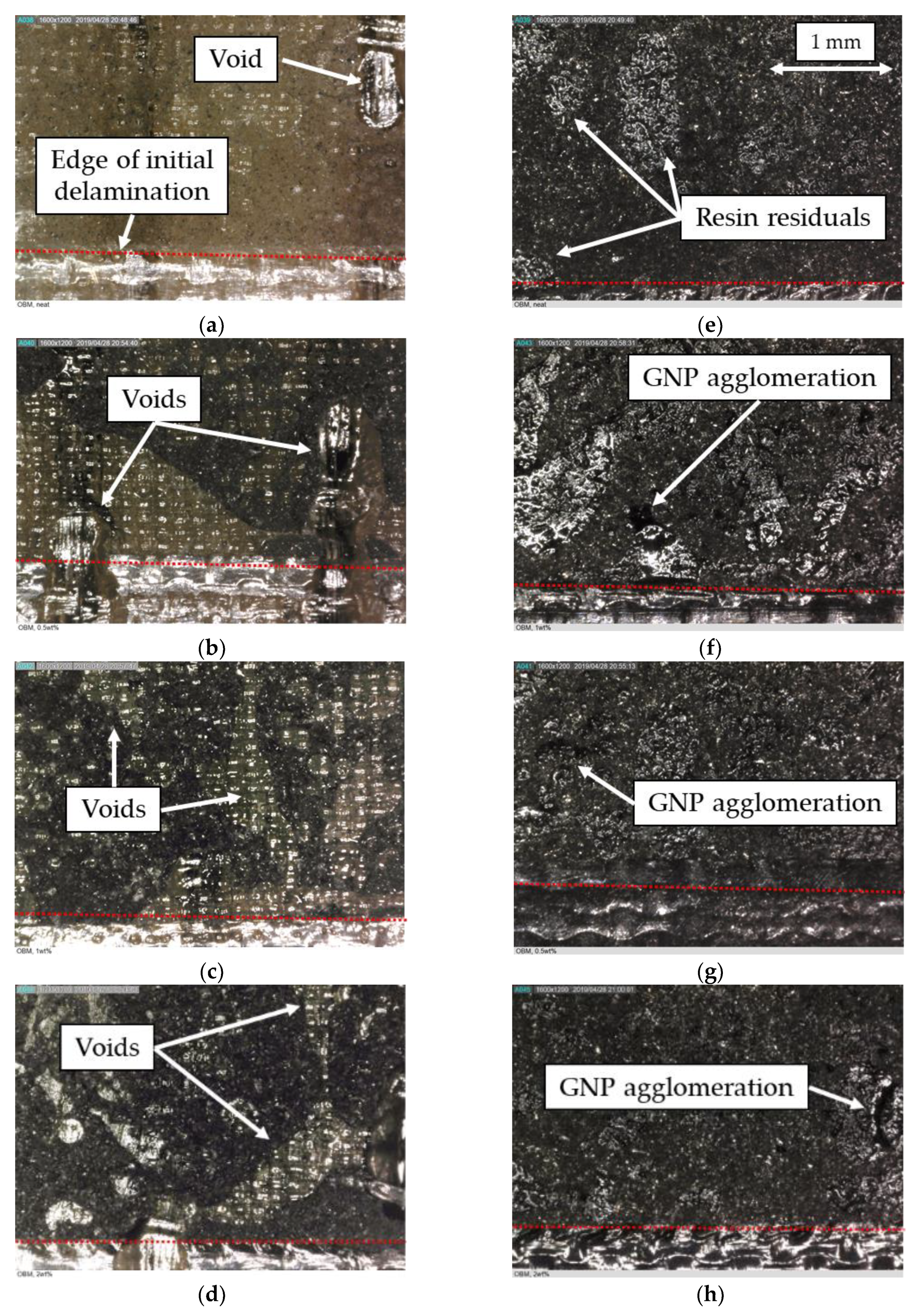

- Microscopic examination revealed the existence of some voids at the bonding interface of the 3D-FMLs.

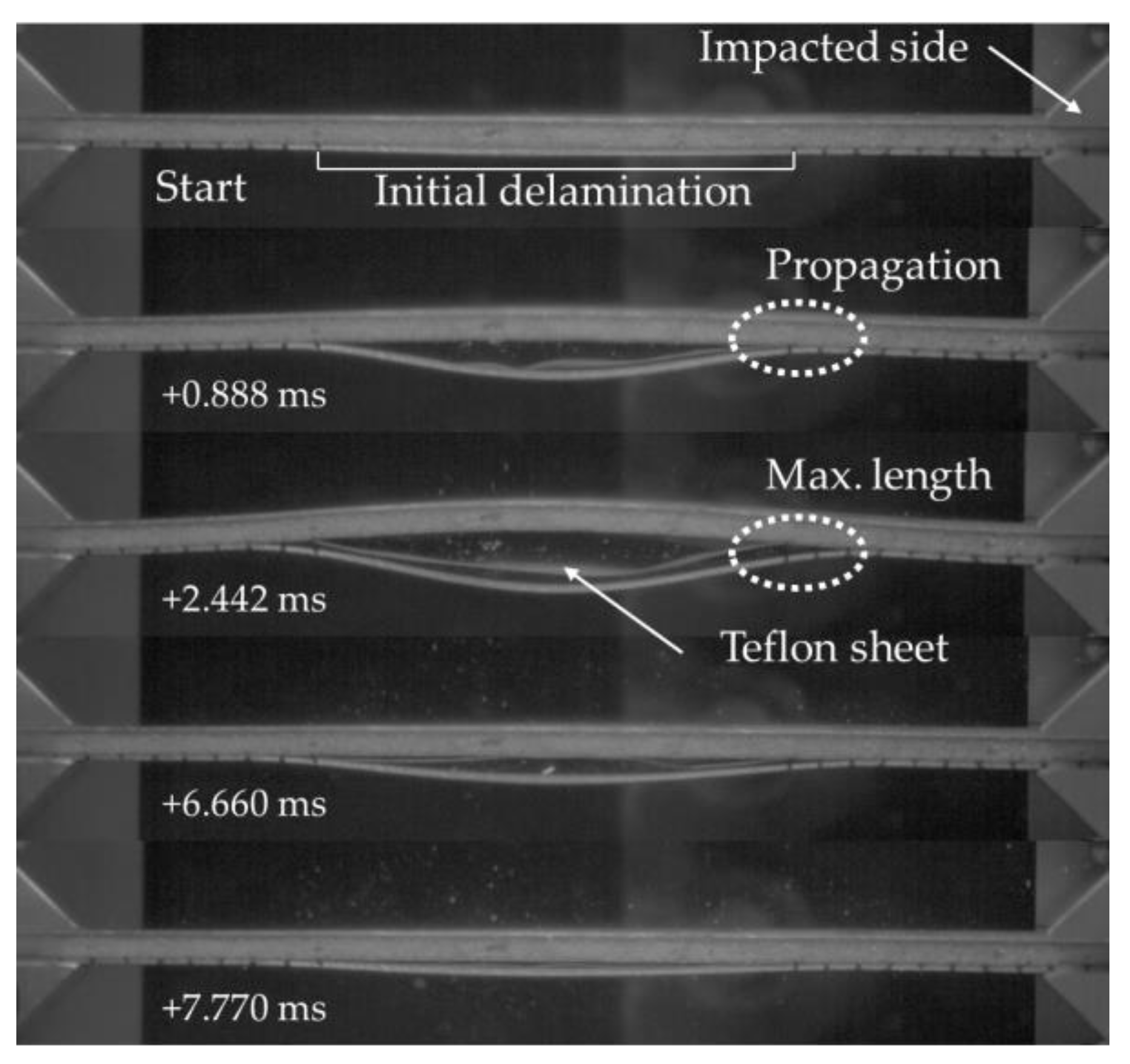

- The delamination propagated in an unstable manner.

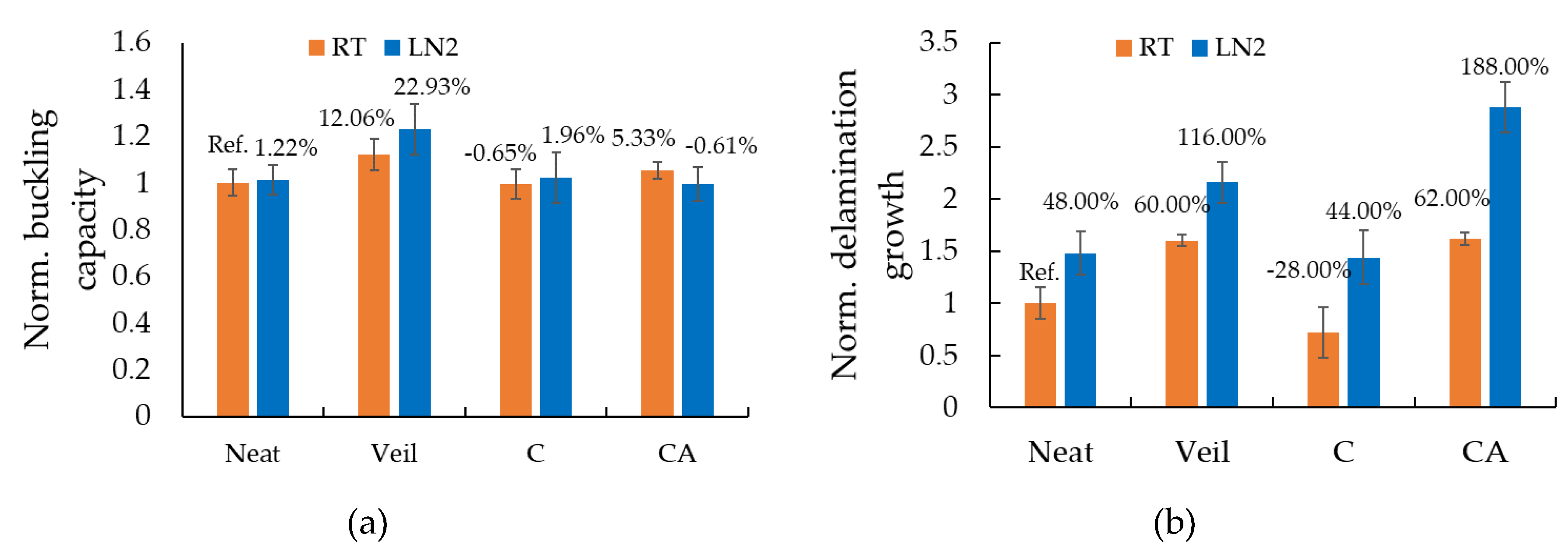

- A higher GNP content led to a higher delamination length, with a 100% increase in delamination growth observed in the CA specimens.

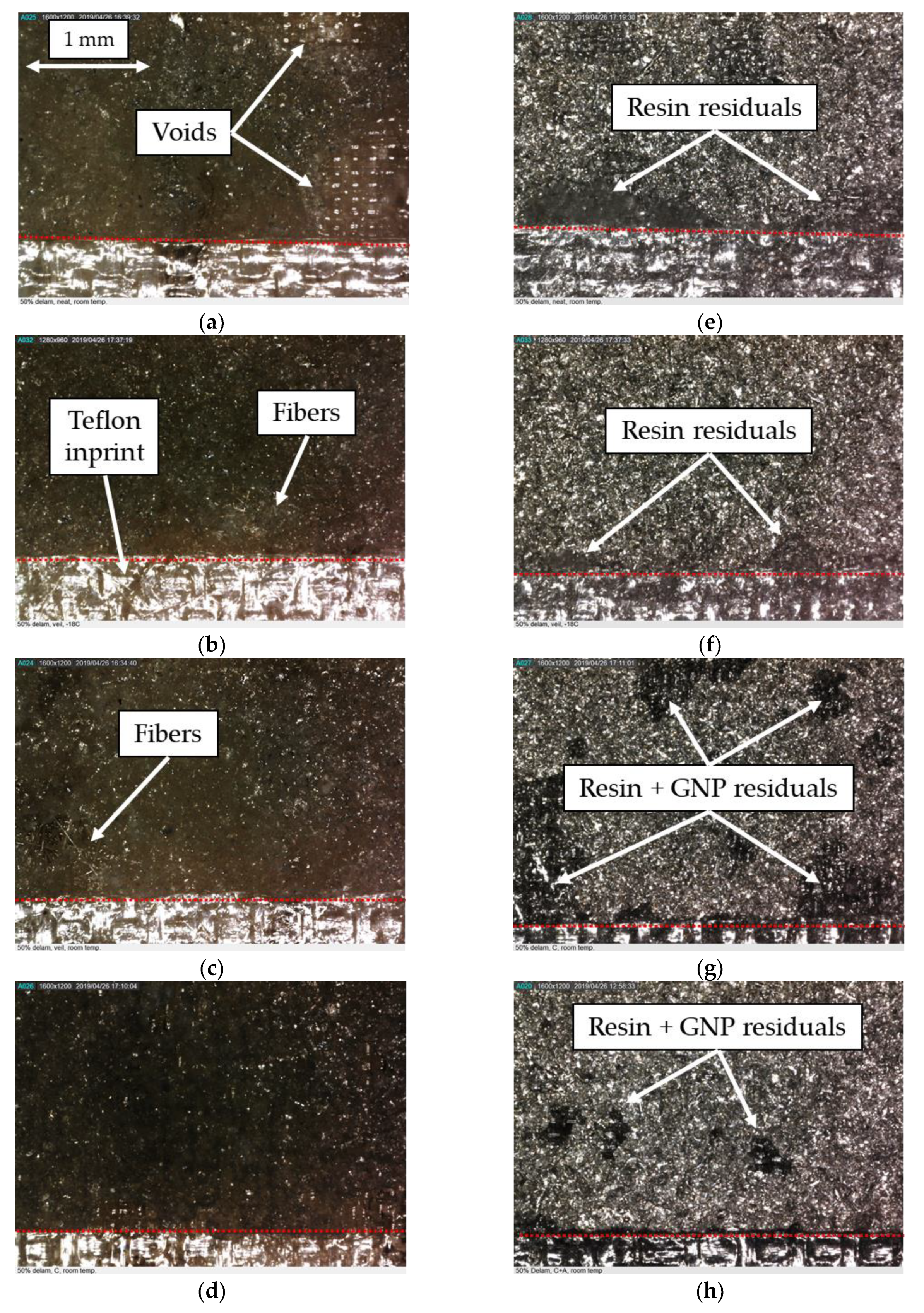

- The use of a fiberglass veil interleaved between the magnesium and the FRP core mitigated the delamination extension by an average of 46% and increased the load-bearing capacity by 6%.

- The GNPs inclusion produced either no effect on the load capacity of most specimens or led to even negative effect in some (a reduction of 8% was observed in the CA specimens).

- The void content in the bonding region was drastically reduced when the SBC method was employed and voids were completely nullified when the veil or GNPs were incorporated within the interface; nonetheless, the delamination growth persisted owing to the lack of optimal chemical compatibility between magnesium and epoxy resin.

- The specimens’ apparent stiffness changed marginally when exposed to the sub-freezing temperature.

- The buckling load capacity was positively affected by the sub-freezing temperature, especially when the veil was used.

- The sub-freezing environment caused an increase in delamination growth, especially in the GNP-reinforced specimens.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations and Acronyms

| 3D-FGF | 3D fiberglass fabric |

| 3D-FML | 3D fiber-metal laminate |

| C | nanoparticles included in the coating |

| CA | nanoparticles included in the coating and the adhesive |

| CNT | carbon nano-tubes |

| FML | fiber-metal laminate |

| FRP | fiber-reinforced polymer |

| GNP | graphene nanoplatelets |

| LN2 | liquid nitrogen |

| N | specimens with neat resin |

| ND | no initial delamination |

| NP | nanoparticles |

| RMS | root-mean square |

| RT | room temperature |

| V | fiberglass veil |

| wt% | weight percentage |

| x% | percentage of initial delamination |

| Note | “s” following above acronyms make them plural |

References

- Kim, J.T.; Hong, S.H.; Park, H.J.; Kim, Y.S.; Suh, J.Y.; Lee, J.K.; Park, J.M.; Maity, T.; Eckert, J.; Kim, K.B. Deformation mechanisms to ameliorate the mechanical properties of novel TRIP/TWIP Co-Cr-Mo-(Cu) ultrafine eutectic alloys. Sci. Rep. 2017, 7, 39959. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.T.; Hong, S.H.; Park, H.J.; Park, G.H.; Suh, J.Y.; Park, J.M.; Kim, K.B. Influence of microstructural evolution on mechanical behavior of Fe-Nb-B ultrafine composites with a correlation to elastic modulus and hardness. J. Alloys Compd. 2015, 647, 886–891. [Google Scholar] [CrossRef]

- Asaee, Z.; Shadlou, S.; Taheri, F. Low-velocity impact response of fiberglass/magnesium FMLs with a new 3D fiberglass fabric. Compos. Struct. 2015, 122, 155–165. [Google Scholar] [CrossRef]

- Asaee, Z.; Taheri, F. Experimental and numerical investigation into the influence of stacking sequence on the low-velocity impact response of new 3D FMLs. Compos. Struct. 2016, 140, 136–146. [Google Scholar] [CrossRef]

- De Cicco, D.; Taheri, F. Delamination Buckling Response of 3D Fiber-Metal Laminates Subjected to Different Loading Rates. In Proceedings of the American Society for Composites: Thirty-First Technical Conference, Williamsburg, VA, USA, 19–23 September 2016; DEStech Publications, Inc.: Lancaster, PA, USA, 2016; p. 12. [Google Scholar]

- De Cicco, D.; Taheri, F. Robust numerical approaches for simulating the buckling response of 3D fiber-metal laminates under axial impact—Validation with experimental results. J. Sandw. Struct. Mater. 2018. [Google Scholar] [CrossRef]

- De Cicco, D.; Taheri, F. Understanding the parameters that influence buckling of 3D fiber-metal laminates. In Proceedings of the 10th Canadian-International Conference on Composites (CANCOM2017), Ottawa, ON, Canada, 17–20 July 2017. [Google Scholar]

- Shahid, M.; Hashim, S.A. Effect of surface roughness on the strength of cleavage joints. Int. J. Adhes. Adhes. 2002, 22, 235–244. [Google Scholar] [CrossRef]

- Baldan, A. Adhesively-bonded joints and repairs in metallic alloys, polymers and composite materials: Adhesives, adhesion theories and surface pretreatment. J. Mater. Sci. 2004, 39, 1–49. [Google Scholar] [CrossRef]

- Harris, A.F.; Beevers, A. The ffects of grit-blasting on surface properties for adhesion. Int. J. Adhes. Adhes. 1999, 19, 445–452. [Google Scholar] [CrossRef]

- Williams, T.S. Surface Modification by Atmospheric Pressure Plasma for Improved Bonding; University of California: Los Angeles, CA, USA, 2013. [Google Scholar]

- Gonzalez, E.; Hicks, R.F. Surface Analysis of Polymers Treated by Remote Atmospheric Pressure Plasma. Langmuir 2009, 26, 3710–3719. [Google Scholar] [CrossRef]

- Livadifiis, G.J. A chemical etching system for creating micromechanical retention in resin-bonded retainers. J. Prosthet. Dent. 1986, 56, 181–188. [Google Scholar] [CrossRef]

- Lefebvre, D.R.; Ahn, B.K.; Dillard, D.A.; Dillard, J.G. The effect of surface treatments on interfacial fatigue crack initiation in aluminum/epoxy bonds. Int. J. Fract. 2002, 114, 191–202. [Google Scholar] [CrossRef]

- Wang, B.; Hu, X.; Lu, P. Improvement of adhesive bonding of grit-blasted steel substrates by using diluted resin as a primer. Int. J. Adhes. Adhes. 2017, 73, 92–99. [Google Scholar] [CrossRef]

- Javni, I.; Zhang, W.; Karajkov, V.; Petrovic, Z.S.; Divjakovic, V. Effect of Nano- and Micro-Silica Fillers on Polyurethane Foam Properties. J. Cell. Plast. 2002, 38, 229–239. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Zheng, Y.X.; Zeng, H.M.; Friedrich, K. Improvement of tensile properties of nano-SiO2/PP composites in relation to percolation mechanism. Polymer (Guildf.) 2001, 42, 3301–3304. [Google Scholar] [CrossRef]

- Jalili, M.M.; Moradian, S.; Dastmalchian, H.; Karbasi, A. Investigating the variations in properties of 2-pack polyurethane clear coat through separate incorporation of hydrophilic and hydrophobic nano-silica. Prog. Org. Coat. 2007, 59, 81–87. [Google Scholar] [CrossRef]

- Ji, G.; Li, G. Effects of nanoclay morphology on the mechanical, thermal, and fire-retardant properties of vinyl ester based nanocomposite. Mater. Sci. Eng. A 2008, 498, 327–334. [Google Scholar] [CrossRef]

- Park, J.H.; Jana, S.C. The relationship between nano-and micro-structures and mechanical properties in PMMA–epoxy–nanoclay composites. Polymer (Guildf.) 2003, 44, 2091–2100. [Google Scholar] [CrossRef]

- Mohan, T.P.; Kanny, K. Water barrier properties of nanoclay filled sisal fibre reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 385–393. [Google Scholar] [CrossRef]

- Dzenis, Y.A.; Reneker, D.H. Delamination Resistant Composites Prepared by Small Diameter Fiber Reinforcement at Ply Interfaces. US Patent Number 6,265,333, 24 July 2001. [Google Scholar]

- van der Heijden, S.; De Bruycker, K.; Simal, R.; Du Prez, F.; De Clerck, K. Use of Triazolinedione Click Chemistry for Tuning the Mechanical Properties of Electrospun SBS-Fibers. Macromolecules 2015, 48, 6474–6481. [Google Scholar] [CrossRef]

- Kucheryavy, P.; He, J.; John, V.T.; Maharjan, P.; Spinu, L.; Goloverda, G.Z.; Kolesnichenko, V.L. Superparamagnetic iron oxide nanoparticles with variable size and an iron oxidation state as prospective imaging agents. Langmuir 2013, 29, 710–716. [Google Scholar] [CrossRef]

- Sardana, S.K.; Chava, V.S.N.; Thouti, E.; Chander, N.; Kumar, S.; Reddy, S.R.; Komarala, V.K. Influence of surface plasmon resonances of silver nanoparticles on optical and electrical properties of textured silicon solar cell. Appl. Phys. Lett. 2014, 104, 073903. [Google Scholar] [CrossRef]

- Chou, C.-W.; Hsu, S.-H.; Chang, H.; Tseng, S.-M.; Lin, H.-R. Enhanced thermal and mechanical properties and biostability of polyurethane containing silver nanoparticles. Polym. Degrad. Stab. 2006, 91, 1017–1024. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.H.; Vahid, S. Improving the fracture toughness and the strength of epoxy using nanomaterials—A review of the current status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef] [PubMed]

- Borowski, E.; Soliman, E.; Kandil, U.F.; Taha, M.R. Interlaminar Fracture Toughness of CFRP Laminates Incorporating Multi-Walled Carbon Nanotubes. Polymers (Basel) 2015, 7, 1020–1045. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Seidel, C.; Schulte, K. Preparation and characterization of graphite nano-platelet (GNP)/epoxy nano-composite: Mechanical, electrical and thermal properties. Eur. Polym. J. 2013, 49, 3878–3888. [Google Scholar] [CrossRef]

- Eskizeybek, V.; Avci, A.; Gülce, A. The Mode I interlaminar fracture toughness of chemically carbon nanotube grafted glass fabric/epoxy multi-scale composite structures. Compos. Part A Appl. Sci. Manuf. 2014, 63, 94–102. [Google Scholar] [CrossRef]

- Wang, P.; Liu, W.; Zhang, X.; Lu, X.; Yang, J. Enhanced fracture toughness of carbon fabric/epoxy laminates with pristine and functionalized stacked-cup carbon nanofibers. Eng. Fract. Mech. 2015, 148, 73–81. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Ghoreishi, S.M.; Esmkhani, M.; Zhao, Z. Effects of graphene nanoplatelets and graphene nanosheets on fracture toughness of epoxy nanocomposites. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1116–1123. [Google Scholar] [CrossRef]

- Alishahi, E.; Shadlou, S.; Doagou-R, S.; Ayatollahi, M.R. Effects of carbon nanoreinforcements of different shapes on the mechanical properties of epoxy-based nanocomposites. Macromol. Mater. Eng. 2013, 298, 670–678. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Shadlou, S.; Shokrieh, M.M.; Chitsazzadeh, M. Effect of multi-walled carbon nanotube aspect ratio on mechanical and electrical properties of epoxy-based nanocomposites. Polym. Test. 2011, 30, 548–556. [Google Scholar] [CrossRef]

- Shen, M.-Y.; Chang, T.-Y.; Hsieh, T.-H.; Li, Y.-L.; Chiang, C.-L.; Yang, H.; Yip, M.-C. Mechanical Properties and Tensile Fatigue of Graphene Nanoplatelets Reinforced Polymer Nanocomposites. J. Nanomater. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Yavari, F.; Rafiee, M.A.; Rafiee, J.; Yu, Z.-Z.; Koratkar, N. Dramatic increase in fatigue life in hierarchical graphene composites. ACS Appl. Mater. Interfaces 2010, 2, 2738–2743. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.U.; Li, C.Y.; Siddiqui, N.A.; Kim, J.-K. Vibration damping characteristics of carbon fiber-reinforced composites containing multi-walled carbon nanotubes. Compos. Sci. Technol. 2011, 71, 1486–1494. [Google Scholar] [CrossRef]

- DeValve, C.; Pitchumani, R. Experimental investigation of the damping enhancement in fiber-reinforced composites with carbon nanotubes. Carbon 2013, 63, 71–83. [Google Scholar] [CrossRef]

- DeValve, C.; Pitchumani, R. Analysis of vibration damping in a rotating composite beam with embedded carbon nanotubes. Compos. Struct. 2014, 110, 289–296. [Google Scholar] [CrossRef]

- Liu, A.; Wang, K.W.; Bakis, C.E. Effect of functionalization of single-wall carbon nanotubes (SWNTs) on the damping characteristics of SWNT-based epoxy composites via multiscale analysis. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1748–1755. [Google Scholar] [CrossRef]

- Soltannia, B.; Haji Gholami, I.; Masajedian, S.; Mertiny, P.; Sameoto, D.; Taheri, F. Parametric Study of Strain Rate Effects on Nanoparticle-Reinforced Polymer Composites. J. Nanomater. 2016, 2016, 1–9. [Google Scholar] [CrossRef]

- Soltannia, B.; Taheri, F. Static, Quasi-Static and High Loading Rate Effects on Graphene Nano-Reinforced Adhesively Bonded Single-Lap Joints. Int. J. Compos. Mater. 2013, 2013, 181–190. [Google Scholar] [CrossRef]

- Haro, E.E.; Odeshi, A.G.; Szpunar, J.A. The energy absorption behavior of hybrid composite laminates containing nano-fillers under ballistic impact. Int. J. Impact Eng. 2016, 96, 11–22. [Google Scholar] [CrossRef]

- Ávila, A.F.; Neto, A.S.; Nascimento, H., Jr. Hybrid nanocomposites for mid-range ballistic protection. Int. J. Impact Eng. 2011, 38, 669–675. [Google Scholar] [CrossRef]

- Haq, M.; Umer, R.; Khomenko, A.; Loos, A.C.; Drzal, L.T. Manufacturing and impact behavior of sandwich composites with embedded graphene platelets. In Proceedings of the 19th International Conference on Composite Materials ICCM19, Montreal, QC, Canada, 28 July–2 August 2014. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Srivastava, I.; Wang, Z.; Song, H.; Yu, Z.Z.; Koratkar, N. Fracture and fatigue in graphene nanocomposites. Small 2010, 6, 179–183. [Google Scholar] [CrossRef] [PubMed]

- Chandrasekaran, S.; Sato, N.; Tölle, F.; Mülhaupt, R.; Fiedler, B.; Schulte, K. Fracture toughness and failure mechanism of graphene based epoxy composites. Compos. Sci. Technol. 2014, 97, 90–99. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.; Koratkar, N. Enhanced Mechanical Properties of Nanocomposites at Low Graphene Content. ACS Nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi-Moghadam, B.; Taheri, F. Influence of graphene nanoplatelets on modes I, II and III interlaminar fracture toughness of fiber-reinforced polymer composites. Eng. Fract. Mech. 2015, 143, 97–107. [Google Scholar] [CrossRef]

- Ahmadi-Moghadam, B.; Sharafimasooleh, M.; Shadlou, S.; Taheri, F. Effect of functionalization of graphene nanoplatelets on the mechanical response of graphene/epoxy composites. Mater. Des. 2015, 66, 142–149. [Google Scholar] [CrossRef]

- Wichmann, M.H.G.; Sumfleth, J.; Gojny, F.H.; Quaresimin, M.; Fiedler, B.; Schulte, K. Glass-fibre-reinforced composites with enhanced mechanical and electrical properties—Benefits and limitations of a nanoparticle modified matrix. Eng. Fract. Mech. 2006, 73, 2346–2359. [Google Scholar] [CrossRef]

- Siegfried, M.; Tola, C.; Claes, M.; Lomov, S.V.; Verpoest, I.; Gorbatikh, L. Impact and residual after impact properties of carbon fiber/epoxy composites modified with carbon nanotubes. Compos. Struct. 2014, 111, 488–496. [Google Scholar] [CrossRef]

- Bortz, D.R.; Heras, E.G.; Martin-Gullon, I. Impressive Fatigue Life and Fracture Toughness Improvements in Graphene Oxide/Epoxy Composites. Macromolecules 2012, 45, 238–245. [Google Scholar] [CrossRef]

- Remmers, J.J.C.; de Borst, R. Delamination buckling of fibre-metal laminates. Compos. Sci. Technol. 2001, 61, 2207–2213. [Google Scholar] [CrossRef]

- Yin, S.; Yu, T.; Bui, T.Q.; Liu, P.; Hirose, S. Buckling and vibration extended isogeometric analysis of imperfect graded Reissner-Mindlin plates with internal defects using NURBS and level sets. Comput. Struct. 2016, 177, 23–38. [Google Scholar] [CrossRef]

- Gong, W.; Chen, J.; Patterson, E.A. Buckling and delamination growth behaviour of delaminated composite panels subject to four-point bending. Compos. Struct. 2016, 138, 122–133. [Google Scholar] [CrossRef]

- Gu, H.; Chattopadhyay, A. An experimental investigation of delamination buckling and post buckling of composite laminates. Compos. Sci. Technol. 1999, 59, 903–910. [Google Scholar] [CrossRef]

- Wang, S.; Harvey, C.M.; Wang, B.; Watson, A. Post-local buckling-driven delamination in bilayer composite beams. Compos. Struct. 2015, 133, 1058–1066. [Google Scholar] [CrossRef]

- Esfahani, M.M.N.; Ghasemnejad, H.; Barrington, P.E. Experimental and numerical buckling analysis of delaminated hybrid composite beam structures. Appl. Mech. Mater. 2010, 24–25, 393–400. [Google Scholar] [CrossRef]

- Kim, H.-J.; Hong, C.-S. Buckling and Postbuckling Behavior of Composite Laminates with a Delamination. Compos. Sci. Technol. 1997, 57, 557–564. [Google Scholar] [CrossRef]

- Asaee, Z.; Mohamed, M.; Soumik, S.; Taheri, F. Experimental and numerical characterization of delamination buckling behavior of a new class of GNP-reinforced 3D fiber-metal laminates. Thin Walled Struct. 2017, 112, 208–216. [Google Scholar] [CrossRef]

- Taraghi, I.; Fereidoon, A.; Taheri-Behrooz, F. Low-velocity impact response of woven Kevlar/epoxy laminated composites reinforced with multi-walled carbon nanotubes at ambient and low temperatures. Mater. Des. 2014, 53, 152–158. [Google Scholar] [CrossRef]

- Shen, X.-J.; Meng, L.-X.; Yan, Z.-Y.; Sun, C.-J.; Ji, Y.-H.; Xiao, H.-M.; Fu, S.-Y. Improved cryogenic interlaminar shear strength of glass fabric/epoxy composites by graphene oxide. Compos. Part B Eng. 2015, 73, 126–131. [Google Scholar] [CrossRef]

- Müller, B.; Sinke, J.; Anisimov, A.G.; Groves, R.M. Thermal Strains in Heated Fiber Metal Laminates. In Proceedings of the Conference on Emerging Technologies in Non-Destructive Testing (ETNDT6), Brussels, Belgium, 27–29 May 2015. [Google Scholar]

- Li, H.; Hu, Y.; Liu, C.; Zheng, X.; Liu, H.; Tao, J. The effect of thermal fatigue on the mechanical properties of the novel fiber metal laminates based on aluminum-lithium alloy. Compos. Part A Appl. Sci. Manuf. 2016, 84, 36–42. [Google Scholar] [CrossRef]

- Khalili, S.M.R.; Sharafi, M.; Eslami-Farsani, R.; Saeedi, A. Effect of thermal cycling on tensile properties of degraded FML to metal hybrid joints exposed to sea water. Int. J. Adhes. Adhes. 2017, 79, 95–101. [Google Scholar] [CrossRef]

- De Cicco, D.; Taheri, F. Enhancement of magnesium-composite bond-interface by a simple combined abrasion and coating method. J. Magnes. Alloys 2019, 7, 227–239. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Cicco, D.; Taheri, F. Effect of Functionalized Graphene Nanoplatelets on the Delamination-Buckling and Delamination Propagation Resistance of 3D Fiber-Metal Laminates Under Different Loading Rates. Nanomaterials 2019, 9, 1482. https://doi.org/10.3390/nano9101482

De Cicco D, Taheri F. Effect of Functionalized Graphene Nanoplatelets on the Delamination-Buckling and Delamination Propagation Resistance of 3D Fiber-Metal Laminates Under Different Loading Rates. Nanomaterials. 2019; 9(10):1482. https://doi.org/10.3390/nano9101482

Chicago/Turabian StyleDe Cicco, Davide, and Farid Taheri. 2019. "Effect of Functionalized Graphene Nanoplatelets on the Delamination-Buckling and Delamination Propagation Resistance of 3D Fiber-Metal Laminates Under Different Loading Rates" Nanomaterials 9, no. 10: 1482. https://doi.org/10.3390/nano9101482

APA StyleDe Cicco, D., & Taheri, F. (2019). Effect of Functionalized Graphene Nanoplatelets on the Delamination-Buckling and Delamination Propagation Resistance of 3D Fiber-Metal Laminates Under Different Loading Rates. Nanomaterials, 9(10), 1482. https://doi.org/10.3390/nano9101482